Single crawler type wall climbing robot based on electrostatic absorption principle

A wall-climbing robot and electrostatic adsorption technology are applied in the field of wall-climbing robots, which can solve the problems of narrow range of wall materials, inability to work for a long time, and difficulty in miniaturization of robots, and achieve the effects of compact structure, low cost and low power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

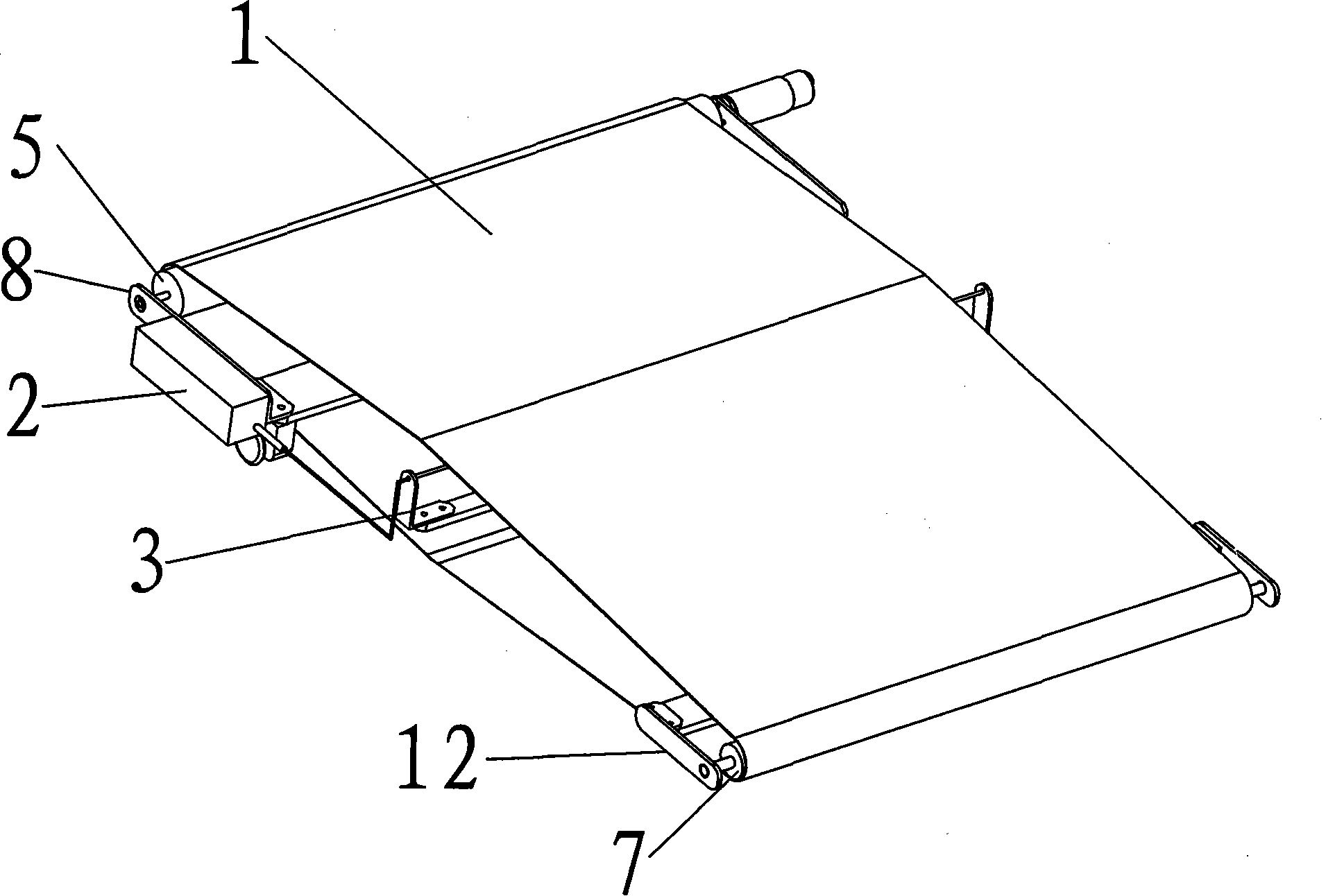

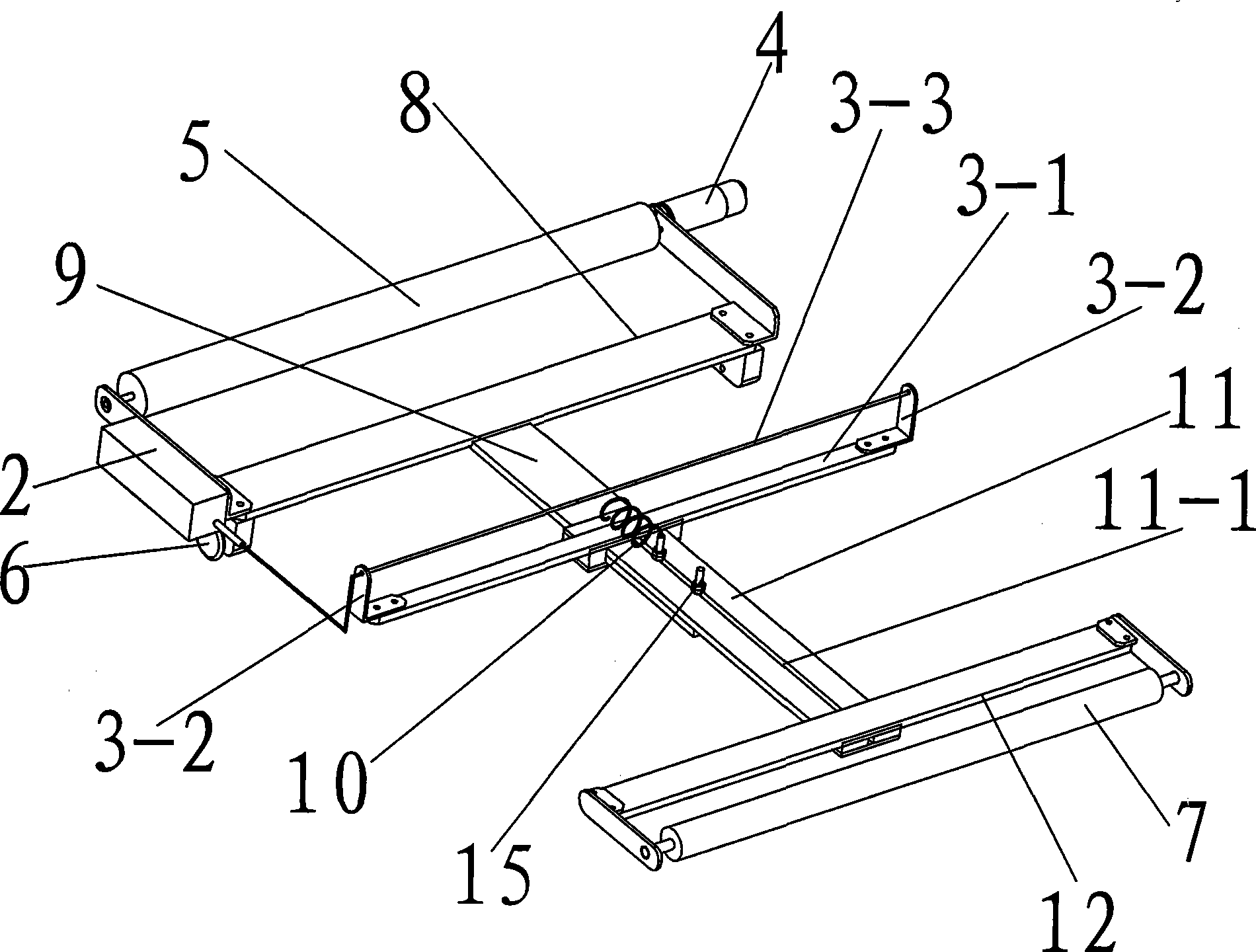

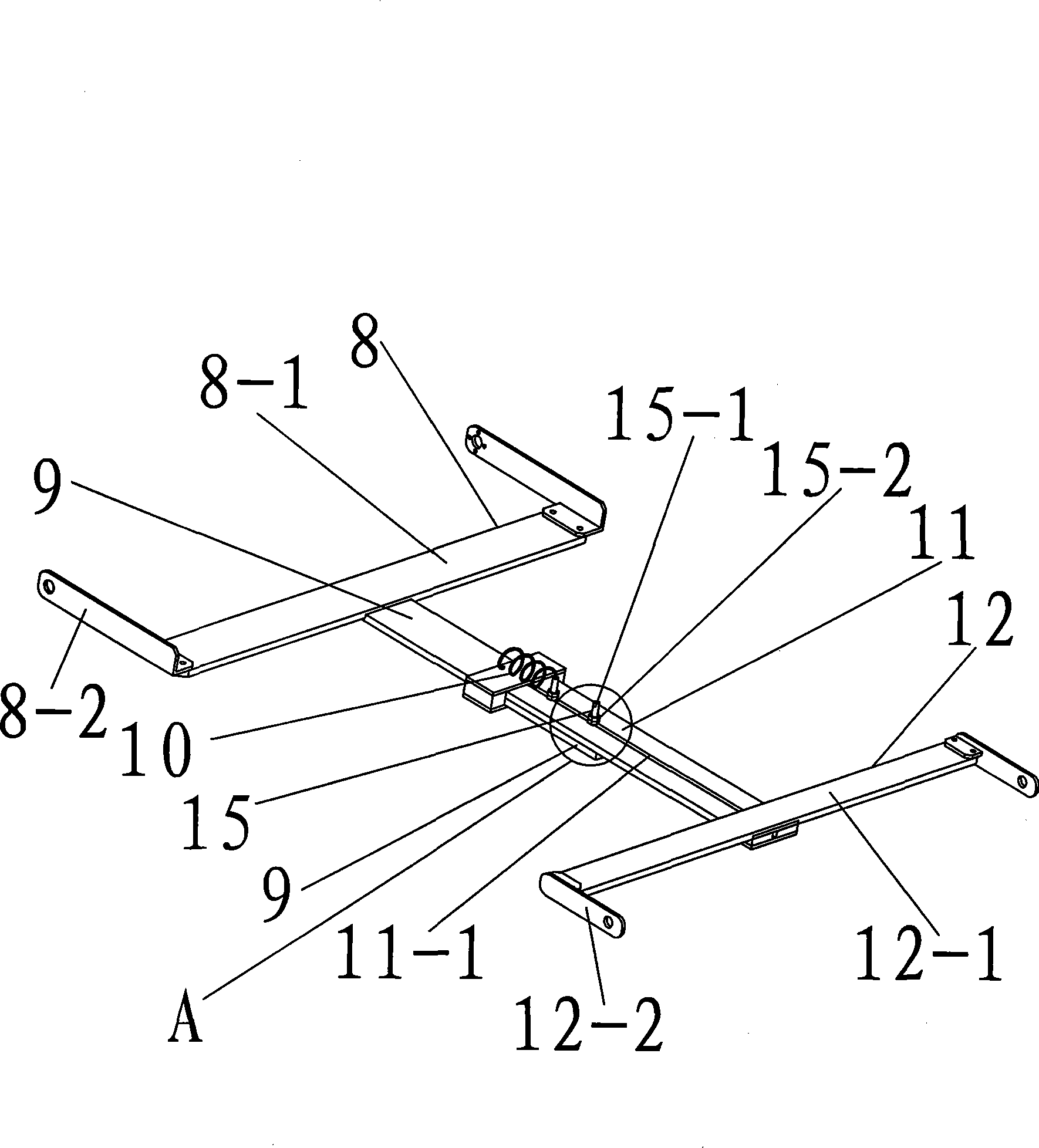

[0010] Specific implementation mode one: as Figure 1-5 As shown, the single-crawler wall-climbing robot based on the electrostatic adsorption principle described in this embodiment includes a robot body, a flexible aluminized film crawler 1, a DC high-voltage module 2, and an electrode guiding mechanism 3; the flexible aluminized film crawler 1 and the DC high-voltage The module 2 is connected by the electrode guide mechanism 3; the flexible aluminized film crawler 1 is covered on the robot body; the robot body is driven by the driving roller motor 4, the driving roller 5, the induced roller 7, the driving roller bracket 8, the sliding bottom plate 9, the spring 10, Sliding guide plate 11, inducing roller support 12 and at least two guiding and positioning rods 15 are composed; one end of sliding bottom plate 9 is overlapped with one end of sliding guiding plate 11, and long through hole 11-1 is arranged on sliding guiding plate 11, described One end of at least two guiding a...

specific Embodiment approach 2

[0011] Specific implementation mode two: as Figure 1-5 As shown, at least two guide and positioning rods 15 in this embodiment are composed of bolts 15-1 and nuts 15-2, each bolt 15-1 passes through the sliding guide plate 11 and its passing end is connected to the corresponding nut 15 -2 connections. The guide and positioning bar 15 composed of bolts 15-1 and nuts 15-2 has a simple structure and is easy to realize the positioning of the sliding guide plate 11 along its length direction and thickness direction. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0012] Specific implementation mode three: as Figure 1-5 As shown, the active roller bracket 8 in this embodiment is composed of the active roller bracket main body 8-1 and two active roller connectors 8-2, and the two ends of the active roller bracket main body 8-1 pass through the active roller connectors 8-2 Connect with the two ends of driving roller 5. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com