Production technology of passion flower vinegar

A technology of passion fruit and production technology, which is applied in the field of production technology of brewing passion fruit vinegar, and can solve the problems of weak flavor of fruit vinegar, masking of passion fruit flavor, difficulty in meeting consumers' taste needs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

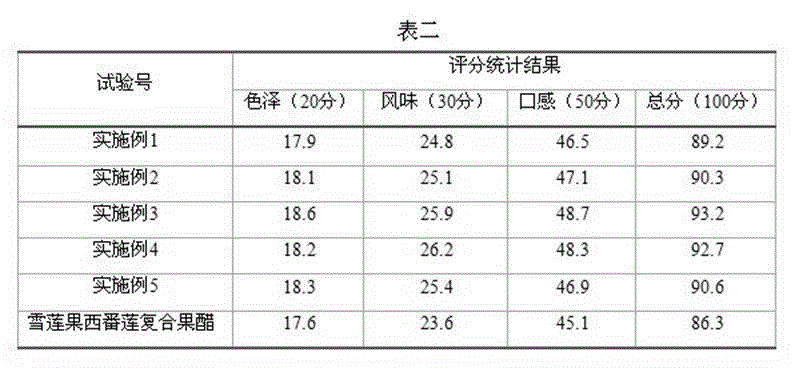

Embodiment 1

[0019] Take by weighing passion fruit puree 4.8kg, add 3.0kg white sugar, 40g wheat oligopeptide, add water to 20kg, make passion fruit juice pH be 3.5, sugar content 18.5Brix, passion fruit juice is poured into airtight container, at 75 Sterilize at ℃ for 30 minutes, add 350mg / L wine active dry yeast, keep the temperature at 18℃ for alcoholic fermentation, the fermentation time is 9 days, stop the fermentation when the sugar content drops to 6.5Brix, and filter to obtain 7.5% alcohol content (V / V) For passion fruit wine, the fermented passion fruit wine was blended into a yeast base with an alcohol content of 4.5% (V / V), inoculated with 8% secondary acetic acid bacteria fermentation broth, fermented at 30°C for 90h, and the fermentation broth was subjected to 121 ℃, 5 seconds high-temperature instantaneous sterilization, sterile filtration, and aging to obtain passion fruit vinegar with a total acidity of 3.5%.

Embodiment 2

[0021] Take by weighing passion fruit puree 4.8kg, add 3.0kg white sugar, 20g wheat oligopeptide, 20g corn oligopeptide, add water to 20kg, make passion fruit juice pH be 3.4, sugar content 18.5Brix, pour passion fruit juice Put it into a closed container, sterilize at 80°C for 20 minutes, add 360mg / L wine active dry yeast, keep the temperature at 20°C for alcoholic fermentation, the fermentation time is 8 days, stop the fermentation when the sugar content drops to 6.3Brix, and filter to obtain an alcohol content of 8% (V / V) passion fruit wine, the fermented passion fruit wine is blended into a yeast base with an alcohol content of 4.5% (V / V), inoculated with 8.5% secondary acetic acid bacteria fermentation broth, and fermented at 31 ° C for 85 hours , the fermented liquid was sterilized at 121° C. for 6 seconds, sterile filtered, and aged to obtain passion fruit vinegar with a total acid content of 3.6%.

Embodiment 3

[0023] Take by weighing passion fruit puree 5.0kg, add 2.8kg high fructose syrup, 40g corn oligopeptide, add water to 20kg, make passion fruit juice pH be 3.2, sugar content 16.5Brix, pour the passion fruit juice after adjusting sugar content Put it into a closed container, sterilize at 85°C for 15 minutes, add 300mg / L wine active dry yeast, and keep the temperature at 22°C for alcoholic fermentation. The fermentation time is 6 days. When the sugar content drops to 6.0Brix, the fermentation is stopped, and the alcohol content is 7%. For passion fruit wine, the passion fruit wine obtained from one fermentation was mixed into a yeast base with an alcohol content of 4% (V / V), inoculated with 9% secondary acetic acid bacteria fermentation broth, fermented at 32°C for 80h, and the fermentation broth was passed through Passion fruit vinegar with a total acidity of 3.8% was obtained after aging at 121°C for 7 seconds at high temperature and instantaneous sterilization, aseptic fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com