PVC plastic film raincoat

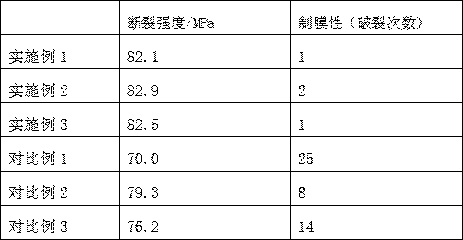

A technology of plastic film and PVC resin, which is applied in the direction of protective clothing, special outerwear, outerwear, etc., can solve the problems of poor quality of disposable raincoats, low tear resistance, waste of resources, etc., and achieve improved breaking strength and film-forming properties. Good film-forming properties, the effect of increasing the use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A PVC plastic film raincoat is made of the following components in parts by weight: PVC resin 90, maleic acid / 2-acrylamide-2-methylpropanesulfonic acid binary copolymer 12, trimethylolpropane Methacrylate 3, zinc stearate 1, acetyl trioctyl citrate 0.2, methyltriacetoxysilane 3-6, inorganic filler 30, plasticizer 1.2; the maleic acid / 2-acrylamide The mass ratio of base-2-methylpropanesulfonic acid binary copolymer to acetyl trioctyl citrate is 60:1.

[0021] Further, the average degree of polymerization of the PVC resin is 1000.

[0022] Further, the preparation method of the maleic acid / 2-acrylamido-2-methylpropanesulfonic acid binary copolymer is:

[0023] Dissolve maleic acid in deionized water to prepare a maleic acid solution with a mass fraction of 10%, then add the maleic acid solution into the reaction kettle, heat to 50°C, keep it warm for 20 minutes, and then use sulfuric acid to adjust the maleic acid solution. The pH of the acid solution is 1.2, heated to ...

Embodiment 2

[0033] A PVC plastic film raincoat is made of the following components in parts by weight: PVC resin 98, maleic acid / 2-acrylamide-2-methylpropanesulfonic acid binary copolymer 18, trimethylolpropane trimethylolpropane methacrylate 5, zinc stearate 4, acetyl trioctyl citrate 0.3, methyltriacetoxysilane 6, inorganic filler 40, plasticizer 1.5; the maleic acid / 2-acrylamide- The mass ratio of 2-methylpropanesulfonic acid binary copolymer to acetyl trioctyl citrate is 60:1.

[0034] Further, the average degree of polymerization of the PVC resin is 1000.

[0035] Further, the preparation method of the maleic acid / 2-acrylamido-2-methylpropanesulfonic acid binary copolymer is:

[0036] Dissolve maleic acid in deionized water to prepare a maleic acid solution with a mass fraction of 10%, then add the maleic acid solution into the reaction kettle, heat to 50°C, keep it warm for 20 minutes, and then use sulfuric acid to adjust the maleic acid solution. The pH of the acid solution is 1....

Embodiment 3

[0046] A PVC plastic film raincoat is made of the following components in parts by weight: PVC resin 92, maleic acid / 2-acrylamide-2-methylpropanesulfonic acid binary copolymer 15, trimethylolpropane trimethylolpropane methacrylate 4, zinc stearate 2, acetyl trioctyl citrate 0.25, methyltriacetoxysilane 5, inorganic filler 35, plasticizer 1.3; the maleic acid / 2-acrylamide- The mass ratio of 2-methylpropanesulfonic acid binary copolymer to acetyl trioctyl citrate is 60:1.

[0047] Further, the average degree of polymerization of the PVC resin is 1000.

[0048] Further, the preparation method of the maleic acid / 2-acrylamido-2-methylpropanesulfonic acid binary copolymer is:

[0049]Dissolve maleic acid in deionized water to prepare a maleic acid solution with a mass fraction of 10%, then add the maleic acid solution into the reaction kettle, heat to 50°C, keep it warm for 20 minutes, and then use sulfuric acid to adjust the maleic acid solution. The pH of the acid solution is 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com