Method for predicting cold filter plugging point of light diesel oil based on blending index concept

A prediction method and cold filter point technology, applied in the direction of material inspection products, etc., can solve problems such as difficulty and achieve the effect of ensuring adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] figure 1 The flow chart of the prediction method of cold filter point of light diesel oil based on the concept of blending index is given. First, convert the units of each component oil of light diesel oil from Celsius to Fahrenheit, then obtain the volume blending index of each component oil, and then calculate by adding the cold filter point (Fahrenheit) of each component oil Cold filter point (degrees Fahrenheit) of light diesel oil. Finally, the cold filter point (Celsius) of light diesel oil is obtained by unit conversion.

[0020] The conversion relationship between Celsius and Fahrenheit is:

[0021] CPF i =CP i ×1.8+32

[0022] CPF i —Cold filter point of component i, unit: °F;

[0023] CP i —Cold filtration point of component i, unit: °C;

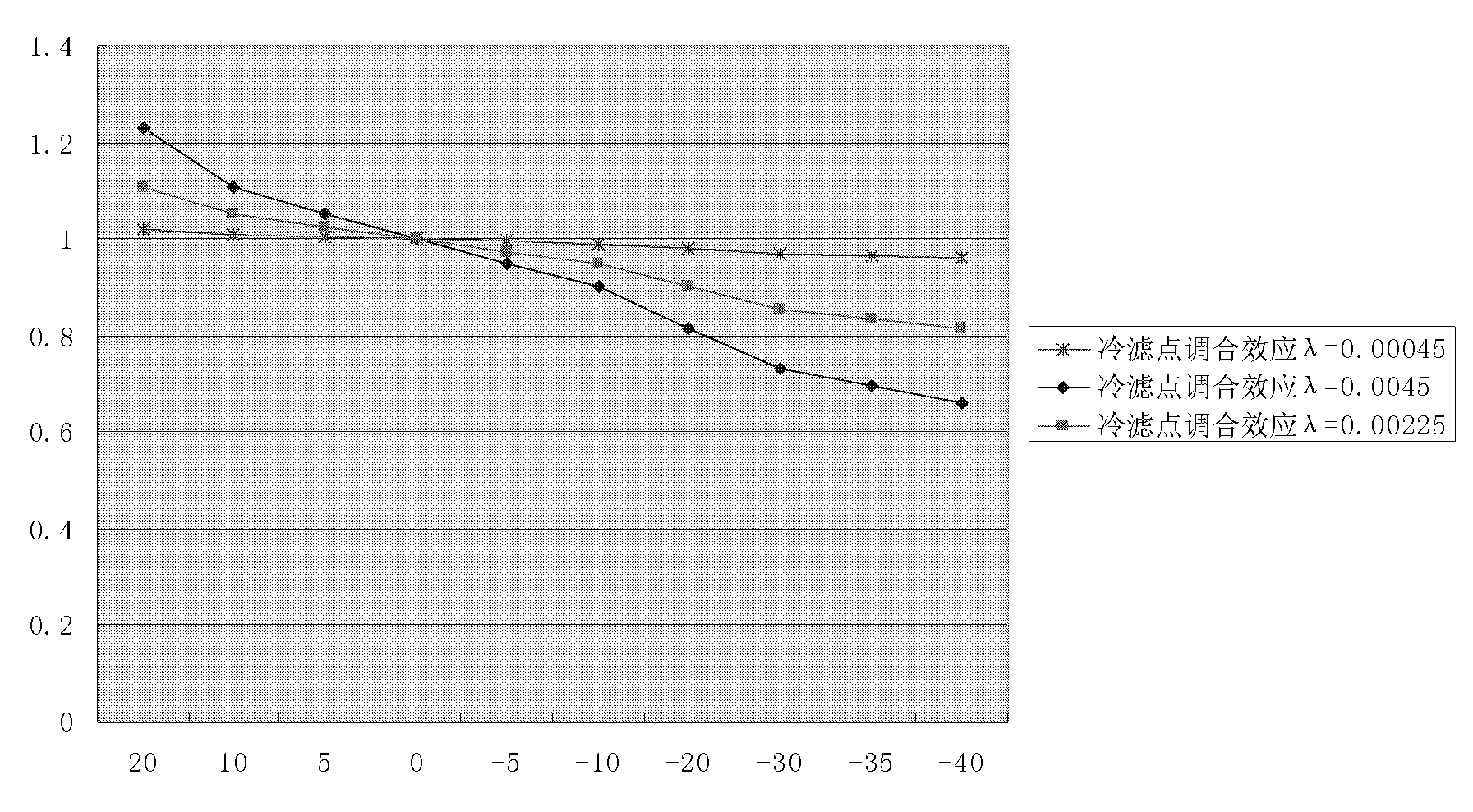

[0024] figure 2 The volume blending index curves of the component oils are given. The abscissa of the figure is the cold filter point value (°F) of the component oil, and the ordinate is the volume blending index...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com