Patents

Literature

38results about How to "Reduce the number of breaks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

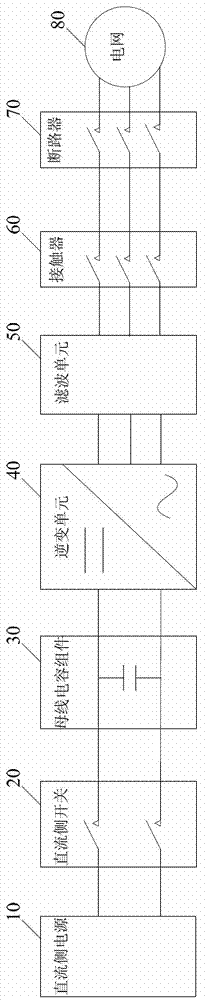

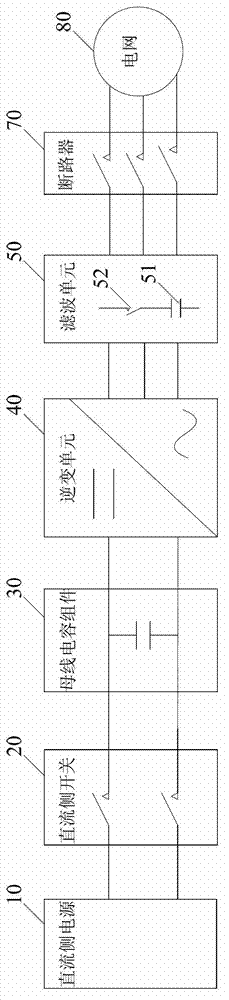

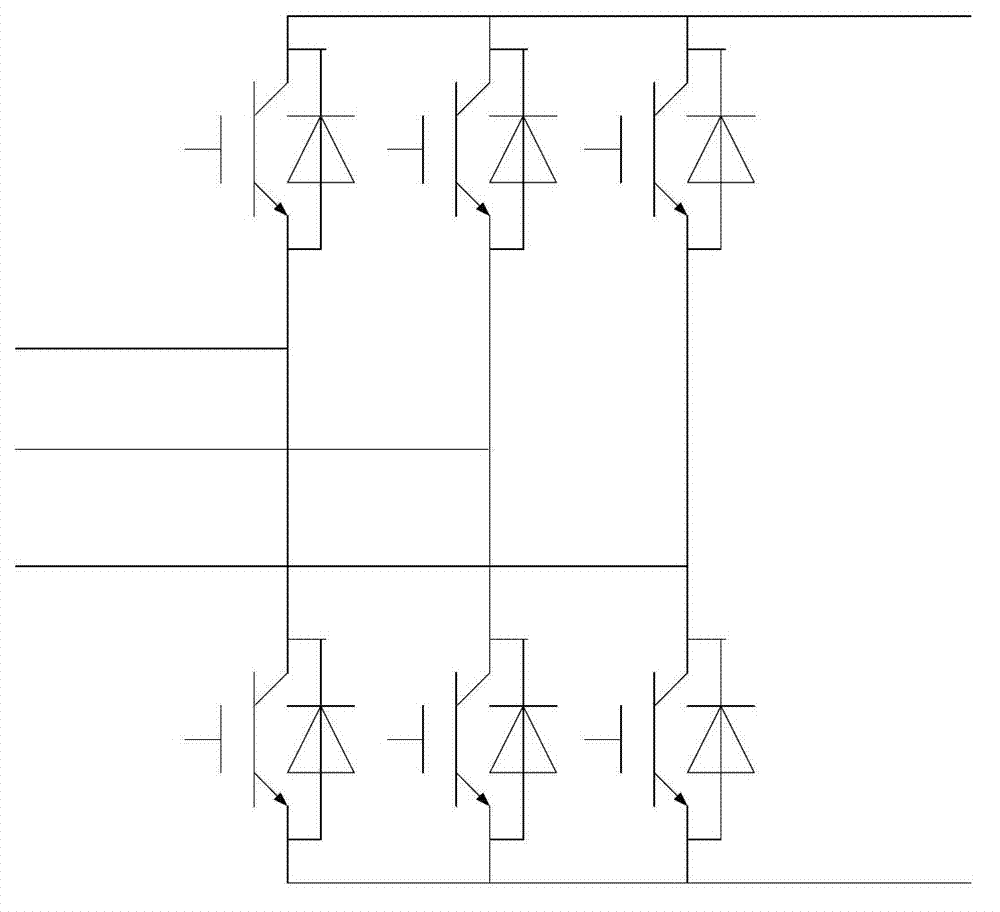

Grid-connected inverter and control method thereof

ActiveCN102904286AGuaranteed lifeReduce the number of breaksSingle network parallel feeding arrangementsDc-ac conversion without reversalCapacitanceGrid connected inverter

The invention relates to a grid-connected inverter and a control method thereof. The grid-connected inverter comprises a master control unit as well as a DC-side power supply, a DC-side switch, a busbar capacitor assembly, an inverter unit, a filter unit and a circuit breaker which are connected in sequence; the filter unit at least comprises a filter capacitor and a switch element connected with the filter capacitor in series; when the detected DC voltage reaches startup voltage, the master control unit sends a PWM (Pulse Width Modulation) wave to start the inverter unit to power on the switch element, and when the output voltage of the filter unit reaches the power grid voltage, the master control unit controls the circuit breaker to be powered on; and the master control unit also controls the inverter unit to stop inversion and power off the switch element when the detected DC voltage is lower than the startup voltage. According to the invention, because the switch element is additionally arranged on a branch of the filter capacitor of the filter unit, the grid-connected inverter is freely controlled not to absorb reactive power from a power grid under the circuit breaker is not powered off, so that the breaking frequency of the circuit breaker is reduced, the system efficiency is improved and the complete machine cost is reduced.

Owner:SHENZHEN HOPEWIND ELECTRIC CO LTD

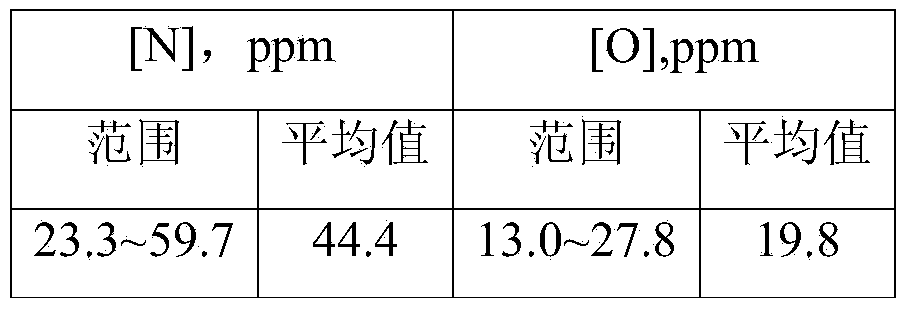

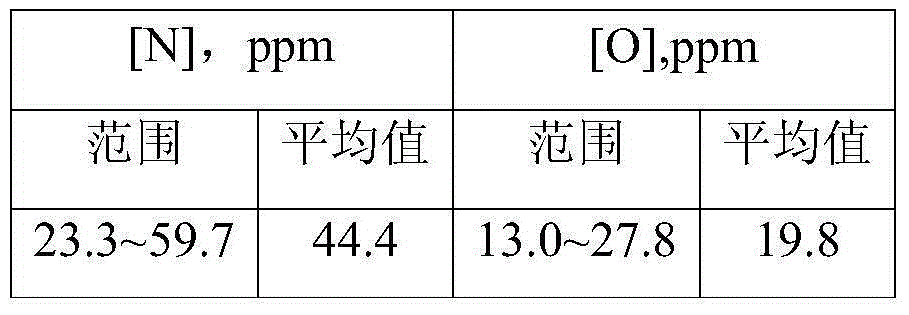

Steel for boron-containing prestressed steel wires and steel strands and smelting process thereof

ActiveCN103834848AGuaranteed qualifiedQuality improvementManufacturing convertersProcess efficiency improvementSmelting processBoron containing

The invention belongs to the technical field of smelting, and particularly relates to a smelting process of steel for boron-containing prestressed steel wires and steel strands. The process comprises the following steps: preparing molten iron, waste steel and raw iron serving as raw materials; during smelting of a revolving furnace, adding slag charge, performing the operation of raising high carbon content and post blowing, controlling the end point C over 0.4 percent, and controlling the end point P below 0.015 percent; during steel tapping of the revolving furnace, adding silicon carbide, lime and an alloy serving as deoxidizing materials in sequence along with the steel flow; during refining, deoxidizing the top of the slag by adopting the silicon carbide, wherein the target refining final alkalinity is 1.7; after refining, performing soft argon blowing at the bottom of a steel ladle; during continuous casting, feeding Xibao special high-carbon steel protection slag to a crystallizer; and electromagnetically stirring the crystallizer, casting at a low superheat degree, performing forced cooling during secondary cooling, and electromagnetically stirring at the tail end. By adopting the smelted steel for the boron-containing prestressed steel wires and the steel strands, qualification of chemical components can be ensured. During pulling and twisting of parent metal, the fracture times due to generic defects, sundries and carbon segregation on the surface of a casting blank can be reduced effectively.

Owner:ZENITH STEEL GROUP CORP

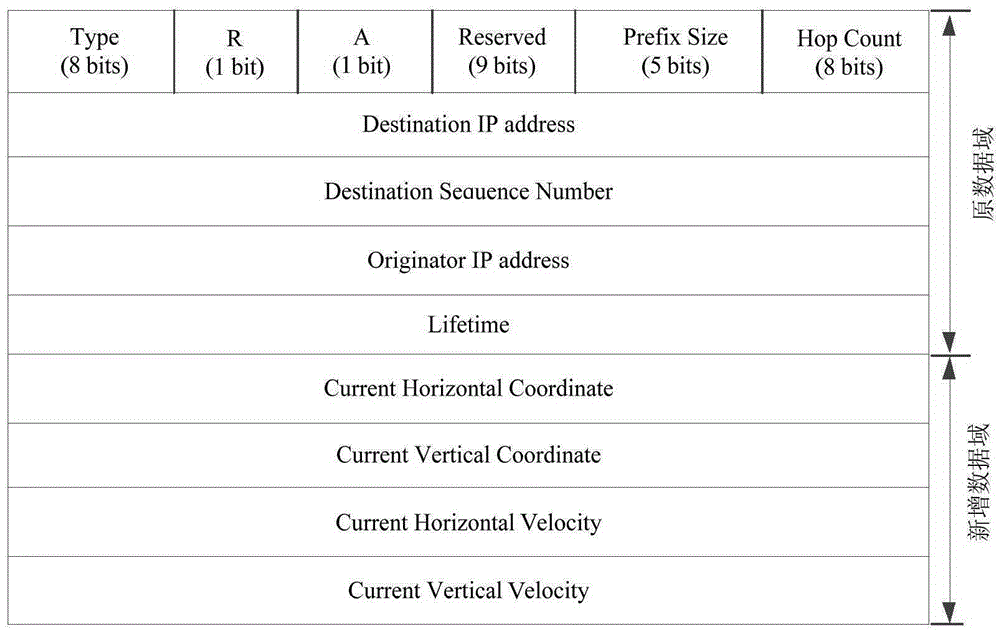

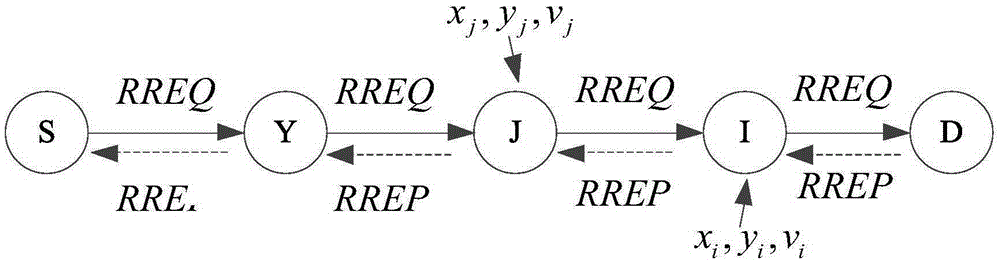

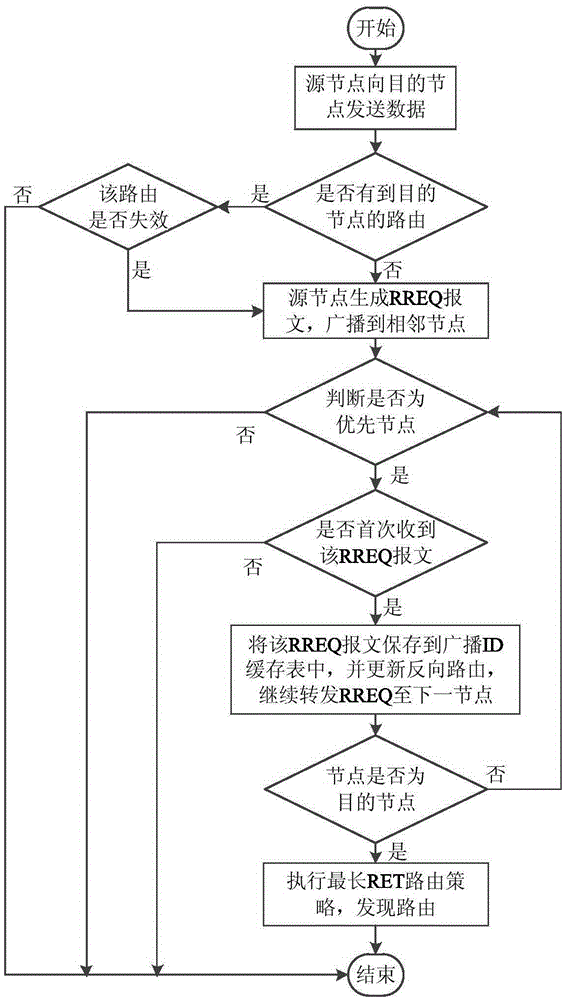

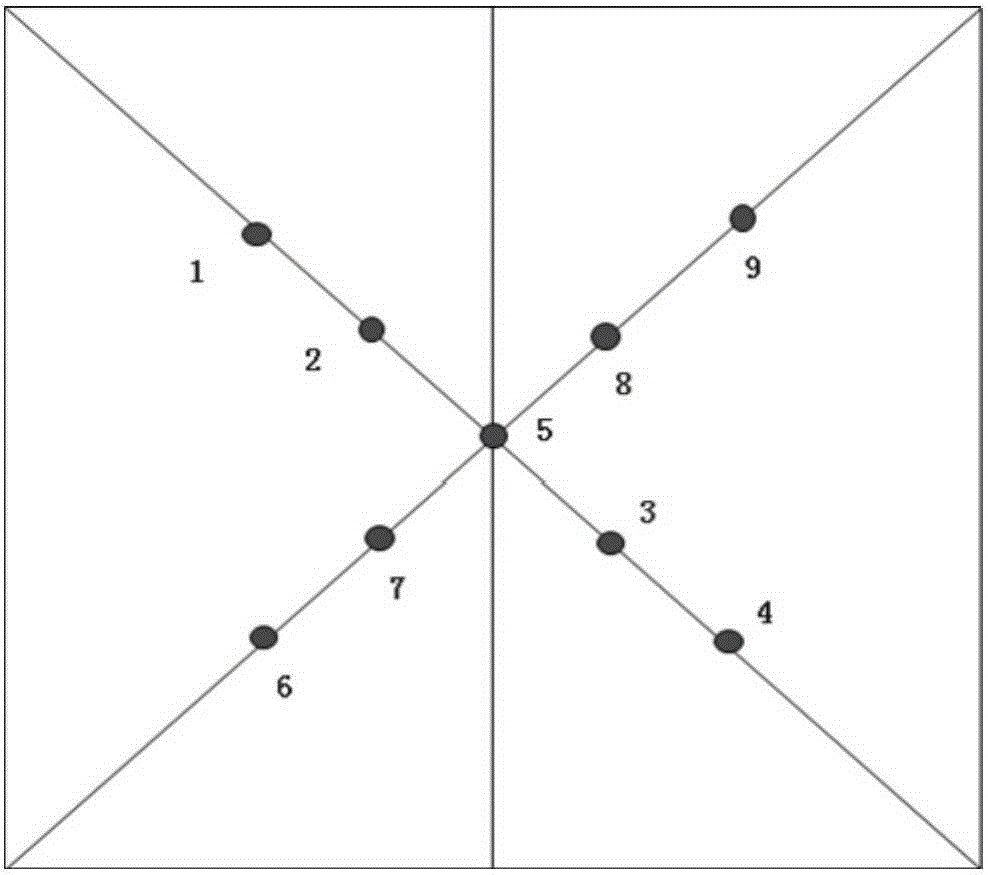

Enhanced stable routing protocol for vehicle Ad Hoc network

InactiveCN105391631AReduce the number of breaksReduce time to discoveryData switching networksWireless communicationTime delaysEffective time

The invention discloses an enhanced stable routing protocol for the vehicle Ad Hoc network. A source node finds a target node and obtains multiple effective routes to the target node; and in the route selection phase, a mechanism of the longest route effective time is introduced to select a route longest in effective time and more stable in performance for data transmission. In the route maintenance phase, if the main route is in failure, the source node directly uses the multipath standby route to repair the route, and the route repairing efficiency is improved. The enhanced stable routing protocol can improve the delivery rate of data packets, reduce the average end-to-end time delay, reduce the routing cost, and improve the performance of the vehicle Ad Hoc network.

Owner:SOUTH CHINA UNIV OF TECH

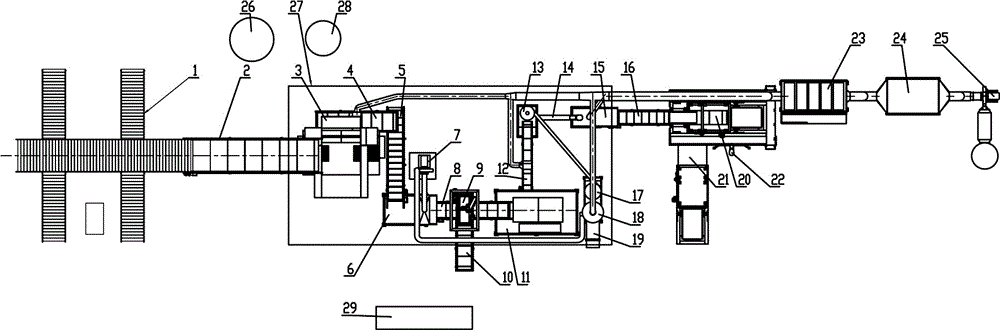

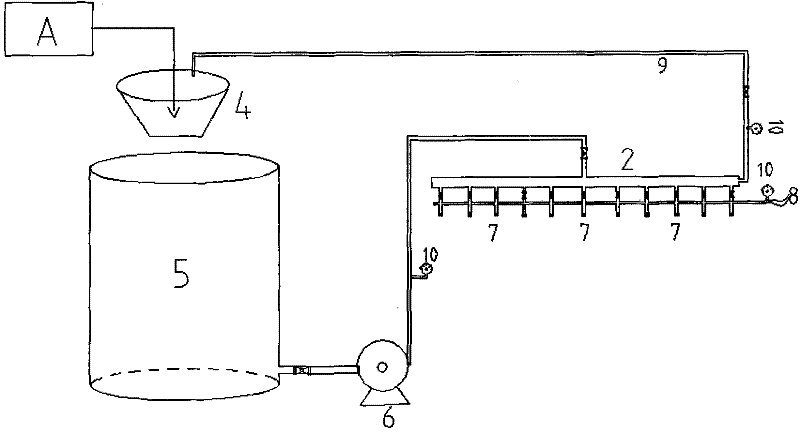

Production line for harmless treatment and efficient resource recovery for waste refrigerators

ActiveCN106734112AImprove efficiencyImprove crushing efficiencyWaste processingSolid waste disposalRefrigerated temperatureCombustion

The invention provides a production line for harmless treatment and efficient resource recovery for waste refrigerators. According to the production line, a first crushing device is connected to a second crushing device through a conveying device; the conveying device between the first crushing device and the second crushing device is provided with an iron removal device; the second crushing device is connected to a distributor; a discharge port at the bottom of the distributor is connected to a metal sorting device; and at least one foam suction device is further arranged between the first crushing device and the metal sorting device and is connected to a foam compressor. The production line has the advantages that the efficiency of the harmless treatment and efficient resource recovery for the waste refrigerators can be improved through reasonable equipment selection and arrangement, the crushing efficiency can be improved, the crushing frequency of polyurethane foam can be reduced, and the risk of fire combustion of polyurethane foam can be reduced.

Owner:HUBEI LIDI MACHINE TOOL

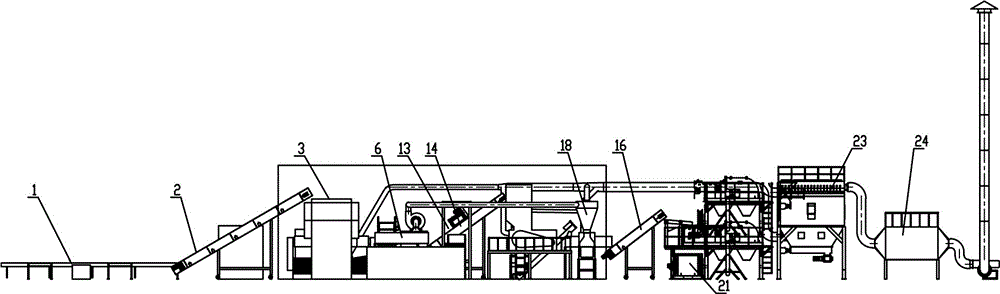

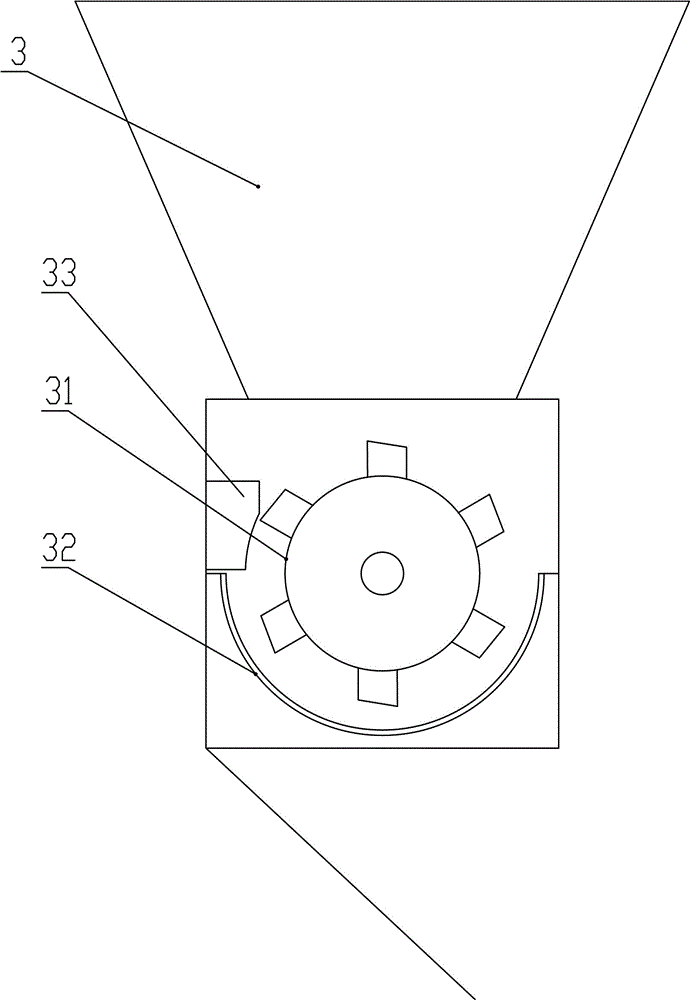

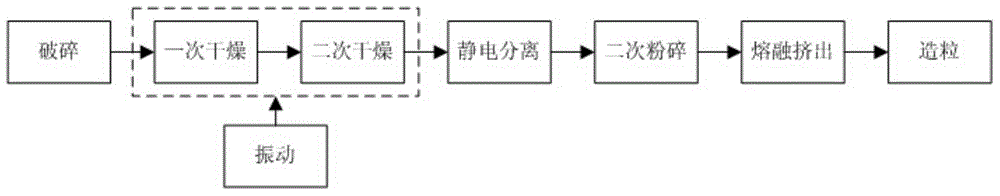

Agricultural film recovery dry-method granulation preparation technology

InactiveCN105710992AReduce secondary pollutionReduce the number of breaksElectrostatic separationAgricultural engineering

The invention provides an agricultural film recovery dry-method granulation preparation technology with advantages of complete impurity removal, high product purity and no secondary pollution. The technology comprises the following steps: 1) fragmentation: recovering the waste and old agricultural films for primary fragmentation; 2) primary drying: placing the fragmented agricultural films in a low-temperature drying furnace for drying the agricultural films; 3) secondary drying: performing secondary drying on the agricultural film fragments through the primary drying; 4) vibration: during a drying process, performing vibration and screening the material simultaneously, promoting the separation of the agricultural film fragments and silt impurity; 5) electrostatic separation: performing electrostatic separation on the agricultural film fragments through twice vibration drying, separating the agricultural films and impurity with a finer manner; 6) secondary crushing: performing secondary crushing on the agricultural film fragments through the electrostatic separation to obtain the finer fragment; and 7) extrusion and granulation: fushing the agricultural film fragments obtained in the step 6), extruding the softened material, and cutting the extruded material to a granular shape.

Owner:TIANJIN XUHUIHENGYUAN PLASTIC PACKAGING CORP

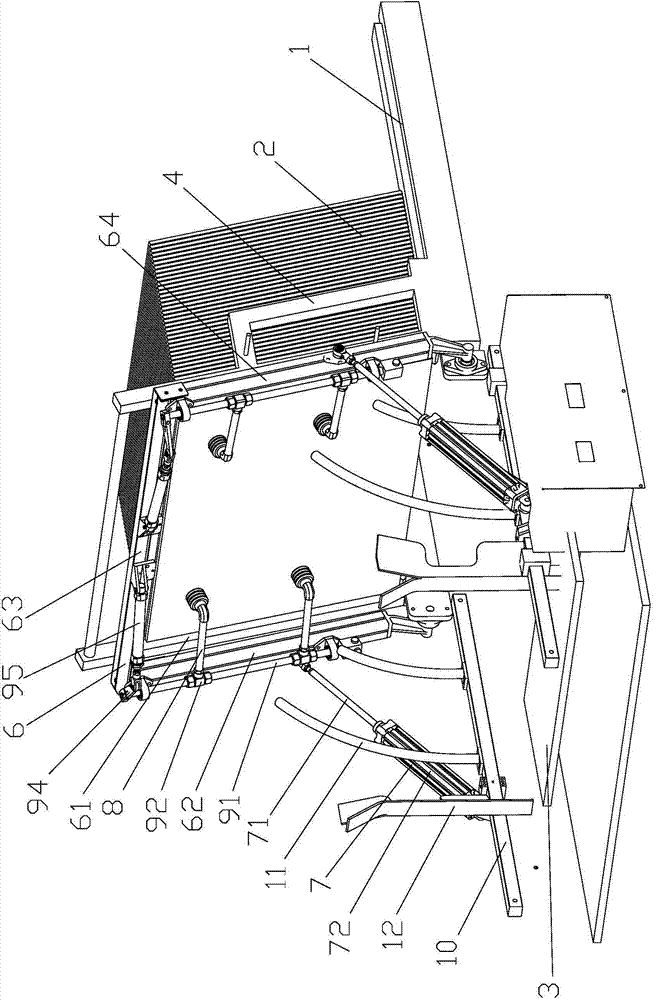

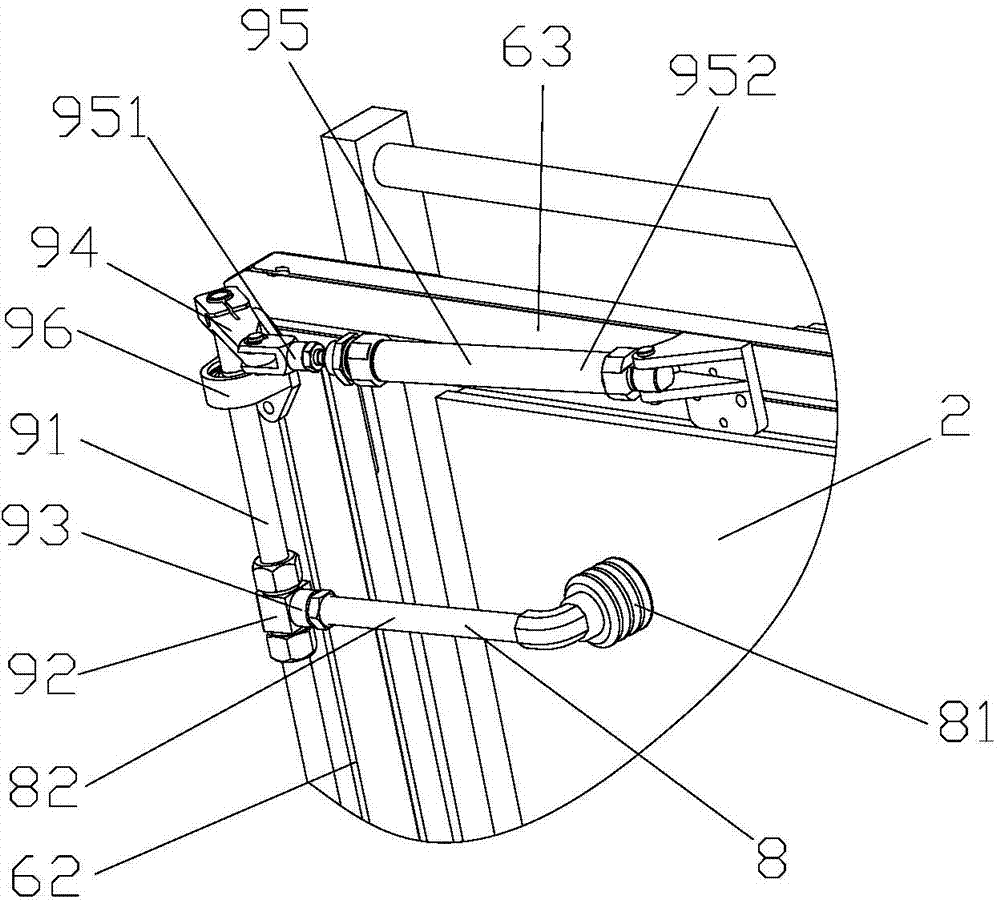

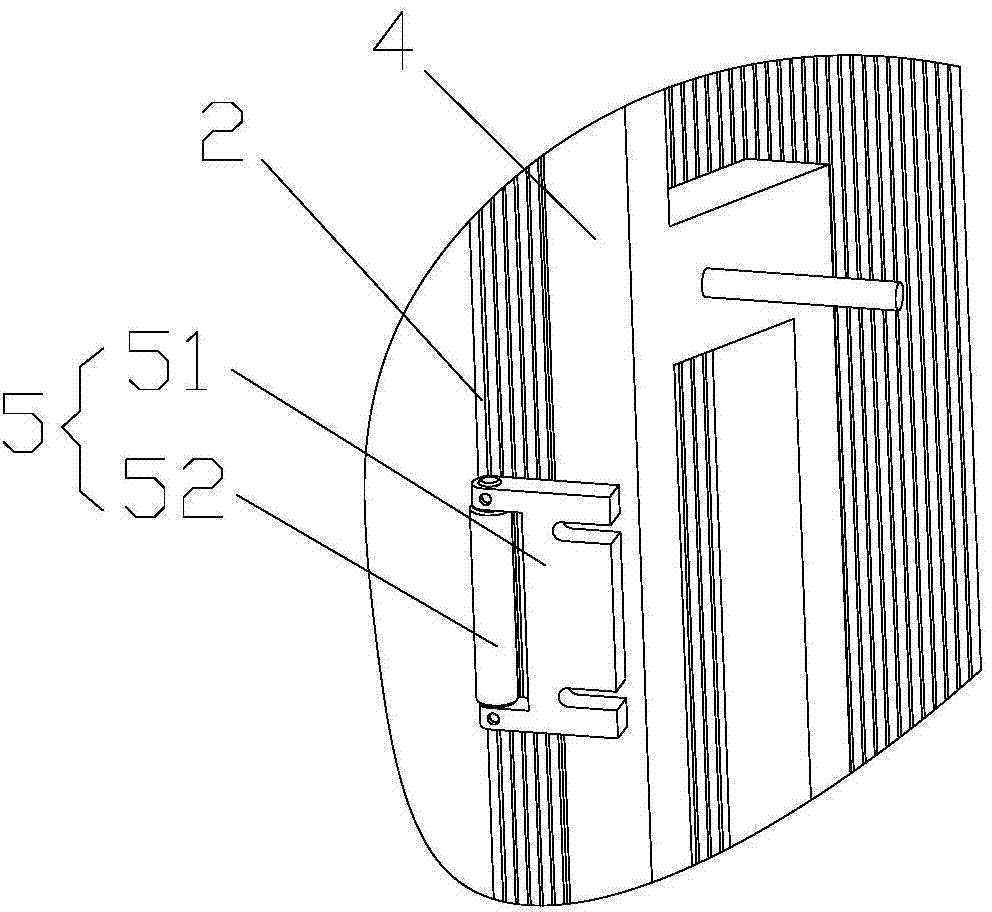

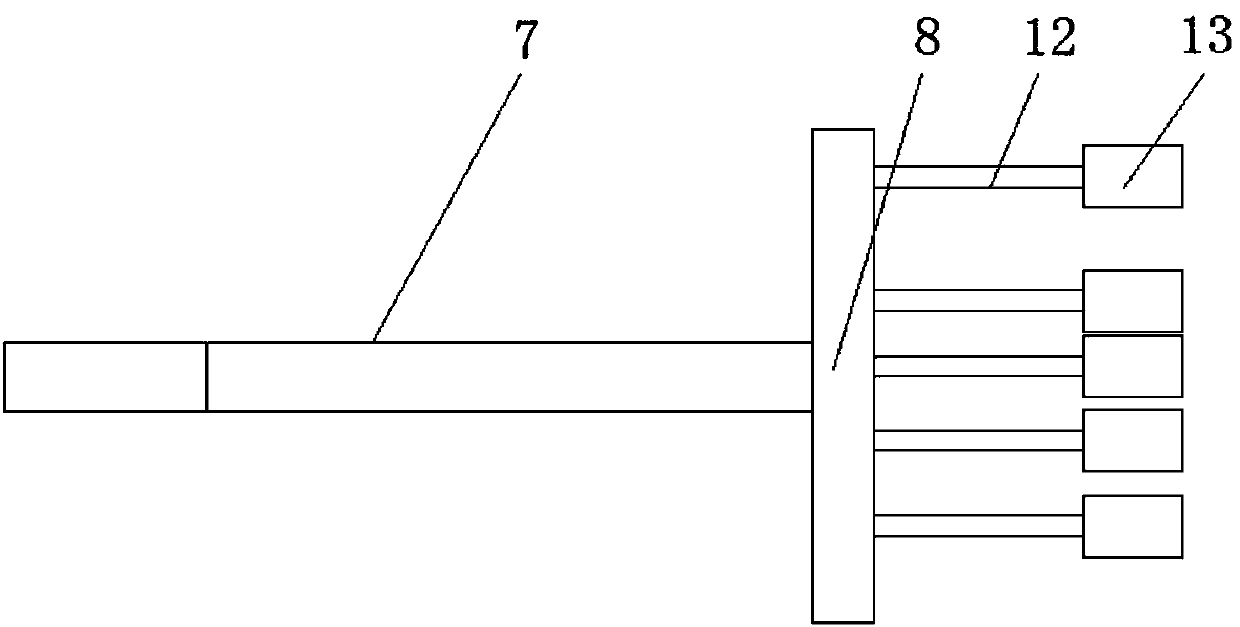

Paper box sucking frame component for box filling machine

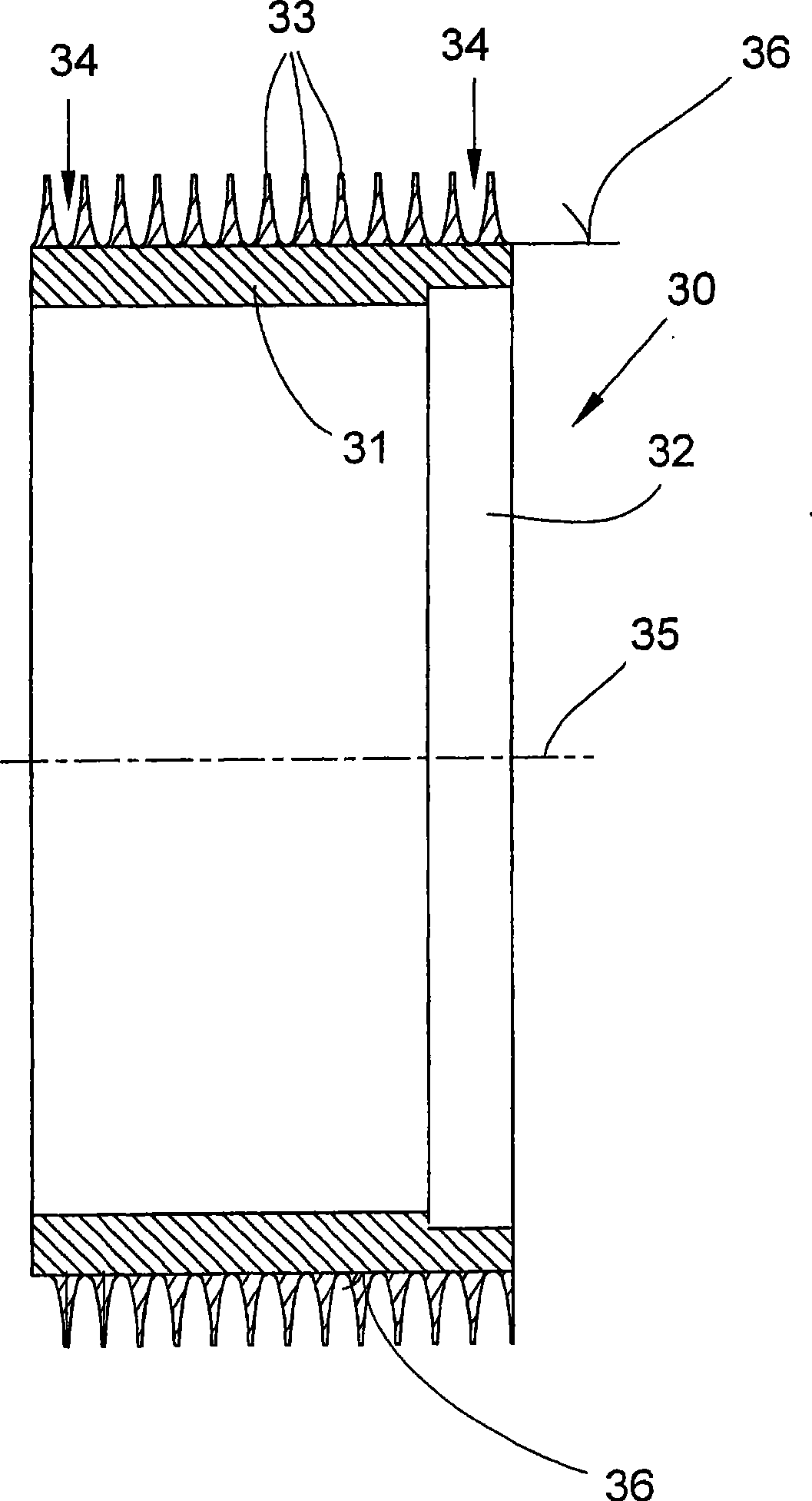

The invention provides a paper box sucking frame component for a box filling machine. The paper box sucking frame component comprises a paper box conveying channel for holding paper boxes, wherein the tail end of the paper box conveying channel is further pivoted with a sucking frame; the rotating shaft of the sucking frame is parallel to the lower edge of each paper box on the paper box conveying channel; the sucking frame rotates between a paper box support rack and a paper box conveyer belt under the driving of at least one frame driving cylinder; a middle space through which the paper boxes penetrate is formed in the middle of the sucking frame; one or more air sucking arms are also arranged on the sucking frame; the air sucking arms rotate under the control of an air sucking arm control system. By adopting the paper box sucking frame component for the box filling machine, two sides of the sucking frame are uniformly stressed, the sucking frame is prevented from deformation, the falling smoothness of the paper boxes is improved, the times that the air sucking arm is damaged are reduced, and moreover the time for recovering faults is shortened.

Owner:SHANGHAI TOBACCO GRP CO LTD

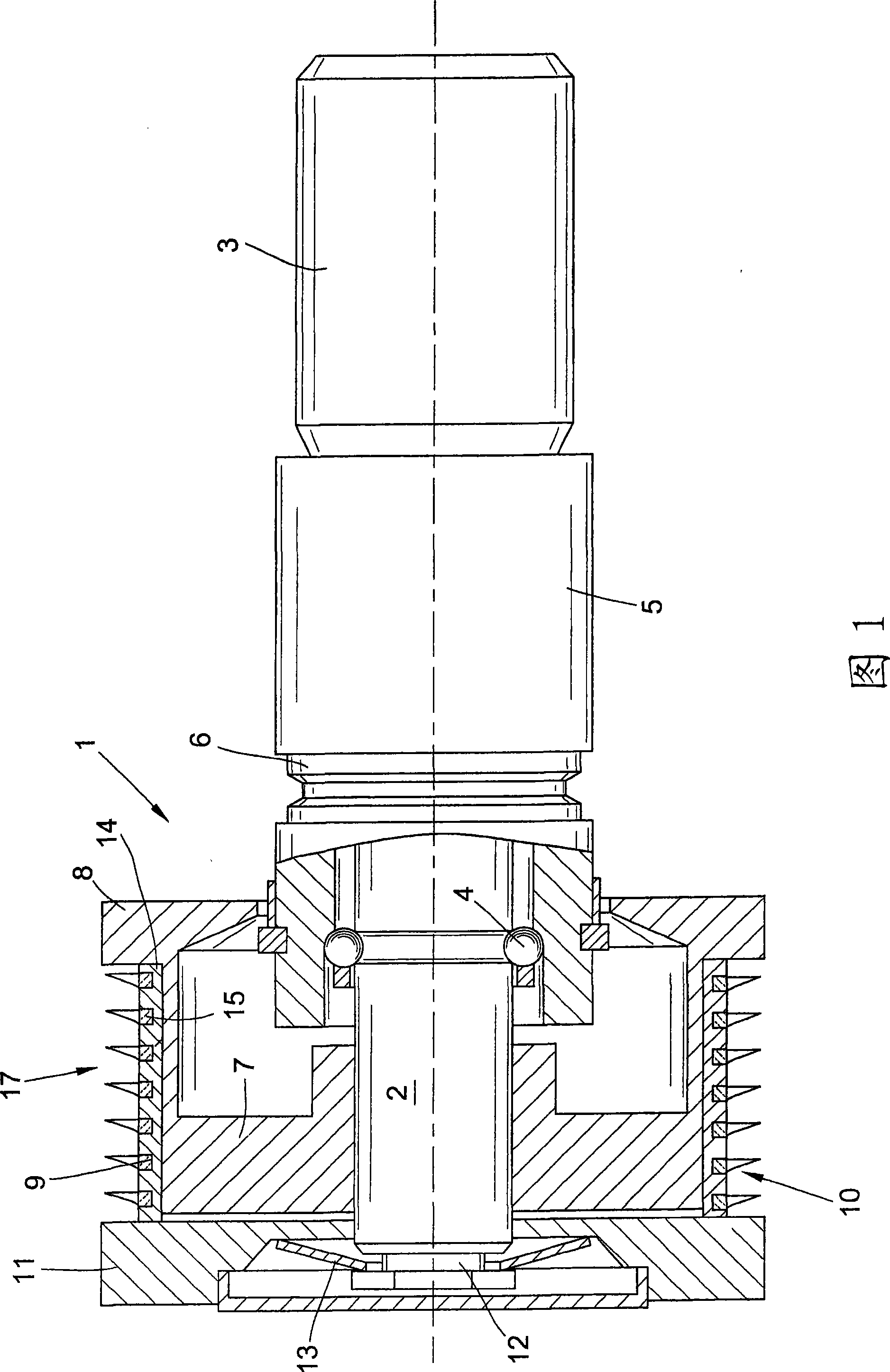

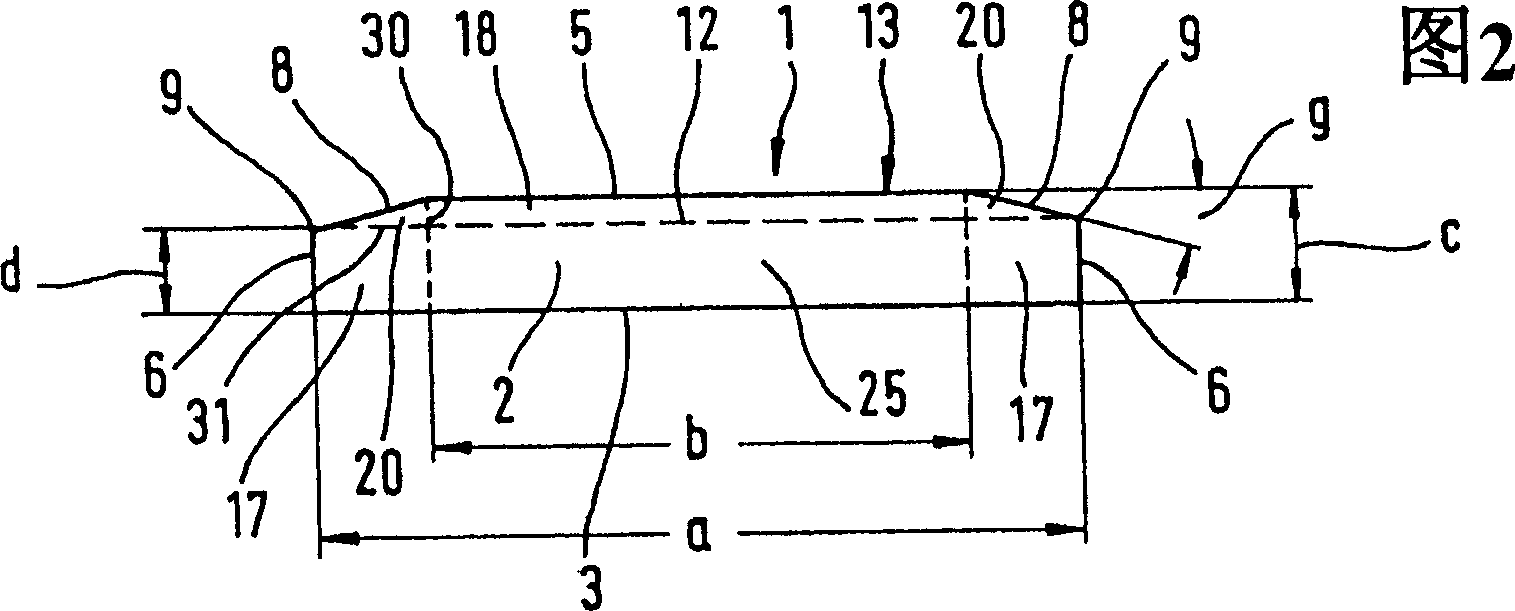

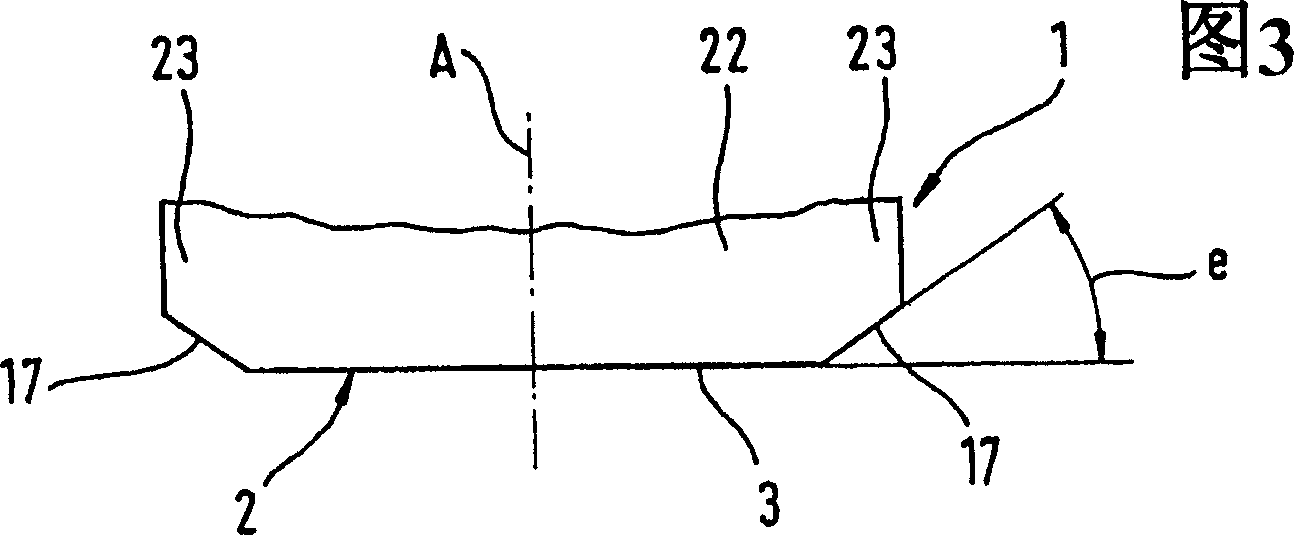

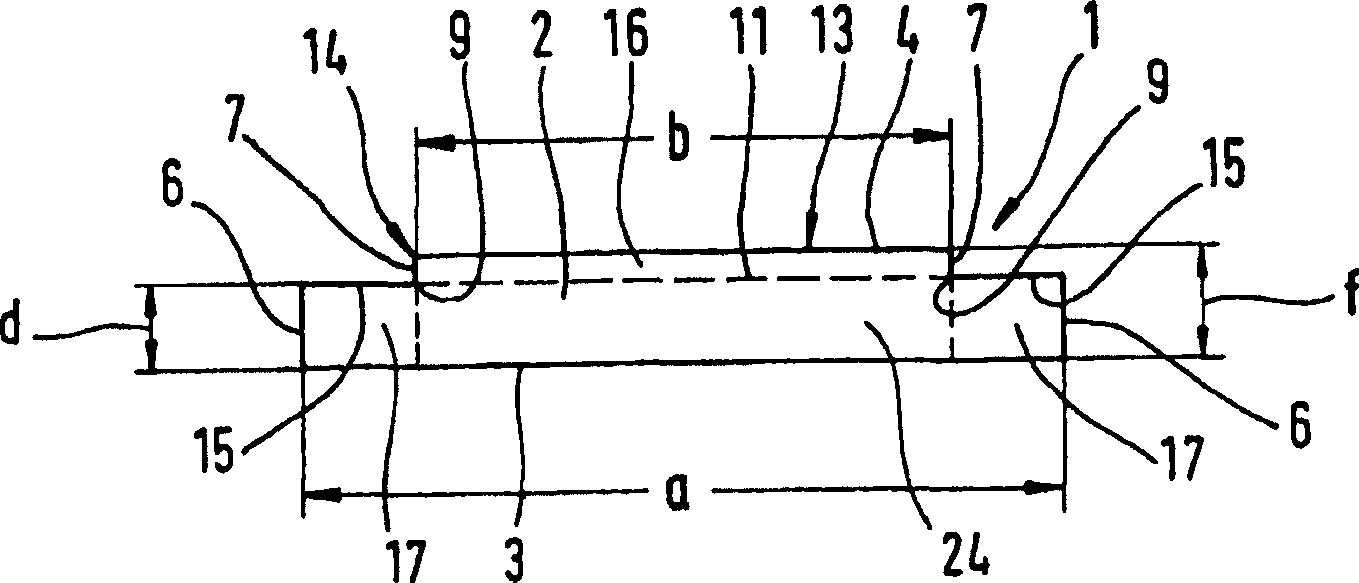

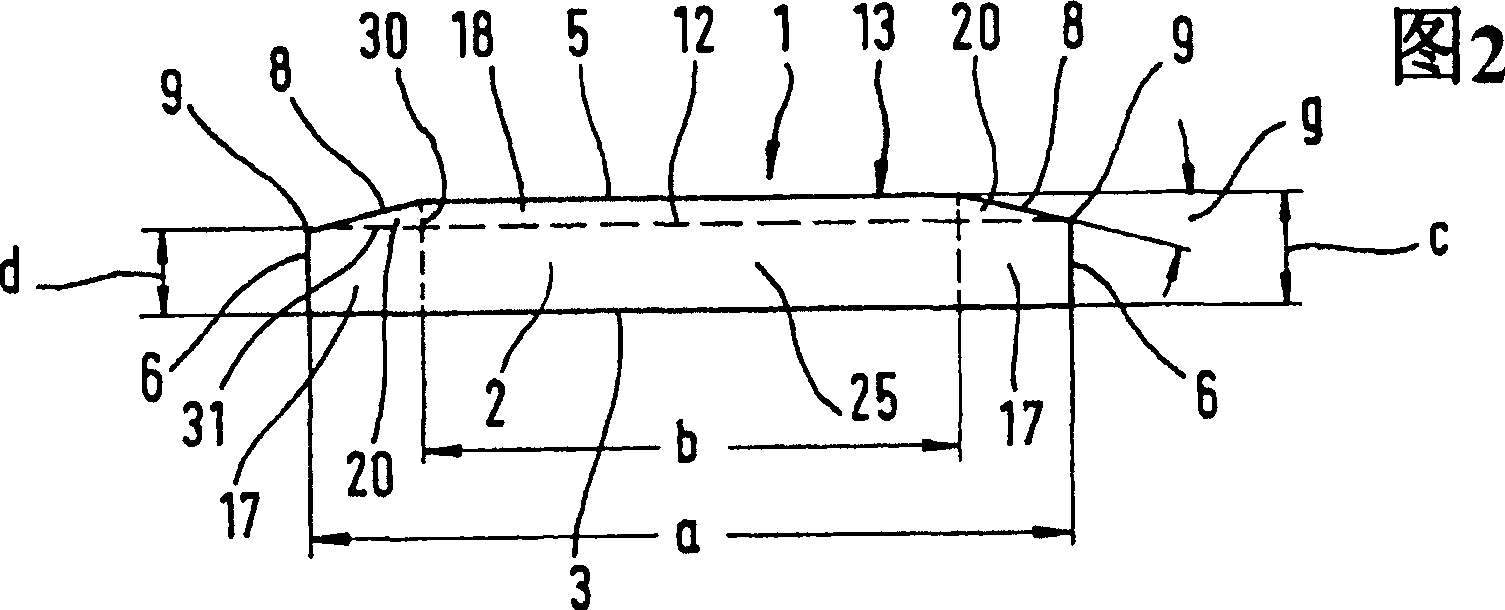

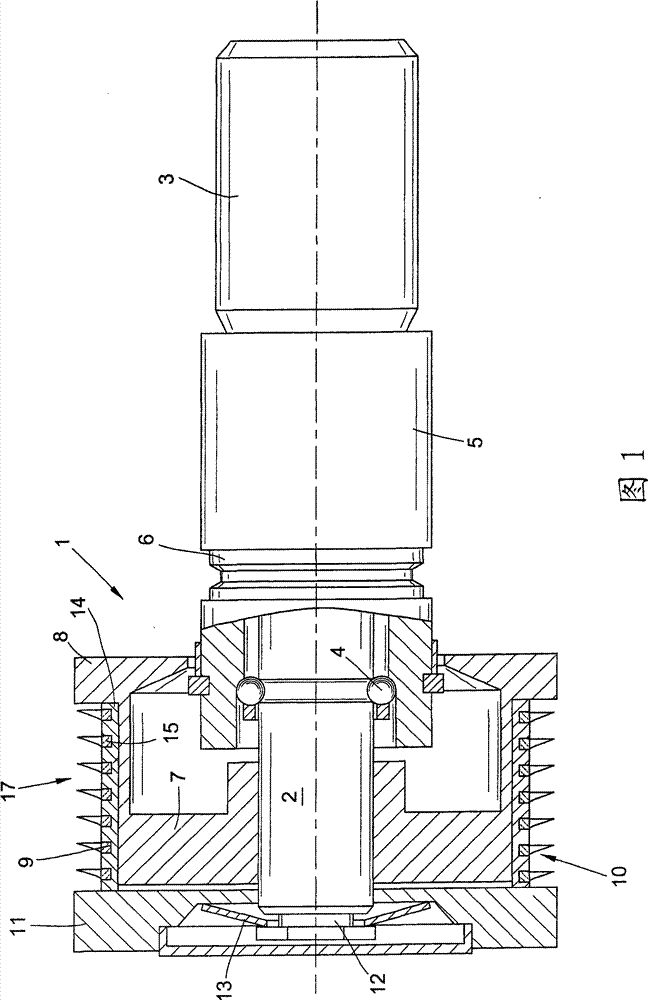

Method for coating opening roller ring and ring used for opening roller

The invention relates to a coating method for the mounting ring (17) of a plucker roller (1) of synthetic fiber materials, which applies at least two layers on the mounting ring (17, 30) via chemical coating. The method comprises steps of: applying a first coating of a nonferrous metal as a base coating on the mounting ring (17, 30); and applying a coating based on a nickel-phosphorus alloy, which does not contain any hardener material as the other layer; then the coated mounting ring (17, 30) is then subjected to heat treatment at a temperature which is below the tempering temperature of the base material of the ring.

Owner:SAURER GERMANY GMBH & CO KG

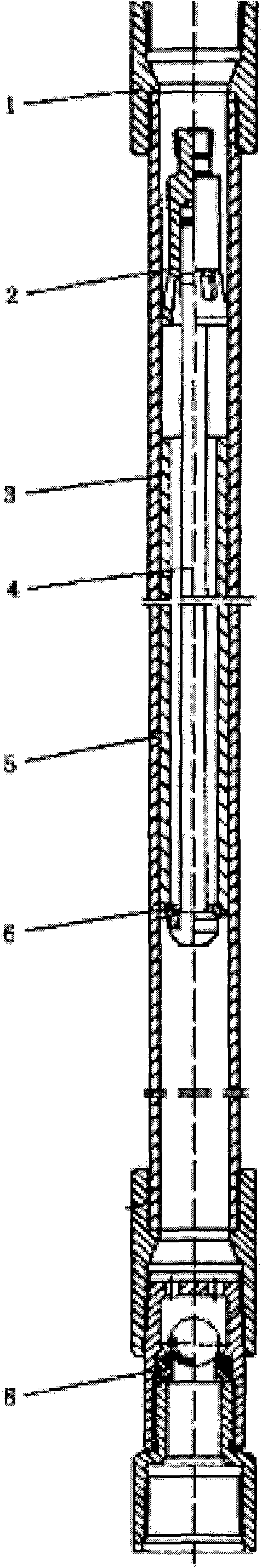

Oil pumping technology based on javelin valve anti-gas pump

InactiveCN103133311AReduce deformation factorReduce the number of breaksPositive displacement pump componentsFlexible member pumpsEngineeringPlunger

The invention discloses an oil pumping technology based on a javelin valve anti-gas pump. The oil pumping technology based on the javelin valve anti-gas pump includes that in an upstroke, an oil pumping rod drives a center rod to move upwards, a javelin valve is closed, a plunger is driven to move upwards, oil liquid on the upper portion of the plunger is lifted to the ground, and meanwhile, the plunger lower portion space becomes large, pressure is reduced, and oil is filled in a pump; and in a down stroke, the oil pumping rod drives the center rod to move, pushes the plunger to descend, and enables the javelin valve to be forcibly opened simultaneously, gas-oil mixtures in a pump lower cavity can smoothly enter an oil tube through the plunger, and therefore the anti-gas effect is achieved. The mechanical opening and closing is driven by the oil pumping rod, and the practice that a delivery valve of a conventional pump is opened and closed through a liquid pressure in the pump is abandoned; the oil pumping rod is in floating connection with the plunger, the oil pumping rod and the plunger can rotate relative to each other, and therefore the deformation factors and the number of breaking disconnection times of the oil pumping rod are reduced; and the javelin valve is opened and closed always through one face when working, and the structure determines that the javelin valve is short in service life.

Owner:严欢

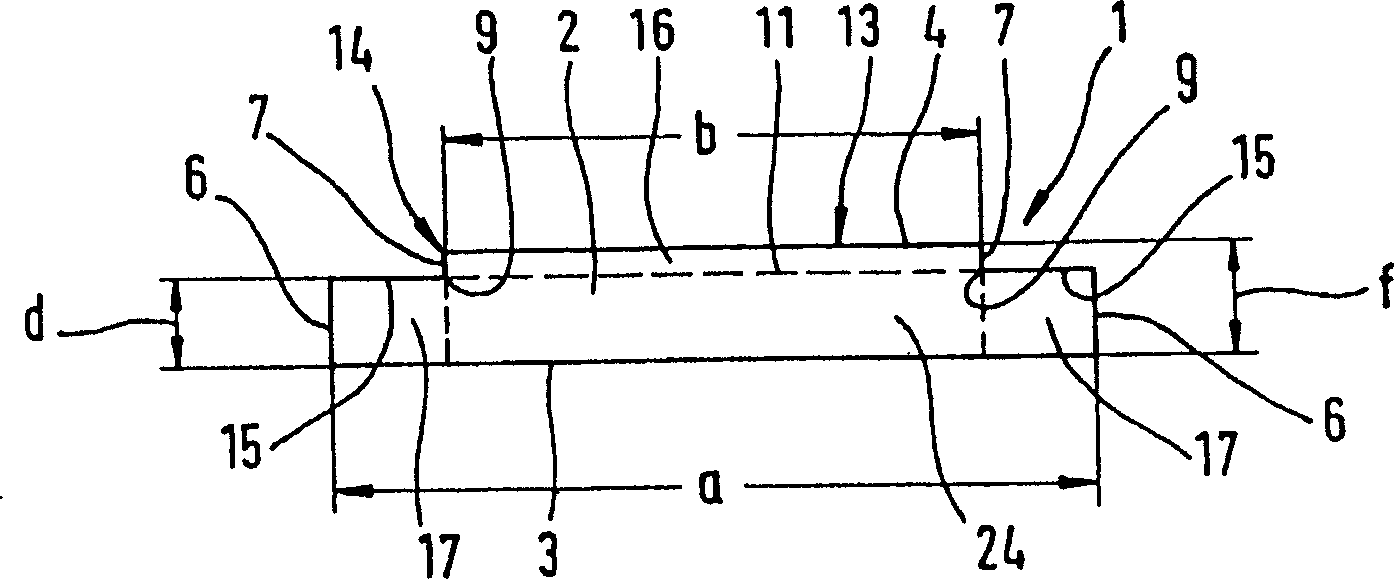

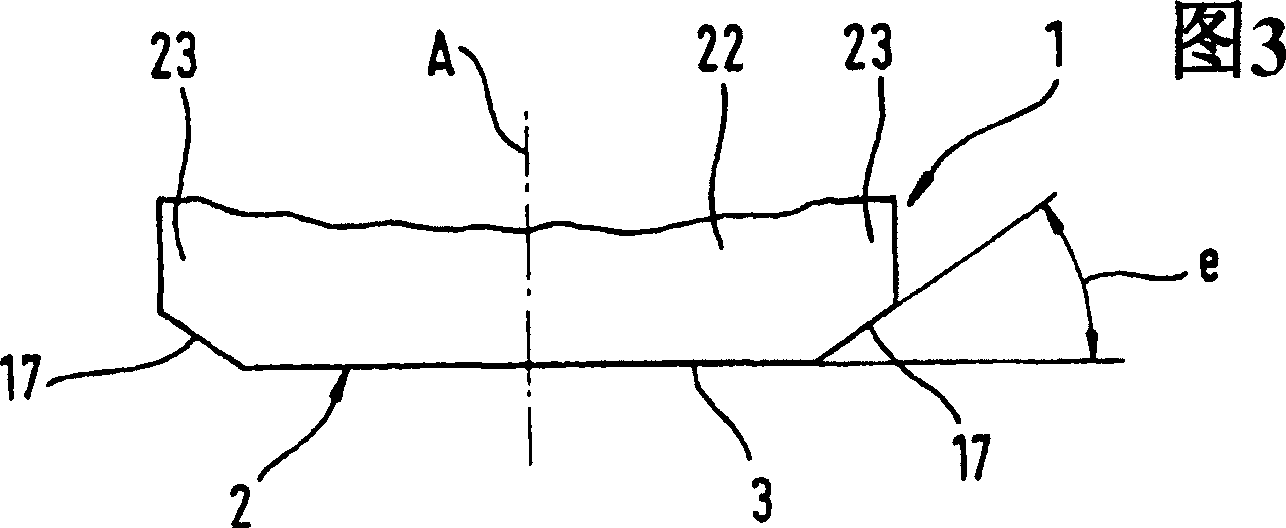

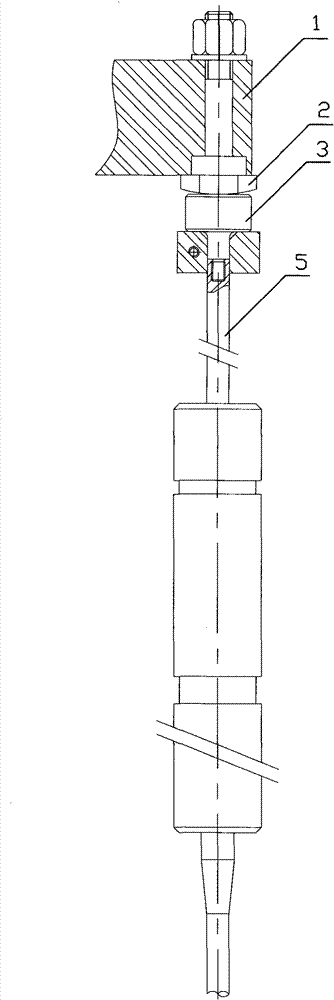

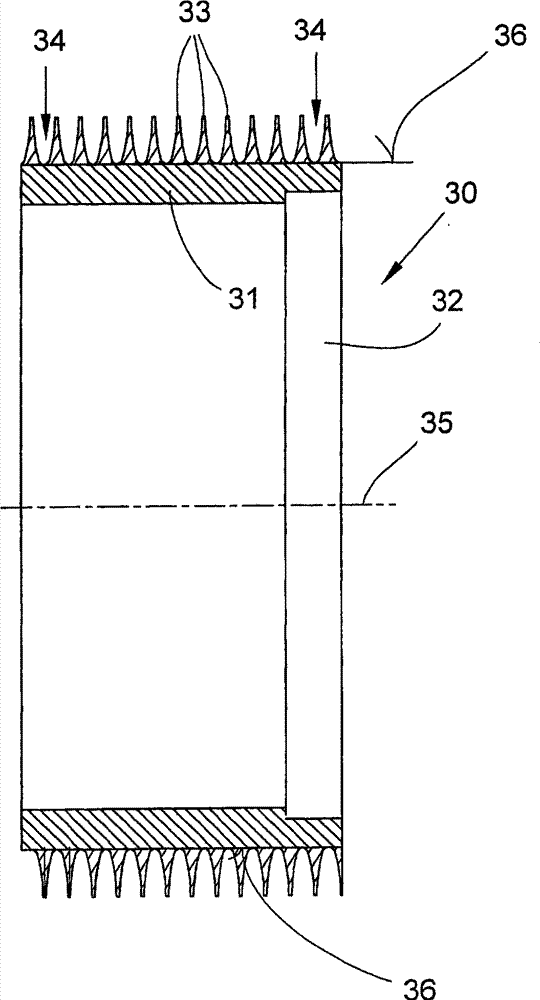

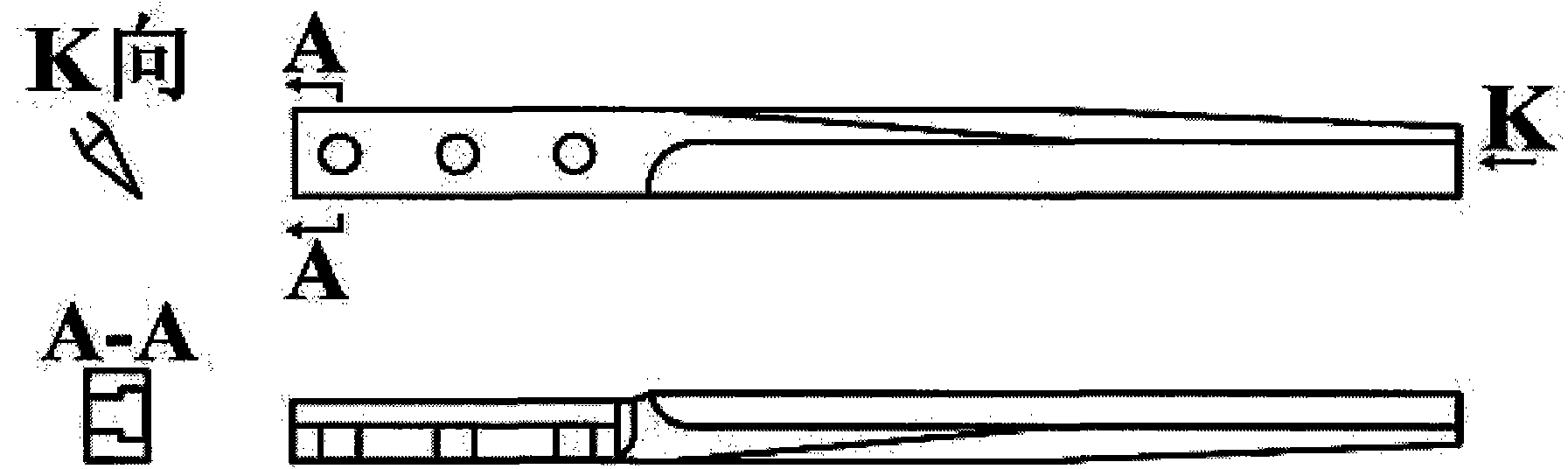

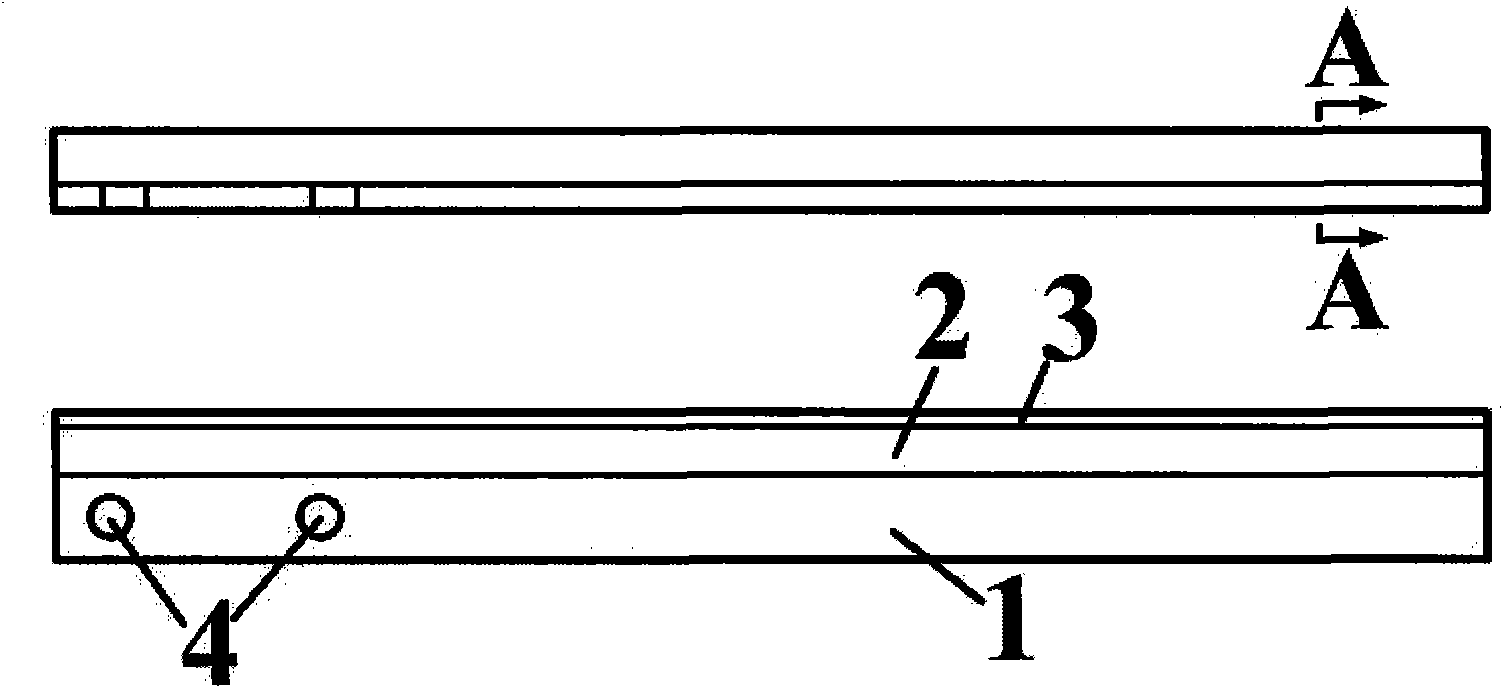

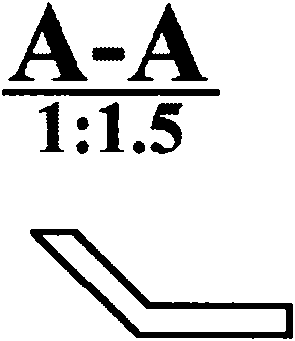

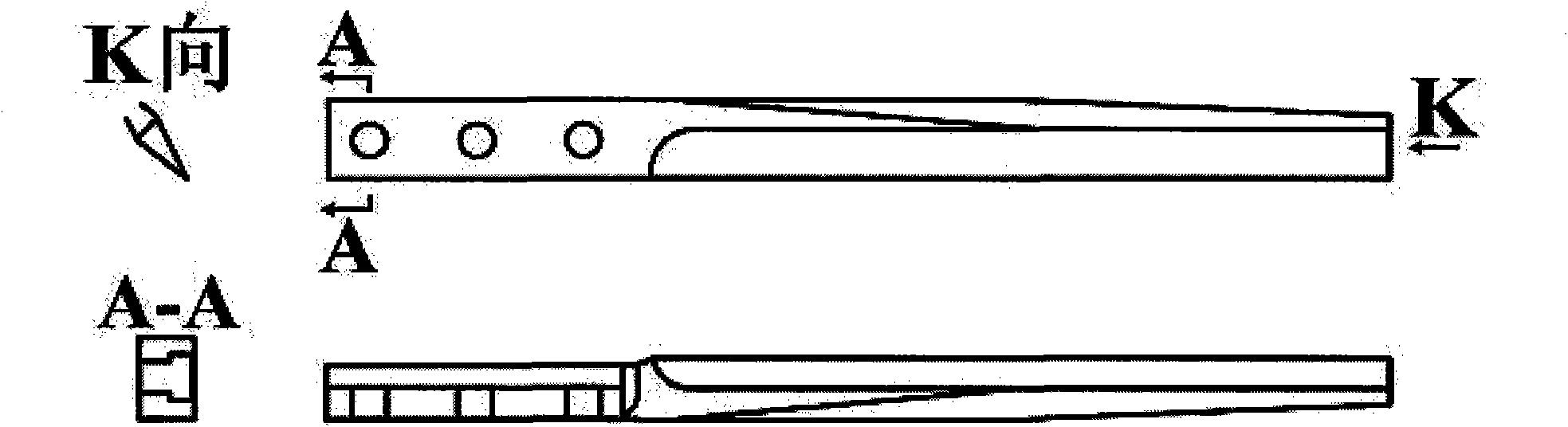

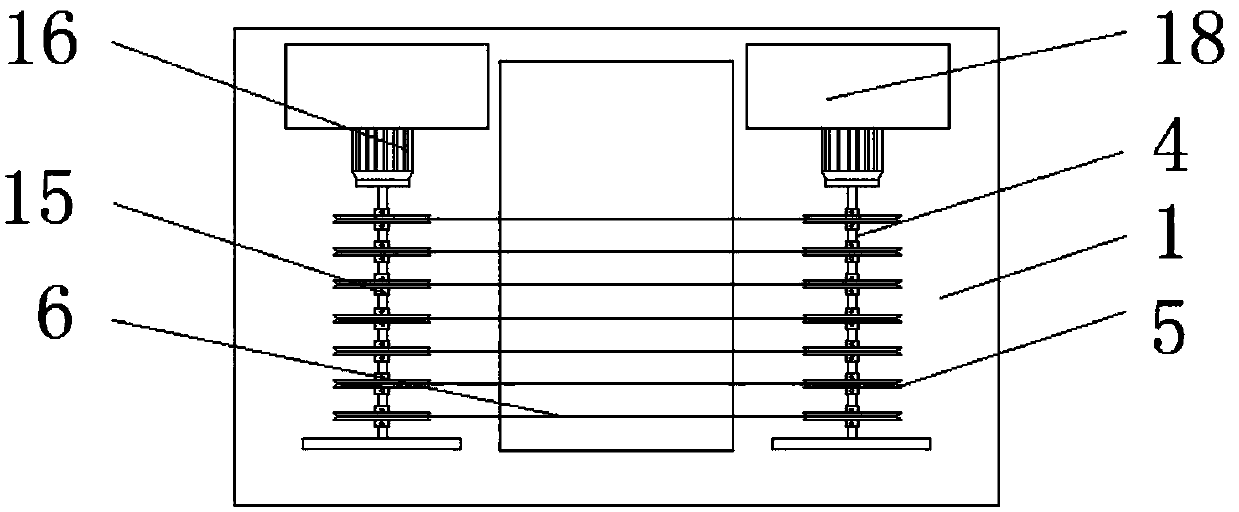

Ram for a plugging device for driving a strip-type retaining element into a bore of a toothbrush head that holds a tuft of bristles

ActiveCN1784158AImprove the immunityIncrease bending momentBrush bodiesBristleMechanical engineering

The invention relates to a plunger (1) of a filling tool according to EP 1 088 495 A1 for inserting a strip-shaped holding element, preferably an anchor, into a bristle hole of a brush head capable of receiving bristle tufts . The push rod (1) has on the end side an embedding surface (2) for engaging the retaining element, its cross-section (3, 4, 15; 3, 5, 8; 3) is defined by the longitudinal face and the end face (6, 7; 6, 8; 6, 10) limited. The push rod (1) has an end region (17, 20, 21) on the end side, which is pierced into the material of the brush head when the retaining element is inserted. According to the invention, the cross-sectional area ( 24 , 25 , 26 ) of the push rod ( 1 ), which enters the bristle opening and lies outside the end area, is wider than the end-side end area ( 17 ).

Owner:BRAUN AG

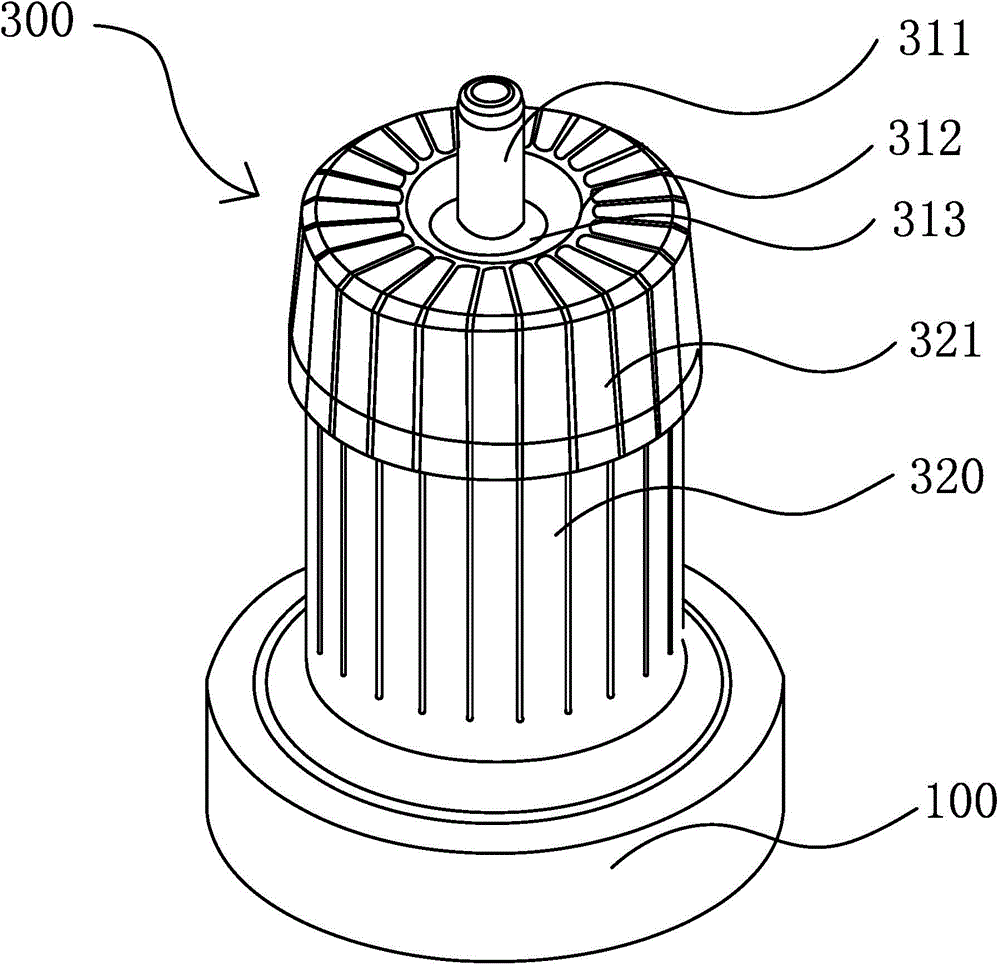

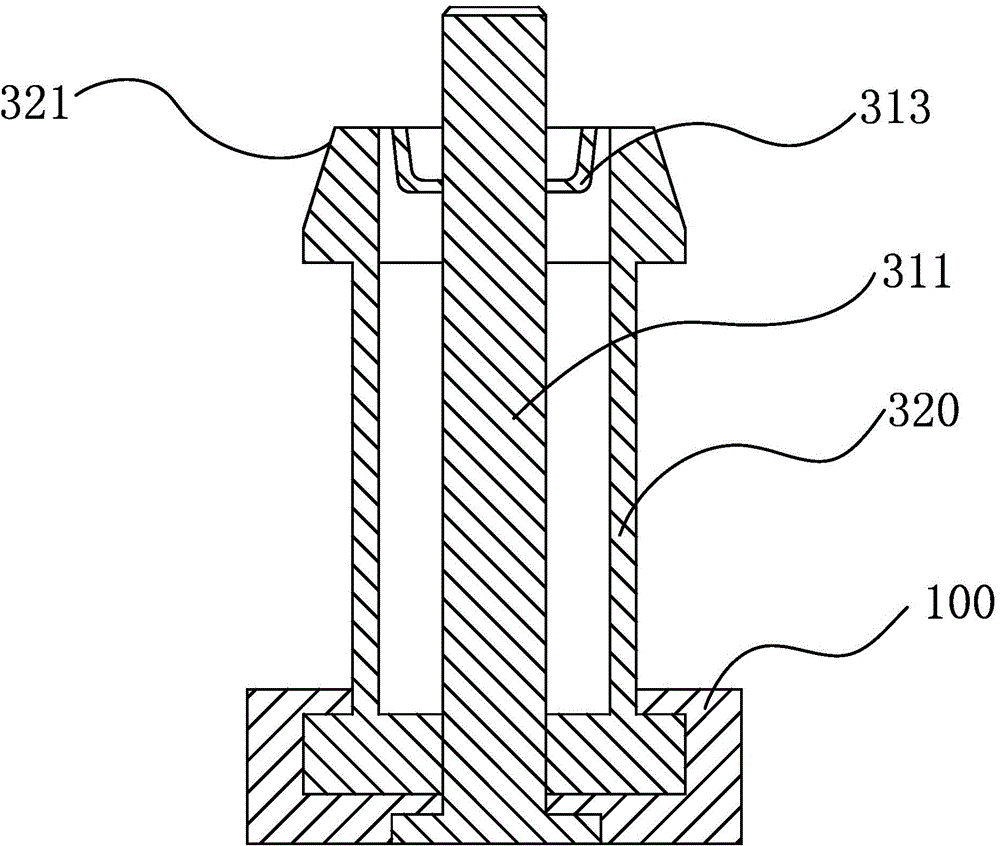

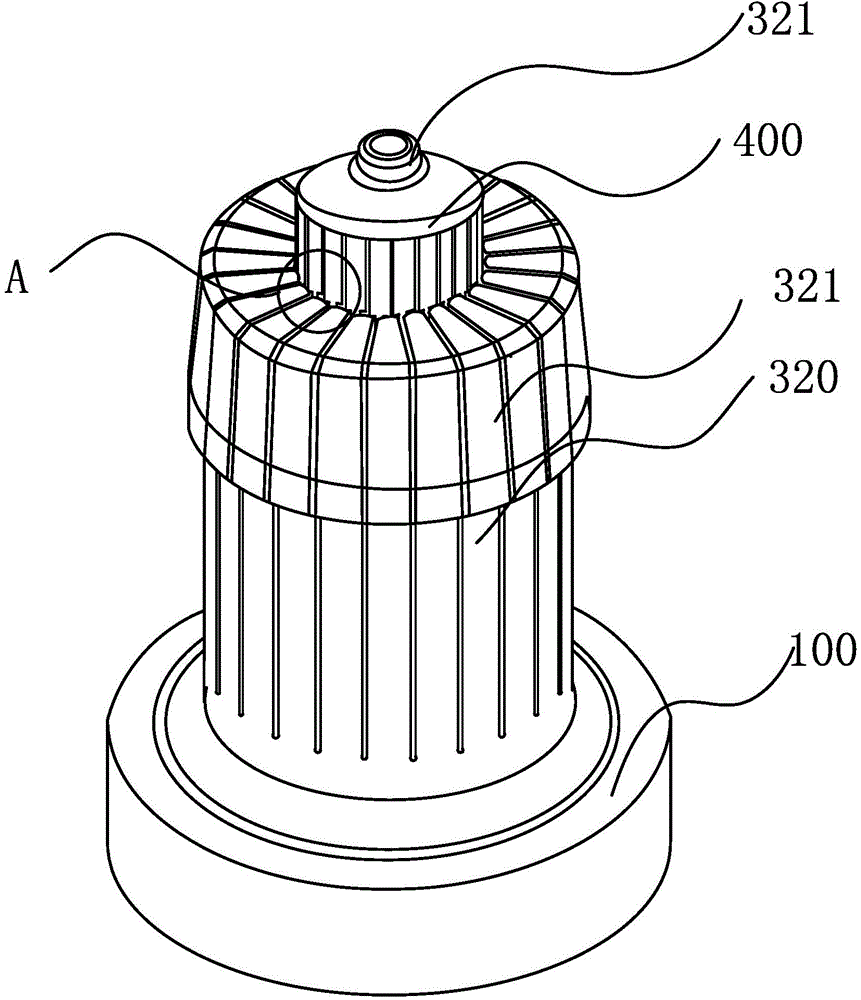

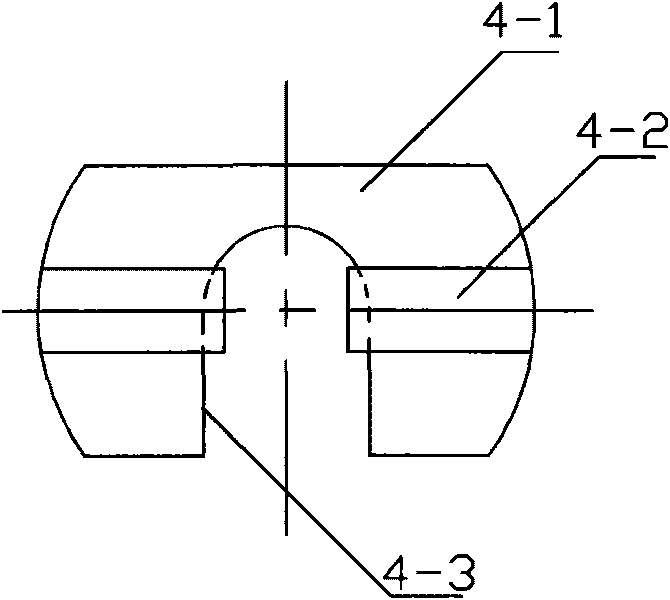

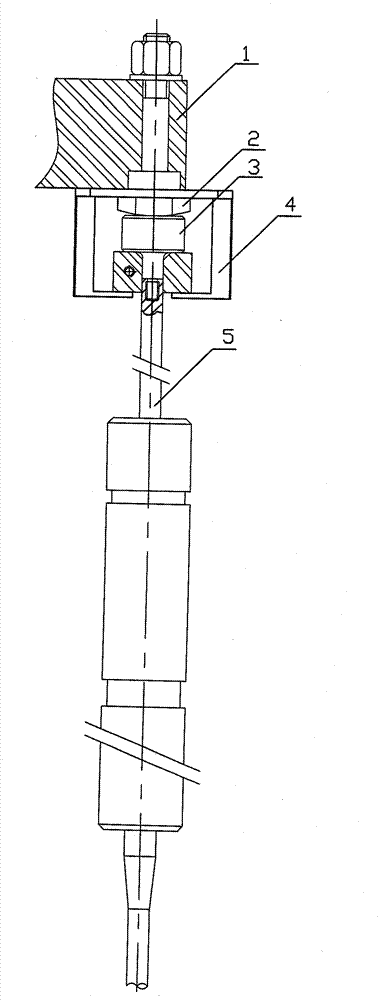

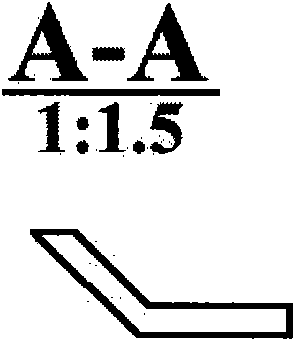

Pin pressing device for commutator

InactiveCN104577631AReduce horizontal widthReduce defective rateDynamoelectric machine connectorsCommutators manufactureEngineeringMechanical engineering

The invention provides a pin pressing device for a commutator, belongs to the technical field of commutator equipment and solve the problem of poor extrusion effect of an existing pin pressing device for the commutator. The pin pressing device for the commutator comprises a base body, a lower mould which is arranged on the base body and is used for mounting the commutator and an upper mould which is matched with the lower mould; the upper mould comprises a pressing cylinder and a connecting shaft; the lower mould comprises a mould core and a plurality of mould plates which uniformly encircle the periphery of the mould core; a gap is formed among the mould plates; when the commutator is arranged on the lower mould, hook pins of the commutator are clamped in the gap, and the upper mould moves downwards to enable the mould plates to be close to the mould core in a radial direction and to extrude the hook pins to be in a boss shape. The pin pressing device for the commutator has the advantages of good extrusion effect and capability of preventing the hook pins of the commutator from being broken.

Owner:HUARUI ELECTRICAL APPLIANCE

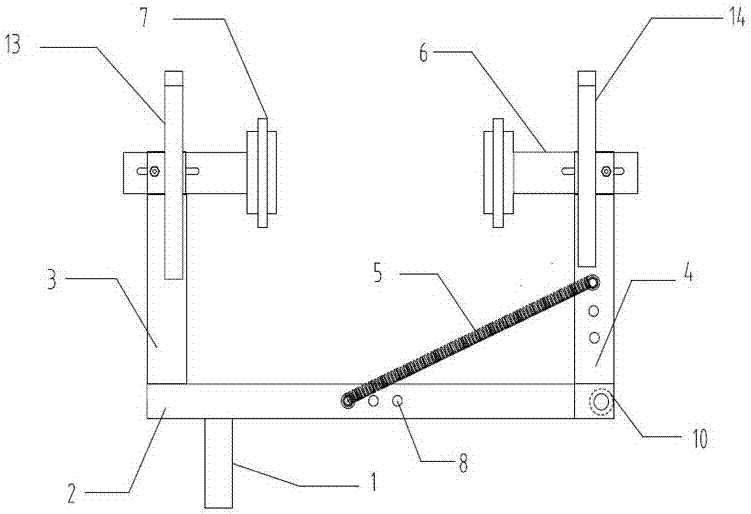

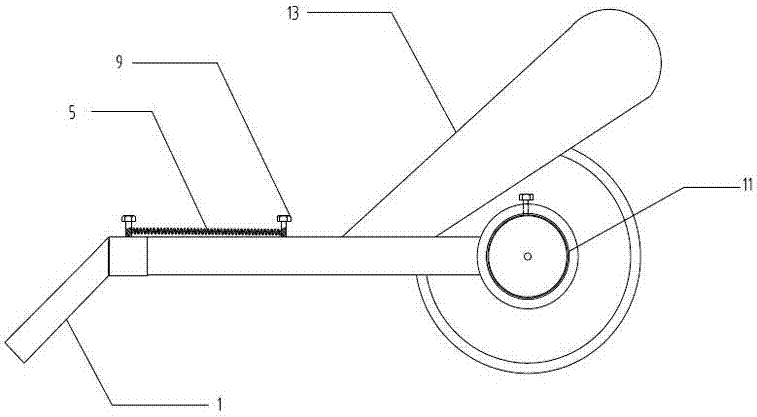

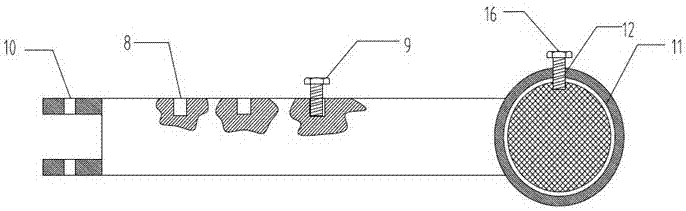

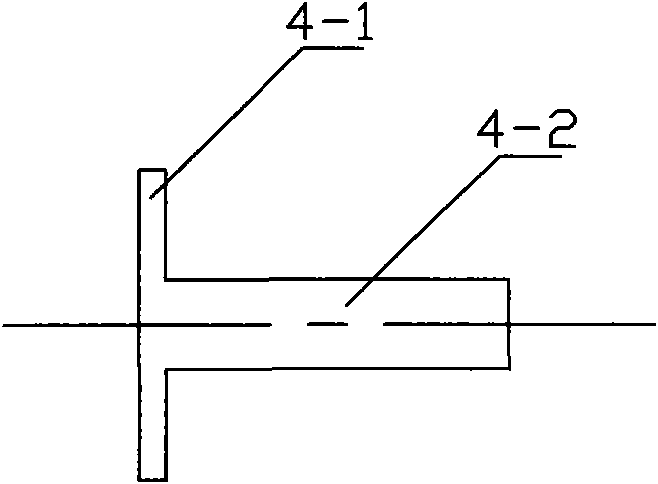

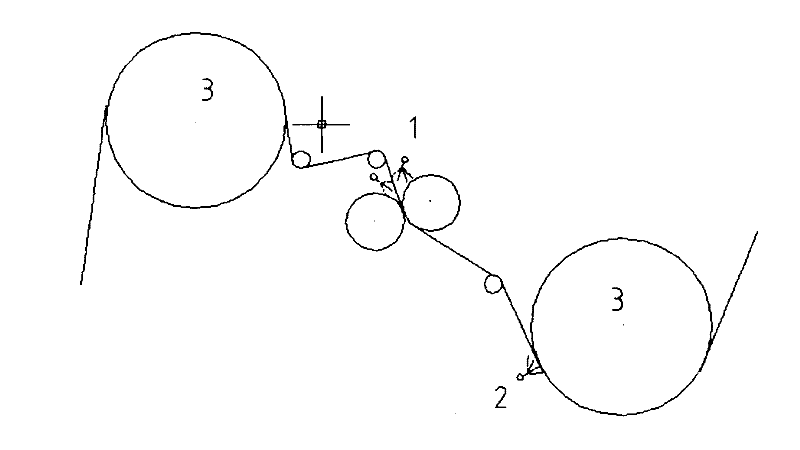

Covering yarn spinning cake special clamp

InactiveCN107352314AReduce resistanceReduce the number of breaksFilament handlingRolling resistanceEngineering

The invention relates to a covering yarn spinning cake special clamp. The covering yarn spinning cake special clamp is applied to an automatic rewinding machine and is characterized by comprising a T-shaped main body, a fixed clamp arm, a movable clamp arm, a spring, movable shafts and clamping heads. A bearing rotating manner is adopted to replace an original automatic shaft rotating rewinding manner. Sliding friction is changed into rolling friction. Resistance of a shot tube cylindrical spinning cake in the rewinding process is reduced. The frequency of fracturing of filaments is reduced. The rewinding efficiency is improved.

Owner:RUGAO XIAYUAN SCI & TECH ESTABLISH A BUSINESS SERVICES CO LTD

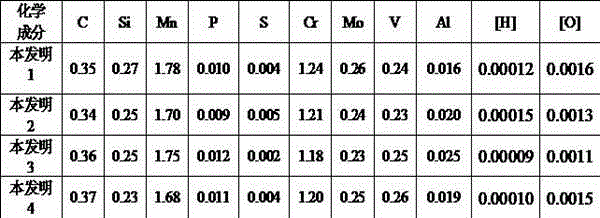

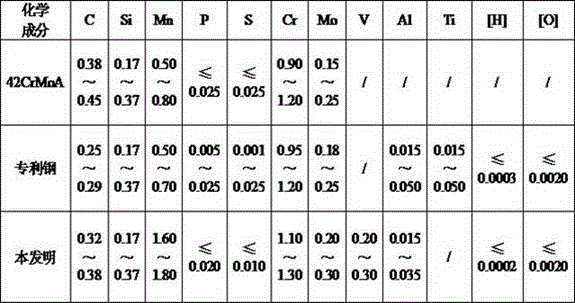

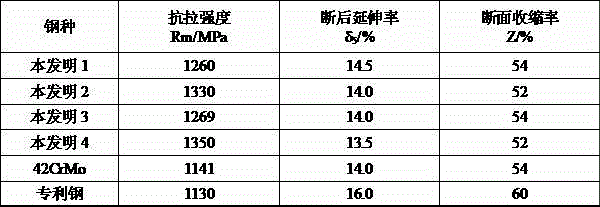

Ultrahigh-strength and high-toughness steel for pumping rod and production process thereof

ActiveCN103233172BHigh strengthImprove toughnessDrilling rodsDrilling casingsChemical compositionLate stage

The invention discloses ultrahigh-strength and high-toughness steel for a pumping rod, which comprises the following chemical components in percentage by mass: 0.32-0.38% of C, 0.17-0.37% of Si, 1.60-1.80% of Mn, 1.10-1.30% of Cr, 0.20-0.30% of Mo, 0.20-0.30% of V, 0.015-0.035% of Al, no more than 0.020% of P, no more than 0.010% of S, no more than 0.002% of [O], no more than 0.0002% of [H] and the balance of Fe. The production process comprises the following steps: smelting in a conventional converter, refining in a refining device, performing silicon-calcium-barium end deoxidation in the late stage of the refining process, performing RH degasification and inclusion removal after refining, casting molten steel into a continuous casting blank, and rolling into phi19-25mm round steel. The invention is reasonable in component design and advanced in process; compared with ultrahigh-strength steel for a pumping rod available on the existing market, the steel disclosed by the invention has higher strength and toughness, the tensile strength Rm is no less than 1200 MPa, the extension percentage delta5 is no less than 12%, the percentage reduction in area Z is no less than 48%, accidents of pumping rod breakage in a high-load environment can be effectively decreased, and the economic loss can be obviously reduced.

Owner:JIANGSU LIHUAI IRON AND STEEL CO LTD +1

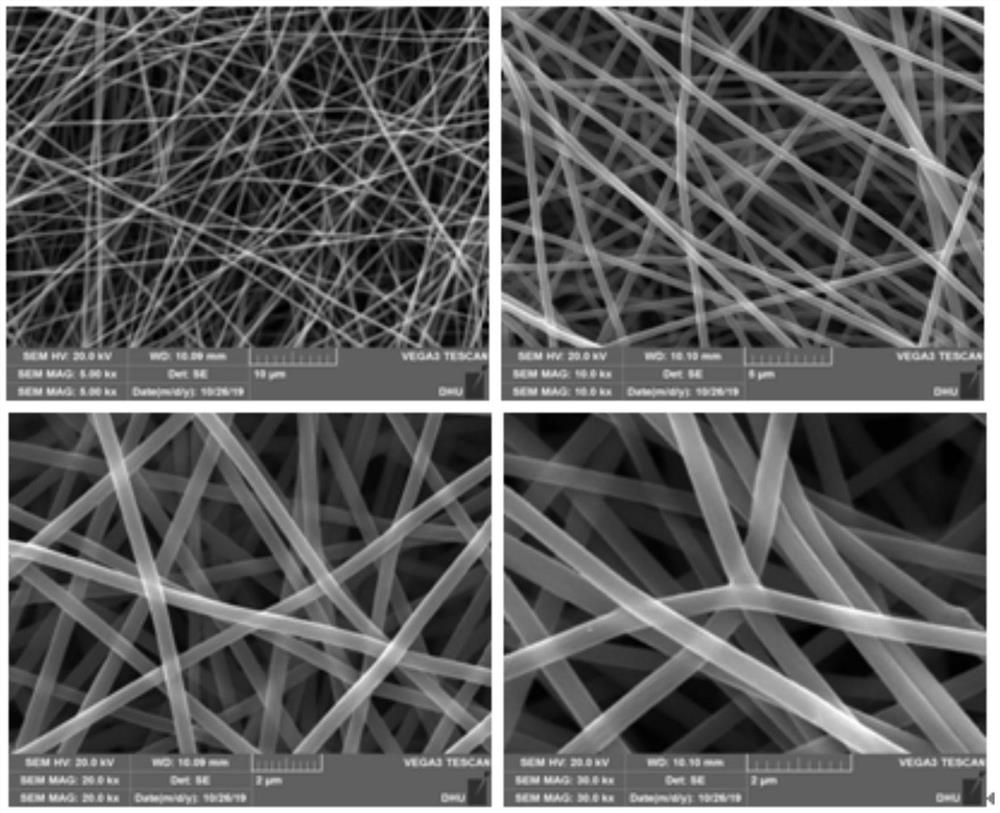

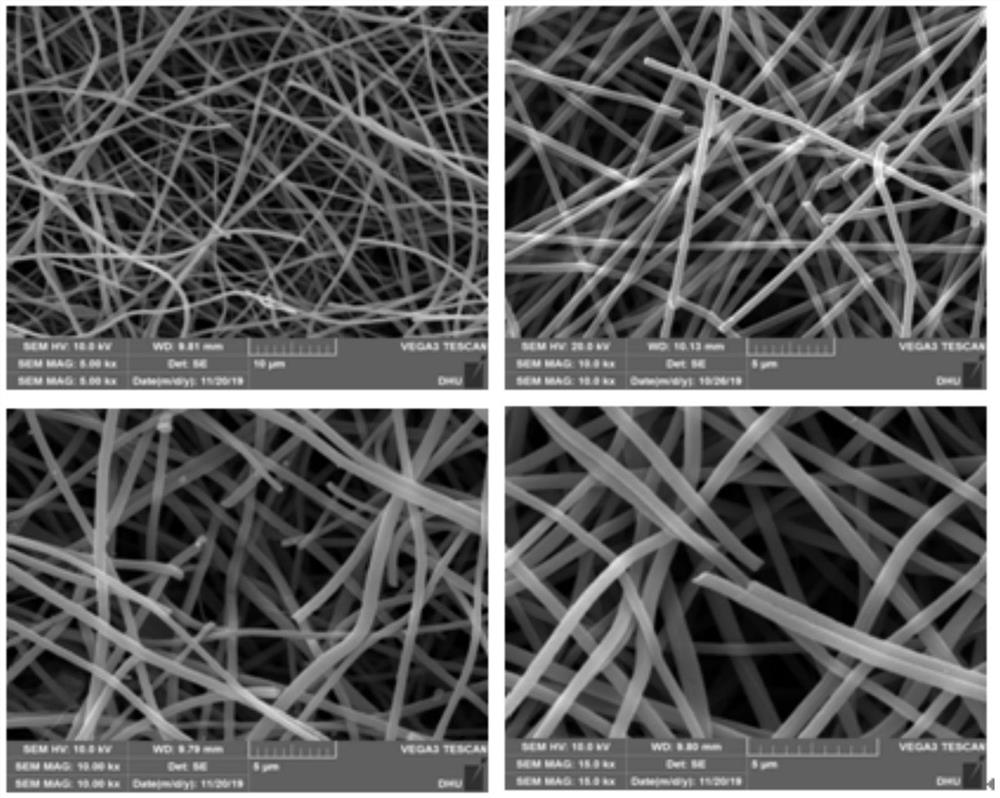

High-strength carbon nanofiber membrane and preparation method thereof

ActiveCN112030353AHigh breaking strengthReduce breakageHeating/cooling textile fabricsNon-woven fabricsSolvent moleculePolymer science

The invention relates to a high-strength carbon nanofiber membrane and a preparation method thereof. The preparation method comprises an electrostatic spinning procedure and a pre-oxidation treatmentprocedure and further comprises a preheating treatment procedure located between the electrostatic spinning procedure and the pre-oxidation treatment procedure, the starting temperature of preheatingtreatment is room temperature, the heating rate is 1-5 DEG C / min, the terminal temperature is (T+a) DEG C, T = max {Tb, Tg}, Ta is the boiling point of a solvent for electrostatic spinning, Tg is theglass-transition temperature of the polymer for electrostatic spinning, a is -5-5, and the heat preservation time is 1-2 hours; and the breaking strength of the finally prepared high-strength carbon nanofiber membrane is 70-120 MPa. According to the preparation method of the high-strength carbon nanofiber membrane, solvent molecules entangled by disorderly-oriented molecular chains can be effectively removed, a large number of structural defects caused by subsequent solvent removal are avoided, meanwhile, fiber breakage is effectively reduced, the fiber breakage number is reduced to about onetenth of the original fiber breakage number, and the breaking strength of the finally prepared high-strength carbon nanofiber membrane is far higher than that in the prior art.

Owner:DONGHUA UNIV

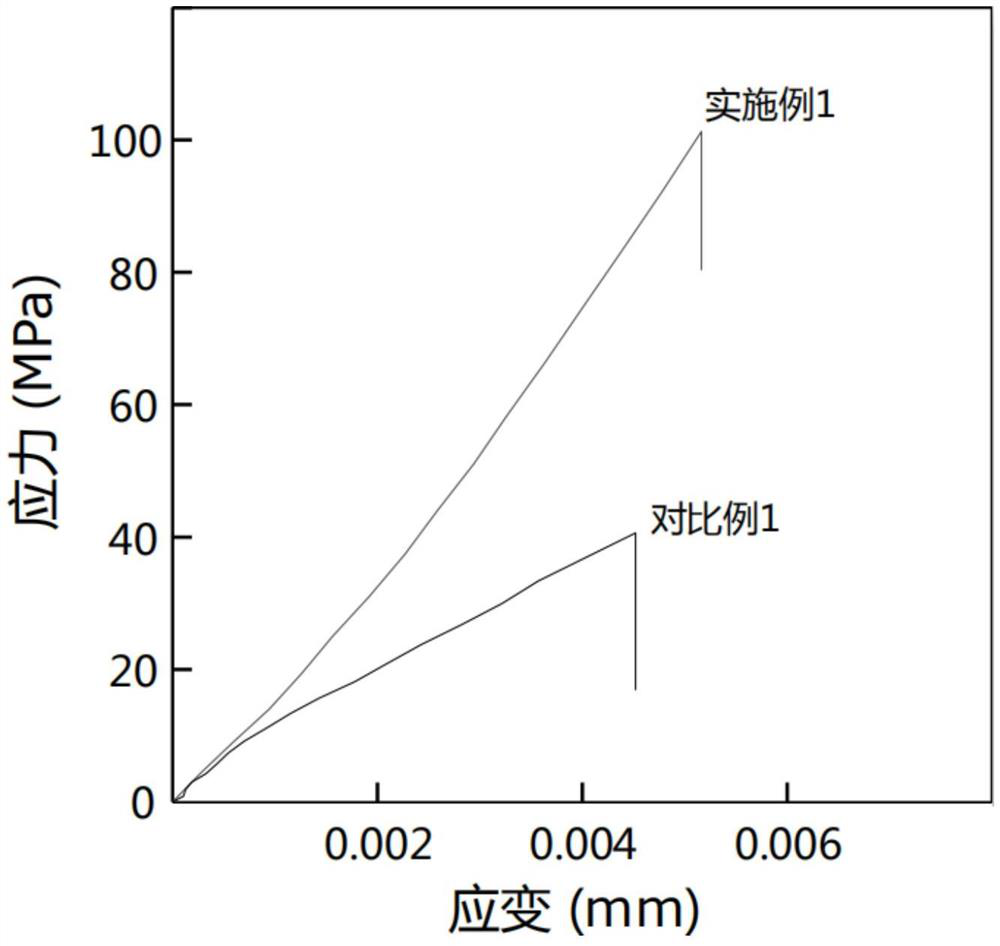

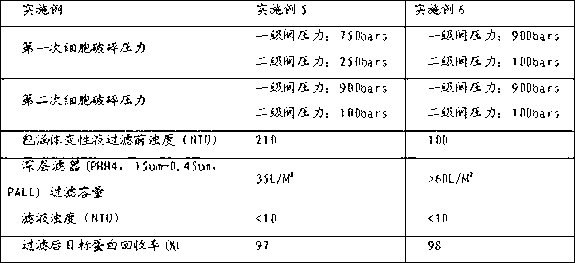

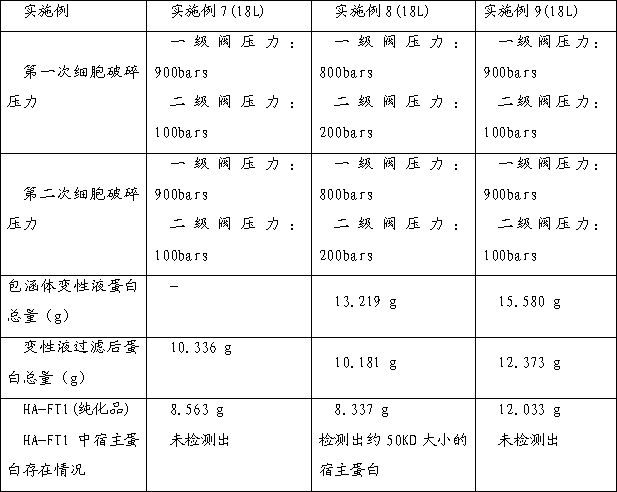

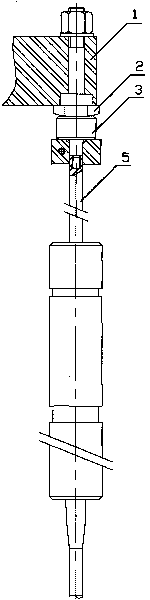

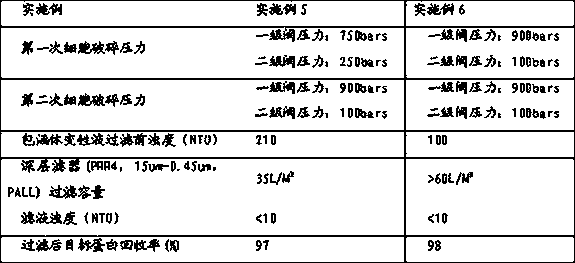

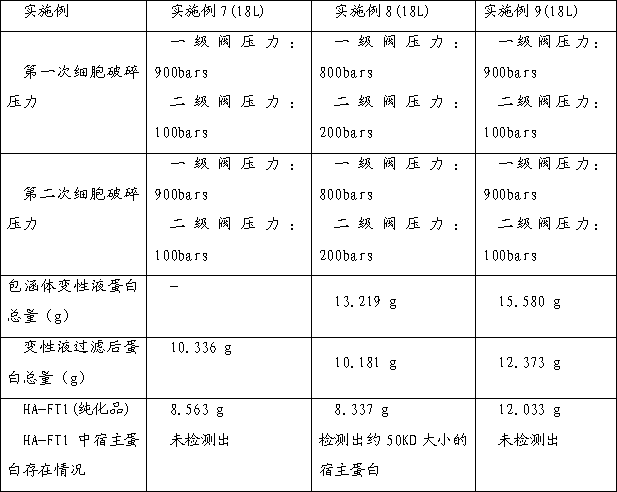

Preparation method of fusion protein inclusion body

ActiveCN102994595AReduce processingReduce the number of breaksMicroorganism based processesFermentationBiotechnologyInclusion bodies

The invention provides a preparation method of a fusion protein inclusion body, which comprises the following steps of: crushing engineering bacteria; washing an inclusion body; and denaturing, dissolving and filtering the inclusion body. According to the invention, a prepared inclusion body denatured dissolved solution is obviously enhanced in clarity, and a filter is obviously increased in filtering capacity.

Owner:广州白云山拜迪生物医药有限公司

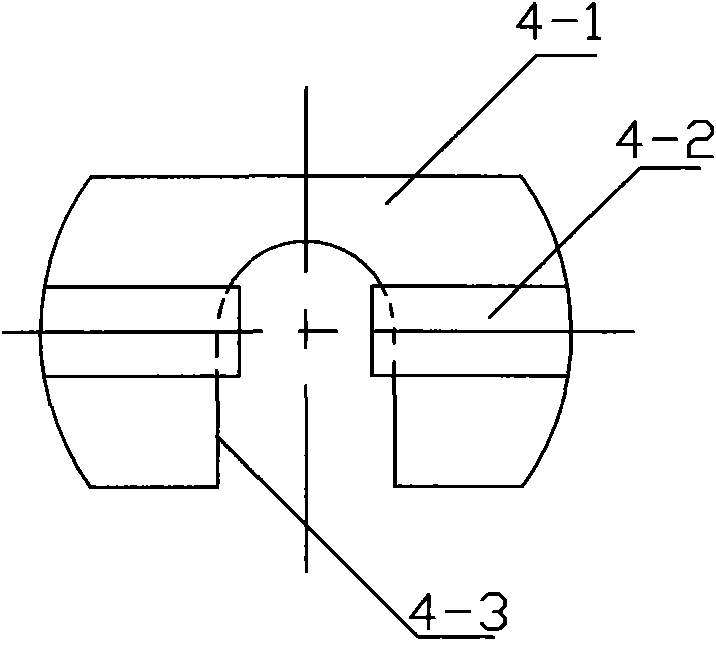

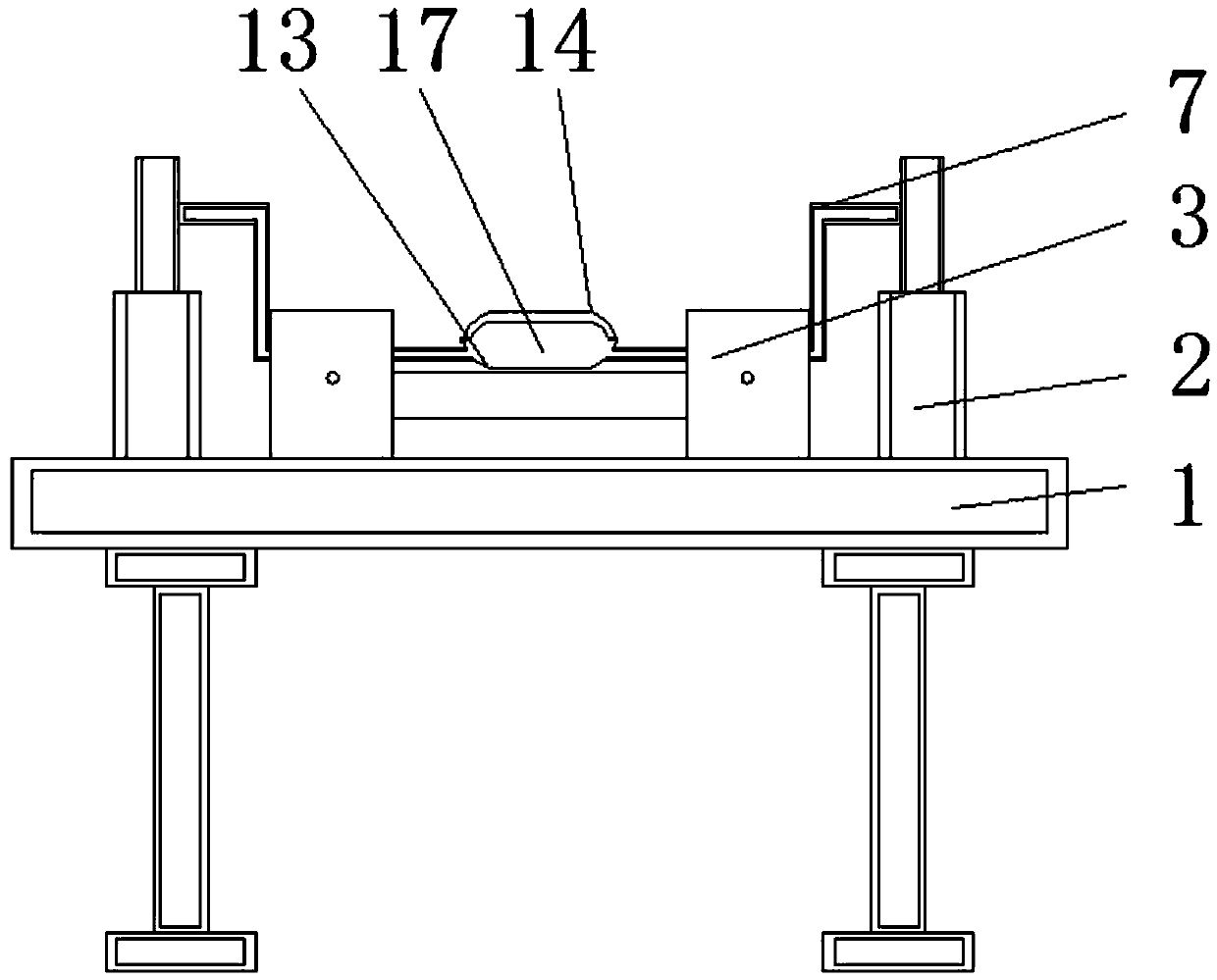

Connecting method of displacement transducer magnetic head and connecting jackcatch

ActiveCN101700530AJam reductionExtended service lifeMeasuring devicesMetal rolling arrangementsControl systemTransducer

The invention relates to a connection method of magnetic heads of a displacement transducer expansion rod of a mandrel pipe mill by using a hydraulic gap control (HGC) system to produce seamless steel tubes and a connecting device. The connecting method comprises the following steps: a connecting jackcatch is arranged between the magnetic head of the displacement transducer expansion rod and a bolt on a bolt installation block connected with a servo cylinder; an opening slot on a connecting plate of the connecting jackcatch is stuck in the screw of the bolt and is fixed on the bolt installation block by the bolt; two grabbers on the connecting plate of the connecting jackcatch grab the bottom part of the magnetic head; and a gap of 0.2-0.3mm is left between the two symmetric grabbers and the bottom part of the magnetic head when the connecting jackcatch is mounted well. In the invention, the connecting jackcatch comprises a connecting plate provided with an opening slot, and two symmetric grabbers are arranged at two ends of the connecting plate.

Owner:衡阳华菱连轧管有限公司 +1

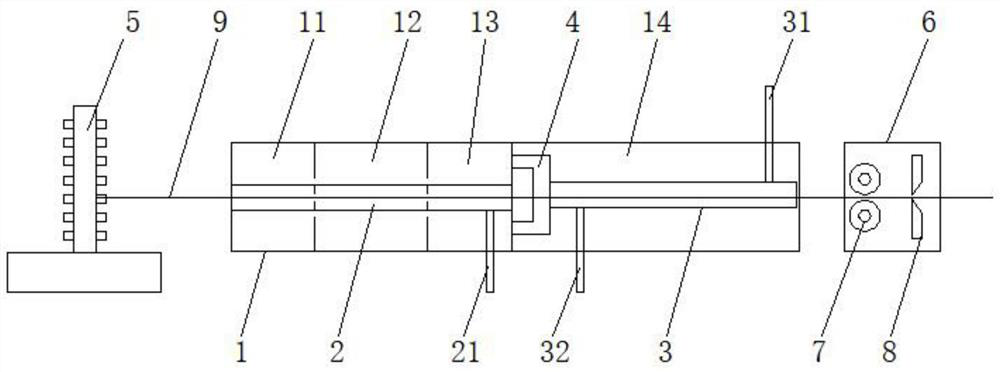

High-temperature alloy wire straightening and shearing device

PendingCN114054635AHigh degree of automationEasy to operateFurnace typesHeat treatment furnacesEngineeringAlloy

The invention provides a high-temperature alloy wire straightening and shearing device, belonging to the field of special alloys. The high-temperature alloy wire straightening and shearing device comprises: a hot straightening furnace, wherein a heating area, a heat preservation area, a shaping area and a cooling area are sequentially arranged in the hot straightening furnace in an alloy wire entering direction; a first interlayer cooling pipeline, which is arranged in the hot straightening furnace and penetrates through the heating area, the heat preservation area and the shaping area, wherein the interlayer of the first interlayer cooling pipeline is filled with argon; a second interlayer cooling pipeline, which is arranged in the hot straightening furnace and penetrates through the cooling area, wherein the interlayer of the second interlayer cooling pipeline is filled with a liquid cooling medium; a shaping mold, which is arranged at the outlet of the shaping area, wherein two ends of the shaping mold respectively communicate with the outlet of the first interlayer cooling pipeline and the inlet of the second interlayer cooling pipeline; and cutting equipment, which is arranged on one side of an outlet of the second interlayer cooling pipeline and is used for receiving the alloy wire discharged from the second interlayer cooling pipeline and cutting the alloy wire. According to the device, a technological process is simple, labor cost is saved, environmental pollution is reduced, and production efficiency is improved.

Owner:陕西鼎益科技有限公司

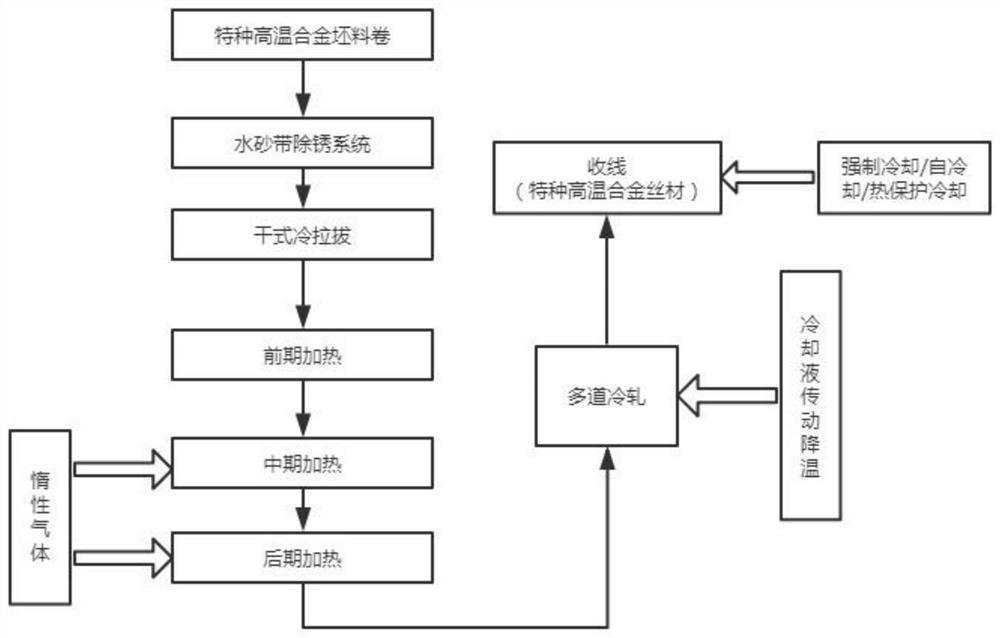

Novel special high-temperature alloy wire hot rolling process

The invention discloses a novel special high-temperature alloy wire hot rolling process, and belongs to the technical field of wire processing. The process comprises the following steps that S1, a special high-temperature alloy bar is subjected to surface pretreatment, and a wire with the specification of phi 8.00-4.00 mm is formed through cold drawing; and S2, the wire obtained in step S1 is sequentially subjected to early-stage heating, middle-stage heating and later-stage heating treatment, then cold rolling is carried out multiple times, cooling is carried out in the cold rolling process, and after the wire is subjected to cold rolling to a certain specification, wire winding is carried out to obtain the novel special high-temperature alloy wire. The process provided by the invention is high in production efficiency, low in process control difficulty, excellent in product quality and low in manufacturing cost.

Owner:陕西鼎益科技有限公司

A kind of preparation device and preparation method of titanium wire

The invention relates to the technical field of preparing titanium wires from titanium alloy or pure titanium, and discloses a preparation device of titanium wires. The preparation device comprises multiple cold wire drawing machines, a polishing machine, a single multiple flaying machine, a wire coiling machine, a cold wire drawing machine unit intelligent control system and a surface treatment automatic integration system. Each cold wire drawing machine comprises a motor, a wire drawing powder box, a pneumatic tensioning roller wheel, a first rotor and a wire drawing grinding apparatus, wherein the pneumatic tensioning roller wheel is provided with a pneumatic tension sensor which is connected with the cold drawing machine unit intelligent control system. A 360-degree rotation type abrasive belt unit, a cooling water tank, a second rotor and a wire coiling machine are connected with the surface treatment automatic integration system. The cold wire drawing unit intelligent control system is connected with the surface treatment automatic integration system. According to the preparation device and method of the titanium wires, operation is simple, the production efficiency is greatly improved, the production environment is remarkably improved, and meanwhile production safety is improved.

Owner:陕西鼎益科技有限公司

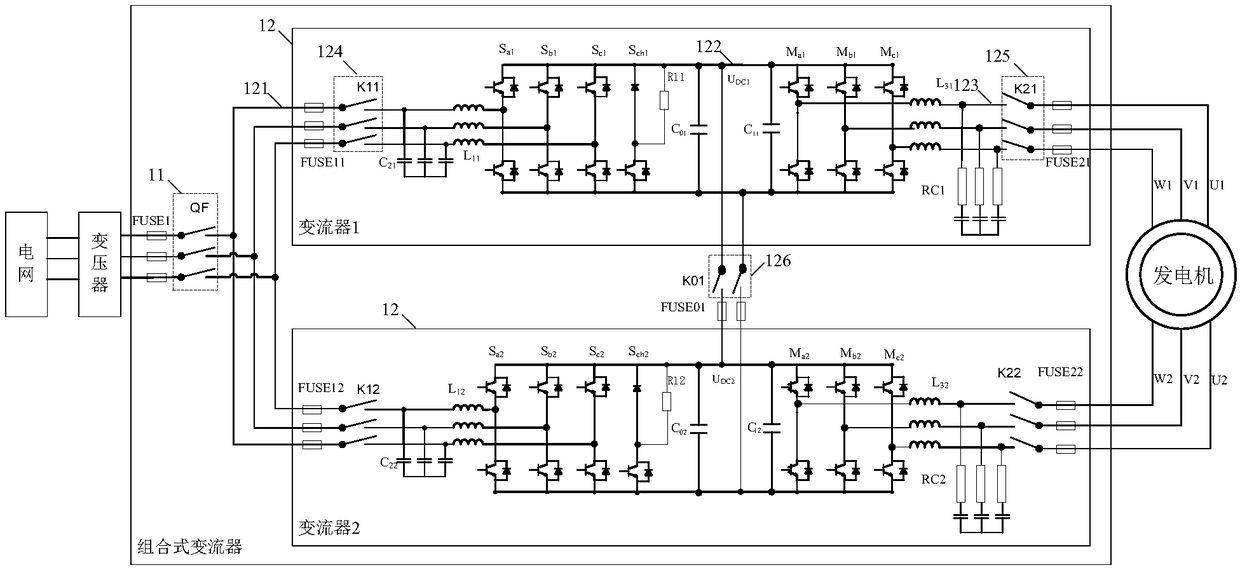

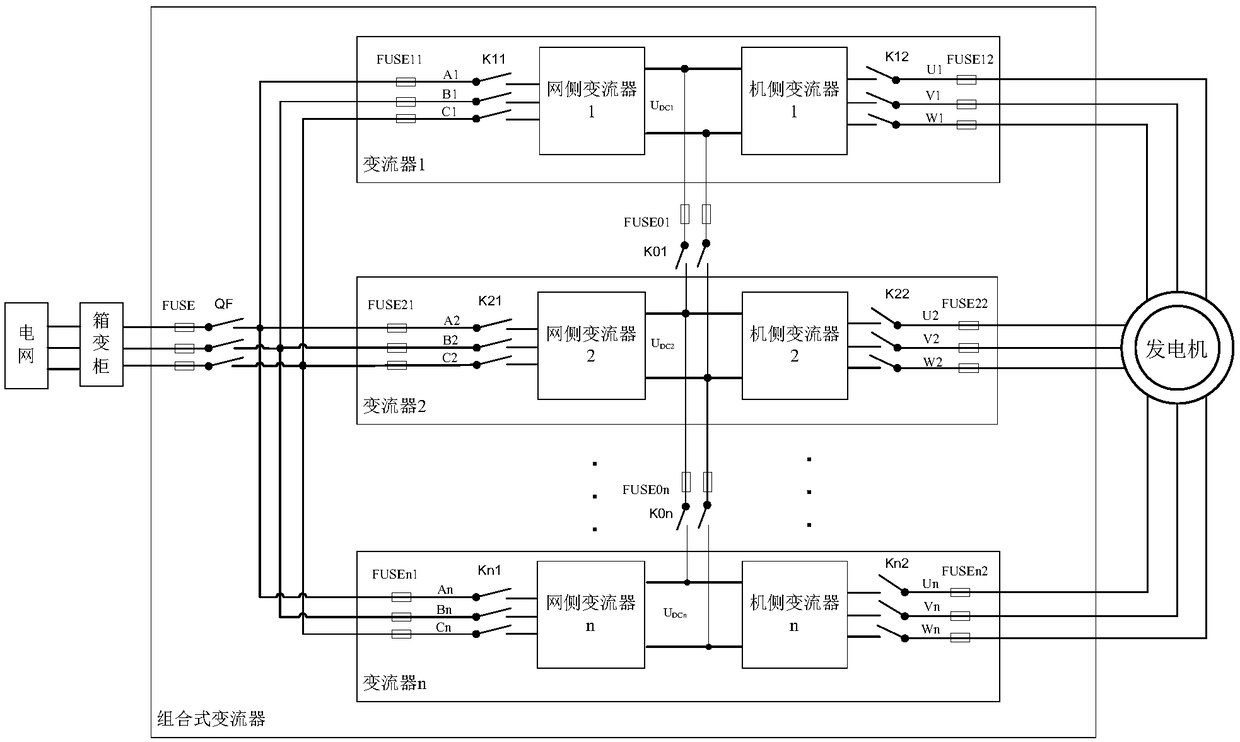

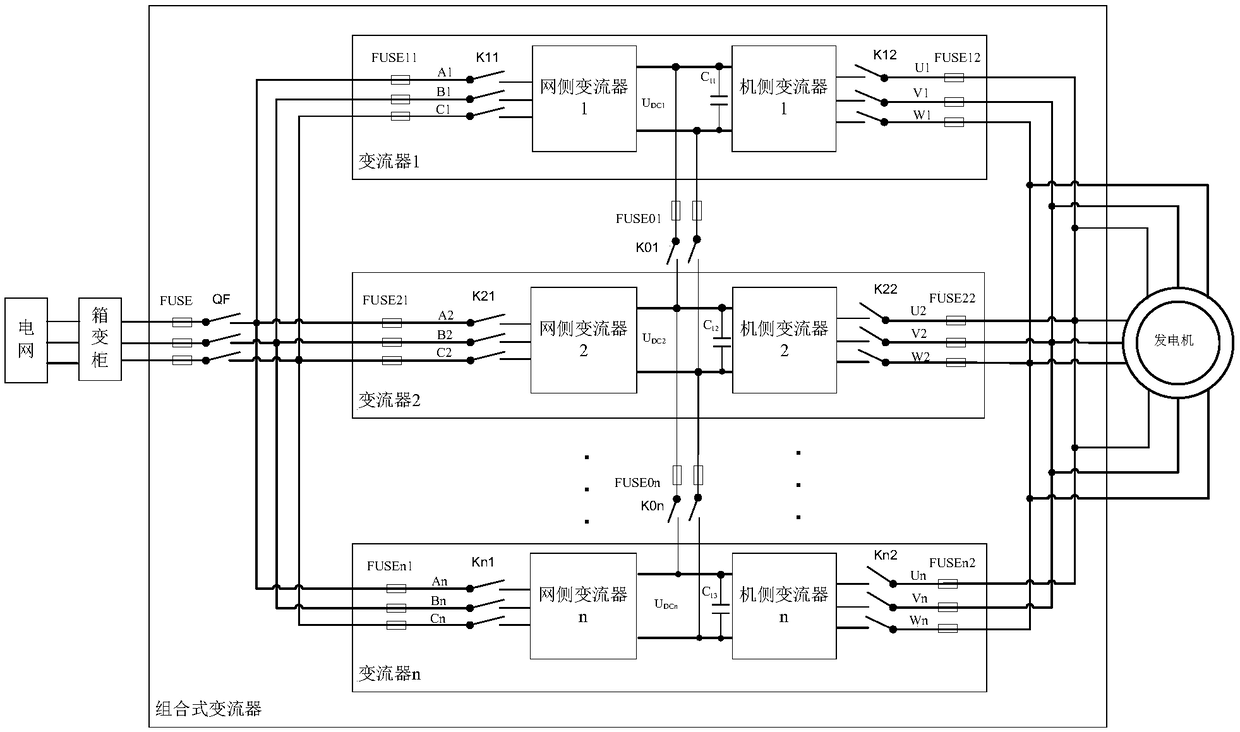

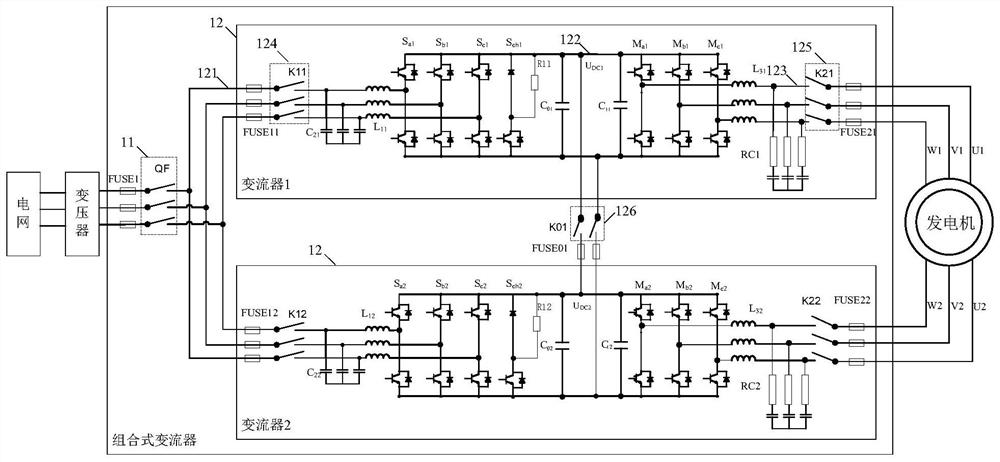

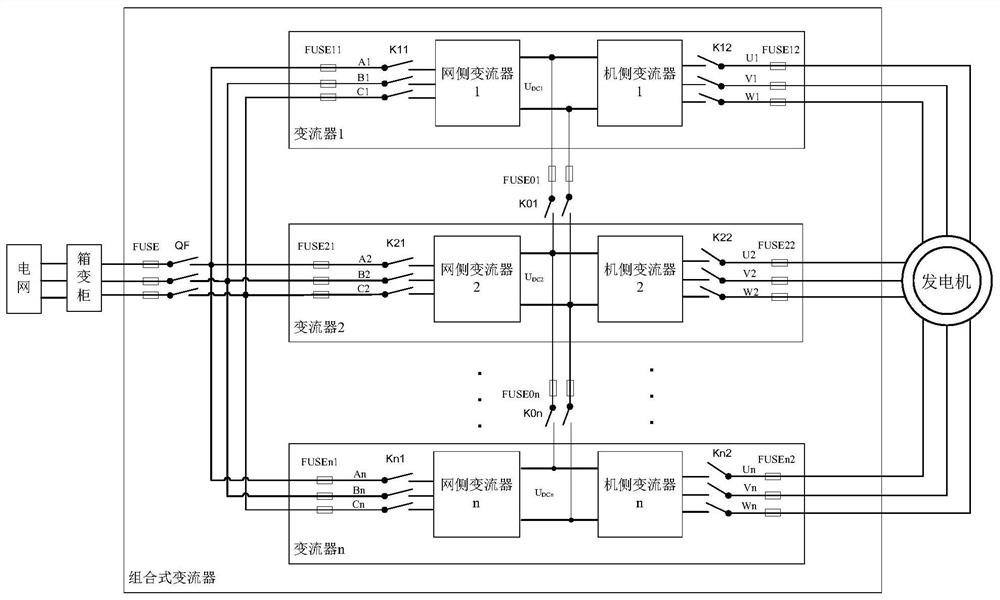

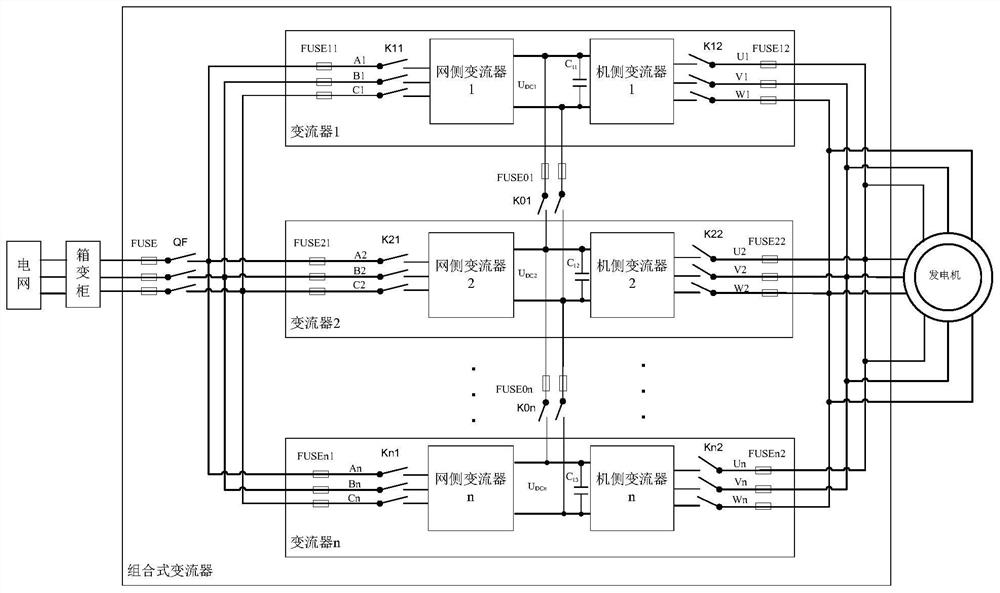

Combined converter and control method thereof

ActiveCN108832659AReduce circulationReduce the number of breaksSingle network parallel feeding arrangementsWind energy generationCirculating currentEngineering

An embodiment of the invention provides a combined converter and a control method thereof. The combined converter comprises a frame circuit breaker and at least two converters, wherein each convertercomprises an AC grid side, a DC side, an AC motor side, a first contactor and a second contactor. According to the combined converter, through controlling the on-off state of the first contactor, thesecond contactor and the third contactor, the accessing state of each converter is individually controlled, and system redundancy is improved. Furthermore the frame circuit breaker can be always in anoff state, thereby reducing the number of on-off times of the frame circuit breaker and furthermore prolonging service life of the frame circuit breaker. Furthermore, because the converters of a plurality of accessing systems are parallelly connected through the third contactor, circulating current among the converters is lowered.

Owner:SUNGROW POWER SUPPLY CO LTD

A push rod

The invention relates to a push rod ( 1 ) of a filler tool according to EP 1088495 A1 for inserting a strip-shaped holding element, preferably an anchor rod, into a bristle tuft-accommodating pore of a brush head. The push rod (1) has an engagement surface (2) on the end side for engagement of the holding element, its cross section (3, 4, 15; 3, 5, 8; 3) consists of a longitudinal face and an end face (6, 7; 6, 8; 6, 10) are limited. The push rod ( 1 ) has end regions ( 17 , 20 , 21 ) on the front side, which are penetrated into the material of the brush head when the retaining element is inserted. According to the invention, the cross-sectional area ( 24 , 25 , 26 ) of the push rod ( 1 ) that enters the brush pore and lies outside the end area is wider than the end-side end area ( 17 ).

Owner:BRAUN AG

Connecting method of displacement transducer magnetic head and connecting jackcatch

ActiveCN101700530BJam reductionExtended service lifeMeasuring devicesMetal rolling arrangementsControl systemTransducer

The invention relates to a connection method of magnetic heads of a displacement transducer expansion rod of a mandrel pipe mill by using a hydraulic gap control (HGC) system to produce seamless steel tubes and a connecting device. The connecting method comprises the following steps: a connecting jackcatch is arranged between the magnetic head of the displacement transducer expansion rod and a bolt on a bolt installation block connected with a servo cylinder; an opening slot on a connecting plate of the connecting jackcatch is stuck in the screw of the bolt and is fixed on the bolt installation block by the bolt; two grabbers on the connecting plate of the connecting jackcatch grab the bottom part of the magnetic head; and a gap of 0.2-0.3mm is left between the two symmetric grabbers and the bottom part of the magnetic head when the connecting jackcatch is mounted well. In the invention, the connecting jackcatch comprises a connecting plate provided with an opening slot, and two symmetric grabbers are arranged at two ends of the connecting plate.

Owner:衡阳华菱连轧管有限公司 +1

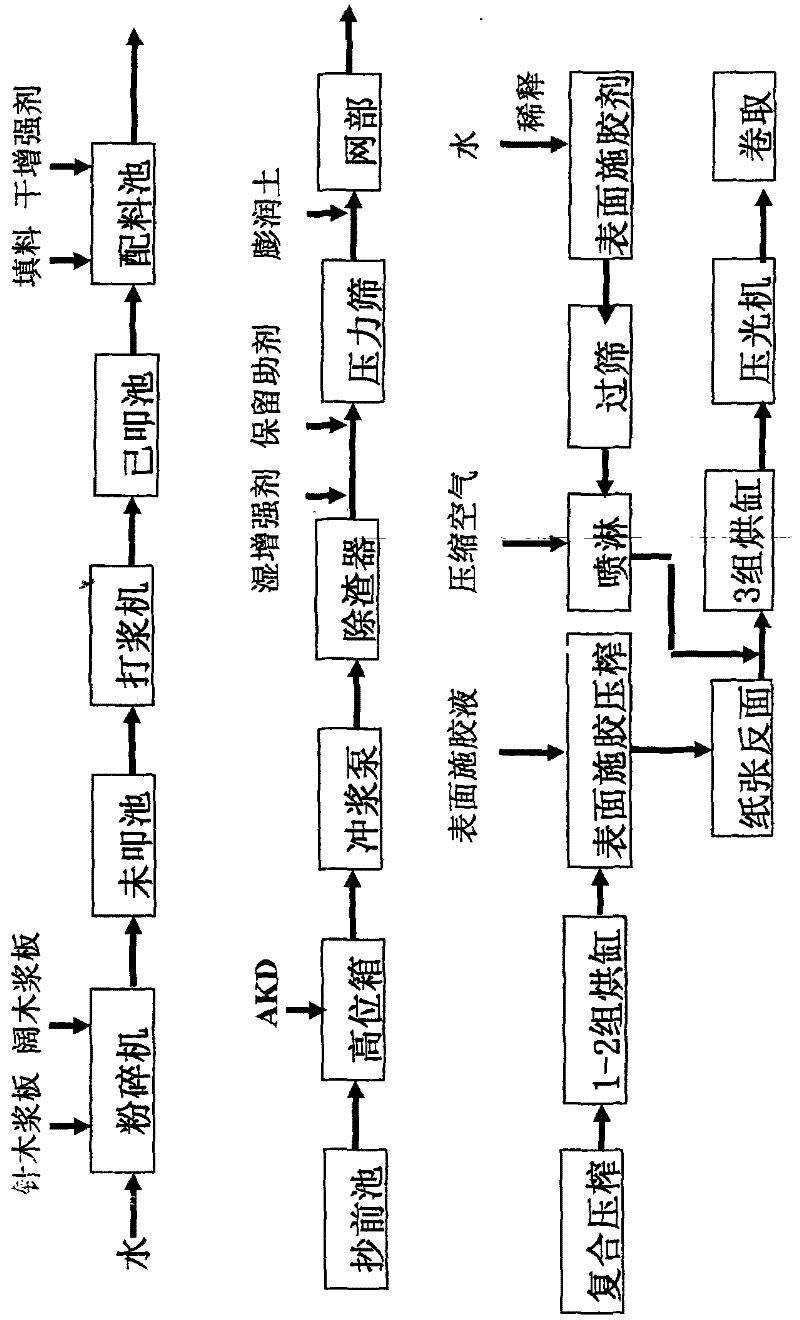

Noodles packing paper and production method thereof

ActiveCN101725080BImprove slipHealth effectsFlexible coversWrappersMethods of productionOptical brightener

The present invention provides noodles packing paper and production method thereof. The noodles packing paper comprises substrate paper, a surface sizing layer and a spraying layer, wherein one surface of the substrate paper is a front surface coated with the surface sizing layer and satisfied the printing requirements, the other surface of the substrate paper is coated with the surface sizing layer, and the surface sizing layer is coated with the spraying layer to form a reverse surface satisfied the requirement of smoothly packing the noodles. The noodles packing paper is produced by adopting common multi-cylinder long mesh paper machines and adding spraying technology devices; and the noodles packing paper is produced by the following steps of: pulping, dosing, adding with fillers and chemical additive to produce the substrate paper, coating the surface sizing layer on the front and reverse surfaces of the substrate paper, coating the spraying layer on the reverse surface, drying, then consequently press finishing and reeling. The noodles packing paper of the present invention does not need a coating machine to coating the paper, thereby avoiding the affect of the fluorescent bleaching agent to health; because the technology method of the present invention does not need special production equipment for producing, the production equipment decreases the condition, saves the production cost and has excellent economic effect.

Owner:ZHENJIANG DADONG PULP & PAPER

Method for coating opening roller ring and ring used for opening roller

ActiveCN101440494BReduce the number of breaksMaintain quality featuresCarding machinesFurnace typesNonferrous metalCompound (substance)

The invention relates to a coating method for the mounting ring (17) of a plucker roller (1) of synthetic fiber materials, which applies at least two layers on the mounting ring (17, 30) via chemical coating. The method comprises steps of: applying a first coating of a nonferrous metal as a base coating on the mounting ring (17, 30); and applying a coating based on a nickel-phosphorus alloy, which does not contain any hardener material as the other layer; then the coated mounting ring (17, 30) is then subjected to heat treatment at a temperature which is below the tempering temperature of thebase material of the ring.

Owner:SAURER GERMANY GMBH & CO KG

Steel for boron-containing prestressed steel wire and steel strand and its smelting process

ActiveCN103834848BGuaranteed qualifiedQuality improvementManufacturing convertersProcess efficiency improvementSmelting processBoron containing

The invention belongs to the technical field of smelting, and particularly relates to a smelting process of steel for boron-containing prestressed steel wires and steel strands. The process comprises the following steps: preparing molten iron, waste steel and raw iron serving as raw materials; during smelting of a revolving furnace, adding slag charge, performing the operation of raising high carbon content and post blowing, controlling the end point C over 0.4 percent, and controlling the end point P below 0.015 percent; during steel tapping of the revolving furnace, adding silicon carbide, lime and an alloy serving as deoxidizing materials in sequence along with the steel flow; during refining, deoxidizing the top of the slag by adopting the silicon carbide, wherein the target refining final alkalinity is 1.7; after refining, performing soft argon blowing at the bottom of a steel ladle; during continuous casting, feeding Xibao special high-carbon steel protection slag to a crystallizer; and electromagnetically stirring the crystallizer, casting at a low superheat degree, performing forced cooling during secondary cooling, and electromagnetically stirring at the tail end. By adopting the smelted steel for the boron-containing prestressed steel wires and the steel strands, qualification of chemical components can be ensured. During pulling and twisting of parent metal, the fracture times due to generic defects, sundries and carbon segregation on the surface of a casting blank can be reduced effectively.

Owner:ZENITH STEEL GROUP CORP

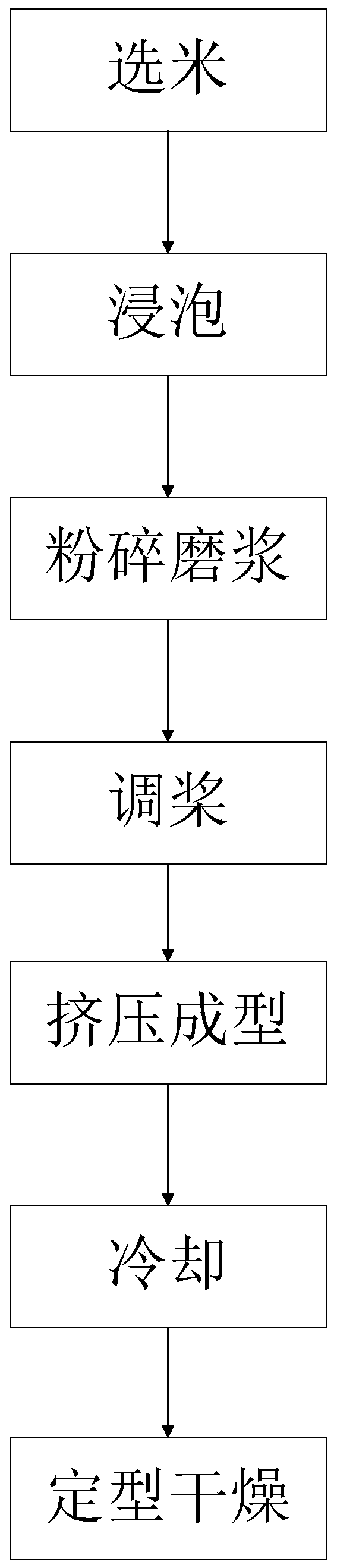

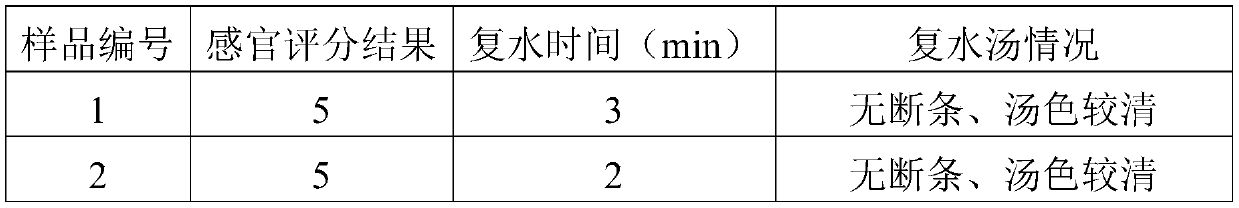

Pu'er tea dry rice noodles and preparation method thereof

PendingCN111296738AShort rehydration timeReduced number of breaksFood ingredient as mouthfeel improving agentMouthfeelRice milk

The invention discloses Pu'er tea dry rice noodles and a preparation method thereof. The preparation method comprises the following steps: elutriating, soaking, crushing and grinding raw material riceto obtain rice slurry; mixing 80-90 parts by weight of the rice slurry, 0.15-1 part by weight of a Pu'er tea raw material and 20-25 parts by weight of starch, and performing extrusion forming to formfresh rice noodles with a cross section diameter of 3-2mm; and sequentially performing cooling and drying shaping on the fresh rice noodles to obtain the Pu'er tea dry rice noodles. The Pu'er tea rawmaterial is ultramicro tea powder with an average particle size of 25-50 microns. The dry rice noodles are rich in taste, the original dried rice noodles are single in taste, and the Pu'er tea tasteof the rice noodles is improved through an existing processing technology.

Owner:景东新裕食品加工有限公司

A kind of preparation method of fusion protein inclusion body

The invention provides a preparation method of a fusion protein inclusion body, which comprises the following steps of: crushing engineering bacteria; washing an inclusion body; and denaturing, dissolving and filtering the inclusion body. According to the invention, a prepared inclusion body denatured dissolved solution is obviously enhanced in clarity, and a filter is obviously increased in filtering capacity.

Owner:广州白云山拜迪生物医药有限公司

A combined converter and its control method

ActiveCN108832659BReduce circulationReduce the number of breaksSingle network parallel feeding arrangementsWind energy generationConvertersElectric machine

Embodiments of the present invention provide a combined converter and a control method. The combined converter includes a frame circuit breaker and at least two converters, wherein each converter includes an AC grid side, a DC side, AC motor side, first contactor, and second contactor. The combined converter provided in this solution, by controlling the switching status of the first contactor, the second contactor and the third contactor, independently controls the connection status of each converter, which improves the redundancy of the system . At the same time, the frame circuit breaker can always be in the closed state, that is, the number of breaking times of the frame circuit breaker is reduced, thereby prolonging the service life of the frame circuit breaker. In addition, since multiple converters connected to the system are connected in parallel through the third contactor, the circulating current between the converters is reduced.

Owner:SUNGROW POWER SUPPLY CO LTD

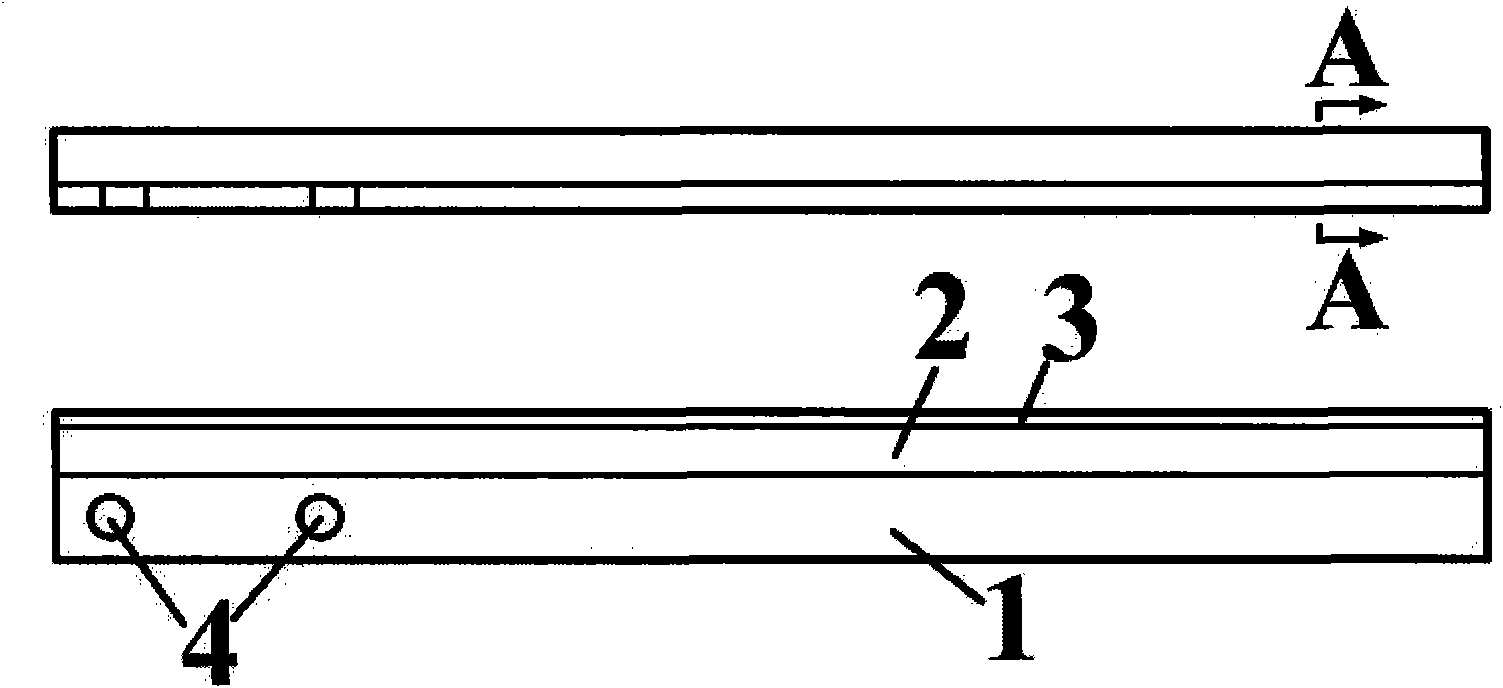

Cutter device of SBS (Styrene-butadiene thermoplastic elastomer) expansion dryer and manufacturing method thereof

ActiveCN102049822BReduce the number of breaksImprove pelletizing effectMetal-working apparatusThermoplastic elastomerMechanical engineering

The invention discloses a novel cutter device and a manufacturing method thereof. The cutter device comprises a cutter and a cutter head; the cutter is molded by integrally pressing a rectangular steel plate on a pressing mould and is provided with a base plate and a cutting edge side plate between which a certain included angle is formed; a cutting edge is formed on the cutting edge side plate; the cutter head includes an inner cutter head and an outer cutter head which are fixed together; and the cutter is fixedly connected with the cutter head to form the cutter device. The cutter provided by the invention is simple to machine and manufacture and has low cost. By adopting the novel cutter device, the service life of the cutter of an expansion dryer is prolonged, the particle-cutting effect is obviously improved, the vibration of the device and the weights of the cutter and the cutter head are reduced, and it is convenient for overhaul and maintenance.

Owner:CHINA PETROLEUM & CHEM CORP

Cutter device of SBS (Styrene-butadiene thermoplastic elastomer) expansion dryer and manufacturing method thereof

ActiveCN102049822AReduced inspection and maintenance workloadGood effectMetal-working apparatusSteel platesButadiene-styrene rubber

The invention discloses a novel cutter device and a manufacturing method thereof. The cutter device comprises a cutter and a cutter head; the cutter is molded by integrally pressing a rectangular steel plate on a pressing mould and is provided with a base plate and a cutting edge side plate between which a certain included angle is formed; a cutting edge is formed on the cutting edge side plate; the cutter head includes an inner cutter head and an outer cutter head which are fixed together; and the cutter is fixedly connected with the cutter head to form the cutter device. The cutter provided by the invention is simple to machine and manufacture and has low cost. By adopting the novel cutter device, the service life of the cutter of an expansion dryer is prolonged, the particle-cutting effect is obviously improved, the vibration of the device and the weights of the cutter and the cutter head are reduced, and it is convenient for overhaul and maintenance.

Owner:CHINA PETROLEUM & CHEM CORP

Low-loss and convenient noodle cutting equipment

The invention discloses low-loss and convenient noodle cutting equipment, which comprises a bottom plate. The upper surface of the bottom plate is fixedly connected with air cylinders, the side facesof the air cylinders are fixedly connected with supporting plates, transmission shafts are mounted at the axes of the supporting plates in a sleeving mode, rotating wheels are mounted outside the transmission shafts in a sleeving mode, steel wires are mounted outside the rotating wheels in a sleeving mode, the upper sides of the left side faces of the air cylinders are fixedly connected with firstconnecting rods, the ends, away from the air cylinders, of the first connecting rods are fixedly connected with sliding rods, sliding grooves are formed in the surfaces, away from the first connecting rods, of the sliding rods, bolts are inserted in the sliding grooves and extend into the sliding rods, and spacers are mounted on the surfaces, extending into the sliding rods, of the bolts in a sleeving mode. According to the low-loss and convenient noodle cutting equipment, by arranging the steel wires, traditional blade cutting is replaced, the weighing force of a cut object can be well reduced, the fracture number of noodles is decreased, and the purpose of reducing the loss is achieved.

Owner:江门市新会区司前贸易中心有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com