Cutter device of SBS (Styrene-butadiene thermoplastic elastomer) expansion dryer and manufacturing method thereof

A manufacturing method and cutting knife technology, which can be applied to metal processing equipment and other directions, can solve the problems of stress concentration on the cutting knife edge, no public technical solution, and cutting knife bearing seat wear, etc., to achieve simple processing and manufacturing, reduce spare parts costs, and run smoothly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

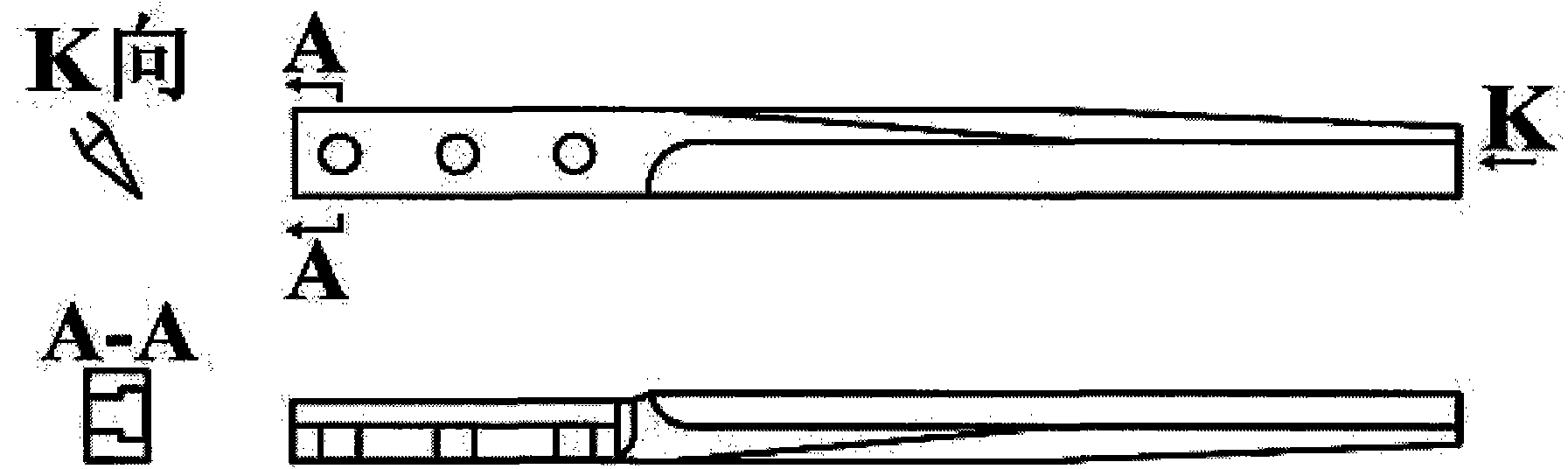

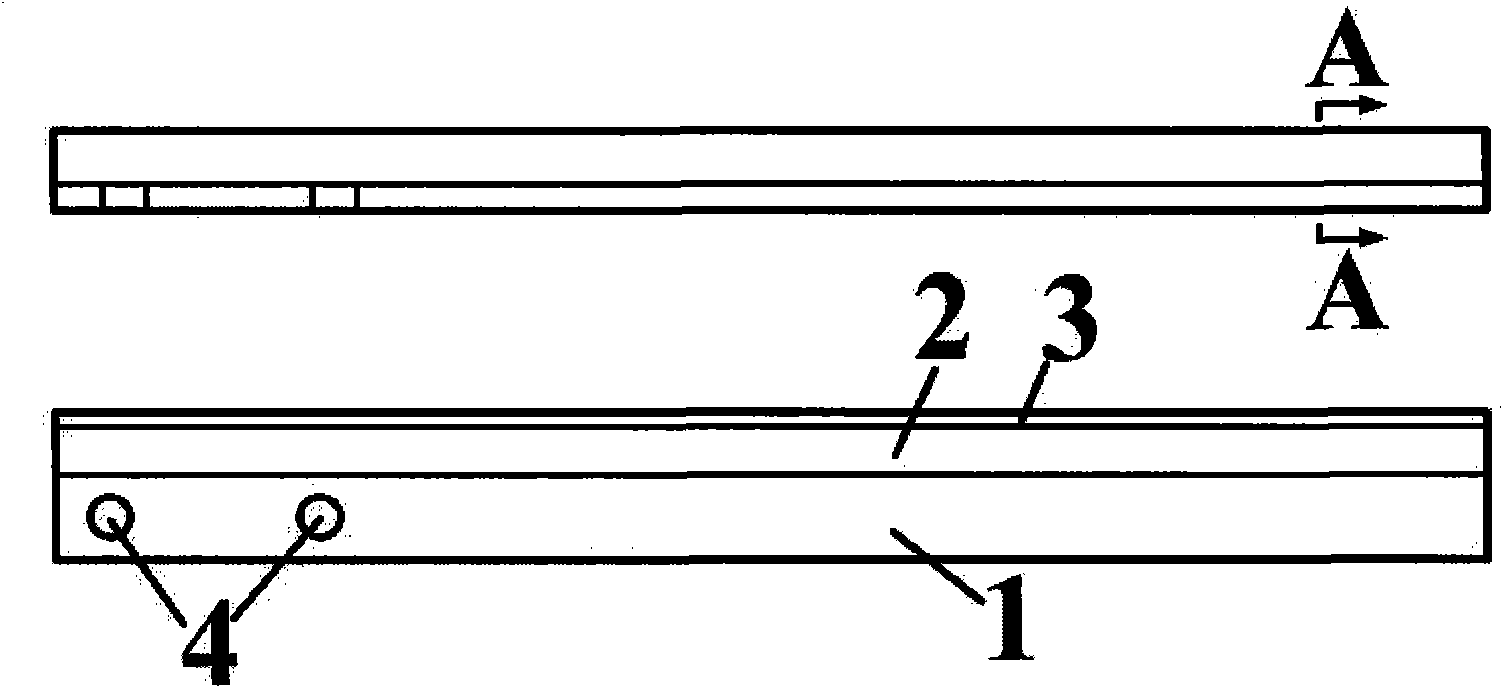

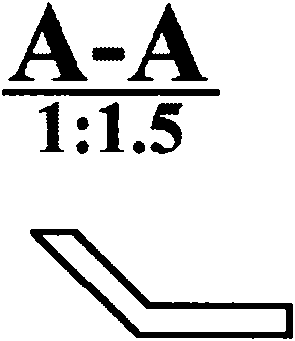

[0027] The cutter of the present invention adopts a 5mm thick stainless steel plate, specifically selects 1Gr13 stainless steel plate, which is machined into a rectangular steel plate, and then a 45-degree pressing die is made by a conventional method, the rectangular steel plate is integrally stamped and formed, and the cutting edge is milled by a milling machine Of course, other common methods can also be used to shape the blade. Finally, the base plate 1 on the side of the cutter is machined to form fixing bolt holes. The number can be reasonably determined according to needs. Formed as Figure 2a , Figure 2b Cutter shown.

[0028] It can be seen from the figure that the integrally press-formed cutter is composed of a base plate 1 and a blade side plate 2. The blade 3 is formed on the outside of the blade side plate 2. The base plate 1 and the blade side plate 2 have the same length and width. An included angle of 135° is formed between them. The bolt holes used to combine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com