Preparation method of special wholewheat staple food flour with long shelf life

A technology of shelf life and special flour is applied in the field of preparation of special flour for whole wheat staple food with long shelf life, which can solve the problems of insufficient nutrients, poor palatability of whole wheat flour, short product shelf life, etc., and achieves the improvement and protection of water-soluble dietary fiber. Nutrient content and bioactive substances, the effect of low equipment operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

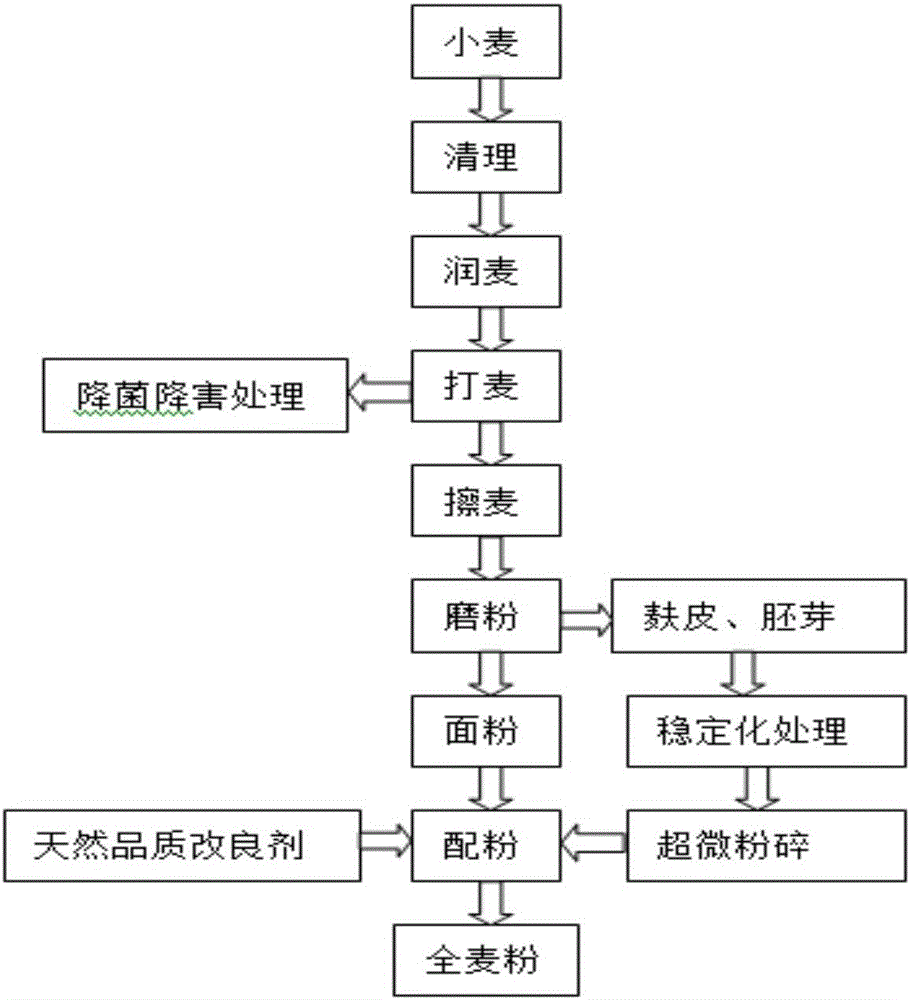

Method used

Image

Examples

Embodiment 1

[0040] a. The raw material wheat is cleaned, tempered, threshed, rubbed and other processes are removed, and then peeled to obtain clean wheat kernels, which are then ground and sieved to separate germ and bran to obtain crushed endosperm.

[0041] b, adjusting the humidity of the germ and bran separated in step (a) to 35%, and then carrying out microwave treatment. The microwave conditions are as follows: the thickness of the germ and bran is 10cm, the microwave power is 800W, and the treatment time is 200s, so that the humidity of the germ and bran after treatment is reduced to 20%.

[0042] c. Extruding and puffing the germ and bran after the microwave treatment in step (b). The extrusion conditions are as follows: the rotational speed of the extrusion rod is 120 rpm, the extrusion force is 8.0 MPa, the extrusion temperature is 130° C., the shear rate of the screw is 150, and the processing time is 60 s.

[0043] d. Low-temperature pulverizing the germ and bran after extru...

Embodiment 2

[0046] a. The raw material wheat is cleaned, tempered, threshed, rubbed and other processes are removed, and then peeled to obtain clean wheat kernels, which are then ground and sieved to separate germ and bran to obtain crushed endosperm.

[0047] b, adjusting the humidity of the germ and bran separated in step (a) to 30% and then carrying out microwave treatment. The microwave conditions are as follows: the thickness of germ and bran is 5cm, the microwave power is 600W, and the treatment time is 150s, so that the humidity of germ and bran after treatment is reduced to 15%.

[0048]c. Extruding and puffing the germ and bran after the microwave treatment in step (b). The extrusion conditions are as follows: the rotational speed of the extrusion rod is 100 rpm, the extrusion force is 6.0 Mpa, the extrusion temperature is 130° C., the shear rate of the screw is 150, and the processing time is 50 s.

[0049] d. Grinding the germ and bran after extrusion and puffing in step (c) b...

Embodiment 3

[0052] a. The raw material wheat is cleaned, tempered, threshed, rubbed and other processes are removed, and then peeled to obtain clean wheat kernels, which are then ground and sieved to separate germ and bran to obtain crushed endosperm.

[0053] b, adjusting the humidity of the germ and bran separated in step (a) to 25%, and then carrying out microwave treatment. The microwave conditions are as follows: the thickness of the germ and bran is 10cm, the microwave power is 400W, and the treatment time is 100s, so that the humidity of the germ and bran after treatment is reduced to 15%.

[0054] c. Extruding and puffing the germ and bran after the microwave treatment in step (b). The extrusion conditions are as follows: the rotation speed of the extrusion rod is 80 rpm, the extrusion force is 5.0 MPa, the extrusion temperature is 120° C., the shear rate of the screw is 150, and the processing time is 40 s.

[0055] d. Grinding the germ and bran after extruding and puffing in st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com