Pu'er tea dry rice noodles and preparation method thereof

A Pu-erh tea and rice noodle technology, applied to the functions of food ingredients, food ingredients as taste improvers, food ingredients, etc., can solve the problems of lack of toughness, reduced taste, easy to break, etc., to increase tea fragrance and taste, rehydration The effect of shortening the time and reducing the number of fractures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

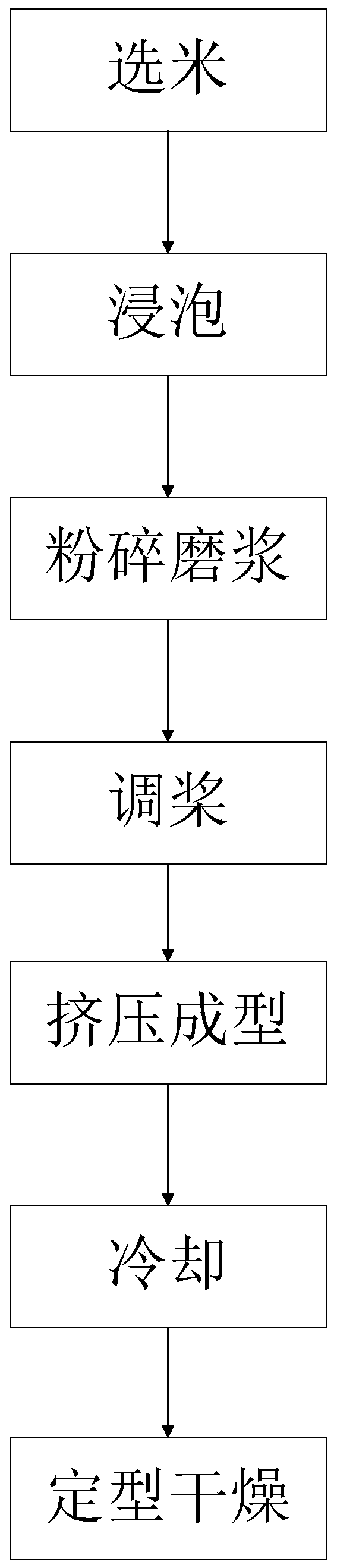

Method used

Image

Examples

Embodiment 1

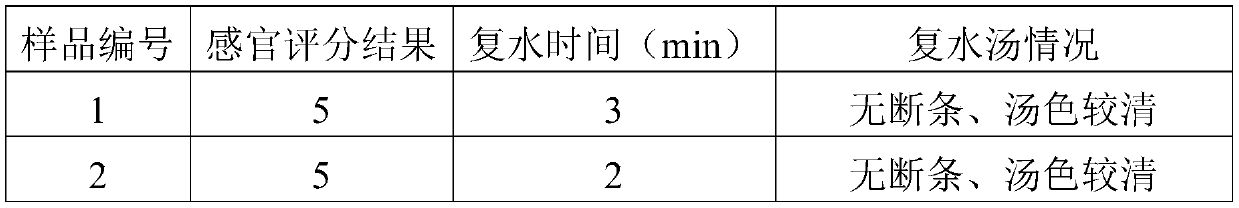

[0042] Example 1 Preparation of Pu'er Tea Dried Rice Noodle Sample 1

[0043] 1) Select soft new rice and hard new rice and mix them according to the volume ratio of 1:2, wash the rice, add water according to the rice water volume ratio of 1:3 and let it soak for 3 hours, after soaking, directly crush and grind to obtain rice milk ; The water content of the rice milk is 50% by mass fraction.

[0044] 2) Adjust the powder by 90 parts by weight of rice milk, 1 part by weight of Pu'er tea raw materials and 25 parts by weight of starch, and then extrude into fresh rice noodles with a cross-sectional diameter of 2mm; tea powder.

[0045] 3) After ventilating and cooling the fresh rice noodle for 10 hours, put it into a shaping dryer, dry and shape it at 70° C. for 10 hours, and obtain Pu-erh tea dry rice noodle sample 1.

[0046] 4) Afterwards, according to the sales requirements, the dried puer tea rice noodles are weighed, bagged, sealed, cooled, put into outer packaging, and p...

Embodiment 2

[0047] Example 2 Preparation of Pu'er tea dry rice noodle sample 2

[0048]1) Mix soft new rice and hard new rice at a volume ratio of 1:3, wash the rice, add water at a rice-to-water volume ratio of 1:2, and soak for 3 hours. After soaking, directly crush and grind to obtain rice milk ; The water content of the rice milk is 60% by mass fraction.

[0049] 2) Adjust the powder by 80 parts by weight of rice milk, 0.15 parts by weight of Pu'er tea raw materials and 19.85 parts by weight of starch, and then extrude into fresh rice noodles with a cross-sectional diameter of 3 mm; tea powder.

[0050] 3) After the fresh rice noodle was ventilated and cooled for 12 hours, it was put into a shaping dryer, and dried and shaped at 70° C. for 12 hours to obtain sample 2 of dried Pu’er tea rice noodle.

[0051] 4) Afterwards, according to the sales requirements, the dried puer tea rice noodles are weighed, bagged, sealed, cooled, put into outer packaging, and packed in order to obtain a...

Embodiment 3

[0052] Example 3 Preparation of Pu'er tea dry rice noodle sample 3

[0053] 1) Select soft new rice and hard new rice according to the volume ratio of 1:2.5, wash the rice, add water according to the rice water volume ratio of 1:2.5 and let it soak for 3 hours, after soaking, directly crush and grind to obtain rice milk ; The water content of the rice milk is 55% by mass fraction.

[0054] 2) adjust the powder by 85 parts by weight of rice milk, 0.5 parts by weight of Pu'er tea raw materials and 22 parts by weight of starch, and then extrude into fresh rice noodles with a cross-sectional diameter of 2.5 mm; Micro tea powder.

[0055] 3) After ventilating and cooling the fresh rice noodle for 11 hours, it was put into a shaping dryer, and dried and shaped at 70° C. for 11 hours to obtain Pu-erh tea dry rice noodle sample 3.

[0056] 4) Afterwards, according to the sales requirements, the dried Pu-erh tea noodles are weighed, bagged, sealed, cooled, put into outer packaging, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Cross section diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com