Patents

Literature

31results about How to "Increase the aroma of wheat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

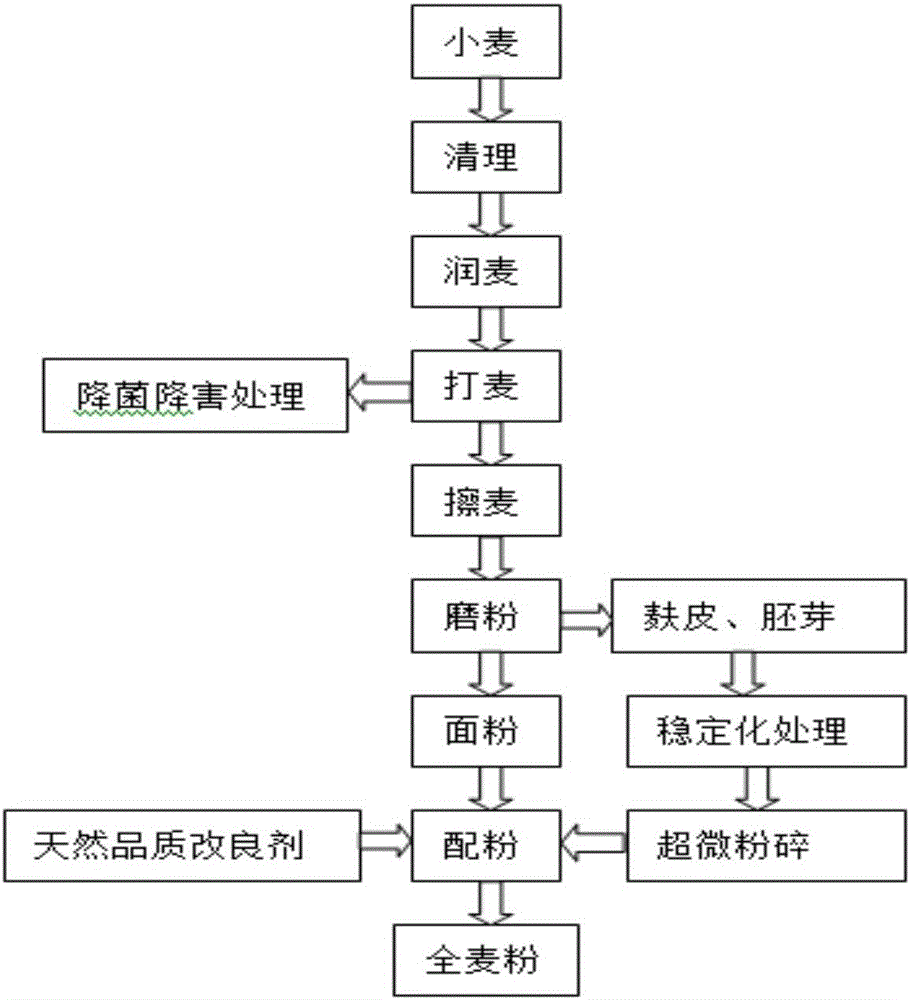

Preparation method of special wholewheat staple food flour with long shelf life

The invention relates to a preparation method of special wholewheat staple food flour with the long shelf life. The method comprises the following steps that a wheat raw material is subjected to impurity removal through the processes such as cleaning, wheat wetting, wheat threshing and wheat rubbing and then threshed, ground and sieved, germs and bran are separated out, and a smashed endosperm material is obtained; the separated germs and bran are treated through microwave humidifying and extrusion expanding and then smashed at the temperature of below 40 DEG C, germ flour and bran flour are obtained and then mixed with endosperms in different proportions, and then the flour special for different kinds of wholewheat staple food is obtained. The preparation method has the following advantages that harmful substances such as eggs and microorganisms can be effectively killed, lipase, protease, amylase and the like can be completely inactivated simultaneously, the product quality is guaranteed, and the shelf life of the product is prolonged; the technological process is shortened, the operation time is short, the nutrient ingredients in wheat grains are protected, and therefore the nutritional value of the product is increased; 3, the wheat aroma of the product is increased, the mouthfeel and the color uniformity are improved, and the specific volume is increased.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

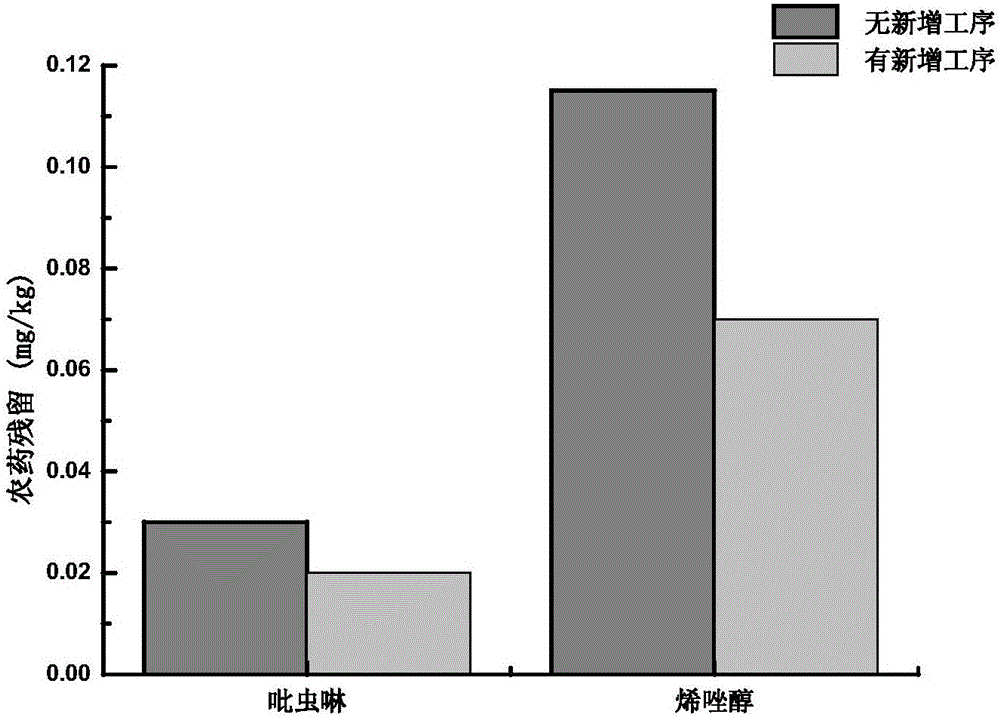

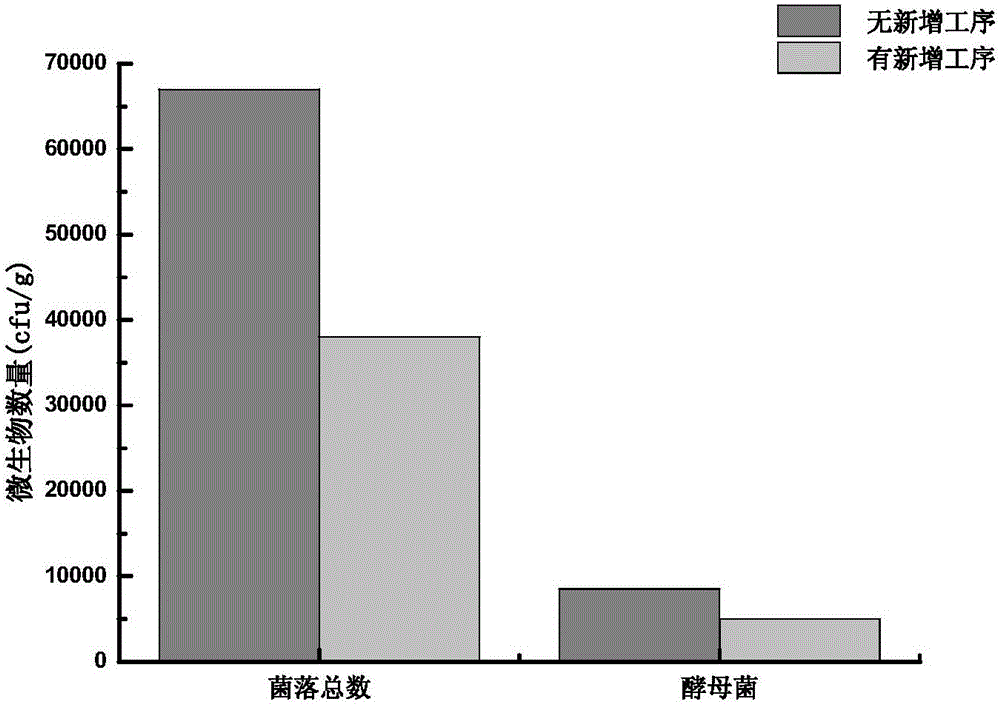

Preparation method of whole wheat flour

InactiveCN104207017APrevent oxidationExtended shelf lifeBakery productsFood preparationPesticide residueImpurity

The invention discloses a preparation method of whole wheat flour. The preparation method comprises the following steps: cleaning wheat to remove impurities, washing by water to moisten wheat, removing epicarp to obtain clean wheat berry containing wheat bran and germ, skinning the obtained clean wheat berry, crushing, separating out the wheat bran and the germ to obtain crushed endosperm, carrying out baking heating and drying on the separated wheat bran and germ to prepare a dry material, mixing the prepared dry material with the prepared crushed endosperm, carrying out low temperature grinding, and screening by a 70-200 mesh screen cloth to obtain the flour. The preparation method of the whole wheat four maintains all nutrition components of wheat, removes pesticide residual, heavy metals and other harmful substances on the skins of the wheat, improves the quality of the flour, ensures the eating safety of the flour, increases the wheat fragrance, improves the eating mouthfeel, and is incomparable to previous flour production methods.

Owner:张付伟

Nutrition strengthened wheat flour

InactiveCN101485348AGreat tasteIncrease the aroma of wheatDough treatmentFood preparationWheat germBaked goods

The invention discloses nutrition-intensified wheat flour, which comprises wheat flour, wherein 3 to 25 weight percent of wheat germ flour is added into the wheat flour. Because wheat germs contain rich nutrient compositions, and particularly have higher content of various vitamins and microelements required by various human bodies, as proved by multi-aspect practices, the addition of the wheat germ flour is 5 to 15 percent of the total weight when various flour products such as flour of cooking food are prepared, and the addition of the wheat germ flour is 10 to 25 percent of the total weight when flour of baking food such as breads, cakes and biscuits is prepared. The nutrition-intensified wheat flour has the effects of not only intensifying the nutrient compositions but also improving the mouthfeel and the wheat flavor of products.

Owner:白臻

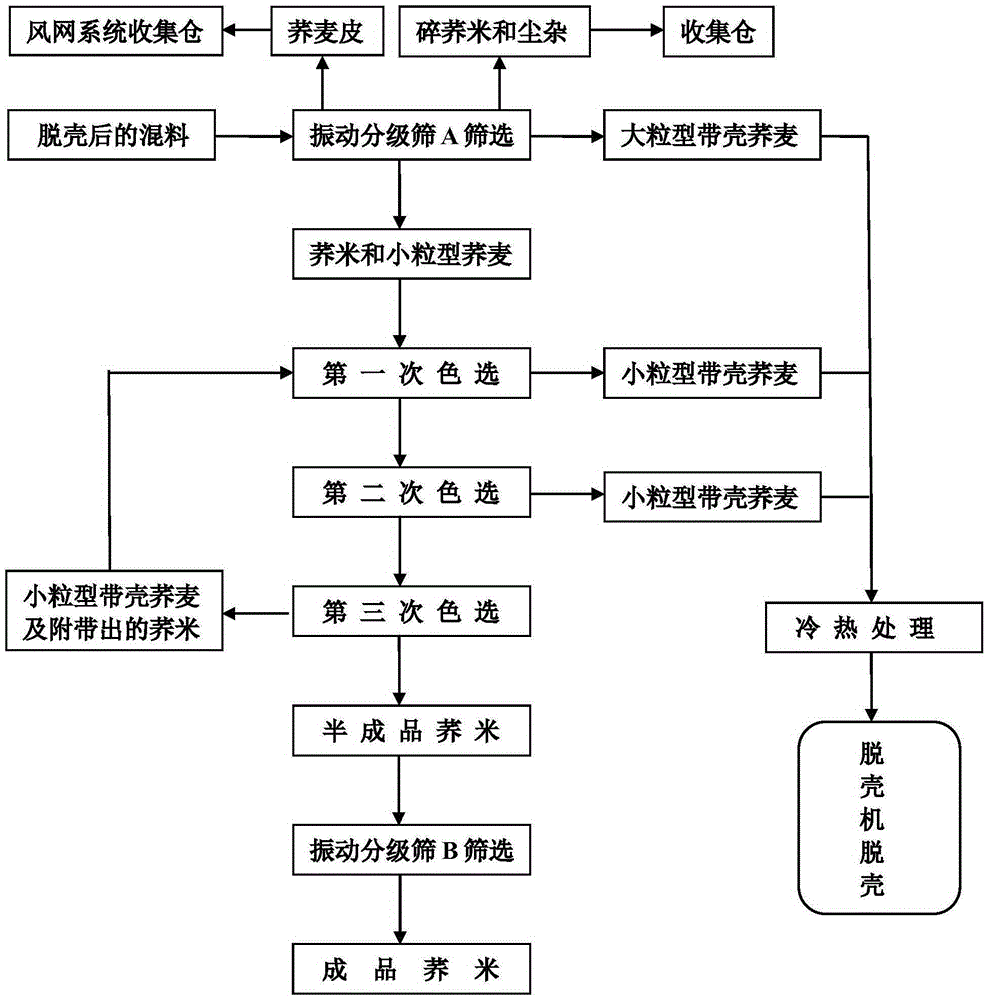

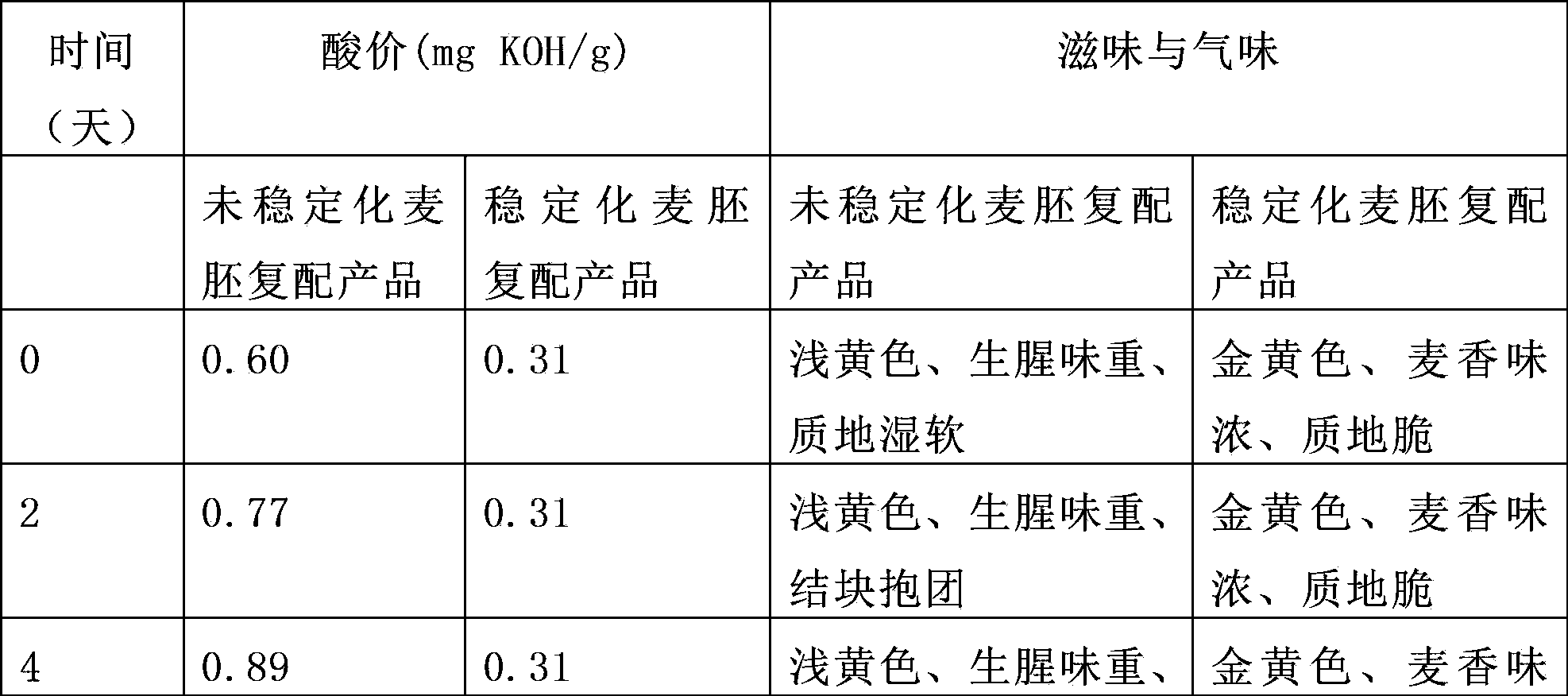

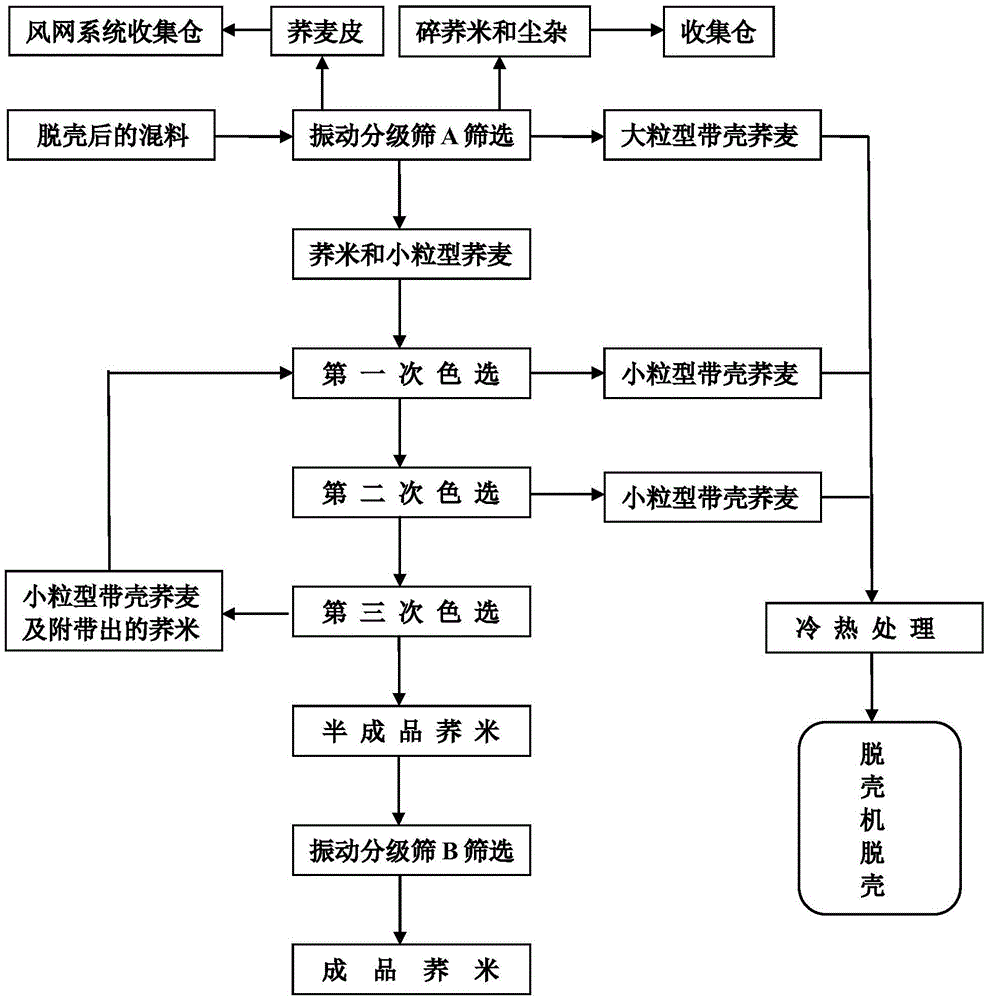

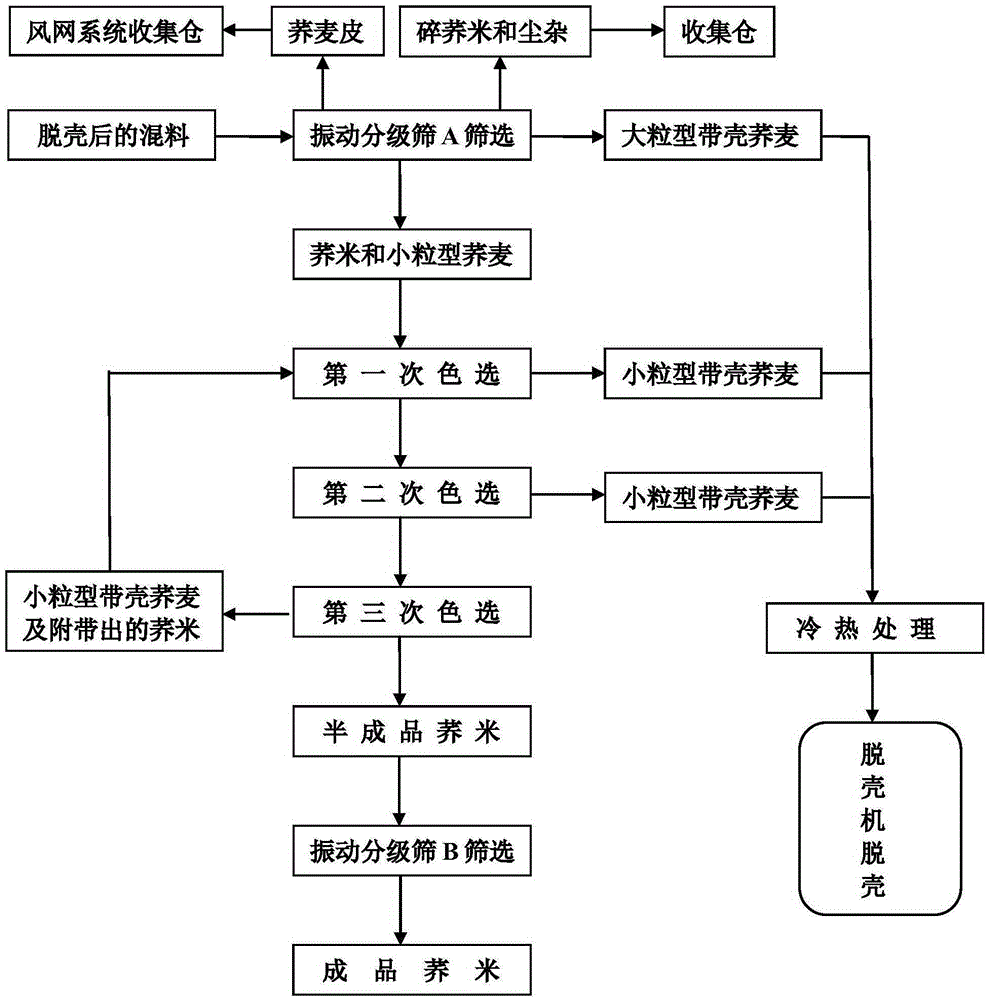

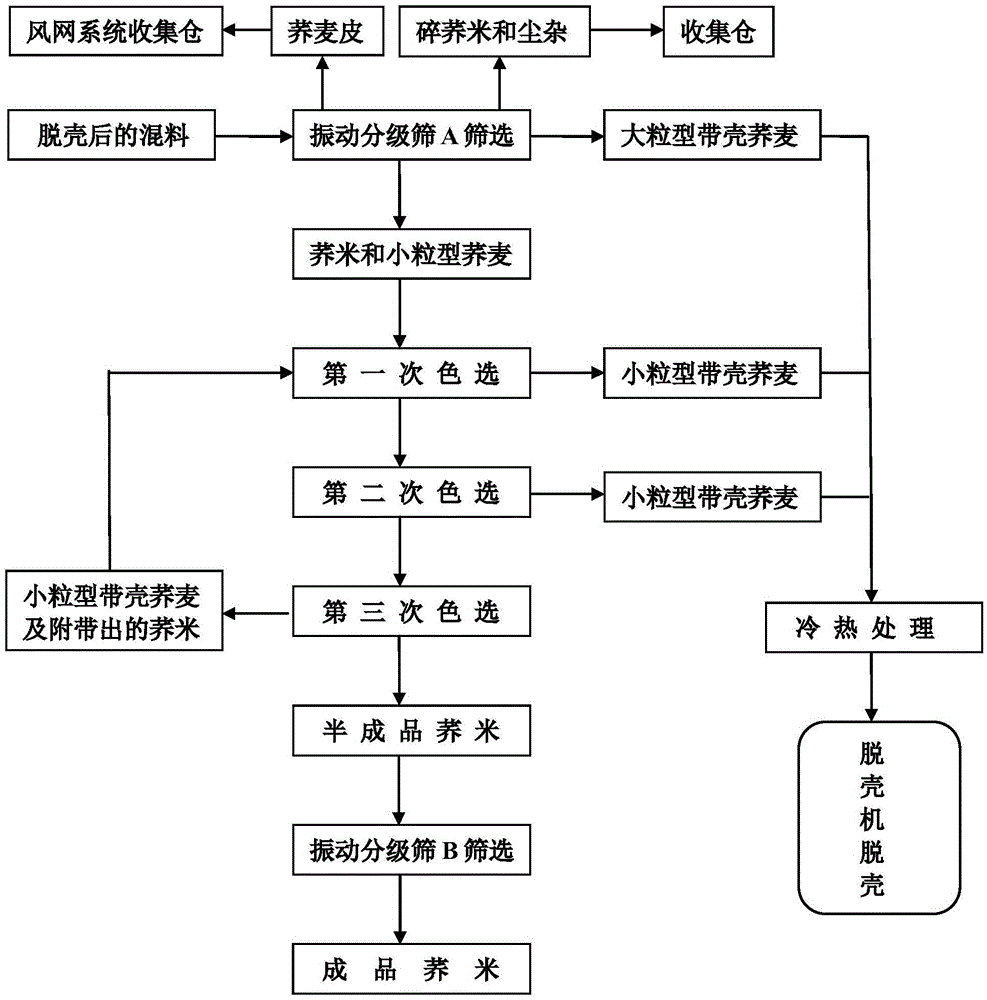

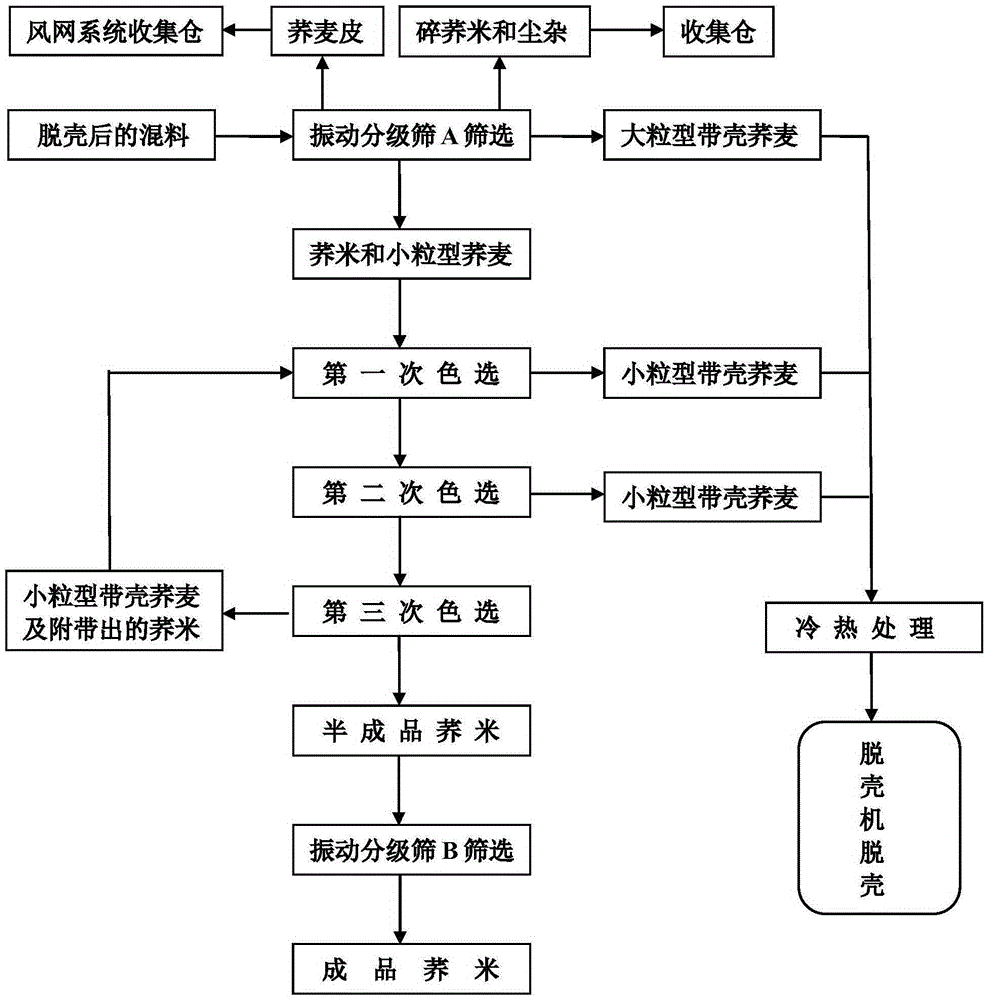

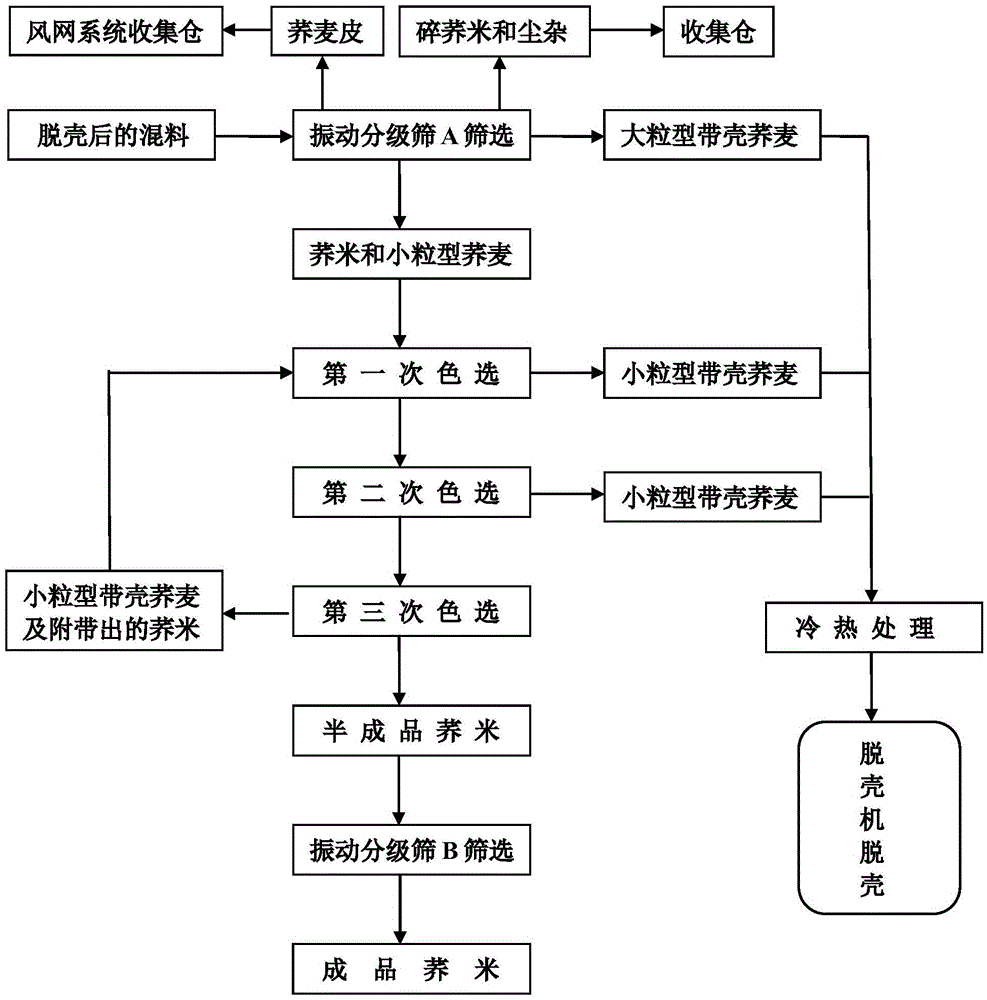

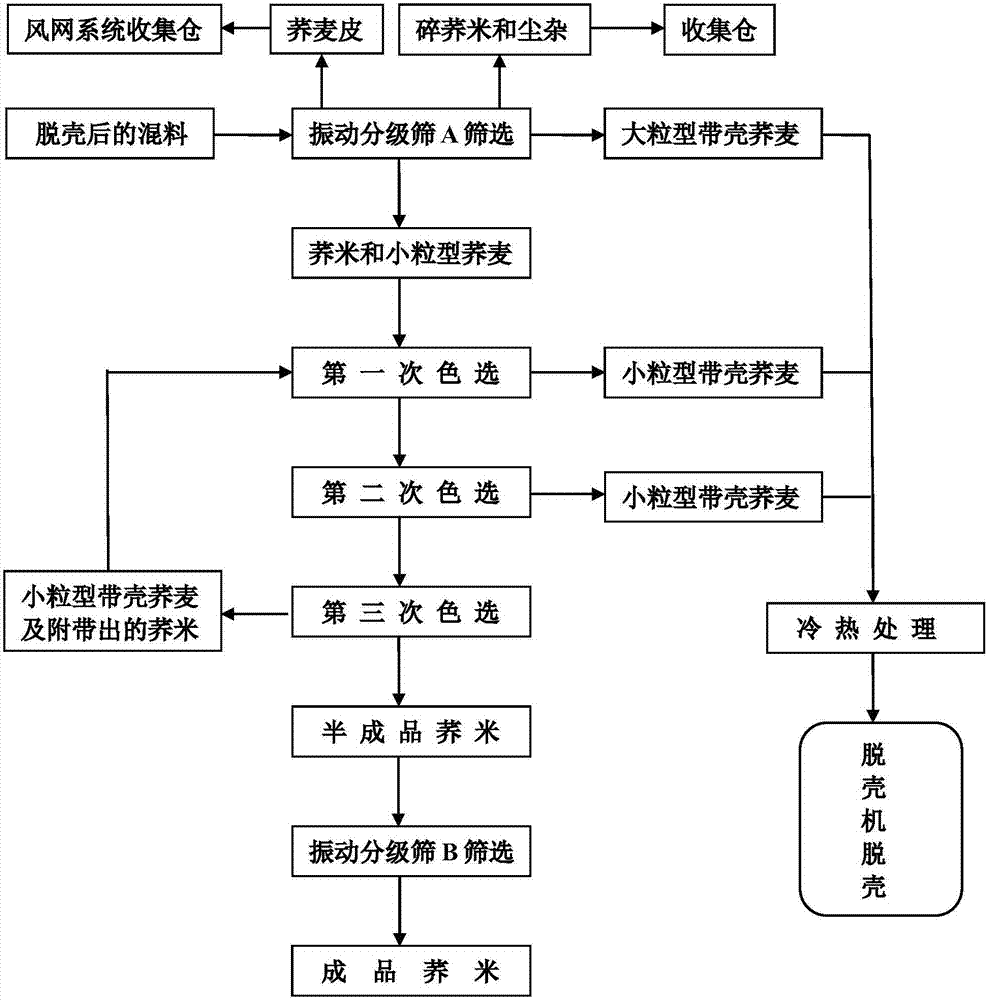

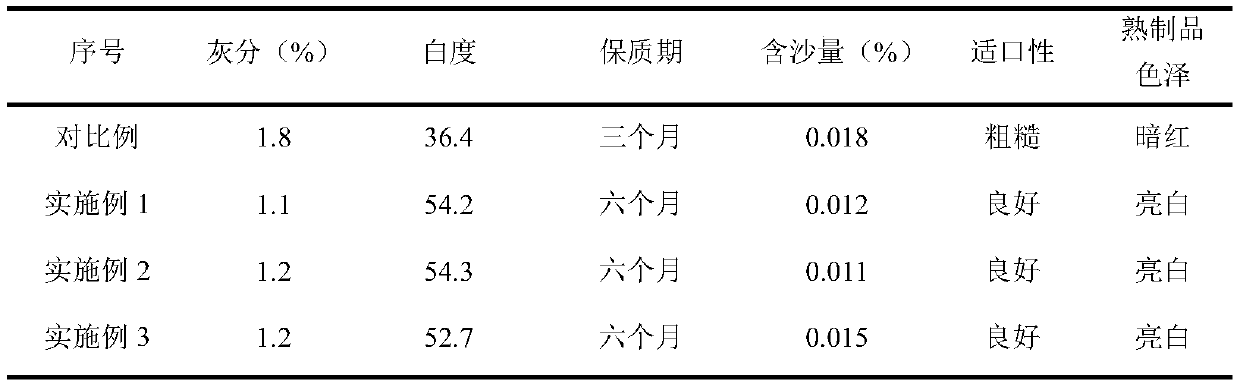

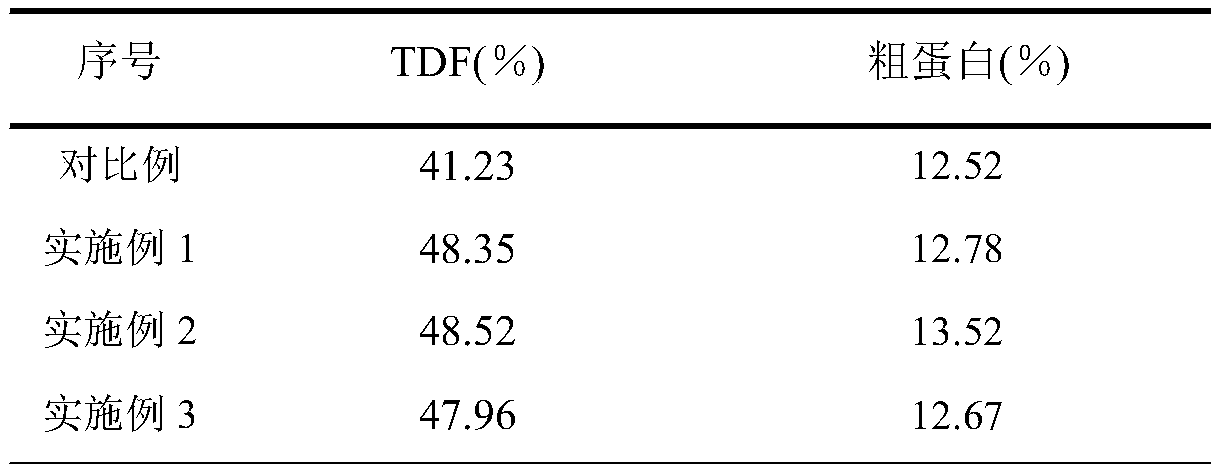

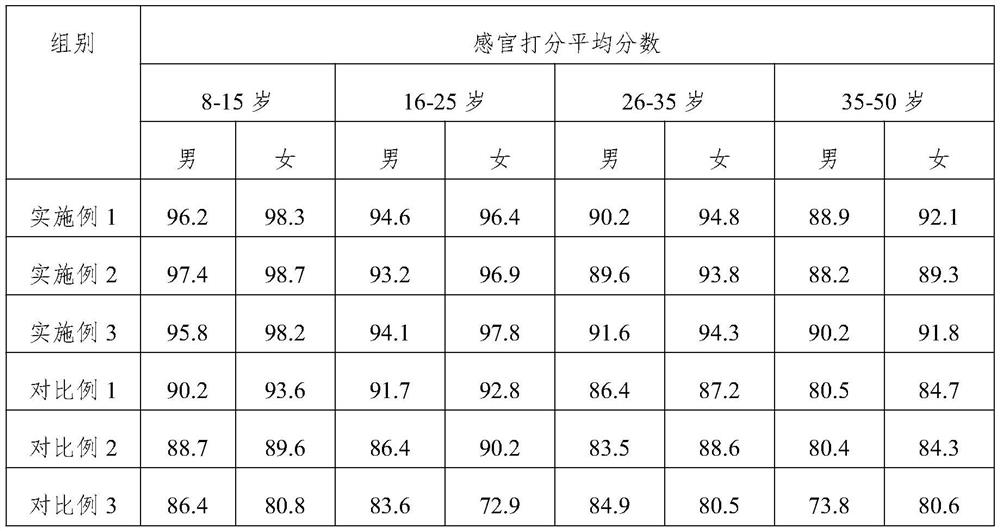

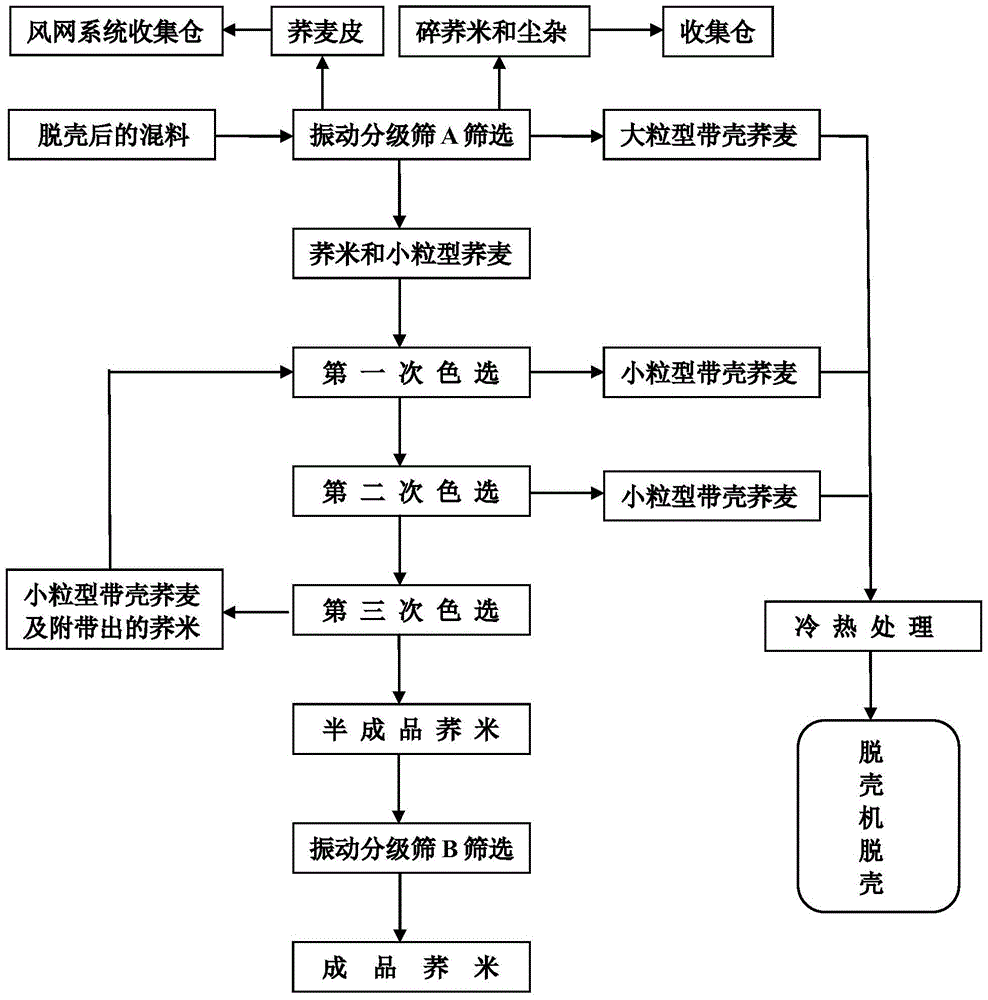

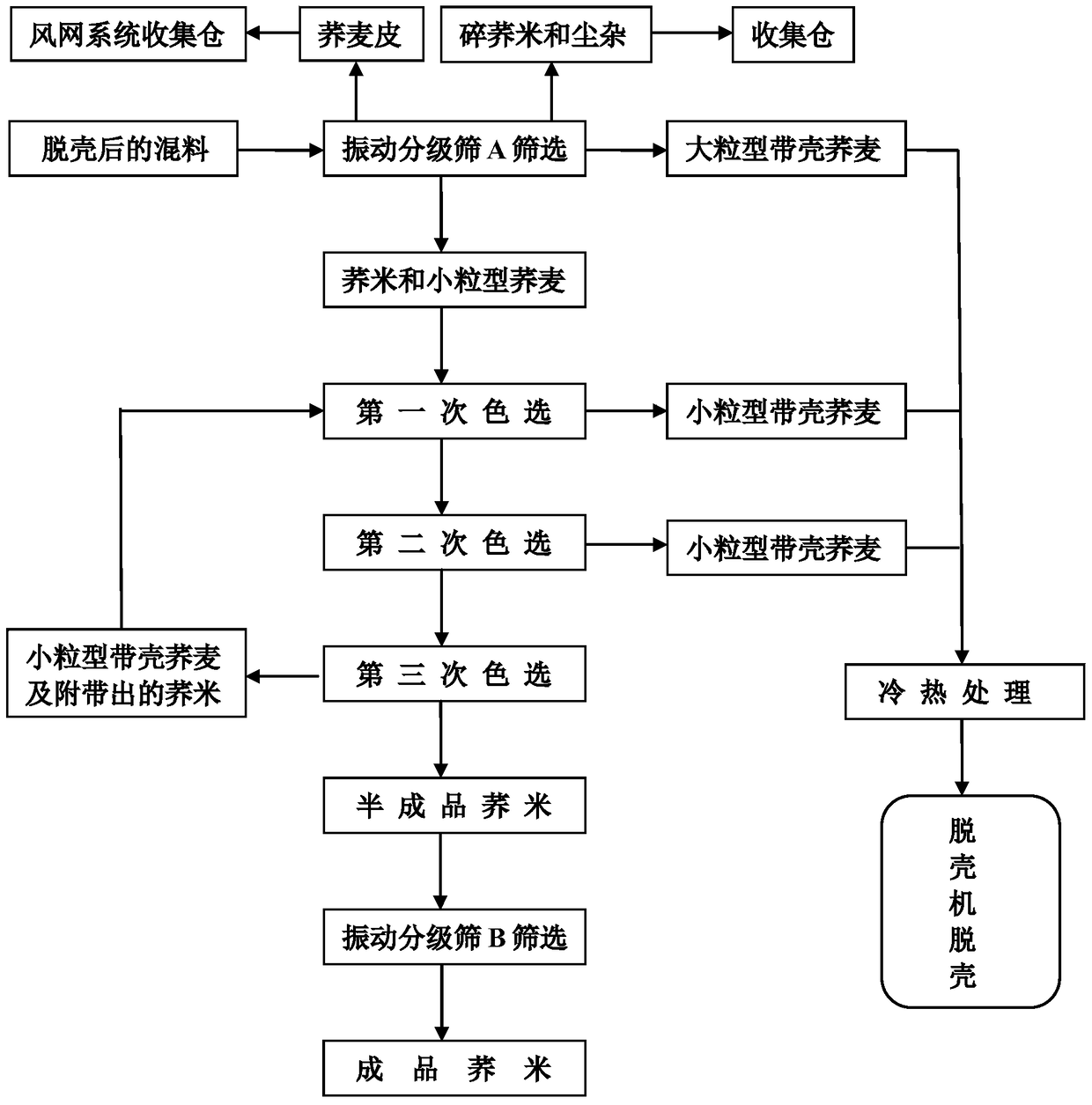

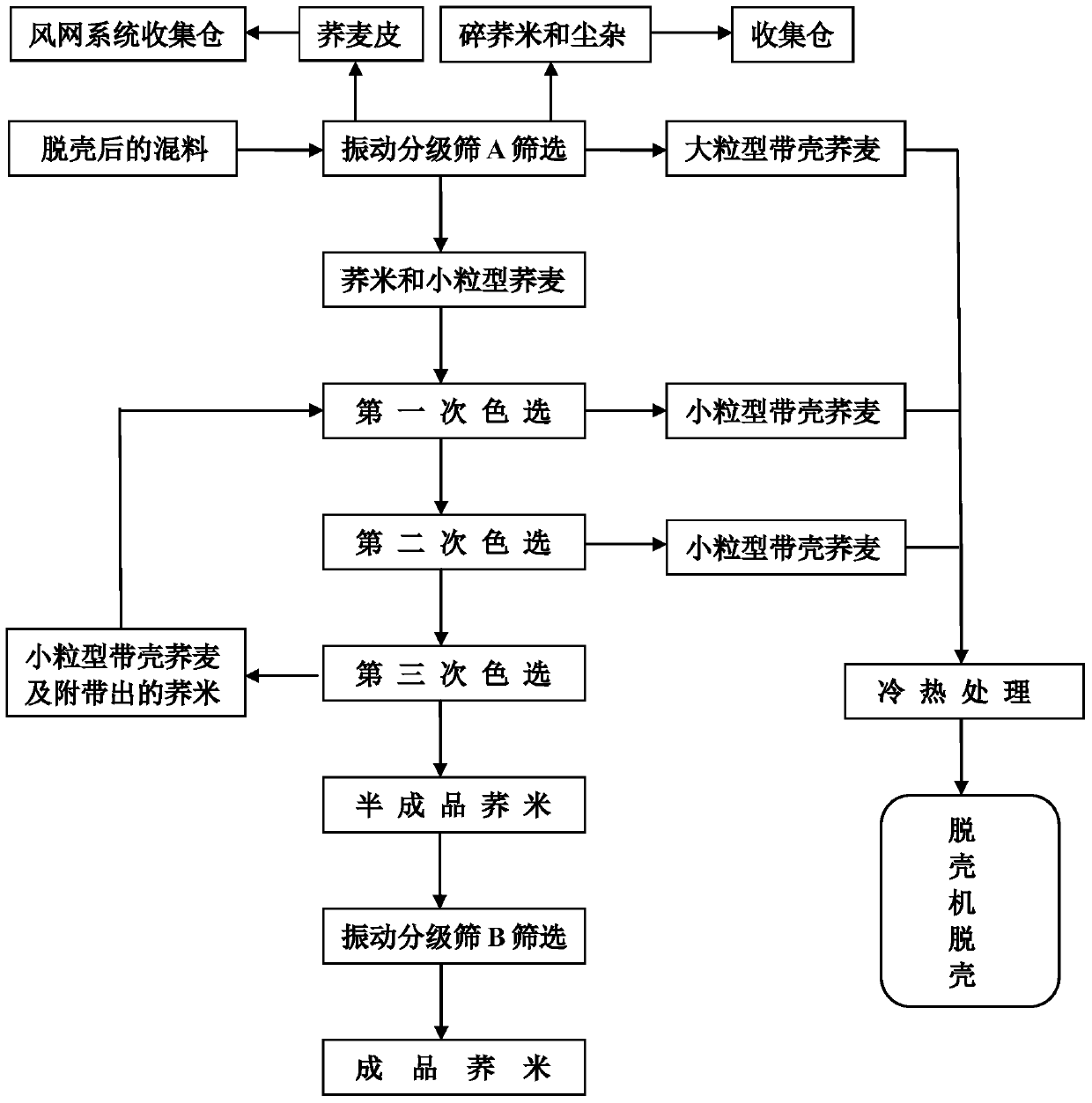

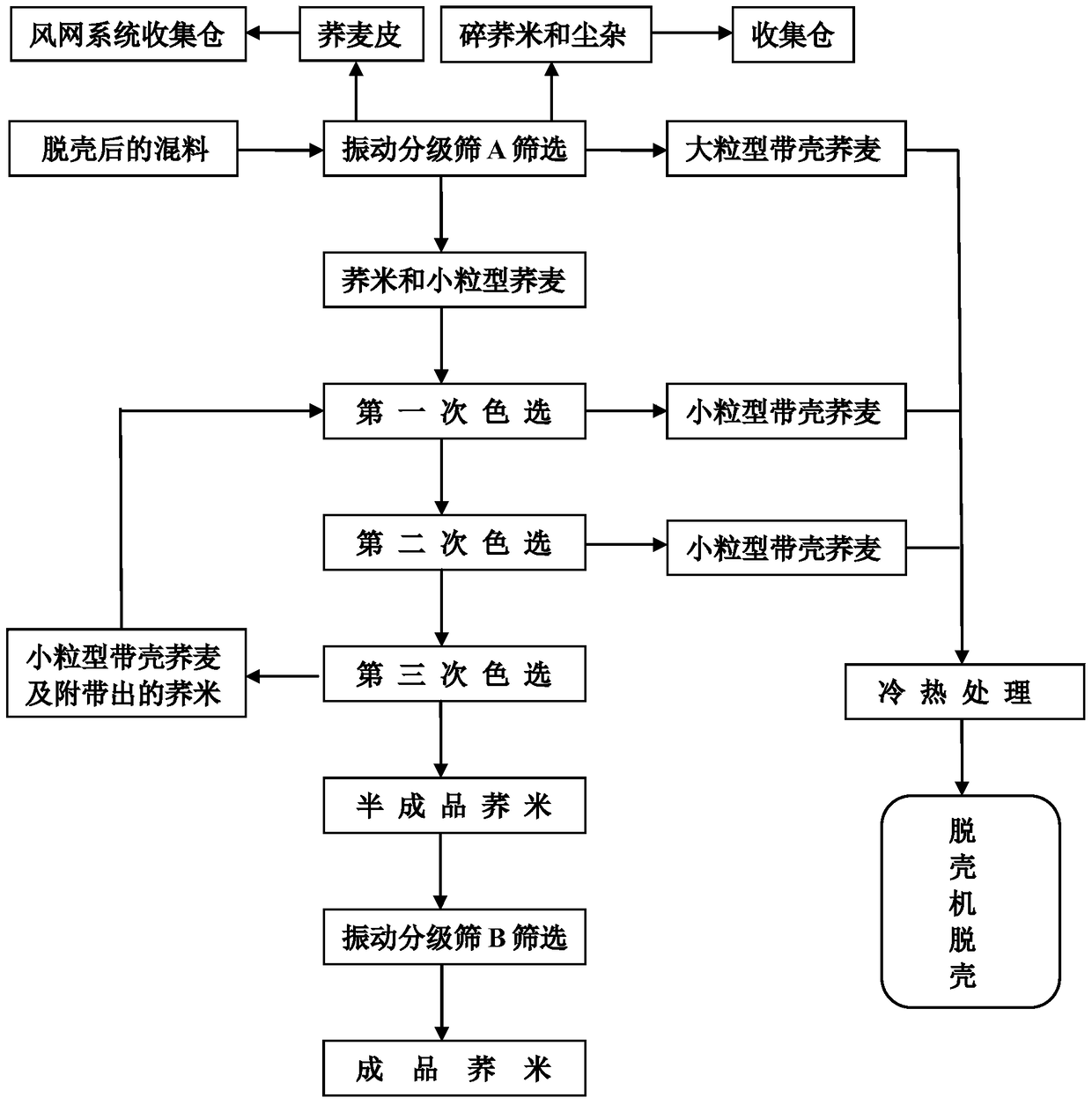

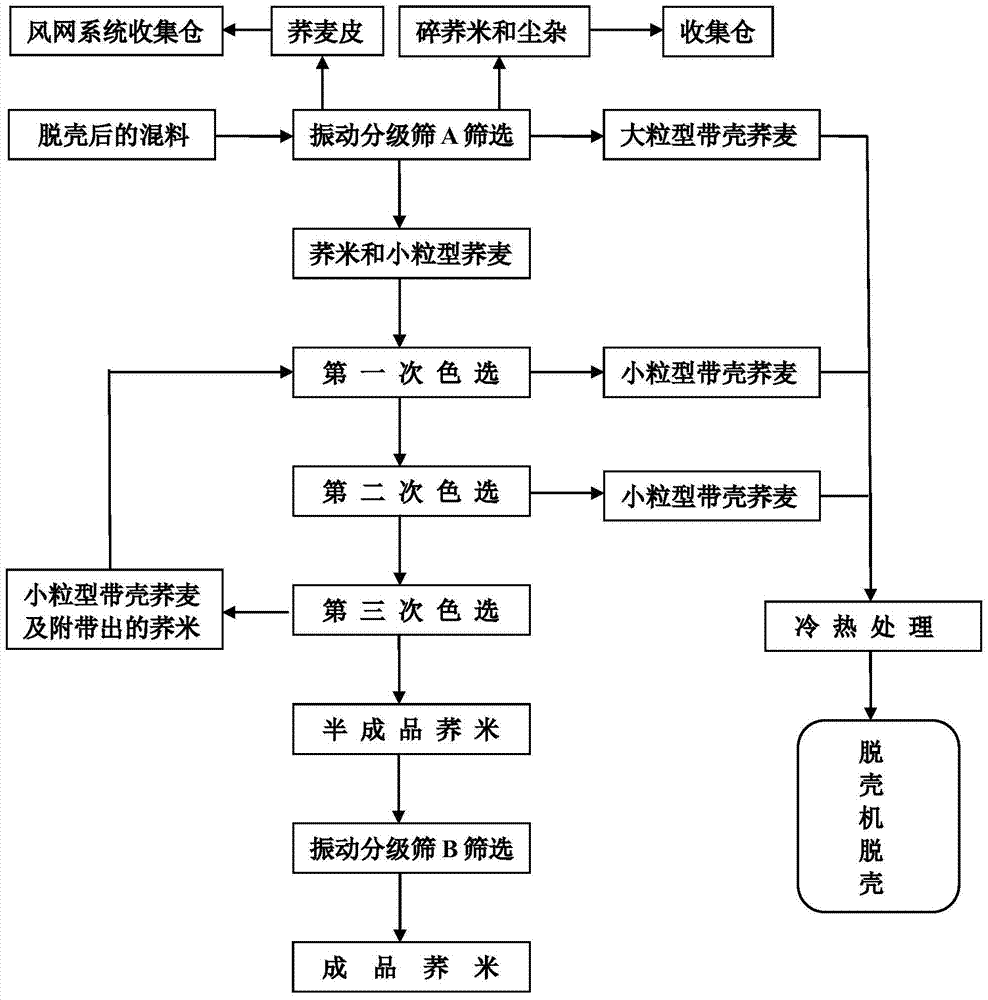

Material grain separation technology used after shelling shells during processing of buckwheat

InactiveCN105414028AFacilitate strippingSecond shelling is convenientSievingGas current separationHuskSeparation technology

The invention discloses a material grain separation technology used after shelling shells during processing of buckwheat. The technology comprises the steps that 1, after the shells of the buckwheat are separated, a mixed material containing a small part of buckwheat husks, buckwheat grains and the buckwheat with the shells is screened through a vibration grading screen at first, oversize products on lower layer screen cloth enter a color sorter through an elevator and the colors of the oversize products are sorted and separated, color sorting is conducted three times sequentially, separated semi-finished buckwheat grains are screened and graded through the vibration grading screen, and high-quality finished buckwheat grains are obtained; 2, small-grain-type buckwheat with the colors being sorted for the first time and the second time is uniformly mixed with large-grain-type buckwheat intercepted by upper layer screen cloth, wherein the small-grain-type buckwheat and the large-grain-type buckwheat are provided with the shells, and after cooling-heating treatment is conducted, the buckwheat enters a huller in batches for secondary shelling; and 3, the final material grain separation rate reaches 99.9%, the secondary shelling rate reaches 95%, the purity of the buckwheat grains can reach 99.9%, the imperfect grain mass is 1% or less, impurities account for 0.10% or less, broken grains account for 1% or less, the surface of the buckwheat is bright and clean, and the buckwheat has obvious buckwheat fragrance. The purpose of large-scale material grain separation with high quality, high efficiency and high yield is achieved for the buckwheat grains with the shells being separated.

Owner:NINGXIA JIADAO HALAL FOOD

Nutritional food, and preparation method thereof

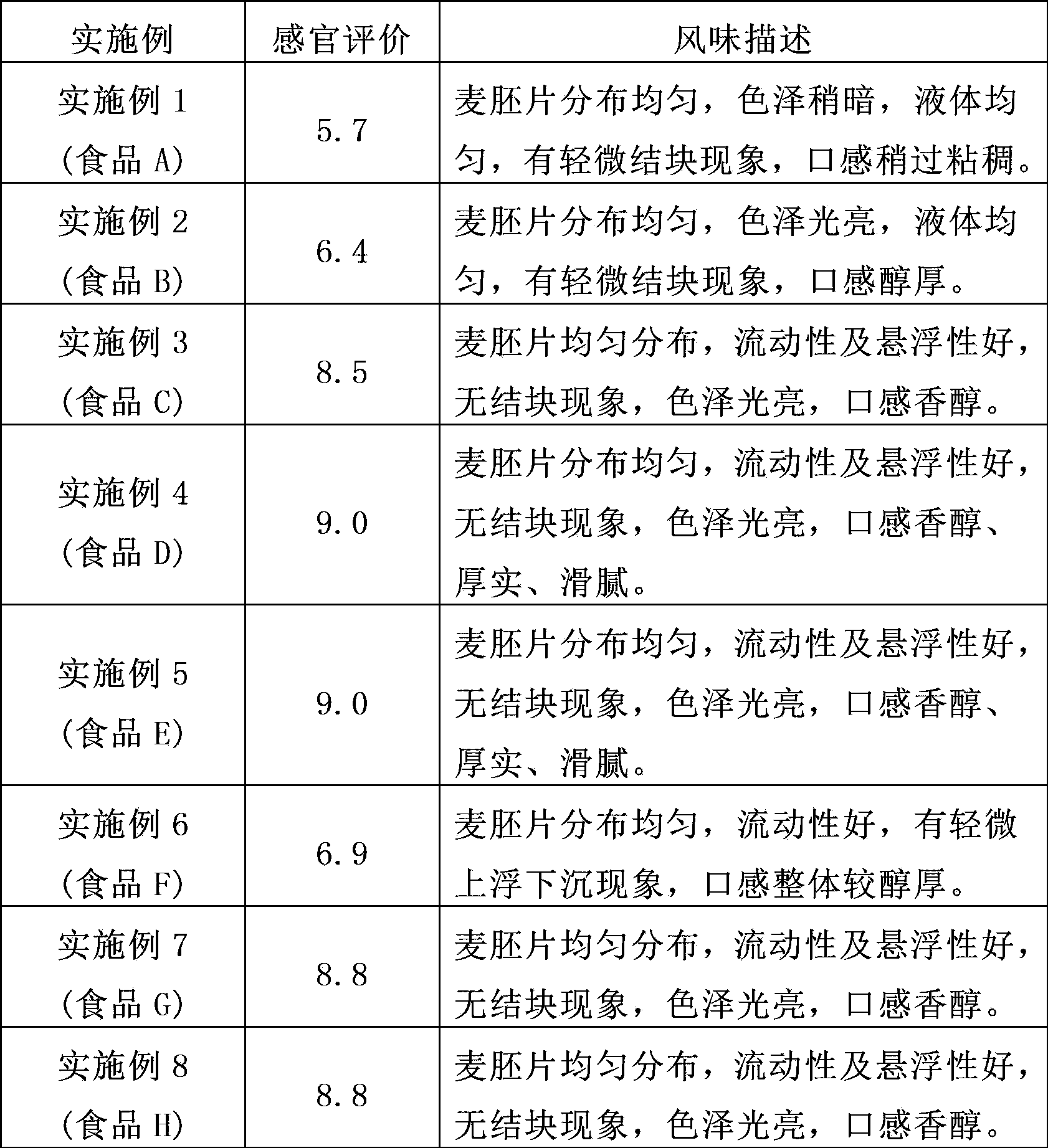

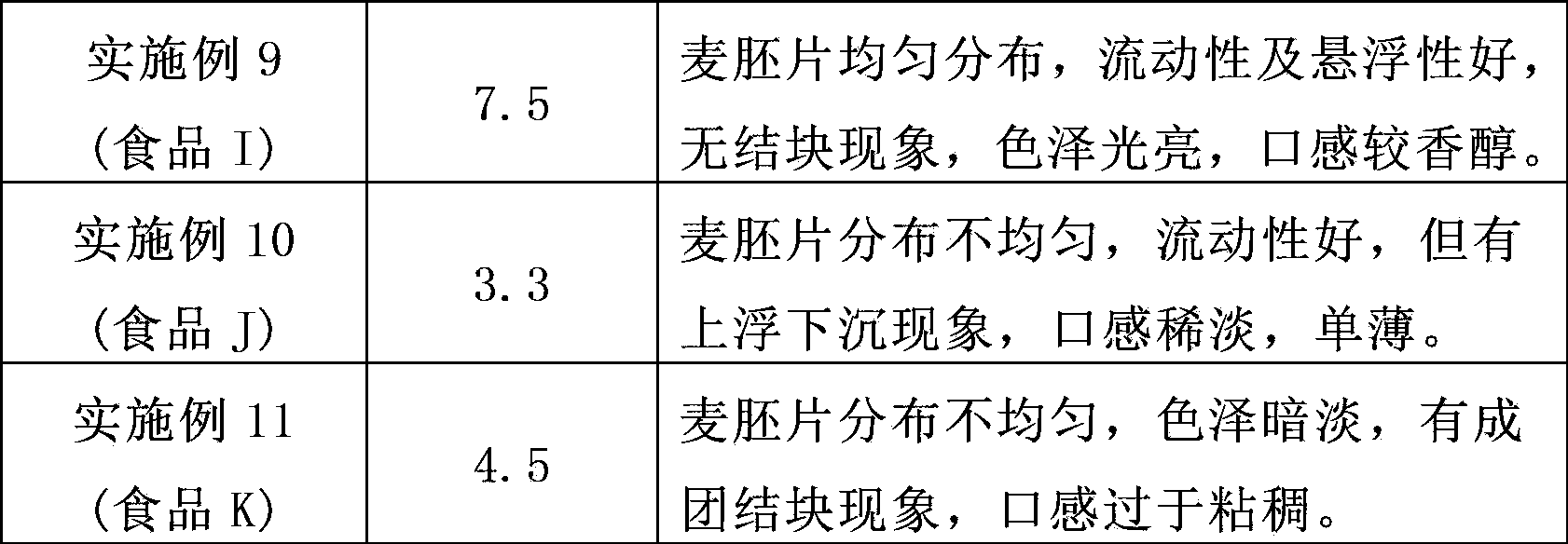

InactiveCN103844249AGreat tasteWith health functionFood shapingFood preparationWheat germSkin protection

The invention provides a nutritional food, and a preparation method thereof. The nutritional food comprises, by weight, 50 to 80 parts of stabilized wheat germ, and 2 to 25 parts of radix puerariae powder. When the nutritional food is mixed with water, mouthfeel is smooth, mellow and thick; color is bright; an uniform liquid is obtained; clustering or caking is not observed; and the nutritional food is capable of realizing face beautifying and skin protection.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

Fagopyrum tataricum tea processing method

The present invention discloses a fagopyrum tataricum tea processing method which comprises the following steps: taking fagopyrum tataricum and removing impurities; soaking the fagopyrum tataricum; steaming and boiling the soaked fagopyrum tataricum with controlled temperatures; oven-drying the steamed and boiled fagopyrum tataricum and controlling the water content at 40-50%; decorticating the oven-dried fagopyrum tataricum, removing the fagopyrum tataricum shells, and retaining the fagopyrum tataricum cores to obtain the fagopyrum tataricum rice; oven-drying the fagopyrum tataricum rice until the water content is less than 20%; and frying the dried fagopyrum tataricum rice with controlled temperatures to obtain the finished products. The fagopyrum tataricum tea processing method can improve the rutin content, wheat flavor and mouthfeel of the fagopyrum tataricum tea finished products.

Owner:WEINING COUNTY GAOYUAN DAXIMEN BUCKWHEAT INDCO LTD

Buckwheat processing process

InactiveCN105499121AFacilitate strippingSecond shelling is convenientGrain huskingSievingMixed materialsComputer science

The invention discloses a buckwheat processing process. The buckwheat processing process comprises the following steps: screening hulled mixed materials containing a few buckwheat husks, buckwheat grains and buckwheat with husks through a vibrating classifying screen, introducing oversize materials of a lower-layer screen into a color selector to carry out color selection and separation, sequentially carrying out color selection for three times, screening and classifying separated semi-finished product buckwheat grains which are subjected to color selection for three times through the vibrating classifying screen to obtain high-quality finished product buckwheat grains; and uniformly mixing small-particle type buckwheat with husks which are subjected to color selection by the first time and by the second time with large-particle type buckwheat with husks retained on an upper-layer screen, carrying out cold-heat treatment, and introducing the buckwheat with husks into a huller in batches to carry out secondary husking. The final material-particle separating rate reaches 99.9%, the secondary husking yield is higher than 95%, the purity of the buckwheat grains can be higher than 99.9%, imperfect grain mass is less than or equal to 1%, the impurities are less than or equal to 0.10%, the broken buckwheat is less than or equal to 1%; and the processed buckwheat is bright and clean in surface, and has obvious buckwheat fragrance, so that the purpose that material-particle separation is high in quality, is high in efficiency, is high in yield and is large-scale is realized after buckwheat husking.

Owner:李秉京

Buckwheat husking technology

The invention discloses a buckwheat husking technology which comprises the steps that a mixture containing few buckwheat husks, buckwheat kernels and buckwheat with husks after husking is screened by a vibration classification screen; an oversize product of a lower layer screen mesh enters a color separator through an elevator to be subjected to color separation for three times sequentially; separated semifinished buckwheat kernels are subjected to screening classification by the vibration classification screen, and high-quality finished buckwheat kernels are obtained; and the small buckwheat with husks after the first-time color separation and the small buckwheat with husks after the second-time color separation are uniformly mixed with the large buckwheat with husks retained by an upper layer screen mesh to form a mixture, and the mixture is subjected to freezing and heating treatment, and then enters a husker in batches to be subjected to secondary husking. A final buckwheat kernel separation rate reaches 99.9%; a secondary husking rate reaches above 95%; the purity of the buckwheat kernels can reach above 99.9%; the mass of unsound kernels is less than or equal to 1%; the mass of impurities is less than or equal to 0.10%; the mass of crushed kernels is less than or equal to 1%; the buckwheat kernels have bright and clean surfaces, and obvious buckwheat fragrance; and the purpose of high-quality, high-efficiency, high-yield and scale buckwheat kernel separation after buckwheat husking is realized.

Owner:宁夏地理标志产业发展有限公司

High polished buckwheat ratio processing process of buckwheat

The invention discloses a high polished buckwheat ratio processing process of buckwheat. The process is characterized in that unshelled mixtures containing few buckwheat husks, buckwheat and buckwheat with shells are screened through a vibration classification screen; oversize materials on a lower screen cloth are fed through a lifter into a color sorter to be subjected to color sorting and separating; the oversize materials are sequentially subjected to color selecting for three times; the separated semi-finished products of buckwheat are screened and classified through the vibration classification screen so as to obtain high-quality finished products of buckwheat; small granular buckwheat with shells, obtained from the first color sorting and the second color sorting, can be uniformly mixed with large granular buckwheat with shells, wherein the large granular buckwheat with shells is intercepted by an upper screen cloth; the mixtures are subjected to cold and heat treatment and then fed by batch into a huller to be unshelled for the second time; the final separation rate of the granules reaches 99.9%, and the secondary unshelling ratio is more than 95%; the purity of the buckwheat is 99.9% or more; the mass of unsound kernels is not greater than 1%; the impurities are not greater than 0.10%; the broken buckwheat is not greater than 1%; the buckwheat has a bright surface and is clean, and the flavor of buckwheat is obvious; the purposes of high-quality and high-efficiency granule separation of unshelled buckwheat, high output and large scale can be achieved.

Owner:宁夏地理标志产业发展有限公司

Household special flour and preparation method thereof

The invention relates to flour specially used in family and a production method thereof. The flour is produced by the following raw materials: waxy wheat which is the main raw material and common hard wheat, wherein, the weight ratio of the waxy wheat to the hard wheat is (70-80) : (30-20). The flour products produced by the flour have luminous luster and good taste and wide application range. The waxy wheat is mainly used for increasing wheat fragrance, improving taste and increasing protein content. The waxy wheat can be used with high gluten wheat to produce flour which is suitable for making fermented food, wherein, the waxy wheat mainly plays a balancing role in the process. Compared with the existing waxy wheat, the waxy wheat adopted by the invention has the advantages that the production quality is not affected and the phenomenon of being sticky can not occur.

Owner:郑州天地人面粉实业有限公司

Buckwheat grain processing technology

ActiveCN105536913AResolve separabilityResolve gradingSievingGrain huskingMixed materialsComputer science

The invention discloses a buckwheat grain processing technology. Unshelled mixed materials containing a small part of buckwheat shells, buckwheat grains and shelled buckwheat are screened through a vibration classification screen firstly, oversize products on a lower screen enter a color selector through an elevator to be subjected to color sorting separation, three times of color sorting is sequentially carried out, separated-out semi-finished buckwheat grains are screened and classified through the vibration classification screen, and high-quality finished buckwheat grains are obtained. Small grain type shelled buckwheat obtained through the first time of color sorting and the second time of color sorting and large grain type shelled buckwheat intercepted by an upper screen are evenly mixed and subjected to cold and heat treatment to enter a huller in batches to be subjected to secondary unshelling. Finally, the material grain separation rate reaches 99.9%, the secondary unshelling rate reaches more than 95%, the purity of the buckwheat grains can reach more than 99.9%, the unsound grain mass is smaller than or equal to 1%, the proportion of impurities is smaller than or equal to 0.10%, and the proportion of broken grains is smaller than or equal to 1%. The surface is bright and clean, the obvious buckwheat fragrance is achieved, and the purposes that after buckwheat unshelling, the material grain separation quality and efficiency are high, the yield is high, and a large scale is achieved are achieved.

Owner:JILIN AGRICULTURAL UNIV +2

Nutritional instant congee rich in colored wheat bran dietary fibers, and production method thereof

The invention provides a nutritional instant congee rich in colored wheat bran dietary fibers, and a production method thereof. The instant congee is a finished product produced through adding an agriculture byproduct colored wheat bran to cereal raw materials, adding Chinese yam, small red beans and other medicinal and eatable plant components, and carrying out pretreatment and extrusion puffing. The instant congee comprises, by weight, 50-60 parts of mixed rice grains, 20-30 parts of mixed wheat grains, 10-20 parts of bean components and 1-2 parts of a seasoning assistant. The nutritional instant congee produced in the invention is instant after being boiled, is convenient to store, is rich in effective components of dietary fibers, can promote absorption of other nutrition elements and prevent rising of the in vivo blood sugar concentration, can dredge the intestine and strengthen the stomach, and is a good health care product used for opposing the three highs and modern urban ills.

Owner:HENAN UNIV OF SCI & TECH

Production process of whole wheat flour

The invention discloses a production process of whole wheat flour. The production process specifically comprises the following steps: (1) cleaning wheat, and carrying out impurity removal and wheat soaking; (2) extruding and crushing the wheat by virtue of a roller crushing mill, and carrying out screening by virtue of a screening net, so as to obtain an endosperm powder substance and solids; (3)stirring the obtained solids for 10-30 minutes, and carrying out winnowing separation, so as to obtain wheat sprouts and bran; (4) placing the wheat sprouts on oil-absorbing paper, and carrying out microwave drying; (5) doping the bran with Na2CO3 which accounts for 0.004%-0.007% of weight of the bran, carrying out uniform mixing, transferring the mixture into a cooking kettle, and removing moisture; (6) adding the wheat sprouts and the bran into a spiral conveying hopper of an ultrafine grinder, and carrying out crushing; and (7) uniformly mixing the crushed bran with crashed sprout endospermpowder, so as to obtain whole wheat flour. The whole wheat flour produced by virtue of the production process has existing exquisite taste and has nutrition of whole wheat, so that double demands ofconsumers on both taste and nutrition are satisfied.

Owner:唐山中宏康远科技有限公司

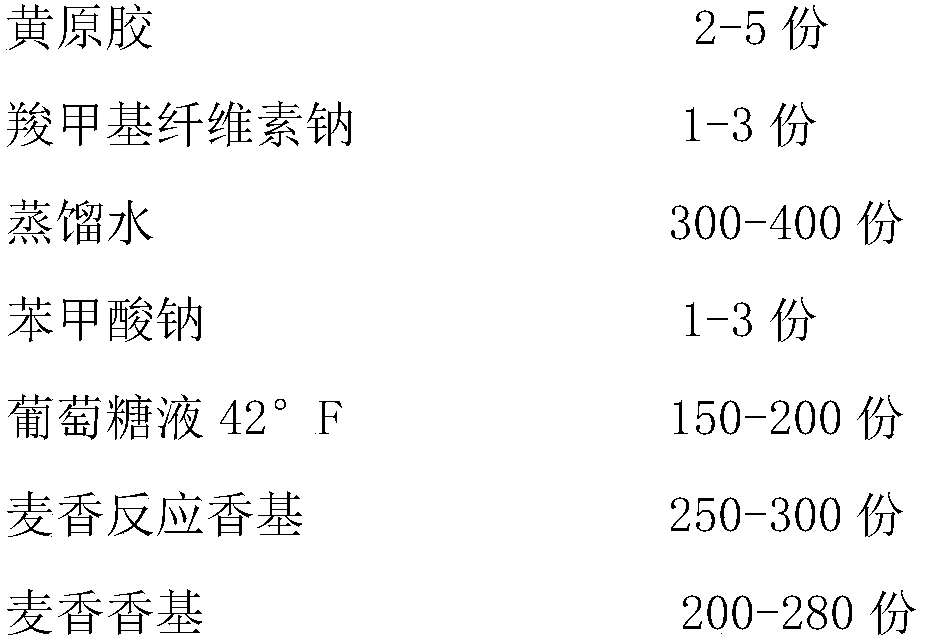

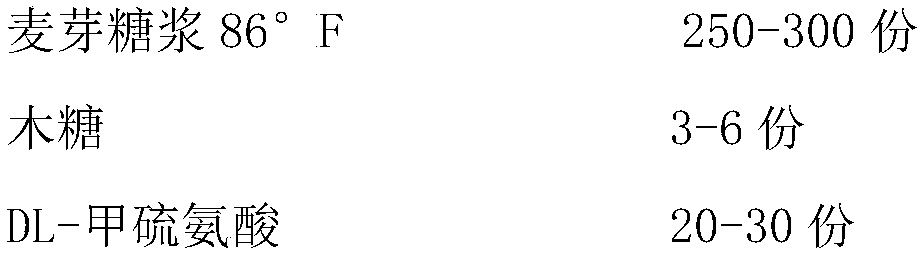

Wheat fragrance type creamy essence and preparation method thereof

InactiveCN108618094AAroma stabilityNatural and full aromaFood ingredient as flavour affecting agentNatural extract food ingredientsDistilled waterGLUCOSE LIQUID

The invention discloses a wheat fragrance type creamy essence. The wheat fragrance type creamy essence is characterized in that a formula comprises the following components in parts by weight: 2-5 parts of xanthan gum, 1-3 parts of sodium carboxymethylcellulose, 300-400 parts of distilled water, 1-3 parts of sodium benzoate, 150-200 parts of glucose liquid 42 Fahrenheit, 250-300 parts of wheat fragrance reaction base, and 200-280 parts of wheat fragrance base. The invention also discloses a preparation method of the wheat fragrance type creamy essence. The method is characterized in that the wheat fragrance base and the wheat fragrance reaction base are mixed to prepare the wheat fragrance type creamy essence, so that the base fragrance can be increased, and the wheat fragrance is increased; in addition, other additives support to enable stable, natural and full fragrance of the essence; the wheat fragrance type creamy essence is of a creamy type and can be mixed with a plurality of foods or drinks, so that the applicable scope is expanded; and the cost of adding to other products can be decreased.

Owner:广州四季风食品科技有限公司

Post-processing technology for buckwheat

The invention discloses a post-processing technology for buckwheat. Hulled mixed materials with a few buckwheat husks, a little buckwheat groat and a little unhusked buckwheat are screened through a vibration classification screen, materials on a lower-layer screen sieve enter a color selector through a lifter for color selecting separation, three times of color selection are carried out in sequence, semi-finished buckwheat groat obtained through separation is screened and classified through the vibration classification screen, and high-quality finished buckwheat groat is obtained; small unhusked buckwheat obtained through color selection of the first time and color selection of the second time is evenly mixed with large unhusked buckwheat stopped on an upper-layer screen, and mixtures enter a husker in batches for secondary husking after cold and heat treatment; and the final material and grain separation rate is 99.9%, the secondary husking rate is above 95%, the purity of buckwheat groat can be above 99.9%, the unsound grain mass is smaller than or equal to 1%, impurities are smaller than or equal to 0.10%, broken groat is smaller than or equal to 1%, the surface is bright and clean, the remarkable buckwheat fragrance is achieved, and the aims of the high quality, high efficiency, high yield and large scale of material and grain separation are achieved after buckwheat husking.

Owner:NINGXIA YUFENG TECH CO LTD

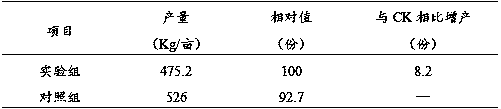

Functional formula fertilizer special for period of seedling establishment of wheat

InactiveCN110436993AStrong stemStrong stress resistanceAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersNon toxicityPesticide residue

The invention discloses functional formula fertilizer special for the period of seedling establishment of wheat. The functional formula fertilizer includes basic nutrient fertilizer of nitrogen, phosphorus and potassium, and is characterized in that the basic nutrient fertilizer includes brassinolide, zinc sugar alcohol, disodium octoborate tetrahydrate, a novel higher aliphatic acid film, cetearyl glucoside and evening primrose seed oil. According to the functional formula fertilizer special for the period of seedling establishment of the wheat, the nutrition is balanced, the use amount is low, the nutrient requirements of the period of seedling establishment of the wheat are completely met, rooting, leafing and tillering are promoted, wheat stalks are thick and strong, stress resistanceis high, the wheat yield, the quality and the protein content are improved, the safety and non-toxicity are achieved, resistance to diseases and pests is enhanced, the pesticide use amount is decreased, pesticide residue on the wheat can be avoided, the soil structure is advantageously improved, the wheat protein content is increased, the wheat fragrance is increased, and the processability is enhanced.

Owner:江西鑫邦生化有限公司

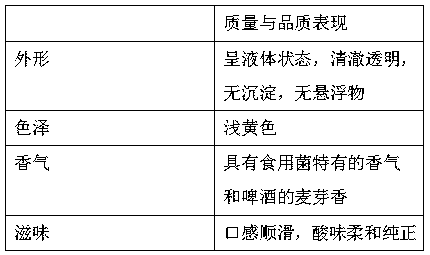

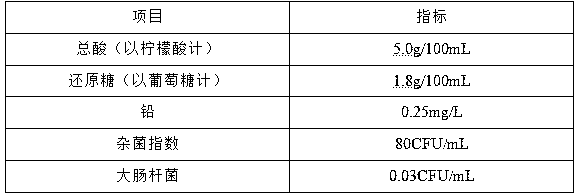

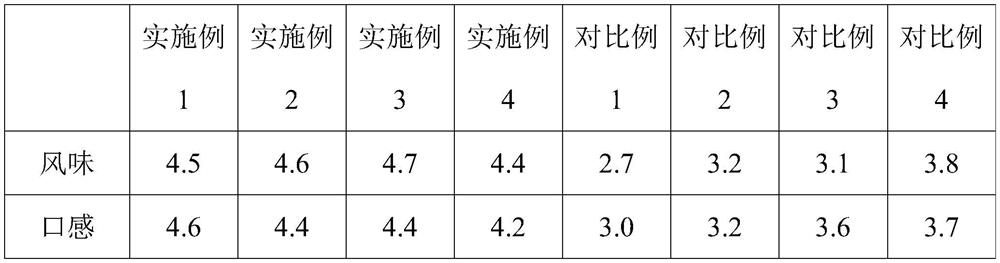

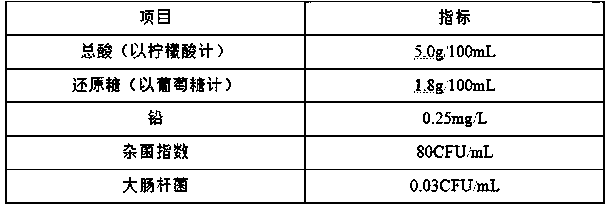

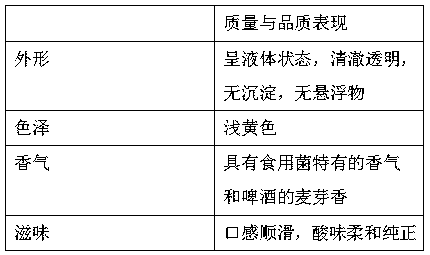

Anti-aging mushroom concentrated beverage and preparation method thereof

InactiveCN106520422AIncrease the aroma of wheatHigh nutritional valueBeer brewingAdditive ingredientTricholoma

The invention provides edible mushroom concentrated beverage with an auxiliary anti-aging effect and a preparation method thereof. The preparation method comprises the following steps: cleaning and crushing mushrooms such as tricholoma lobayense heim, shiitake, lucid ganoderma, agrocybe cylindracea, pleurotus ostreatus, pholiota nameko and dictyophora indusiata which serve as raw materials, and adding beer for leaching and extracting to obtain mushroom concentrate; and uniformly mixing with prepared mushroom proteins and mushroom polysaccharide, adding ingredients, and performing homogenization, sterilization, hot-canning, sealing and cooling. The concentrated beverage prepared based on the preparation method has the advantages of rich nutrition and unique flavor, and the conditions of whole technological process are mild, active ingredients of edible mushrooms can be well retained. The concentrated beverage is edible mushroom concentrated beverage with the auxiliary anti-aging effect.

Owner:FUJIAN AGRI & FORESTRY UNIV

Buckwheat shelling and separating process

InactiveCN105536912AResolve separabilityResolve gradingGrain treatmentsPolygonum fagopyrumMixed materials

The invention discloses a buckwheat shelling and separating process, comprising the following steps: first screening a mixed material containing a small part of buckwheat husk, buckwheat grains and unshelled buckwheat after shelling with a vibration classification screen, enabling oversize products on a lower layer of screen to enter a color sorter via an elevator for color sorting separation, wherein color sorting is carried out for three time in sequence, screening separated semi-product buckwheat grains with the vibration classification screen for classification to obtain high-quality buckwheat grain finished products; and uniformly mixing small-granular unshelled buckwheat obtained by first time and second time of color sorting with large-granular unshelled buckwheat intercepted by an upper layer of screen, carrying out cold and hot treatment, and then enabling the buckwheat to enter a husker in batches for secondary shelling. Finally, grain separation rate reaches 99.9%, secondary shelling rate reaches more than 95%, the purity of the buckwheat grains can reach more than 99.9%, incomplete grain quality is less than or equal to 1%, impurity rate is less than or equal to 0.10%, and broken grain rate is less than or equal to 1%; the buckwheat has bright and clean surface and obvious buckwheat fragrance; and the purposes of realizing high quality, high efficiency, high yield and large-scale grain separation operation after buckwheat shelling are achieved.

Owner:NINGXIA YUFENG TECH CO LTD

Concentrated mushroom beverage for improving immunity and preparation method thereof

ActiveCN106472934BIncrease the aroma of wheatHigh nutritional valueFood ingredient functionsPolysaccharide/gum food ingredientsFlavorAdditive ingredient

The invention provides an edible mushroom concentrated beverage having the efficacy of assisting in enhancing immunity and a preparation method. The preparation method comprises the following steps of cleaning main materials of glossy ganoderma, shiitake mushrooms, agrocybe cylindracea, black wood ears, bamboo funguses, pholiota nameko, grifola frondosa and other mushrooms, crushing the cleaned main materials, and adding beer for leaching so as to obtain mushroom concentrate; and uniformly mixing the mushroom concentrate with prepared mushroom protein and mushroom polysaccharides, adding ingredients, performing homogenizing, performing sterilization, performing hot canning, performing can sealing, and performing cooling. The concentrated beverage prepared by the preparation method disclosed by the invention is rich in nutrition, unique in flavor and mild in conditions in the whole technological course, active components of edible mushrooms can be well reserved, and the concentrated beverage is the edible mushroom concentrated beverage having the efficacy of assisting in enhancing the immunity.

Owner:FUJIAN AGRI & FORESTRY UNIV

A kind of buckwheat processing technology

InactiveCN105499121BFacilitate strippingSecond shelling is convenientGrain huskingSievingHuskWork in process

Owner:李秉京

Whole wheat flour making process

The invention discloses a whole wheat flour making process. The process specifically includes following steps: (1), washing wheat to remove impurities, and wetting the wheat; (2), utilizing a roller crusher to extrude-smash the wheat, and obtaining endosperm powder and solid through a screen; (3), stirring the obtained solid for 10-30min, and obtaining wheat germ and bran through winnowing separation; (4), putting the wheat germ onto oil absorbing paper, and performing microwave drying; (5), doping Na2CO3 accounting for 0.004-0.007% of weight of the bran into the bran, well mixing, and transferring into a steaming kettle to remove moisture; (6), adding the wheat germ and the bran into a screw conveying hopper of an ultrafine smasher for smashing; (7), well mixing smashed bran and smashed germ endosperm powder to obtain whole wheat flour. The whole wheat flour produced by adopting the making process has existing exquisite taste and has nutrition of whole wheat, so that the needs of consumers for both taste and nutrition are met.

Owner:唐山中宏康远科技有限公司

A kind of preparation technology of antioxidant compound grain fermented bread

ActiveCN112889874BHigh in nutrientsImprove antioxidant capacityDough treatmentModified nutritive productsBiotechnologyGreen teas

The invention provides a preparation process of antioxidant compound grain fermented bread, which relates to the technical field of bread processing. The preparation process of the antioxidant compound grain fermented bread mainly includes: raw bread preparation, raw bread flour preparation, liquid material preparation, raw material processing, raw material mixing, dough fermentation, bread baking and other steps. The invention overcomes the deficiencies of the prior art, and improves the comprehensiveness of the nutritional structure of the bread through the addition of ingredients such as tomatoes, grapes, and green tea leaves, and at the same time improves the taste and flavor of the bread, making it more suitable for the tastes of various groups of people.

Owner:ANHUI PANPAN FOOD CO LTD

A process for separating grains after husking in buckwheat processing

InactiveCN105414028BFacilitate strippingSecond shelling is convenientSievingGas current separationSeparation technologyMixed materials

Owner:NINGXIA JIADAO HALAL FOOD

Processing method of whole wheat bread with rich wheat flavor

PendingCN113519585AIncrease the aroma of wheatIncrease the fragranceDough treatmentBakery productsBiotechnologyWheat bread

The invention discloses a processing method of whole-wheat bread with rich wheat flavor, and relates to the technical field of food processing, and the processing method comprises the following steps: adding water into tartary buckwheat for soaking, pulping and filtering, taking filtrate, adding ethyl maltol into the filtrate, and stirring to obtain tartary buckwheat slurry; placing the puffed oats in a pressure container, pressurizing, maintaining, releasing pressure, then adding the tartary buckwheat slurry, vacuumizing, and drying to obtain pretreated puffed oats; adding whole wheat flour, wheat flour, pretreated puffed oats, eggs, brown sugar, dry yeast, dried fruits, table salt and a proper amount of water into a dough mixer, and kneading into dough; performing primary fermentation on the dough, taking out the dough after fermentation, kneading the dough to exhaust air, cutting the dough into small pieces, performing fermentation, and then performing secondary fermentation to obtain a green body; and shaping, baking, cooling and packaging the green body to obtain the product. The whole-wheat bread prepared by the method is rich in wheat flavor, the rich wheat flavor can be felt in the oral cavity when the whole-wheat bread is eaten, and the comprehensive sensory quality of the whole-wheat bread is improved.

Owner:HEFEI CAREER TECHNICAL COLLEGE

Antioxidant concentrated mushroom beverage and preparation method thereof

ActiveCN106261444BIncrease the aroma of wheatHigh nutritional valueFood scienceAdditive ingredientBULK ACTIVE INGREDIENT

The invention provides an edible mushroom concentrated beverage having assistant antioxidative efficacy and a preparation method. The preparation method includes following steps: using mushrooms like agaricus biporus, pleurotus ostreatus, ganoderma lucidum, pleurotus geesteranus, pleurotus eryngii, agrocybe cylindracea and bamboo fungus as main materials, washing, smashing, and adding beer for extraction to obtain mushroom concentrate; well mixing the mushroom concentrate with mushroom protein and mushroom polysaccharide which are prepared, adding ingredients, homogenizing, sterilizing, thermally canning, sealing cans, and cooling. The concentrated beverage prepared by the method is rich in nutrition and unique in flavor, the whole process is mild in conditions and can well retain active ingredients of edible mushrooms, and the edible mushroom concentrated beverage has assistant antioxidative efficacy.

Owner:FUJIAN AGRI & FORESTRY UNIV

A kind of buckwheat processing separation technology

ActiveCN105435878BFacilitate strippingSecond shelling is convenientGas current separationGrain treatmentsPolygonum fagopyrumFlavor

The invention discloses a buckwheat processing and separation process. The buckwheat processing and separation process comprises the following steps: firstly screening a hulled mixed material containing a small part of buckwheat husks, buckwheat grains and hull-carried buckwheat by using a vibration classification screen; sending the material on the lower layer screen into a color selector for color separation by using a lifter; sequentially performing three times of color separation; screening and classifying the separated semi-finished product buckwheat grains by using the vibration classification screen to obtain high-quality finished product buckwheat grains; uniformly mixing small-grain type hull-carried buckwheat which is obtained after the first and second times of color separation with large-grain type hull-carried buckwheat which is retained on the upper layer screen; performing cold treatment and thermal treatment; performing secondary hulling on the buckwheat in batches in a hulling machine, wherein the final material particle separation rate is as high as 99.9%; the secondary hulling rate is above 95%; the purity of the buckwheat grains is above 99.9%; the mass of imperfect particles is smaller than or equal to 1%; the percent of impurities is smaller than or equal to 0.10%; the percent of crushed buckwheat grains is smaller than or equal to 1%; the obtained product is bright in surface and clean and has obvious buckwheat flavor; the aims of high separation quality, high separation efficiency, high yield and large-scale treatment of material particles after the buckwheat is hulled are realized.

Owner:JILIN AGRICULTURAL UNIV +2

A buckwheat shelling process

ActiveCN105478184BFacilitate strippingSecond shelling is convenientGrain treatmentsPolygonum fagopyrumHusk

Owner:宁夏地理标志产业发展有限公司

A kind of instant highland barley slices and its processing method

The invention provides a processing method of instant highland barley tablets. The processing method specifically comprises the following steps: (1) sorting out for removing impurities; (2) shelling; (3) washing; (4) pelleting; (5) wetting; (6) tabletting; and (7) drying. The invention further provides an application of the processing method of the instant highland barley tablets. According to the instant highland barley tablets and the processing method thereof, a highland barley pelleting machine and an infrared and hot air hybrid curing drying machine which are independently developed are adopted, the highland barley tablets developed can be instantly eaten after being brewed by hot water, therefore, the eating convenience and the edibility of highland barley tablets are improved, meanwhile, the production is high in efficiency, safe and sanitary, the prepared instant highland barley tablets can be instantly eaten after being brewed by hot water conveniently, mellow in wheat flavor and moist in mouthfeel, the efficacies of natural weight losing and blood glucose reduction are achieved, and the trouble of the diabetes about the food is also alleviated.

Owner:昌都市君亲农业科技开发有限公司

A kind of buckwheat rice processing technology

ActiveCN105536913BFacilitate strippingSecond shelling is convenientSievingGrain huskingPolygonum fagopyrumMixed materials

The invention discloses a buckwheat grain processing technology. Unshelled mixed materials containing a small part of buckwheat shells, buckwheat grains and shelled buckwheat are screened through a vibration classification screen firstly, oversize products on a lower screen enter a color selector through an elevator to be subjected to color sorting separation, three times of color sorting is sequentially carried out, separated-out semi-finished buckwheat grains are screened and classified through the vibration classification screen, and high-quality finished buckwheat grains are obtained. Small grain type shelled buckwheat obtained through the first time of color sorting and the second time of color sorting and large grain type shelled buckwheat intercepted by an upper screen are evenly mixed and subjected to cold and heat treatment to enter a huller in batches to be subjected to secondary unshelling. Finally, the material grain separation rate reaches 99.9%, the secondary unshelling rate reaches more than 95%, the purity of the buckwheat grains can reach more than 99.9%, the unsound grain mass is smaller than or equal to 1%, the proportion of impurities is smaller than or equal to 0.10%, and the proportion of broken grains is smaller than or equal to 1%. The surface is bright and clean, the obvious buckwheat fragrance is achieved, and the purposes that after buckwheat unshelling, the material grain separation quality and efficiency are high, the yield is high, and a large scale is achieved are achieved.

Owner:JILIN AGRICULTURAL UNIV +2

A new processing technology of buckwheat

ActiveCN105414041BFacilitate strippingSecond shelling is convenientSolid separationCold treatmentHusk

The invention discloses a new processing technology for buckwheat grains. Hulled mixed material containing few buckwheat husks, the buckwheat grains and buckwheat with hulls undergoes screening by a vibrating classification screen firstly, oversize material on a lower-layer screen net enters a color sorter for color sorting separation through an elevator and sequentially undergoes color sorting of three times, and the separated half-finished buckwheat grains are screened and classified through the vibrating classification screen for obtaining the high-quality finished buckwheat grains; the small-grain buckwheat with the hulls separated through primary and secondary color sorting and the large-grain buckwheat with the hulls intercepted by an upper-layer screen net are uniformly mixed, undergo cold treatment and hot treatment and then enter a huller for secondary hulling in a batched mode; the separation rate of final grain material reaches 99.9%, the secondary hulling rate is higher than 95%, the purity of the buckwheat grains is higher than 99.9%, the mass of unsound grains is smaller than or equal to 1%, the mass of impurities is smaller than or equal to 0.10%, the mass of broken grains is smaller than or equal to 1%, the buckwheat grains are bright and clean in surface and have obvious buckwheat fragrance, and the purposes of high quality, high efficiency, high yield and large scale of grain separation of the hulled buckwheat can be realized.

Owner:吴起县红利技术服务有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com