Instant millet porridge and preparation method thereof

A millet porridge, millet technology, applied in the directions of food drying, food science, food ingredients, etc., can solve the problems of great difference in taste and flavor, loss of millet particle shape, low production cost, etc., and achieve a simple and feasible processing method and low cost. , the effect of excellent product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

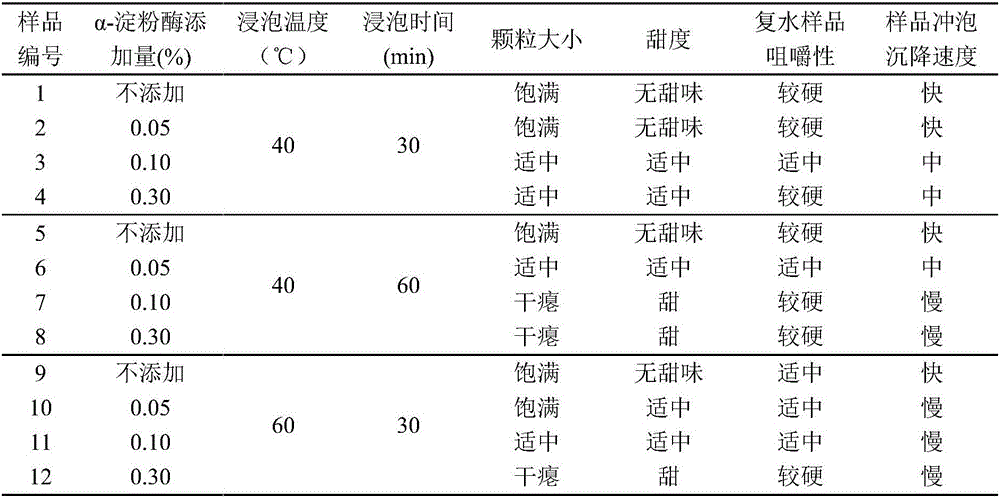

Embodiment 1

[0024] (1) Pretreatment of millet: after millet is washed three times (material-to-water ratio 1:3), drain the water, and add 0.05%, 0.1% and 0.3% of millet by weight to medium-temperature α-amylase and 2.3 times millet respectively weight of water, and taking the treatment without adding enzymes as a control, shake at a constant temperature of 40°C for 30 minutes, 40°C for 60 minutes, and 60°C for 30 minutes;

[0025] (2) Gelatinization: Pour the enzyme-treated millet into the container together with the soaking water in step (1), add 5 drops of melted butter, cover with tin foil with holes left in advance, and steam in a steamer for 30 minutes , make millet gelatinization;

[0026] (3) Drying: Take out the gelatinized millet in step (2), spread it evenly on an 18-mesh stainless steel screen with a thickness of about 5 mm, blow it with a blower for 25 minutes (at a temperature of about 70°C), and stir continuously during this period to make the millet Scatter among the granu...

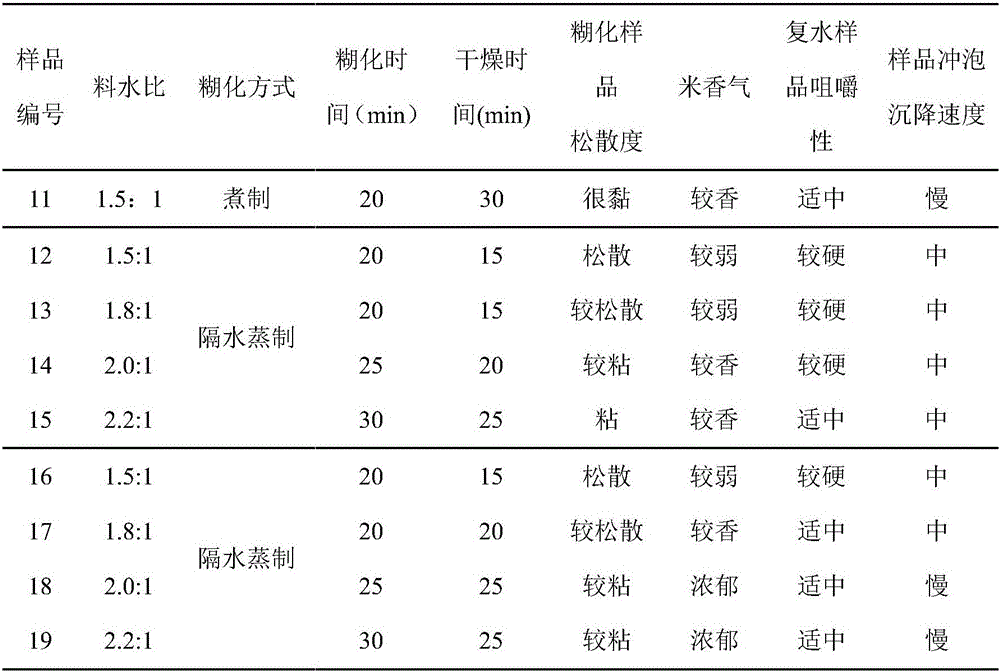

Embodiment 2

[0033] (1) Pretreatment of millet: After millet is washed three times (material-to-water ratio 1:3), drain the water, add 0.05% of millet-medium temperature α-amylase by weight, and then add 1.5 times, 1.8 times and 2.0 times respectively times and 2.2 times the weight of millet, shake at a constant temperature of 60°C for 30 minutes;

[0034] (2) Gelatinization: Pour the enzyme-treated millet into the container together with the soaking water in step (1), add 5 drops of melted butter, cover with tin foil with holes left in advance, and steam it in a steamer for 20 minutes. ~30min, the millet is gelatinized; the millet of the control group adopts the cooking process;

[0035] (3) Drying: Take out the gelatinized millet in step (2), spread it evenly on an 18-mesh stainless steel screen with a thickness of about 5 mm, blow it with a blower for 15-25 minutes (at a temperature of about 70°C), and keep stirring during the period. Disperse the millet grains until the millet grains ...

Embodiment 3

[0042] The preparation of instant millet also comprises the steps:

[0043] (1) Composite packaging: add auxiliary materials to the obtained instant millet, the addition amount is: soft white sugar 5%, pregelatinized starch 2%, fully mix the millet and auxiliary materials, and seal the package according to the net content of each product is 15g;

[0044] (2) Rehydration: Add each product (15g) into a cup, pour 150ml of boiling water, cover and soak for 8-10 minutes, open the lid and stir and then eat; or pour 250ml of water into a pot, add 15g of product after the water boils , after boiling for 2-3 minutes, it can be eaten.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com