Patents

Literature

59 results about "Fahrenheit degrees" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fahrenheit (more precisely, a degree Fahrenheit) is a unit of measurement used to measure temperature. The conversion rate to Celsius is C= 5/9 x (F − 32).

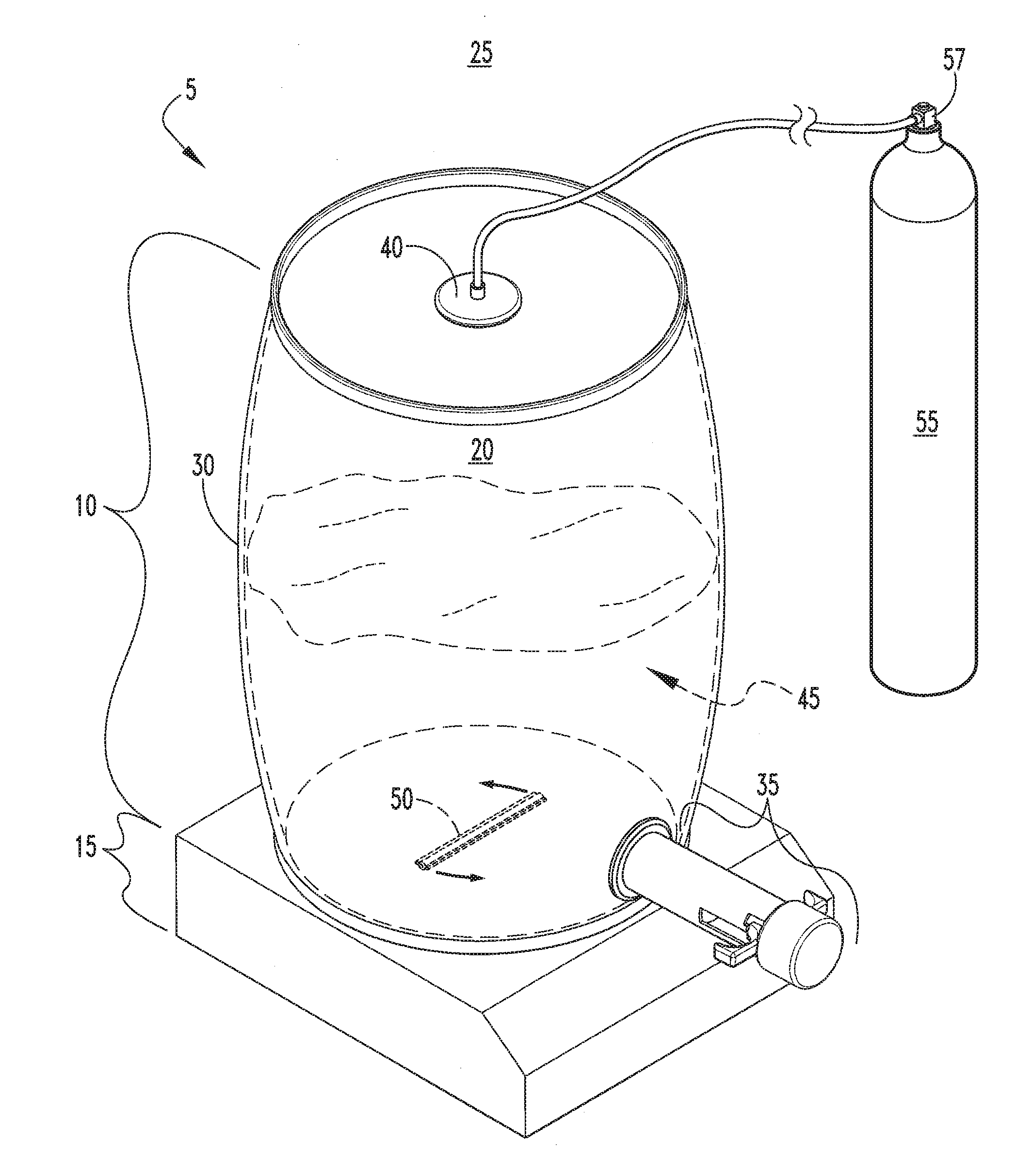

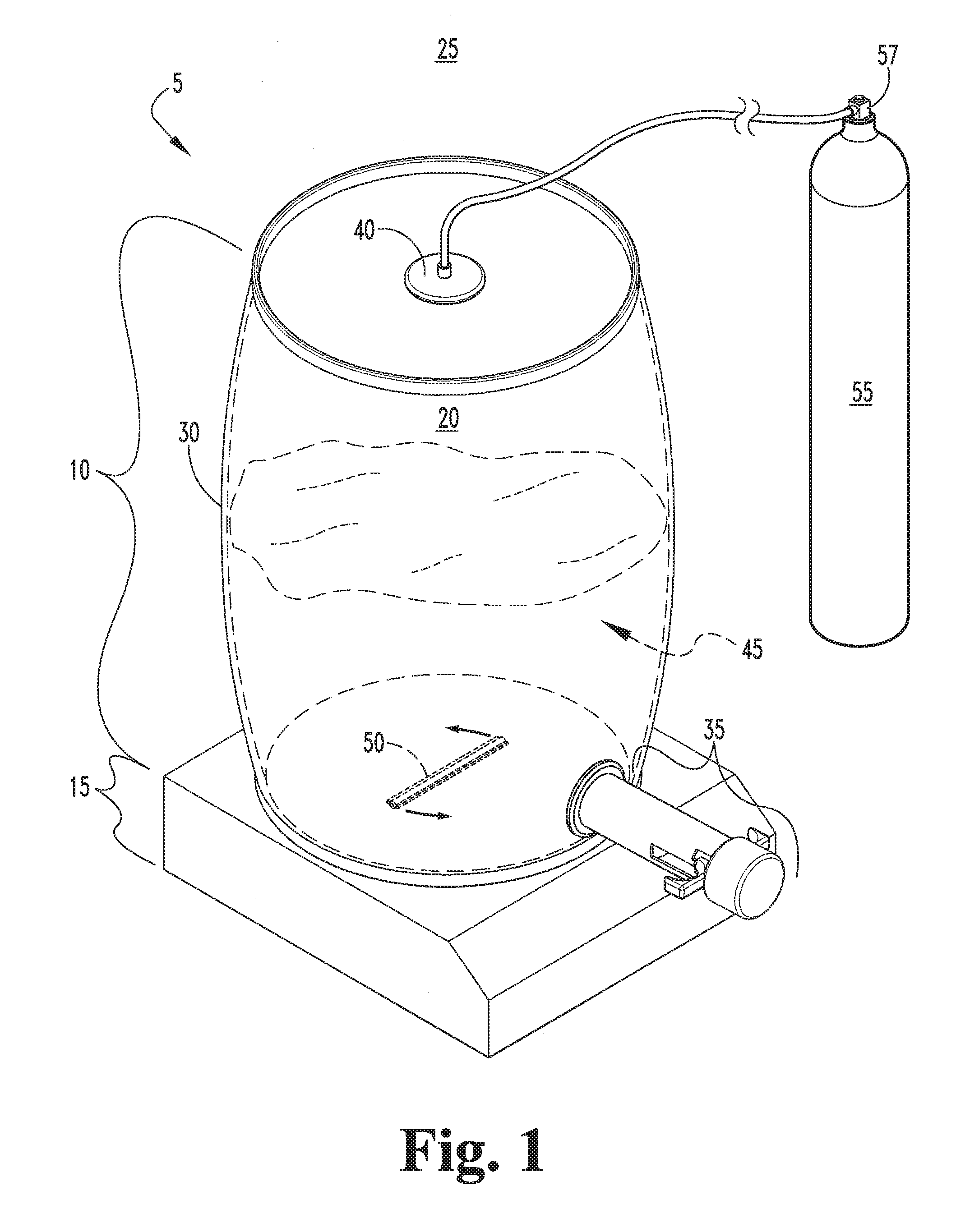

Systems and methods for distributing and dispensing chocolate

Systems and methods for preparing and dispensing food context typically molten chocolate. In one aspect, a method for treating chocolate includes placing a quantity of chocolate in a pressure-controllable environment; heating the quantity of chocolate to a temperature of about 115 degrees Fahrenheit; decreasing the pressure of the pressure-controllable environment to about 5 Torr; and holding the pressure of the pressure-controllable environment at about 5 Torr for a predetermined period of time. Additional steps may include decreasing the pressure of the pressure-controllable environment to about 5 Torr at an average rate of about 8 Torr per minute; heating the quantity of chocolate to a temperature of about 115 degrees Fahrenheit may occur at a rate of about 2 degrees Fahrenheit per minute; and / or heating the quantity of chocolate to a temperature of about 115 degrees Fahrenheit may occur at a rate of no more than 1 degree Fahrenheit per minute.

Owner:TRADE SECRET CHOCOLATES

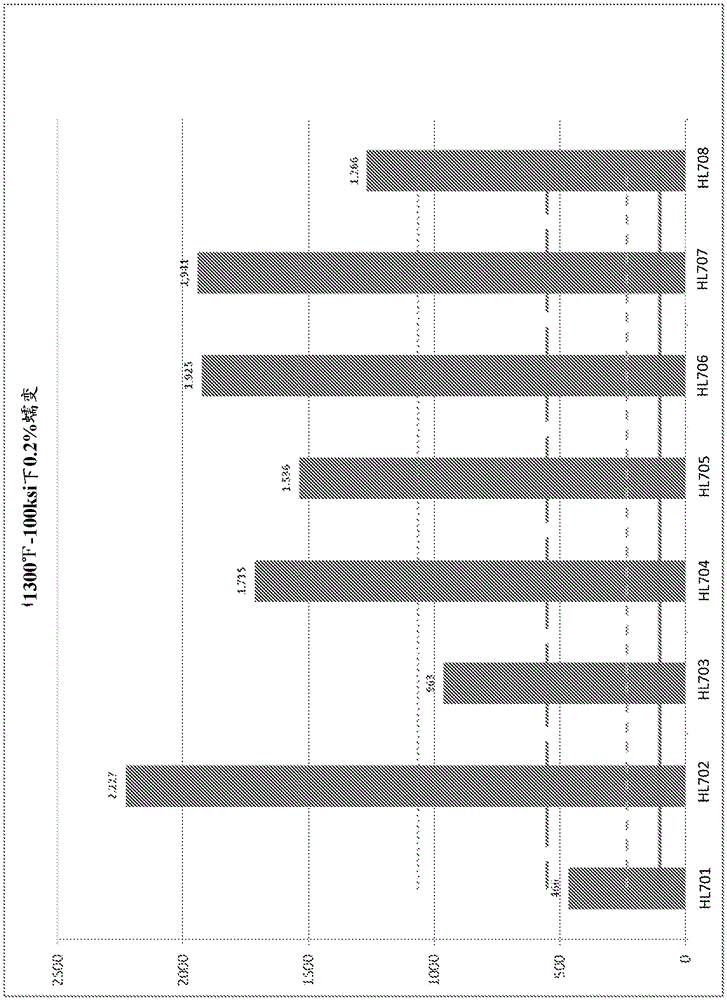

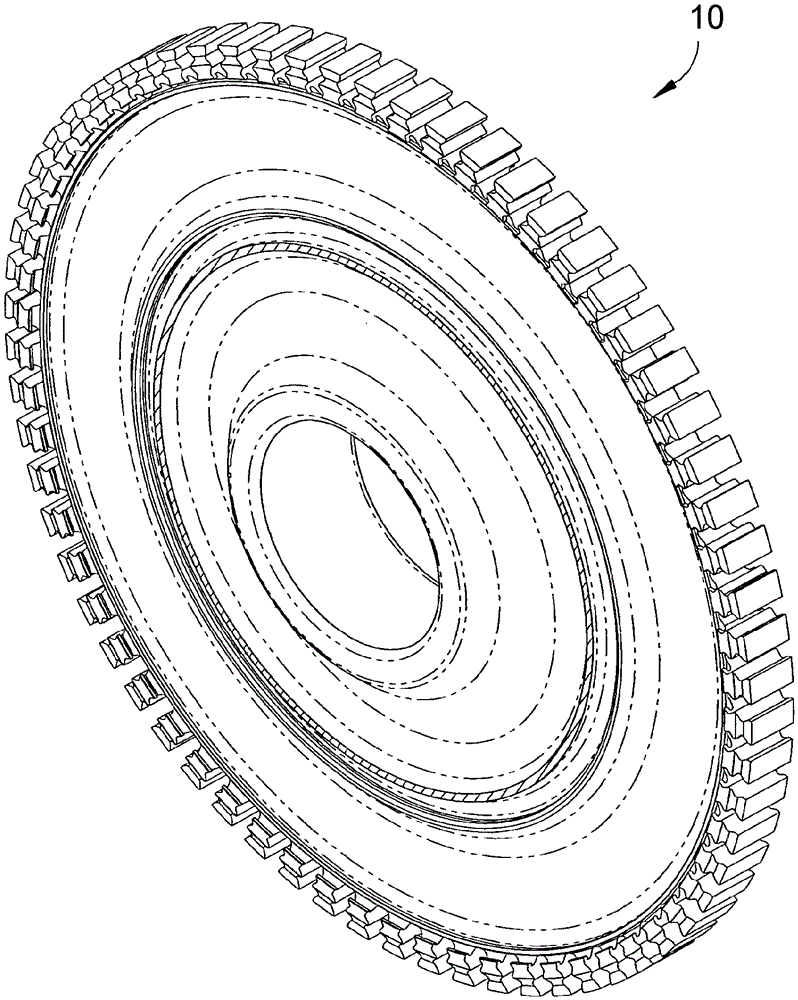

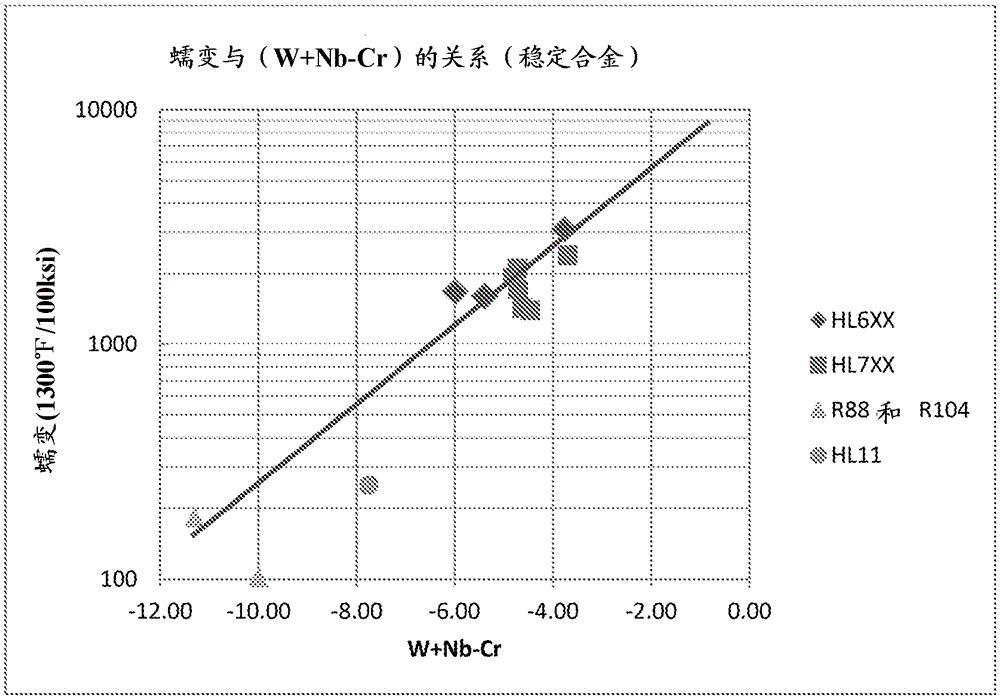

Superalloys and components formed thereof

ActiveCN105492639AImproved high temperature and pressure holding propertiesImproved creep characteristicsEfficient propulsion technologiesNiobiumHafnium

A gamma prime nickel-base superalloy and components formed therefrom that exhibit improved high-temperature dwell capabilities, including creep and hold time fatigue crack growth behavior. A particular example of a component is a powder metallurgy turbine disk of a gas turbine engine. The gamma-prime nickel-base superalloy contains, by weight: 16.0 to 30.0% cobalt; 9.5 to 12.5% chromium; 4.0 to 6.0% tantalum; 2.0 to 4.0% aluminum; 2.0 to 3.4% titanium; 3.0 to 6.0% tungsten; 1.0 to 4.0% molybdenum; 1.5 to 3.5% niobium; up to 1.0% hafnium; 0.02 to 0.20% carbon; 0.01 to 0.05% boron; 0.02 to 0.10% zirconium; the balance essentially nickel and impurities. The superalloy has a W+Nb-Cr value of at least-6, is free of observable amounts of sigma and eta phases, and exhibits a time to 0.2% creep at 1300 Fahrenheit and 100 ksi of at least 1000 hours.

Owner:GENERAL ELECTRIC CO

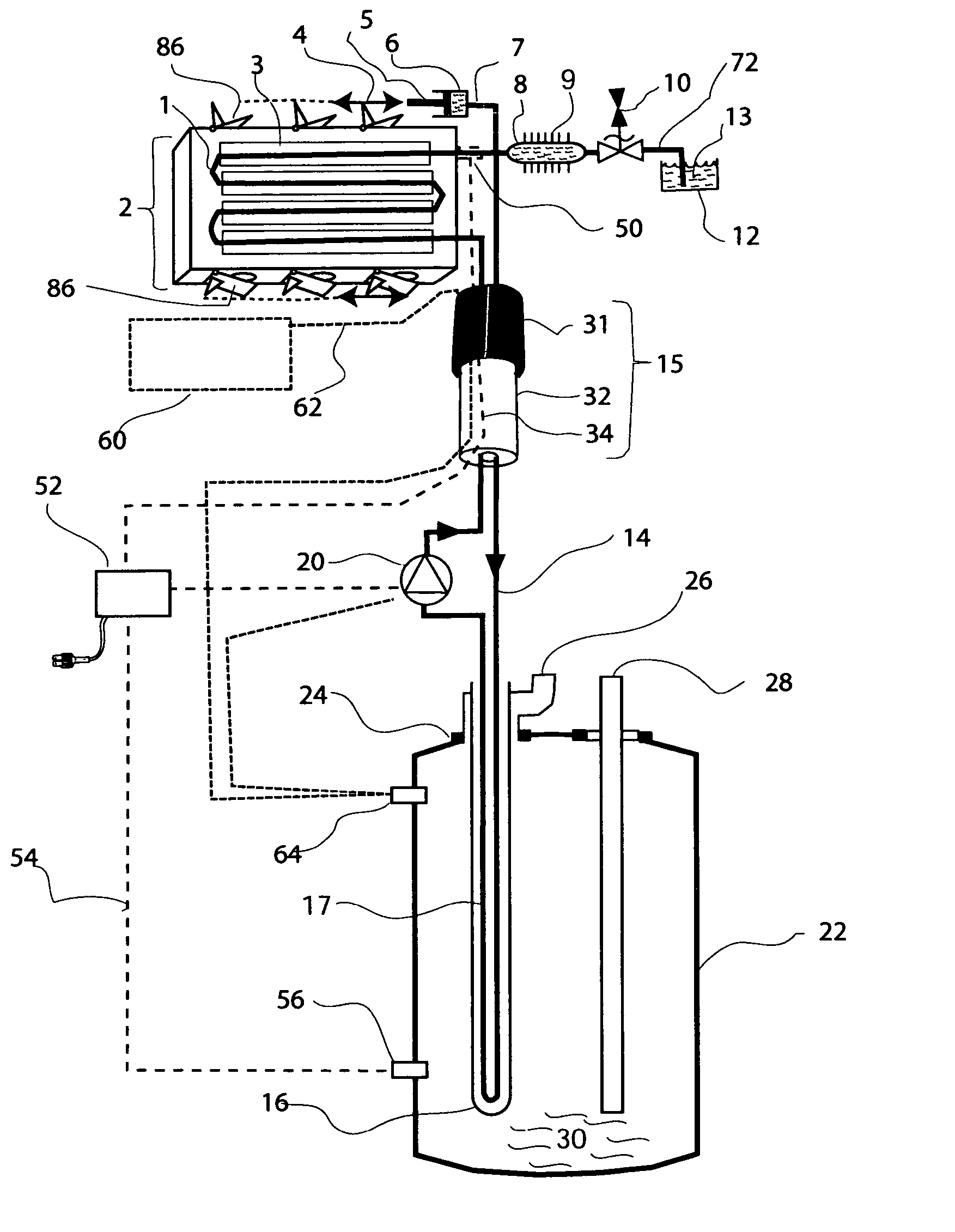

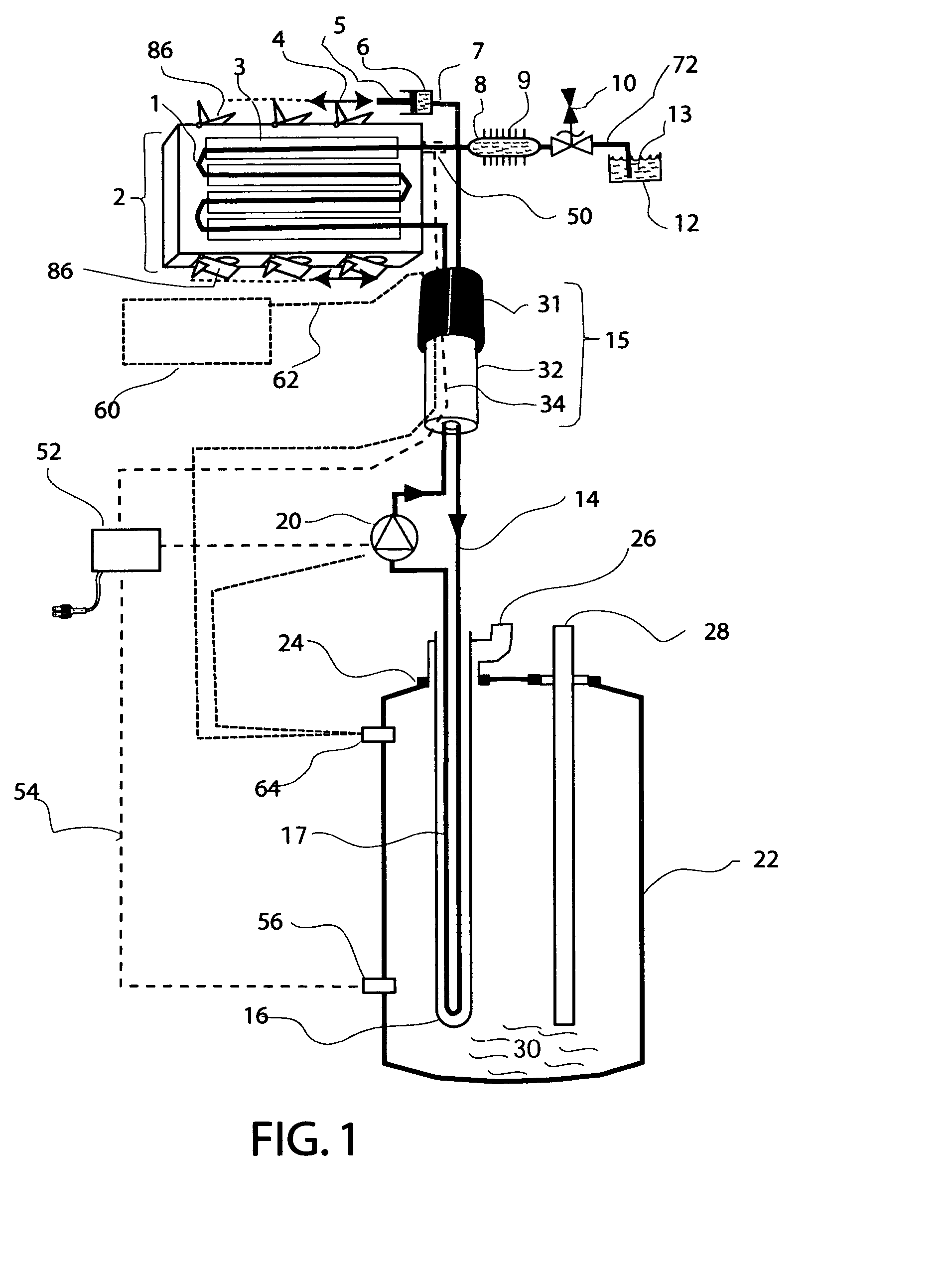

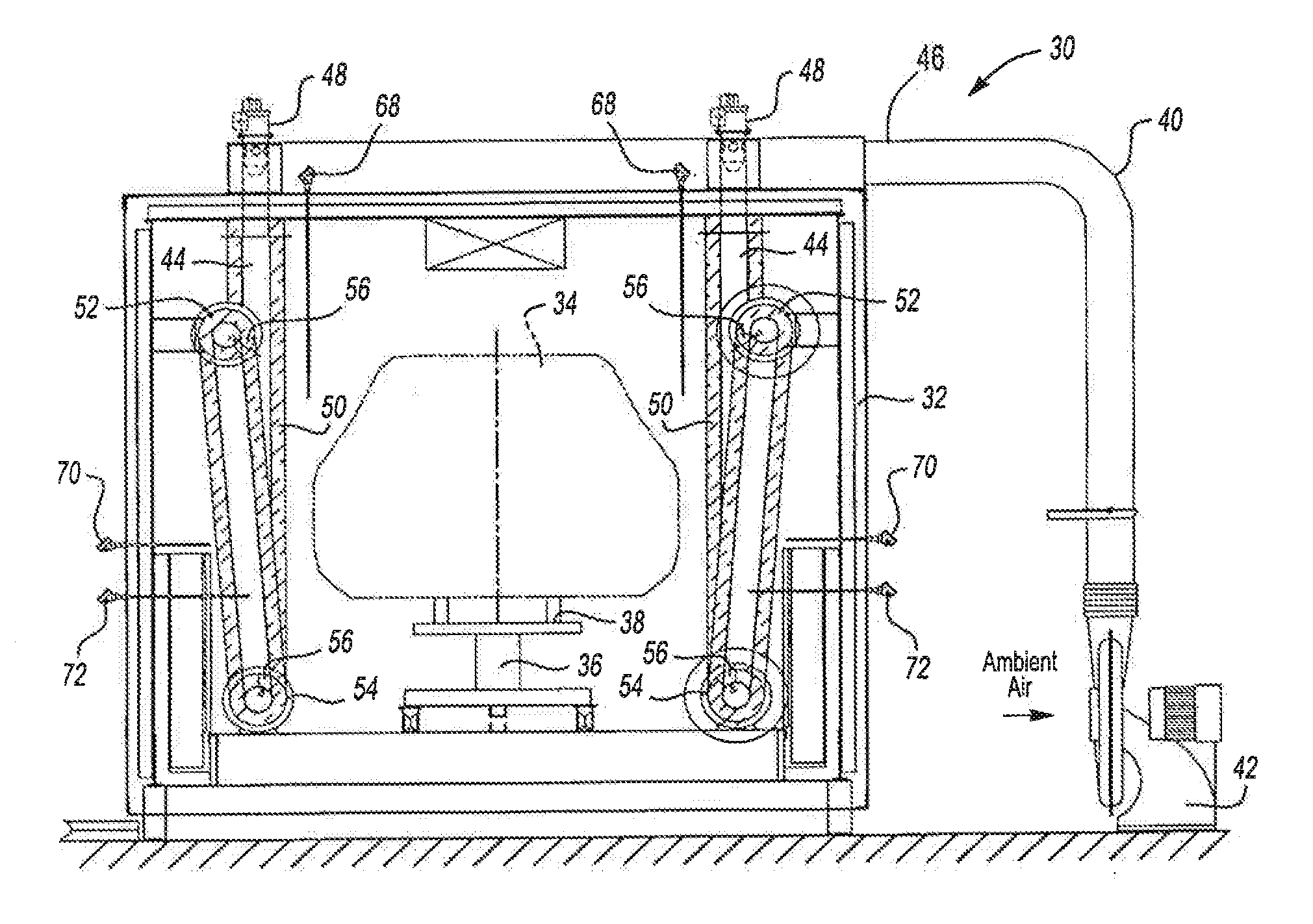

Solar heat transfer system (HTPL), high temperature pressurized loop

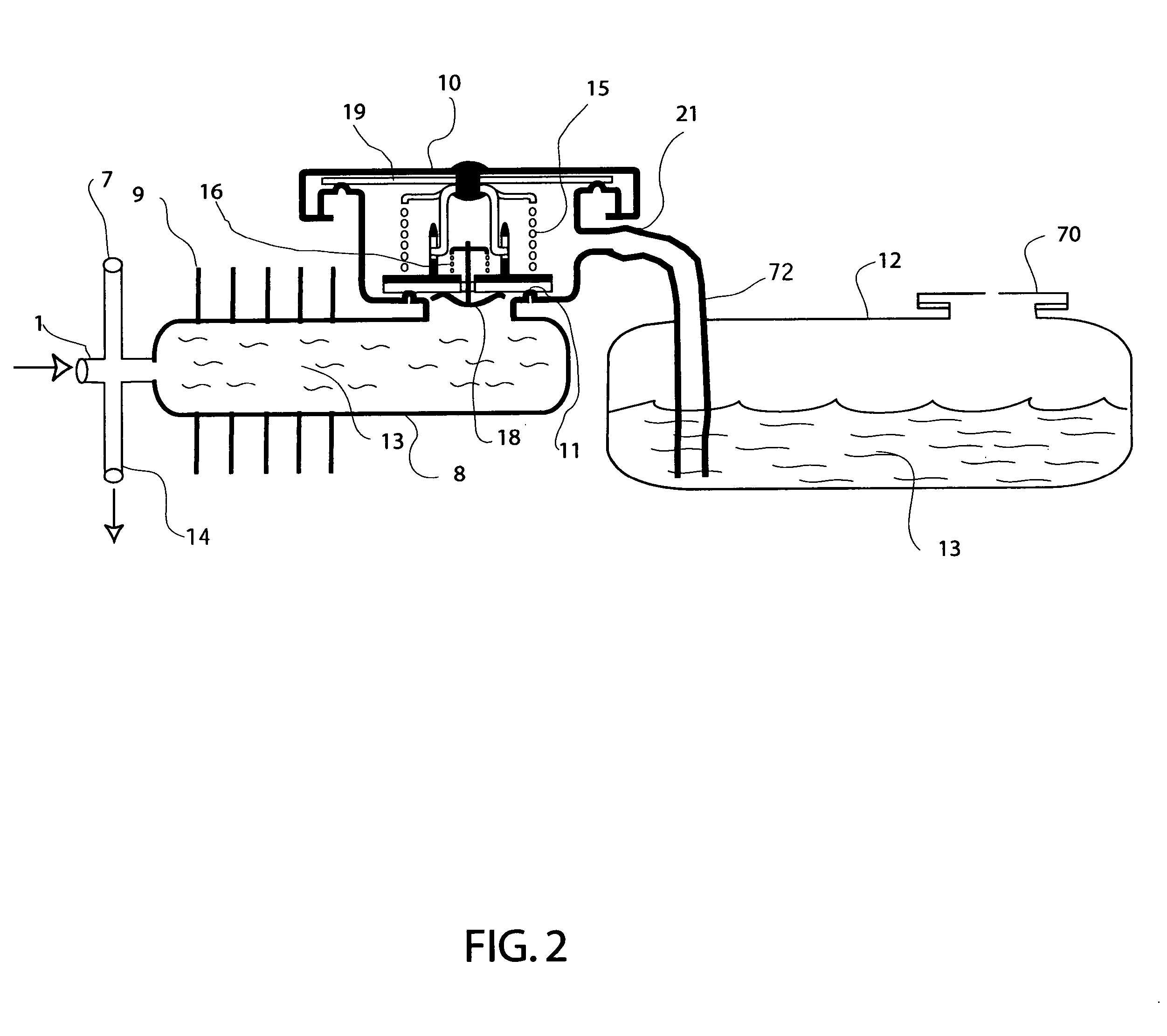

InactiveUS7913684B2More materialReduce material usageSolar heating energySolar heat devicesModem deviceEngineering

Delivering heat from modem high temperature solar collectors to hot water storage tanks is more effectively done using unpressurized when cold, self-pressurized on heat up, automatic air eliminating, higher temperature fluid loops. A pressurizing valve, an overflow reservoir and a vacuum relief valve are used. Non-toxic water / antifreeze mixtures are pressurized up to about two atmospheres resulting in a 265° Fahrenheit boiling point. Loss of circulation under full sun results in solar collector boiling under pressure. The steam generated in the solar collector is condensed in the pressurized liquid-to-air radiator, a steam heat pipe, and water is returned to the solar collector to keep it completely full of fluid and steam. A set of pressure-actuated air dampers on the solar collector can also be used to shed the excess solar collector heat.

Owner:BUTLER BARRY LYNN

Cigar alcoholization method

InactiveCN103445289AReduce bitter tasteAlcoholization process is simpleTobacco treatmentFlavorChemical composition

Owner:HUBEI CHINA TOBACCO IND

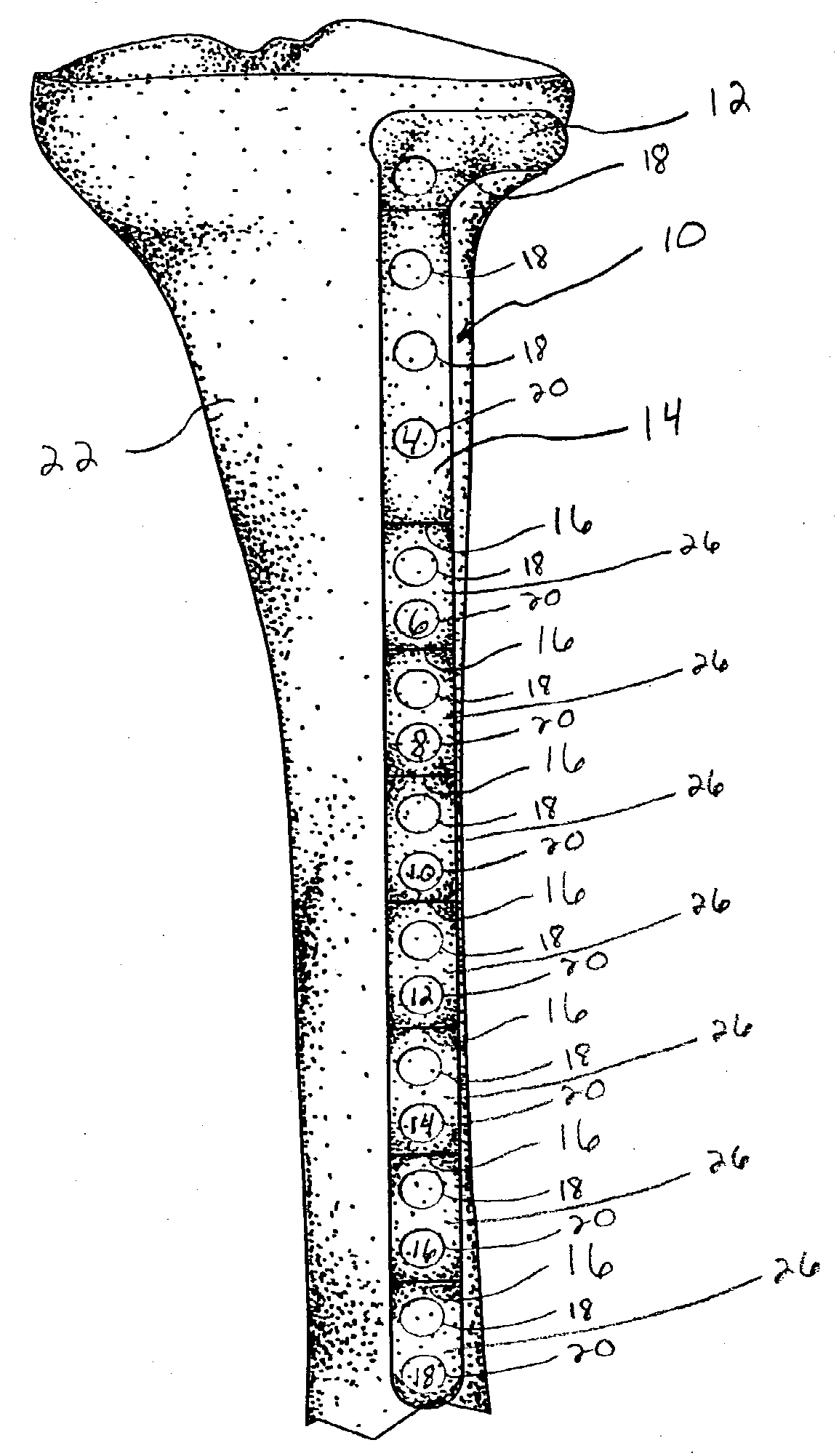

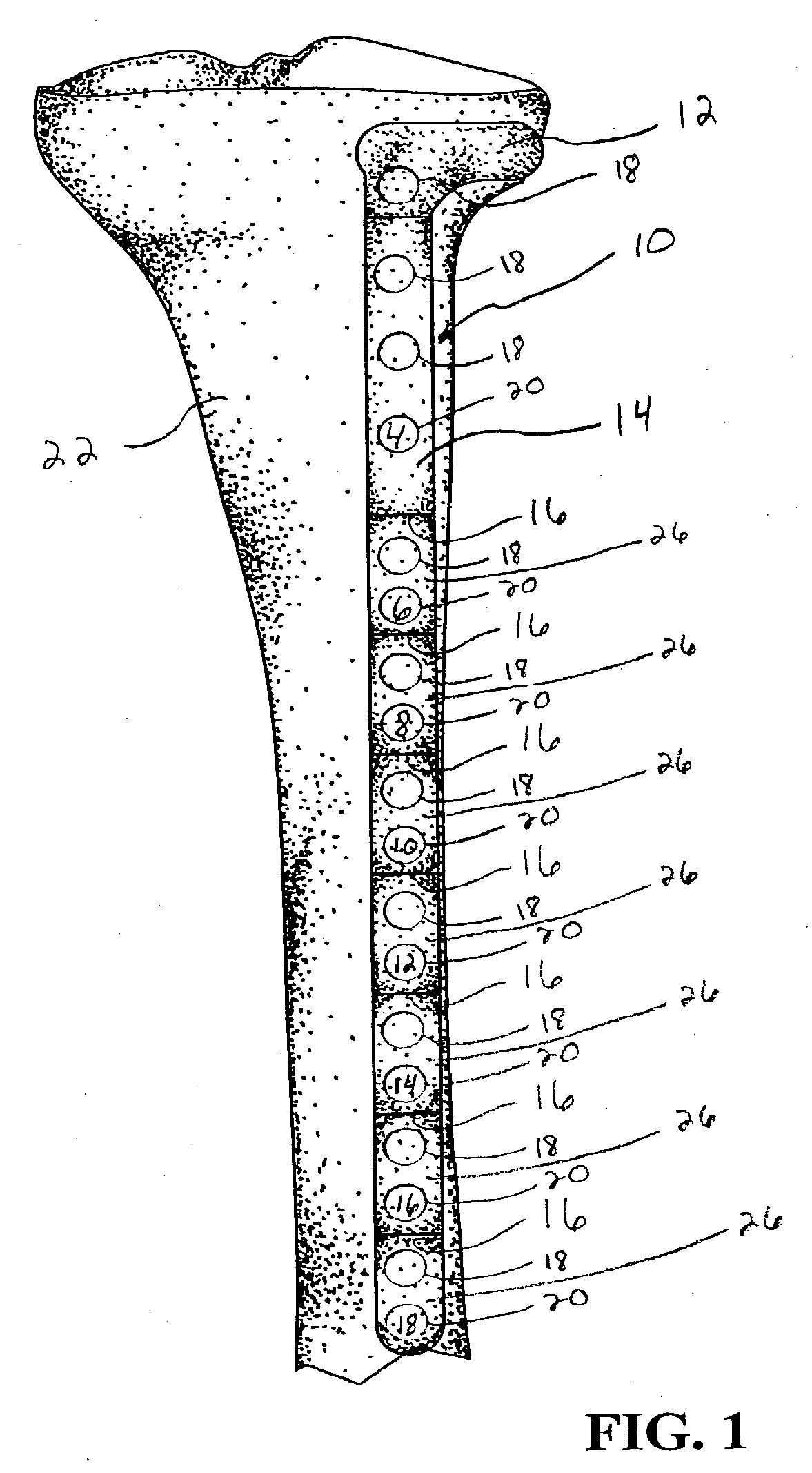

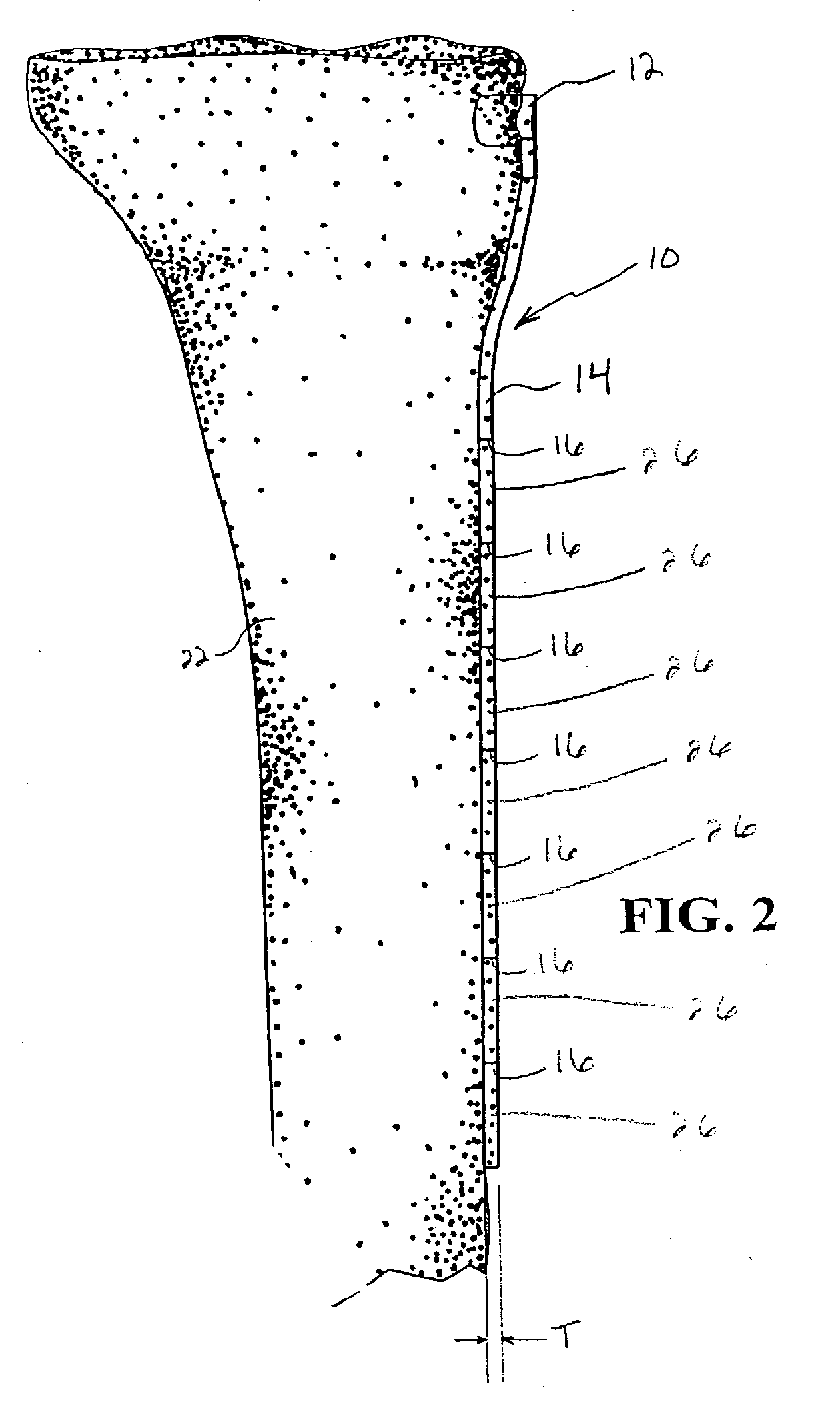

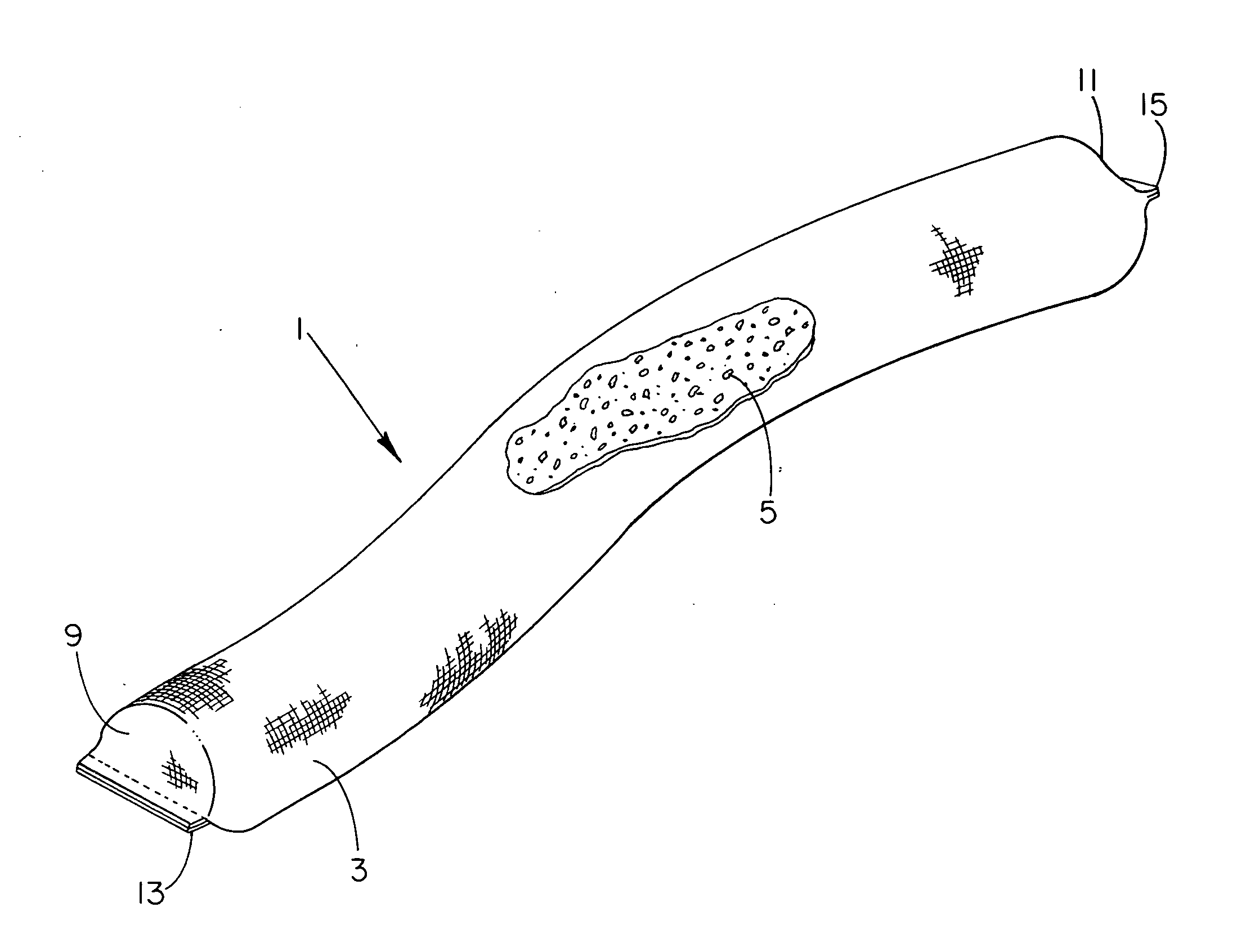

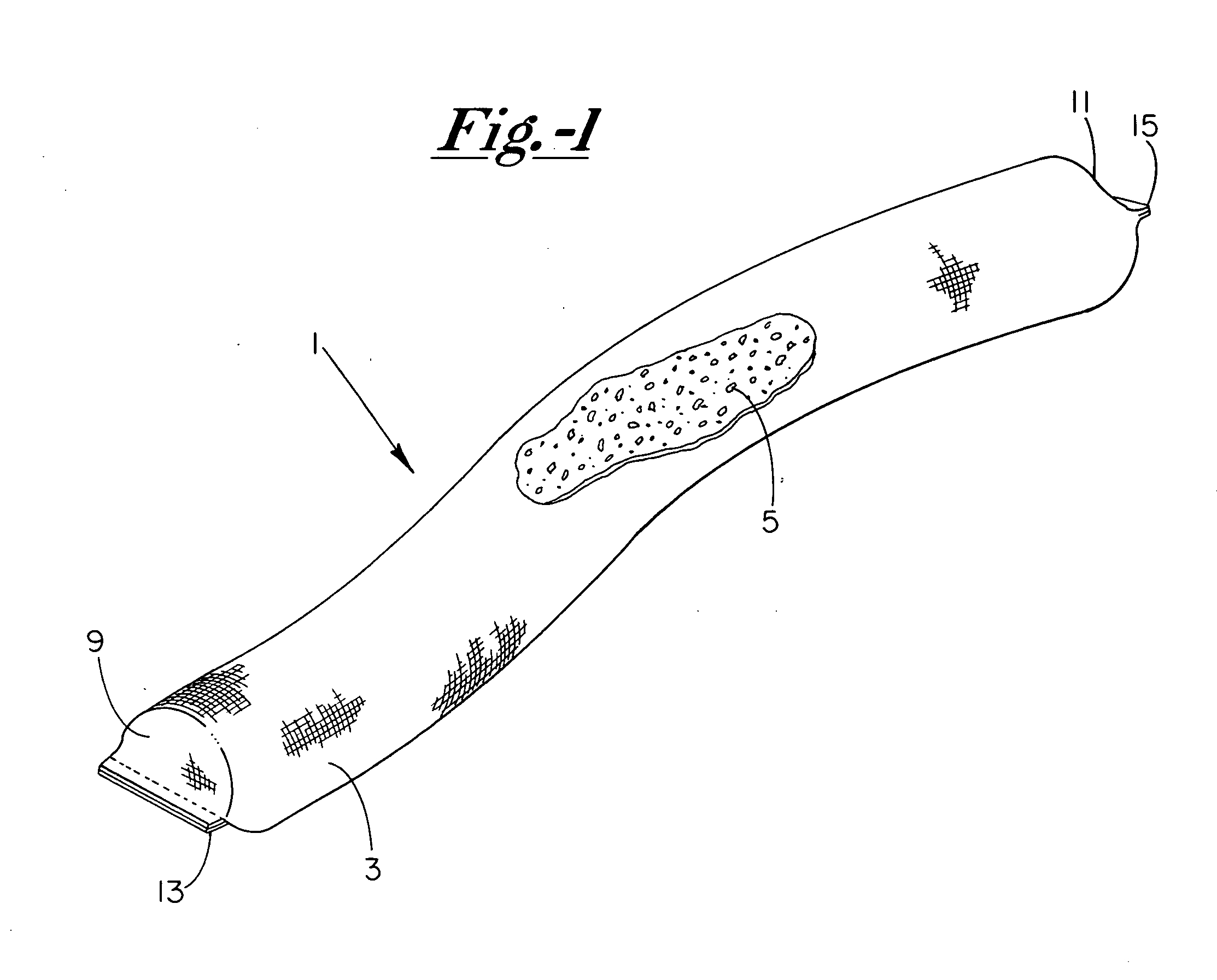

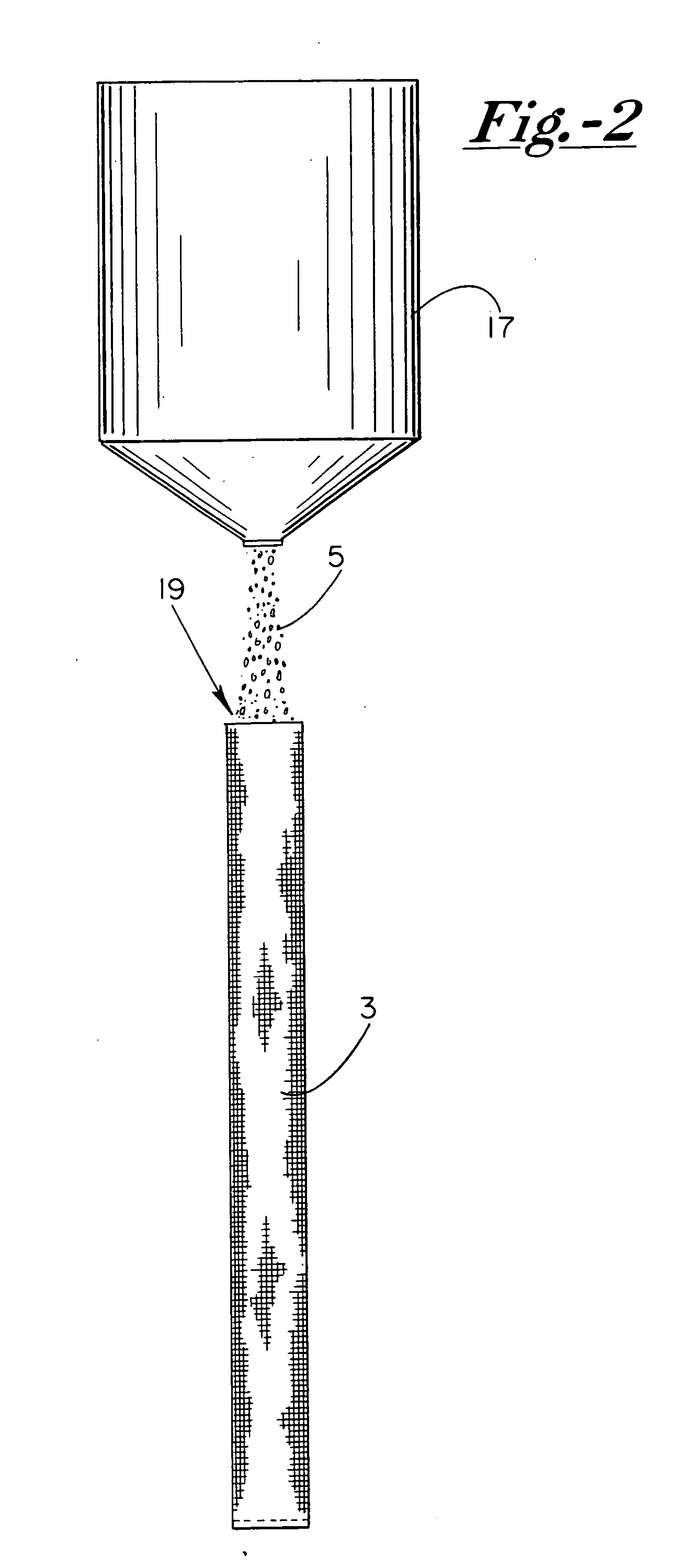

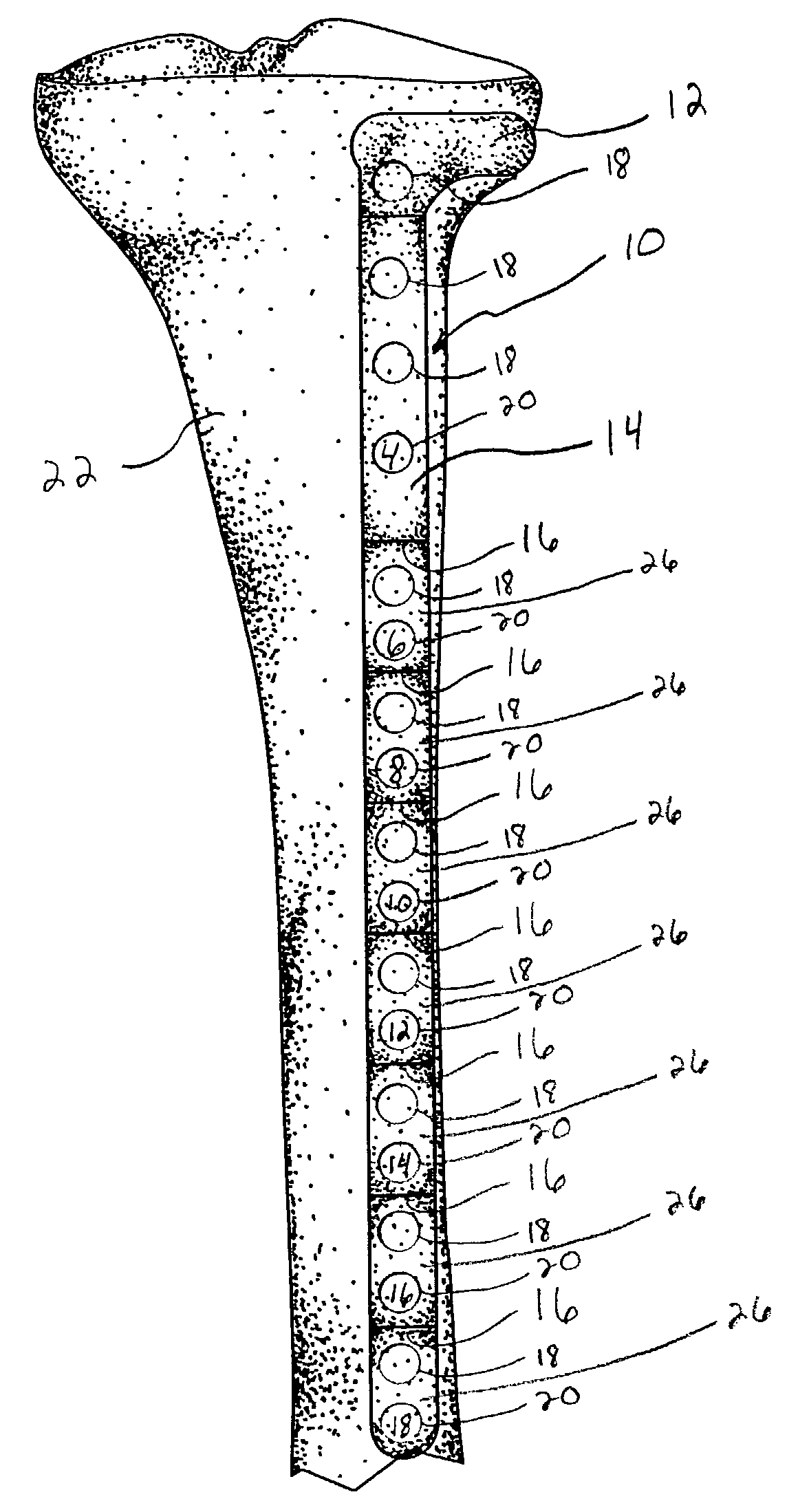

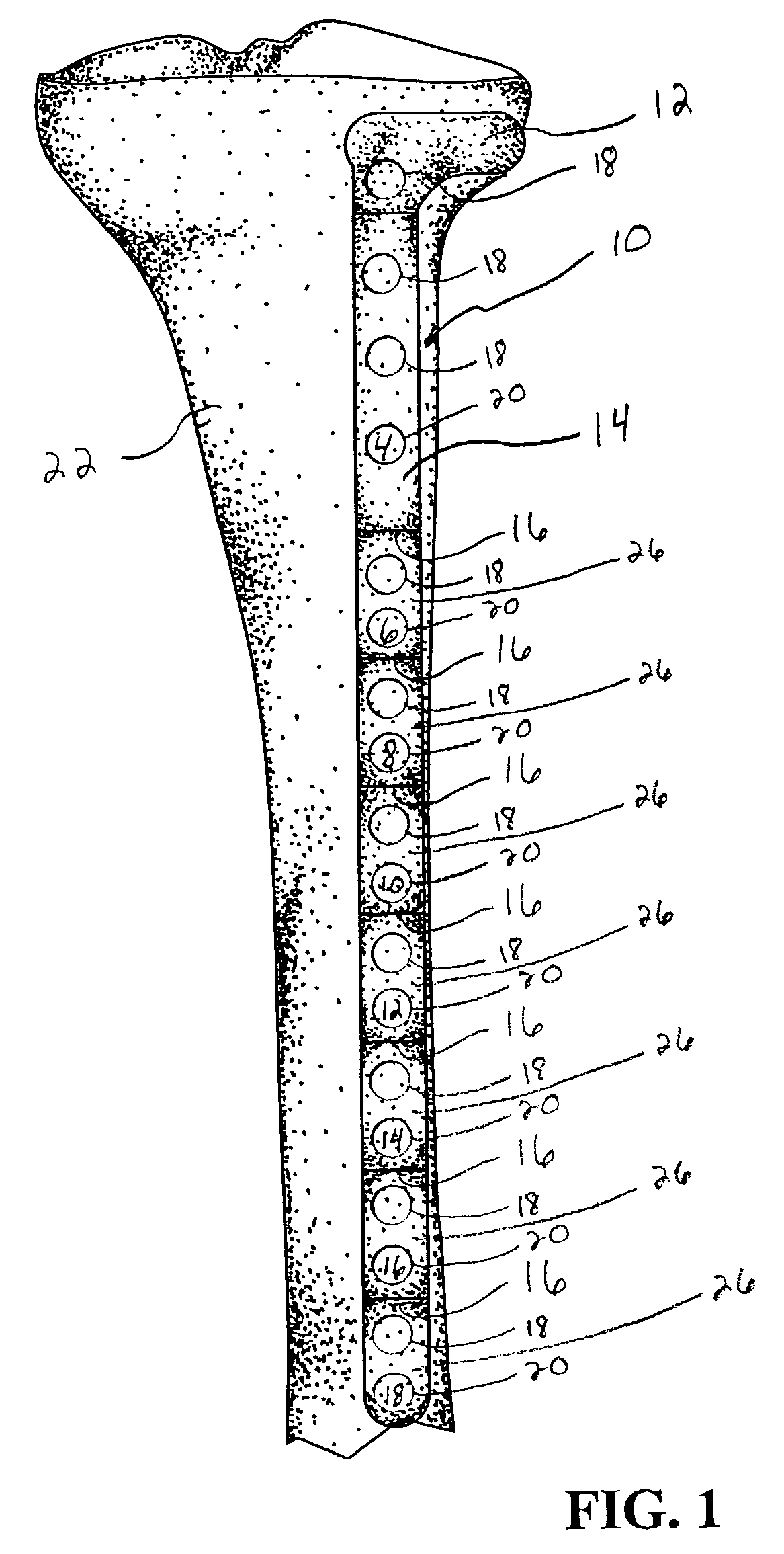

Provisional bone plate

A provisional bone plate formed of an implantable plastic and having a length corresponding to the longest bone plate in a particular family of bone plates. The provisional bone plate includes a head contoured to match the head of a particular bone as well as a shaft for placement adjacent the bone shaft. The provisional bone plate includes a plurality of circumferential notches surrounding the elongate body or shaft of the bone plate. The circumferential notches are substantially transverse to a longitudinal axis of the bone plate and define frangible portions of the bone plate which can be removed from the distal end thereof to alter the length of the provisional periarticular bone plate to correspond to the length of the various bone plates in a family of bone plates. The provisional bone plate is constructed of a biologically suitable plastic, is radiographic, and melts at a temperature less than 200° Fahrenheit.

Owner:ZIMMER TECH INC

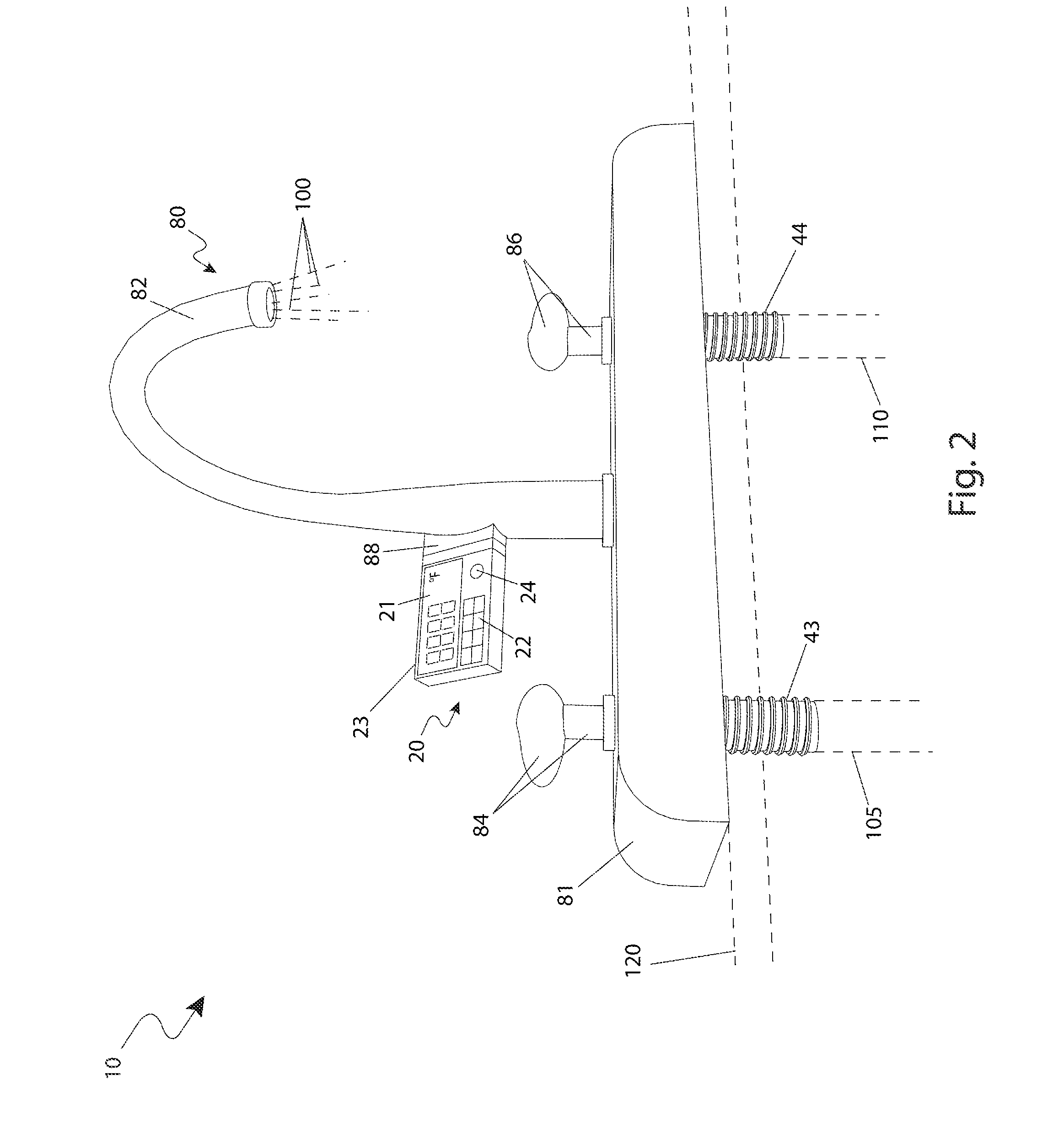

Ice dam removal system

Apparatus for melting and preventing the formation of roof ice or ice dams on the upper surface of a roof which includes an elongated water-porous container having a closed interior within which a deicing mixture is contained that is composed of a heat-generating deicing agent and a corrosion-inhibiting agent. The container rests on the roof of a building above the ice dam in a transverse, obstructing position relative to the path along which water normally runs so that the water passes through the container and absorbs the deicing mixture to produce a strong deicing brine solution. The brine solution melts any ice it contacts in a medium having a temperature above −15° Fahrenheit, and inhibits corrosion of associated drains, gutters, etc. Heat-absorbing and ecologically friendly deicing agents may also be added to the mixture to prolong the deicing action and aid surrounding vegetation.

Owner:IDRS

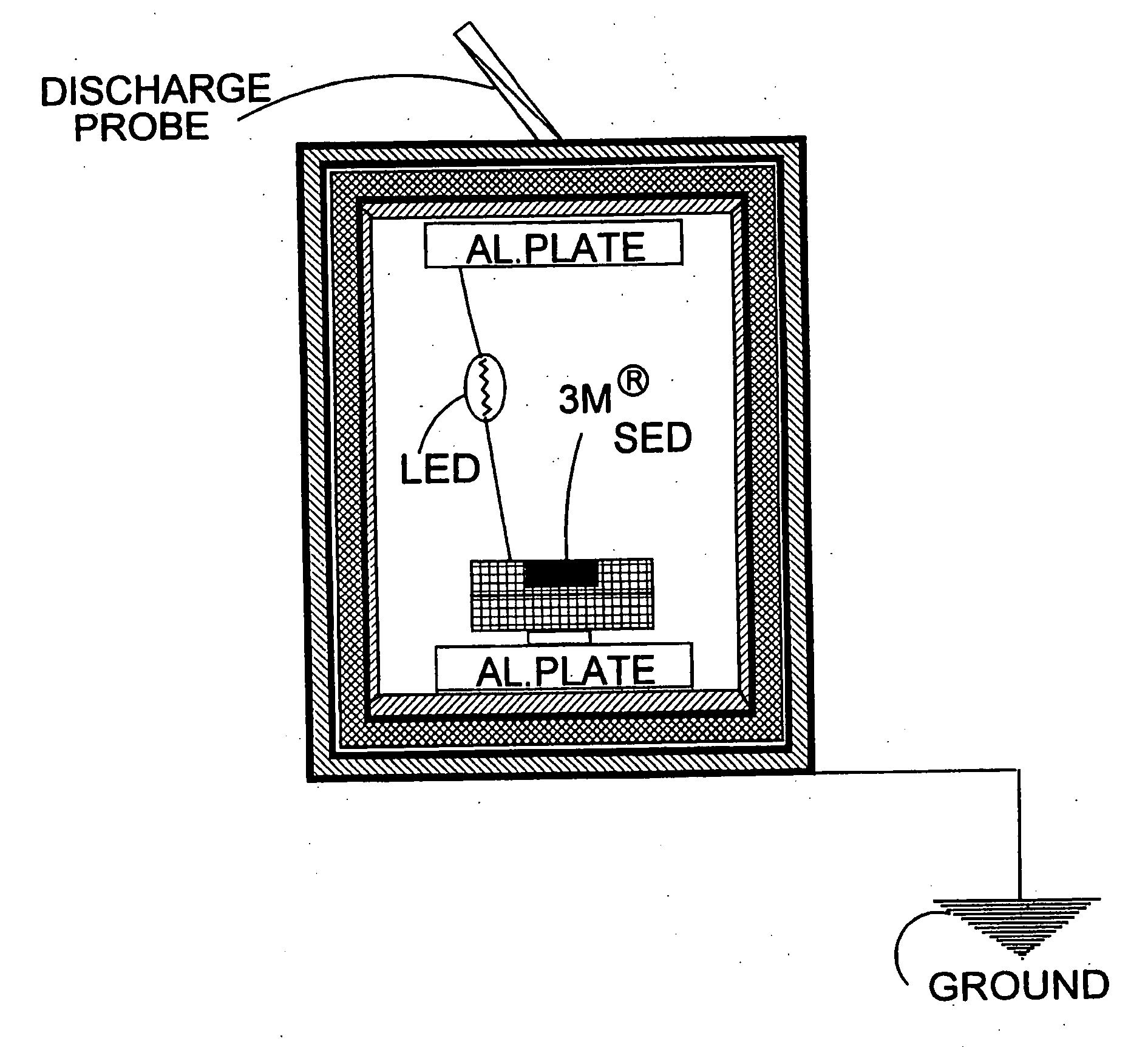

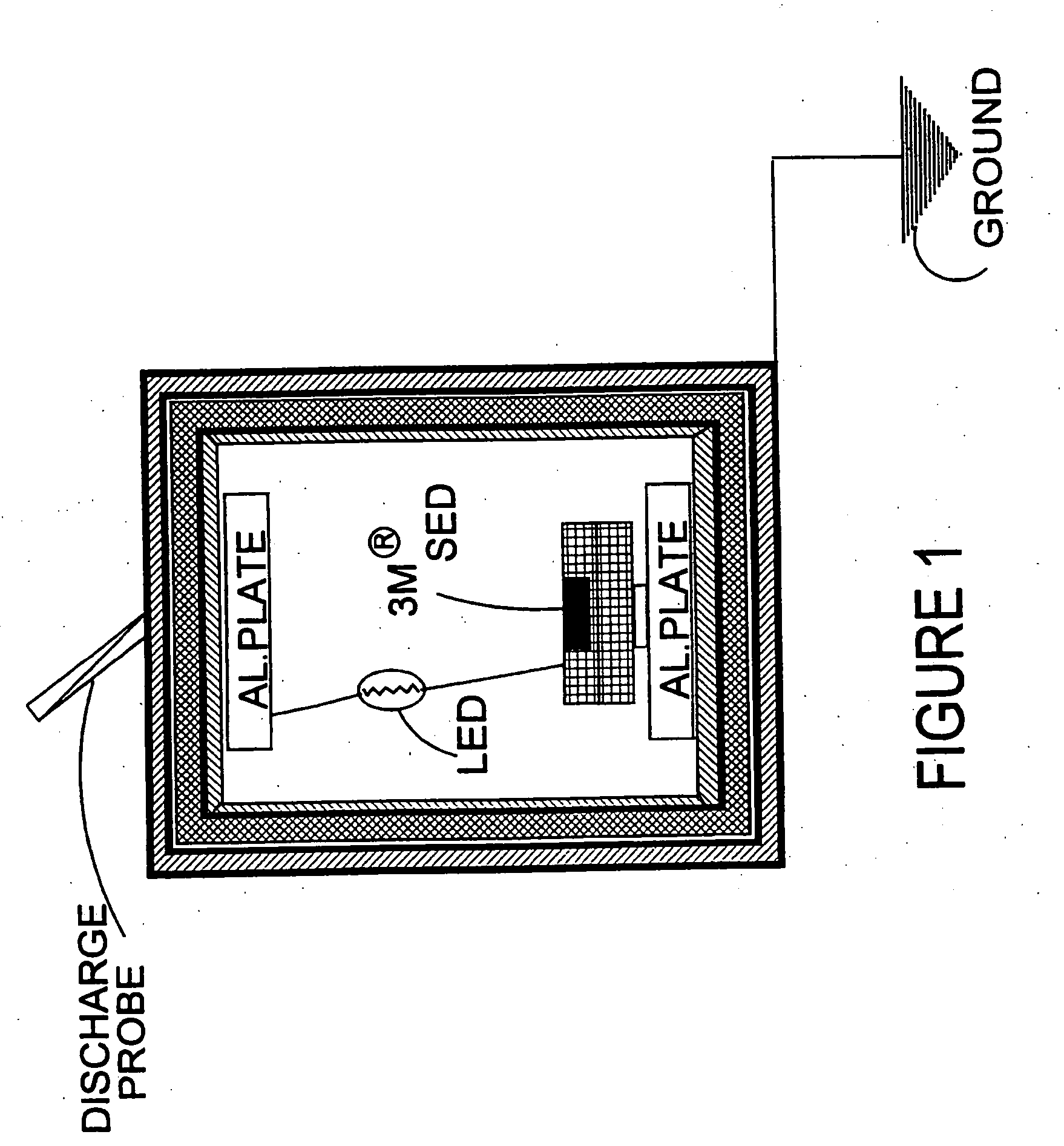

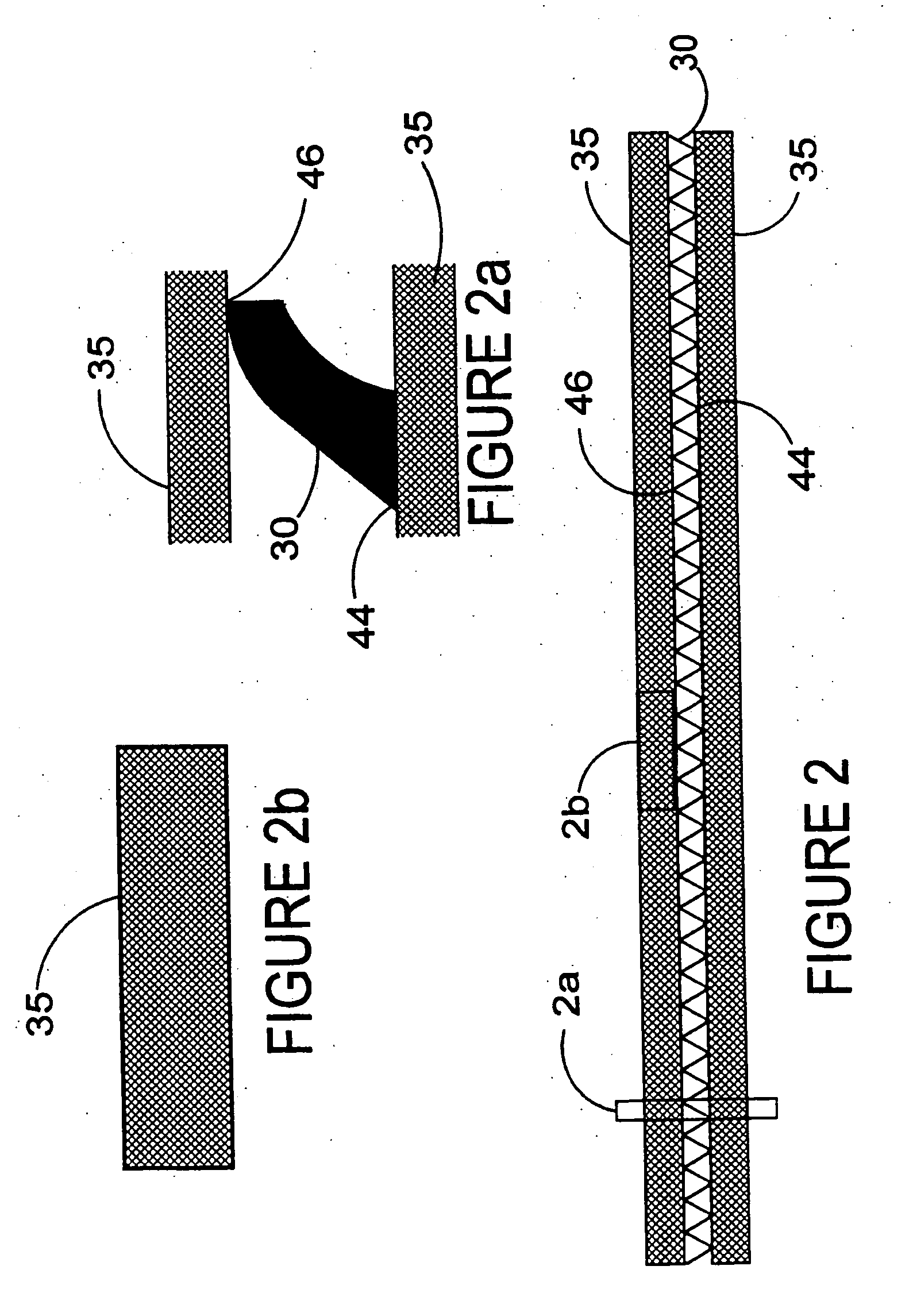

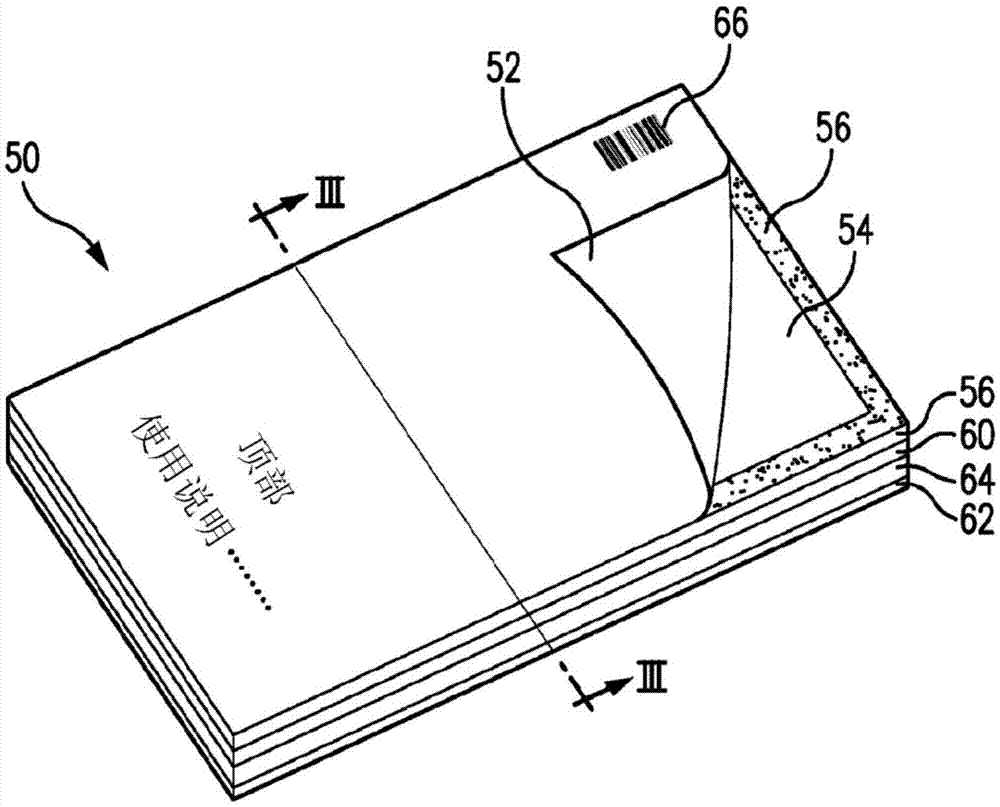

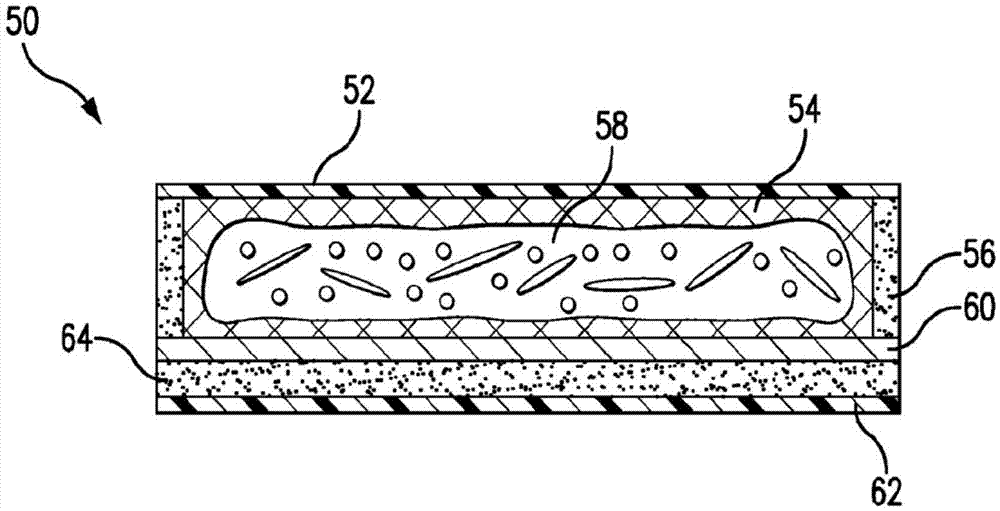

Packaging material for electrostatic sensitive devices

Fiberboard to protect sensitive electronic components and devices from the hazards of ESD (electrostatic discharge) incorporates a homogeneous conductive shielding paperboard having an electrical resistance of less than or equal to one thousand ohms resistance that has been adhered together throughout the corrugation process or lamination process with one or more homogeneous static dissipative linerboards. The liners have a surface resistance range between a targeted 1x10<7 >to 1x10<11 >at twelve percent relative humidity and 73° Fahrenheit. The static dissipative linerboard and conductive shielding paperboard can be used as static safe packaging cushioning material, shelving liners, dividers, in-plant handlers, specialty static free packaging, and dissipative or shielding paper bags.

Owner:VERMILLION ROBERT J

Suspended deck for liquid natural gas tank

InactiveUS20070094971A1Avoid pollutionHigh strengthVessel manufacturingVessel geometry/arrangement/sizeCelsius DegreeEngineering

A non-welded deck used to support insulation from the roof of a low temperature or cryogenic storage tank is disclosed. The deck may be comprised of a plurality of spaced apart bars with metal sheets covering the spaces between the bars. The edge of the metal sheets may be clamped to the bars to form the deck. The edges of adjacent metal sheets may overlap and be clamped together in such a way as to deform the sheets creating a metal-to-metal vapor and dust proof seal. The plurality of clamping bars and support bars may secure the metal sheets with sufficient strength to allow the entire deck to support loadings as a stressed membrane. The tank may be constructed with hardware that remains secure even after being subjected to repeated thermal cycling of over 200° Celsius (360° Fahrenheit).

Owner:ULTRAFLOTE CORP

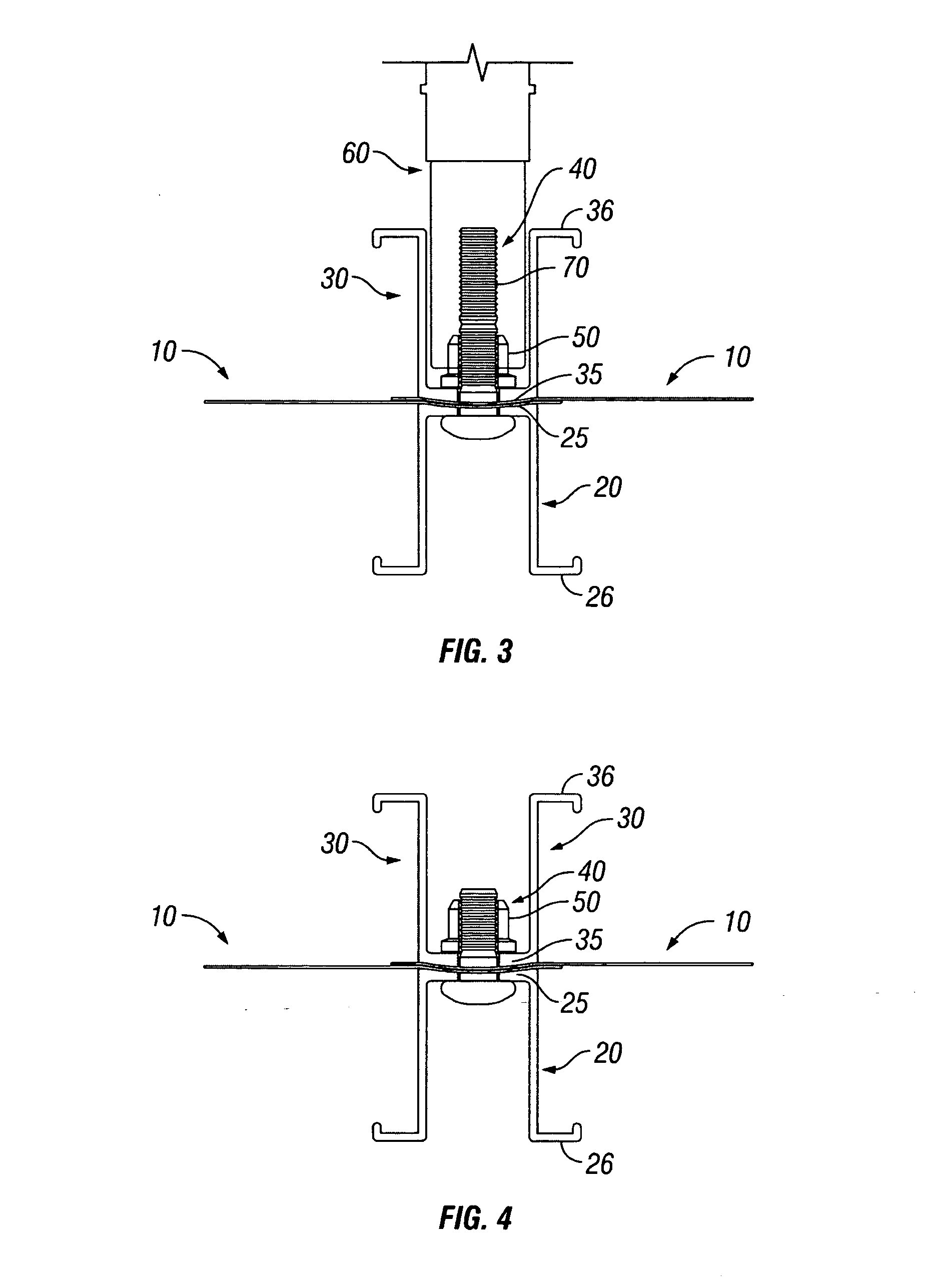

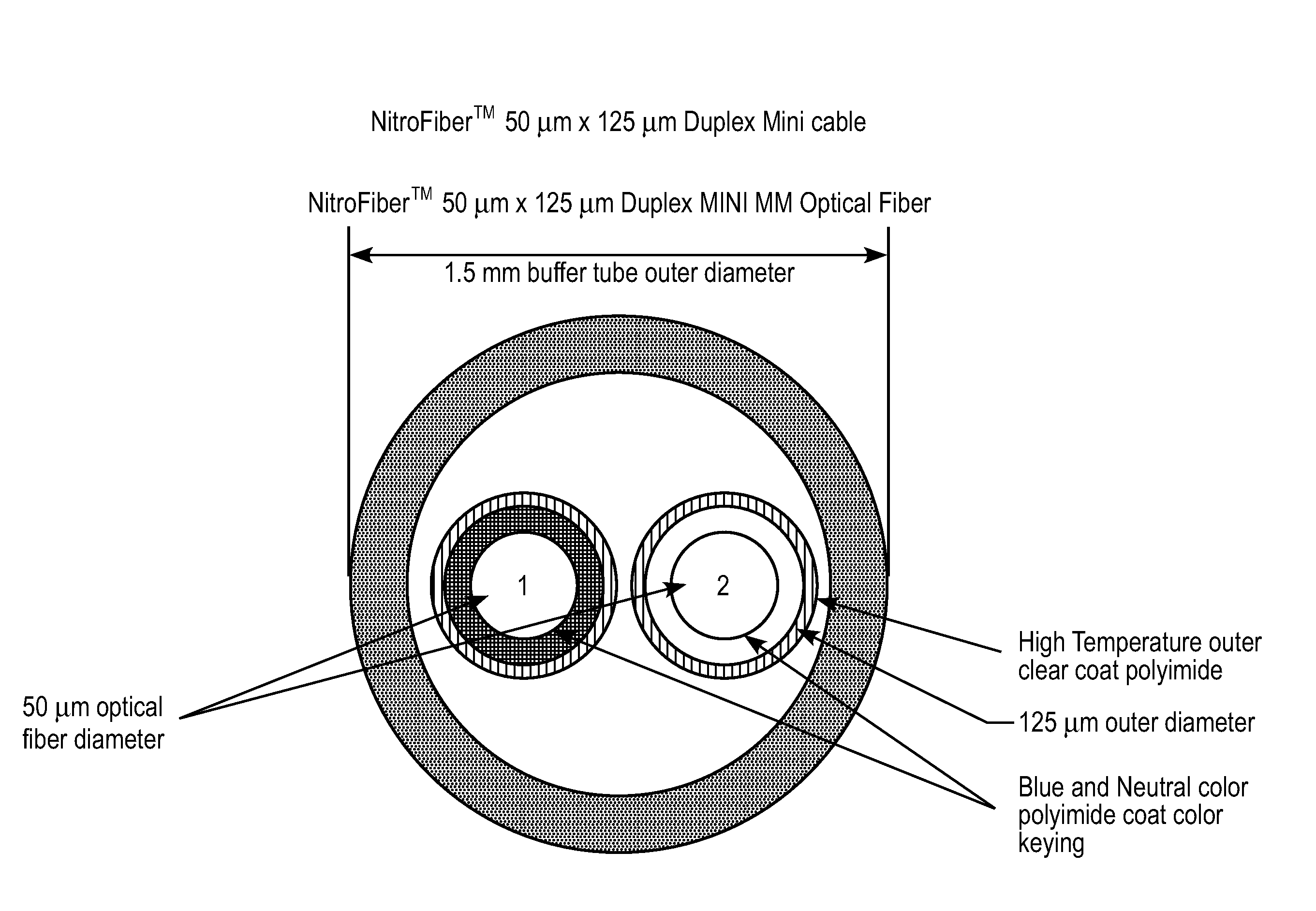

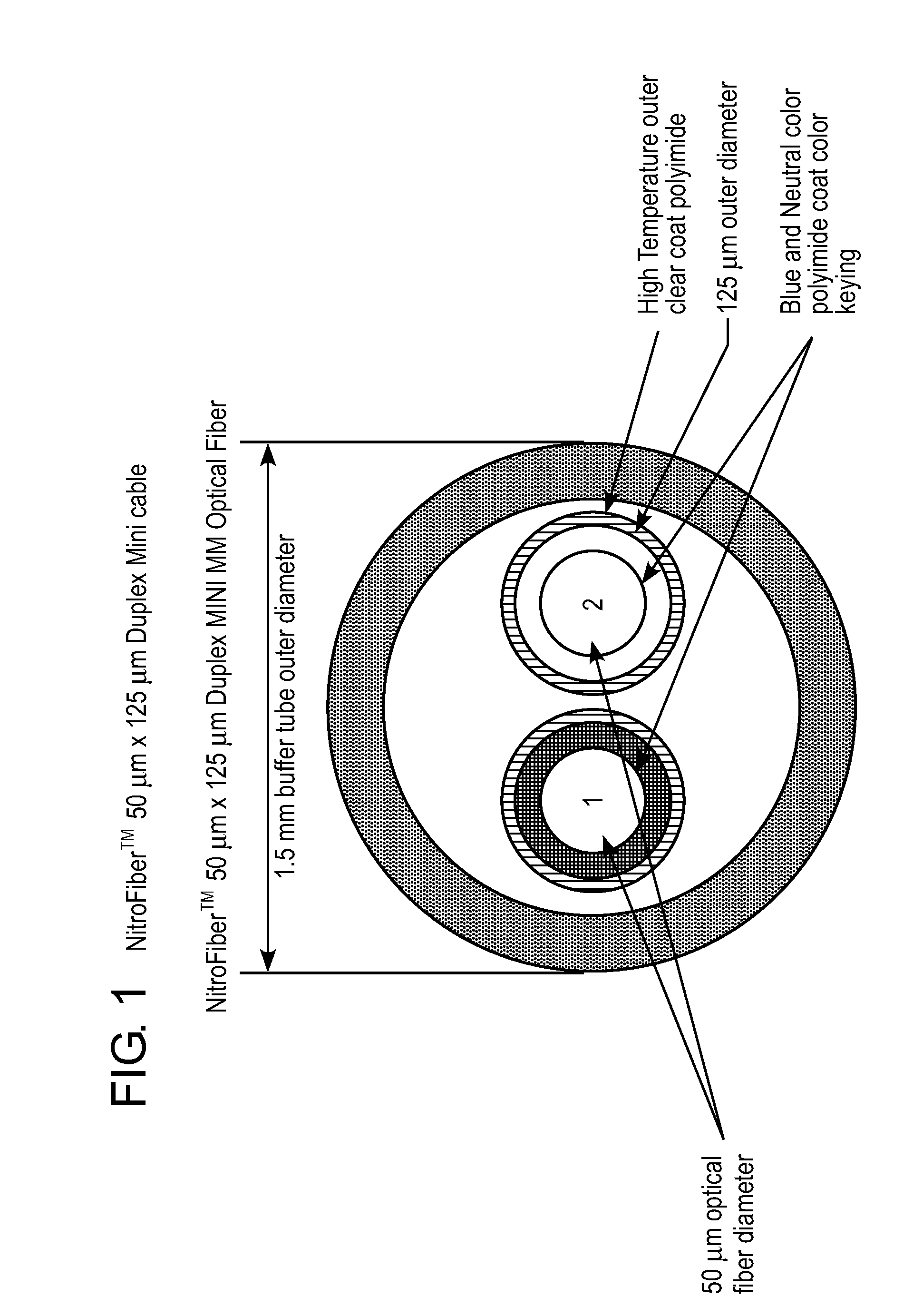

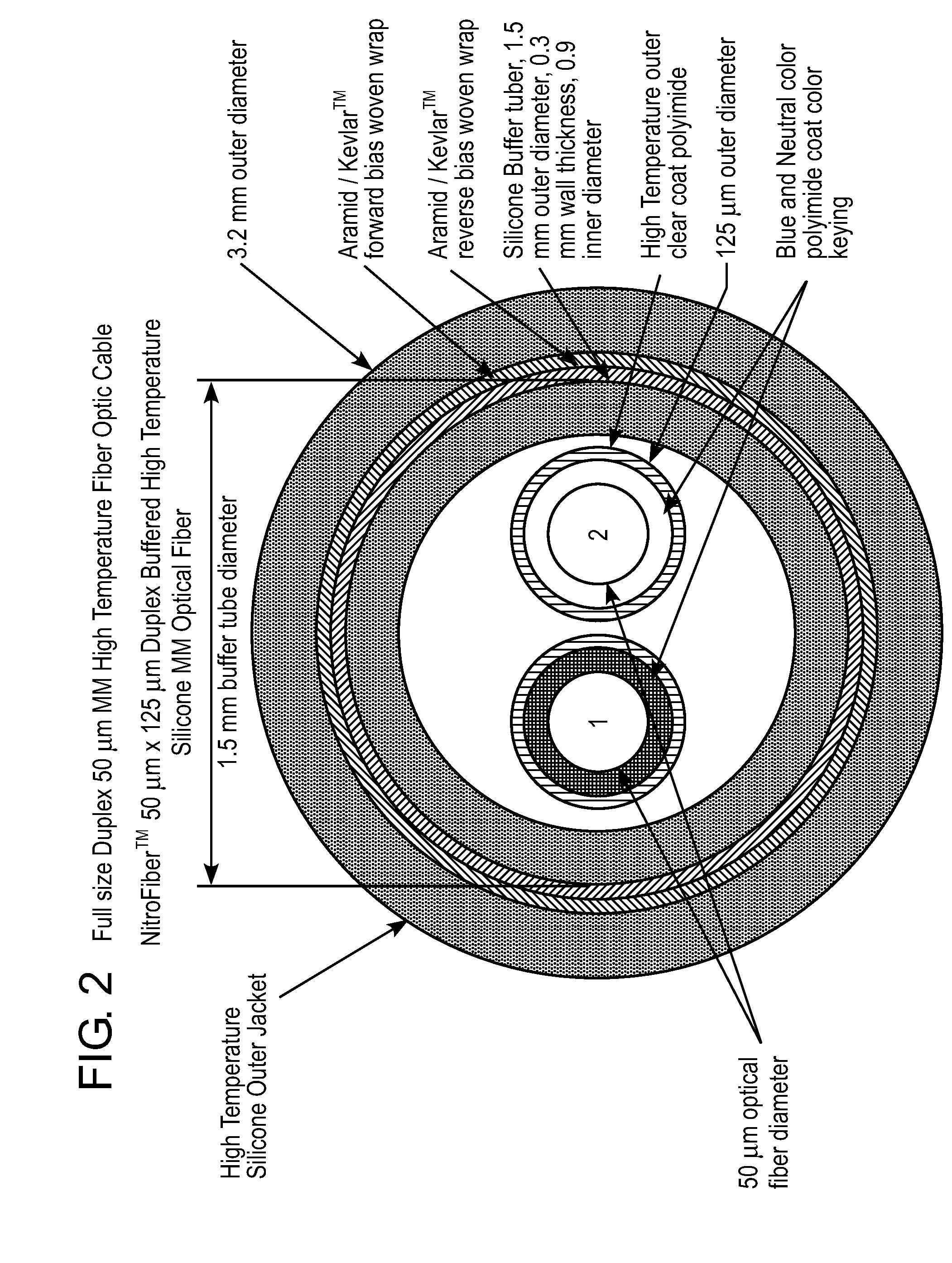

Communications Cable and Method of Making Same

InactiveUS20090226177A1Withstand mechanical forceFacilitate a simple buffer tube onlyCommunication cablesFibre mechanical structuresEngineeringProtection layer

A communications cable and method for making same wherein a communications cable is able to withstand significantly higher thermal temperatures than conventional fiber whether it be general purpose, or rated as Plenum / Riser rating, or even MIL Spec type cables. A core fiber glass material with at least an 800 Fahrenheit degree operating ability allows the communications cable to survive in high heat or stress conditions. A polyimide coating on the outside of the fiber is a high temperature material and lends to this high operating temperature capability. By containing and protecting an optical pair of these fibers or even up to 4 glass fibers within a silicone rubber 1 mm diameter buffer tube, thermal protection of the high temperature glass within is increased. A single buffer tube type product and market that as a mini solution for fiber optic requirements within equipment or we individually or group wise mechanically protect these buffer tubes. The choice and decision to apply 2 layers of opposing woven aramid / KEVLAR™ fibers now begins to apply a enhance tensile strength capability resulting in significant increase of currently available fiber optic cables. Once this mechanical protection layer has been applied a second, but thicker layer of silicone rubber is applied as an outer protection jacket either over the single paired Duplex Cable or the 24 Pair or larger cable design.

Owner:TECH MINING COMPANY

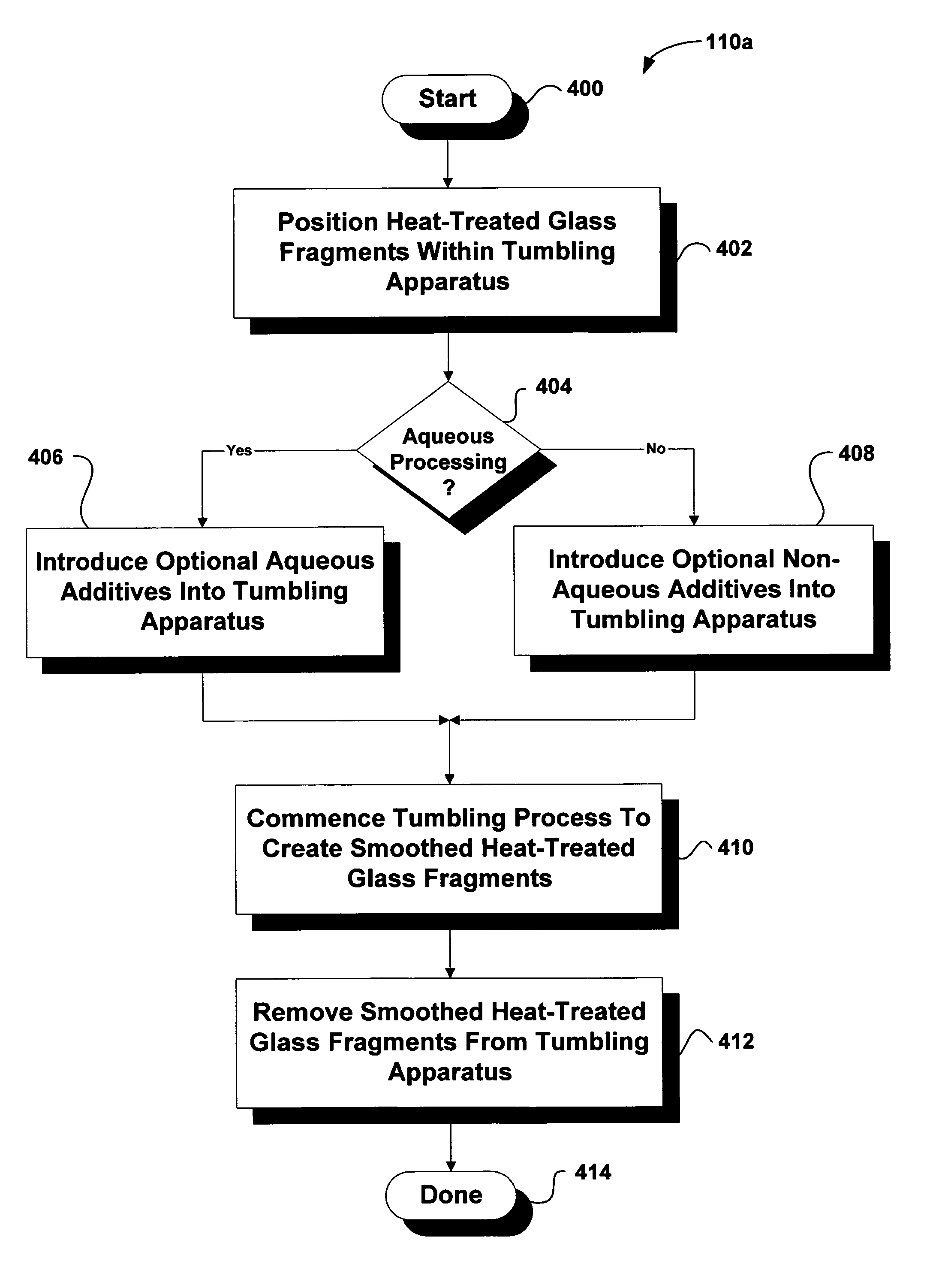

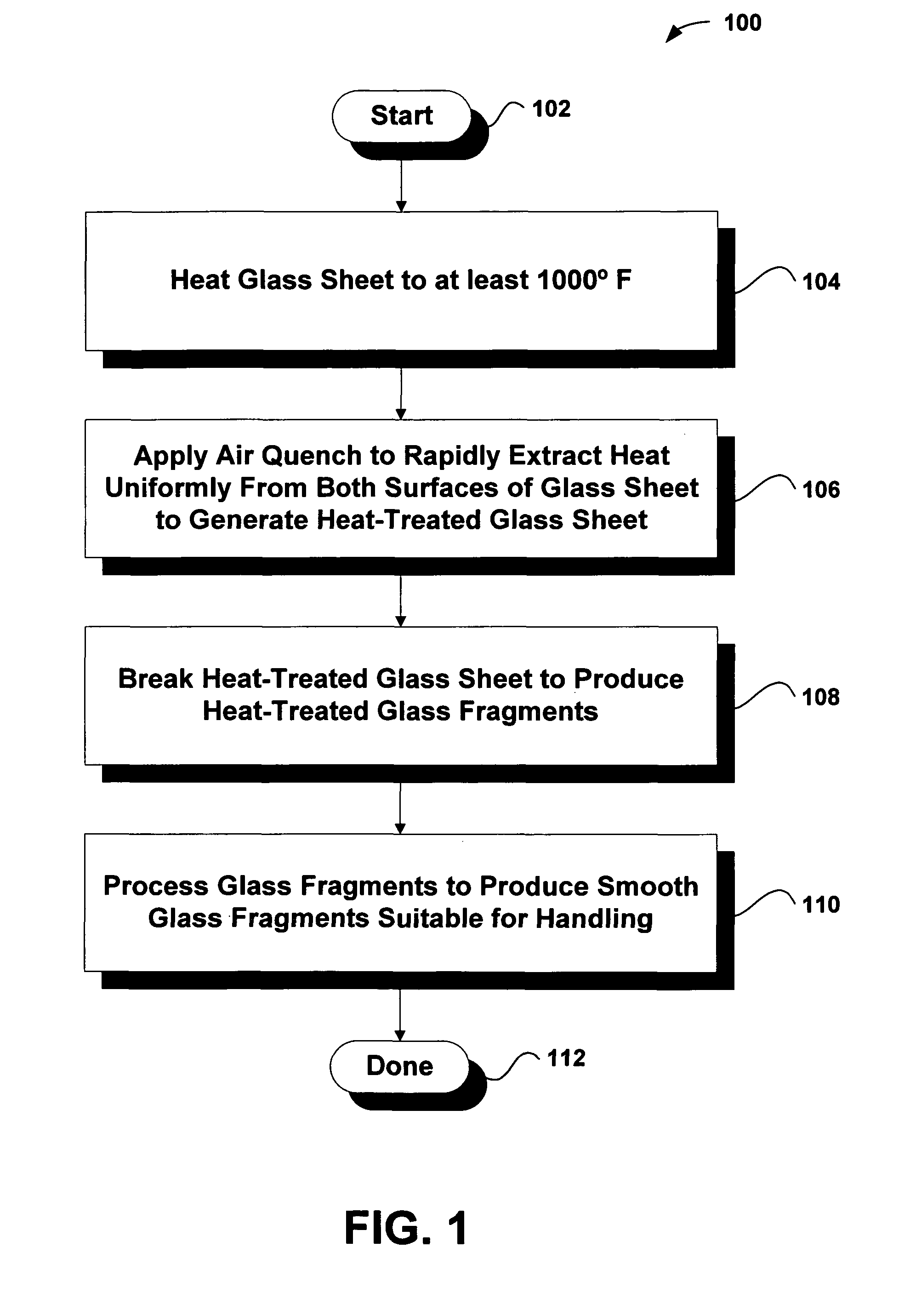

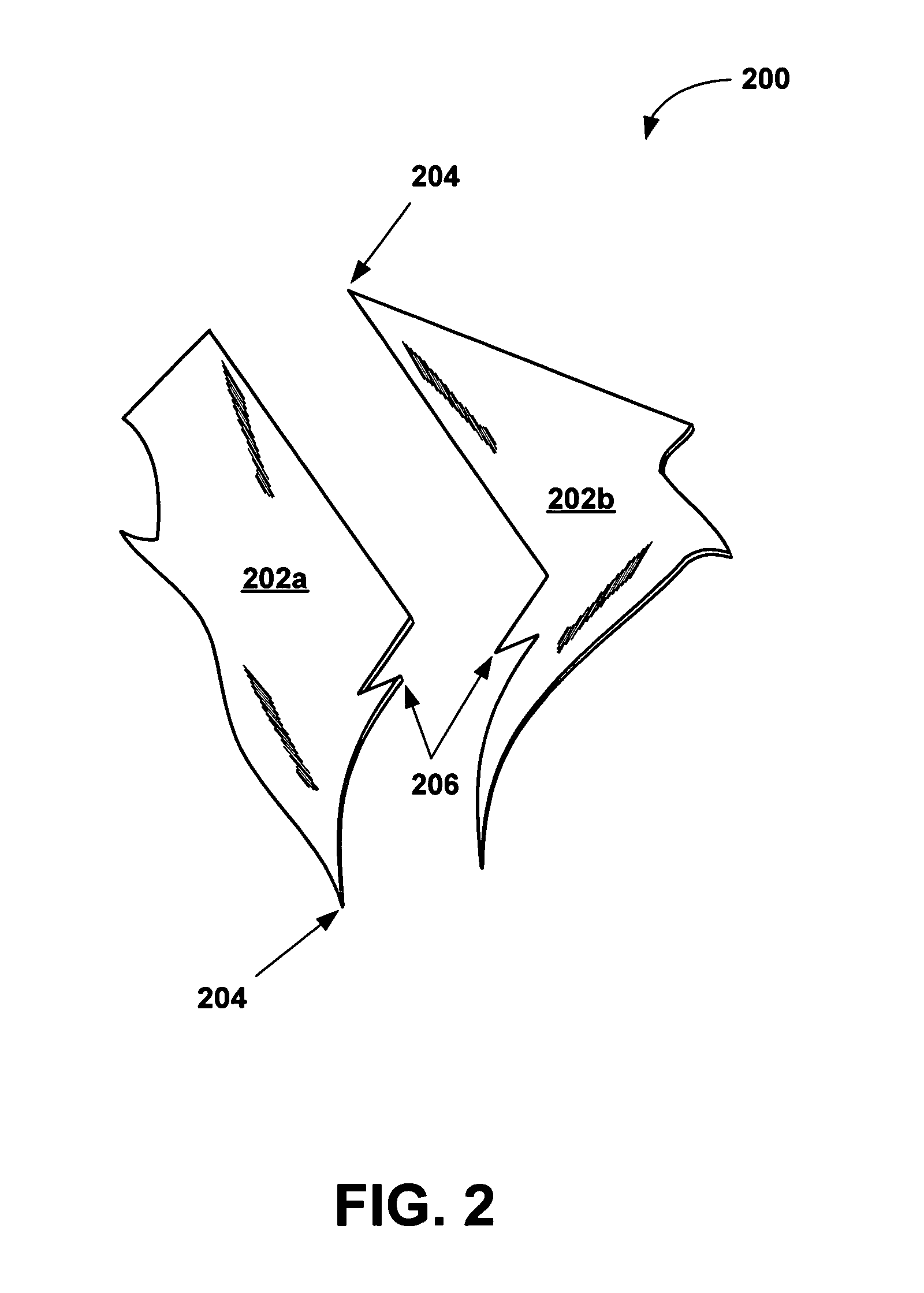

Tumbled, polished, vibrated broken tempered glass pieces

An invention is provided for creating smoothed, heat-treated glass fragments. The invention includes placing a plurality of heat-treated glass fragments into a tumbling or vibrating apparatus. Each heat-treated glass fragment is formed from glass that has been heated to a temperature of at least 1000° Fahrenheit and rapidly cooled to a temperature below 700° Fahrenheit. The plurality of glass fragments are then tumbled or vibrated for a predetermined period of time such that surfaces of the heat-treated glass fragments are smoother than prior to tumbling. The glass fragments are thereafter removed from the tumbling apparatus, resulting in smoothed, heat-treated glass fragments that are suitable for direct handling without hand protection.

Owner:MODERUSTIC

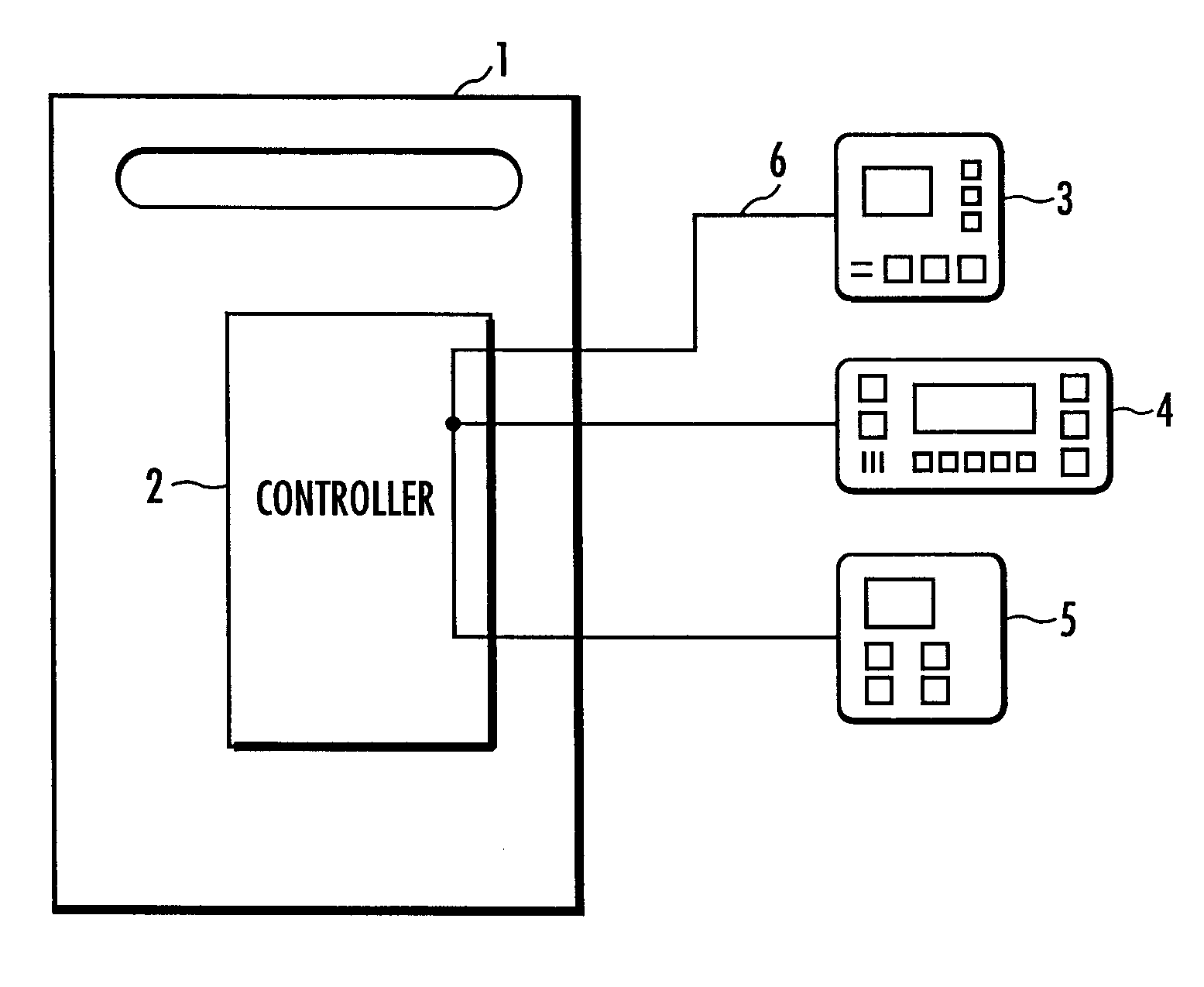

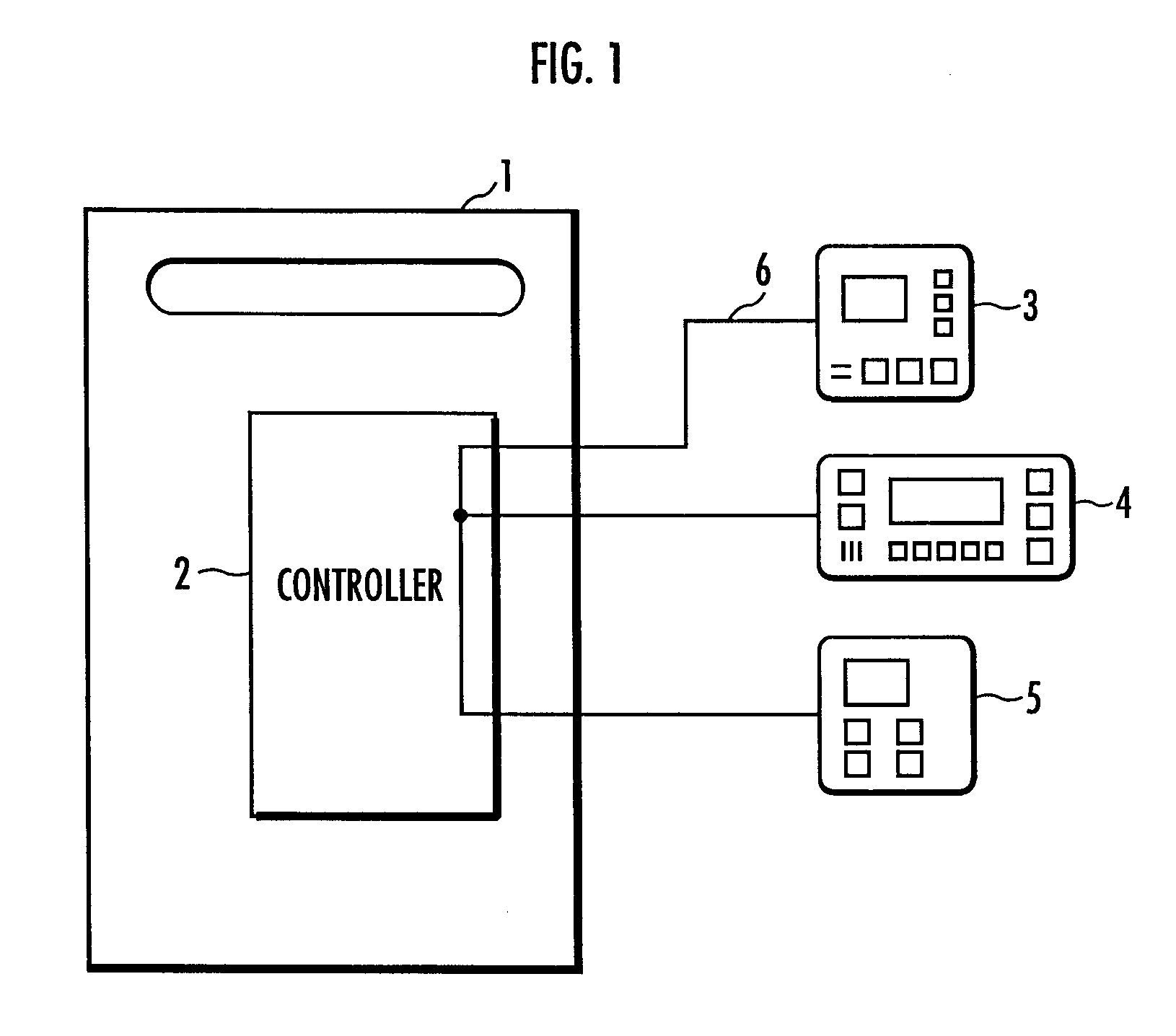

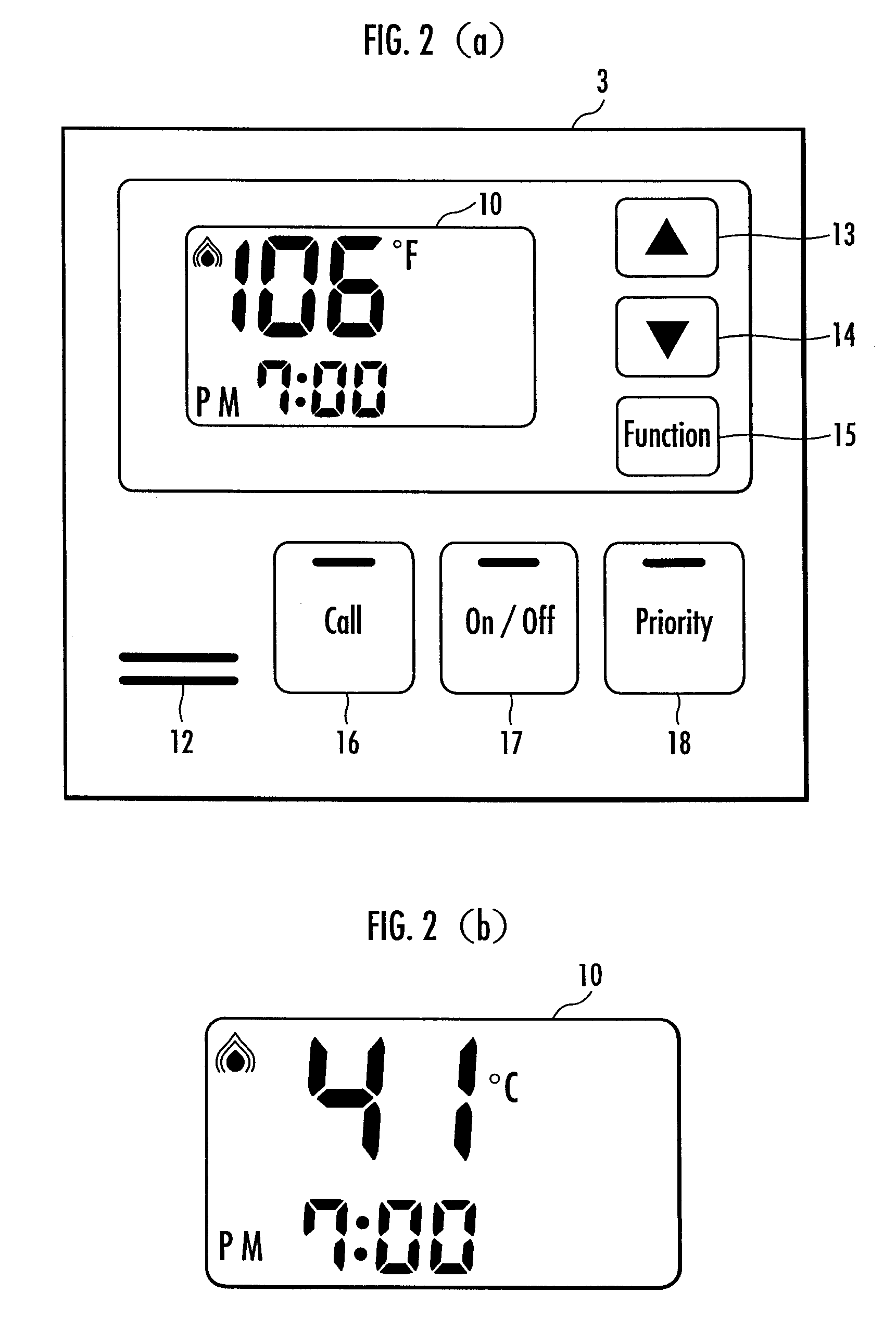

Hot-water supply system

ActiveUS20060237550A1Improve availabilityEasy to changeFluid heatersTemperature control without auxillary powerCelsius DegreeEngineering

To provide an inexpensive hot-water supply system that allows a user to readily select a desired unit for a physical quantity indicated on a display section of a remote controller. A bathroom-installed remote controller 4 is provided with a indication unit switching device that switches the units of hot-water temperature and hot-water amount represented by data transmitted from a water heater and indicated on a display section 20 between Fahrenheit / gallon (shown in FIG. 3(a)) and Celsius / liter (shown in FIG. 3(b)) depending on the presence or absence of long press of an operational switch 32 while the water heater is in a stand-by state.

Owner:RINNAI CORP

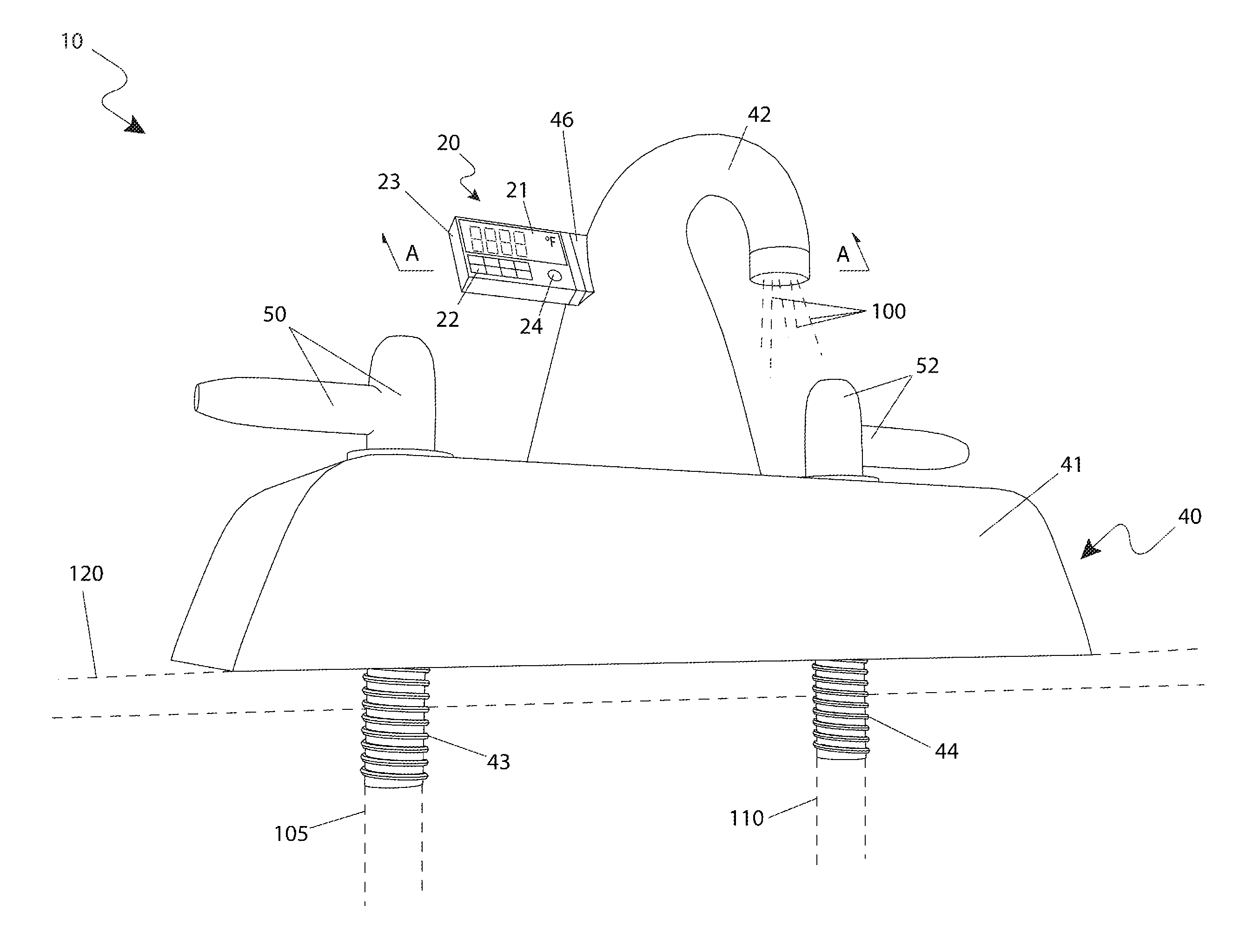

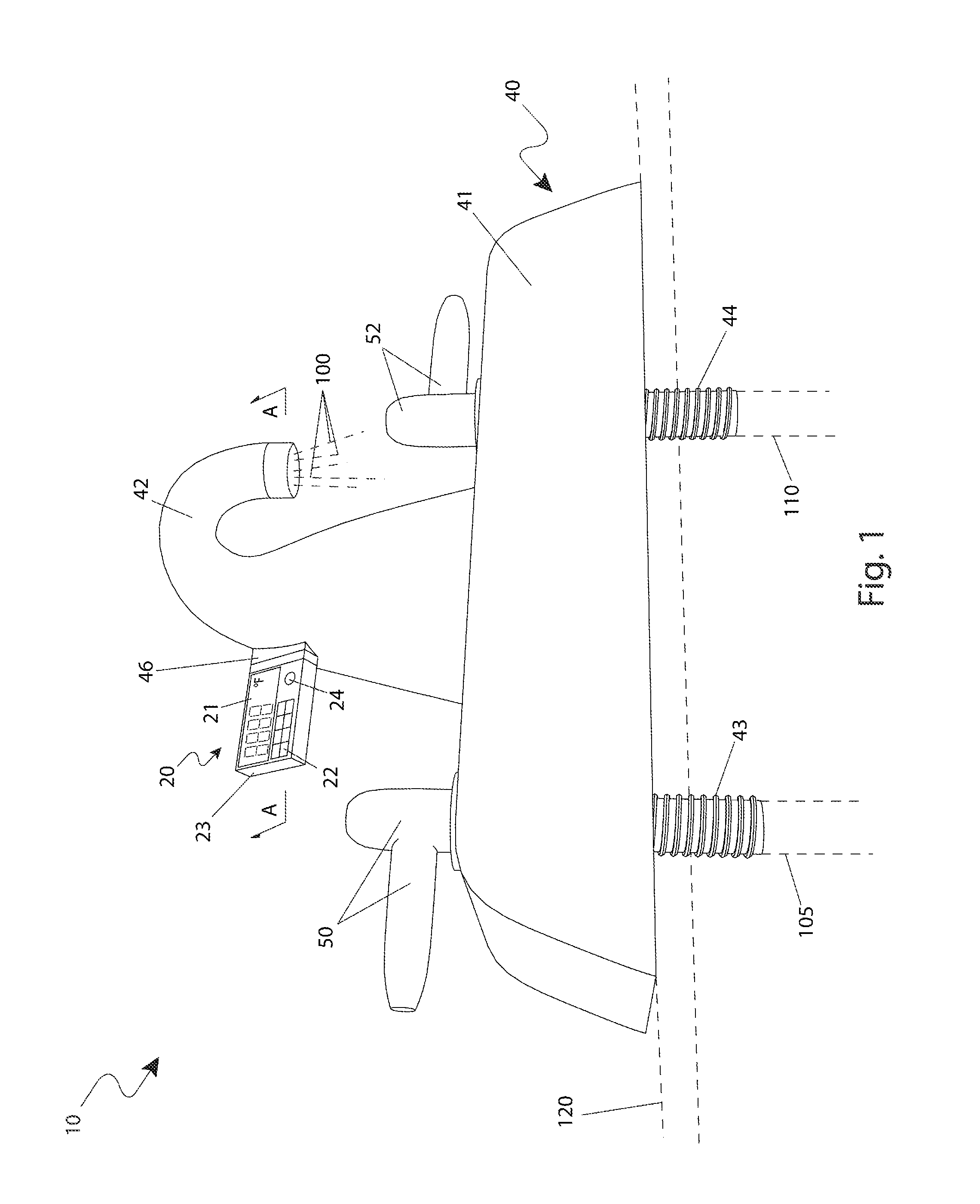

Water faucet temperature gauge and display

InactiveUS8316883B1Easy to viewSelectively removableThermometer detailsPlug valvesWater useCelsius Degree

A water faucet providing a digital temperature readout indicating the temperature of the water exiting the faucet is herein disclosed. The faucet provides a switch to change the display between Fahrenheit and Celsius and is powered by a small integral solar cell and an internal battery for periods of low ambient light. The display and corresponding circuitry is mounted inside of a waterproof enclosure which is removably mounted to the faucet spout by locking fasteners. The display is removable and allows for replacement or maintenance should it malfunction or break. During use, an internal thermocouple senses a change in temperature to activate the apparatus, thereby conserving energy. Such features are ideal for measuring the temperature of water used to wash hands or dishes to ensure compliance with health department requirements.

Owner:WATSON CRAIG

Provisional bone plate

A provisional bone plate formed of an implantable plastic and having a length corresponding to the longest bone plate in a particular family of bone plates. The provisional bone plate includes a head contoured to match the head of a particular bone as well as a shaft for placement adjacent the bone shaft. The provisional bone plate includes a plurality of circumferential notches surrounding the elongate body or shaft of the bone plate. The circumferential notches are substantially transverse to a longitudinal axis of the bone plate and define frangible portions of the bone plate which can be removed from the distal end thereof to alter the length of the provisional periarticular bone plate to correspond to the length of the various bone plates in a family of bone plates. The provisional bone plate is constructed of a biologically suitable plastic, is radiographic, and melts at a temperature less than 200° Fahrenheit.

Owner:ZIMMER INC

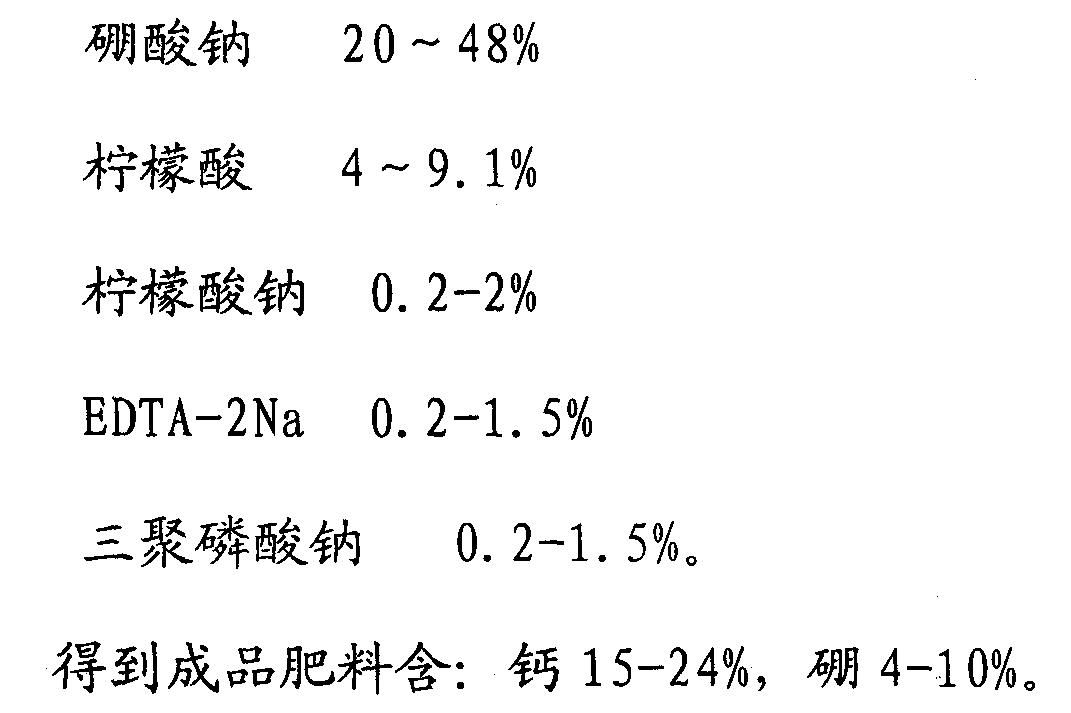

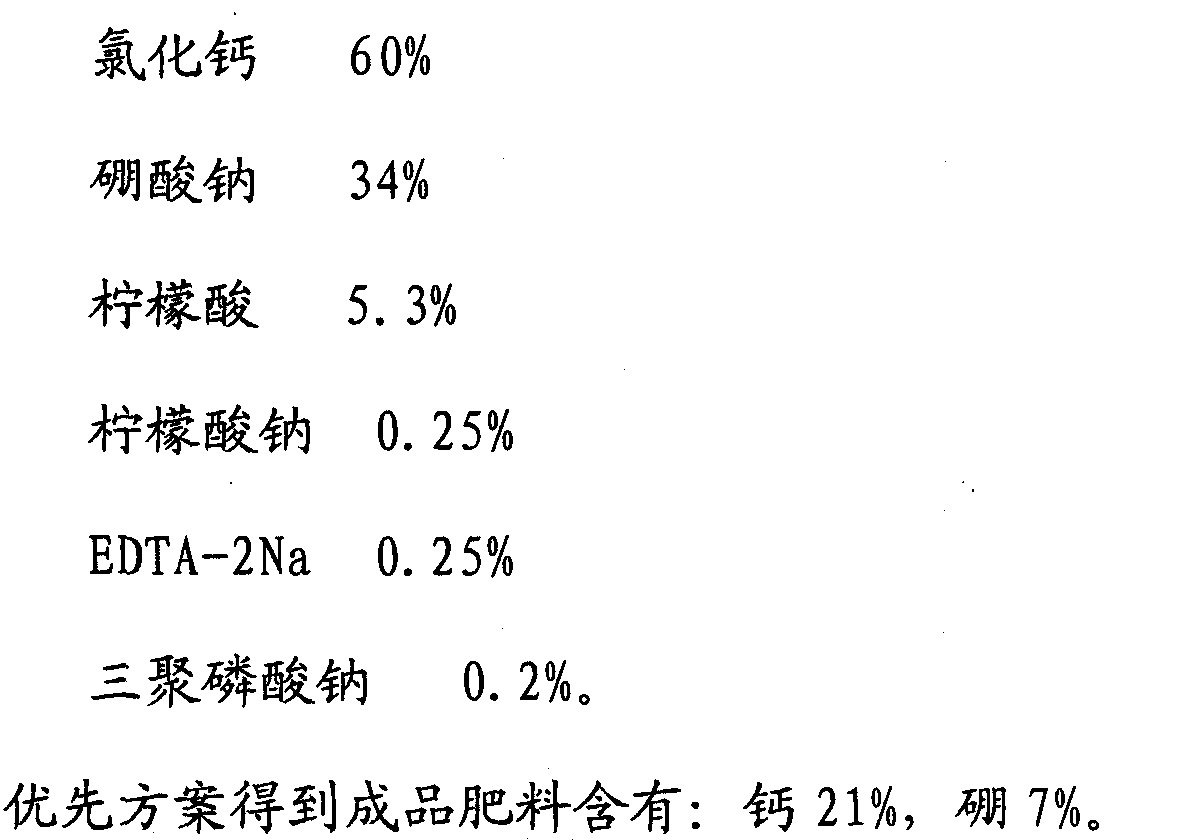

Calcium-boron compound fertilizer and preparation method thereof

ActiveCN102180723AIncrease demandMeet a small number of needsFertilizer mixturesCalcium EDTANutrient

The invention discloses a calcium-boron compound fertilizer. The raw materials of the calcium-boron compound fertilizer comprise the following components in percentage by weight: 43-70% of calcium chloride, 20-48% of sodium borate, 4-9.1% of citric acid, 0.2-2% of sodium citrate, 0.2-1.5% of EDTA-2Na (ethylene diamine tetraacetic acid-2Na) and 0.2-1.5% of sodium tripolyphosphate. The finished compound fertilizer product comprises the following components in percentage by weight: 15-24% of calcium and 4-10% of boron. The invention also provides a preparation method of the calcium-boron compound fertilizer, which comprises the following steps: (1) respectively weighing the calcium chloride, sodium borate, citric acid, sodium citrate, EDTA-2Na and sodium tripolyphosphate; (2) grinding every raw material into granules by using a grinder, and passing the granules through a 50-mesh screen for later use; (3) after grinding, respectively adding the calcium chloride, EDTA-2Na, sodium tripolyphosphate, and part of citric acid and sodium citrate into a V-shaped mixing machine with a jacket, and stirring for 20 minutes, wherein in the stirring process, the humidity is controlled at 1-2%, and the temperature is controlled at 120-150 Fahrenheit degrees; (4) adding the sodium borate, and stirring for 20 minutes while continuing keeping the temperature and humidity; and (5) regulating the pH value to 3-6 with the citric acid and sodium citrate. Calcium and boron in the fertilizer are scientifically proportioned to obtain the fertilizer with rich nutrients, and the fertilizer can be used for producing excellent fruits and crops.

Owner:凡美(广州)农业科技有限公司

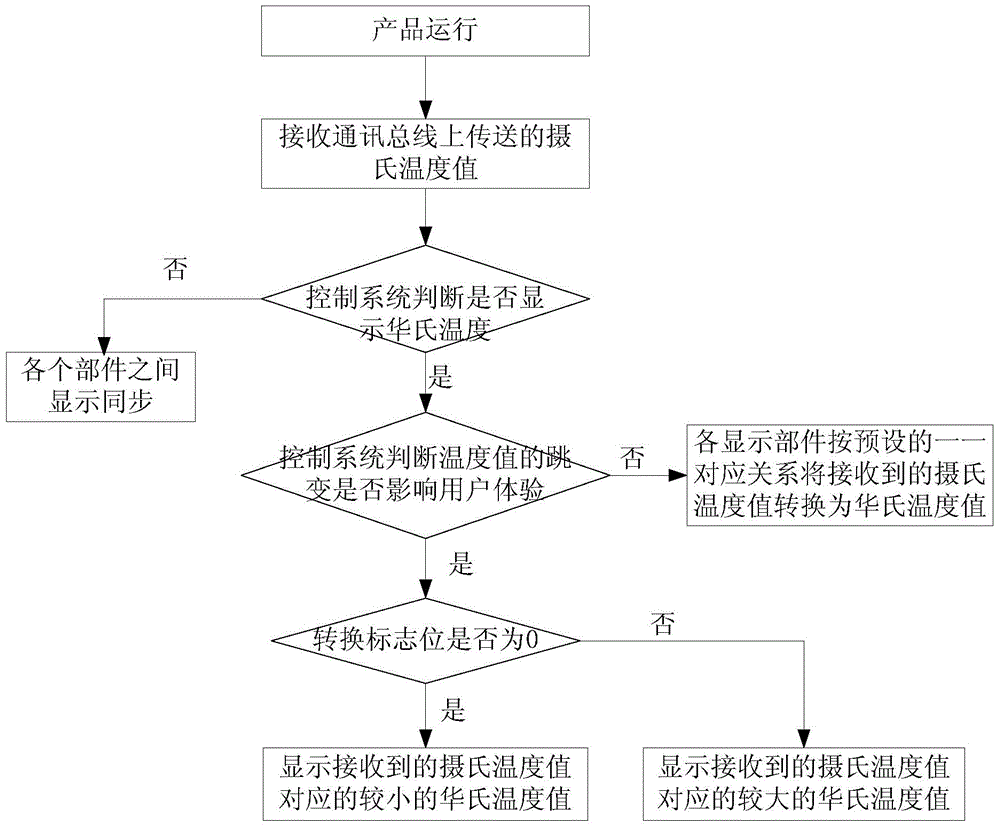

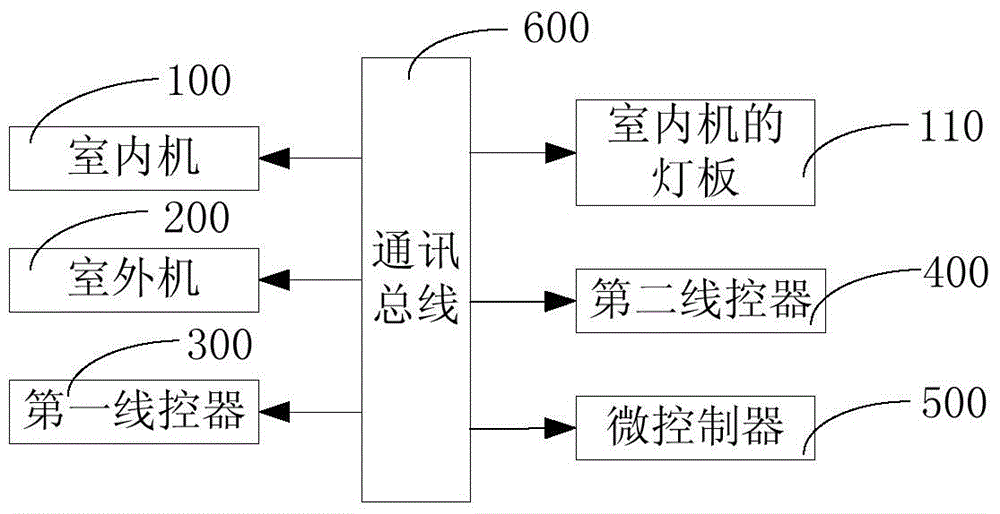

Method for synchronously displaying Fahrenheit temperature and air conditioning system

ActiveCN104949279AEasy to expandSolve the problem that the display is out of syncMechanical apparatusSpace heating and ventilation safety systemsAir conditioningCommunications protocol

The invention provides a method for synchronously displaying Fahrenheit temperature. The method comprises the following steps that all display parts receive a centigrade temperature value transmitted by a communication bus; Fahrenheit temperature values corresponding to the received centigrade temperature value are displayed according to the states of a transformation flag bit set in the communication protocol of the communication bus; if the state of the transformation flag bit in the communication protocol is zero, the smaller Fahrenheit temperature value corresponding to the centigrade temperature value is displayed; if the state of the transformation flag bit in the communication protocol is one, the larger Fahrenheit temperature value corresponding to the centigrade temperature value is displayed. The invention further provides an air conditioning system. According to the method for synchronously displaying the Fahrenheit temperature and the air conditioning system, the problem that display is unsynchronized caused by the phenomenon that the same centigrade temperature integral value corresponds to two Fahrenheit temperature integral values is solved; meanwhile, bytes needed by the transformation flag bit which is additionally set in the communication protocol are less, and therefore the expansion of the communication protocol can be conveniently achieved.

Owner:GREE ELECTRIC APPLIANCES INC

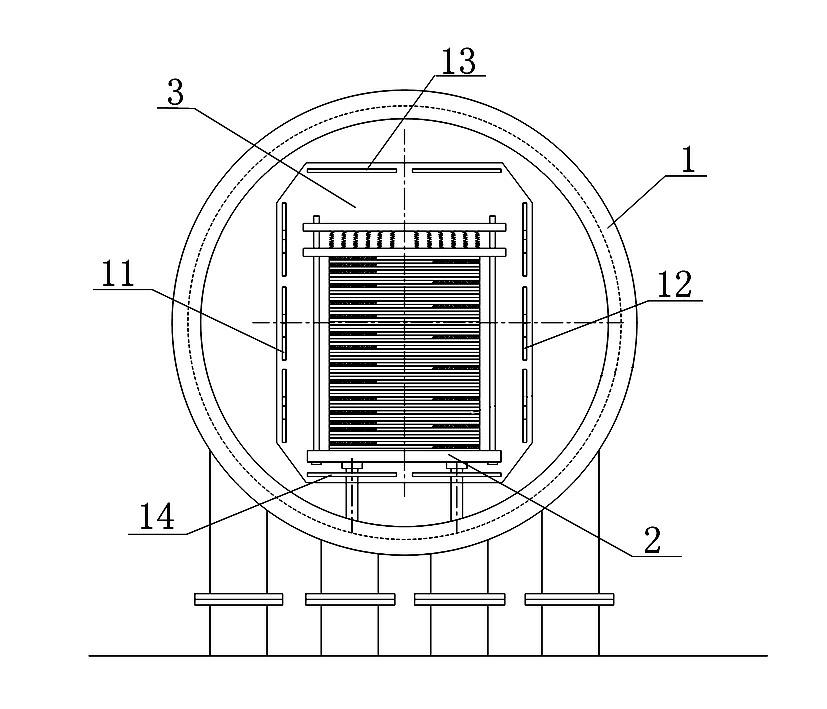

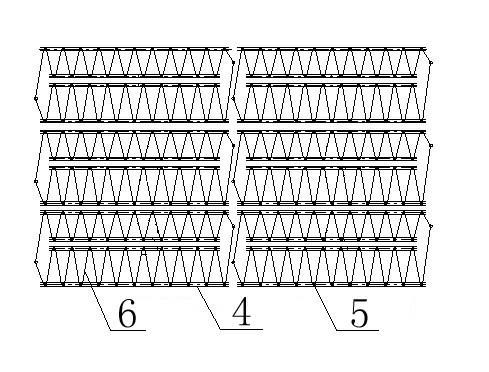

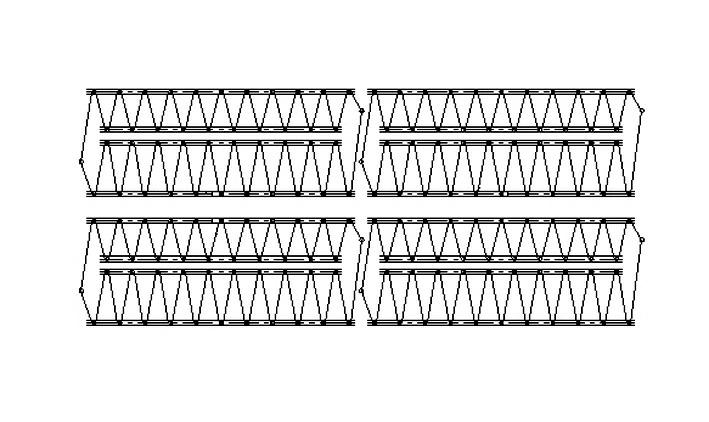

Braze welding heating furnace of aluminum alloy plate-fin heat exchanger and heating partitioning and control methods

InactiveCN102615375ARealize automatic brazingEasy to operateHeating appliancesHeating furnacePlate fin heat exchanger

The invention discloses a braze welding heating furnace of an aluminum alloy plate-fin heat exchanger and heating partitioning and control methods. The braze welding heating furnace comprises a horizontal furnace body, wherein a support for placing a workpiece to be brazed is arranged in the furnace body, and a heating device is also arranged in the furnace body and comprises at least four heating areas which are arranged around the position of the workpiece to be brazed in the furnace body. The heating partitioning method comprises the following steps of: partitioning the heating areas on left and right sides of a heating space into upper subareas, middle subareas, lower subareas and eight loops for control, wherein totally 48 heaters are arranged on two side surfaces; and partitioning the heating areas on the top and at the bottom into eight loops according to an eight-loop partitioning mode for control, wherein in one subarea, totally 16 heaters are arranged on the top and at the bottom; and the heating control method comprises the following steps of: dividing the braze welding into three major stages, and subdividing the major stages into thirteen small stages, wherein the first stage belongs to baking and is started from normal temperature until the central temperature of the workpiece is 650 Fahrenheit degrees, the second stage is performed until the central temperature of the workpiece is 1,000 Fahrenheit degrees, and the third stage is performed until the central temperature of the workpiece meets a technological requirement. The braze welding heating furnace has the characteristics of energy saving, high performance and capability of realizing automatic braze welding of a large-volume plate-fin heat exchanger, and has excellent control performance.

Owner:HANGZHOU HANGYANG

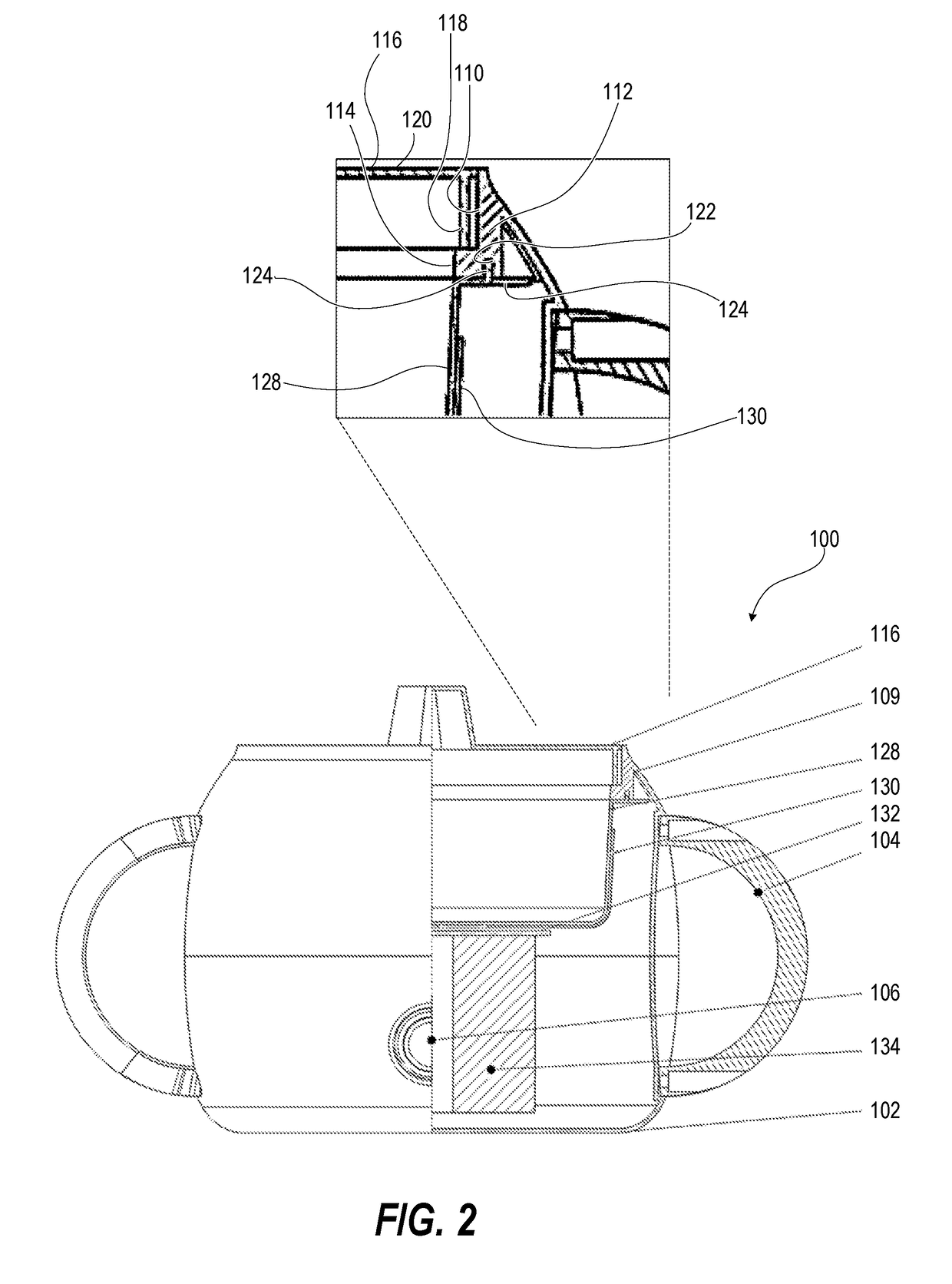

Convection combustion oven

ActiveUS20110111357A1Reduce heat dissipationReduce air volumeDrying gas arrangementsPretreated surfacesCombustionConvection

Owner:DURR SYST INC

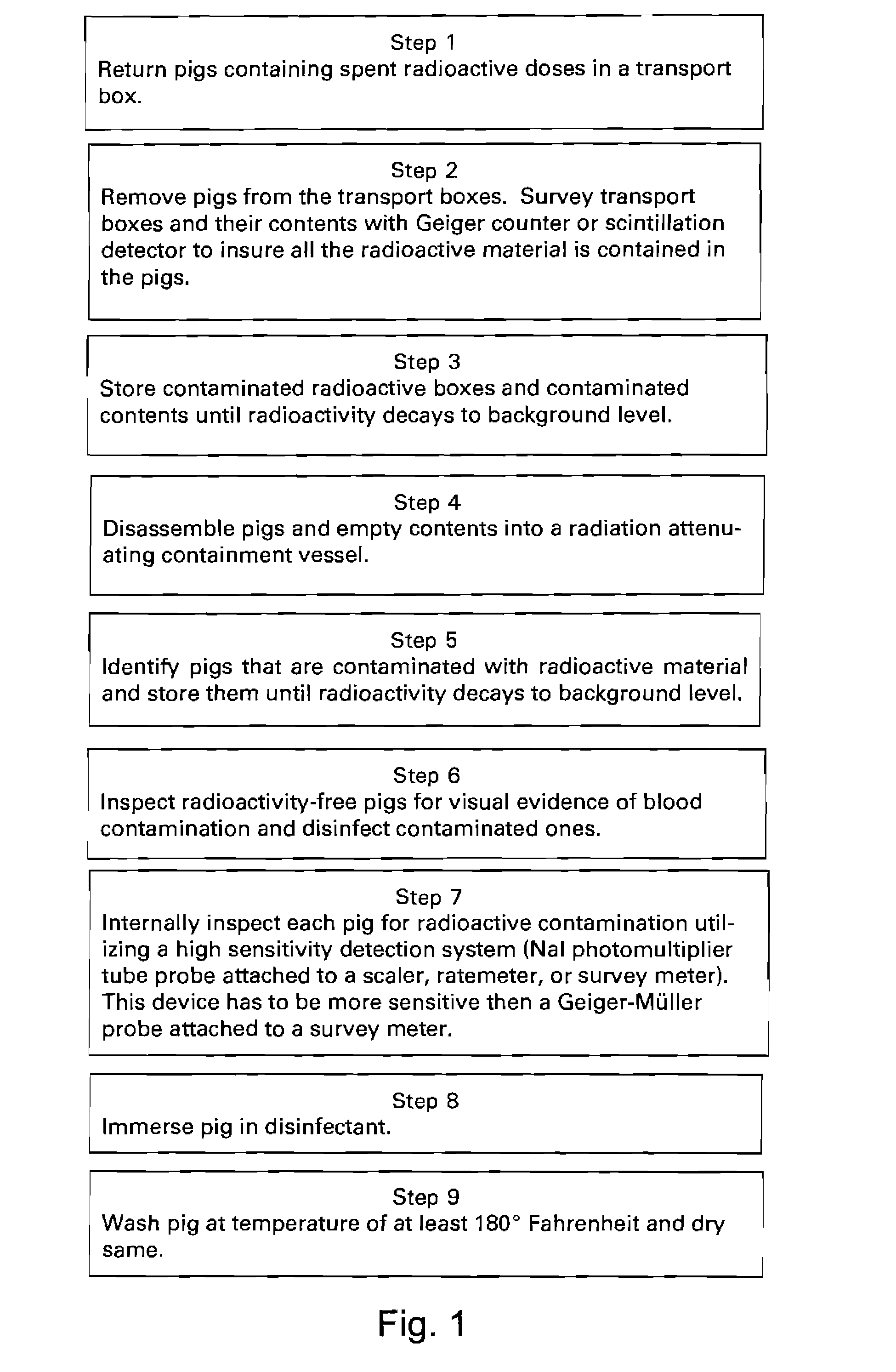

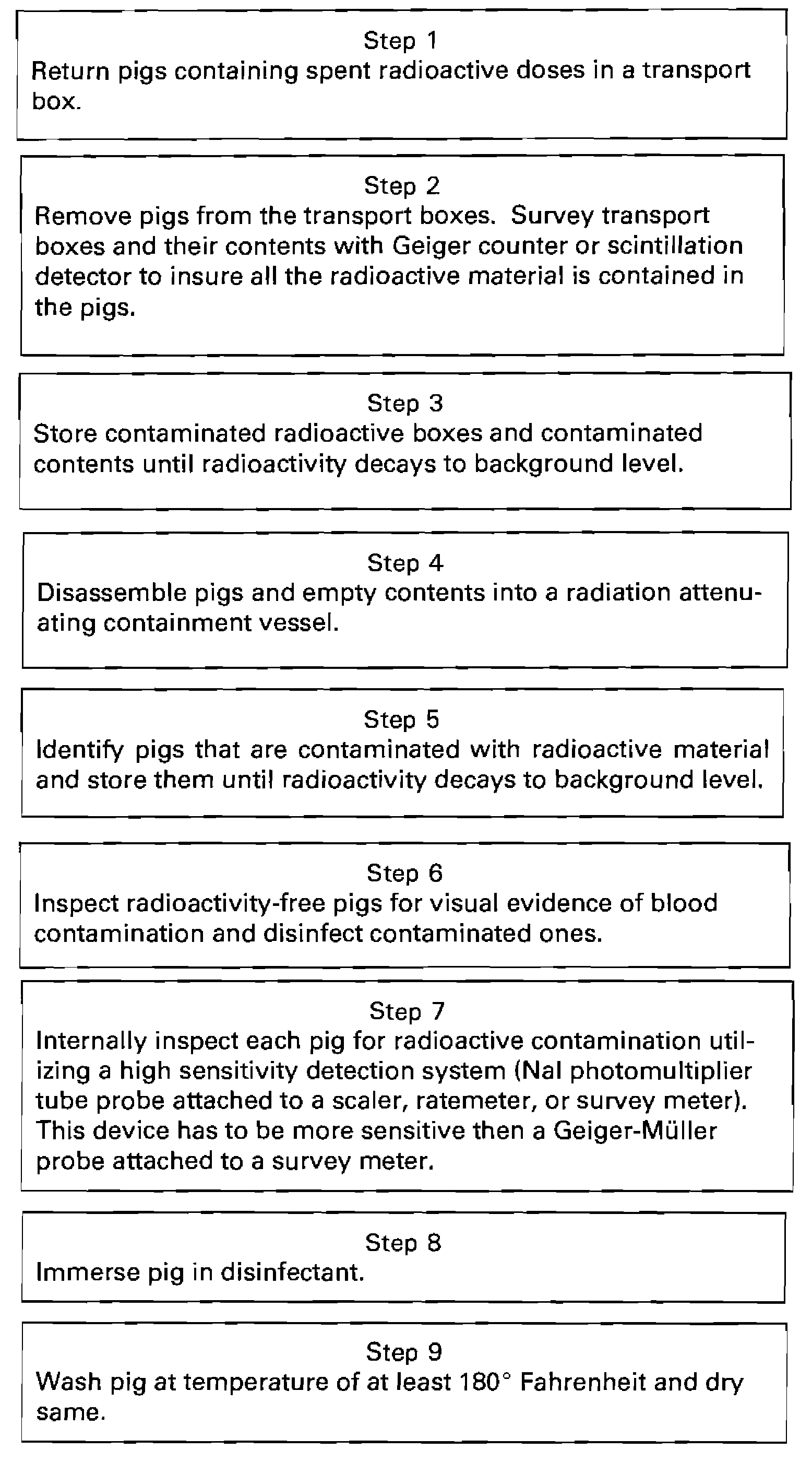

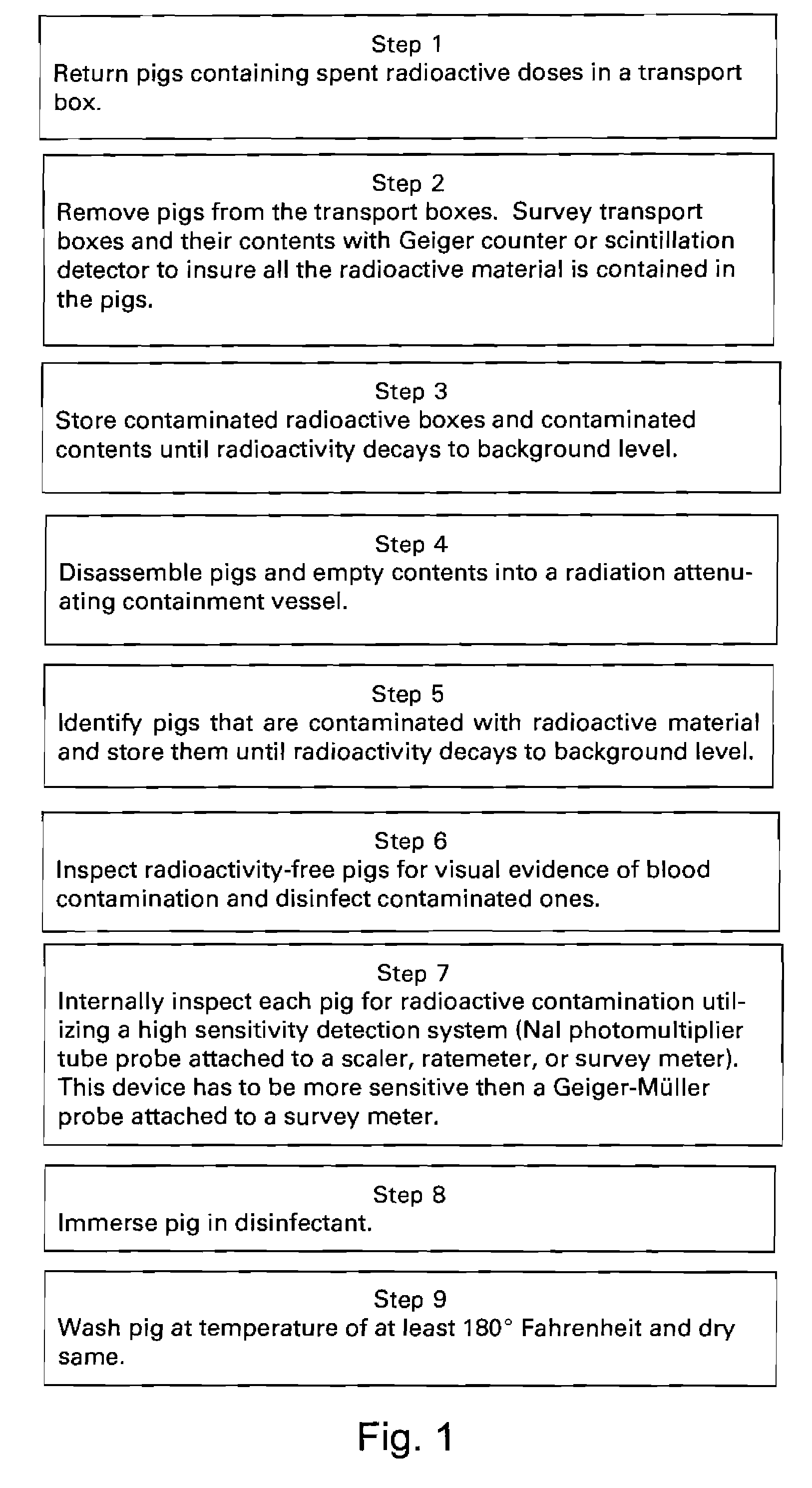

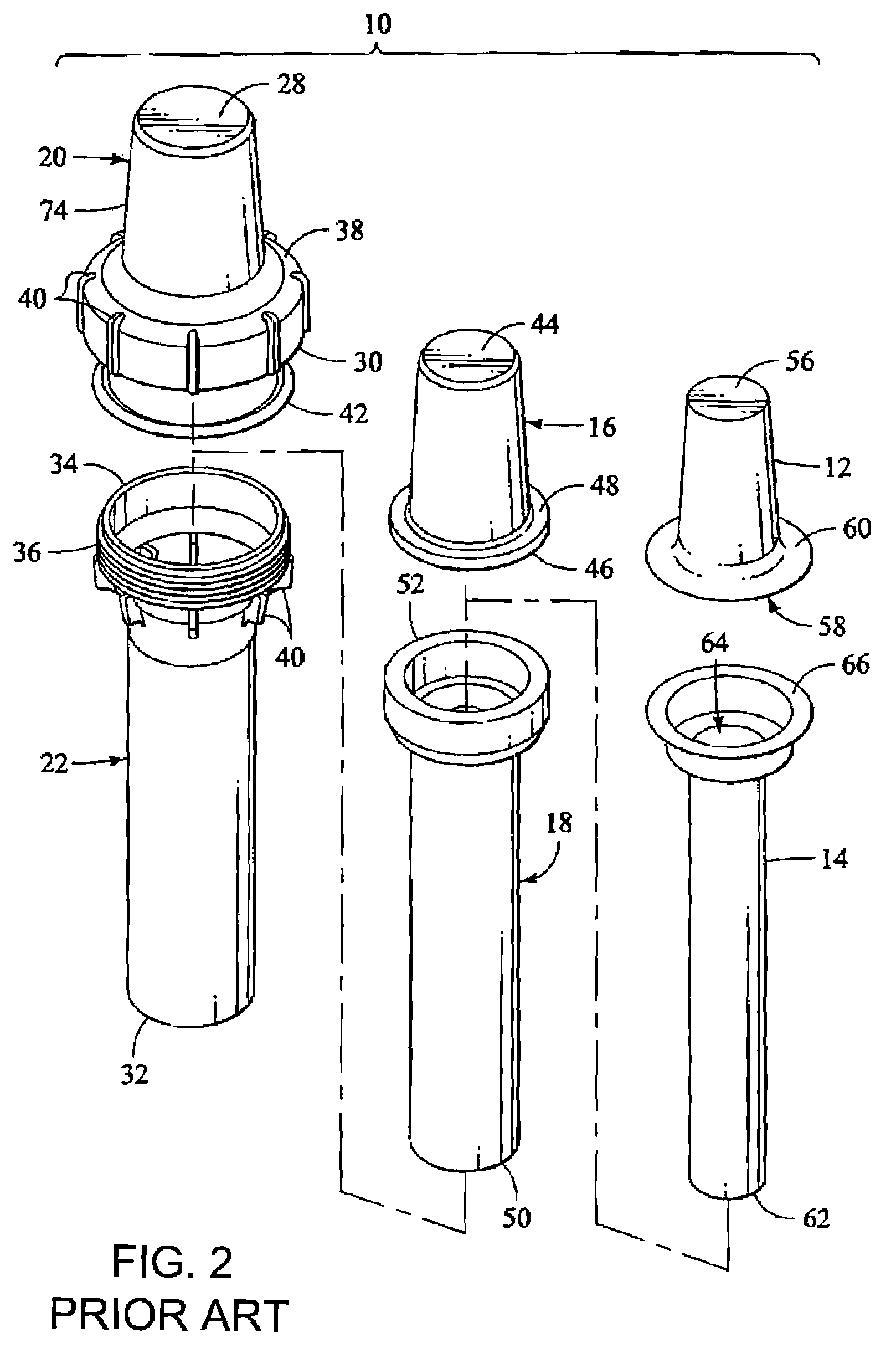

Cleaning process for radiopharmaceutical reusable pigs

ActiveUS20100084585A1Remove pollutantsIntravenous devicesPortable shielded containersRadioactive drugDisinfectant

A process for cleaning containers (pigs) in which radioactive drugs are shipped to health care providers, after than are returned to a pharmacy and may contain residual radioactive material, blood, microorganisms and other contaminants. Those pigs that are contaminated with radioactive material are removed from the cleaning process until they have decayed to the background radiation level. The upper and lower portions of each blood contaminated pig is disinfected. Each pig is washed at a temperature of at least 180° Fahrenheit for a least one minute to kill bacteria and viruses. The combination of a disinfectant and high washing temperature water provides an optimum level of sterilization.

Owner:NUCLEAR DIAGNOSTIC SERVICES INC

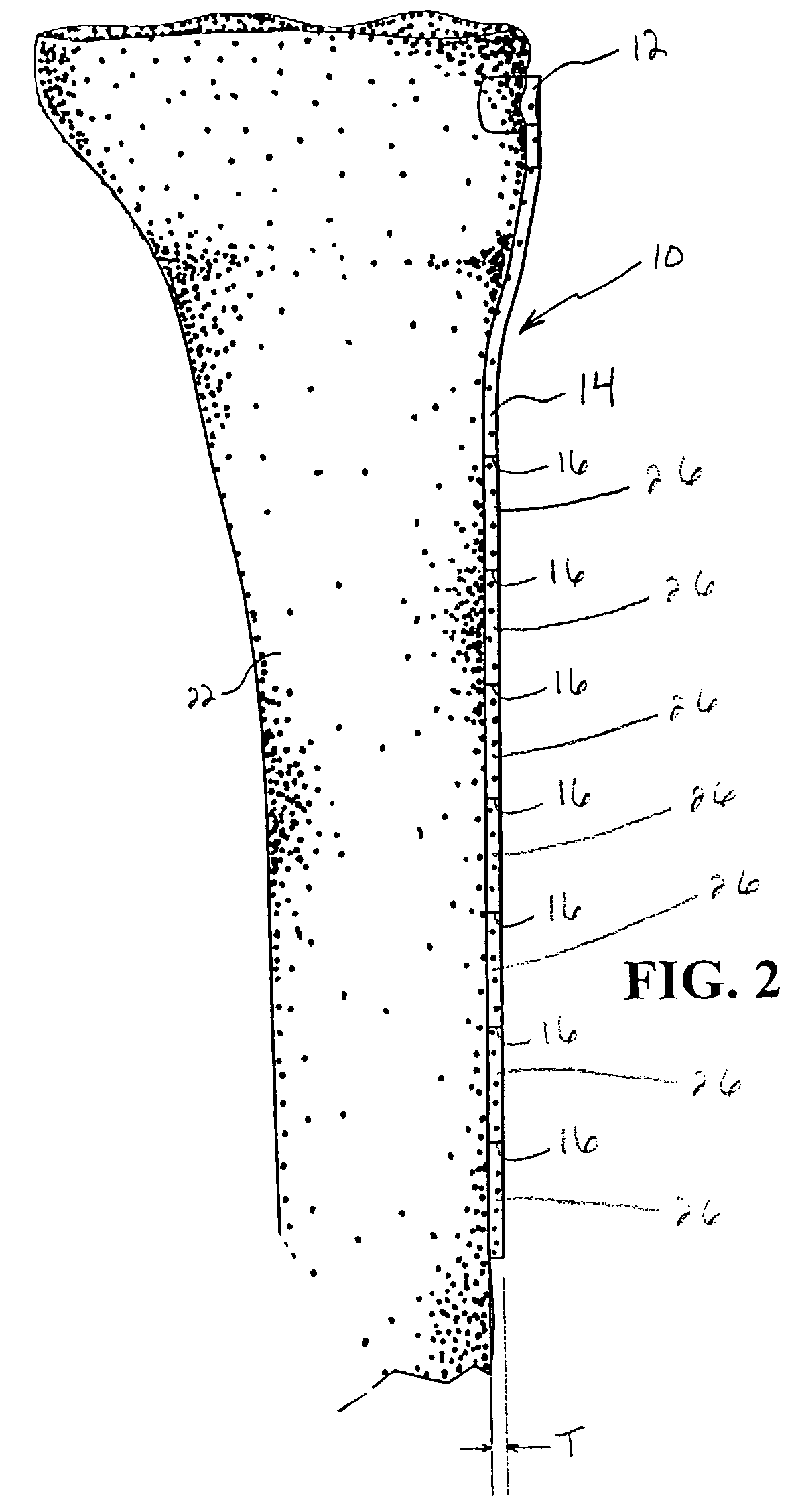

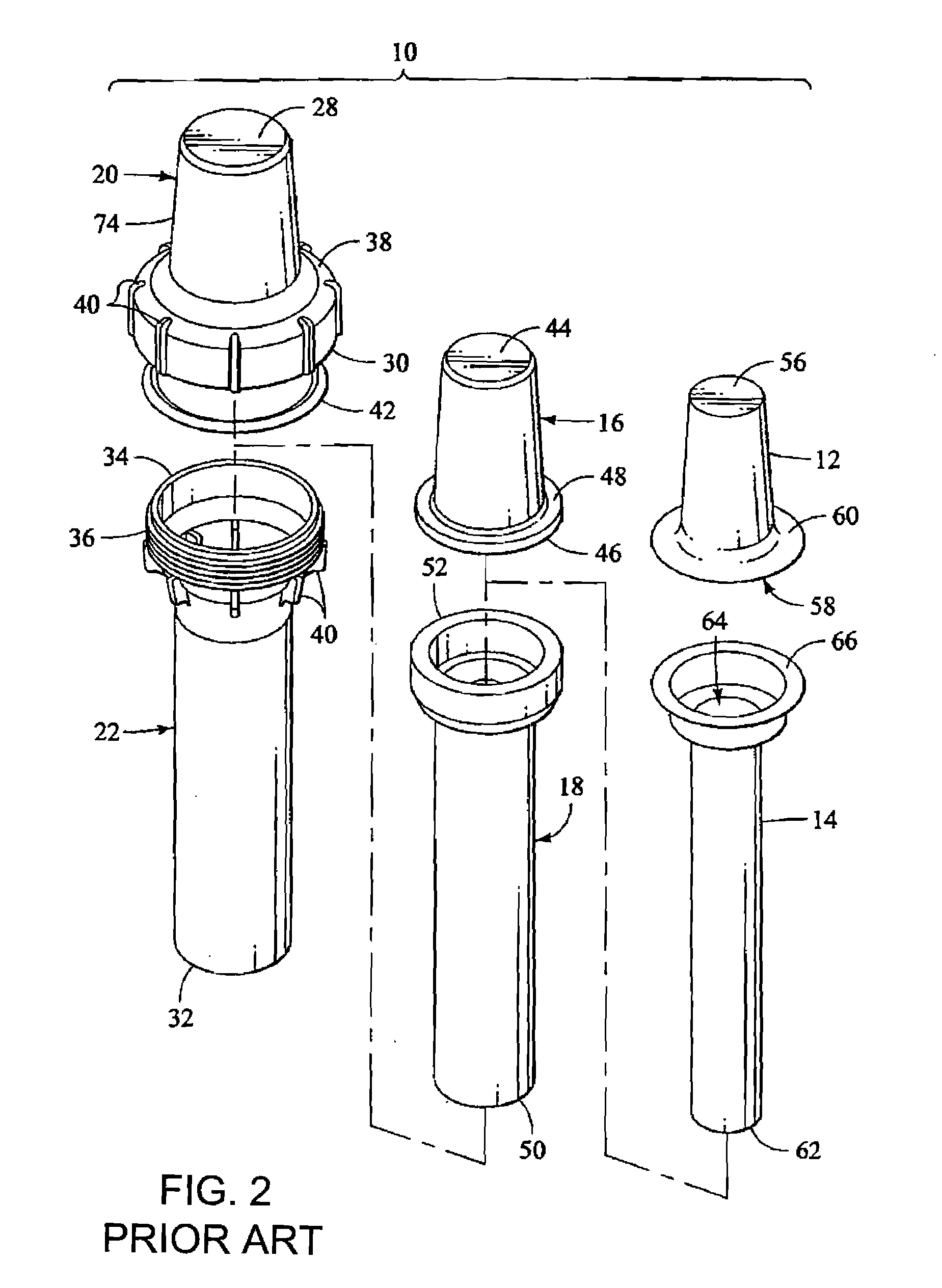

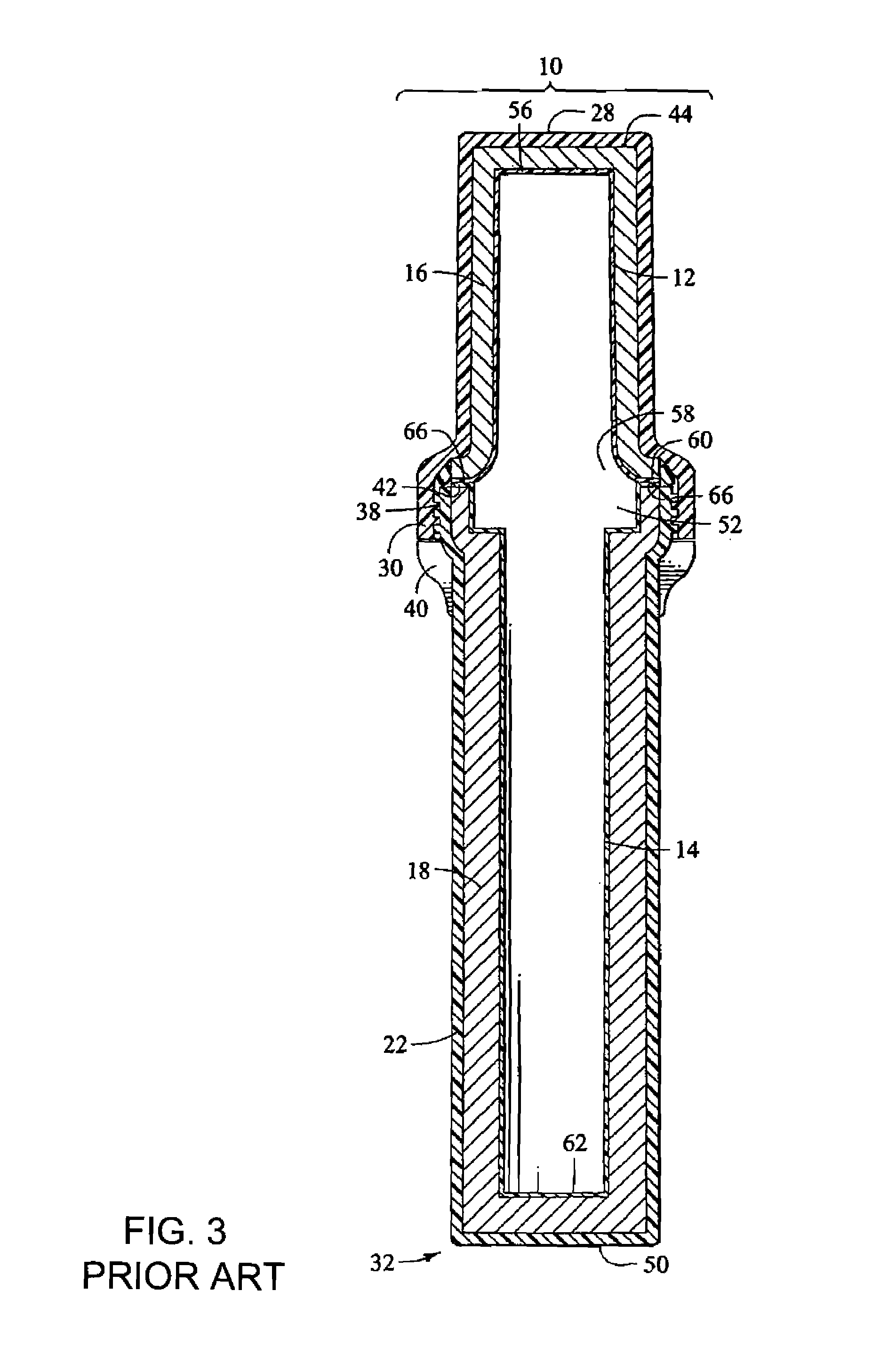

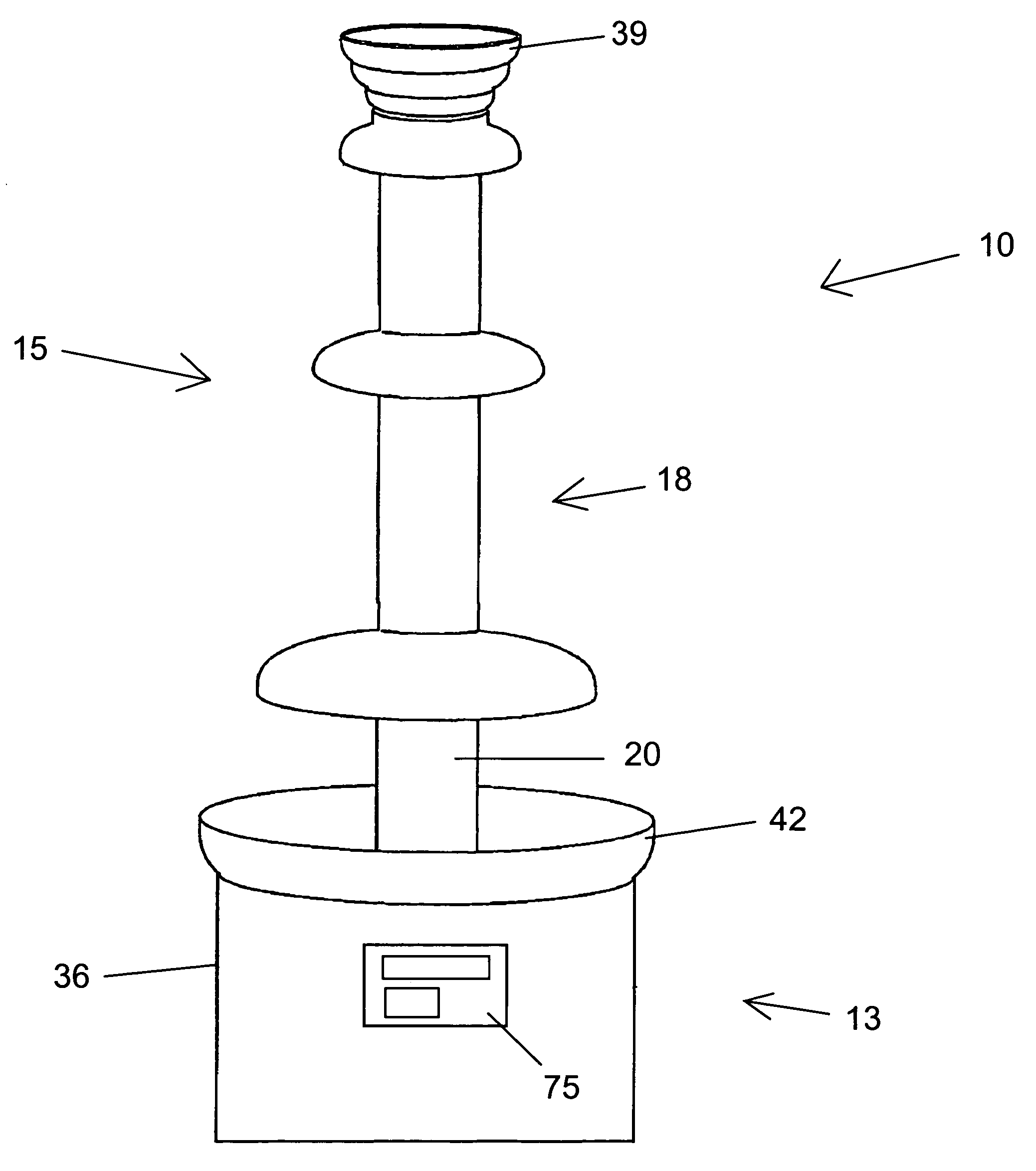

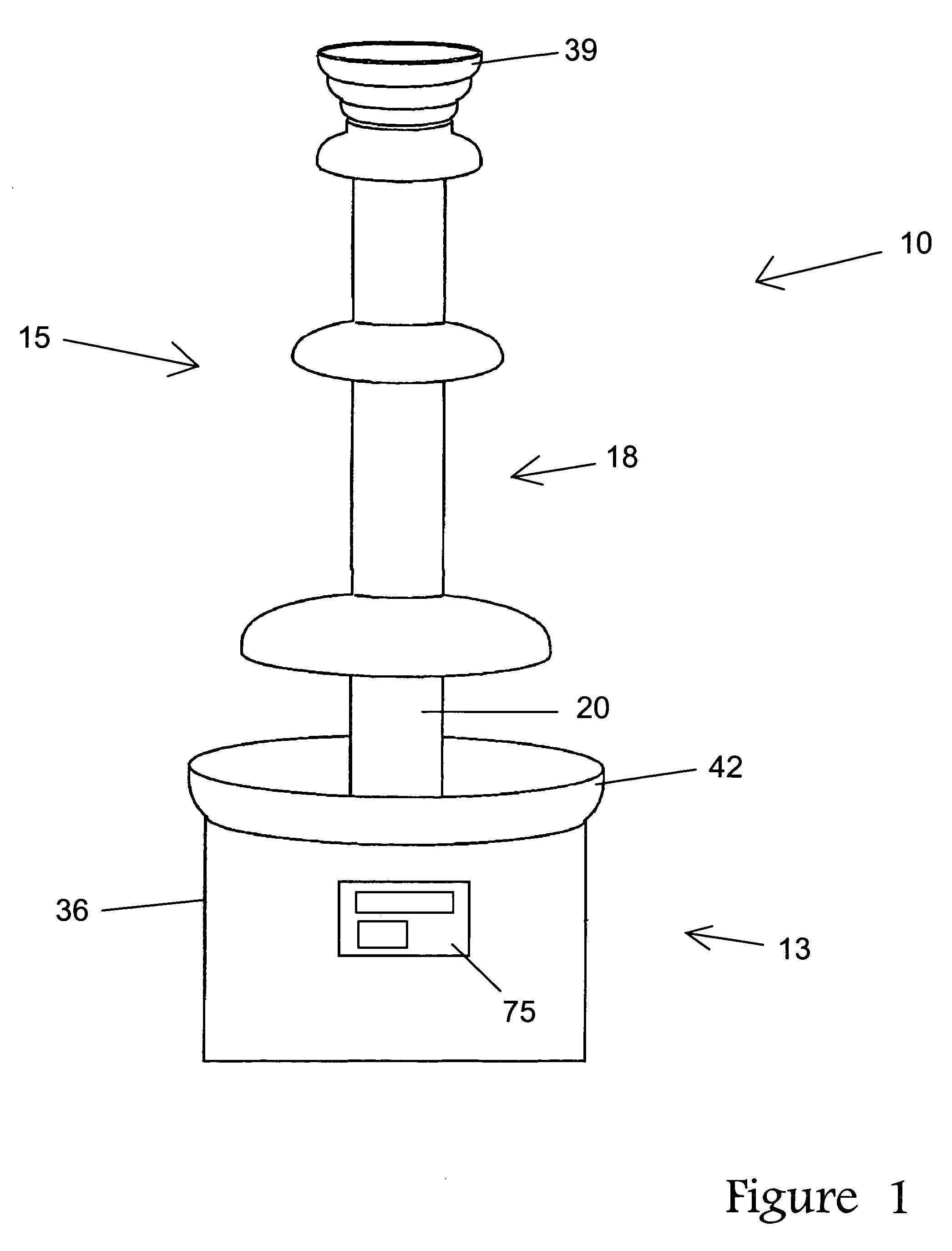

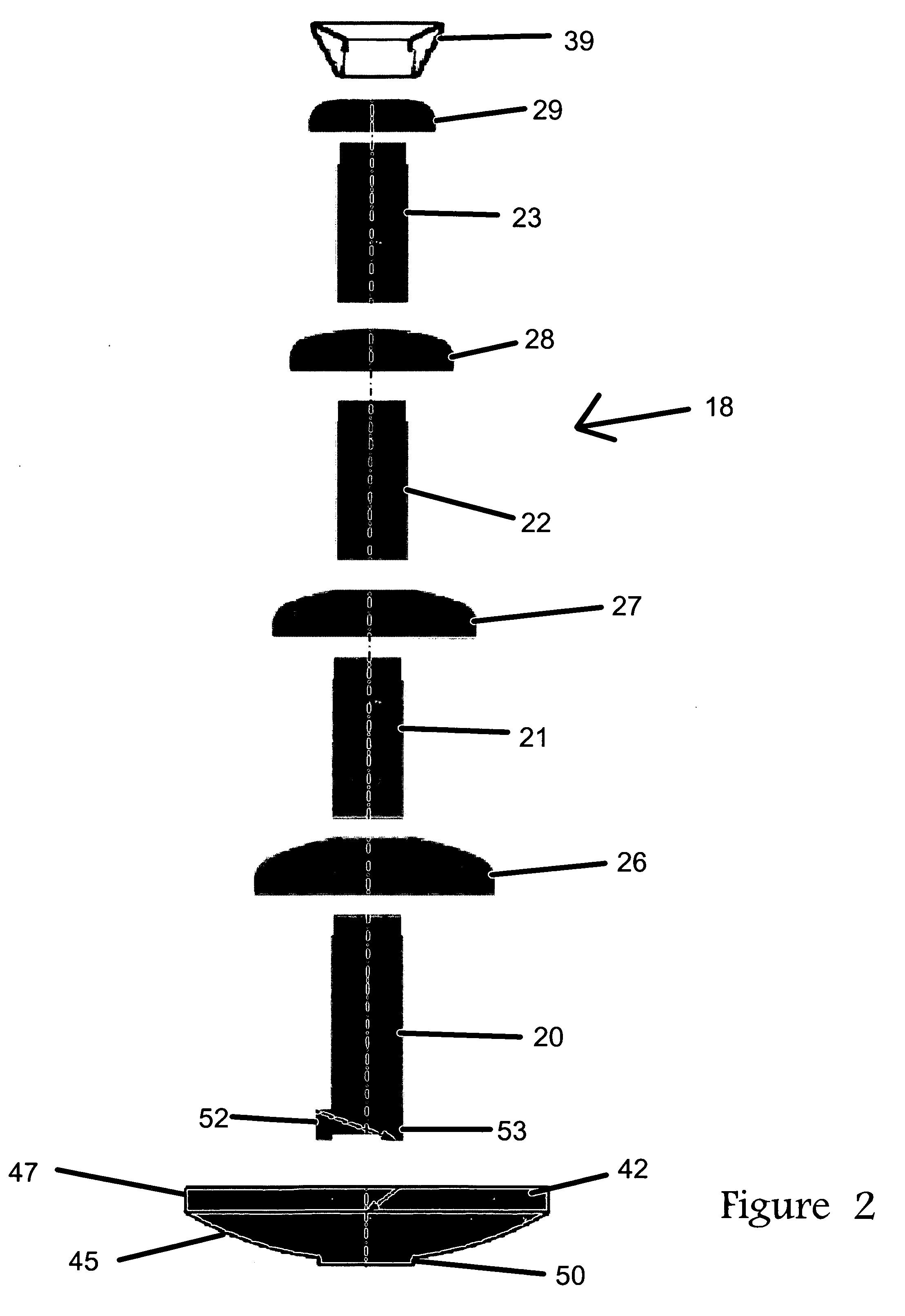

Fountain

InactiveUS7367263B2Easy to disassembleEasy to cleanMilk preservationMilk treatmentDrive shaftModularity

A modular fountain assembly for controlling the temperature and flow of viscous fluid with a melting point between ambient and approximately 150 degrees Fahrenheit is disclosed. The modular assembly for controlling the heating and flow of fluid includes an enclosed controlling base and an upper recirculation module having a detachable lower basin, one or more modular tubular sections, a small high basin on top of the highest tubular section, an Archimedes screw of a set pitch dimension to facilitate the flow of the fluid from the lower reservoir to the small high reservoir atop the tubular section or sections, and a series of circular tiers atop each tubular section. The lower basin is attached to the controlling base using mechanical or electro mechanical support structures. The controlling base provides rotational force for the Archimedes screw at variable rotational speeds to drive the fluid upward within the modular tubes as well as a heating sub module. The lower basin has an upper bowl and a lower pool of fixed set depth with an opening to permit a drive shaft attach to the Archimedes screw. The circular base controls the temperature of the fluid using a temperature probe protruding from the lower base into the lower basin. The bottom modular tube attaches to one or more vertical support structures that extends from the controlling base thru the lower reservoir. The circular tiers are held stationary between modular tube sections or between the highest tubular section and the high basin.

Owner:JAFFE MARTIN J

Sim card adaptor

A SIM card adaptor for allowing use of a smaller format SIM card in an electronic device using a larger format SIM card is provided. The SIM card adaptor may include, an adaptor body having a cutout region defined by walls in the adaptor, the cutout region preferably shaped to receive the smaller format SIM card therein; and the adaptor body may be sized and shaped for use in the electronic device using the larger format SIM card, and wherein the adaptor body includes plastic and / or nylon, carbon fiber, aluminum, or similar material capable of withstanding heat levels up to at least about 200° Fahrenheit without degradation.

Owner:SHARPE INNOVATIONS

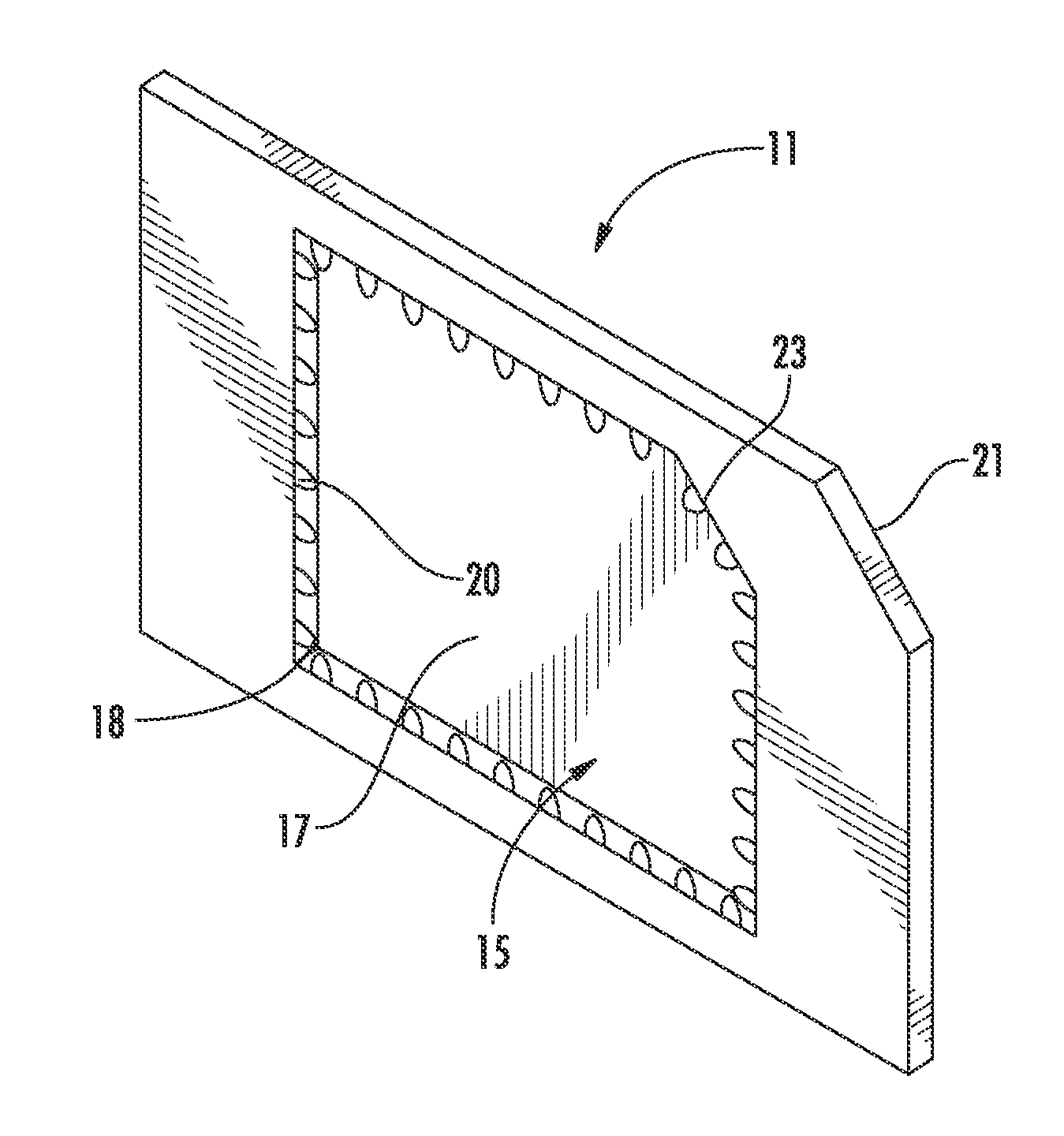

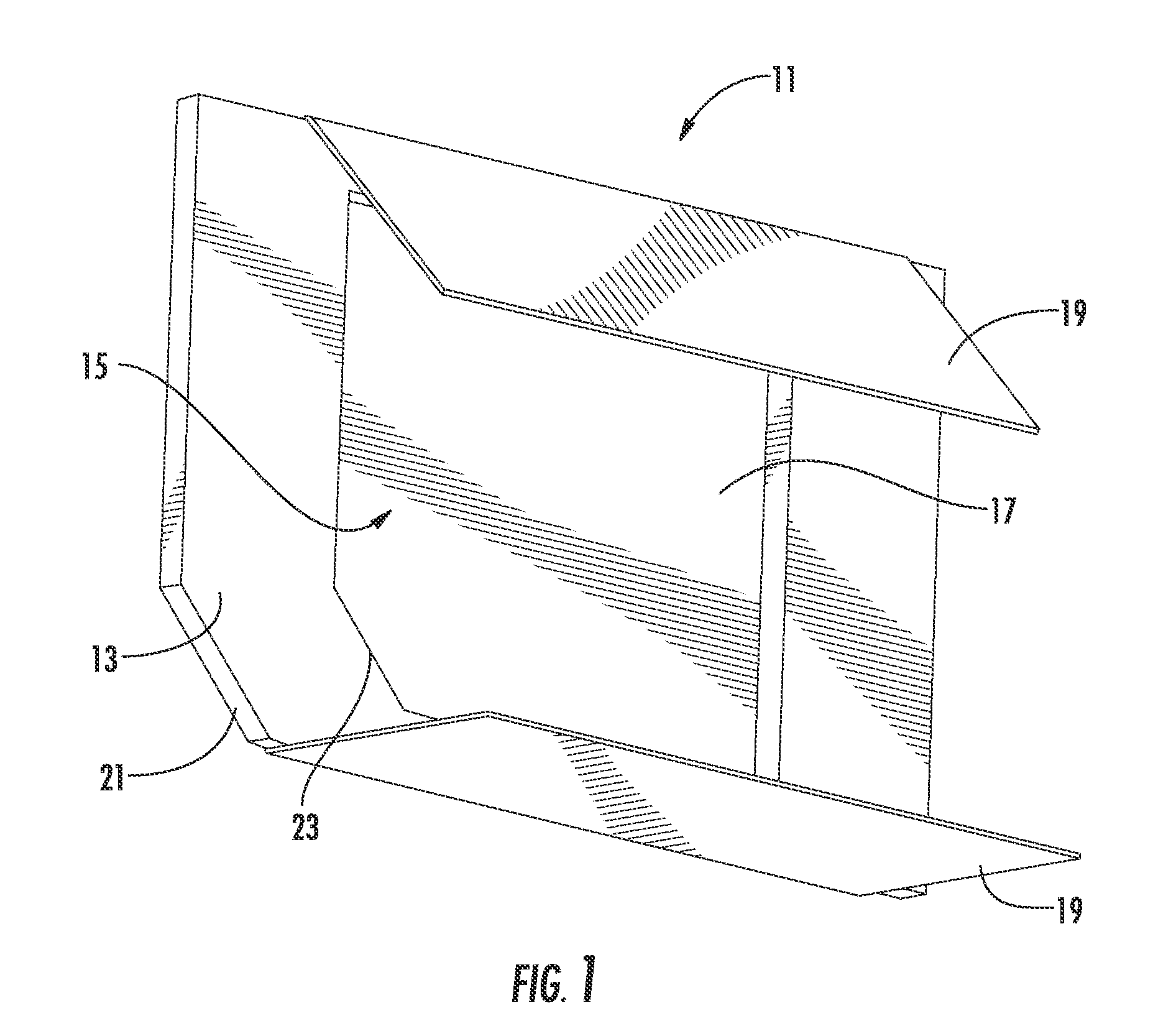

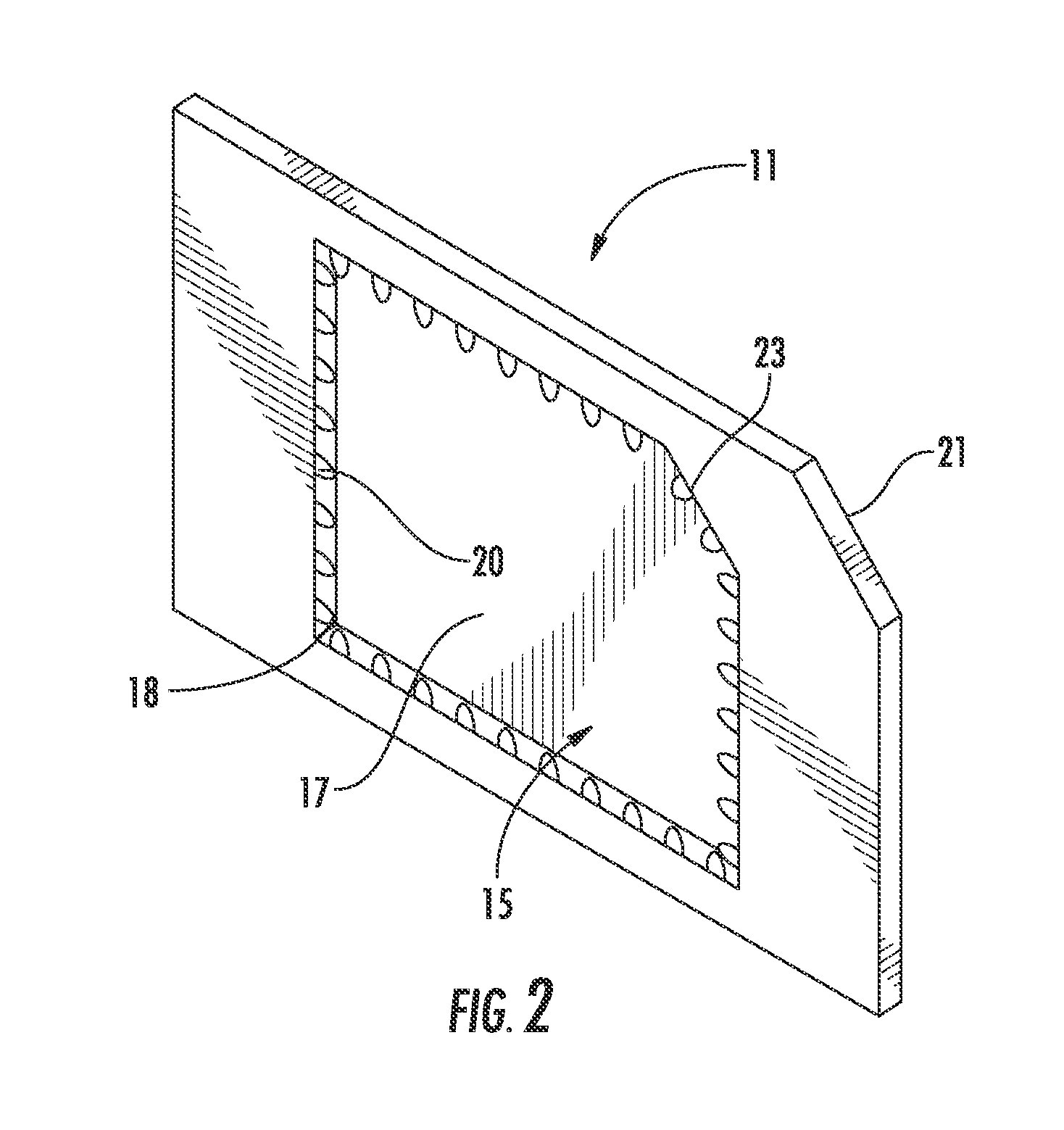

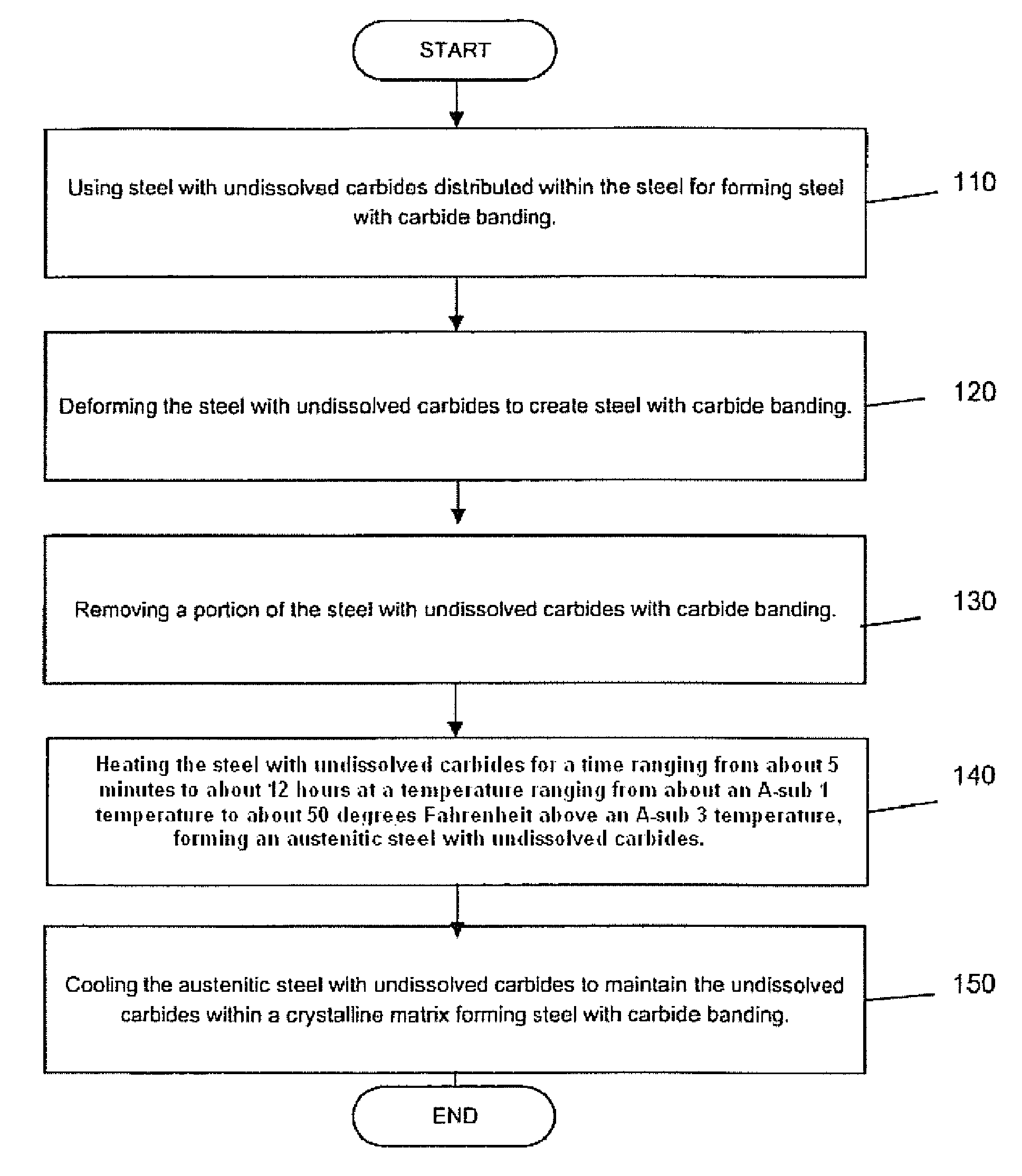

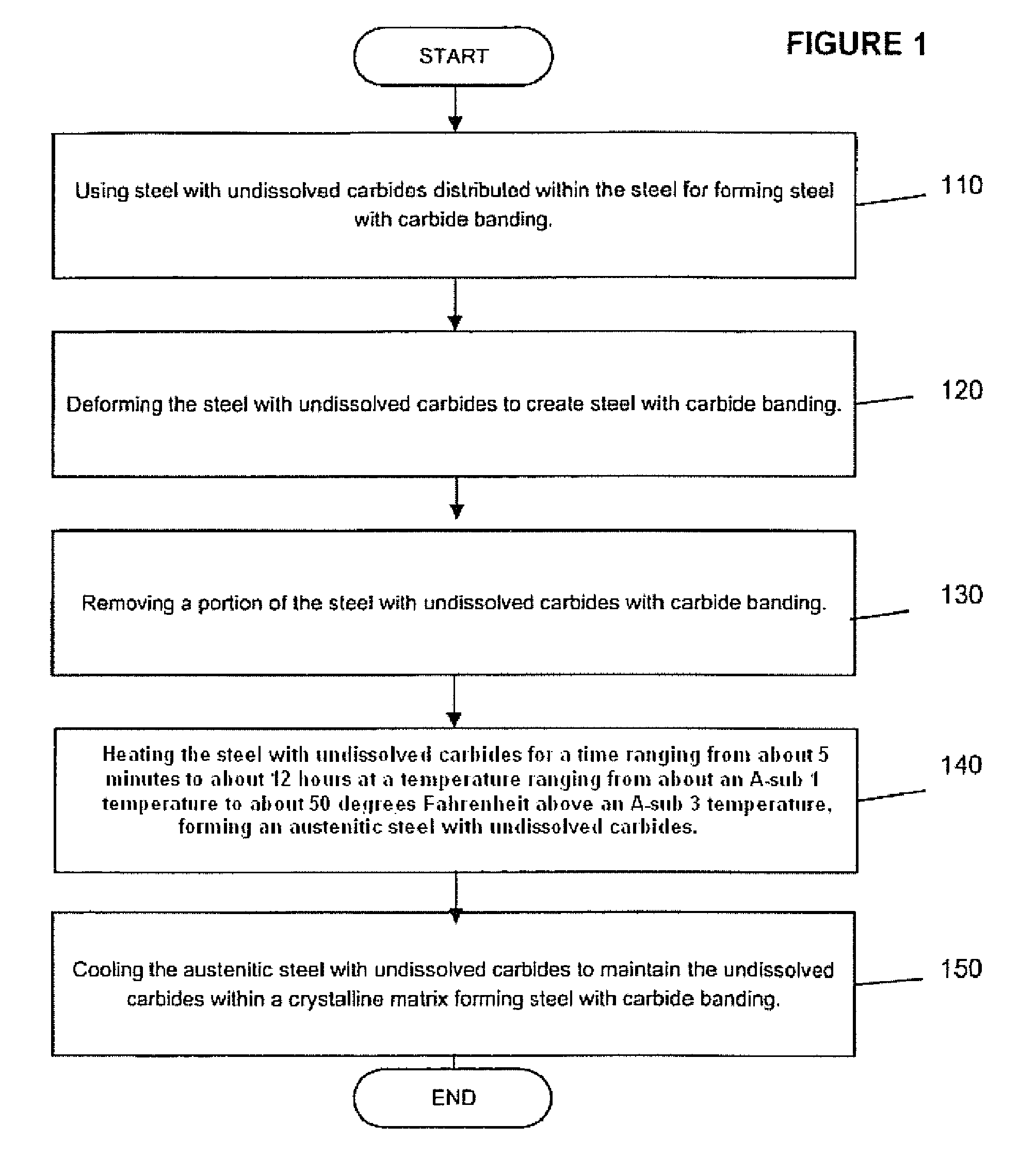

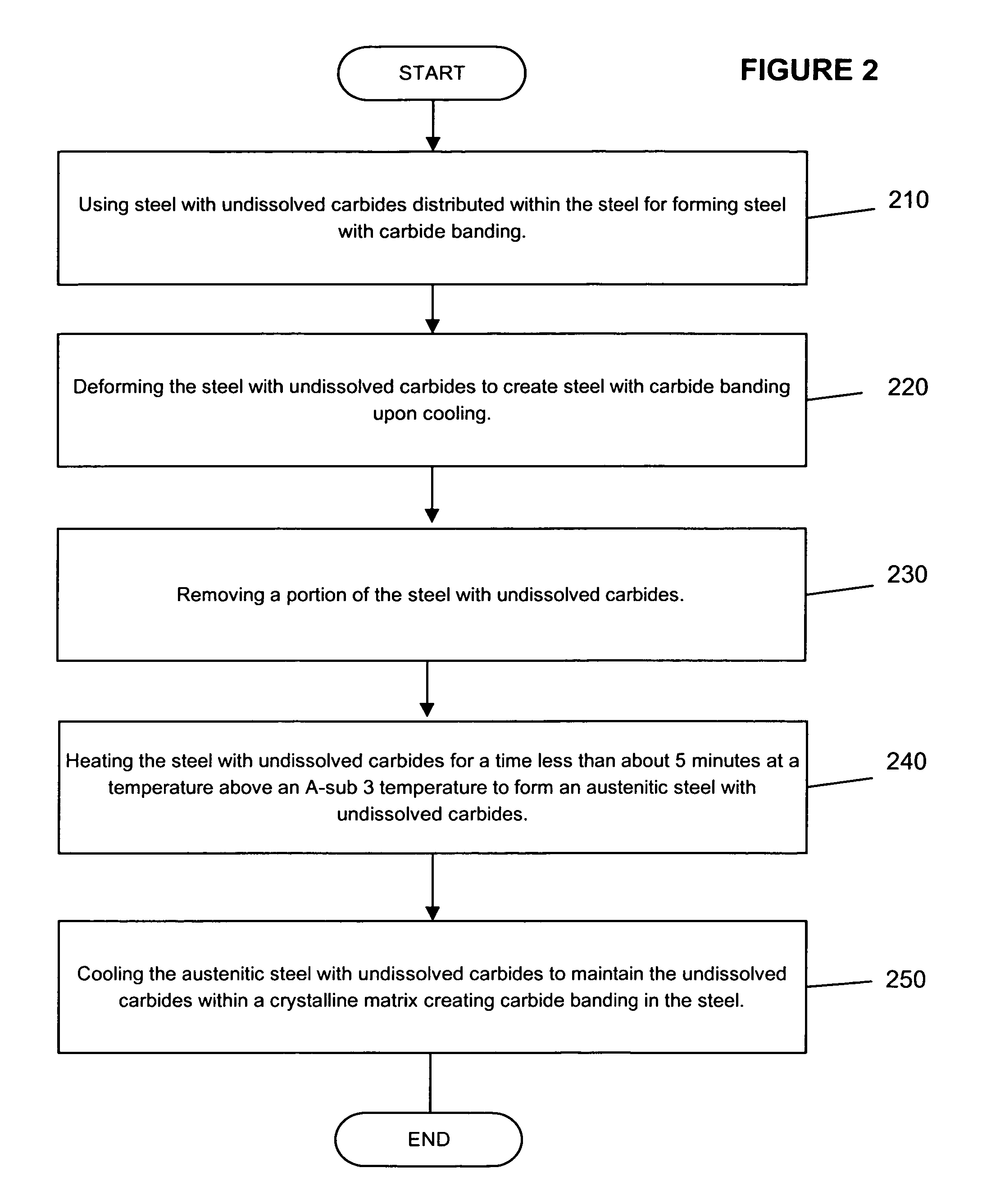

Method for making steel with carbides already in the steel using material removal and deformation

The invention is method of making steel with carbide banding obtaining steel with undissolved carbides distributed within the steel for forming steel with carbide banding, wherein the steel is about 0.3 weight percent to about 2.2 weight percent carbon and at least 0.003 weight percent of chromium, molybdenum, aluminum, vanadium, tungsten, or a similar carbide forming element; then, deforming the steel with undissolved carbide, moving a portion of the steel with undissolved carbides, heating the steel with undissolved carbides for a time ranging from about 5 minutes to about 12 hours at a temperature above an A-sub 1 temperature and below 50 degrees Fahrenheit of an A-sub 3 temperature to form an austenitic steel with undissolved carbides, and cooling the austenitic steel with undissolved carbides to maintain the undissolved carbides within a crystalline matrix forming steel with carbide banding.

Owner:WATSON DANIEL

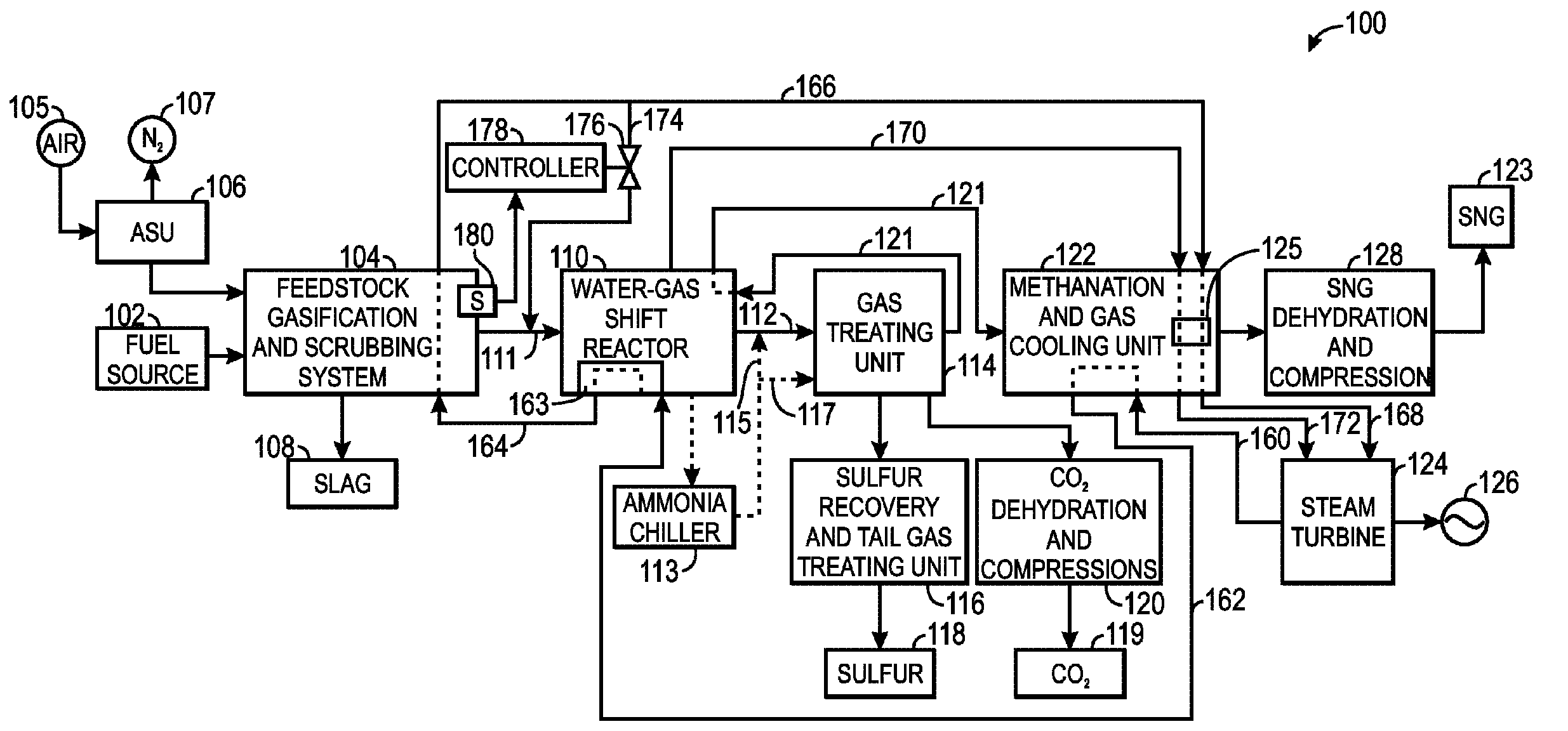

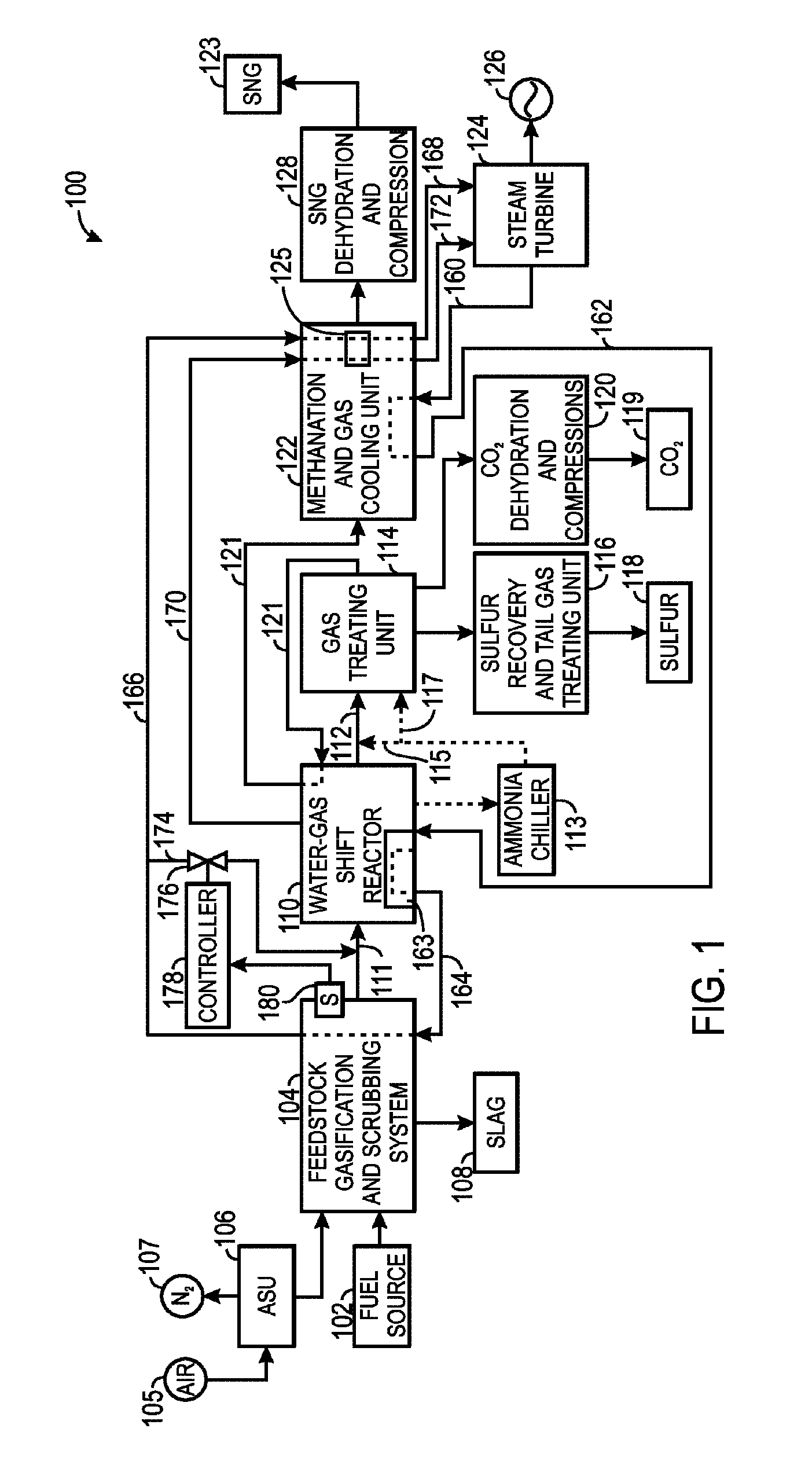

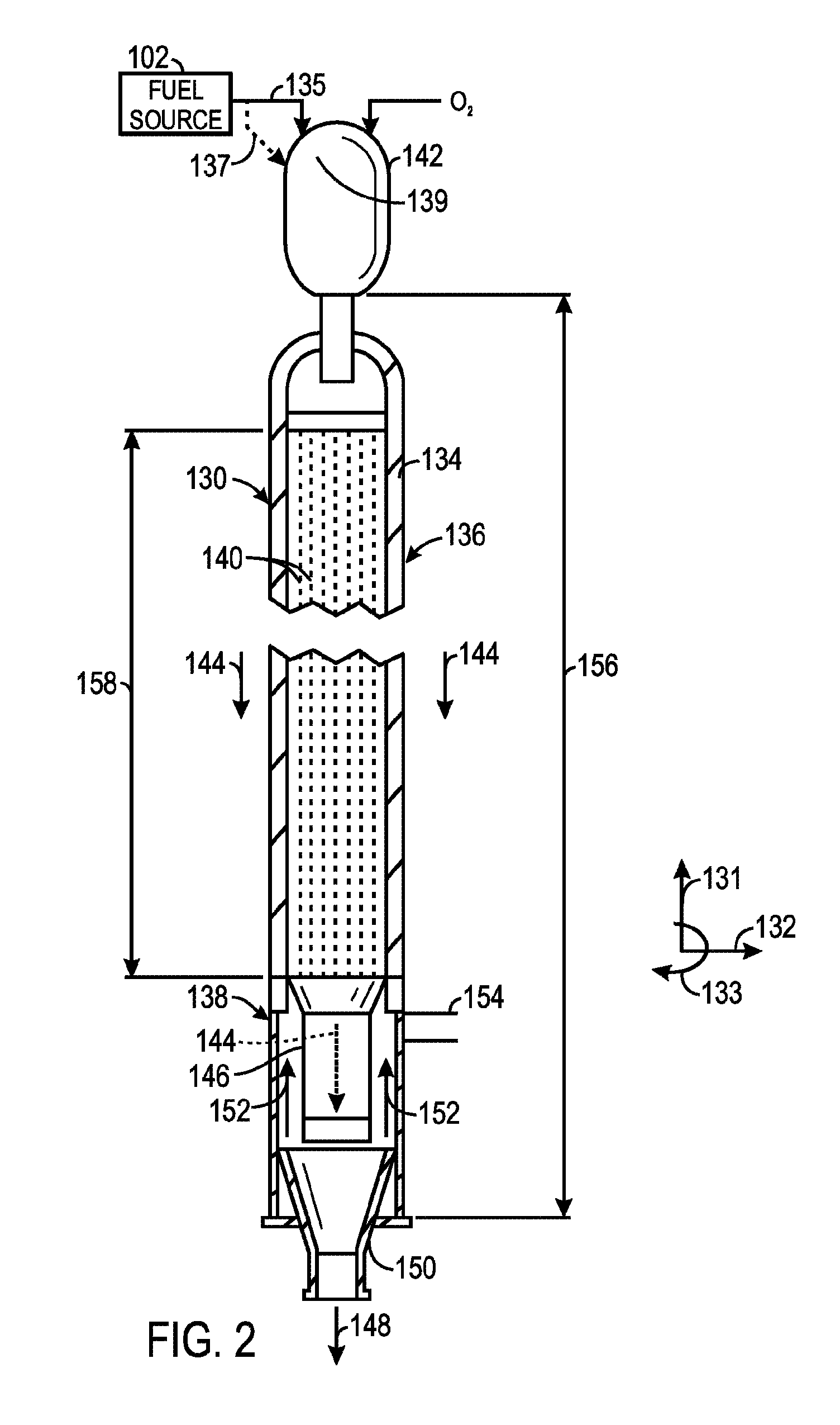

System and method of substitute natural gas production

ActiveUS8420031B2Organic chemistryChemical/physical/physico-chemical processesEngineeringSubstitute natural gas

Owner:AIR PROD & CHEM INC

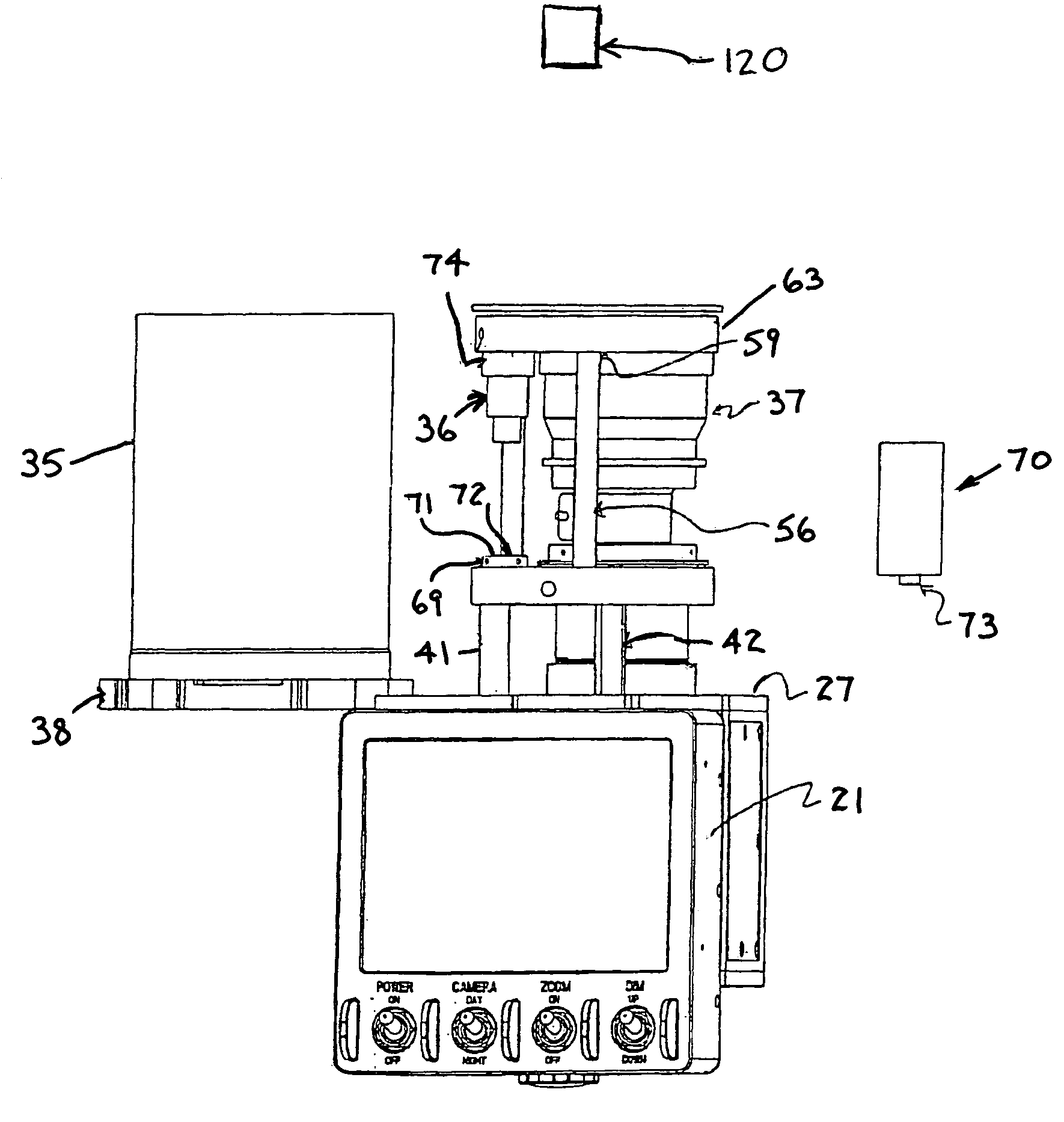

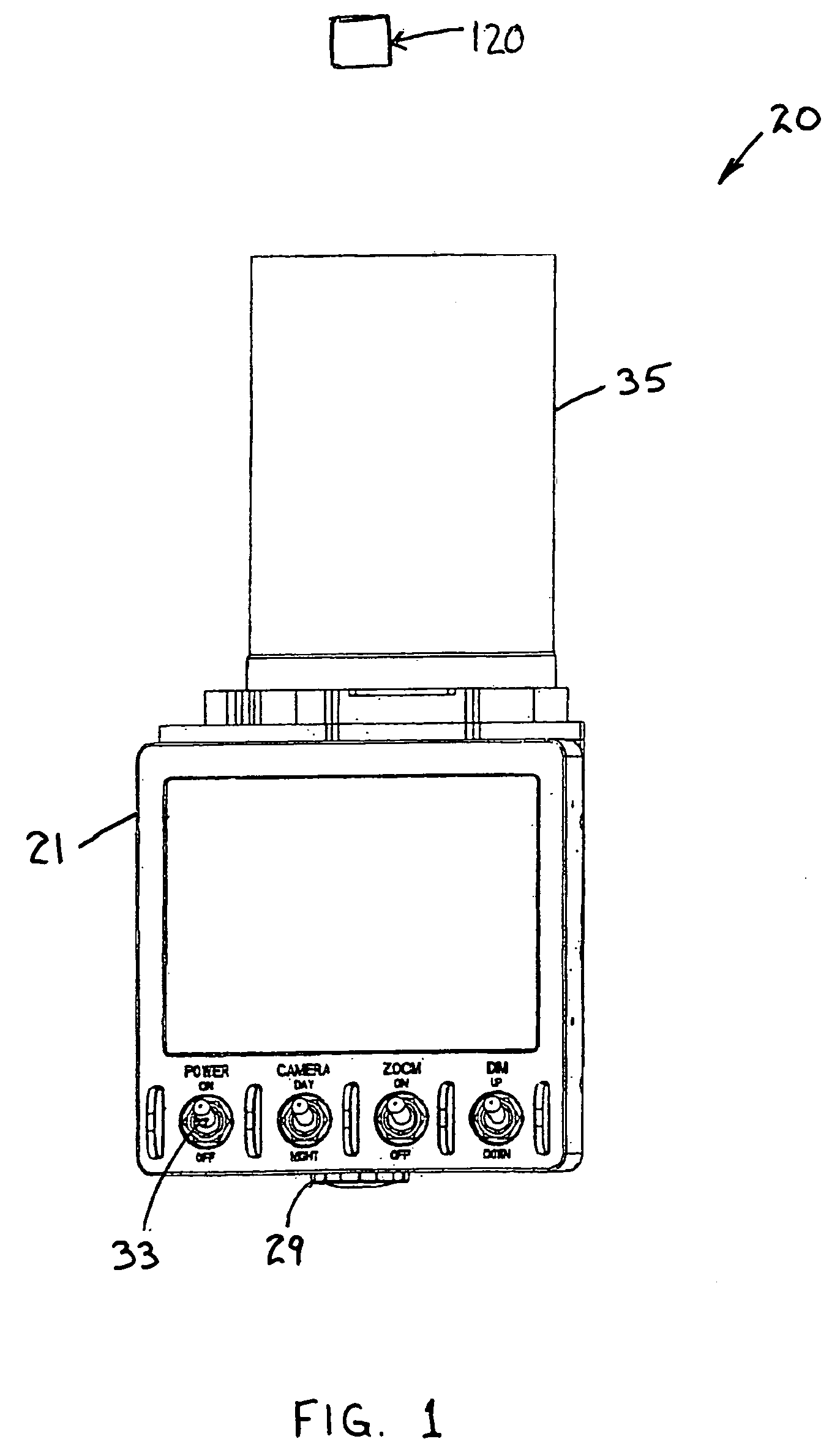

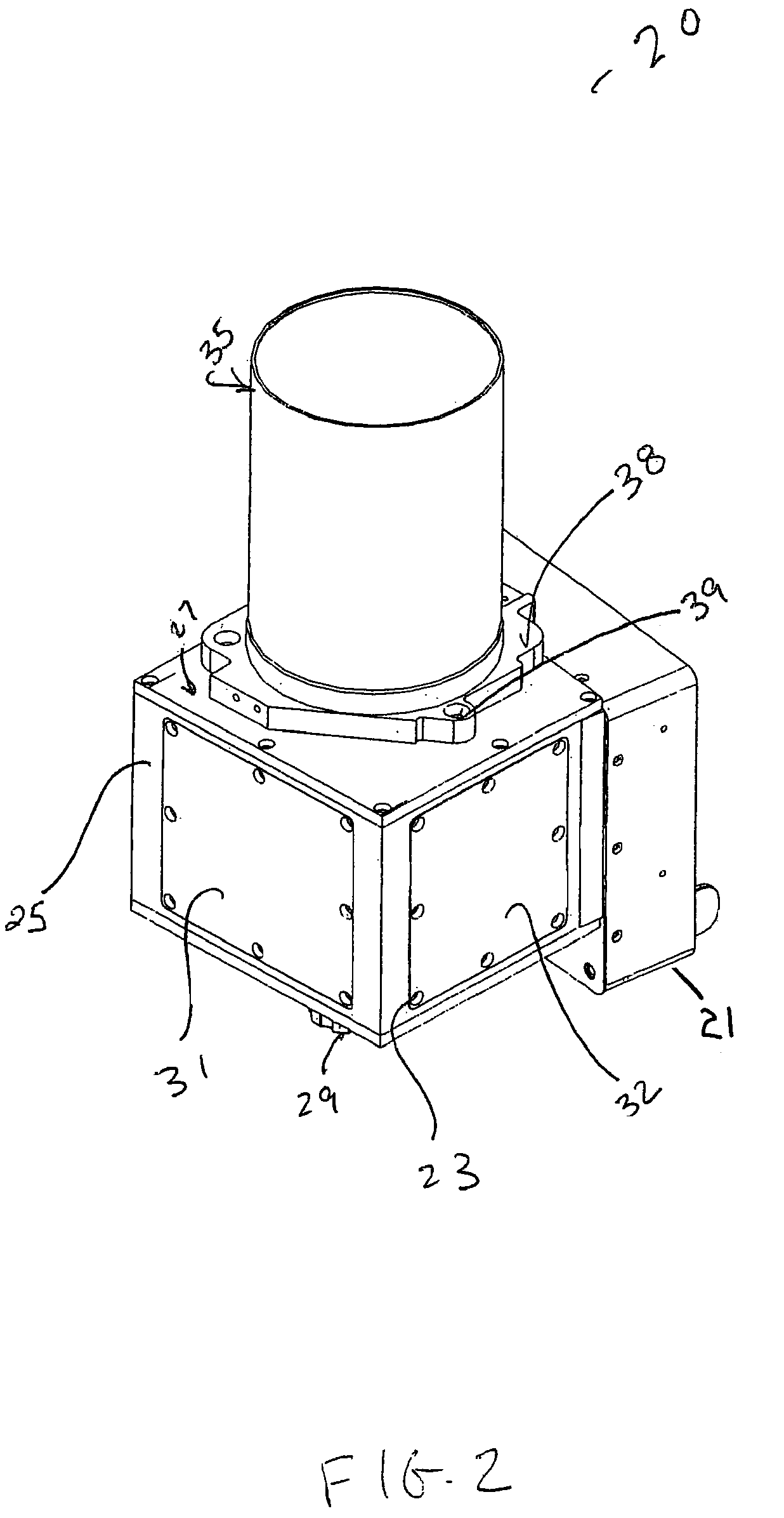

Optical and infrared periscope with display monitor

InactiveUS7880962B2Easy to manufactureProduced cost-effectivelyTelescopesFlat panel displayComputer science

The present invention includes a periscope, which has two camera objectives. The cameras are housed on top of the viewing monitor inside of a housing cell, so as to efficiently utilize the cabin space of the vehicle. One camera objective is a day camera bullet that may be used during day time or low light viewing. Another camera objective is the night board camera that may be used for night time viewing. Both cameras are electronically connected to a flat panel display, so that the optical picture may be displayed by others. In addition, the periscope of the present invention utilizes a heater sensor system that allows the day or night camera to be operated at or below temperatures of 32° Fahrenheit. The periscope of the present invention also implements an 18 mm image intensifier tube, which has the capability of detecting and amplifying low light level images during night time viewing and surveillance, under moonlight or starlight.

Owner:SEILER INSTR & MFG

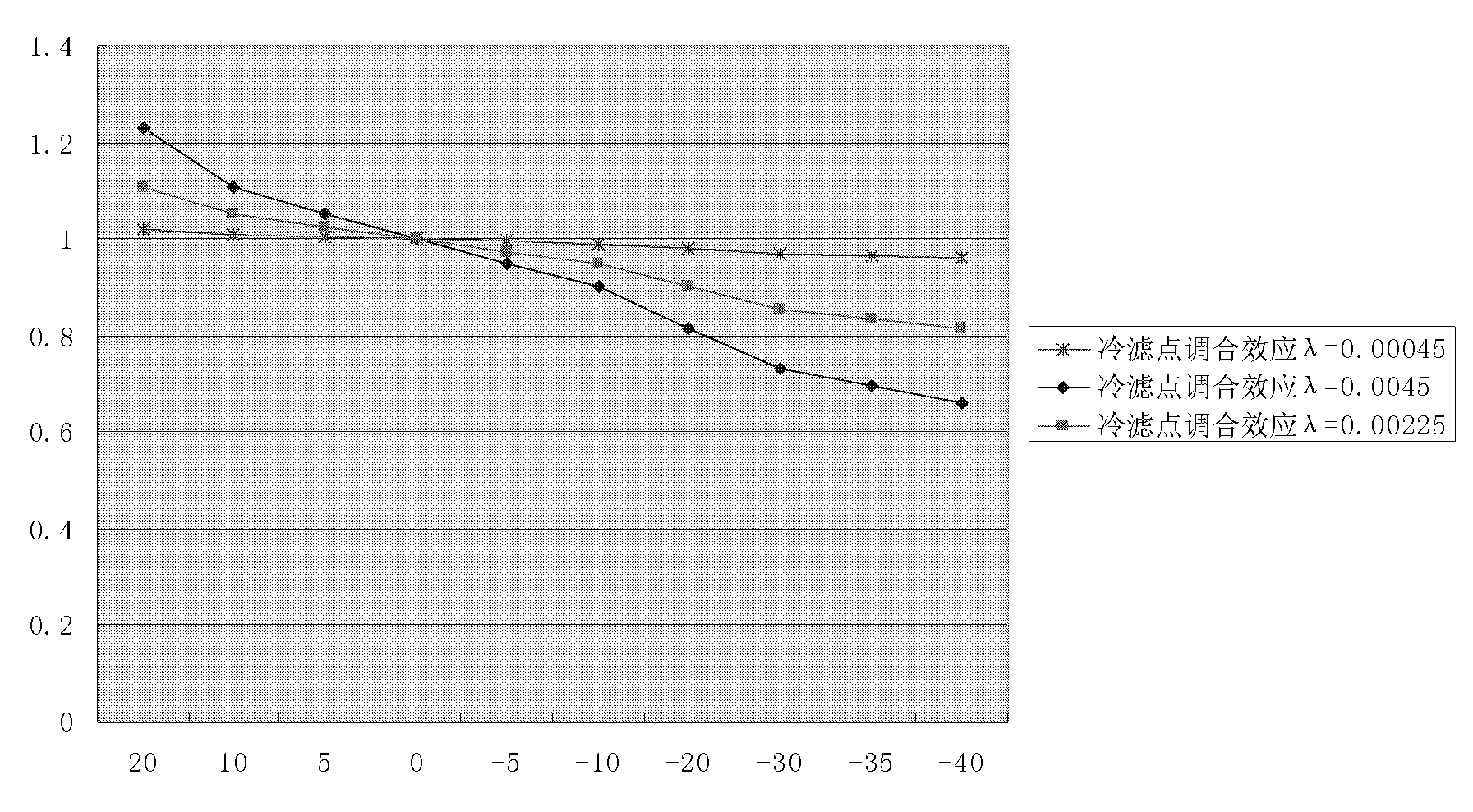

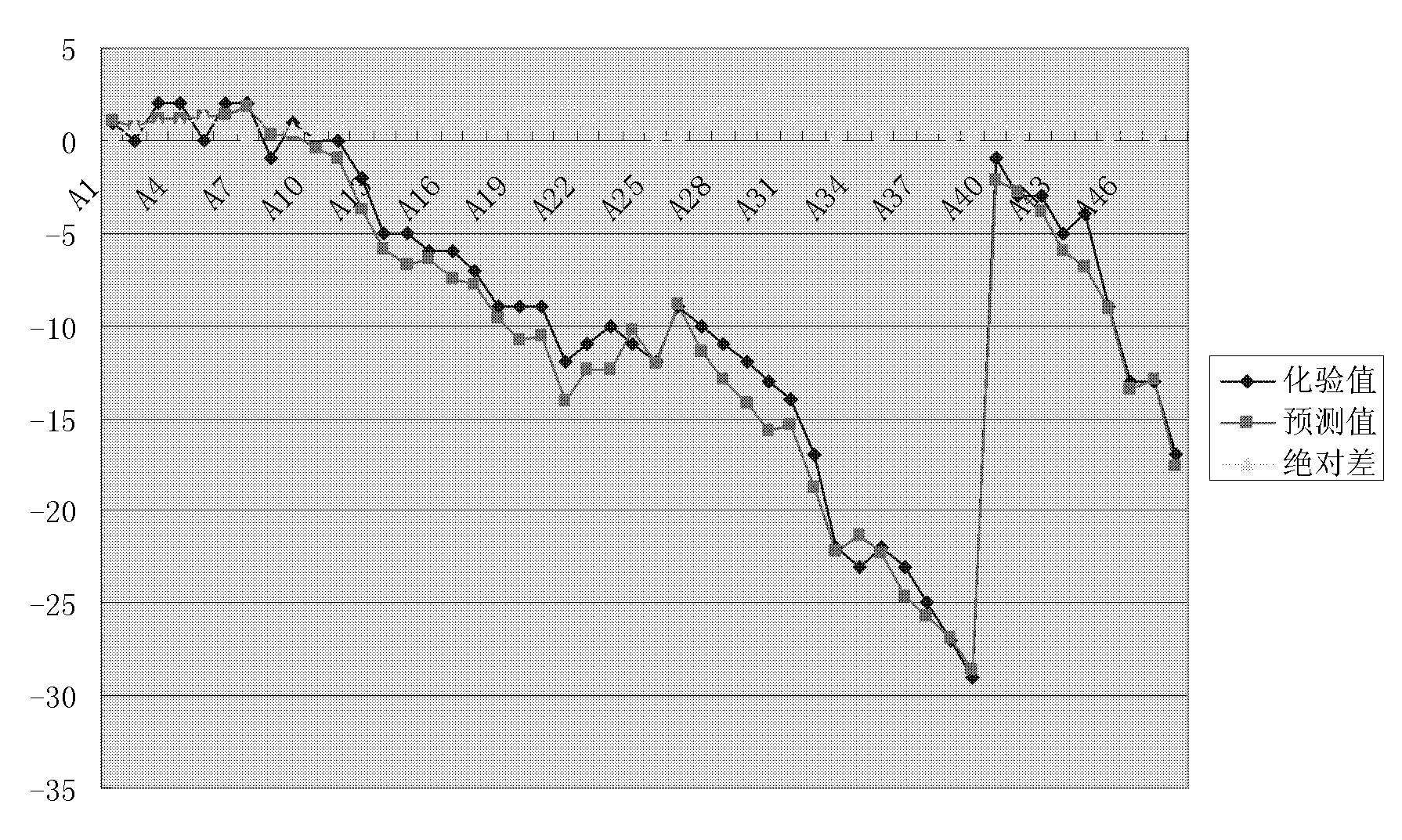

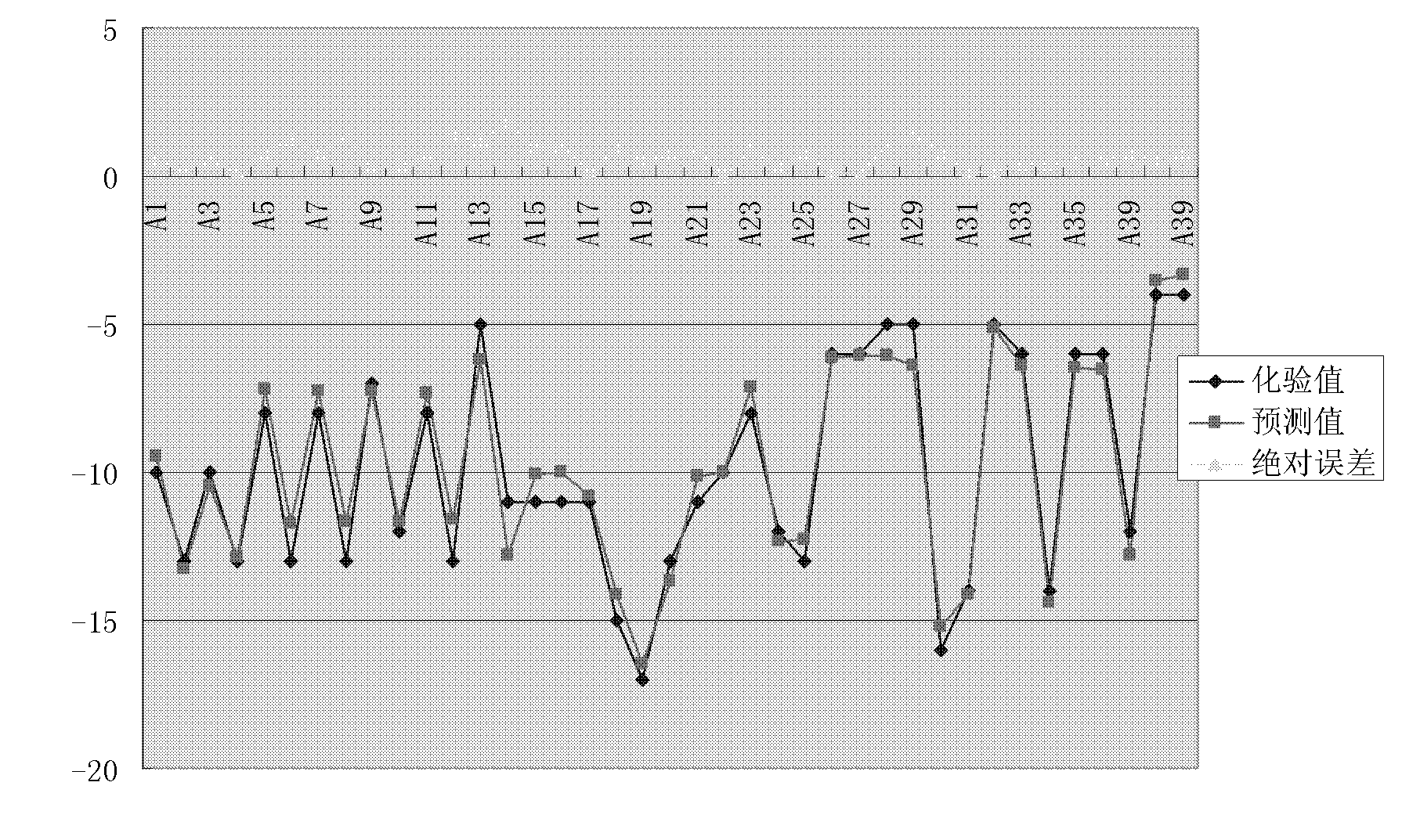

Method for predicting cold filter plugging point of light diesel oil based on blending index concept

InactiveCN103217513ABlending effect changeGuaranteed adaptabilityMaterial testing goodsCelsius DegreePredictive methods

The invention relates to a method for predicting the cold filter plugging point of light diesel oil based on a blending index concept. The method comprises the following steps: 1, cold filter plugging point unit transformation: transforming the unit of the cold filter plugging point of light diesel oil to Fahrenheit degree from Celsius degree; 2, cold filter plugging point volume blending index solving: solving through utilizing the blending volumes and the cold filter plugging point Fahrenheit degrees of all component oils to obtain the cold filter plugging point volume blending indexes of all the component oils; 3, light diesel oil cold filter plugging point calculation: adding the cold filter plugging point volume blending indexes of all components and the cold filter plugging point Fahrenheit degrees of all the components to obtain the cold filter plugging point Fahrenheit degree of the light diesel oil; and 4, light diesel oil cold filter plugging point calculation: calculating through using the cold filter plugging point Fahrenheit degree of the light diesel oil to obtain the Celsius degree. The method allows the blending effect of the light diesel oil to be described through a parameter, and the blending effects of all the component oils to be conveniently changed through correcting the parameter against different crude oils and different processing technologies, so the cold filter plugging point prediction adaptability of the light diesel oil is guaranteed.

Owner:PETROCHINA CO LTD +1

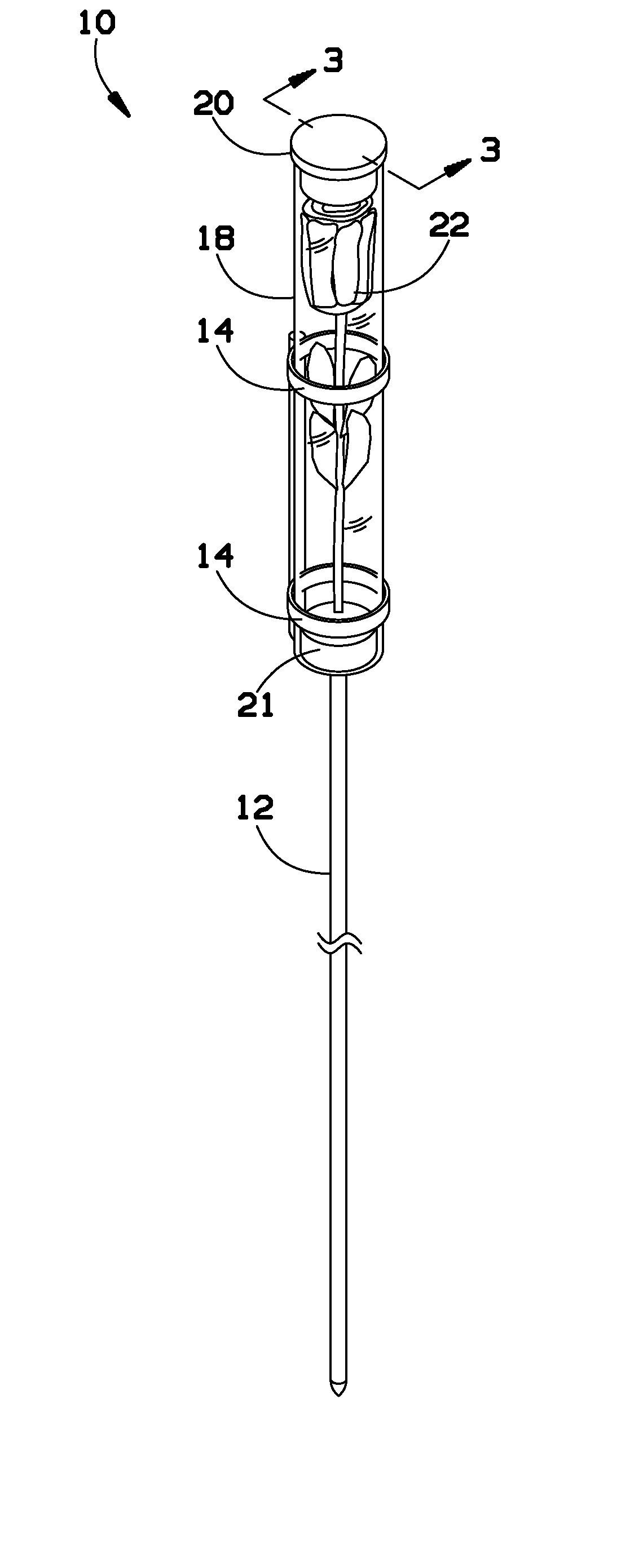

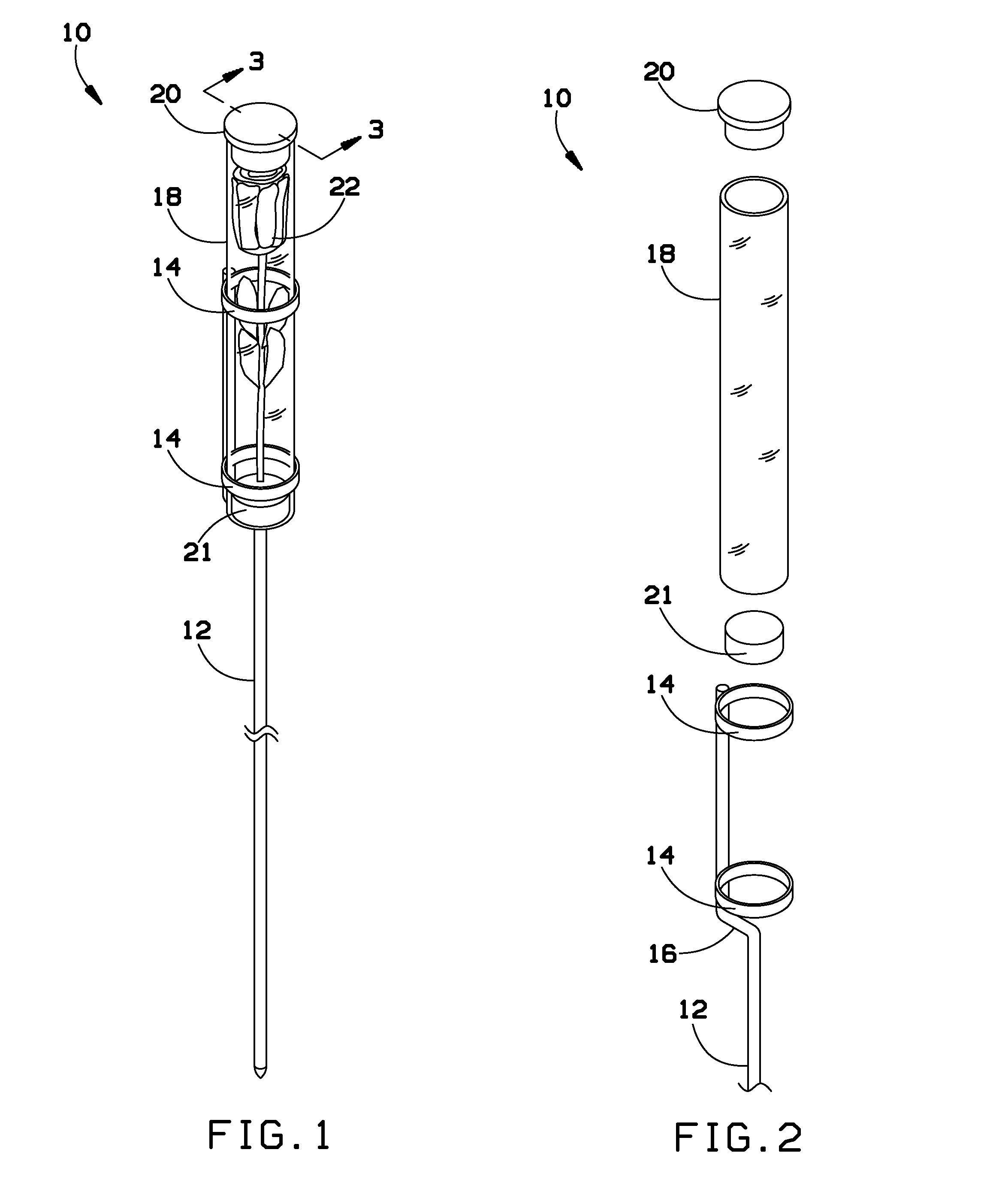

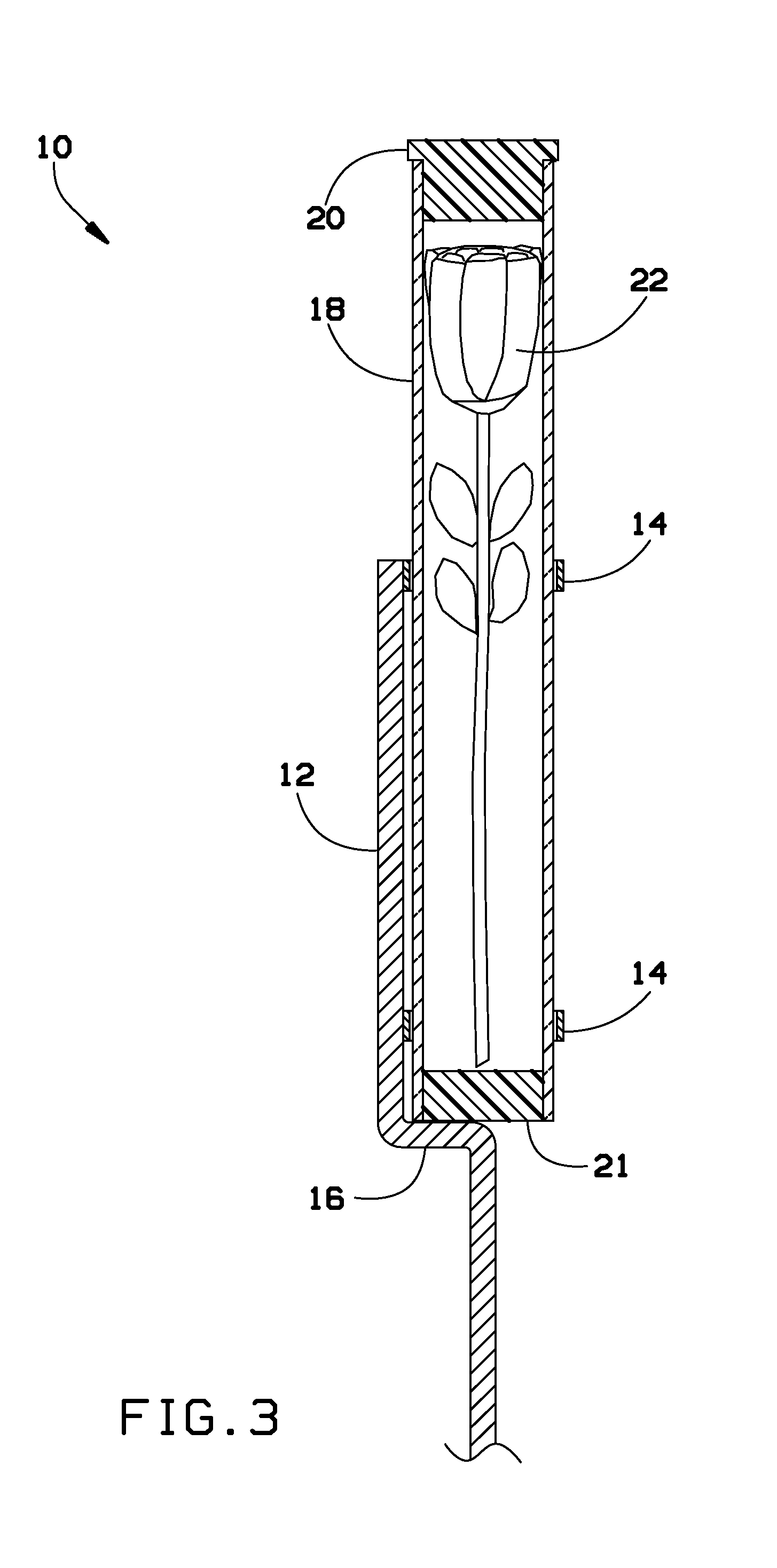

Betty's rose saver fresh flower holder

A flower holder keeps a flower looking fresh during a long period of time, under adverse weather conditions with temperatures under 40° Fahrenheit. The flower holder includes a rod with one of its ends inserted into the ground, at least one ring holder connected to the vertical rod, an elongated tube including a cap on each end, the elongated tube slides through the ring holder.

Owner:REGNER WILLIAM R

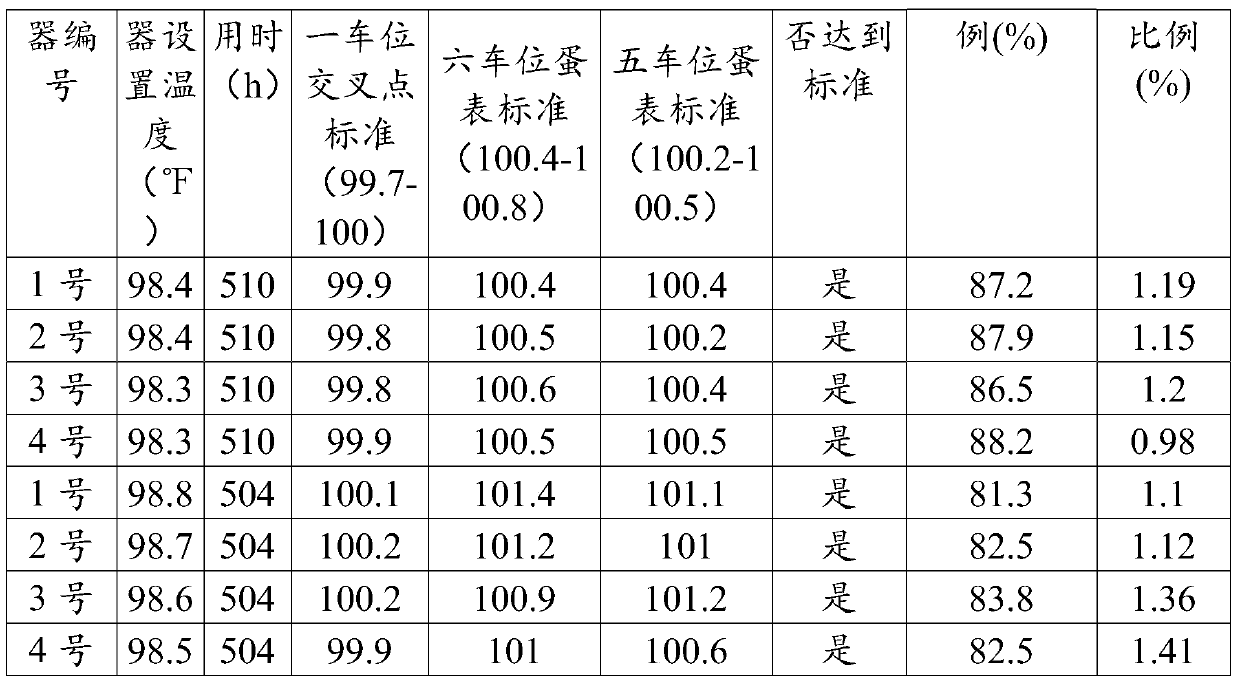

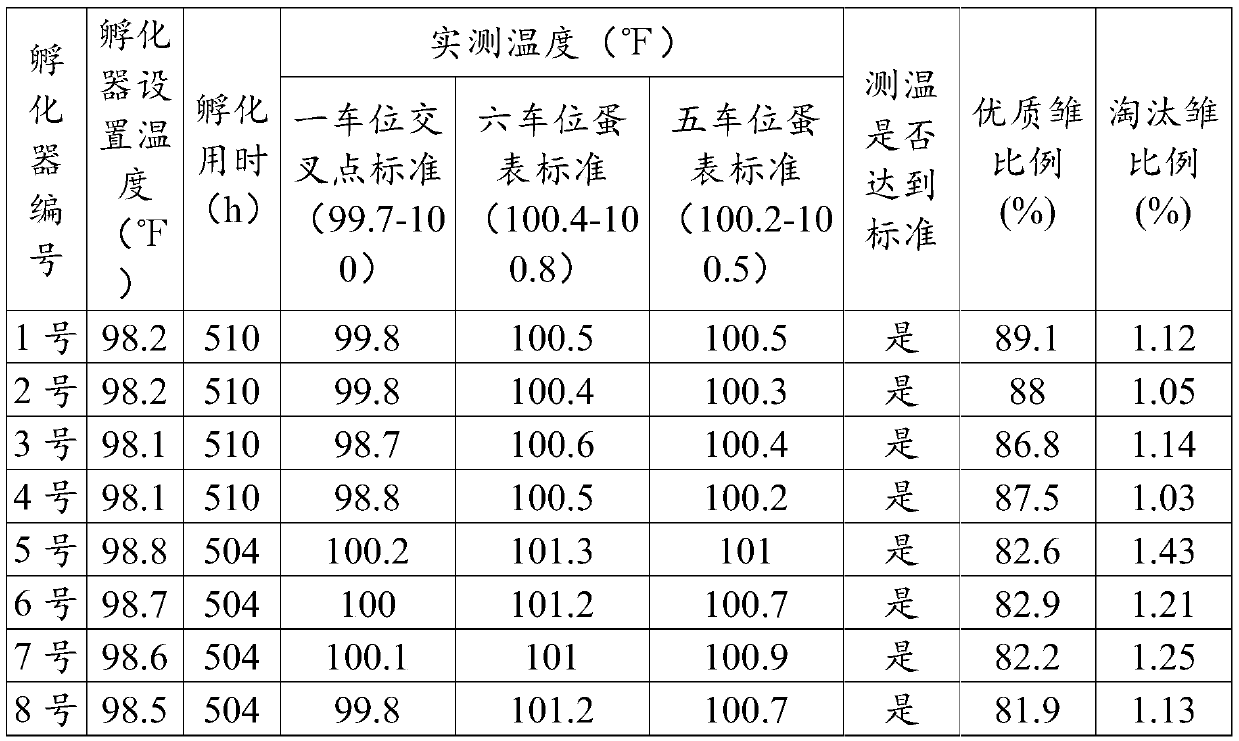

Method for hatching poultry eggs

The invention discloses a method for hatching poultry eggs, and relates to the field of poultry breeding. The method for hatching the poultry eggs comprises the following steps: hatching the poultry eggs in a hatching environment, dropping the screened eggs with normal embryos into a tray on the 18th day and / or the 19th day after hatching, and hatching in a hatchling environment until hatchling. The temperature of the hatching environment is 98.1 Fahrenheit-98.4 Fahrenheit, and the relative humidity is 50%-55%. By reducing the temperature of the hatching environment, the quality of chicks is effectively improved, and the production benefit of the chicks is maximized in a feeding process; and the proportion of high-quality chicks can be increased by 5%, and the proportion of eliminated chicks can be reduced by 0.15%.

Owner:秦皇岛正大有限公司

Cleaning process for radiopharmaceutical reusable pigs

ActiveUS7825392B2Remove pollutantsIntravenous devicesPortable shielded containersRadioactive drugRadioactive agent

A process for cleaning containers (pigs) in which radioactive drugs are shipped to health care providers, after than are returned to a pharmacy and may contain residual radioactive material, blood, microorganisms and other contaminants. Those pigs that are contaminated with radioactive material are removed from the cleaning process until they have decayed to the background radiation level. The upper and lower portions of each blood contaminated pig is disinfected. Each pig is washed at a temperature of at least 180° Fahrenheit for a least one minute to kill bacteria and viruses. The combination of a disinfectant and high washing temperature water provides an optimum level of sterilization.

Owner:NUCLEAR DIAGNOSTIC SERVICES INC

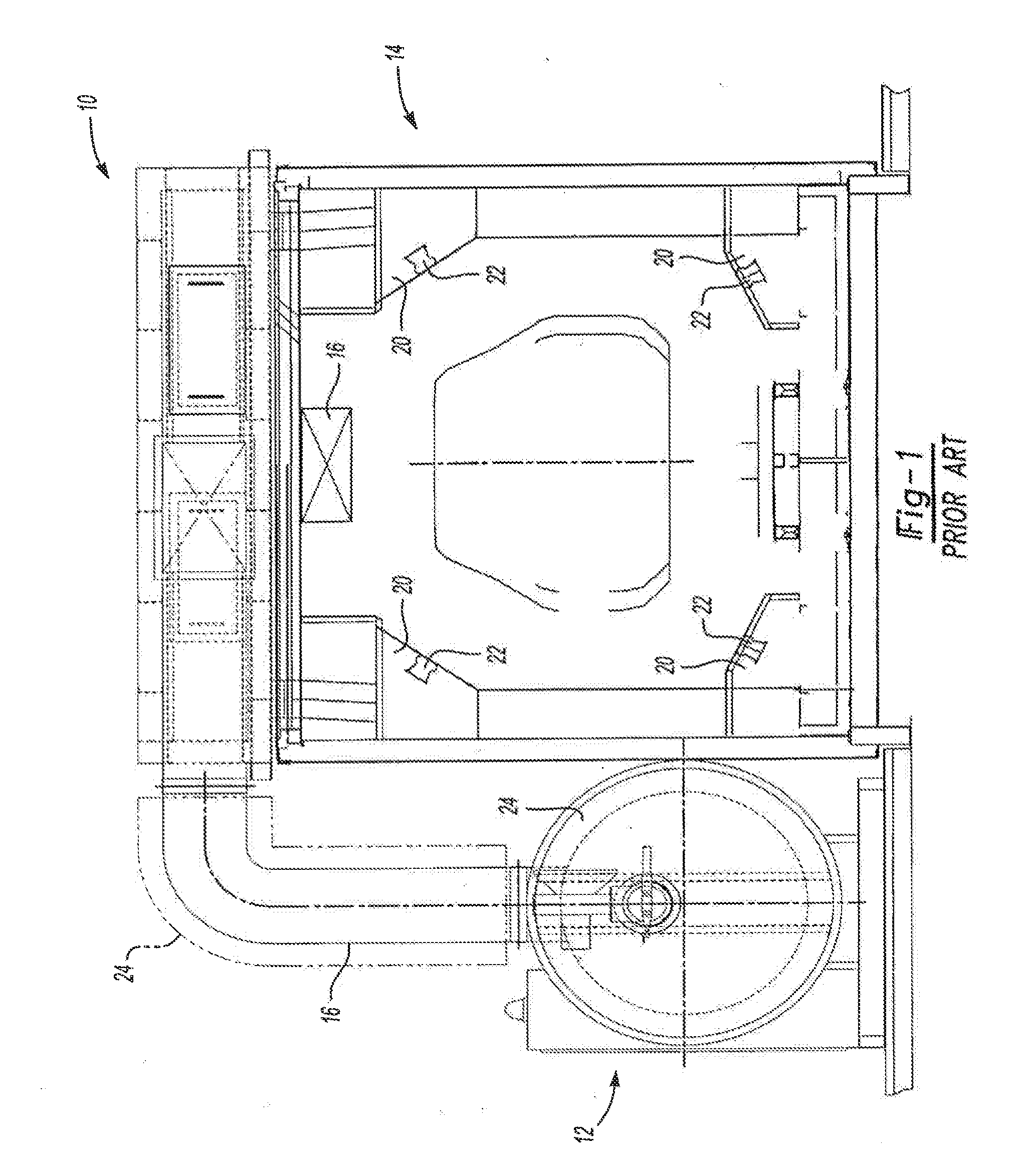

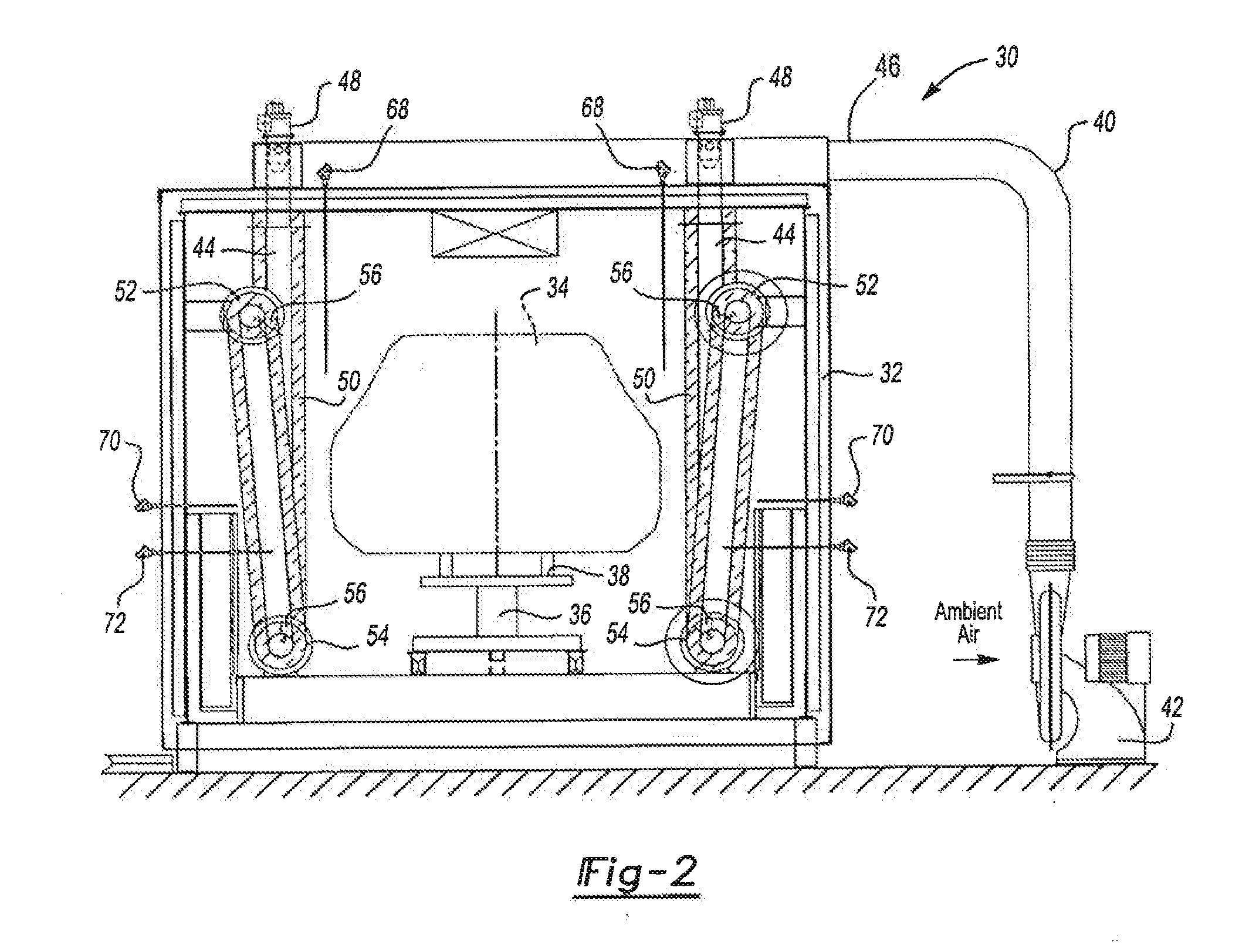

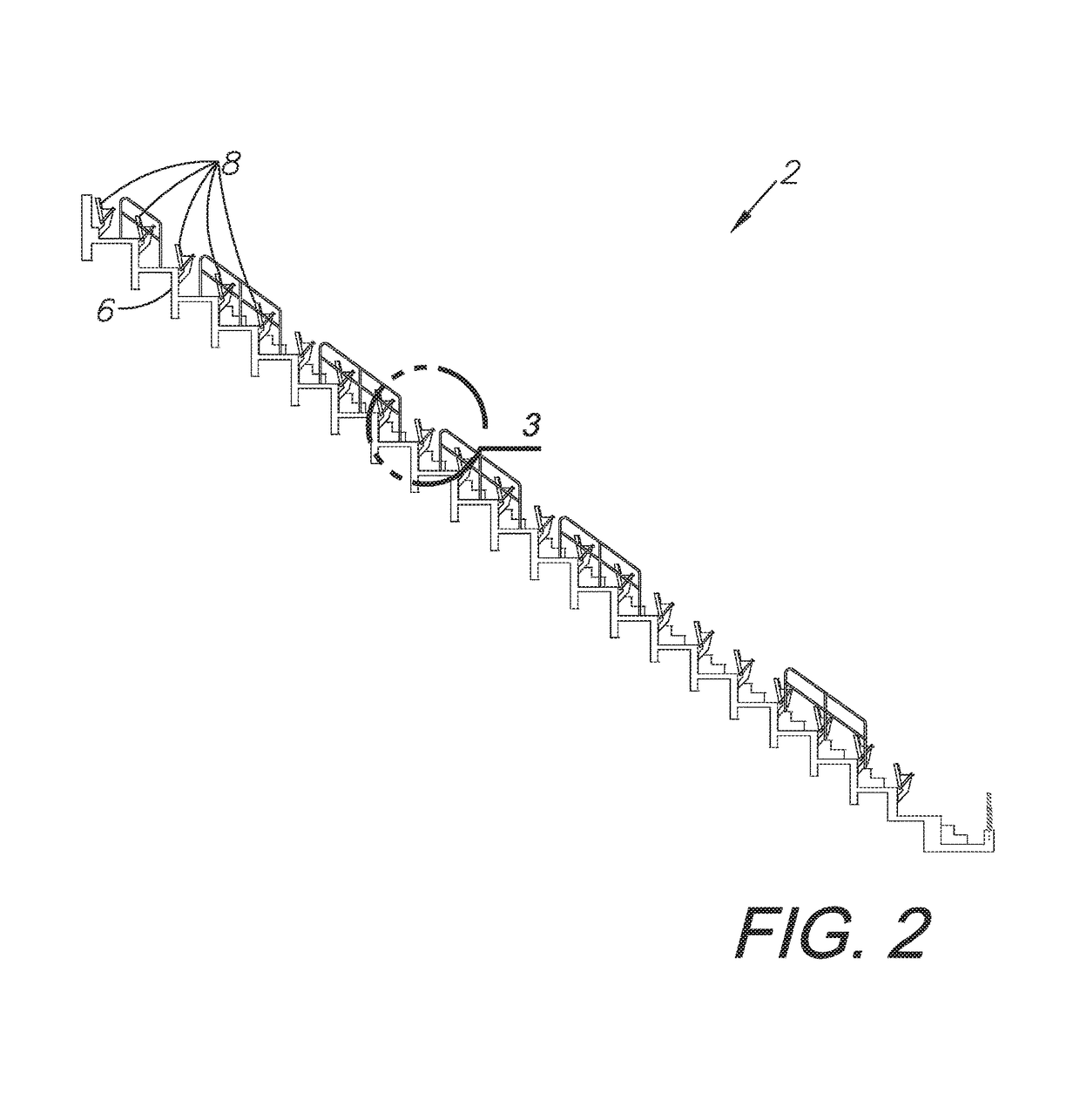

Stadium ambient temperature control system

ActiveUS9835343B2Improve comfortExtreme temperatureMechanical apparatusSpace heating and ventilation safety systemsTemperature controlCelsius Degree

Owner:HENDERSON ENGINEERS INC

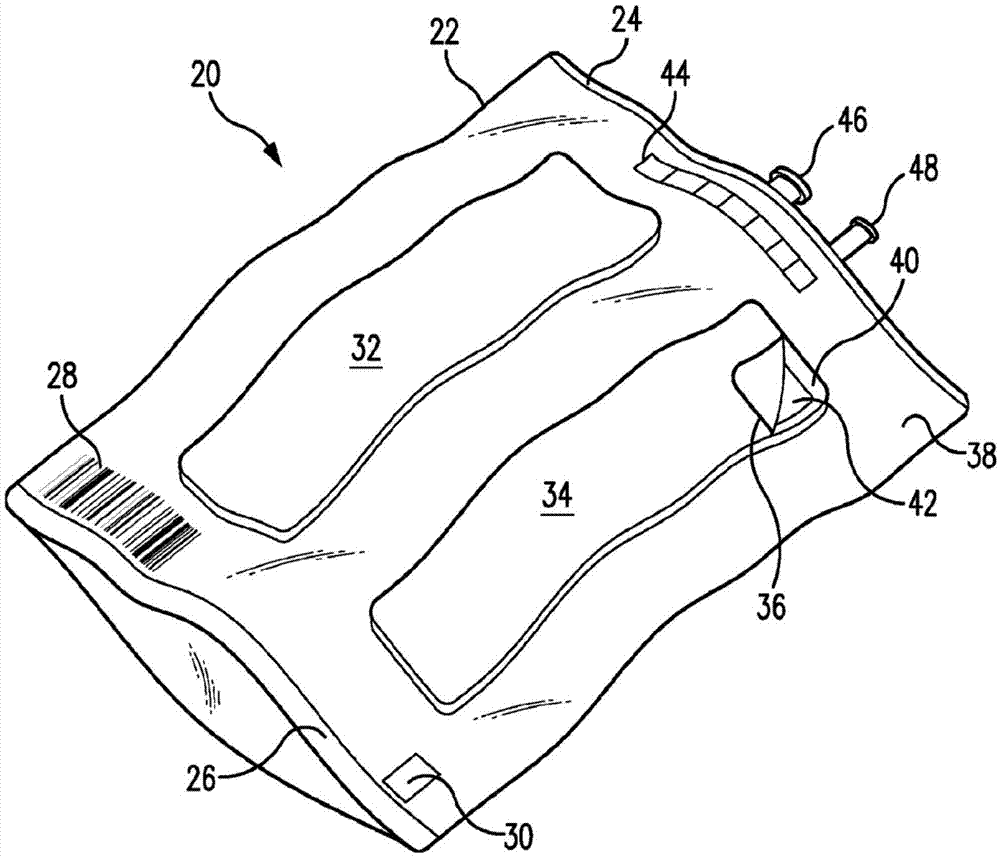

Self-warming peritoneal dialysis solution bag

ActiveCN105451789ATemperature monitoringExothermal chemical reaction heat productionPharmaceutical containersPeritoneal dialysis fluidBiological activation

A self-warming peritoneal dialysis solution bag (20) is provided that contains a peritoneal dialysis solution. The solution bag (20) can have an outer surface and a non-electric, warming patch (32, 34) adhered or affixed to the outer surface. The non-electric, warming patch (32, 34) can include an activatable agent that undergoes an exothermic reaction when activated. The warming patch (32, 34) can retain a sufficient amount of activatable agent to generate enough heat, upon activation, to warm the contents of the bag (20) to at least 95 Fahrenheit degrees. Warming patches that are separate from a peritoneal dialysis solution bag are also provided, as are kits for warming a peritoneal dialysis solution bag. Methods of warming a peritoneal dialysis solution bag with a non-electric, warming patch, are also provided.

Owner:FRESENIUS MEDICAL CARE HLDG INC

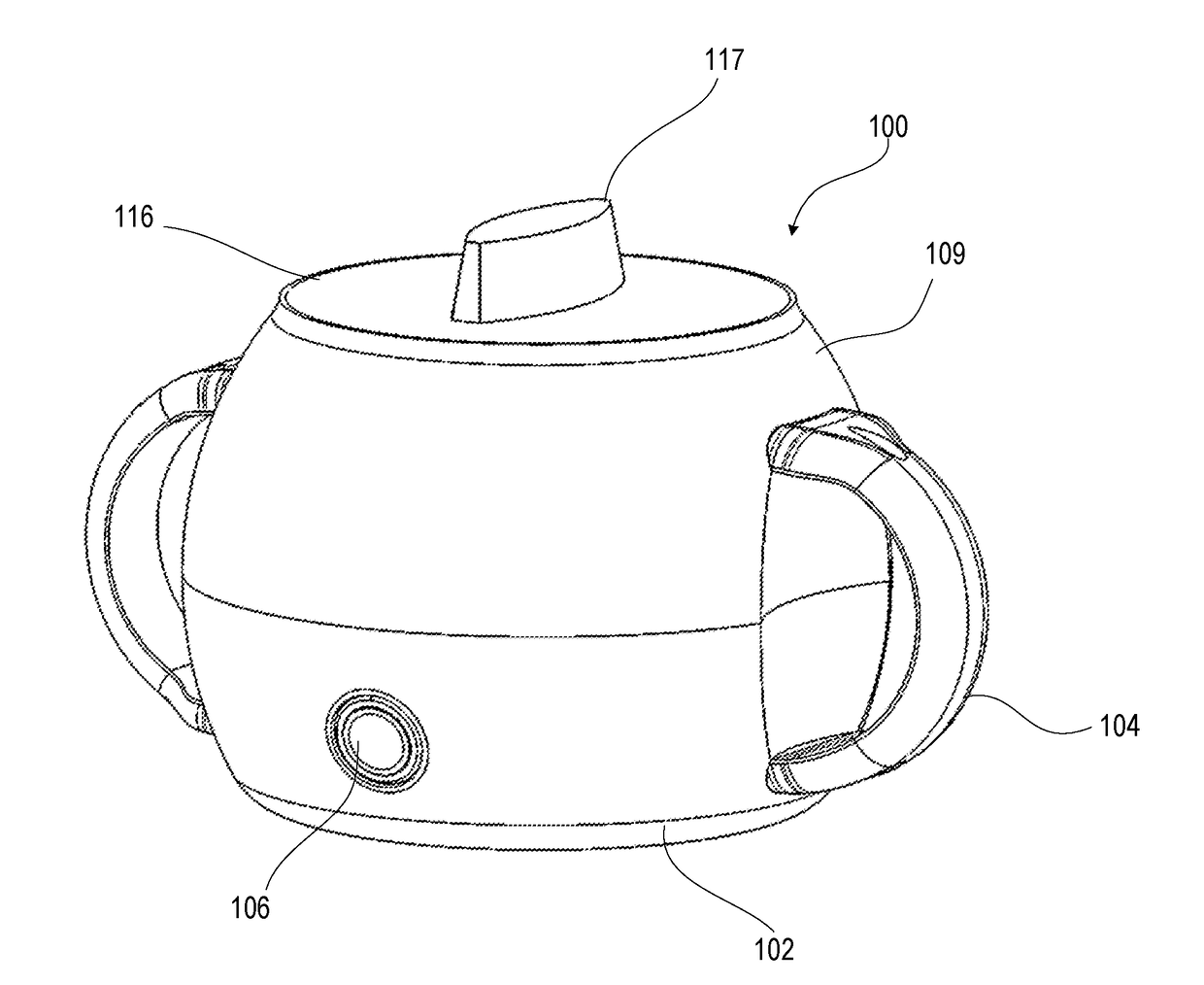

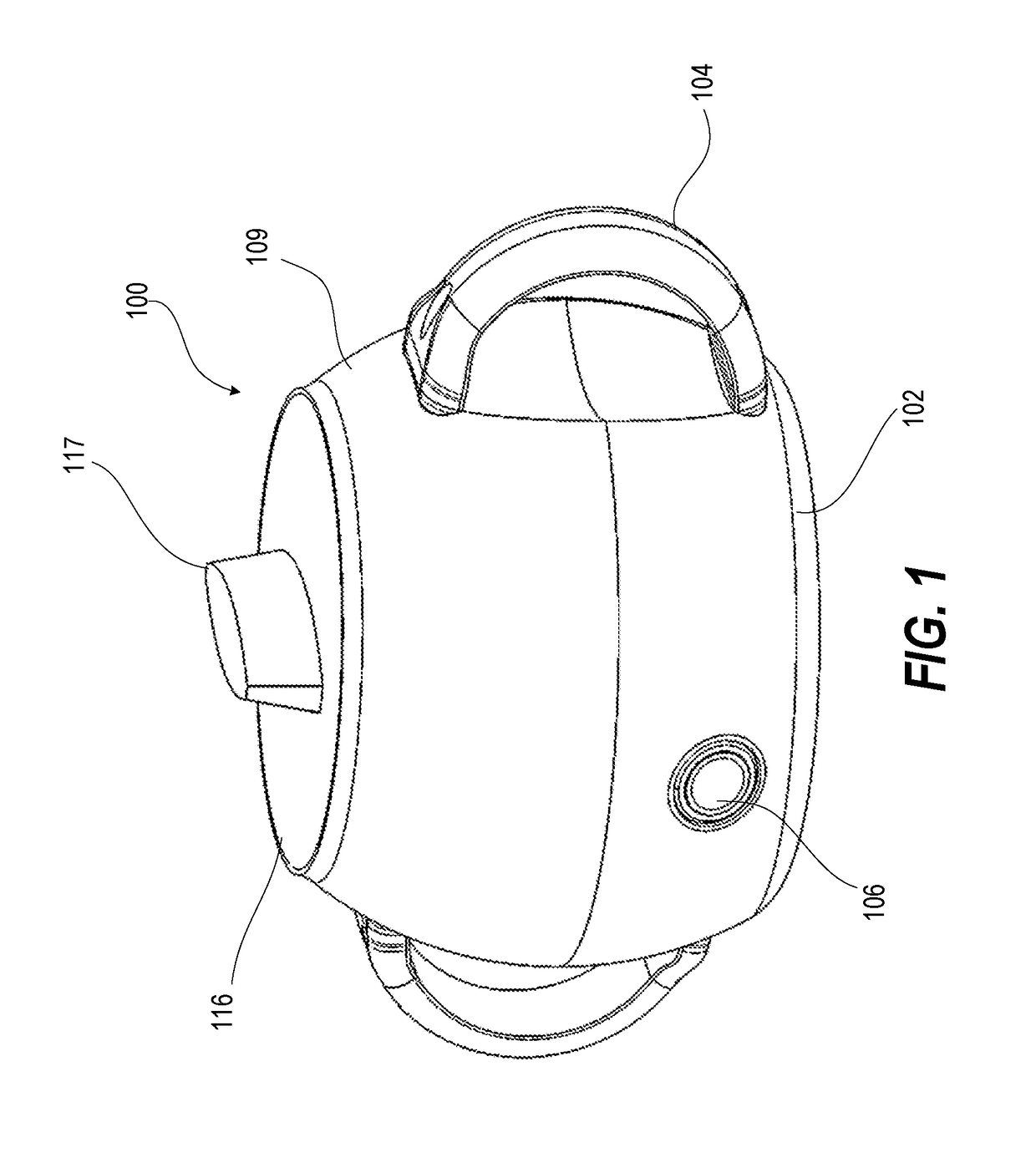

Food heating container

InactiveUS20180249863A1Superior in pointDomestic stoves or rangesLighting and heating apparatusThe InternetBluetooth

The present invention provides for a portable, wireless and rechargeable heating container (HC) that allows an individual to warm up food. The heating of the food is achieved through an electric heating system powered by the accumulators and controlled by an electronic circuit. HC can heat up the food or drink, up to 40 degrees Celsius (104° Fahrenheit). HC can be used for multiple complete heating cycles on one charging. It contains an on and off switch to activate heating mechanism and an LED indicator for the accumulators, heating and charging status. HC can include a Wi-Fi, BLUETOOTH chip, or any other wireless solution that will enhance its versatility and mobility, allowing it, for example, to access the Internet from a plurality of access points. For purposes of such communication, device preferably includes either or both a wired communications port and a wireless communications port. The system makes it perfect for frequent traveling, outdoors activities and work. The heating container has a convenient design both holding carrying in a bag, an attaching.

Owner:SOMI LLC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com