Wheat fragrance type creamy essence and preparation method thereof

A technology of whey and essence, applied in food ingredients as odor modifiers, food ingredients containing natural extracts, food science and other directions, can solve the problems of no wheat flavor, small use range, and unnatural aroma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

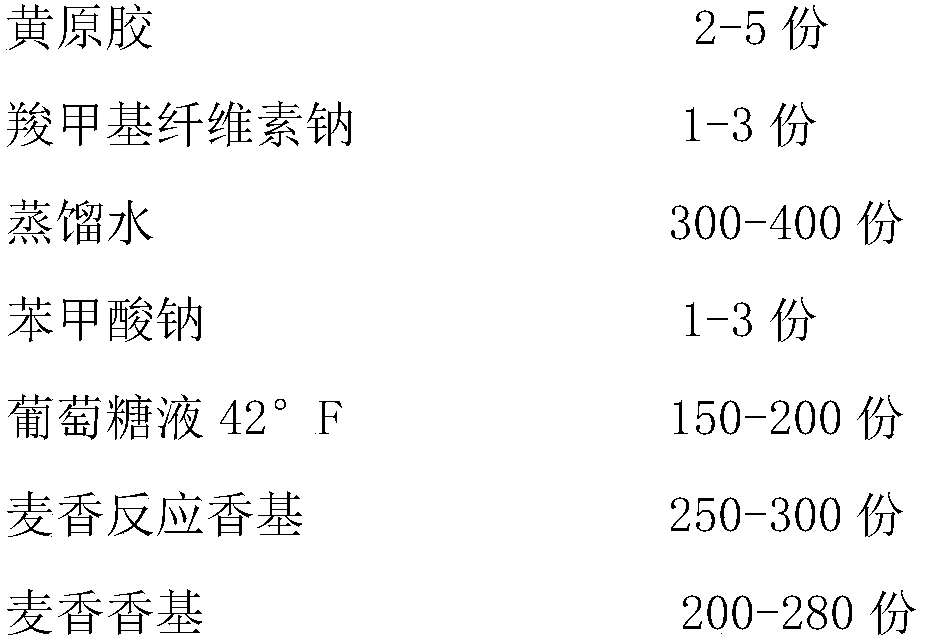

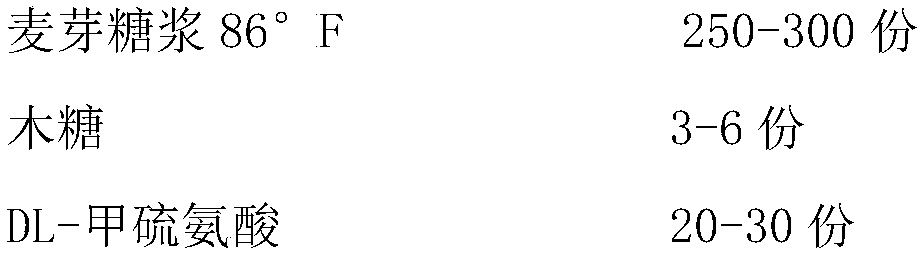

[0030] The preparation method of the wheat fragrance reaction fragrance base is as follows:

[0031] Add maltose syrup 86°F, xylose, DL-methionine, partially distilled water, baking soda (add if necessary) to tank A, mix well, stir and heat to 60°C to dissolve; heat to 85°C, stir at constant temperature for 1.5 hour; add methylcyclopentenolone (add if there is), ethyl maltol (add if there is), propylene glycol raw materials in tank B, heat to 50°C and stir to dissolve; add cornstarch and remaining distilled water into tank C, Stir well and evenly; add the raw materials of tanks B and C to tank A in sequence, stir at a constant temperature of 85°C for 5 minutes, and cool to room temperature to obtain the finished product of wheat fragrance reaction fragrance base.

[0032] The Maixiang base is described according to the following ratio:

[0033]

[0034]

[0035] Note: "-" means no such substance

[0036] The preparation method of wheat fragrance base is as follows:

...

Embodiment 1

[0041] In Example 13, the wheat aroma reaction base of Example 1 and the wheat aroma base of Example 7 are used for mixing, just to illustrate that this is a kind of mixing method, but the wheat aroma reaction aroma base of Example 1 is not limited here. The base can only be mixed with the malt fragrance base of Example 7, and it can be mixed with the malt fragrance base of any one of Examples 7-12.

[0042] Wheat flavor milk paste essence of the present invention is based on the above-mentioned substances mixed, and its specific preparation method is as follows: weigh xanthan gum, sodium carboxymethyl cellulose, and distilled water in proportion, mix, heat, and stir until completely dissolved , the heating temperature does not exceed 40°C, then add glucose solution and sodium benzoate, stir until completely dissolved, add wheat fragrance reaction fragrance base and wheat fragrance base, stir evenly, and homogenize under the condition of 10MPa to obtain wheat fragrant milk Pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com