Patents

Literature

97results about How to "Sufficient adhesiveness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

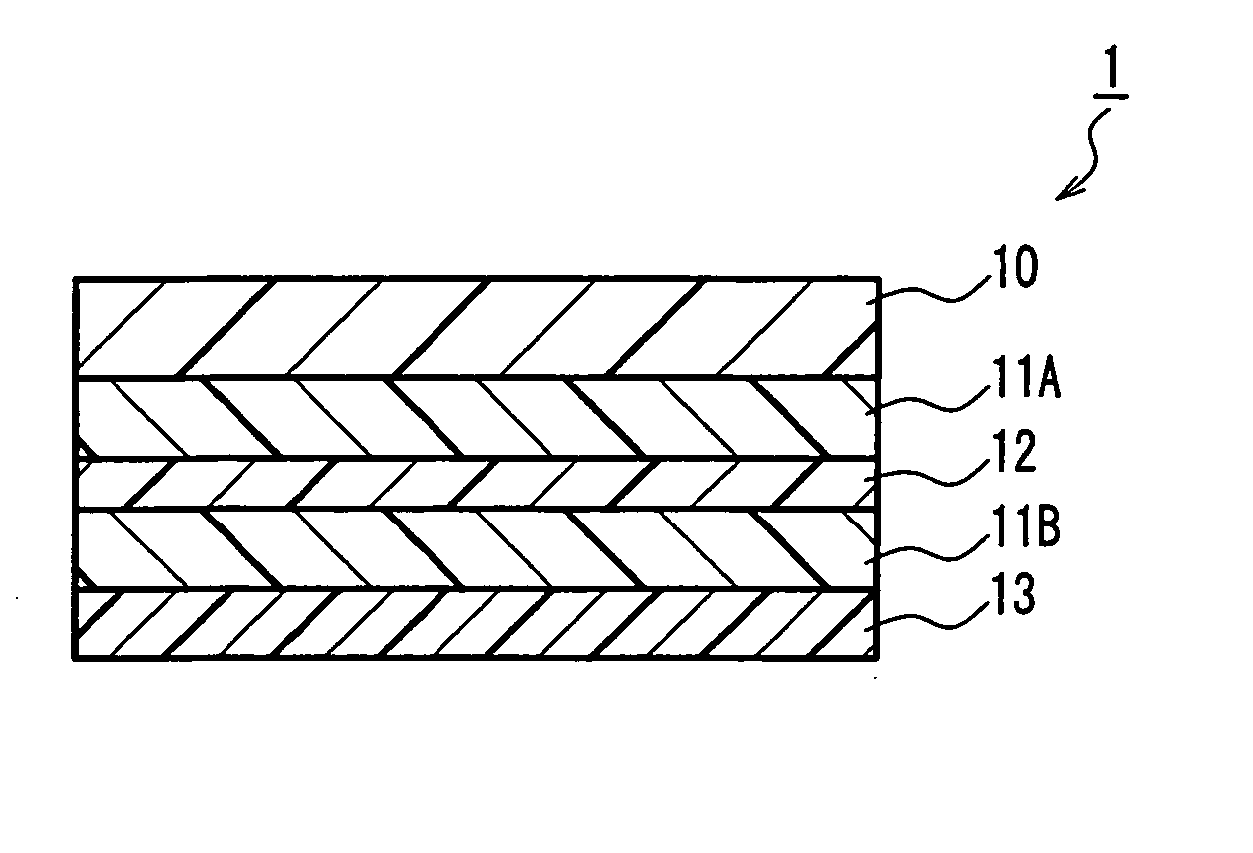

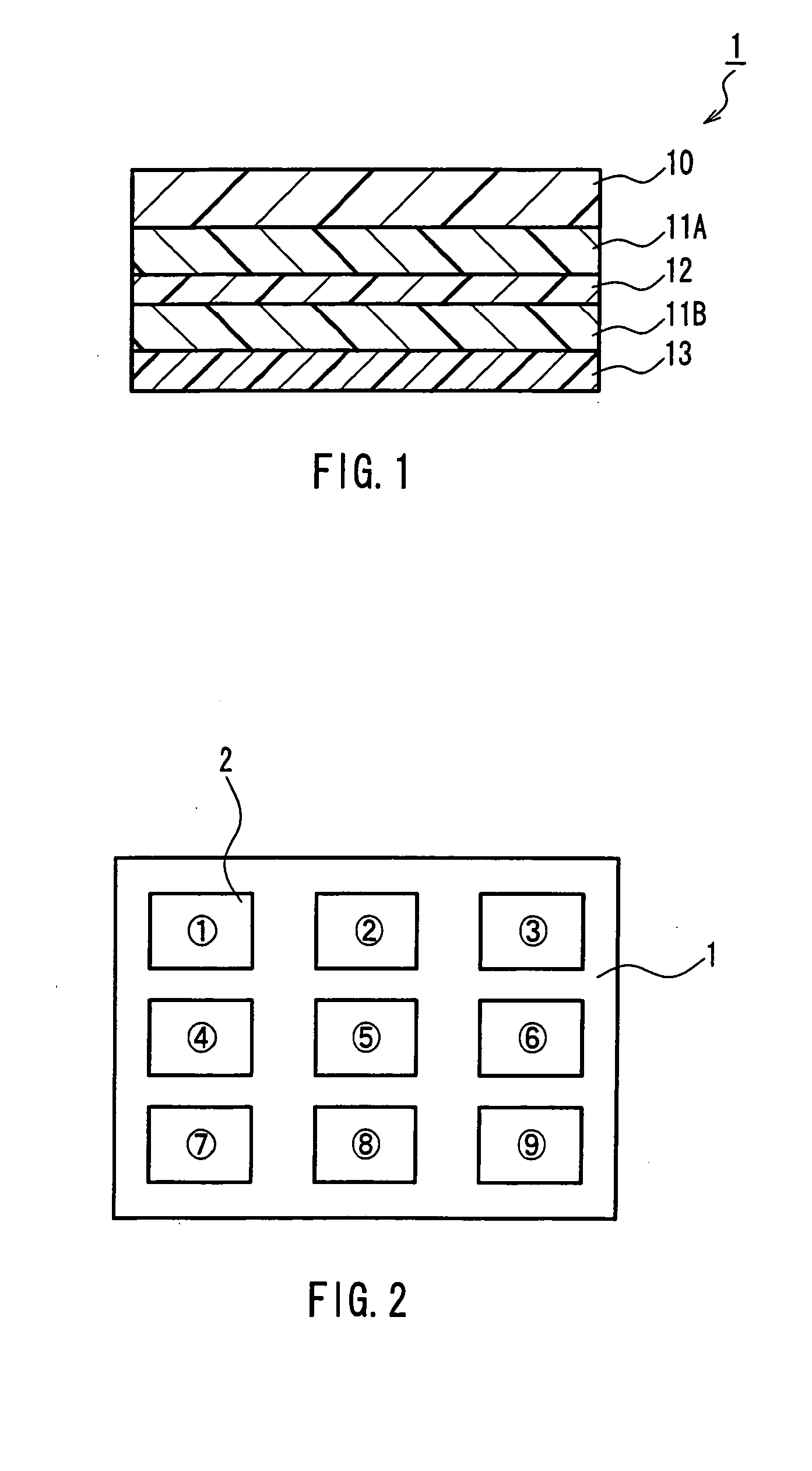

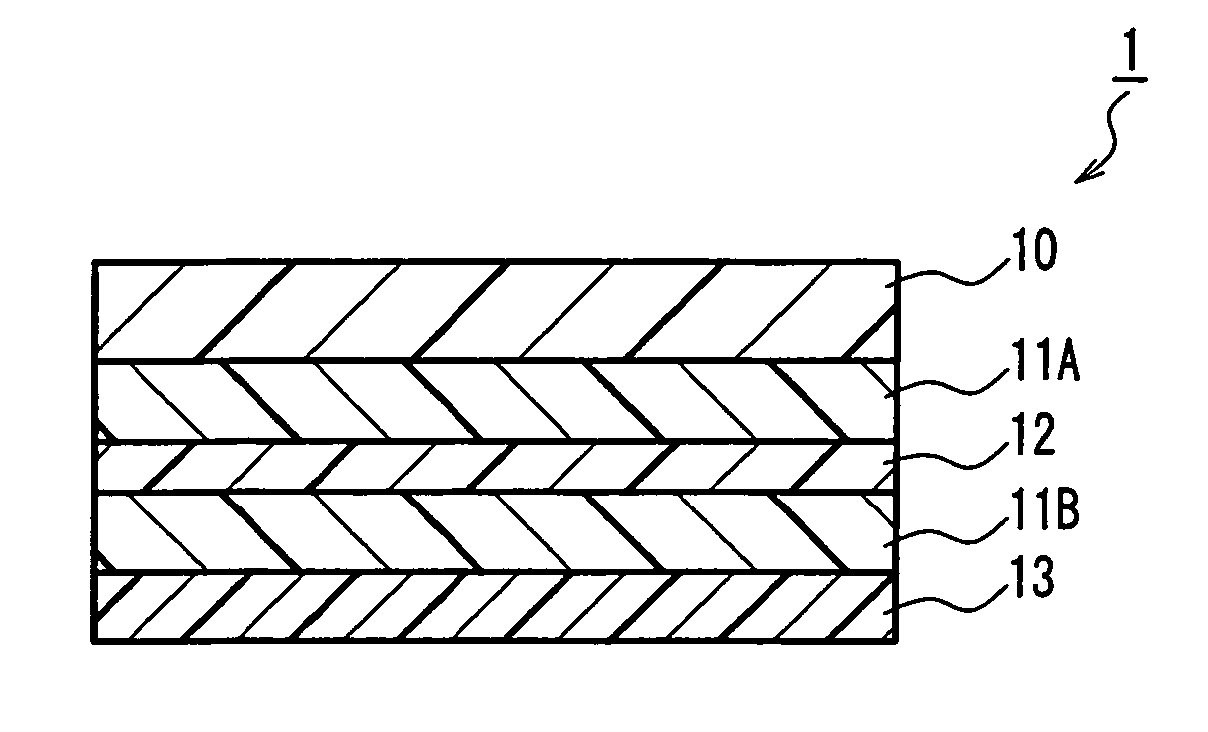

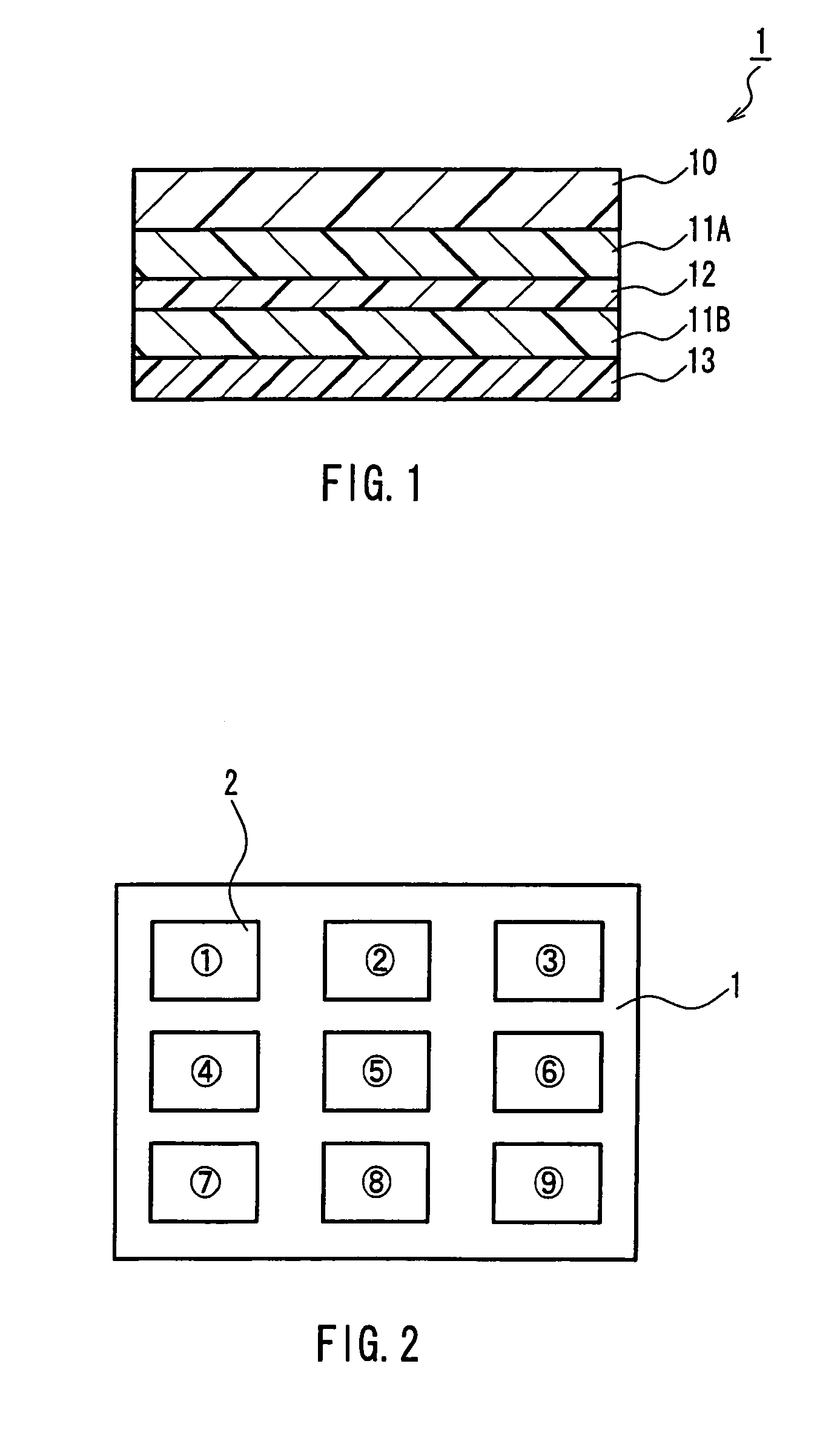

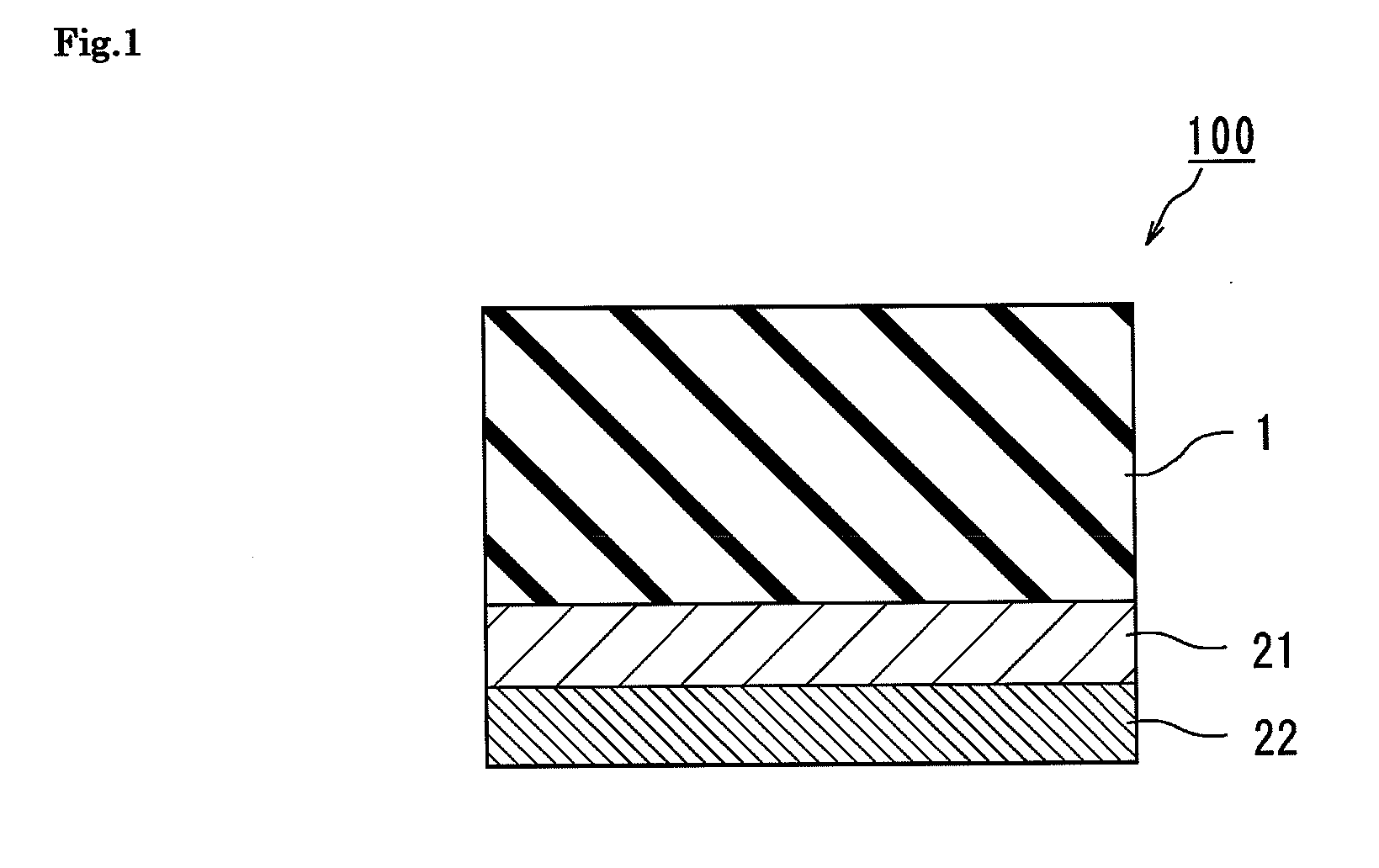

Polarization plate with optical compensation layer and image display device

InactiveUS20050117217A1Sufficient adhesivenessEasily reattachedLiquid crystal compositionsElectroluminescent light sourcesPolarizerEngineering

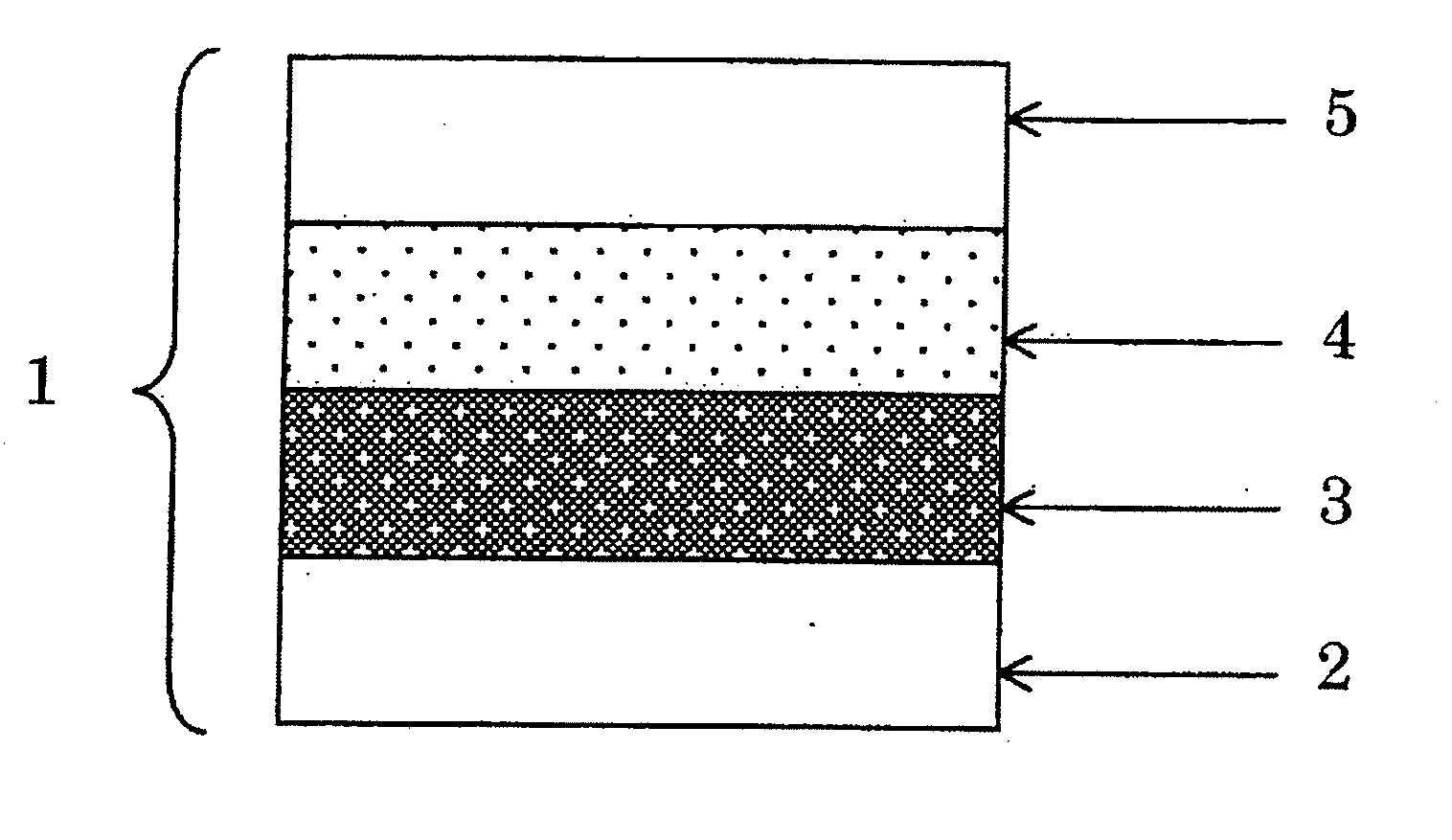

A polarizing plate with an optical compensation layer is provided, which has an excellent peelability and is easy to reattach after mounted on an image display apparatus. A pressure-sensitive adhesive layer satisfying the condition (I) below is formed on both surfaces of an optical compensation layer, and one of the pressure-sensitive adhesive layers is further laminated with a polarizing plate. condition (I): in the case where a pressure-sensitive adhesive layer causing the optical compensation layer and the polarizing plate to adhere to each other is expressed by a pressure-sensitive adhesive layer (A) and the other pressure-sensitive adhesive layer is expressed by a pressure-sensitive adhesive layer (B) and attached to a glass substrate, the pressure-sensitive adhesive layer (A) causing the optical compensation layer and the polarizing plate to adhere to each other has an adhesive strength exceeding 12 N / 25 mm, and the pressure-sensitive adhesive layer (B) causing the optical compensation layer and the glass substrate to adhere to each other has an adhesive strength of 1 to 10 N / 25 mm.

Owner:NITTO DENKO CORP

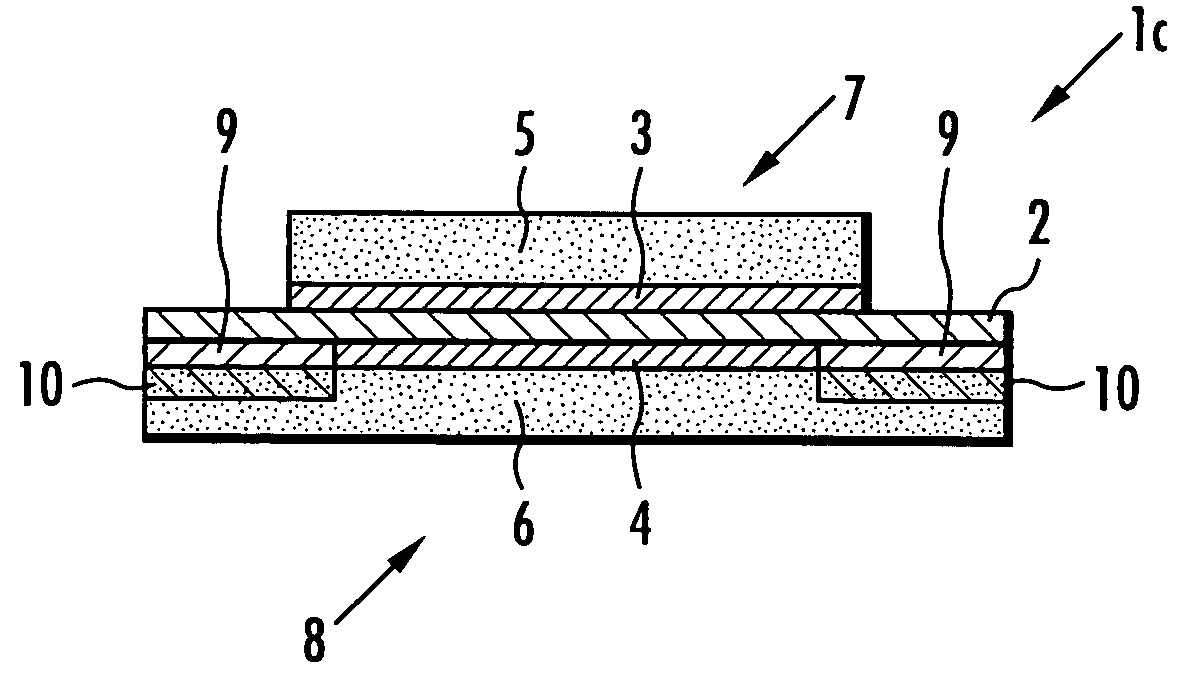

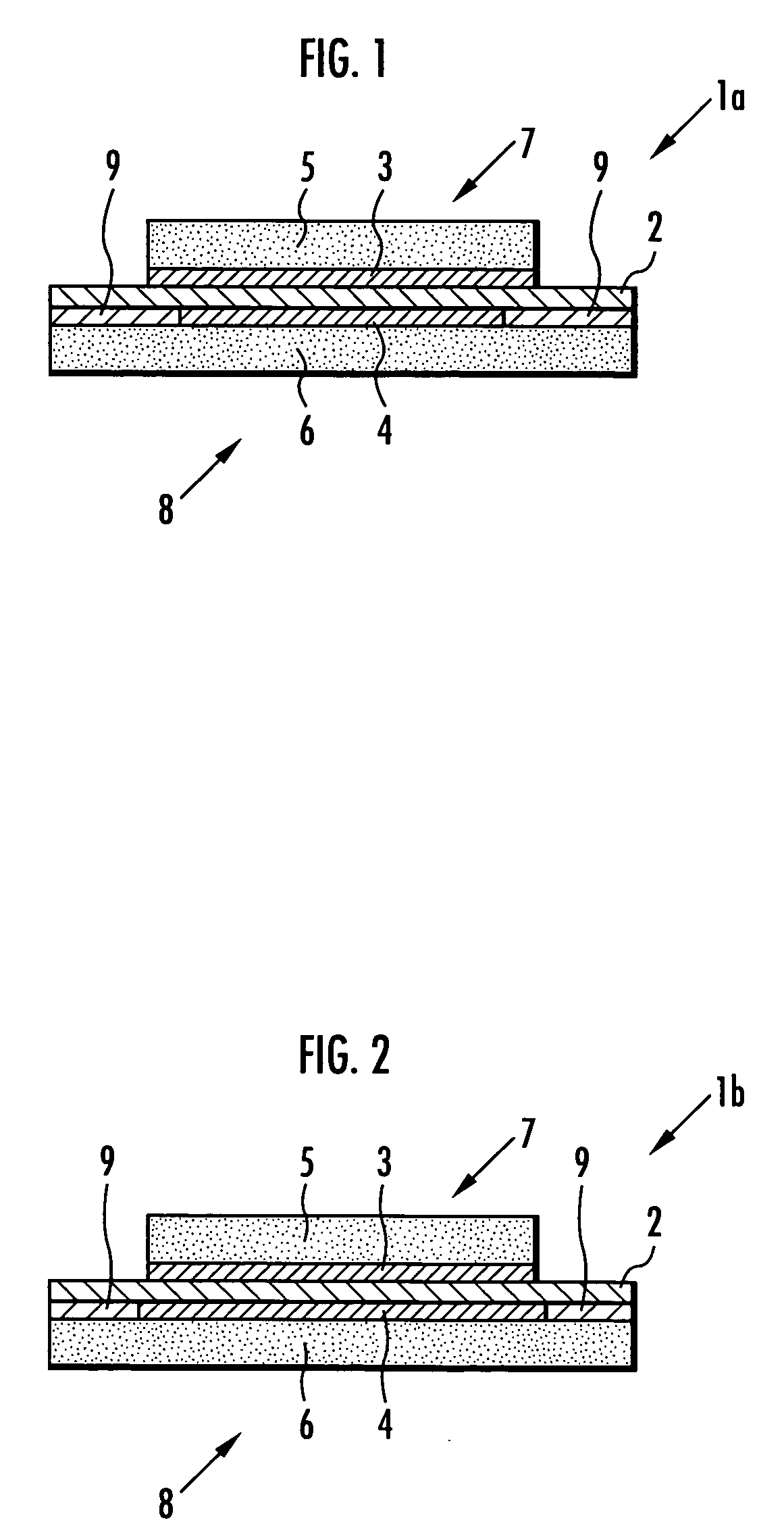

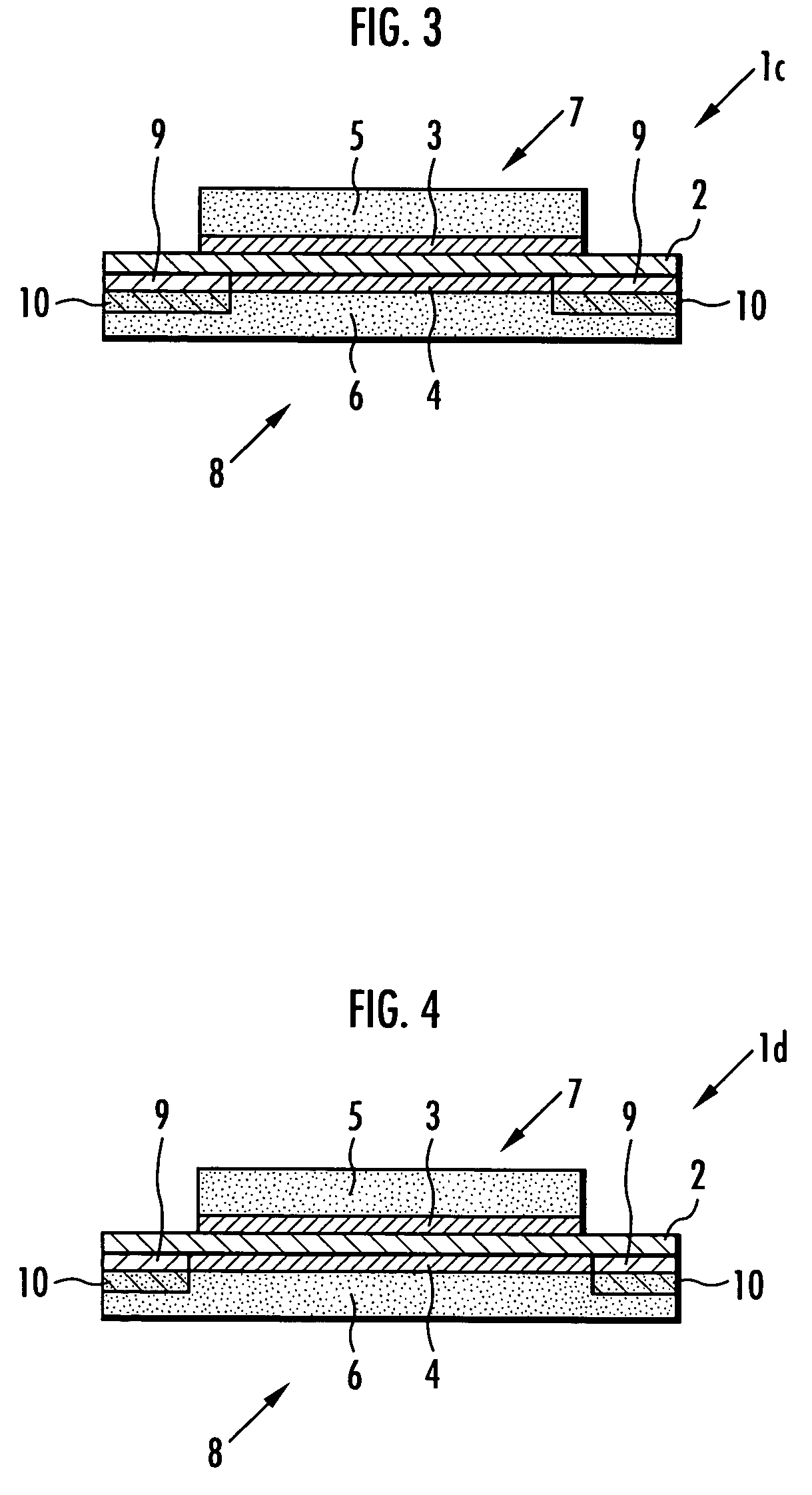

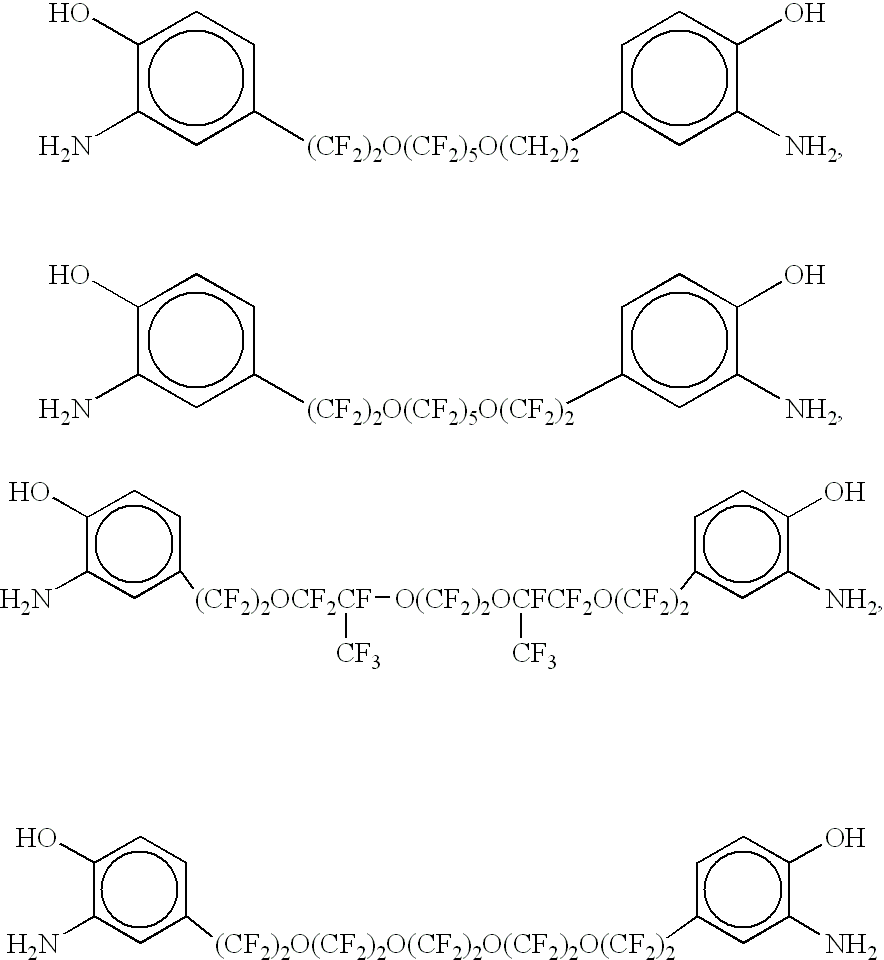

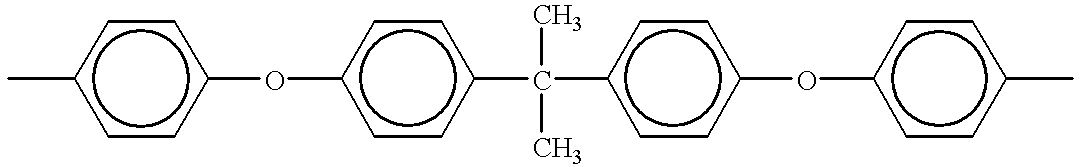

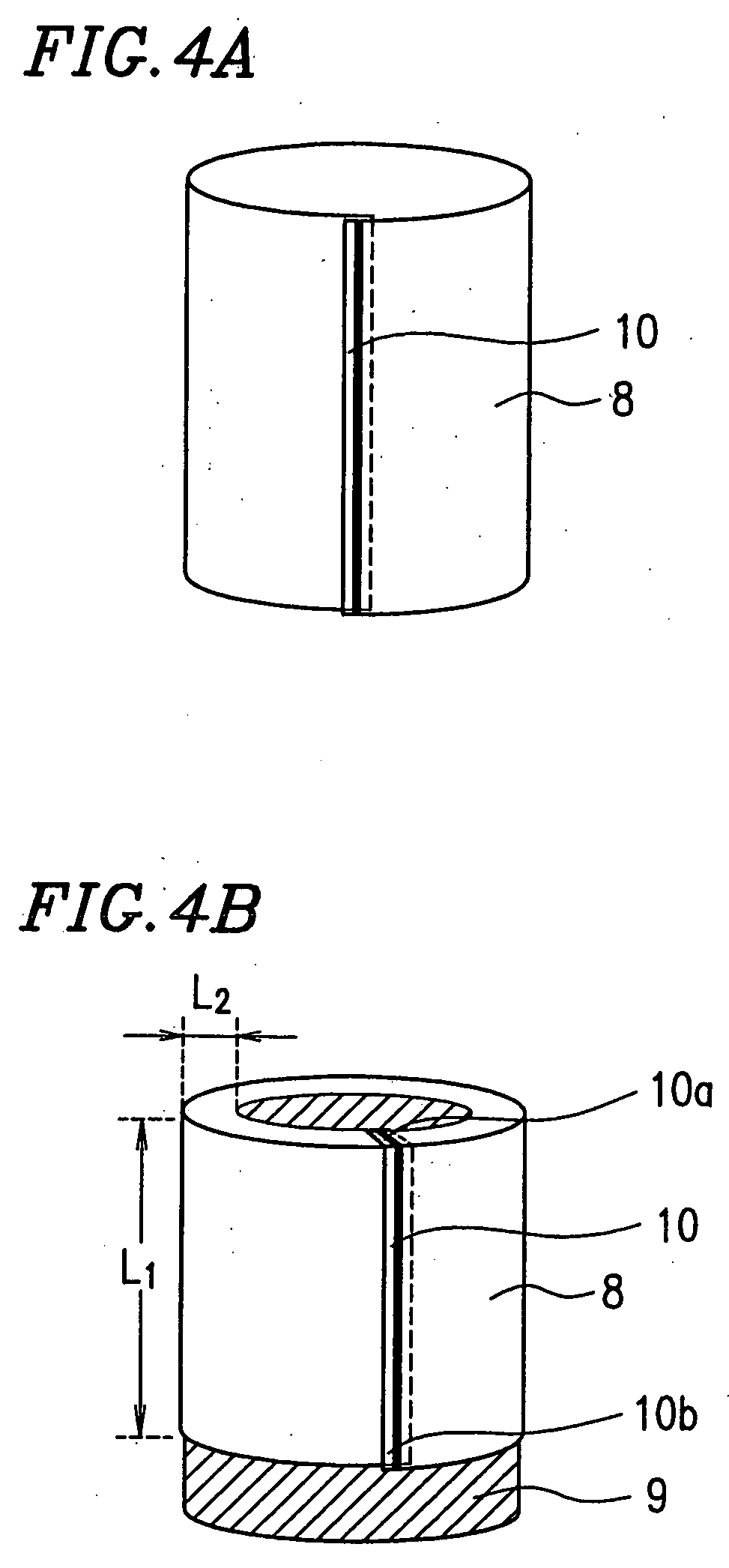

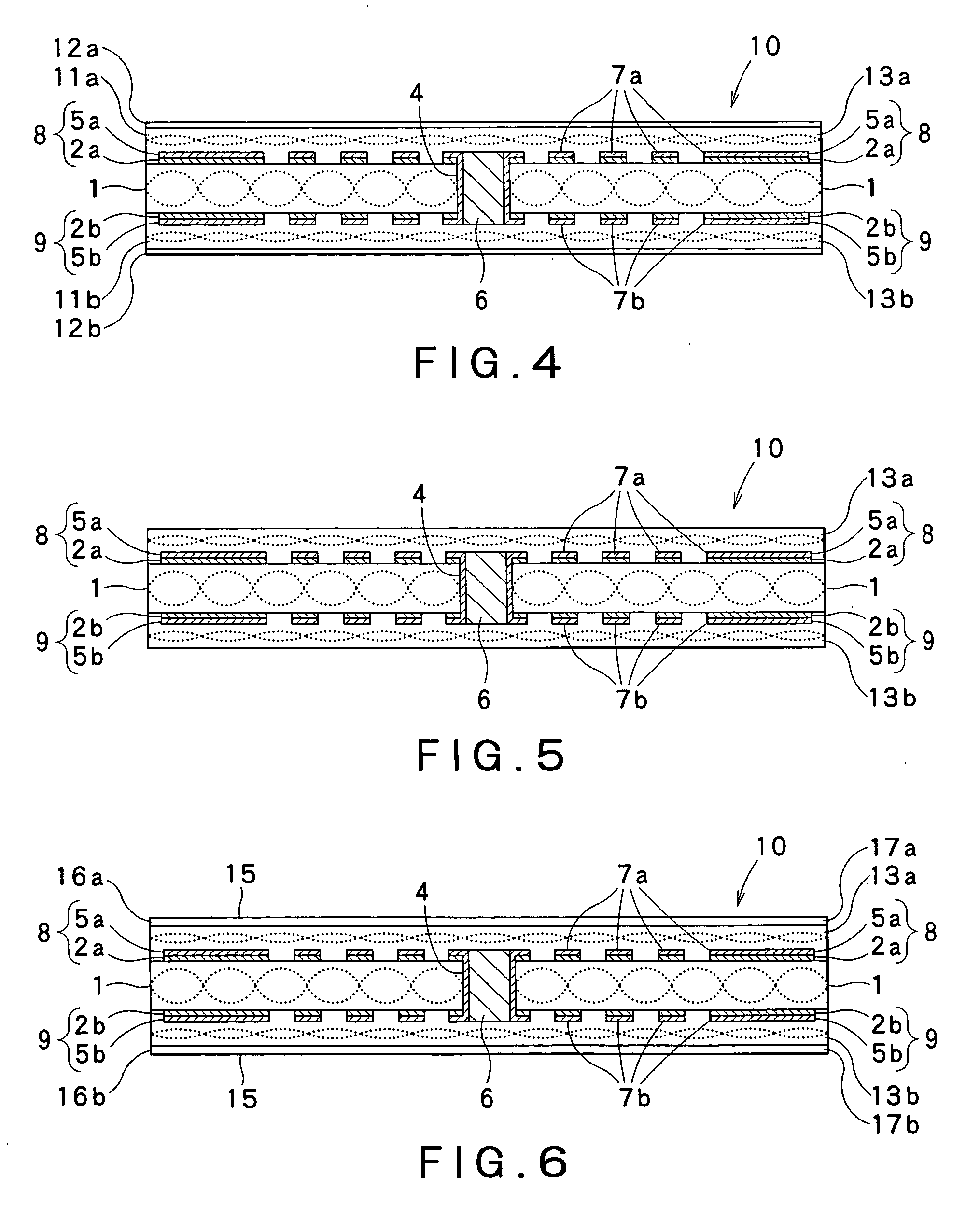

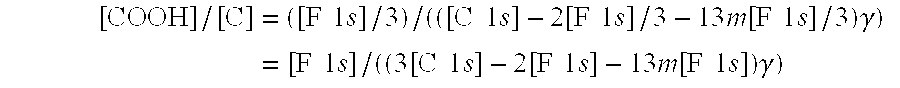

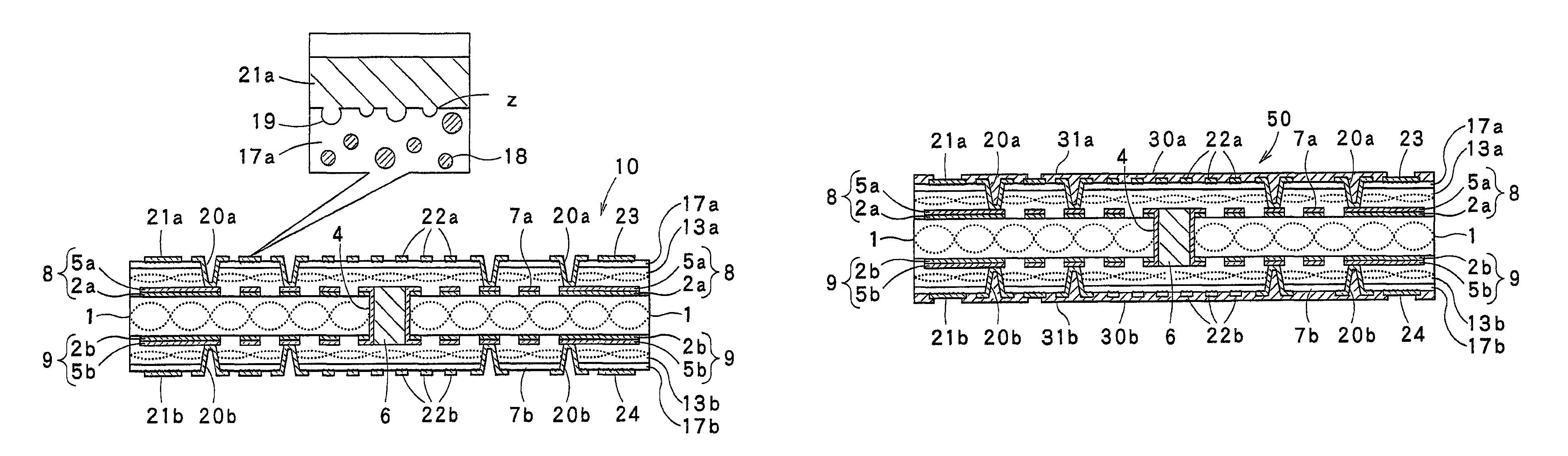

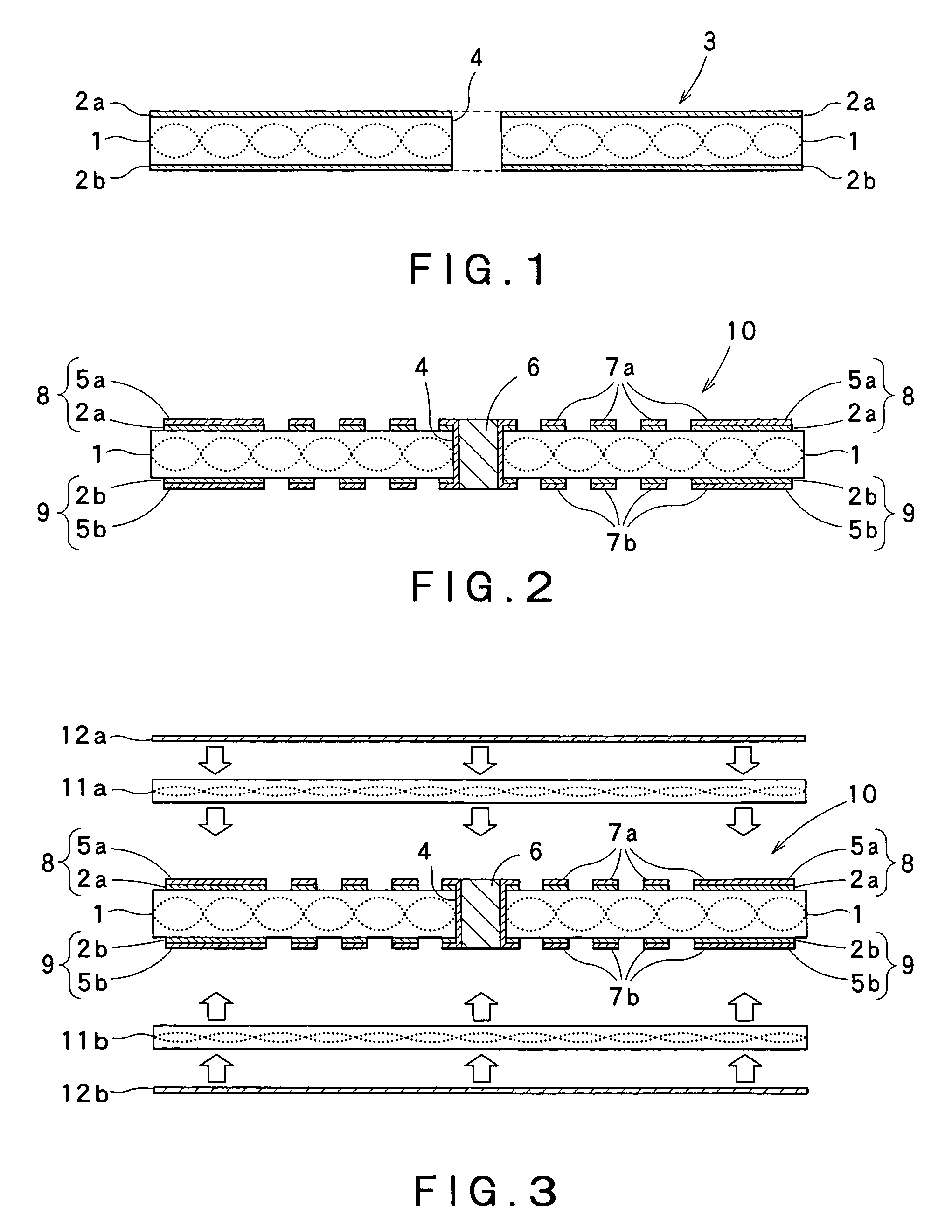

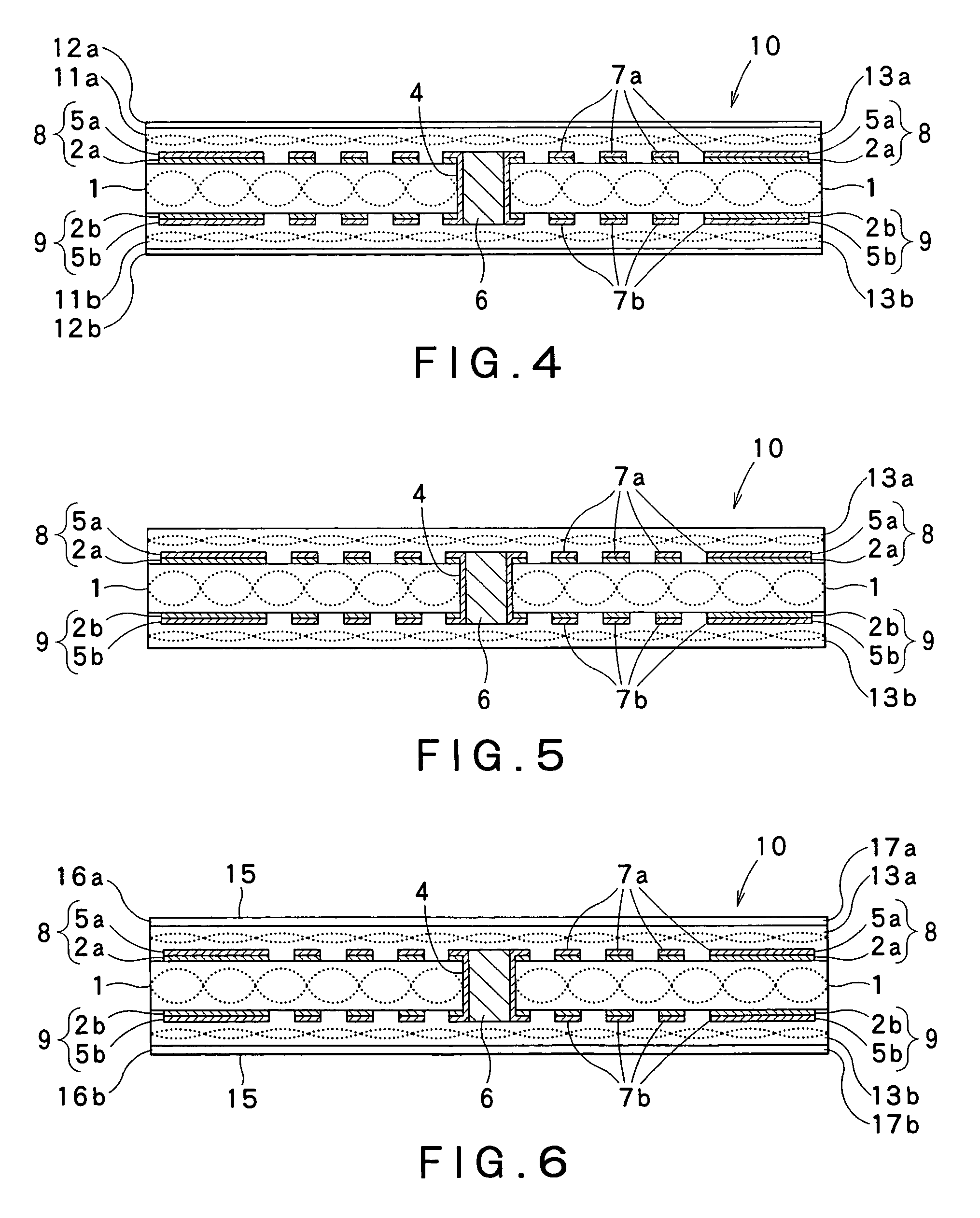

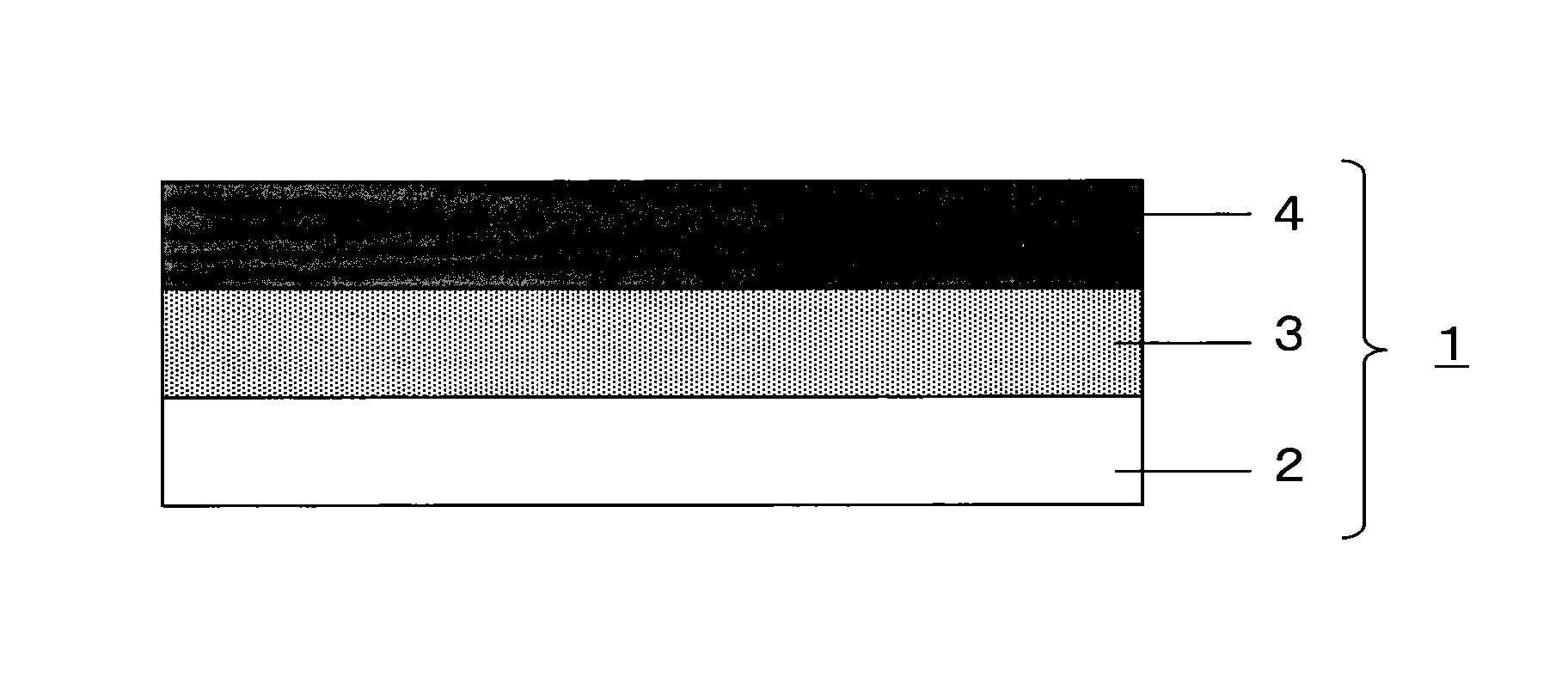

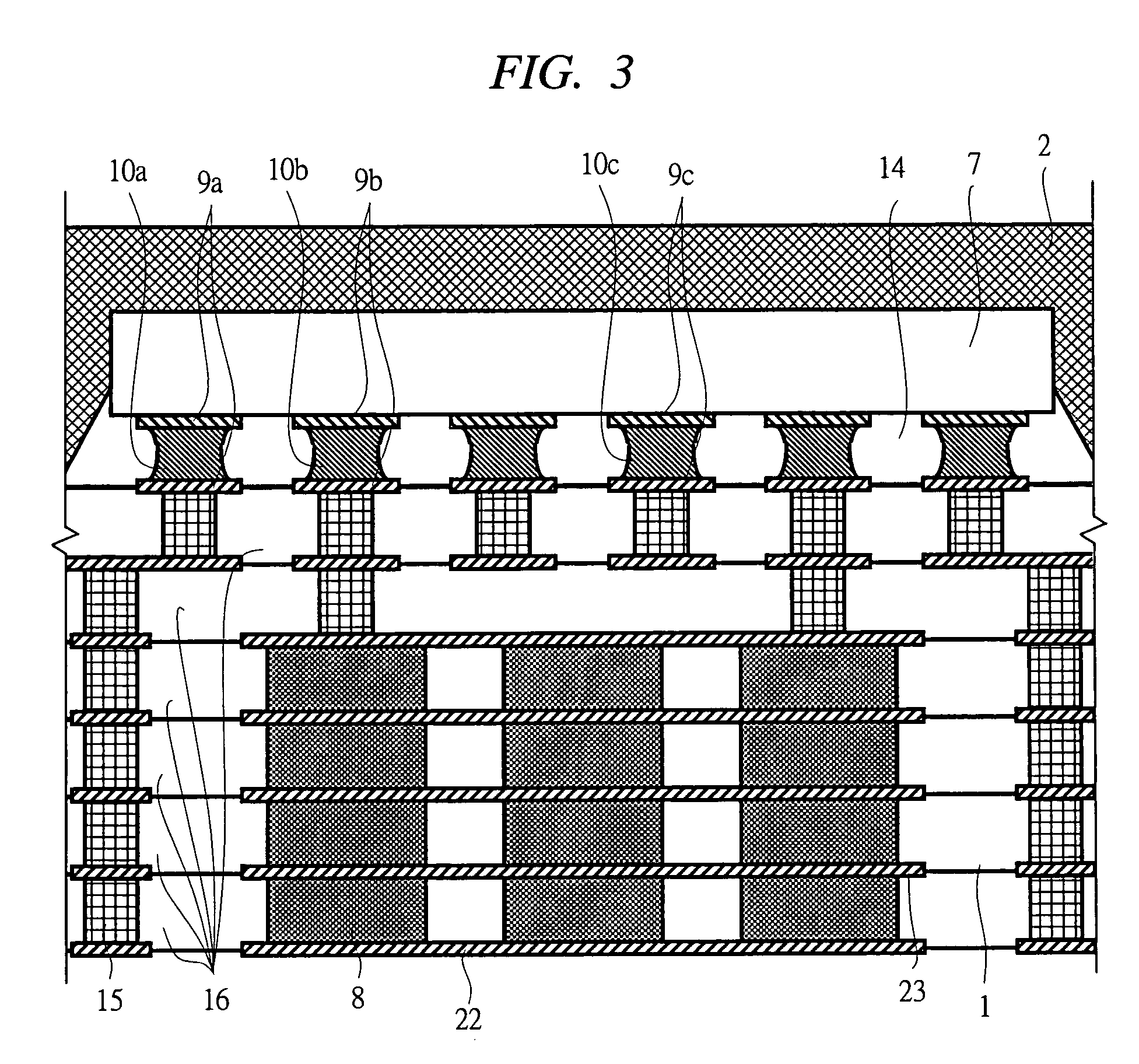

Membrane-electrode structure and method for producing the same

InactiveUS20050181267A1Avoid damageStrong adhesionSolid electrolytesCell electrodesPolymer electrolytesFuel cells

The present invention provides a membrane-electrode structure having an adhesive support layer that does not peel off the solid polymer electrolyte membrane in a high-temperature high-humidity environment during the operation of a fuel cell, and a producing method thereof. The present invention also provides a polymer electrolyte fuel cell that uses the membrane-electrode structure, and an electric apparatus and a transport apparatus that use the polymer electrolyte fuel cell. The solid polymer electrolyte membrane 2 is sandwiched by catalyst layers 3 and 4 positioned in the inner circumferential side thereof, and one face is coated with the catalyst layers 3 and 4 and the adhesive support layer 9. The adhesive support layer 9 is formed of an adhesive that has fluorine atoms in the molecular structure. The adhesive has a tensile elongation at break of 150% or more after curing. Having porous diffusion layers 5 and 6 that coat the catalyst layers 3, 4 and the adhesive support layer 9, the adhesive support layer 9 is integrated with the diffusion layer 6 through adhesive permeating layers 10. Irregularity that has a maximum height Rmax of surface roughness within a range between 3 and 20 μm is formed on the area coated by the adhesive support layer 9 of the solid polymer electrolyte membrane 2, and the adhesive support layer 9 is bonded to the area where the irregularity has been formed by pressing under heating.

Owner:HONDA MOTOR CO LTD

Thermoresistance adhesive and semiconductor device using the same

InactiveUS6372859B1Sufficient adhesivenessSecure bondingSemiconductor/solid-state device detailsSolid-state devicesImideAdhesive

A thermoresistance adhesive which does not dissolve in the sealer-composing resins at the sealer molding temperature and is capable of providing a semiconductor chip / lead frame adhesive strength under shear of 1 N / 4 mm2 or greater, and including, for example, amide, imide, ester or ether linkage is suited for use in producing thermoresistance adhesive solutions and thermoresistance resin pastes, and the semiconductor chips, lead frames, films, etc., made by using such an adhesive are suited for providing low-cost semiconductor devices.

Owner:HITACHI CHEM CO LTD

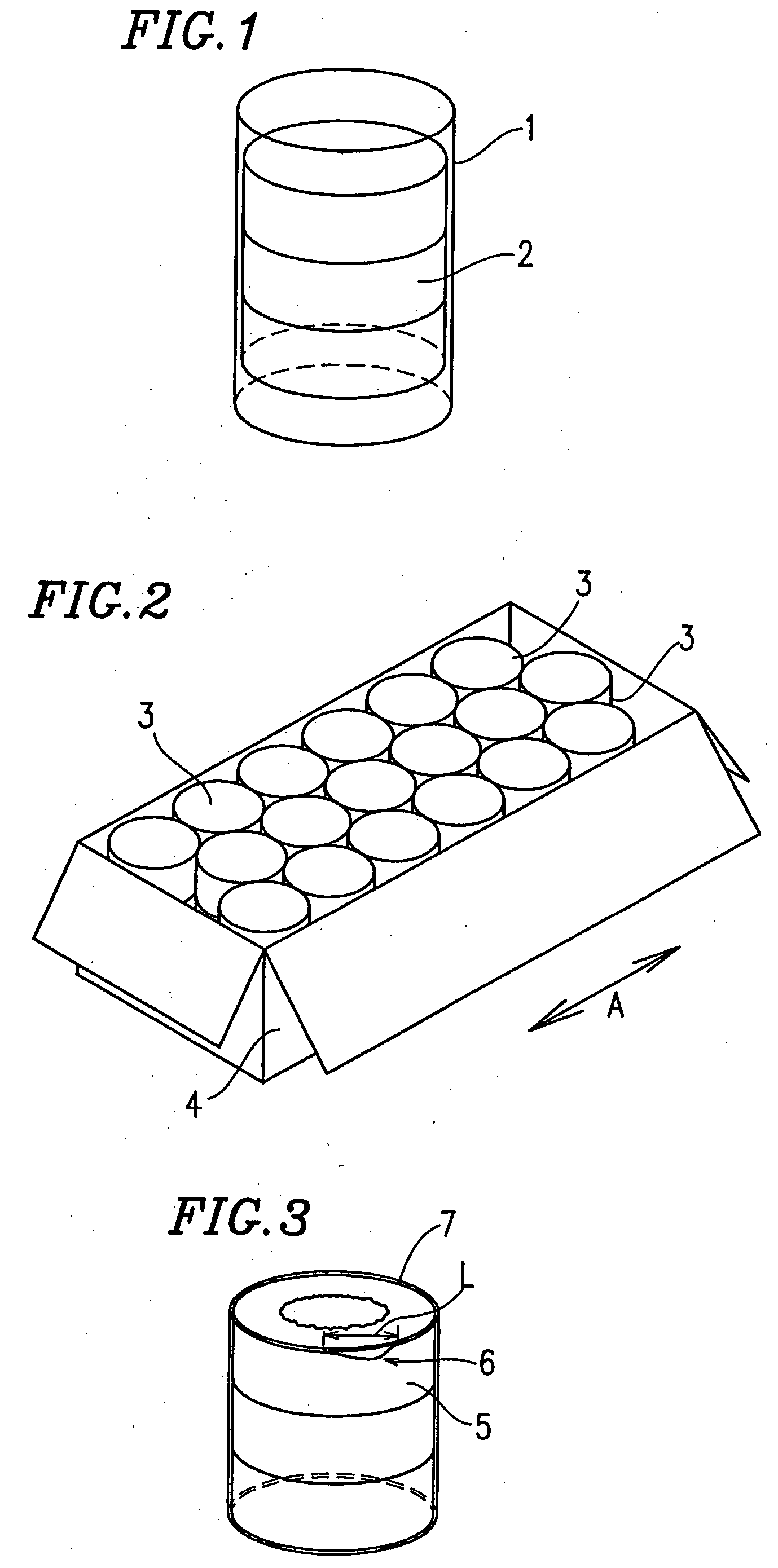

Heat shrinkable polyester film

InactiveUS20050196563A1Improve seismic performanceHigh adhesive retentionEnvelopes/bags making machineryLayered productsPolyesterPolymer science

A heat shrinkable polyester film of the present invention has a transverse tear defect percentage of about 20% or less as determined in the following vibration test: the film is rolled into a tubular shape, two of its opposite edges bonded together, and then the tubular film is placed around a vertical stack (total weight: 660 g) of three food container cans each having a diameter of 72 mm and a height of 55 mm; the can stack with the tubular film placed therearound is passed through a shrink tunnel to shrink the tubular film onto the can stack; a total of 18 packs of such can stacks are placed into a cardboard box having a length of 455 mm, a width of 230 mm and a height of 165 mm (6 packs in the length direction by 3 packs in the width direction), and the cardboard box is sealed; the cardboard box is vibrated along the width direction for 30 min by a stroke of 50 mm and at a vibration rate of 180 reciprocations / min, after which the transverse tearage of the tubular film is visually observed; and the transverse tear defect percentage (%) is determined based on the number of defective packs per 18 packs, wherein the defective pack is any pack having a tear flaw of 30 mm or longer along a can periphery. The heat shrinkable polyester film of the present invention has a good shock resistance during shipping especially under low temperatures, with a good finish after shrinkage and a sufficient solvent adhesiveness. Thus, the heat shrinkable polyester film of the present invention is suitable for use in a multi-packaging label for packaging, inter alia, a stack of cans.

Owner:ITO HIDEKI +4

Polarization plate with optical compensation layer and image display device

InactiveUS7126754B2Sufficient adhesivenessEasily reattachedLiquid crystal compositionsElectroluminescent light sourcesAdhesivePolarizer

Owner:NITTO DENKO CORP

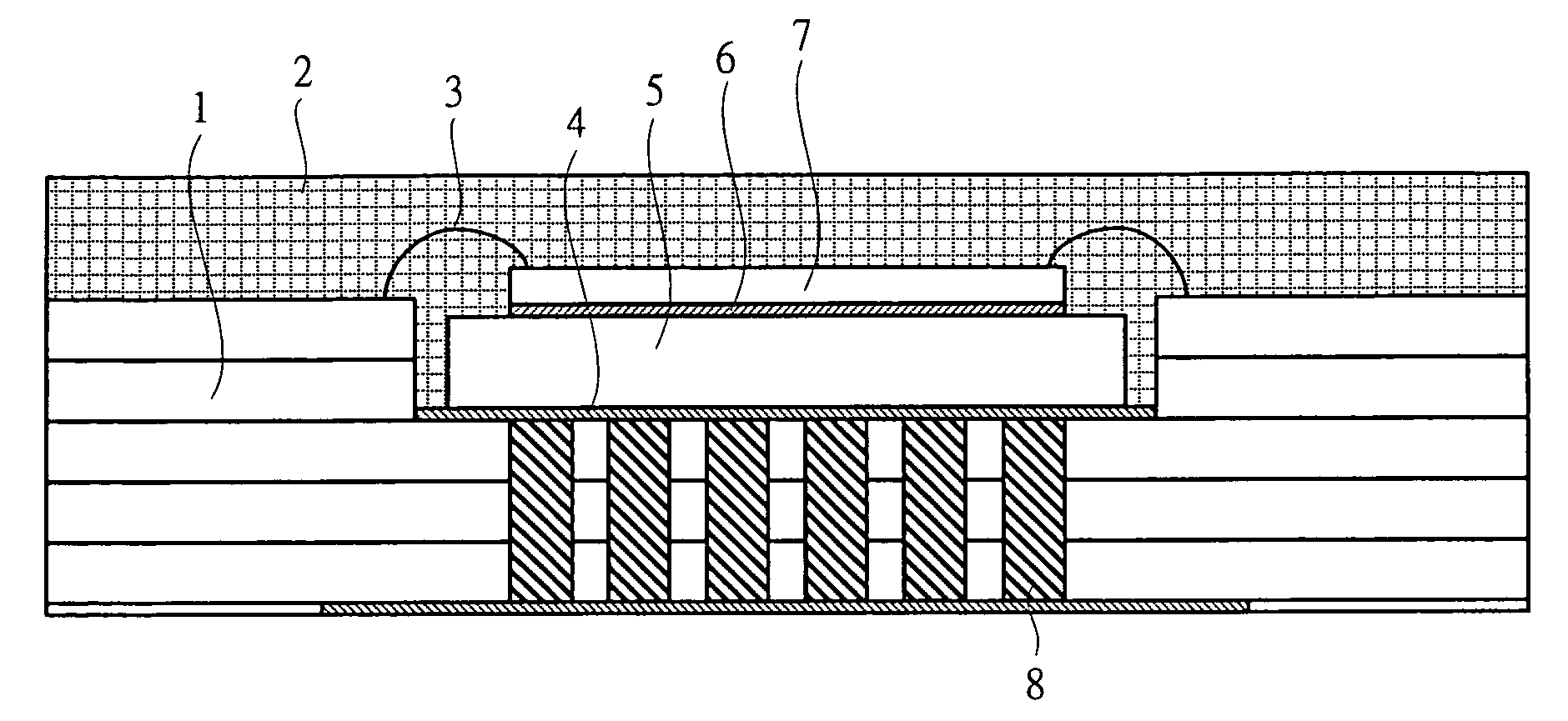

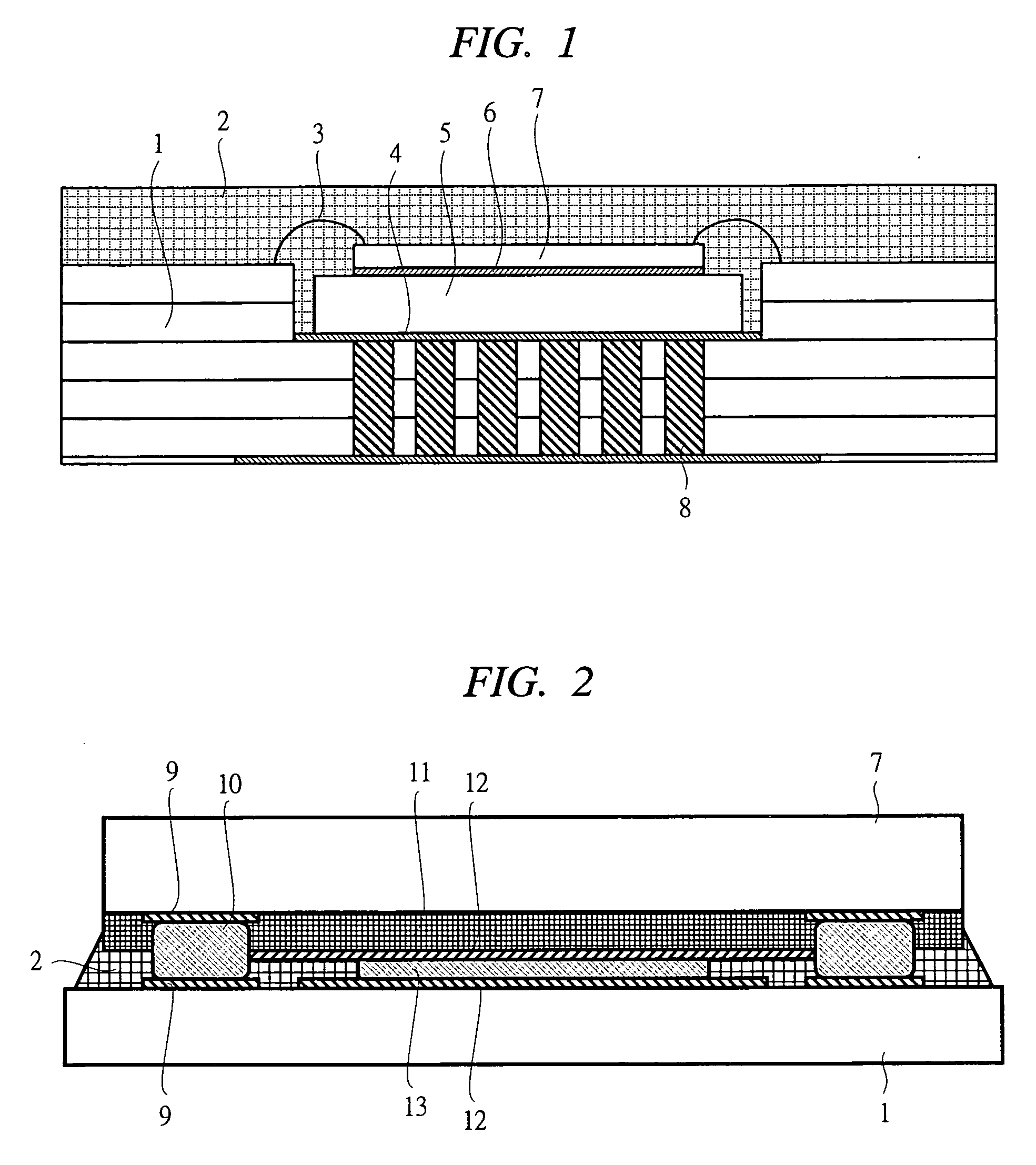

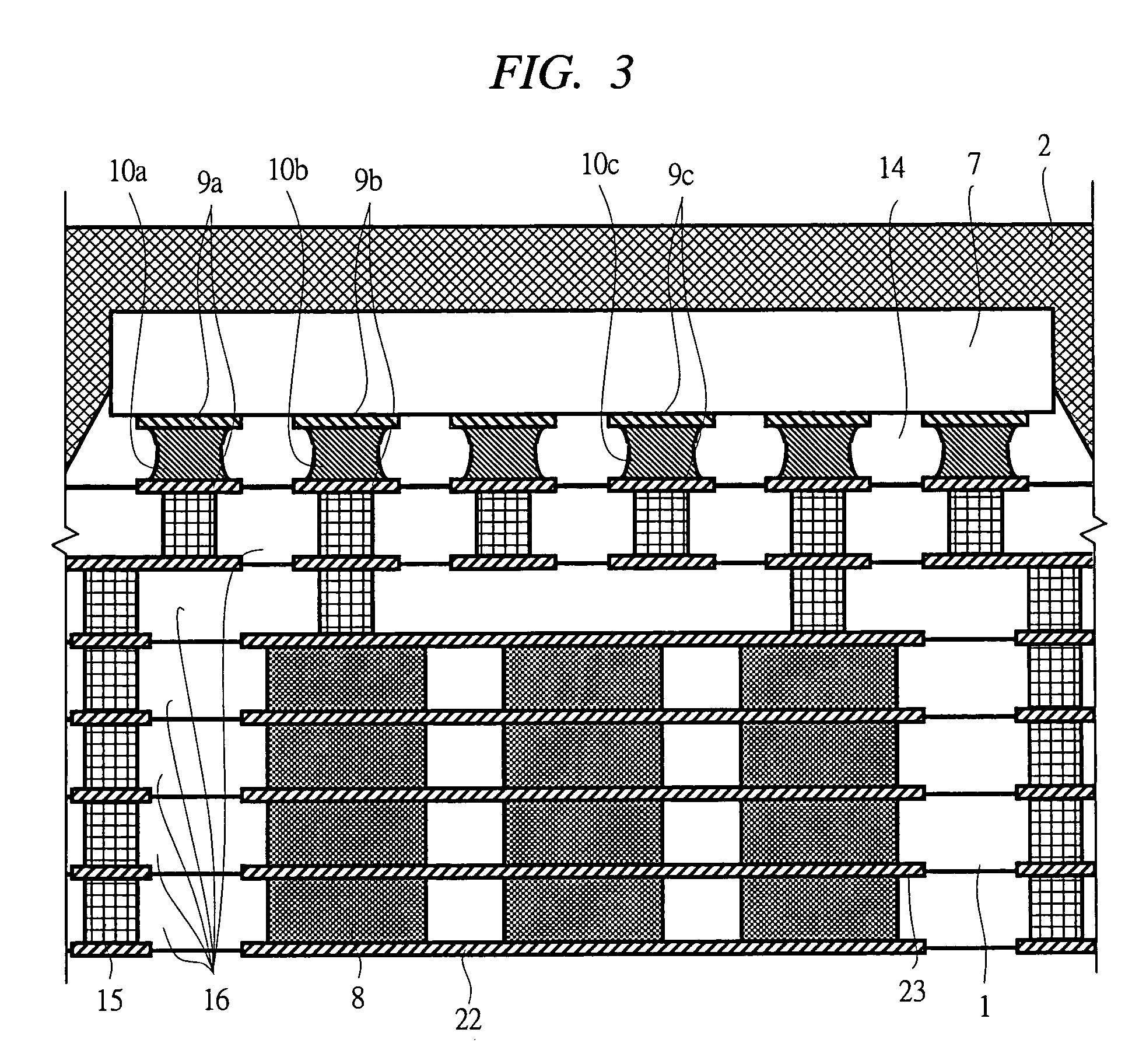

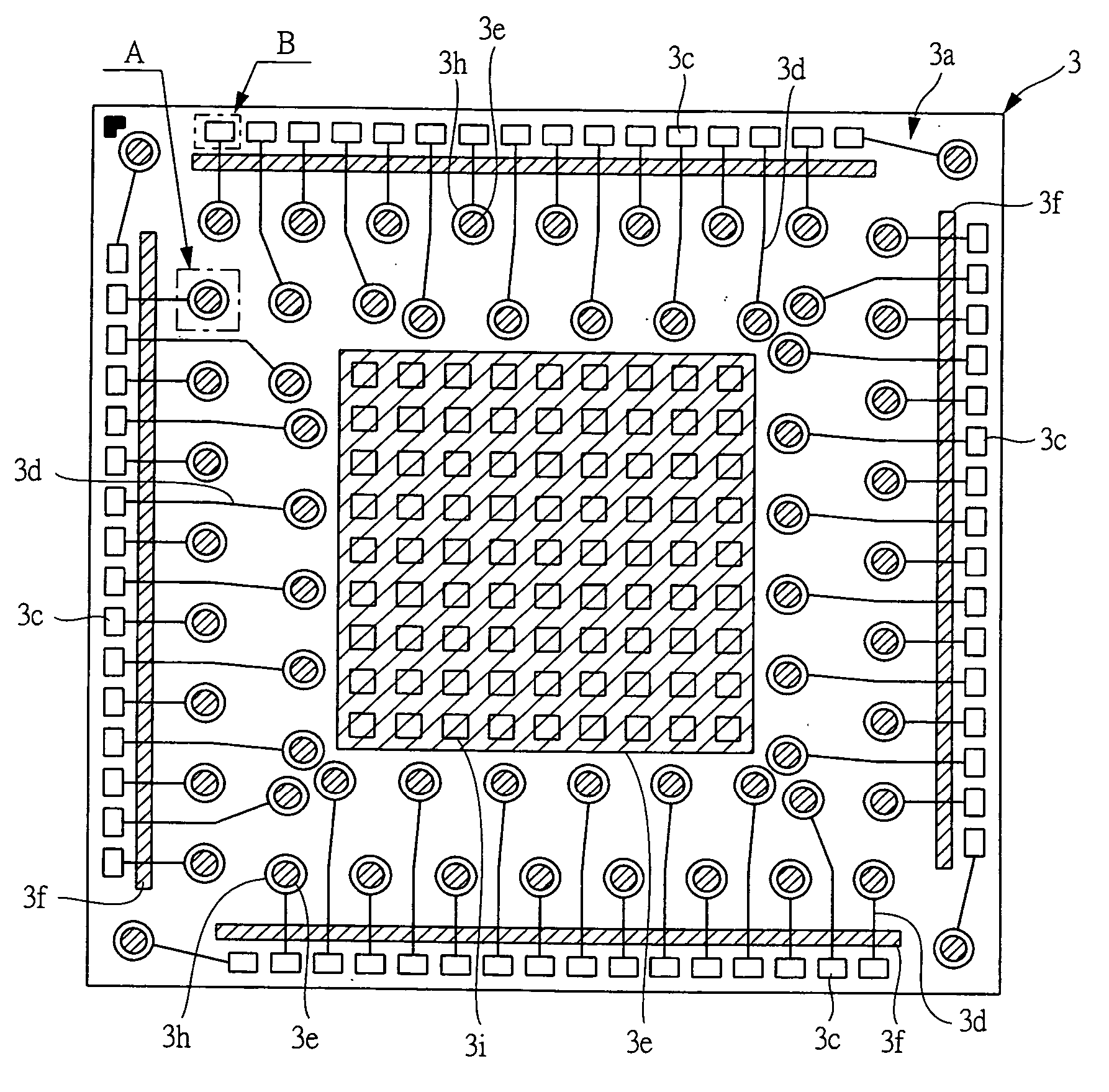

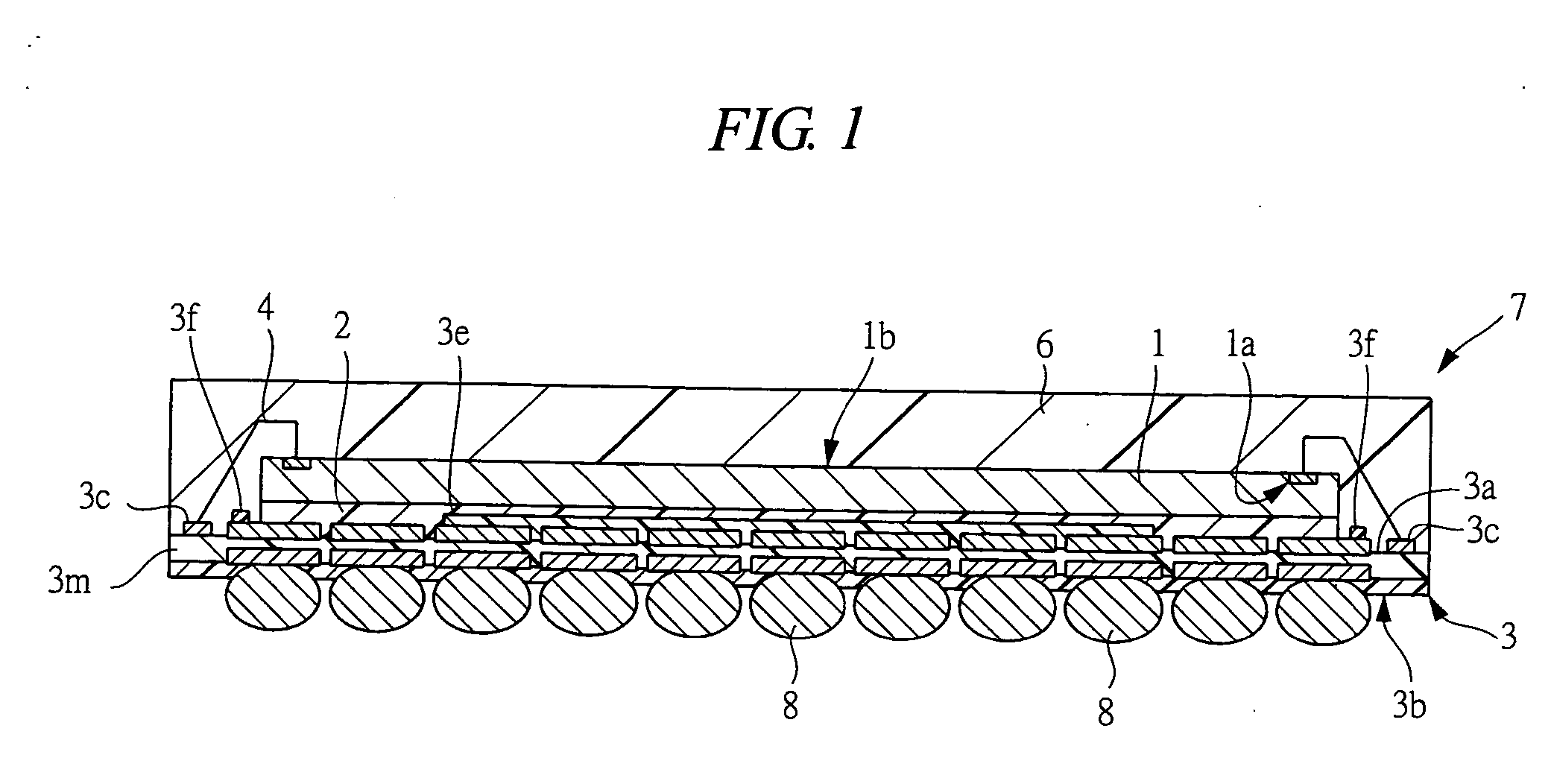

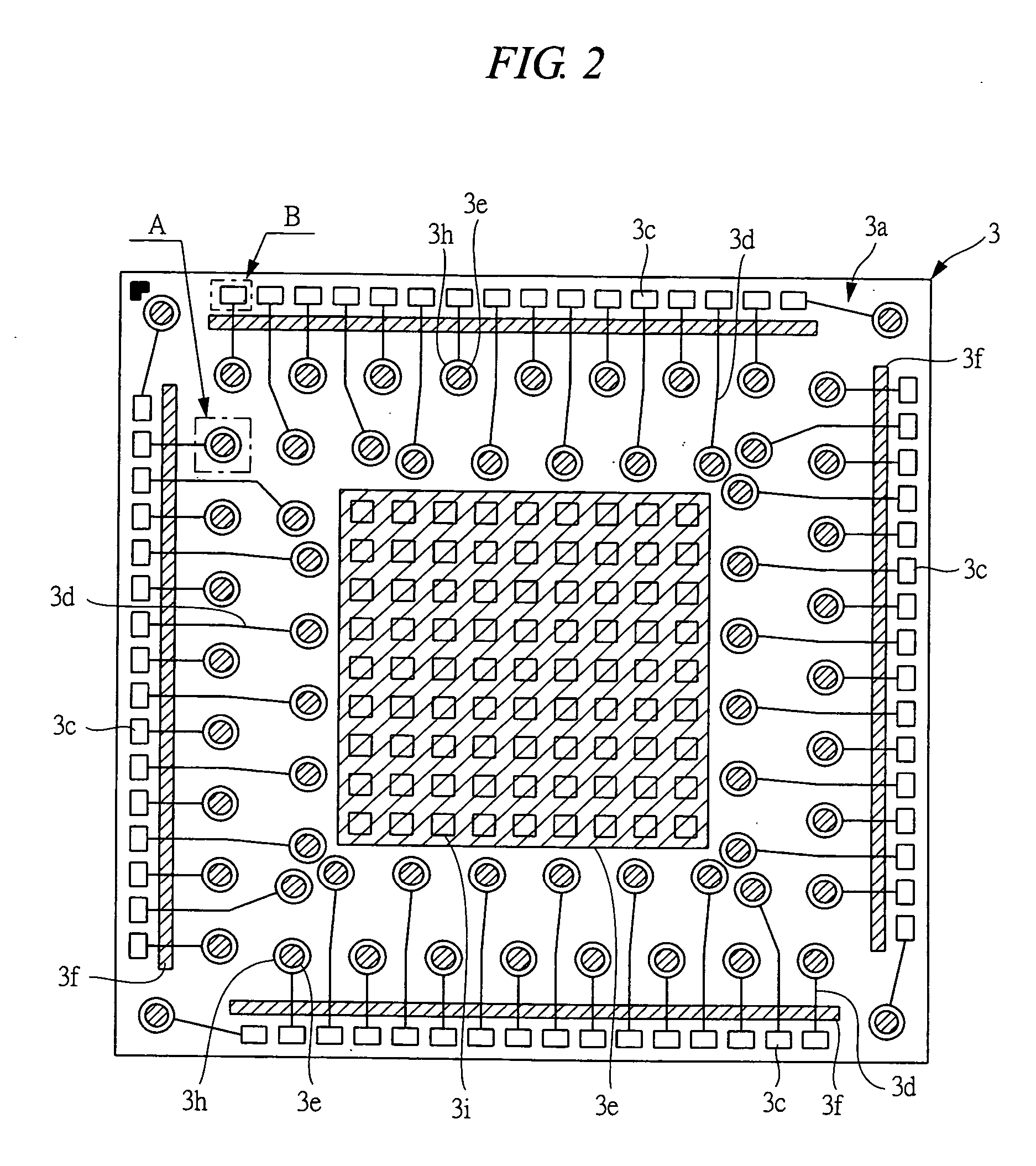

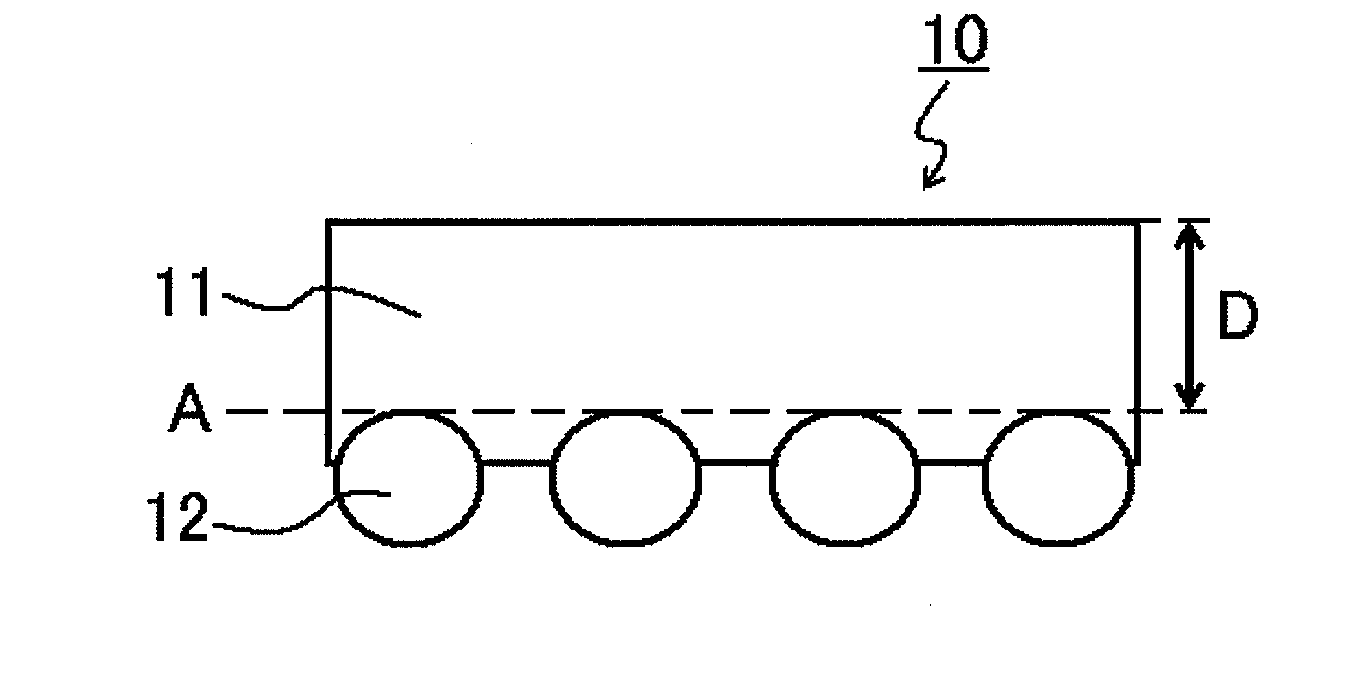

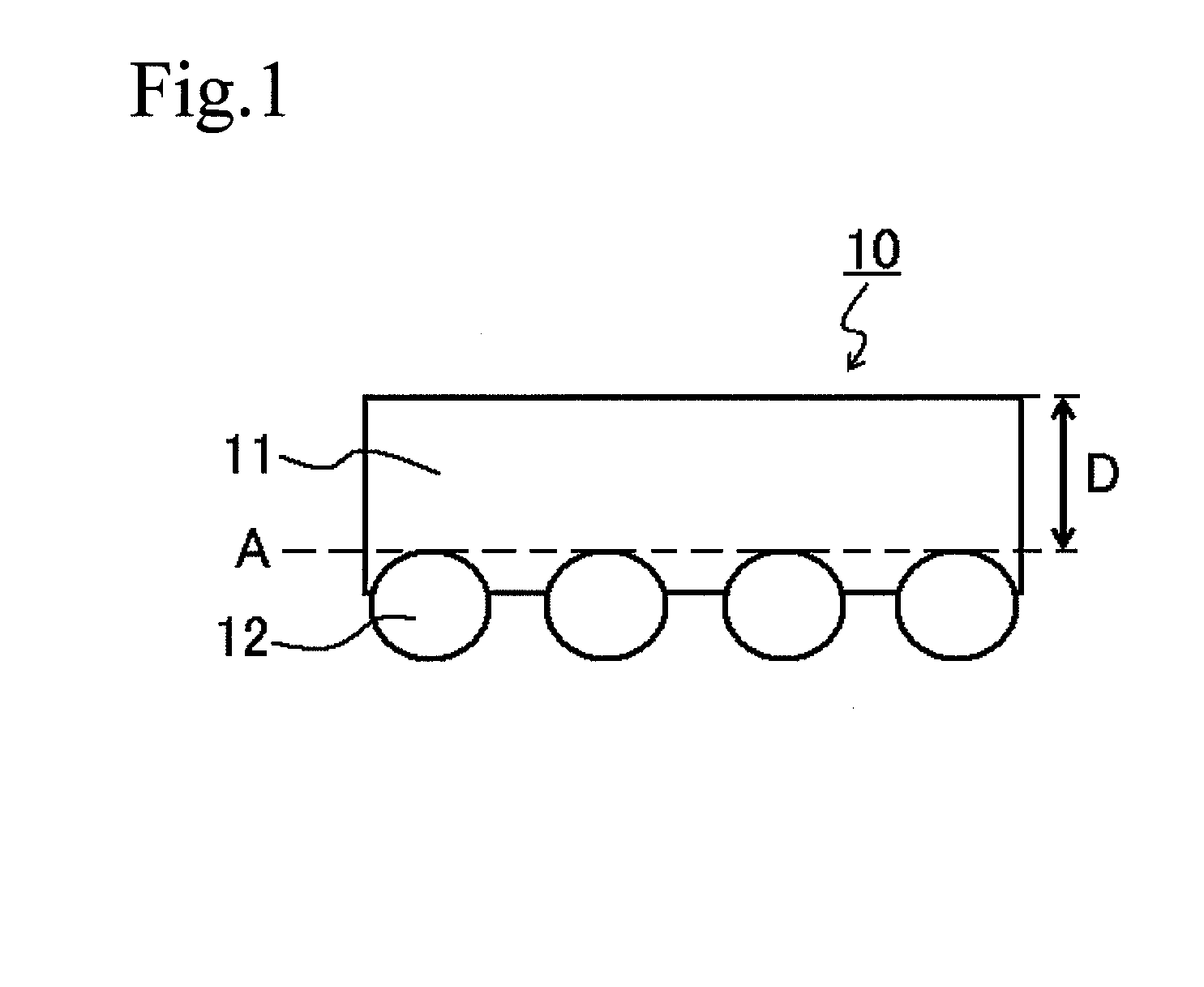

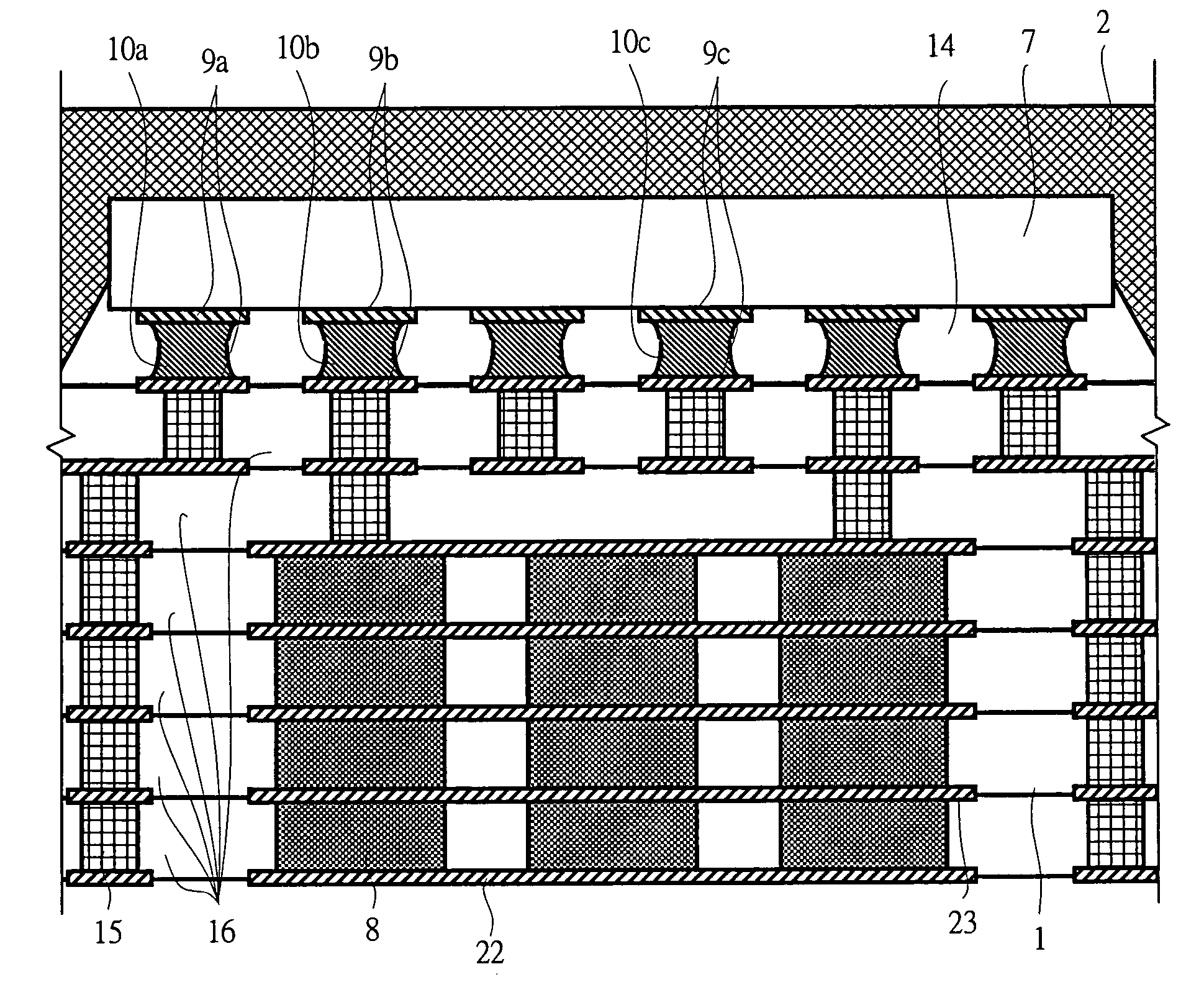

Semiconductor device

InactiveUS20070040255A1Ease of mass productionImprove Radiation PerformanceSemiconductor/solid-state device detailsSolid-state devicesDevice materialControl circuit

A semiconductor device capable of reducing the thermal resistance in a flip chip packaging structure while achieving both the high radiation performance and manufacturing readiness without increasing the manufacturing cost is provided. In a semiconductor device having a semiconductor circuit for power amplification and a control circuit of the semiconductor circuit laminated on a multilayer circuit board, the semiconductor circuit for power amplification and the control circuit are aligned in parallel on the same semiconductor element, and the semiconductor element is flip-chip connected on the multilayer circuit board. Further, a second semiconductor element mounted in addition to the first semiconductor element and all components and submodules are flip-chip connected. Also, a plurality of bumps are united in order to improve the radiation performance and thermal vias of the multilayer circuit board are formed in second and lower layers of the wiring layers in the multilayer circuit board.

Owner:RENESAS ELECTRONICS CORP

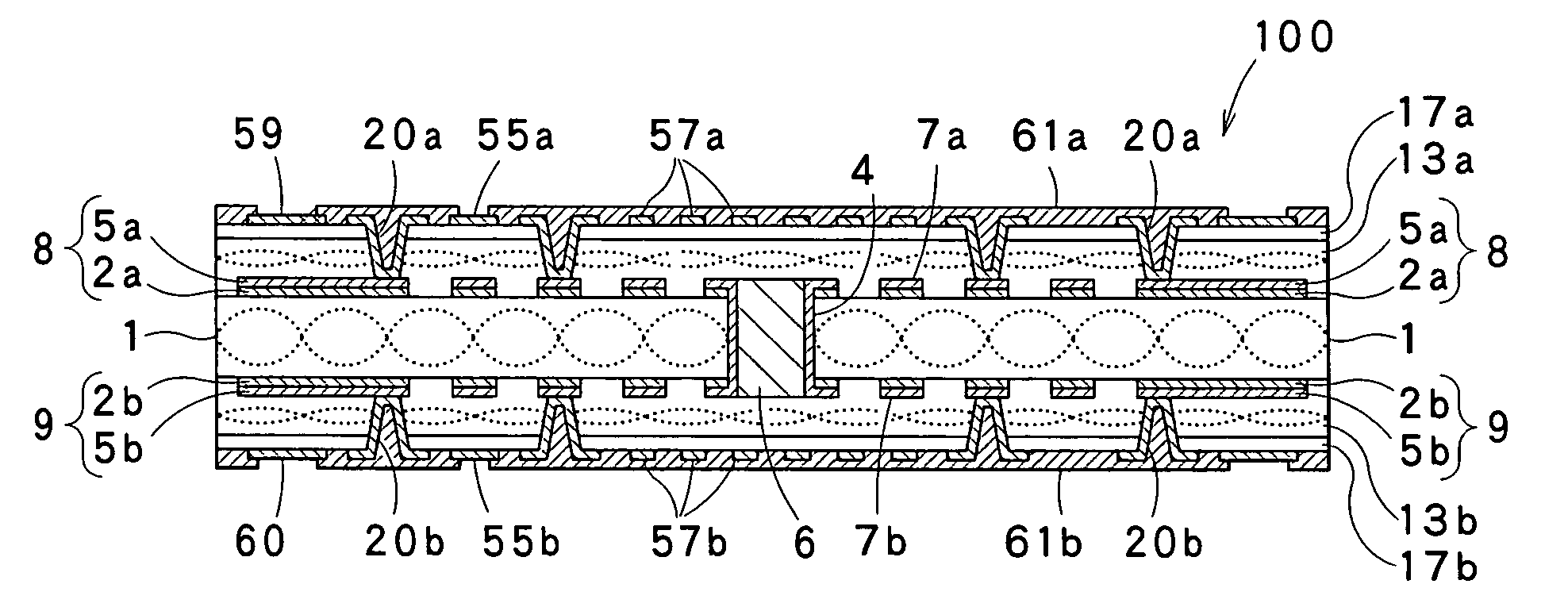

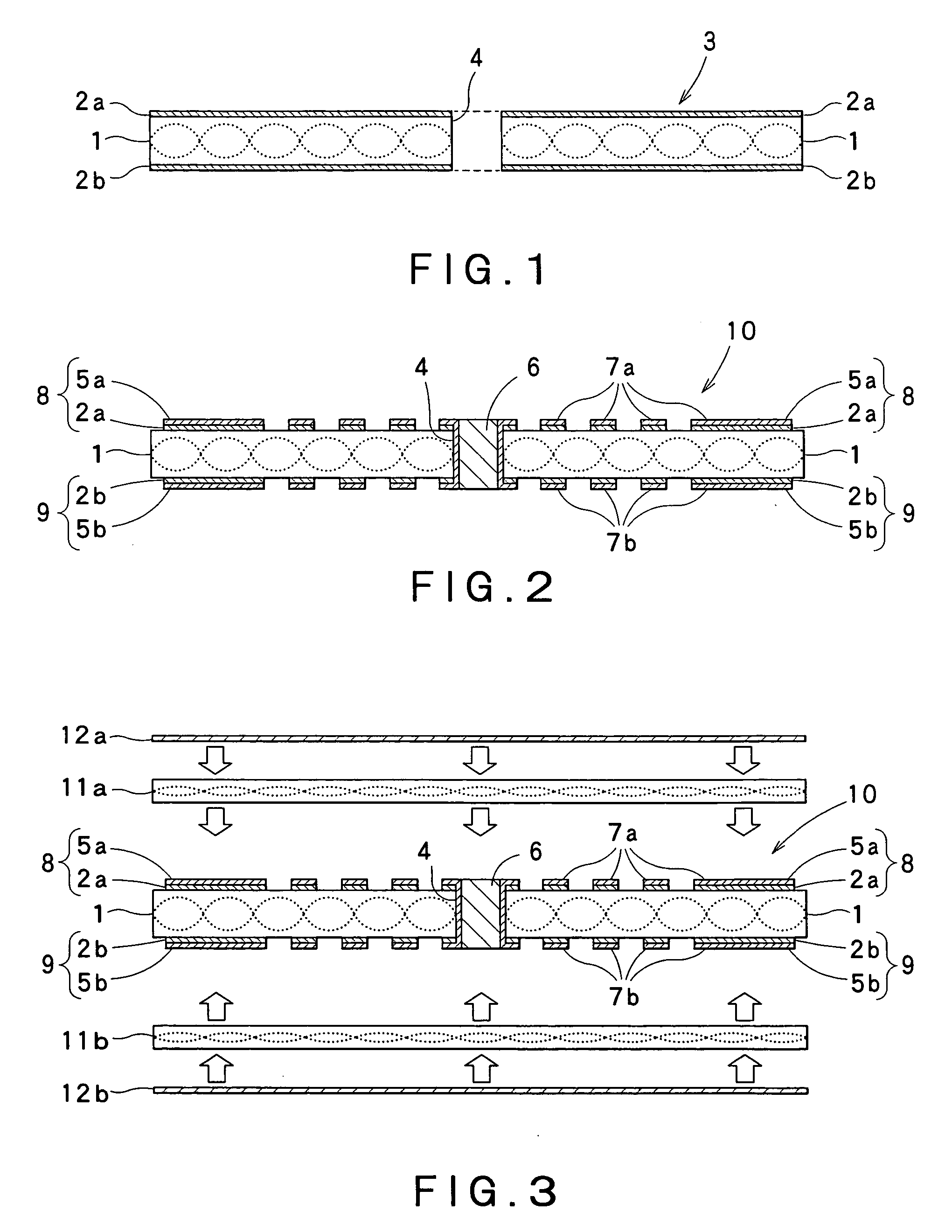

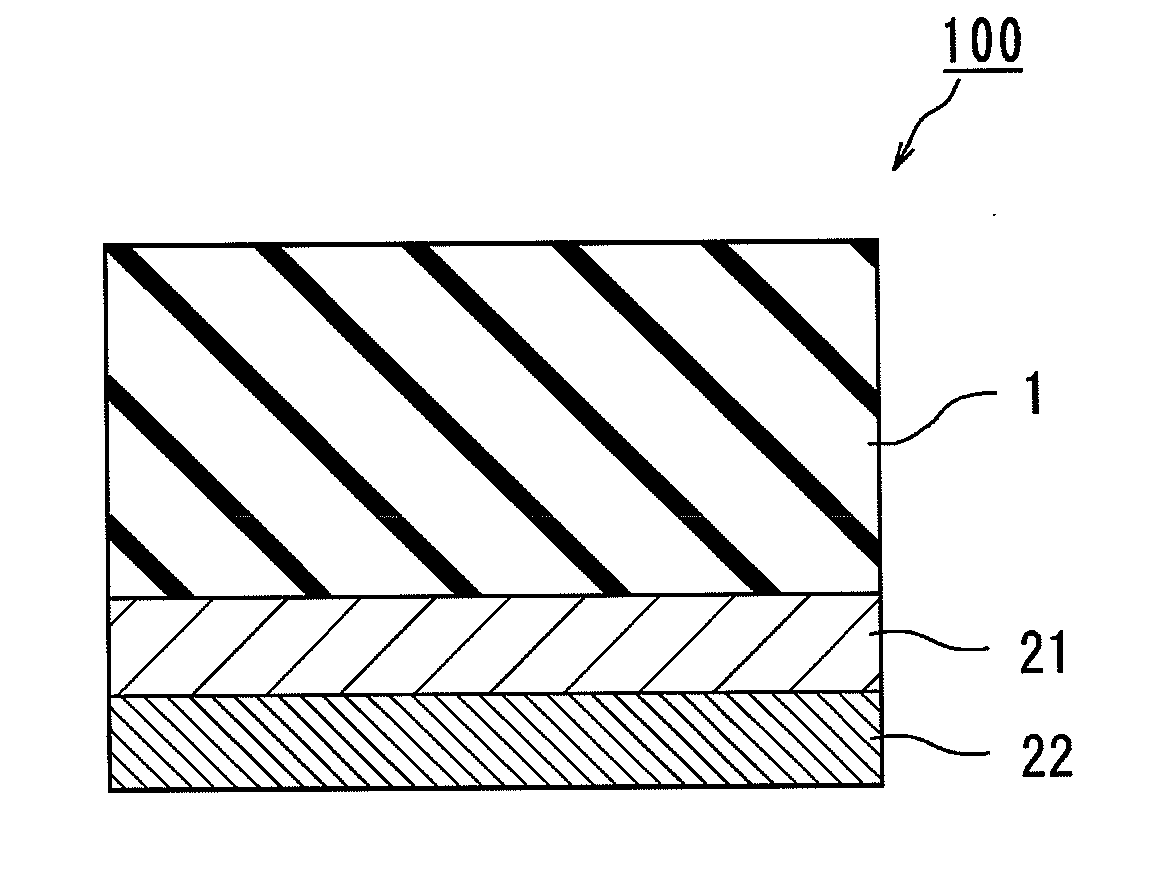

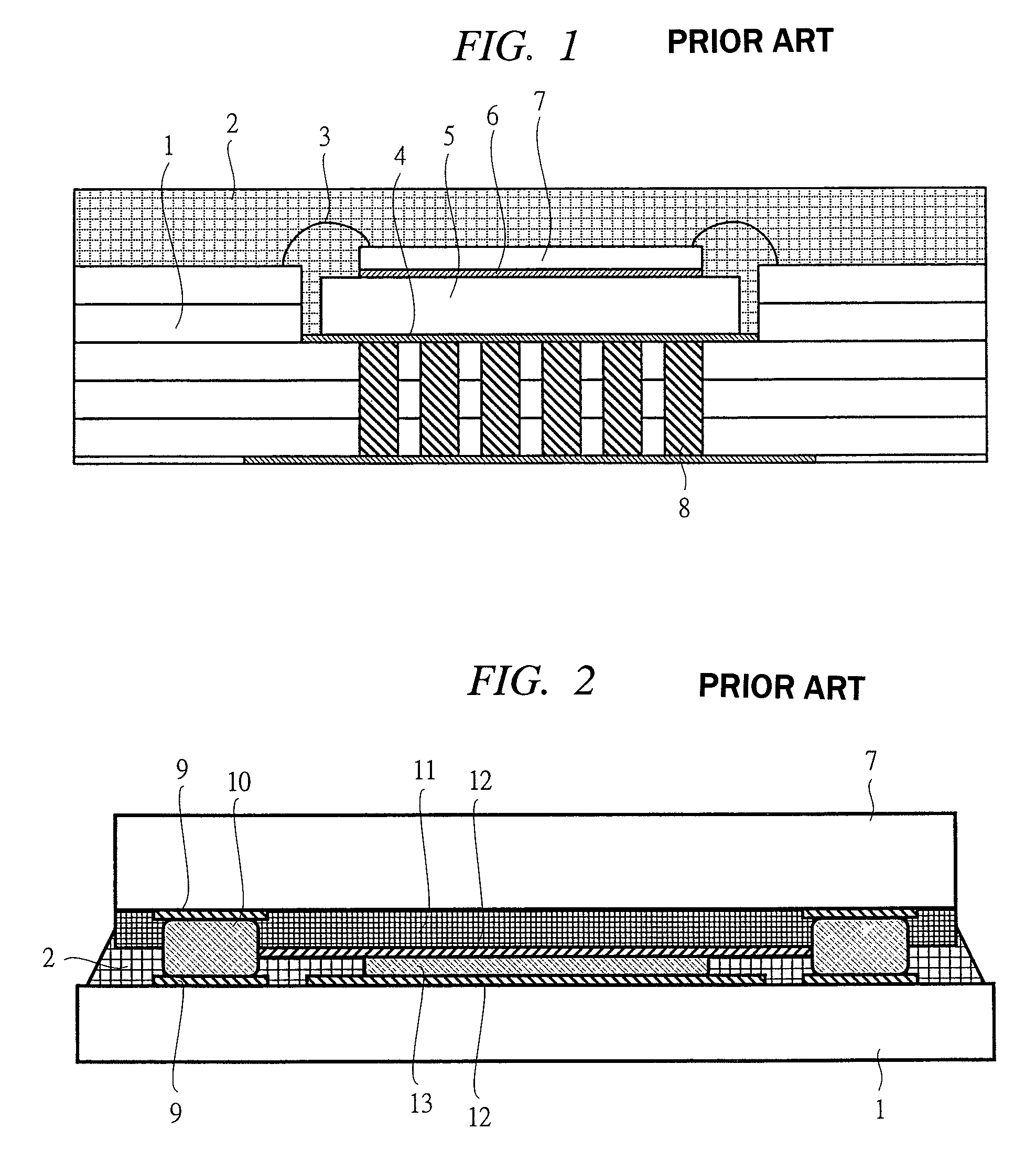

Printed wiring board and production method therefor

InactiveUS20070025091A1Increase stiffnessSufficient adhesivenessPrinted circuit aspectsPrinted circuit manufactureConductive materialsElectrical and Electronics engineering

A printed wiring board has a first wiring layer formed at least on one surface of an insulative substrate, an insulating layer formed as covering the first wiring layer, and a second wiring layer formed on the insulating layer. The insulating layer is formed of a cured insulative sheet made of a high-stiff sheet-type reinforcing material containing resin. The first and second wiring layers are electrically connected to each other through at least one hole having a bottom. The second wiring layer is united with the insulating layer at an interface thereof with a conductive material of the second wiring layer injected into concave sections provided on the interface. Another printed wiring board has an insulative substrate having a first surface and a second surface, a first insulating layer and a second insulating layer formed on the first surface and the second surface, respectively, and a first wiring layer formed on the first insulating layer and a second wiring layer formed on the second insulating layer. The first and second wiring layers are electrically connected to each other via at least one through hole. The first wiring layer is united with the first insulating layer at an interface thereof with a conductive material of the first wiring layer injected into concave sections provided on the interface. The second wiring layer is united with the second insulating layer at an interface thereof with a conductive material of the first wiring layer injected into concave sections provided on the interface.

Owner:MEIKO ELECTRONICS CO LTD

Cellulose-based fire retardant composition

InactiveUS6524653B1Stable shelf lifeSufficient adhesiveness and malleabilityFireproof paintsAntifouling/underwater paintsDiammonium phosphateLiquid ammonia

A cellulose-based fire retardant composition is made by (1) adding cellulose to water, thereby forming a solution; (2) adding liquid ammonia to the solution; and (3) subsequently adding solid diammonium phosphate to the solution, thereby forming a viscous cellulose-based fire retardant liquid.

Owner:NIPONI

Light-transmitting electromagnetic-shielding laminate and method for producing the same, light-transmitting radio wave absorber, and adhesive composition

InactiveUS20100147578A1High transparencyImprove visibilityMagnetic/electric field screeningShieldingElectricitySilane compounds

Disclosed is a light-transmitting electromagnetic-shielding laminate, which is characterized in that two or more layers including an electromagnetic-shielding layer are arranged in layers using a (meth)acrylate adhesive composition which contains a (meth)acrylate monomer, a (meth)acrylate oligomer and at least one member selected from the group consisting of acrylic amide derivatives, silane compounds and organophosphorus compounds. Also disclosed is a light-transmitting radio wave absorber which is characterized in that a resistive layer, a dielectric spacer and a reflective layer are arranged in layers using a (meth)acrylate adhesive composition which contains a (meth)acrylate monomer, a (meth)acrylate oligomer and at least one member selected from the group consisting of acrylic amide derivatives, silane compounds and organophosphorus compounds.

Owner:MITSUBISHI GAS CHEM CO INC

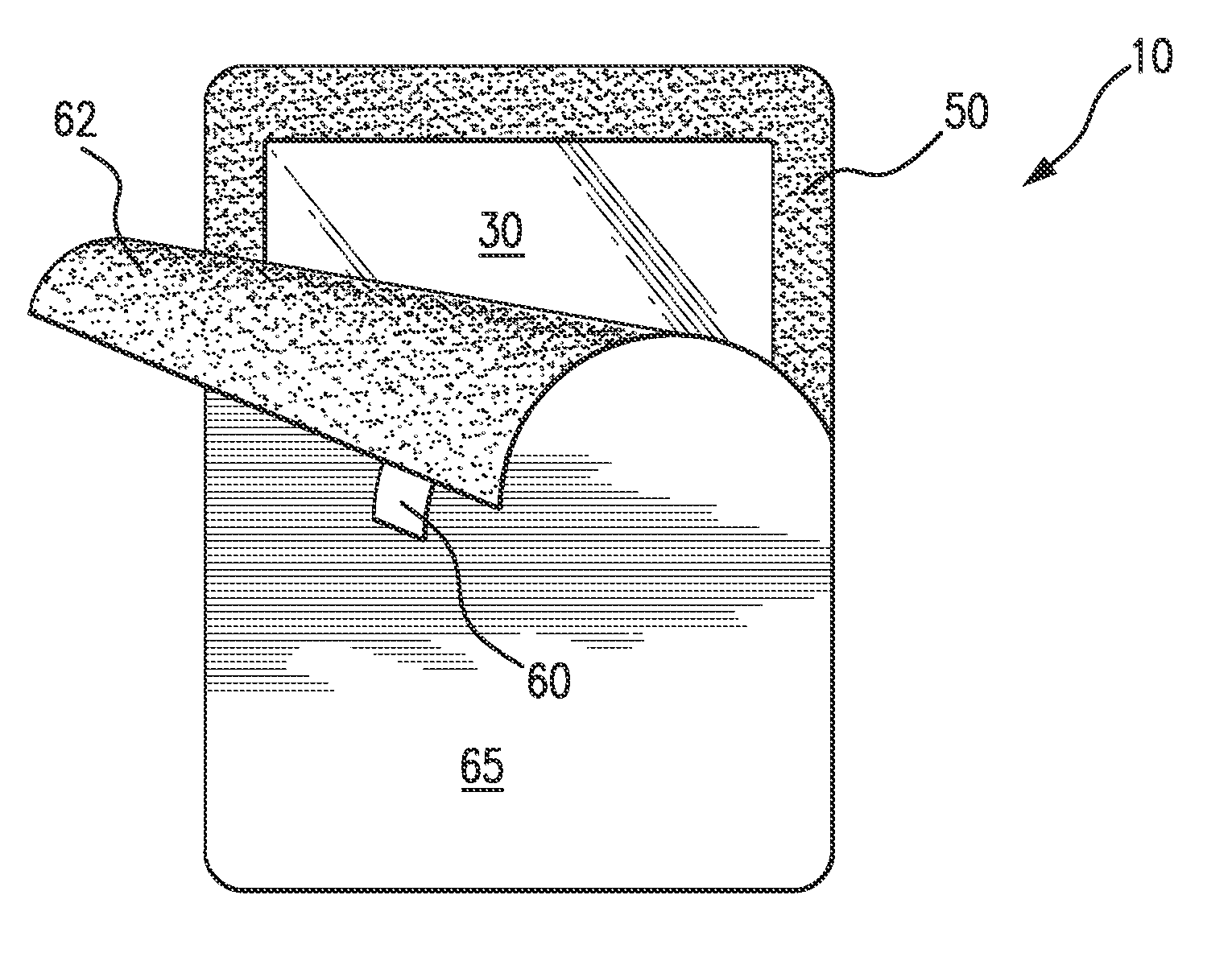

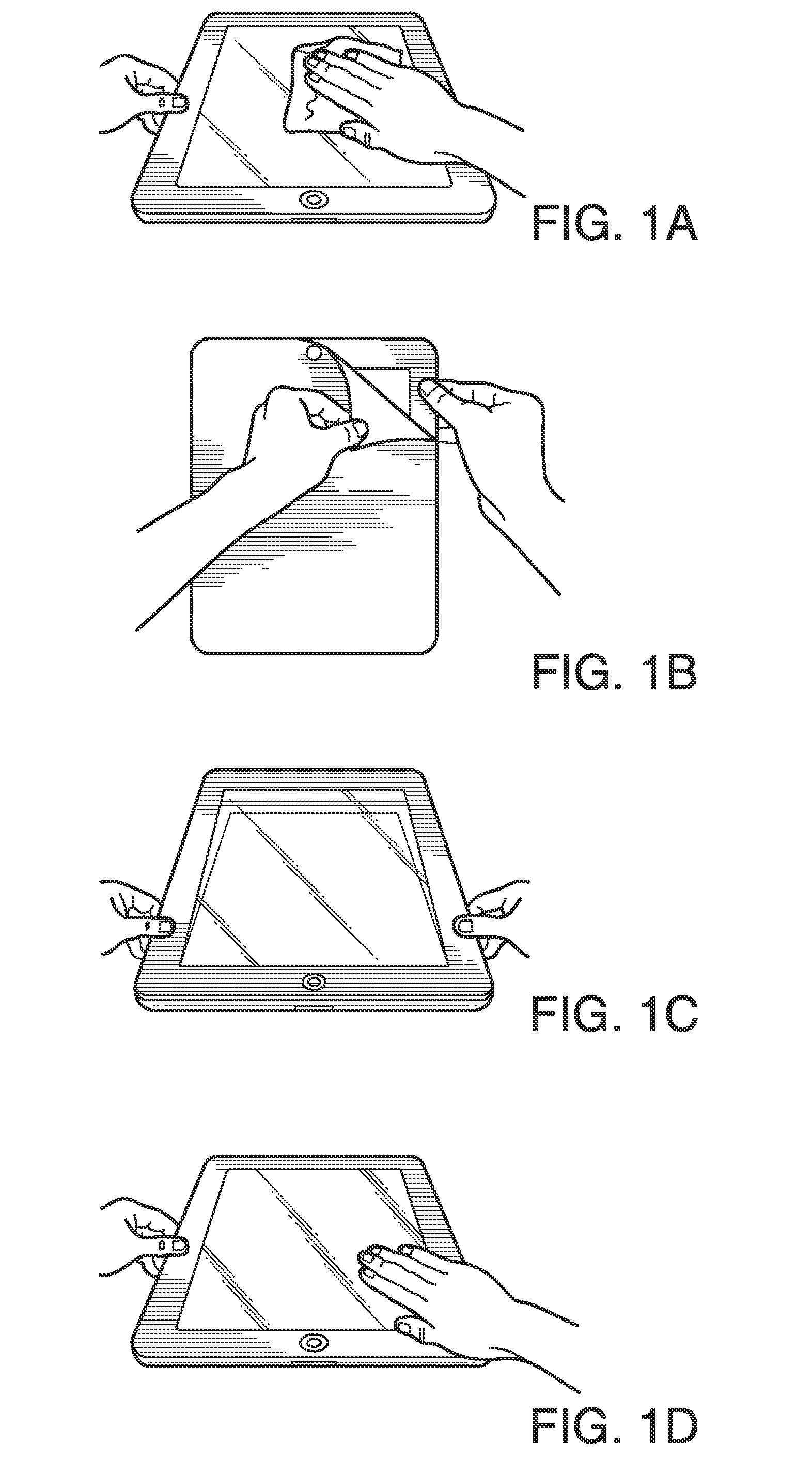

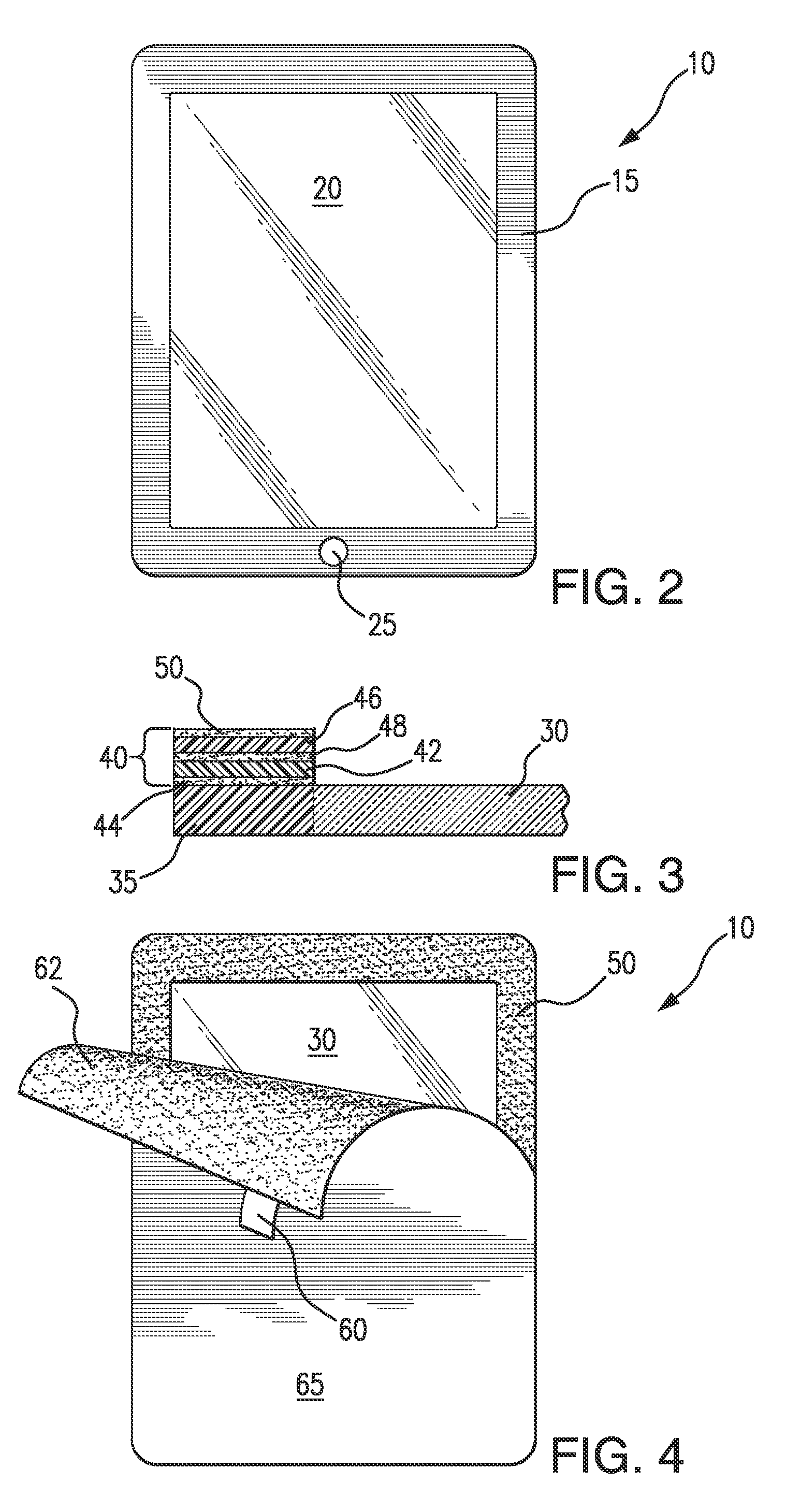

Touch screen protector

ActiveUS20120183713A1Avoid insufficient thicknessDirect contact guaranteeLayered productsHousing of computer displaysTectorial membraneAdhesive

The invention relates to a touch screen protector for a hand held electronic device having a front face that includes a touch screen portion and a non-functional band. The touch screen protector of the invention comprises a plastic film having front and back sides, an outer perimeter that corresponds to that of the device, and a transparent window; a spacer provided along the outer perimeter of the plastic film surrounding the transparent window, having a thickness sufficient to space the plastic film near but not in contact with the touch screen portion; an exposed adhesive for removably mounting the protector upon the outer perimeter of the front face to form an enclosed air space between the transparent window of the plastic film, the spacer and the touch screen portion of the device; and a joining adhesive for adhering the spacer to the back side of the plastic film.

Owner:AEVOE

Semiconductor device

ActiveUS20050046023A1Sufficient adhesivenessLow reliabilitySemiconductor/solid-state device detailsSolid-state devicesResistDevice material

A semiconductor device comprises: a package substrate having a plurality of bonding electrodes arranged in a peripheral region of a main surface thereof and wirings connected to the respective bonding electrodes and electrolessly plated; a semiconductor chip mounted on the package substrate; a plurality of wires connecting pads of the semiconductor chip and the bonding electrodes; a sealing body for sealing the semiconductor chip and the wires with resin; and a plurality of solder balls arranged on the package substrate. The wirings are formed only at the inner side of the plurality of bonding electrodes on the main surface of the package substrate, and no solder resist film is formed at the outer side of the plurality of bonding electrodes. With this arrangement, the region outside the bonding electrodes can be minimized and the semiconductor device can be downsized without changing the size of the chip mounted thereon.

Owner:RENESAS ELECTRONICS CORP +1

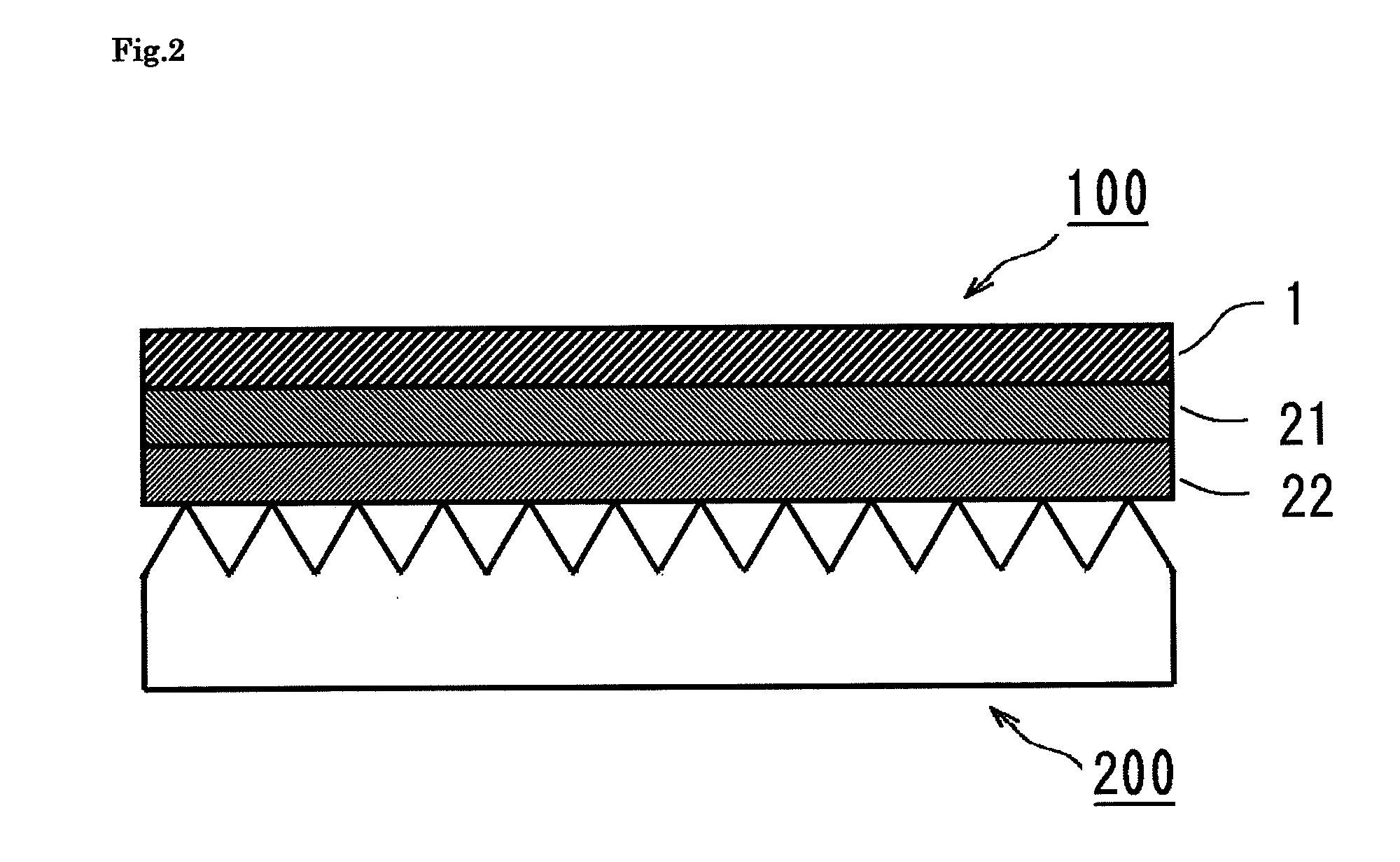

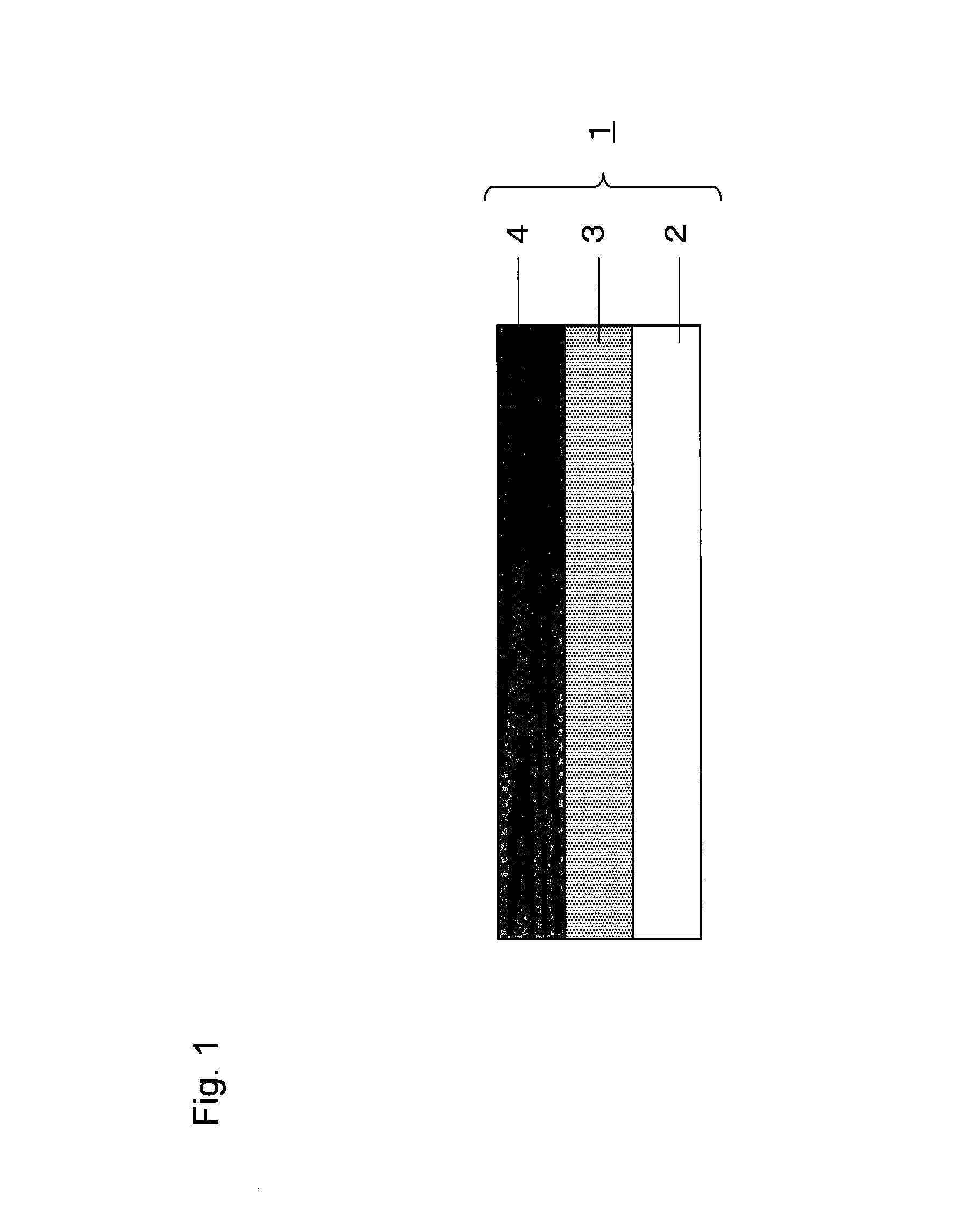

Pressure-sensitive adhesive tape

InactiveUS20110033699A1Sufficient adhesivenessSufficient releasabilityPrismsAdhesive articlesEngineeringPrism

Provided is such a pressure-sensitive adhesive tape as described below, which is capable of protecting the uneven surface of a member having unevenness on its surface. The pressure-sensitive adhesive tape brings together sufficient pressure-sensitive adhesiveness for, and sufficient releasability from, the member. In addition, even upon deformation of the member protected with the pressure-sensitive adhesive tape by, for example, lamination or continuous winding, the uneven shape does not deform and a base material layer in the pressure-sensitive adhesive tape is not damaged. Also provided is a pressure-sensitive adhesive tape useful as such a surface protective film for a prism sheet as described below, which is capable of effectively protecting, for example, a lens surface of a prism sheet having multiple triangle pole-shaped prisms fixed on its surface. The surface protective film brings together sufficient pressure-sensitive adhesiveness for, and sufficient releasability from, the prism sheet. In addition, when the prism sheet protected with the surface protective film is brought into a state such as a laminated state or a continuously wound state, the emergence of irregularity (indentation) in the external appearance of the prism sheet to which the surface protective film is attached can be suppressed. A pressure-sensitive adhesive tape of the present invention is a pressure-sensitive adhesive tape including a base material layer, a first pressure-sensitive adhesive layer, and a second pressure-sensitive adhesive layer in the stated order, in which: the base material layer contains a thermoplastic resin; the storage modulus of the first pressure-sensitive adhesive layer is higher than the storage modulus of the second pressure-sensitive adhesive layer; and a difference between the storage modulus of the first pressure-sensitive adhesive layer at a frequency of 10 Hz and 23° C., and the storage modulus of the second pressure-sensitive adhesive layer at a frequency of 10 Hz and 23° C. is 3×105 Pa or more.

Owner:NITTO DENKO CORP

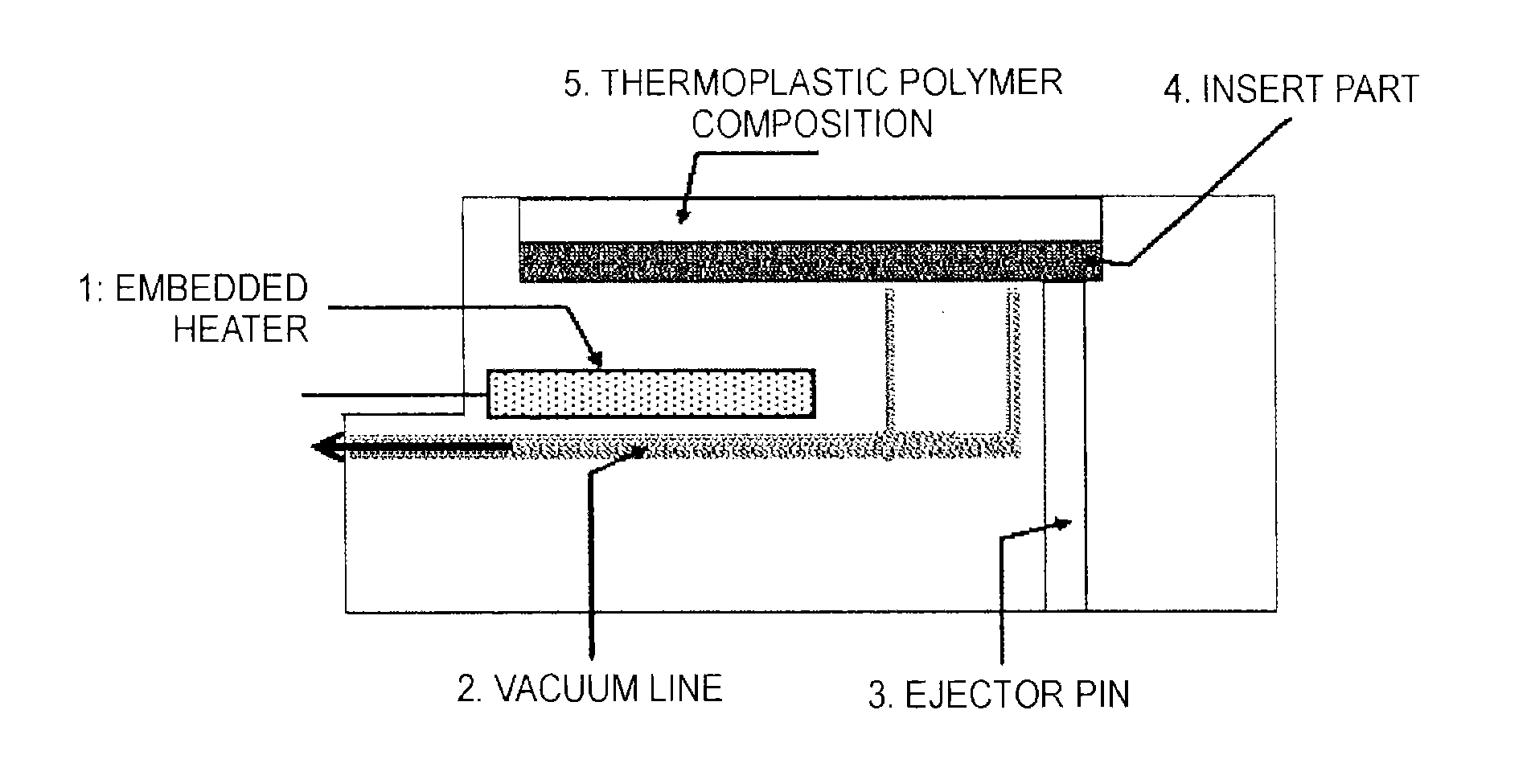

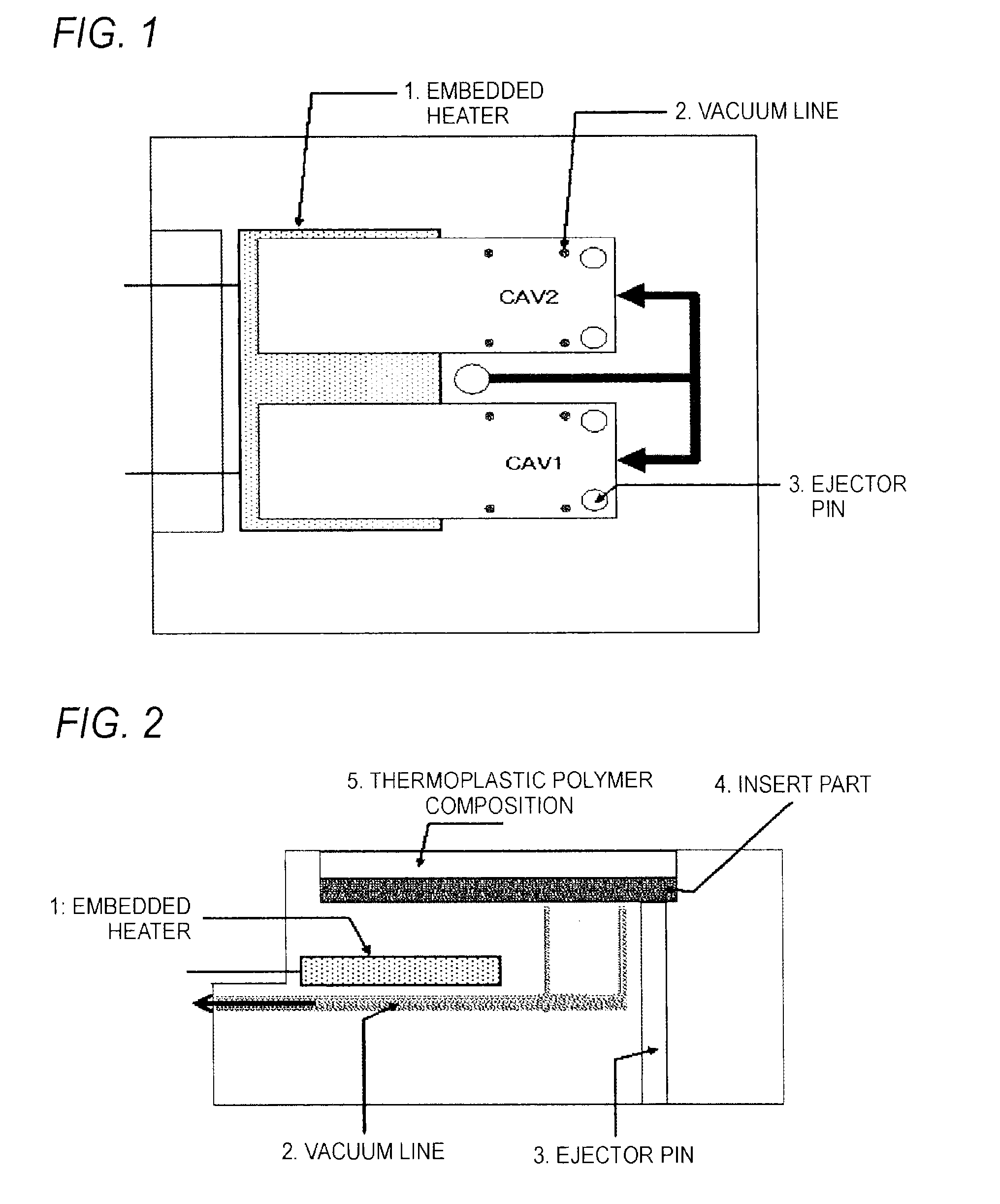

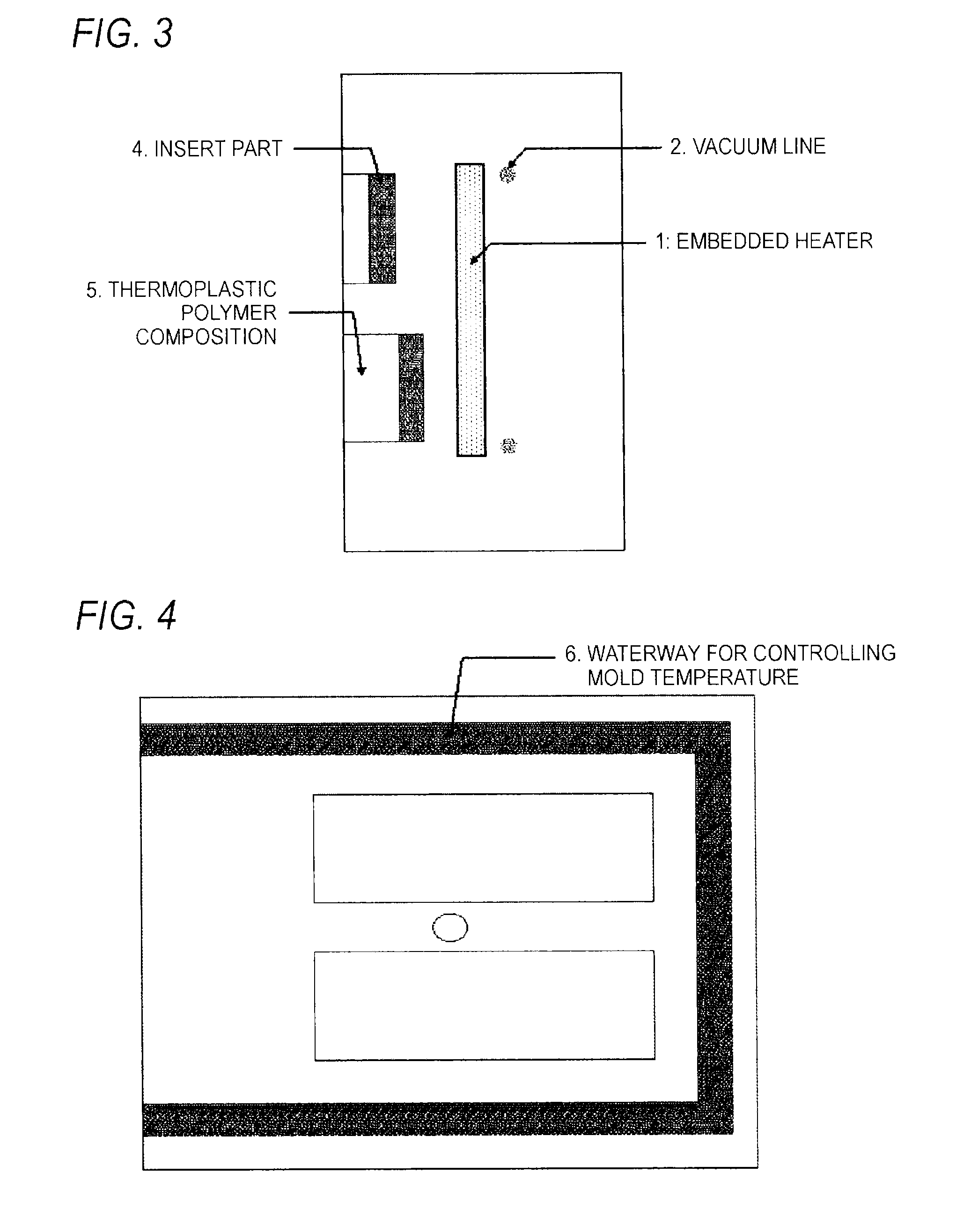

Thermoplastic polymer composition and molded article

InactiveUS20140349127A1Excellent flexibility propertyImprove mechanical propertiesFilm/foil adhesivesSynthetic resin layered productsPolyvinyl alcoholThermoplastic elastomer

The present invention is a thermoplastic polymer composition which contains 10-120 parts by mass of a polar group-containing polypropylene resin (B) per 100 parts by mass of a thermoplastic elastomer (A) that is a block copolymer having a polymer block containing an aromatic vinyl compound unit and a polymer block composed of a conjugated diene unit having 40% by mole or more of 1,2-bonds and 3,4-bonds in total, or a hydrogenated product of the block copolymer (provided that a thermoplastic polymer composition containing 1 part by mass or more of a polyvinyl acetal resin is excluded). This thermoplastic polymer composition is able to be bonded with a ceramic, a metal or a synthetic resin without requiring a primer treatment, and has excellent flexibility, mechanical characteristics, moldability, heat resistance and storage stability.

Owner:KURARAY CO LTD

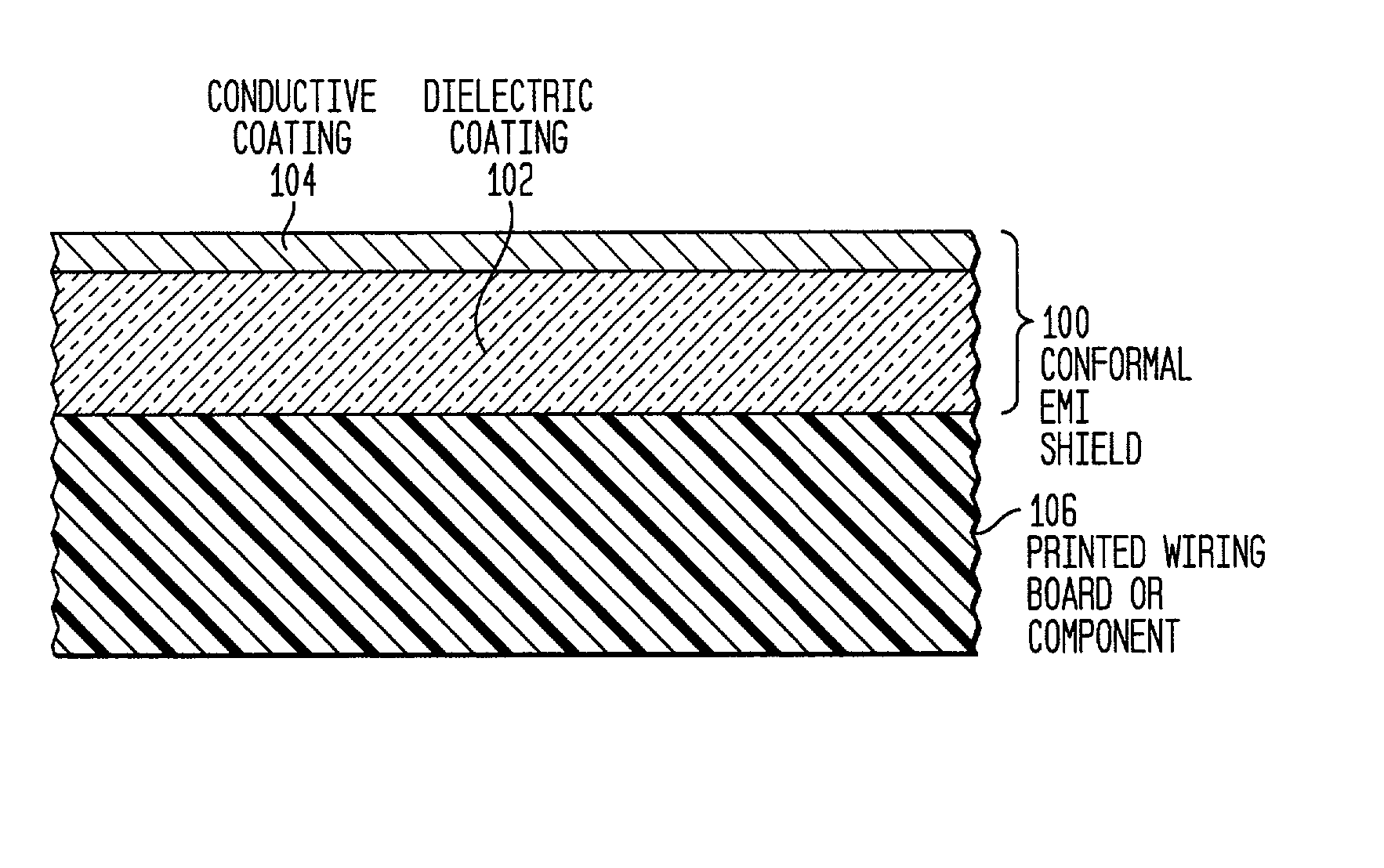

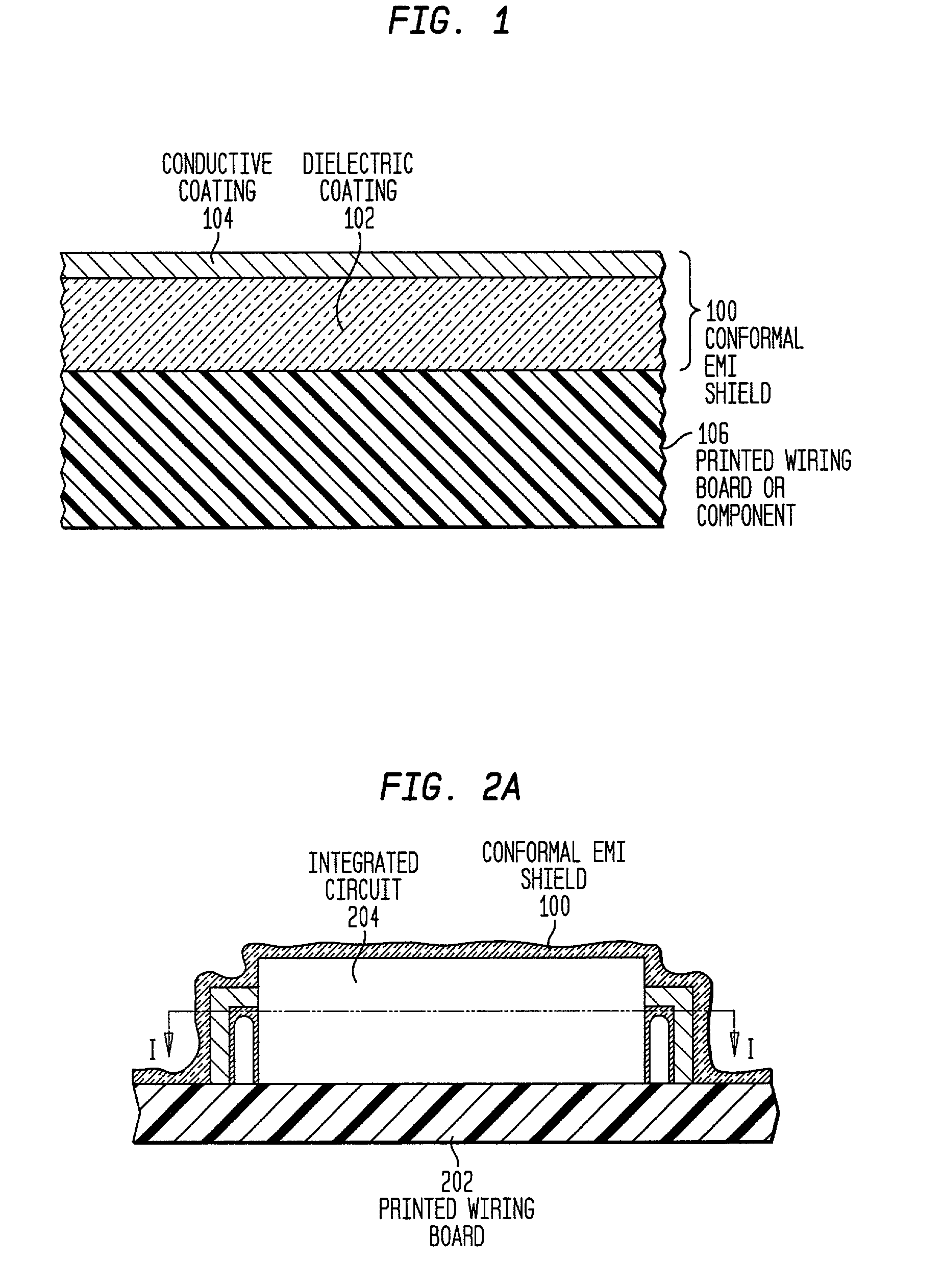

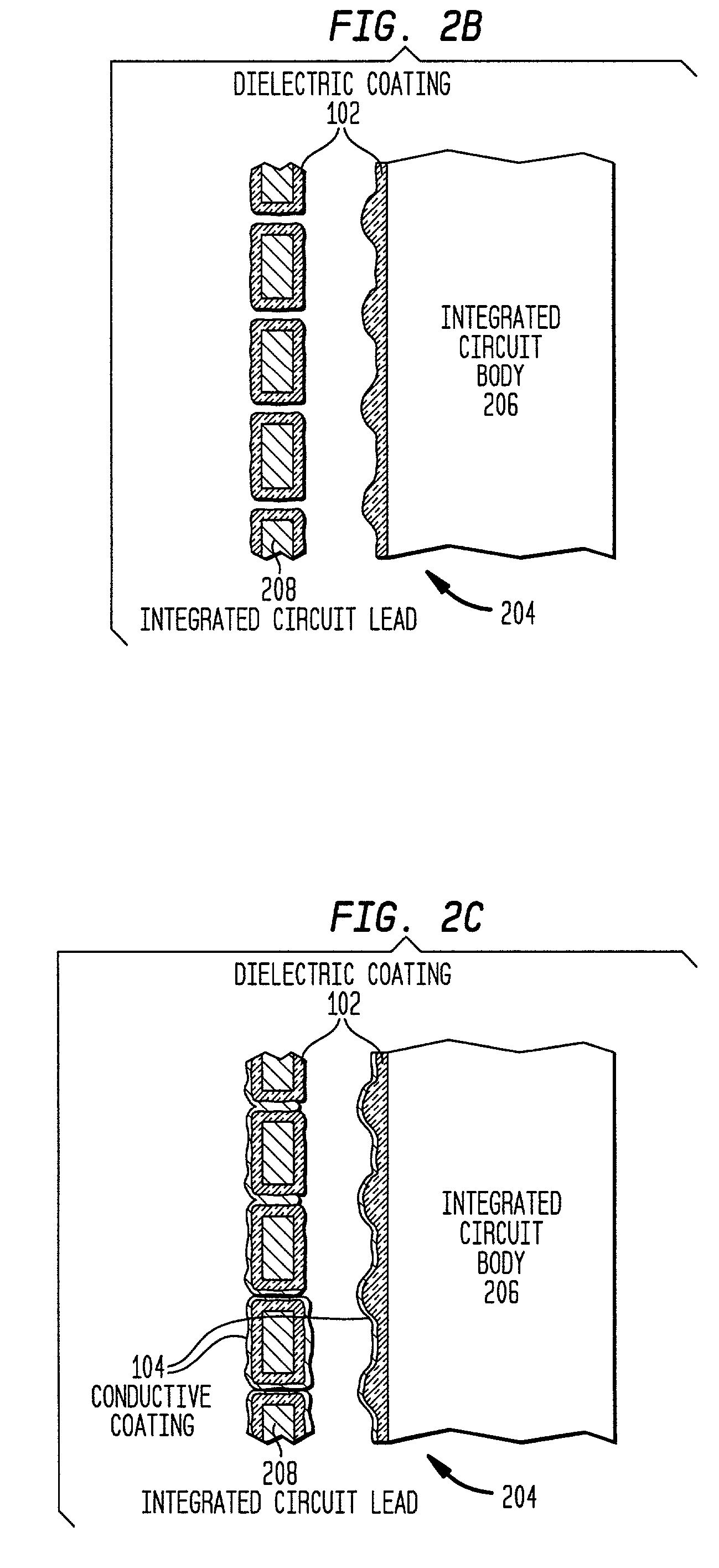

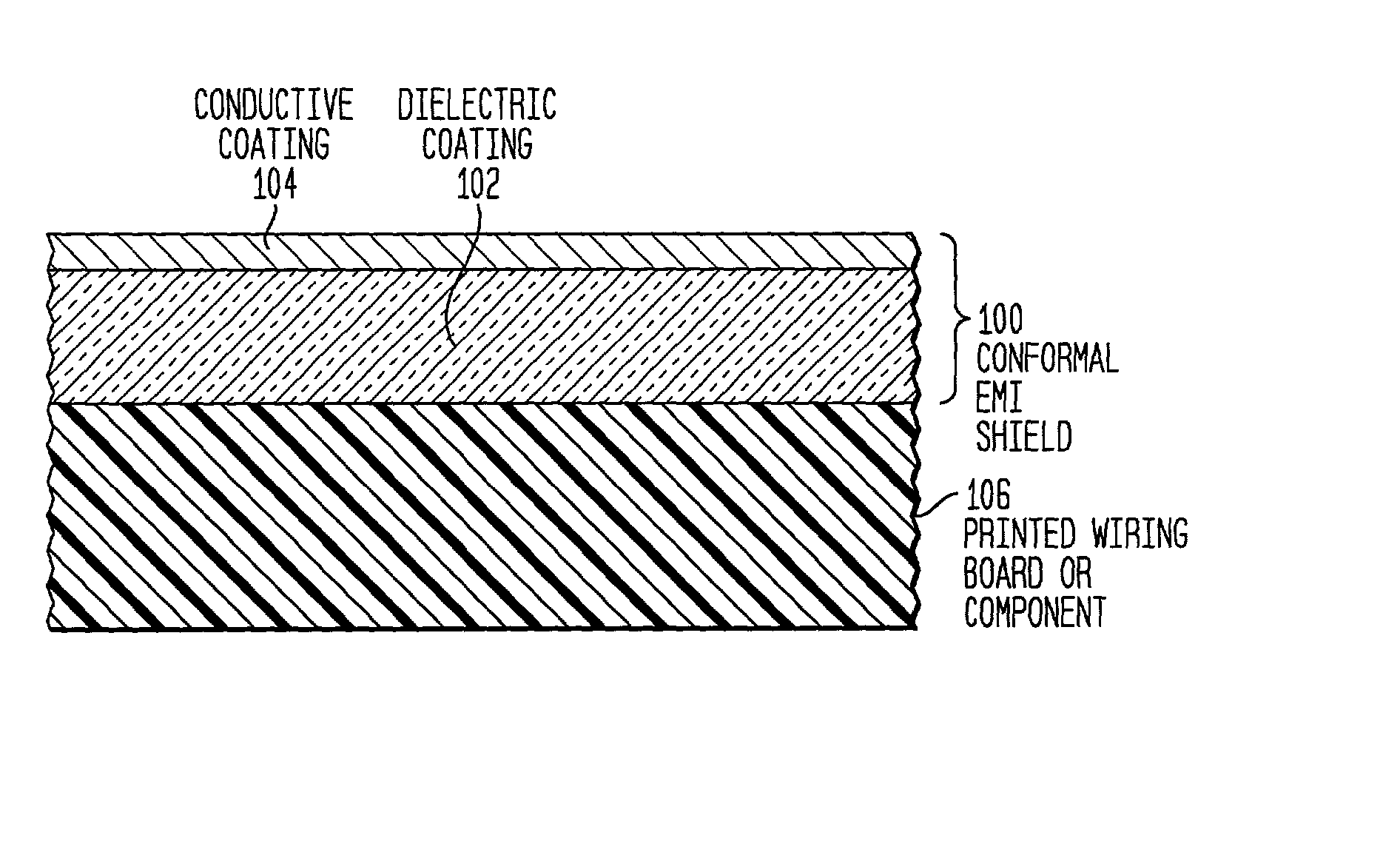

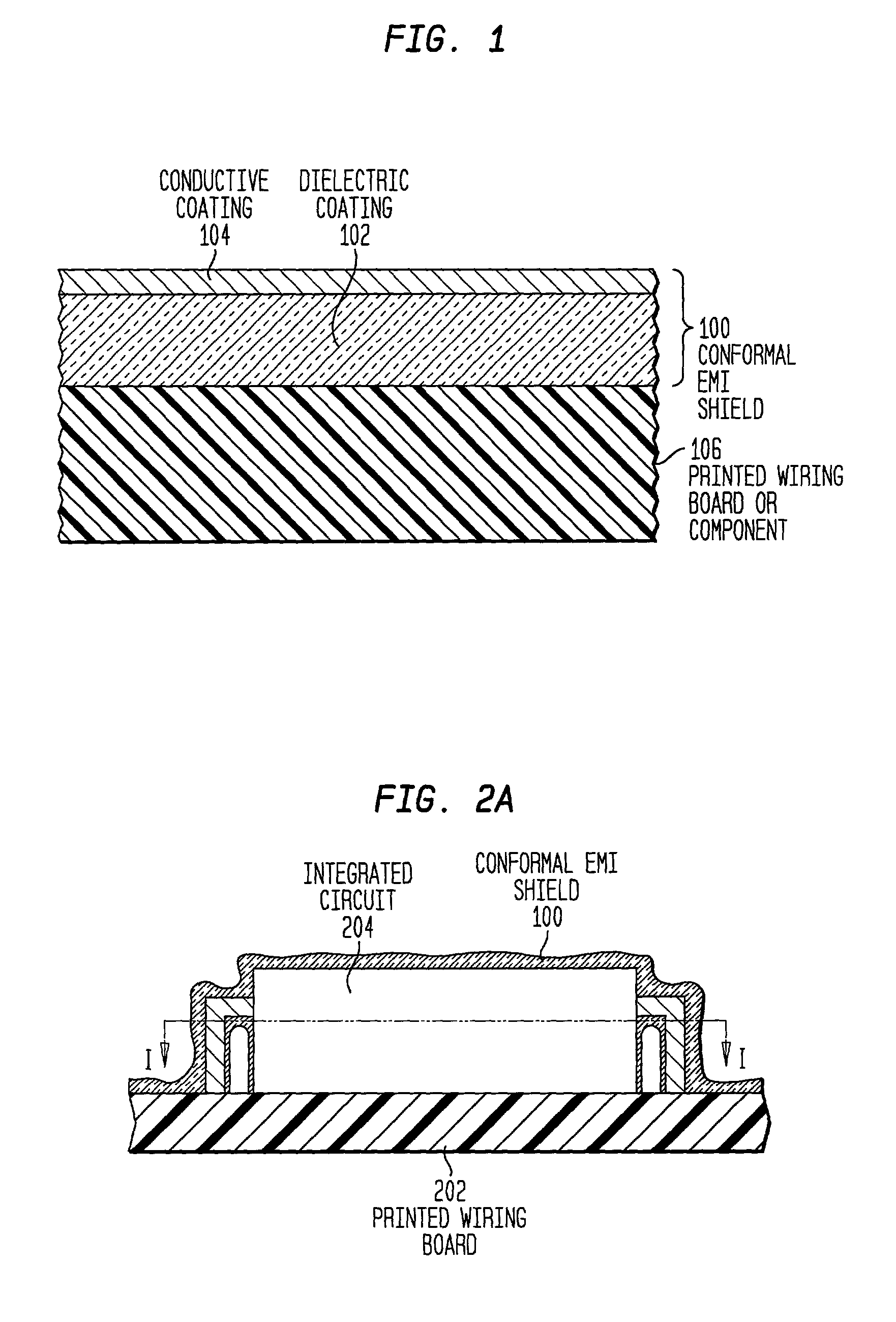

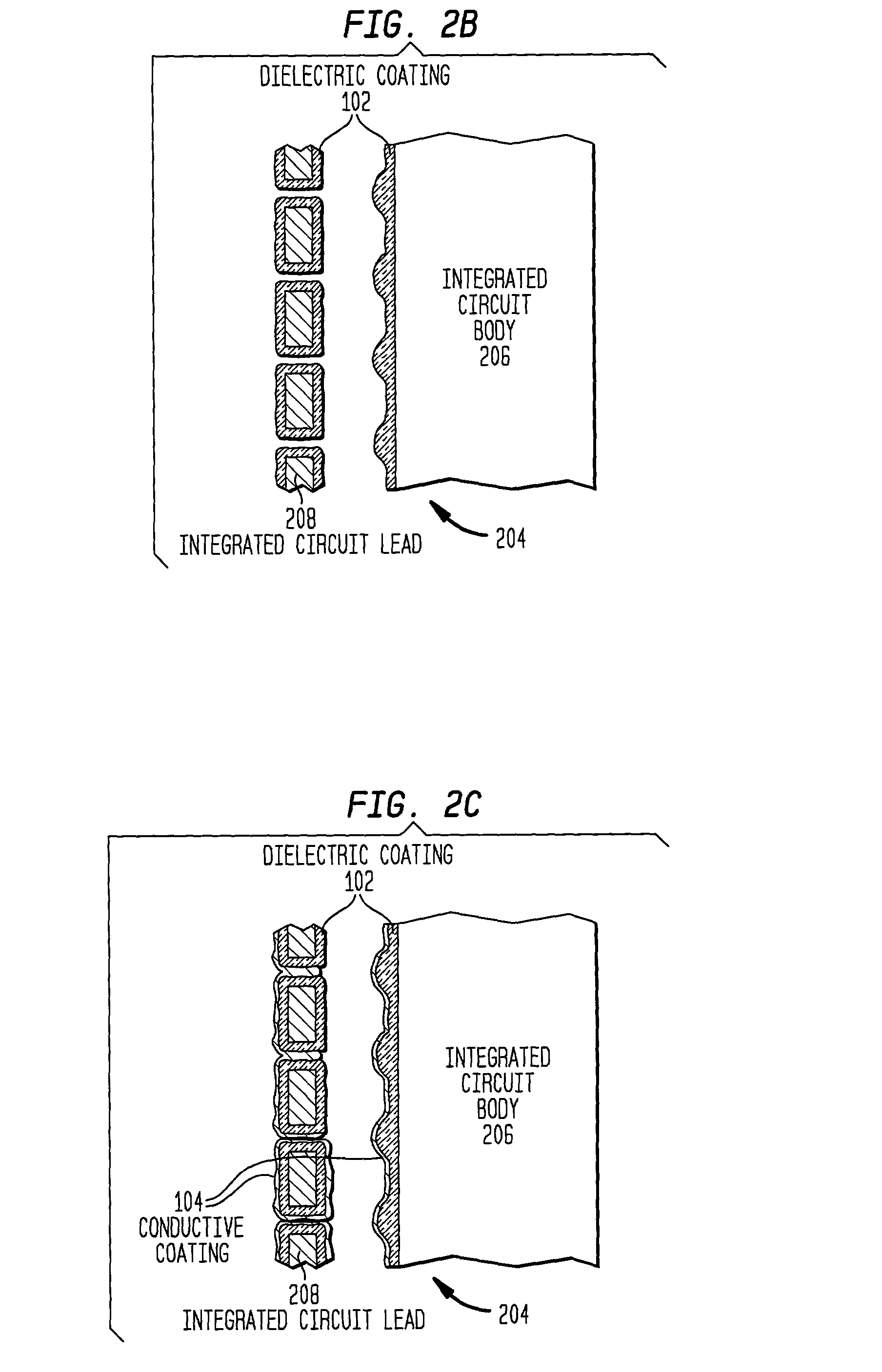

Board-level conformal EMI shield having an electrically-conductive polymer coating over a thermally-conductive dielectric coating

InactiveUS20020166681A1Improve heat distributionLift restrictionsMagnetic/electric field screeningCross-talk/noise/interference reductionConductive coatingConductive polymer

An electrically continuous conformal EMI protective shield for conformingly adhering directly to surfaces of a printed circuit board is disclosed. The EMI protective shield comprises a dielectric coating and a conductive coating. The dielectric coating adheres directly to surfaces of the printed circuit board to provide an electrically nonconductive, contiguous coating that covers all such printed circuit board surfaces. The conductive coating comprises a substantially contiguous layer of an intrinsically conducting polymer adhering directly to surfaces of the dielectric coating to provide an electrically conductive layer that prevents the passage of electromagnetic emissions through the conformal EMI shield.

Owner:HEWLETT PACKARD DEV CO LP

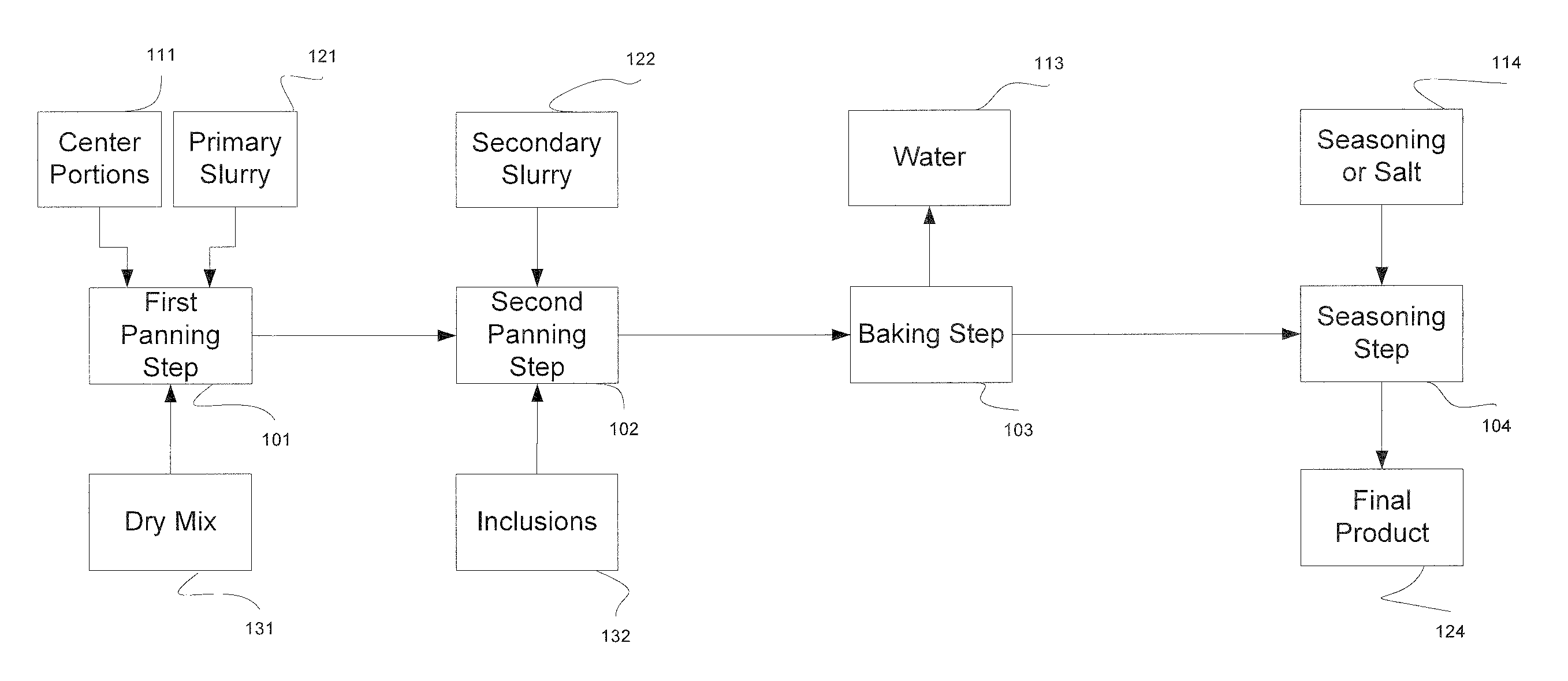

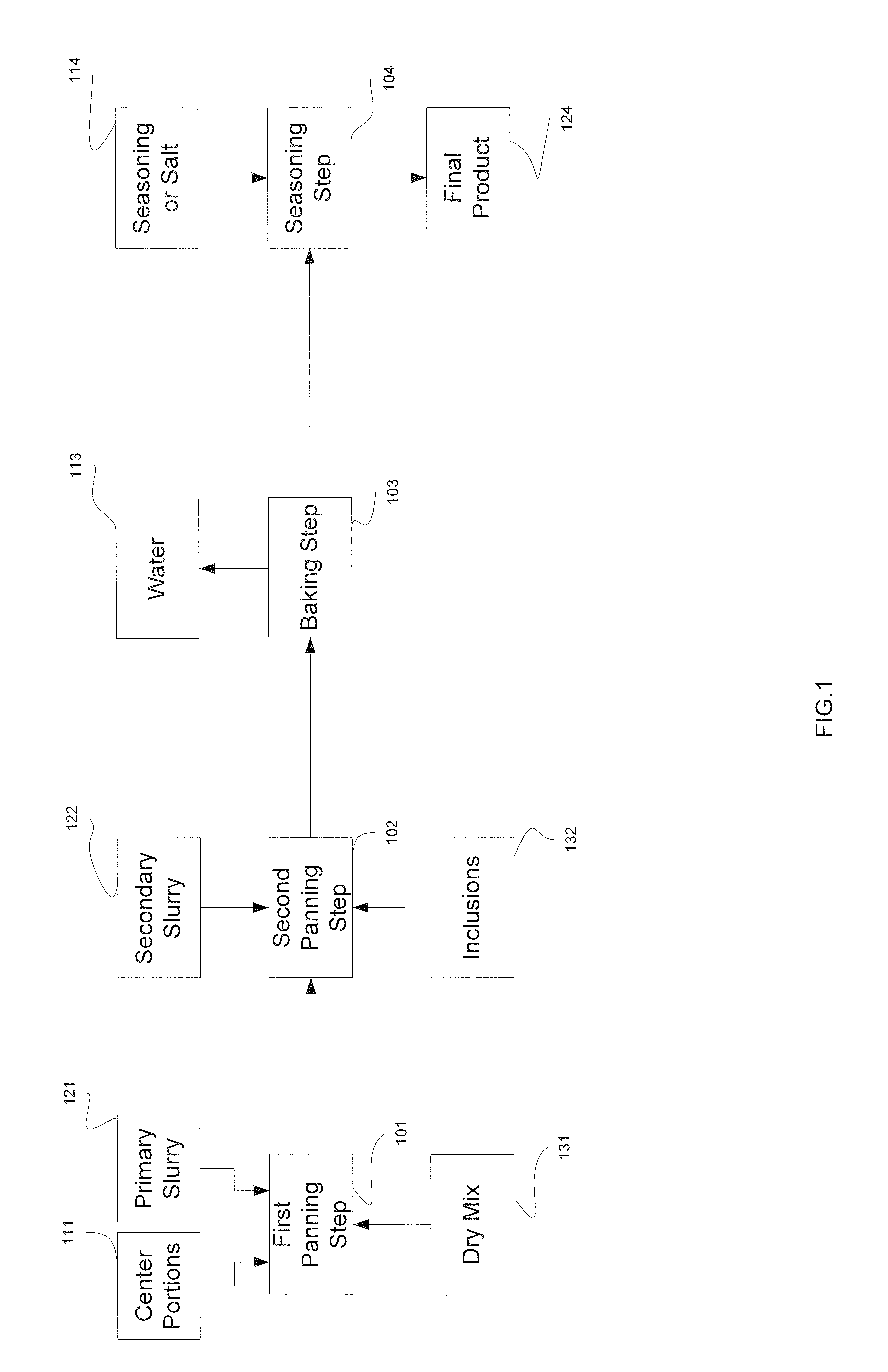

Method for producing a crunchy food product

InactiveUS20090208609A1High in nutrientsSufficient adhesivenessConfectionerySweetmeatsSlurryEngineering

A food producing method used in panning for delivering enhanced nutrition benefits and for decoupling adhesion and texture and the resulting product. First a plurality of center portions are obtained and introduced into a mixer. Then primary slurry is added followed by a dry mix which adheres to said center portions. Next, a secondary slurry is prepared which provides the adhesiveness required to adhere inclusions to the center portion. The use of a secondary slurry allows the decoupling of adhesion and texture whereby a softer product is produced which does not yield a hard, glassy texture.

Owner:FRITO LAY NORTH AMERICA INC

Highly adhesive polyester film and packaging material using the same

ActiveUS20110081512A1Sufficient adhesivenessFacilitate performance improvementsPretreated surfacesCeramic layered productsPolytetramethylene terephthalateOligomer

Disclosed is a highly adhesive polyester film having a highly adhesive primer layer disposed on at least one side of a substrate polyester film. The substrate polyester film is a stretched film having linear tearability and formed of a mixed polyester resin containing polyethylene terephthalate and a modified polybutylene terephthalate, and the highly adhesive primer layer contains a polyester resin (A) having an acid number of 20 to 60 mg KOH / g and a hydroxyl number of 30 to 150 mg KOH / g, and having an oligomer content of 2.0% by mass or less, and substantially contains no crosslinking agent component.

Owner:UNITIKA LTD

Photocatalyst coated body

ActiveUS20170087534A1Improve adhesionGood weather resistanceCatalyst activation/preparationCoatingsMetallurgyNanometre

The present invention provides a photocatalyst coated body which can realize a sufficient photocatalytic activity and adhesiveness with a substrate, without significantly impairing an appearance of a substrate, especially an exterior building material. The photocatalyst coated body has a structure including a substrate, an intermediate layer formed on the substrate, and a photocatalyst layer formed on the intermediate layer. The intermediate layer includes inorganic oxide particles having an average particle diameter of nanosize. The photocatalyst layer includes photocatalyst particles having an average particle diameter of more than 0 μm to less than 10 μm and inorganic oxide particles having an average particle diameter of nanosize. A sum of a film thickness of the intermediate layer and a film thickness of the photocatalyst layer is 0.3 μm or more to 1.5 μm or less.

Owner:TOTO LTD

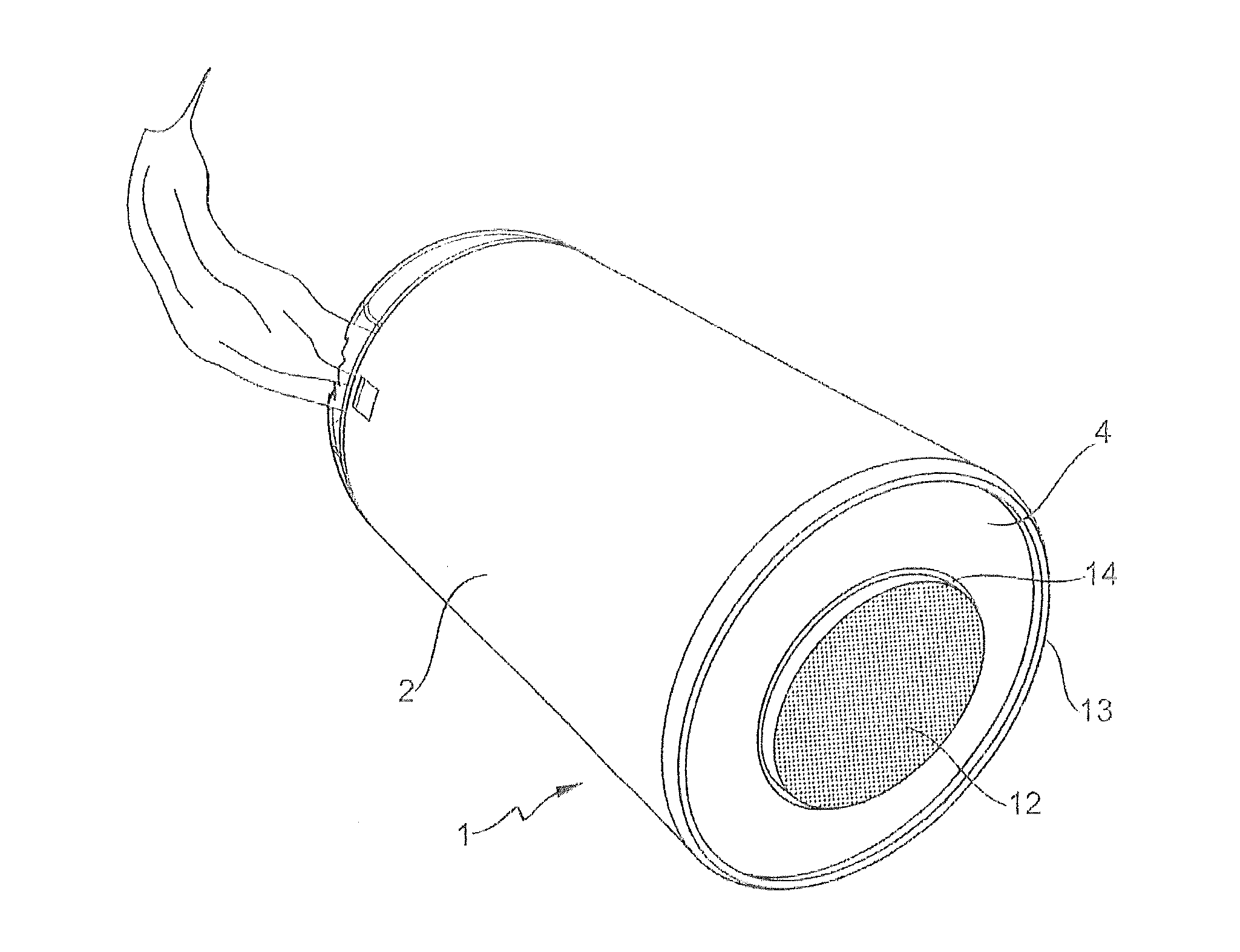

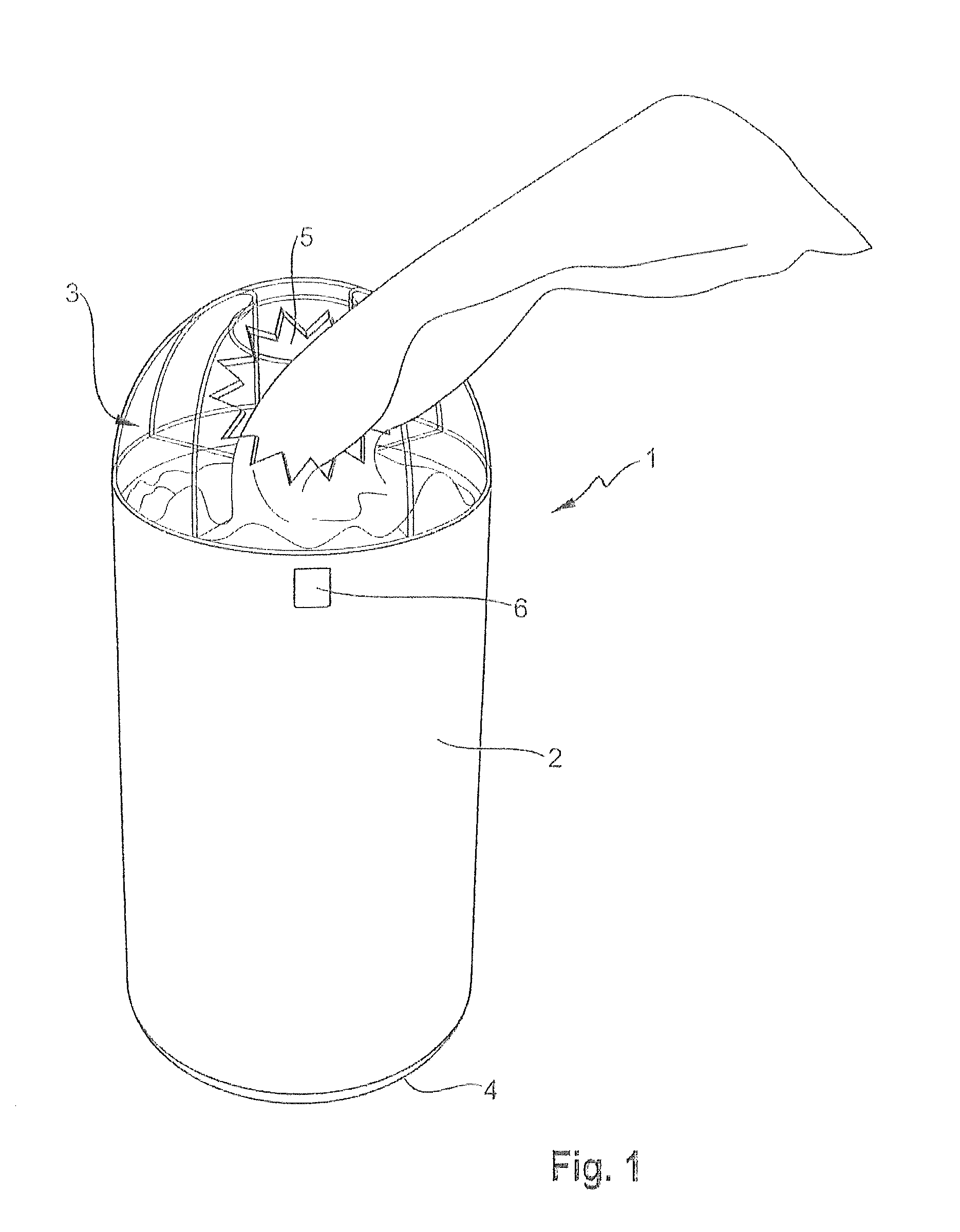

Use of a tacky mat for securing a portable roll dispenser to a horizontal surface and portable roll dispenser

InactiveUS20150053812A1Sufficient adhesivenessContainers for annular articlesDispensing apparatusElastomerEngineering

A tacky mat is made from a tacky elastomeric polymer composition for releasably securing a portable roll dispenser to a surface and a portable roll dispenser on which a tacky mat is arranged, preferably on the bottom of the dispenser, wherein the mat is made from a tacky elastomeric polymer composition.

Owner:SCA HYGIENE PROD AB

Adhesive sheet for water jet laser dicing

InactiveUS20090311474A1Smooth penetrationAvoid precisionFilm/foil adhesivesLayered productsFiberEngineering

An object of the present invention is to provide an adhesive sheet which, through improvement in the permeability of liquids originating in a liquid stream during water jet laser dicing, allows chips, IC components, or the like to be detached, prevents machining precision from being compromised such as by chipping or the scattering of chips and the like, and allows extremely thin semiconductor wafers or materials to be processed. The adhesive sheet for water jet laser dicing of the present invention comprises an adhesive layer laminated on a base film, the base film made of mesh fiber.

Owner:NITTO DENKO CORP

Board-level conformal EMI shield having an electrically-conductive polymer coating over a thermally-conductive dielectric coating

InactiveUS20020166680A1Improve heat distributionLift restrictionsElectrically conductive connectionsMagnetic/electric field screeningConductive coatingConductive polymer

An electrically continuous conformal EMI protective shield for adhering directly to and conforming with surfaces of a printed circuit board is disclosed. The conformal EMI shield includes a thermally conductive dielectric coating adhering directly to surfaces of the printed circuit board to provide an electrically nonconductive, thermally conductive, contiguous coating that covers all such printed circuit board surfaces. The conformal EMI shield also includes a conductive coating adhering directly to surfaces of the dielectric coating to provide an electrically conductive layer that prevents electromagnetic emissions from passing through the conformal EMI protective shield.

Owner:HEWLETT PACKARD DEV CO LP

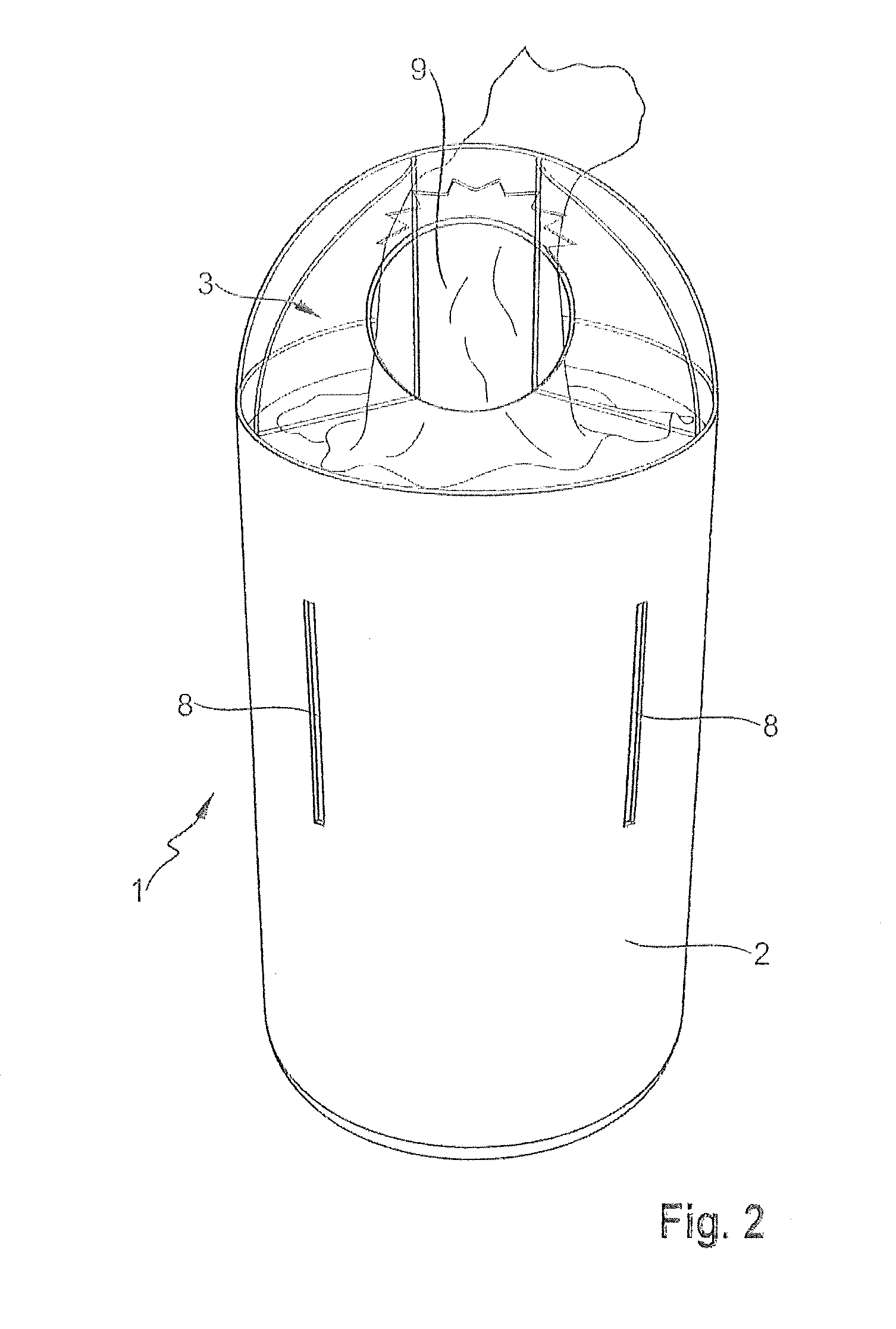

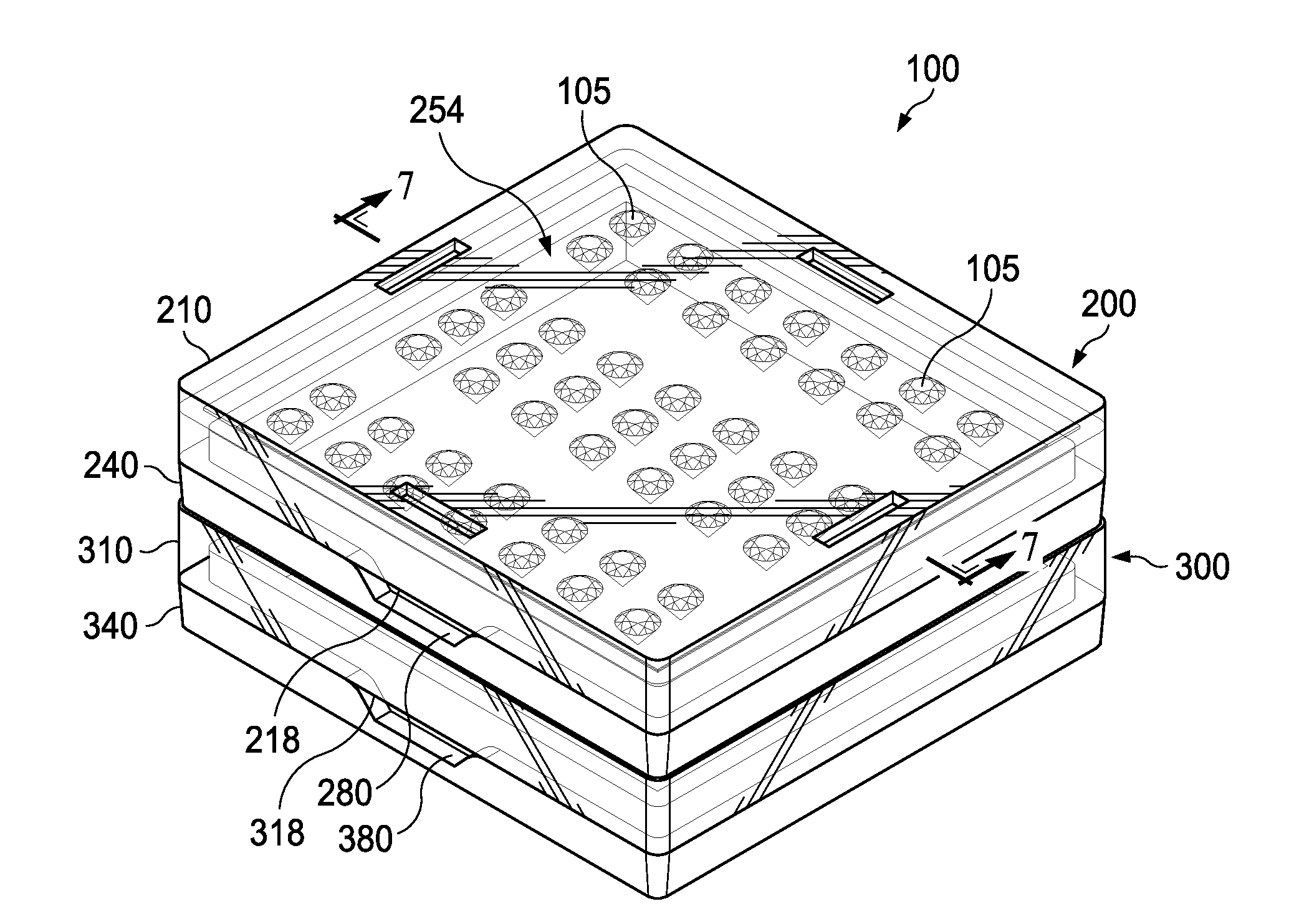

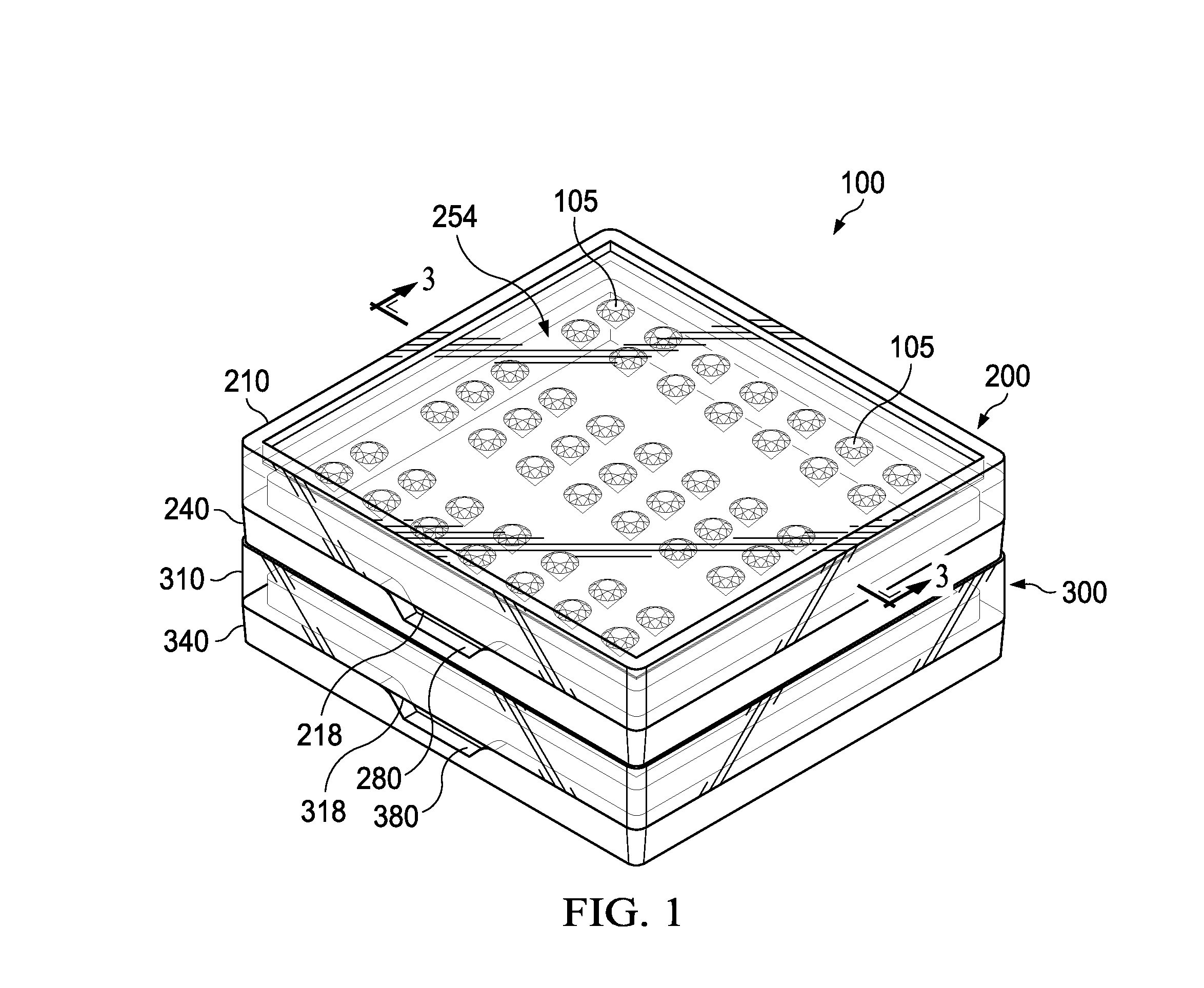

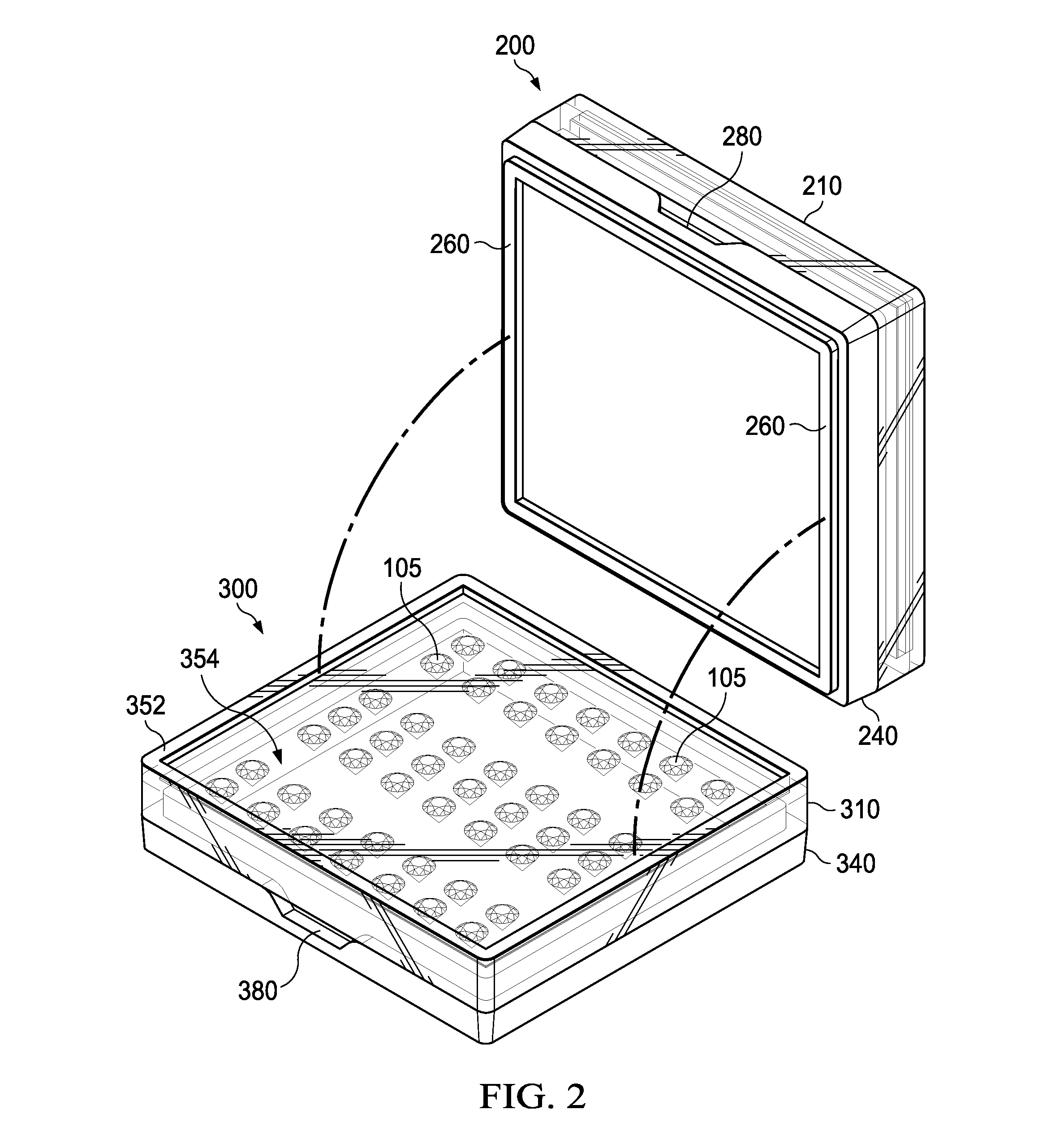

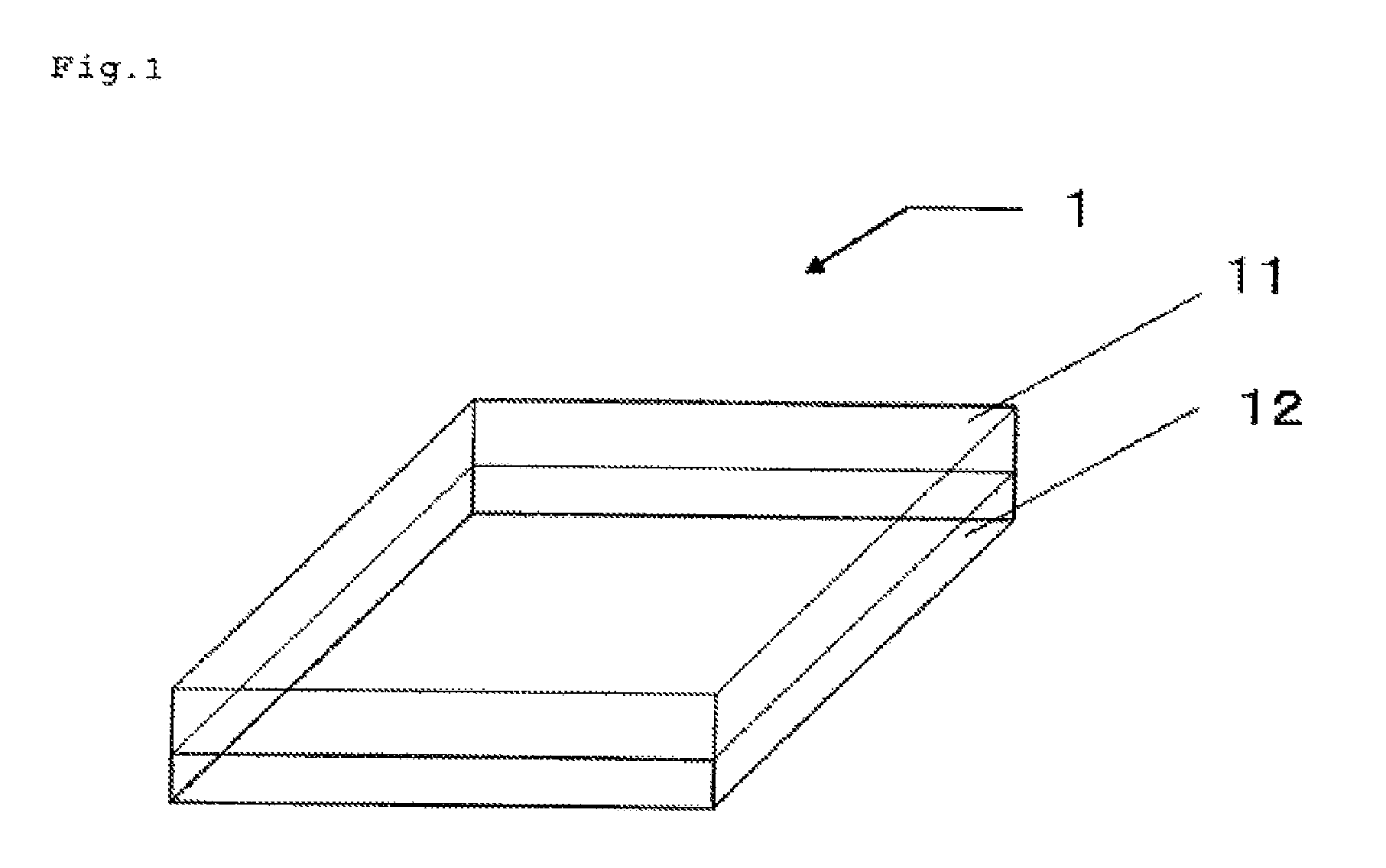

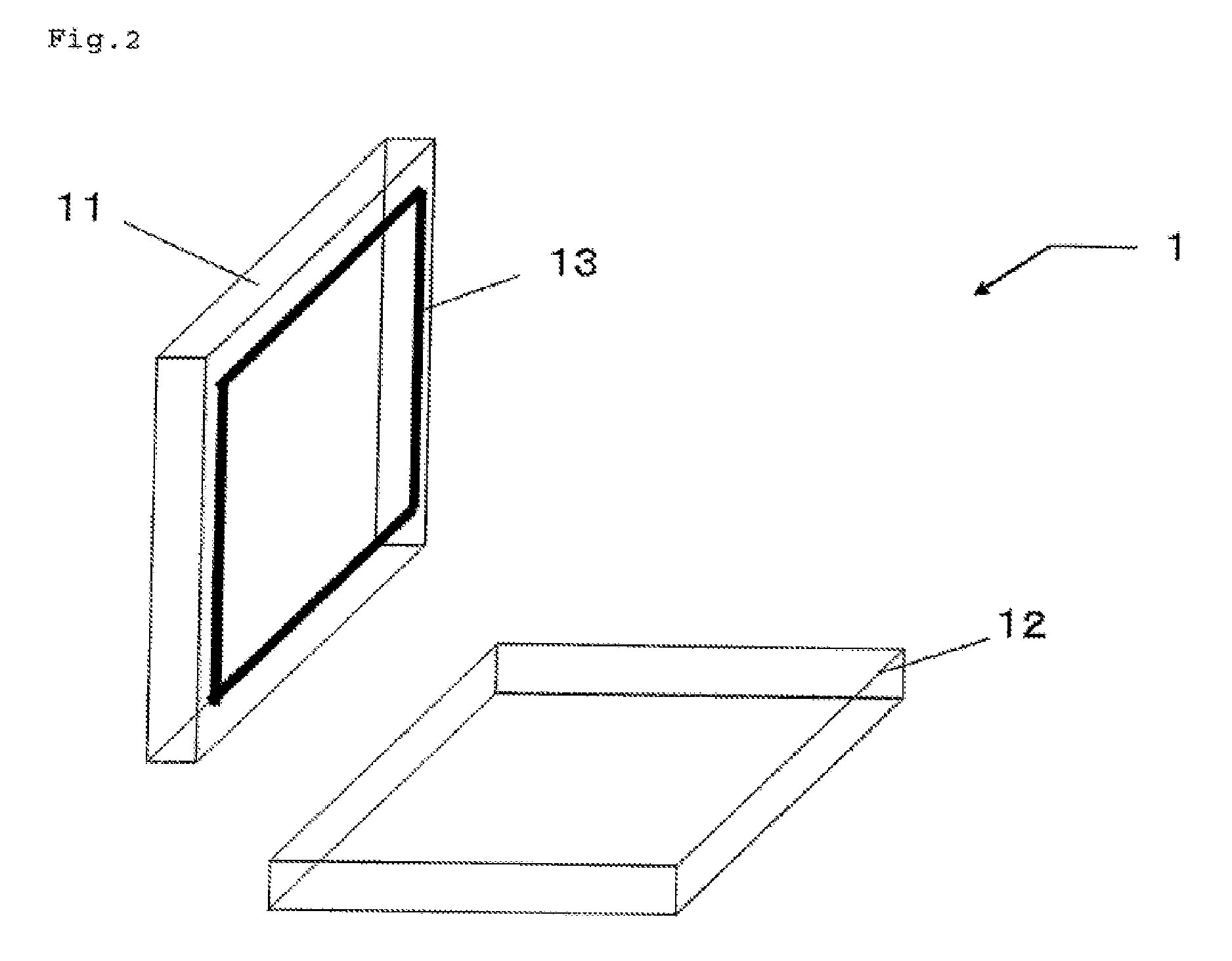

Stackable Gemstone Carrying Case

ActiveUS20160174675A1Degree of adhesivenessMinimize distortionShow cabinetsOther accessoriesOptical propertyAdhesive

An exemplary embodiment provides a stackable container for gemstones that has an optically clear lid having an optically planar upper surface with a first optical property, such as a refractive index. The lid has an underside coating of a clear gel adhesive having a second optical property matched with the first optical property to minimize optical distortion. The gel releasably adheres gemstones to the lid. The base and lid of the stackable container clamp releasably together without hinges and without a snap fit closure. The container has a gemstone containment volume wherein gemstones appear to “float” and can be examined. For stackability, an upper region of the lid mounts releasably to an underside of a base of a like second stackable container; and the base mounts releasably to an upper region of a lid of a like third stackable container such that a plurality of stackable containers are stackable in an array.

Owner:BEDMAN MARGO OTYSON +2

Printed wiring board

InactiveUS7800917B2Increase stiffnessSufficient adhesivenessPrinted circuit aspectsPrinted circuit manufactureConductive materialsElectrical and Electronics engineering

A printed wiring board has a first wiring layer formed at least on one surface of an insulative substrate, an insulating layer formed as covering the first wiring layer, and a second wiring layer formed on the insulating layer. The insulating layer is formed of a cured insulative sheet made of a high-stiff sheet-type reinforcing material containing resin. The first and second wiring layers are electrically connected to each other through at least one hole having a bottom. The second wiring layer is united with the insulating layer at an interface thereof with a conductive material of the second wiring layer injected into concave sections provided on the interface. Another printed wiring board has an insulative substrate having a first surface and a second surface, a first insulating layer and a second insulating layer formed on the first surface and the second surface, respectively, and a first wiring layer formed on the first insulating layer and a second wiring layer formed on the second insulating layer. The first and second wiring layers are electrically connected to each other via at least one through hole. The first wiring layer is united with the first insulating layer at an interface thereof with a conductive material of the first wiring layer injected into concave sections provided on the interface. The second wiring layer is united with the second insulating layer at an interface thereof with a conductive material of the first wiring layer injected into concave sections provided on the interface.

Owner:MEIKO ELECTRONICS CO LTD

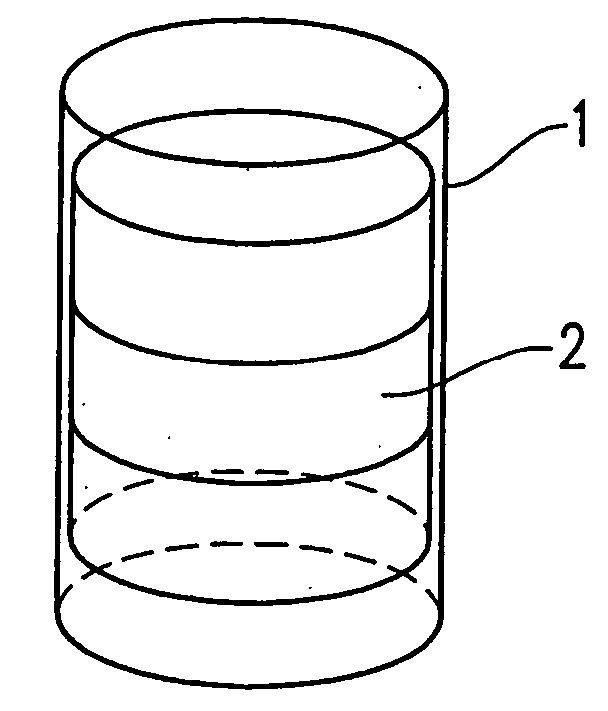

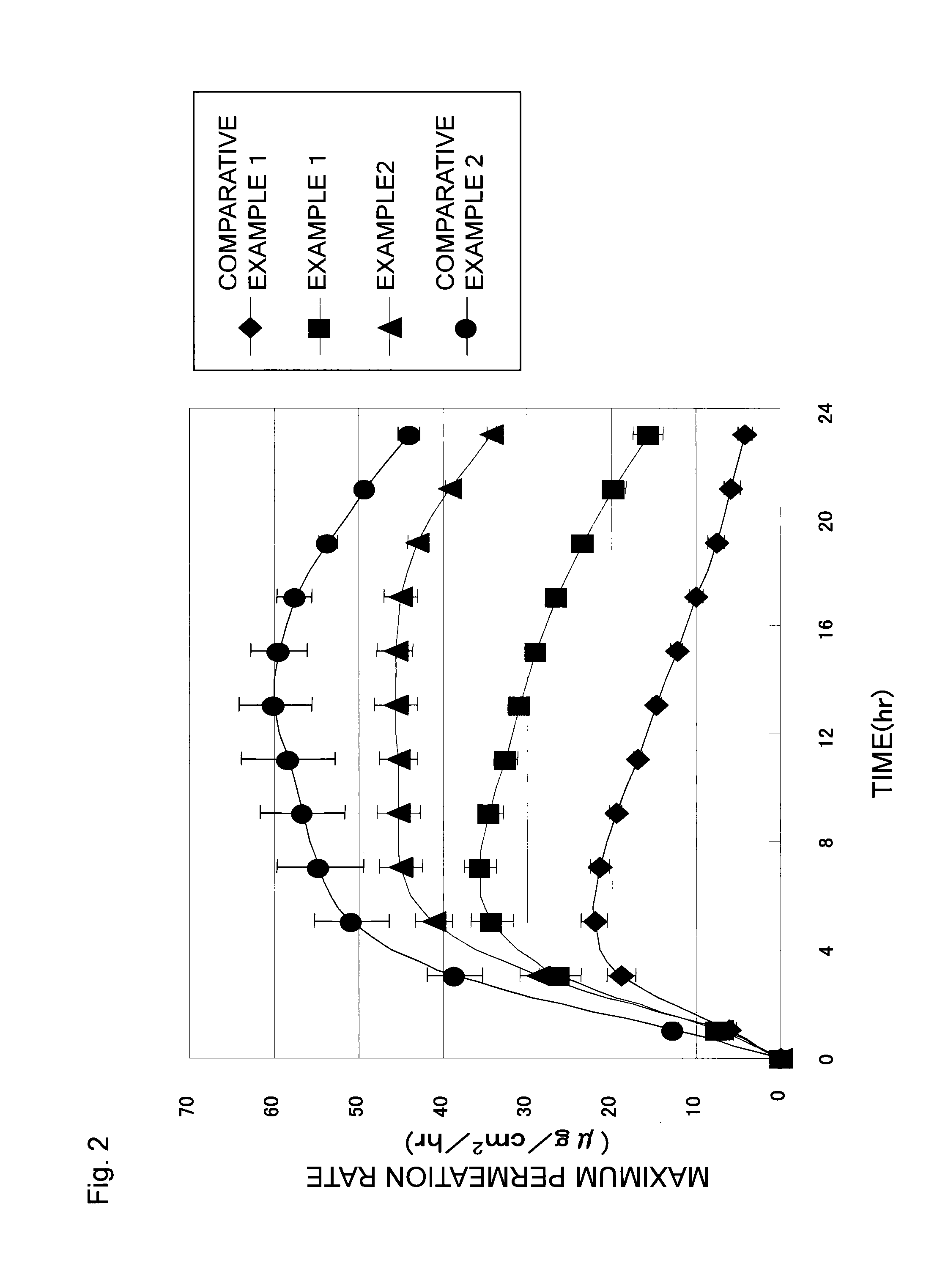

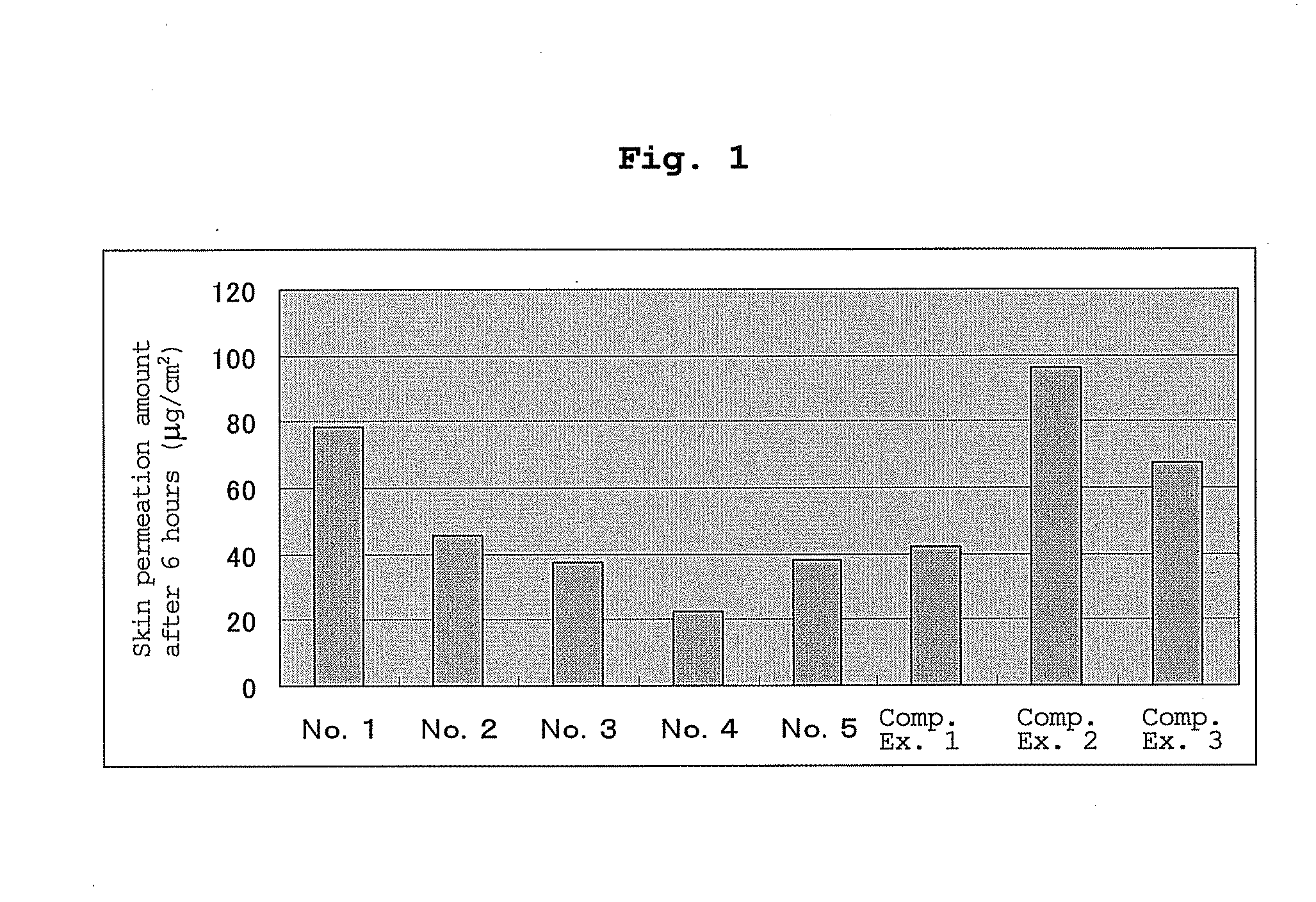

Ropinirole-containing patch and package thereof

ActiveUS20140170205A1Excellent skin permeabilitySufficient adhesivenessBiocideNervous disorderChemistryRopinirole

A ropinirole-containing patch comprises an adhesive agent layer and a support layer, the adhesive agent layer containing ropinirole and / or a pharmaceutically acceptable salt thereof, wherein a content of the ropinirole and / or the pharmaceutically acceptable salt thereof in terms of free ropinirole in the adhesive agent layer satisfies the following two conditions:5 to 13.2% by mass relative to a total mass of the adhesive agent layer, and0.12 to 2.7 mg / cm2 per unit area of the adhesive agent layer.

Owner:HISAMITSU PHARM CO INC

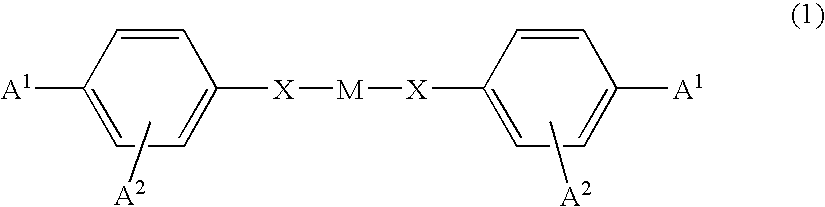

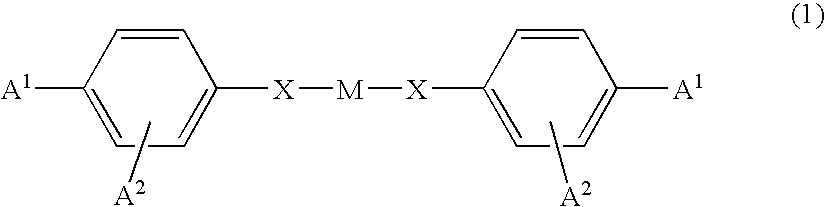

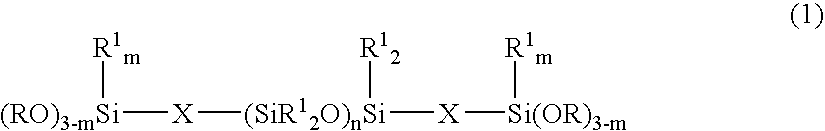

Room temperature-curable organopolysiloxane composition

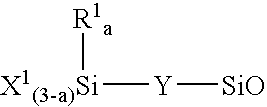

A room temperature-curable organopolysiloxane composition is provided. The composition comprises(A) 100 parts by weight of a organopolysiloxane represented by the following general formula (1):wherein R is a monovalent hydrocarbon group containing 1 to 5 carbon atoms, R1 is independently a substituted or unsubstituted monovalent hydrocarbon group containing 1 to 10 carbon atoms; n is an integer of at least 10; X is oxygen atom or an alkylene group containing 2 to 5 carbon atoms, and m is independently an integer of 0 or 1; or a mixture of such organopolysiloxane;(B) 50 to 150 parts by weight of a colloidal calcium carbonate having a specific surface area measured by BET method of at least 10 m2 / g;(C) 100 to 200 parts by weight of a heavy calcium carbonate having a specific surface area measured by BET method of up to 8 m2 / g;(D) 1 to 25 parts by weight of an organosilicon compound having at least 3 hydrolyzable groups bonded to silicon atom in one molecule represented byR2aSi(OR3)4-a wherein R2 is a monovalent hydrocarbon group containing 1 to 12 carbon atoms, R3 is a monovalent hydrocarbon group containing 1 to 5 carbon atoms, and a is 0 or 1; or its partial hydrolysate; and(E) 0.01 to 10 parts by weight of a curing catalyst. The mass ratio of the component (B) to the component (C) is less than 1.

Owner:SHIN ETSU CHEM IND CO LTD

Heat-peelable pressure-sensitive adhesive sheet for cutting laminated ceramic sheet and method for cut-processing laminated ceramic sheet

InactiveUS20100215882A1Sufficient adhesivenessEasy to peelLamination ancillary operationsLaminationPressure sensitivePolymer

The invention relates to a heat-peelable pressure-sensitive adhesive sheet for cutting a laminated ceramic sheet, which is used for temporary fixing at cutting of the laminated ceramic sheet, the heat-peelable pressure-sensitive adhesive sheet including a base material and, formed on at least one surface of the base material, a heat-expandable pressure-sensitive adhesive layer containing a pressure-sensitive adhesive, a foaming agent and a tackifying resin, in which the heat-expandable pressure-sensitive adhesive layer has a gel fraction of 50% by weight or more, and the base polymer of the pressure-sensitive adhesive forming the heat-expandable pressure-sensitive adhesive layer has an acid value of 350 mg-KOH / g or less and the tackifying resin contained in the heat-expandable pressure-sensitive adhesive layer has an acid value of 80 mg-KOH / g or less.

Owner:NITTO DENKO CORP

Multistage gasket

InactiveUS8400730B2Sufficient adhesivenessPrevent peelingEngine sealsOther chemical processesHigh humidityMechanical engineering

A multi-stage gasket having a multi-stage structure constituted by multiple kinds of gasket materials and being used by holding between a cover plate and a base plate, the multi-stage gasket having contactness of a gasket as the lowermost layer to the cover plate or the base plate in contact with the gasket that is higher than contactness of a gasket as the uppermost layer to the cover plate or the base plate in contact with the gasket. A gasket can be provided that provides good reworkability of a cover plate and a base plate of a hard disk device, provides sufficient adhesiveness of the gasket to a cover plate and a base plate even when used in a high humidity and temperature environment, and is prevented from being toppled sideways or peeled off even when applied with a force in an oblique direction.

Owner:BRIDGESTONE CORP

Semiconductor device

InactiveUS7554193B2Reduce thermal resistanceResistance reducing effect is limitedSemiconductor/solid-state device detailsSolid-state devicesControl circuitSemiconductor device

A semiconductor device capable of reducing the thermal resistance in a flip chip packaging structure while achieving both the high radiation performance and manufacturing readiness without increasing the manufacturing cost is provided. In a semiconductor device having a semiconductor circuit for power amplification and a control circuit of the semiconductor circuit laminated on a multilayer circuit board, the semiconductor circuit for power amplification and the control circuit are aligned in parallel on the same semiconductor element, and the semiconductor element is flip-chip connected on the multilayer circuit board. Further, a second semiconductor element mounted in addition to the first semiconductor element and all components and submodules are flip-chip connected. Also, a plurality of bumps are united in order to improve the radiation performance and thermal vias of the multilayer circuit board are formed in second and lower layers of the wiring layers in the multilayer circuit board.

Owner:RENESAS ELECTRONICS CORP

Transdermal preparation

InactiveUS20130224262A1Sufficient adhesivenessReduce skin irritationBiocideAntipyreticElastomerOrganic acid

The invention provides a transdermal absorption preparation showing sufficient adhesiveness on adhesion to the skin, causing low skin irritation, and capable of well controlling releaseability of lidocaine. The transdermal absorption preparation contains a support and an adhesive layer formed on the support. The adhesive layer contains a drug, as well as a thermoplastic elastomer, more than 300 parts by weight of liquid paraffin per 100 parts by weight of the elastomer, not more than 10 wt % of a tackifier, lidocaine, and an organic acid.

Owner:KM TRANSDERM LTD +1

Light-transmitting electromagnetic-shielding laminate and method for producing the same, light-transmitting radio wave absorber, and adhesive composition

InactiveUS8889570B2High transparencyImprove visibilityMagnetic/electric field screeningVehicle componentsSilane compoundsElectricity

Disclosed is a light-transmitting electromagnetic-shielding laminate, which is characterized in that two or more layers including an electromagnetic-shielding layer are arranged in layers using a (meth)acrylate adhesive composition which contains a (meth)acrylate monomer, a (meth)acrylate oligomer and at least one member selected from the group consisting of acrylic amide derivatives, silane compounds and organophosphorus compounds. Also disclosed is a light-transmitting radio wave absorber which is characterized in that a resistive layer, a dielectric spacer and a reflective layer are arranged in layers using a (meth)acrylate adhesive composition which contains a (meth)acrylate monomer, a (meth)acrylate oligomer and at least one member selected from the group consisting of acrylic amide derivatives, silane compounds and organophosphorus compounds.

Owner:MITSUBISHI GAS CHEM CO INC

Adhesive skin patch

InactiveUS20150030666A1Good skin permeabilitySufficient adhesivenessBiocideUrinary disorderSolventDrug

The present invention provides an adhesive skin patch containing a support and an adhesive layer containing a drug which is formed on the support, wherein the adhesive layer comprises a thermoplastic elastomer, a liquid component in an amount exceeding 300 parts by weight per 100 parts by weight of the thermoplastic elastomer, a therapeutic drug having an anticholinergic activity or a salt thereof for overactive bladder as a drug, (A) a non-volatile hydrocarbon oil as a liquid component, and one or more kinds selected from the group consisting of (B) an amide solvent, (C) an alcohol solvent and (D) a liquid organic acid as a liquid component, or a fatty acid salt, and optionally comprises a tackifier at a content of not more than 10 wt % of the adhesive layer.

Owner:KM TRANSDERM LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com