Method for coating opening roller ring and ring used for opening roller

An opening roller and card clothing technology, which is applied in the field of coating opening roller card clothing rings, can solve the problems of reduced strength value and tensile value, chemical fiber damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

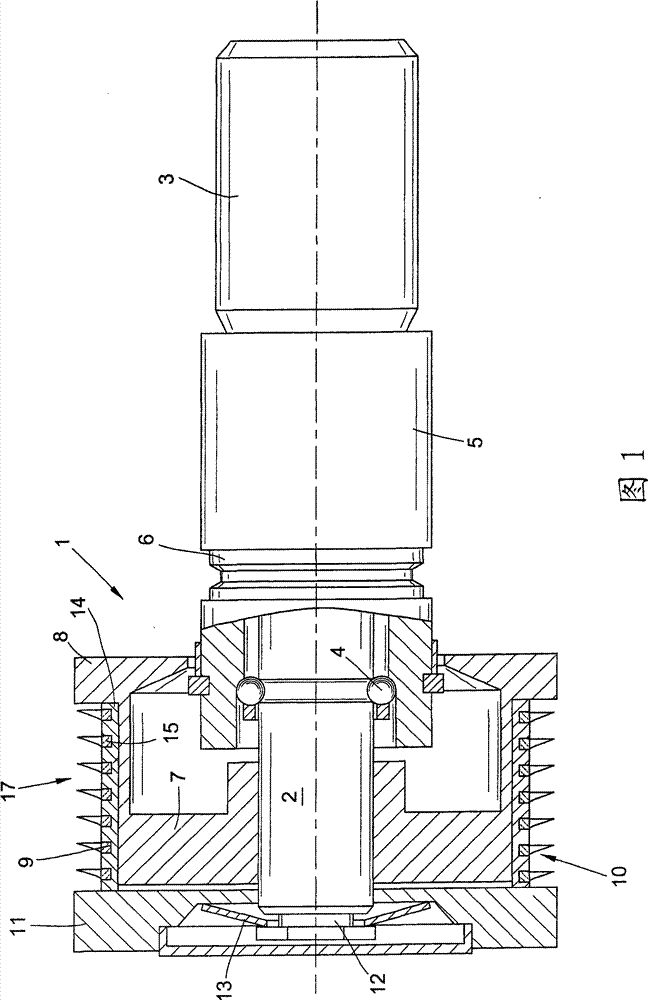

[0021] The invention is described in greater detail below on the basis of the embodiments shown in the drawings. figure 1 Shown is an opening roll with a rotatably mounted cylindrical roll body and a toothed card clothing. Basically known opening rollers associated with open-end spinning devices, in figure 1 Indicated with the reference number 1, it rotates in a not shown opening roller housing. The task of the opening roller 1 is to break down the fiber strands fed to it by the feed rollers into individual fibers. The individual fibers are then fed into the spinning mechanism (eg spinning rotor) by means of fiber-guiding channels.

[0022] During the spinning process, such opening rollers 1 are usually operated at a rotational speed of 6000 to 12000 revolutions per minute.

[0023] The opening roller 1 has a bearing shaft 2 at the end of which a so-called drive spindle 3 is fastened. A not shown tangential belt acts on the drive spindle 3 during the spinning operation. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com