Production process of whole wheat flour

A production process and technology of whole-wheat flour, applied in the field of food processing, can solve the problems of non-standard food requirements, high inorganic content of whole-wheat flour, poor cleaning effect, etc. demand, easy crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

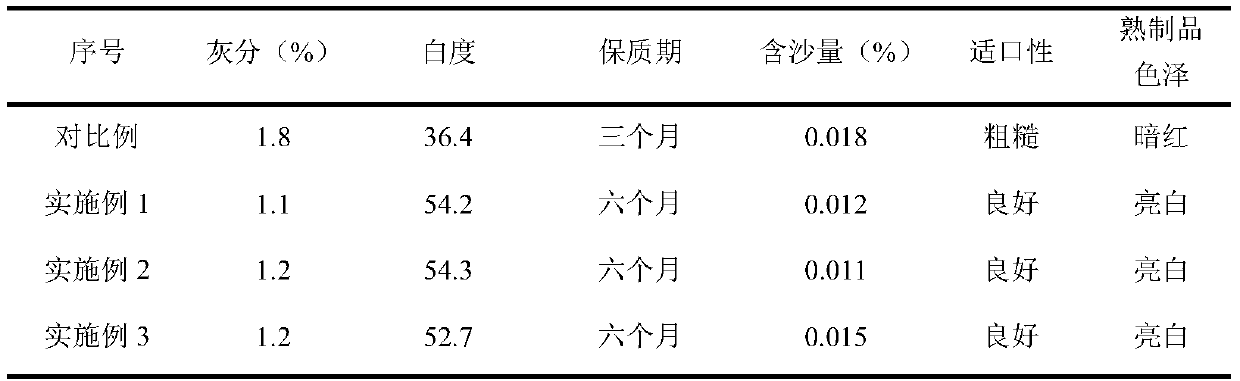

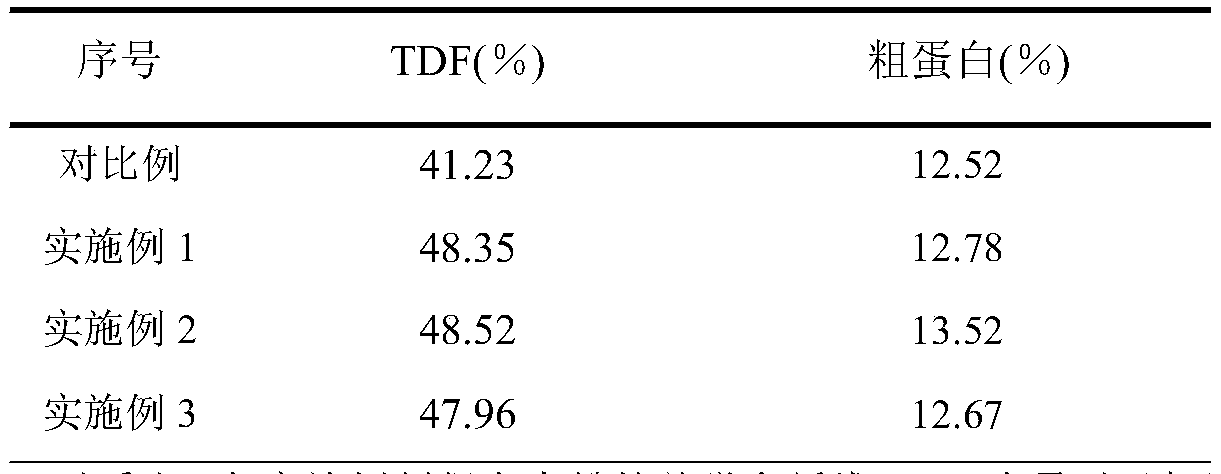

Examples

Embodiment 1

[0028] A kind of whole wheat flour production process, specifically comprises the following steps:

[0029] (1) cleaning the wheat, cleaning and removing impurities after airing; moistening the wheat, controlling the water content of the wheat to be 12%;

[0030] (2) Utilize the roller mill to crush the wheat processed in step (1), and then pass through a screen to obtain endosperm powder and solids;

[0031] (3) Stir the solid matter obtained in step (2) for 10 min, then separate by winnowing to obtain wheat germ and bran;

[0032] (4) the wheat germ obtained in step (3) is placed on the oil-absorbing paper, and under the condition of power 600W, microwave drying 6min;

[0033] (5) in the bran that obtains in step (4), mix and account for the Na of bran weight 0.04‰ 2 CO 3 , mix evenly, then transfer to a cooking kettle, and cook for 35 minutes at a temperature of 75°C and a pressure of 0.7Mpa to remove water;

[0034] (6) the wheat germ obtained in the step (4) and the b...

Embodiment 2

[0037] A kind of whole wheat flour production process, specifically comprises the following steps:

[0038] (1) cleaning the wheat, cleaning and removing impurities after airing; moistening the wheat, controlling the water content of the wheat to be 14%;

[0039] (2) Utilize the roller mill to crush the wheat processed in step (1), and then pass through a screen to obtain endosperm powder and solids;

[0040] (3) Stir the solid obtained in step (2) for 20 min, then separate by winnowing to obtain wheat germ and bran;

[0041] (4) Place the wheat germ obtained in step (3) on oil-absorbing paper, and dry it by microwave for 5min under the condition of power 650W;

[0042] (5) in the bran that obtains in step (4), mix and account for the Na of bran weight 0.06‰ 2 CO 3 , mixed evenly, and then transferred to a cooking kettle, cooking at a temperature of 80°C and a pressure of 0.8Mpa for 40 minutes to remove water;

[0043] (6) the wheat germ obtained in the step (4) and the br...

Embodiment 3

[0046] A kind of whole wheat flour production process, specifically comprises the following steps:

[0047] (1) cleaning the wheat, cleaning and removing impurities after airing; moistening the wheat, controlling the water content of the wheat to be 16%;

[0048] (2) Utilize the roller mill to crush the wheat processed in step (1), and then pass through a screen to obtain endosperm powder and solids;

[0049](3) Stir the solid matter obtained in step (2) for 30min, then separate by winnowing to obtain wheat germ and bran;

[0050] (4) the wheat germ obtained in step (3) is placed on oil-absorbing paper, and under the condition of power 700W, microwave drying 3min;

[0051] (5) in the bran that obtains in step (4), mix and account for the Na of bran weight 0.07‰ 2 CO 3 , mixed evenly, and then transferred to a cooking kettle, cooking at a temperature of 85°C and a pressure of 0.9Mpa for 50 minutes to remove water;

[0052] (6) the wheat germ obtained in the step (4) and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com