Patents

Literature

146results about How to "Secure bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

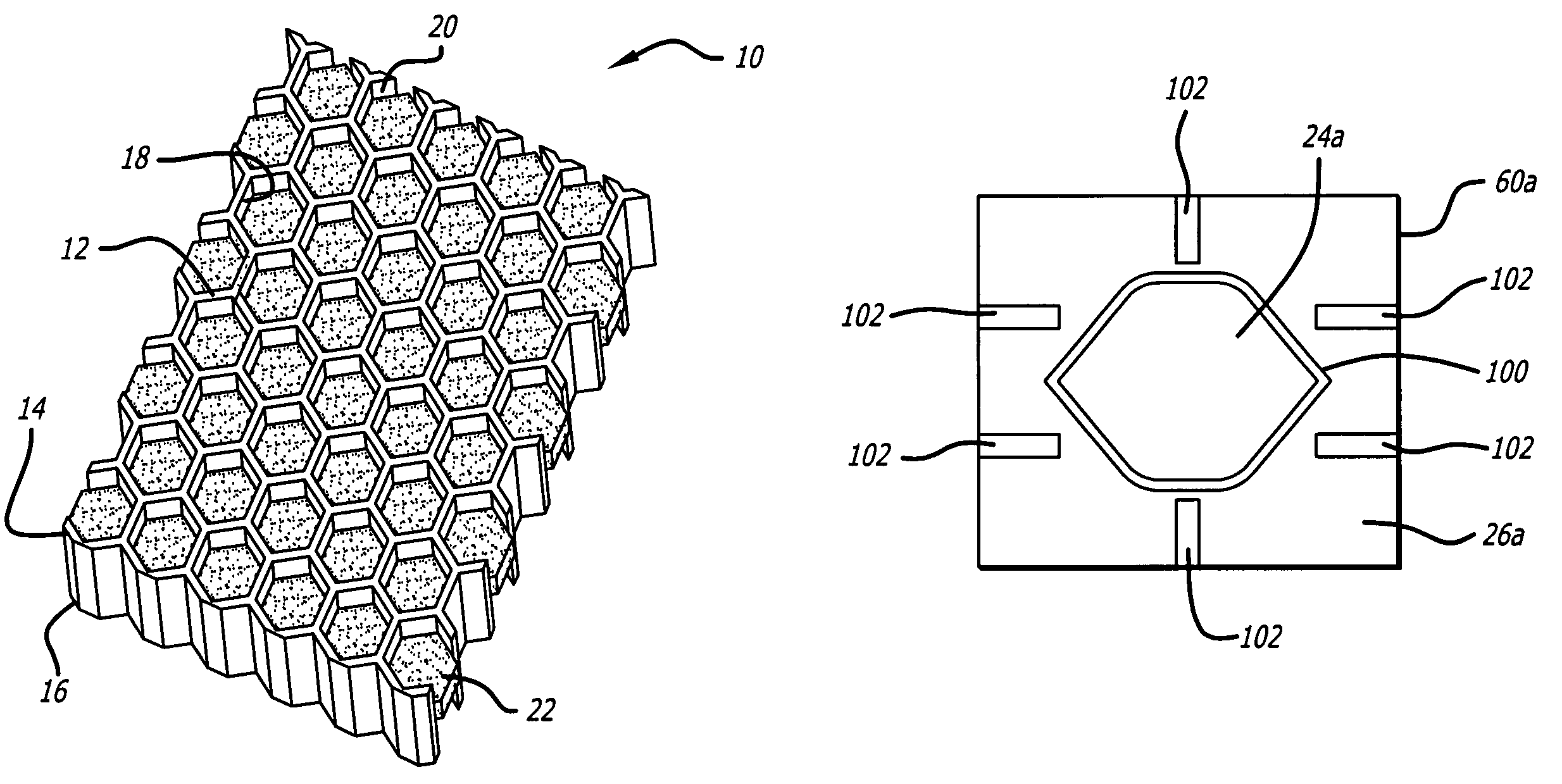

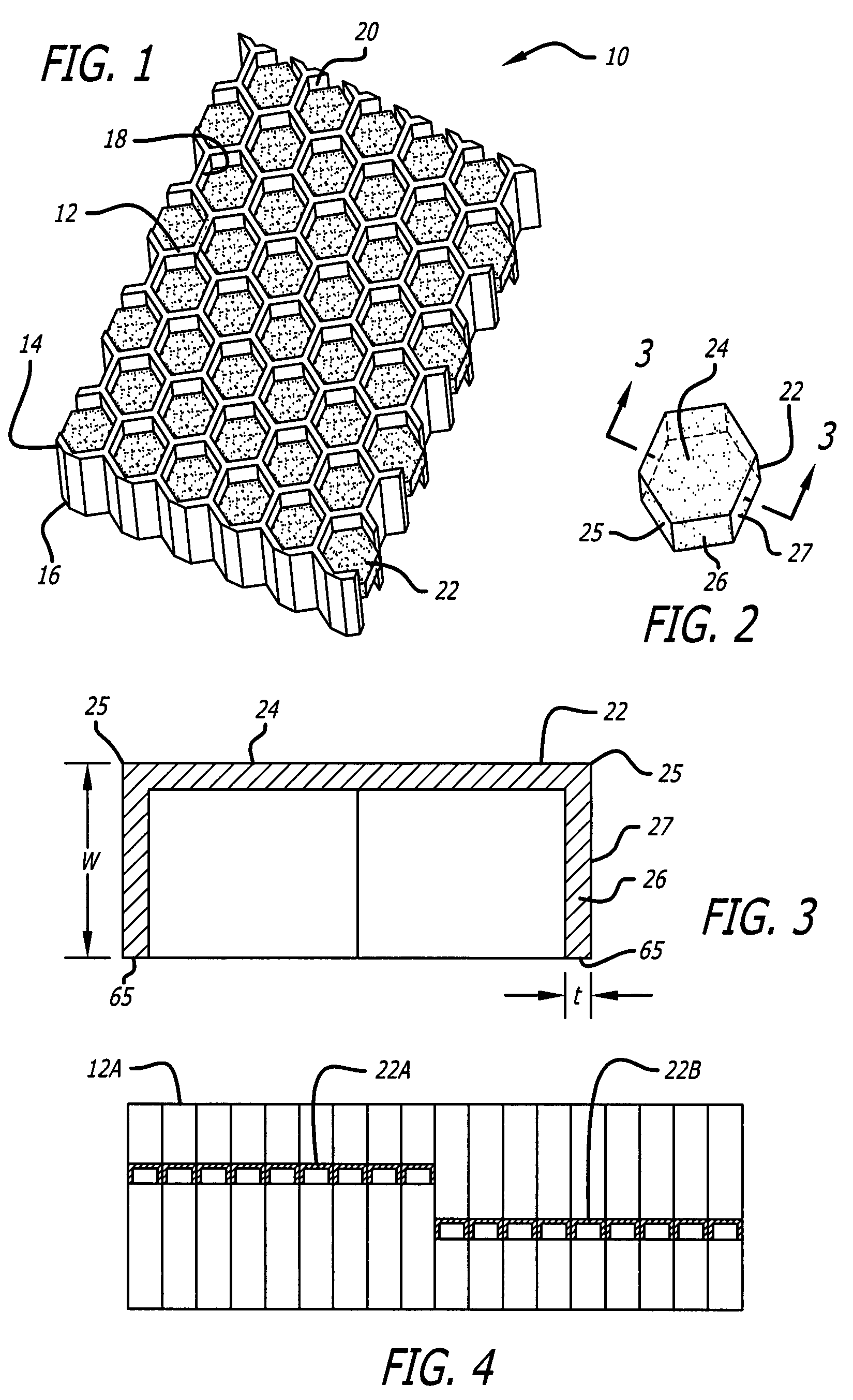

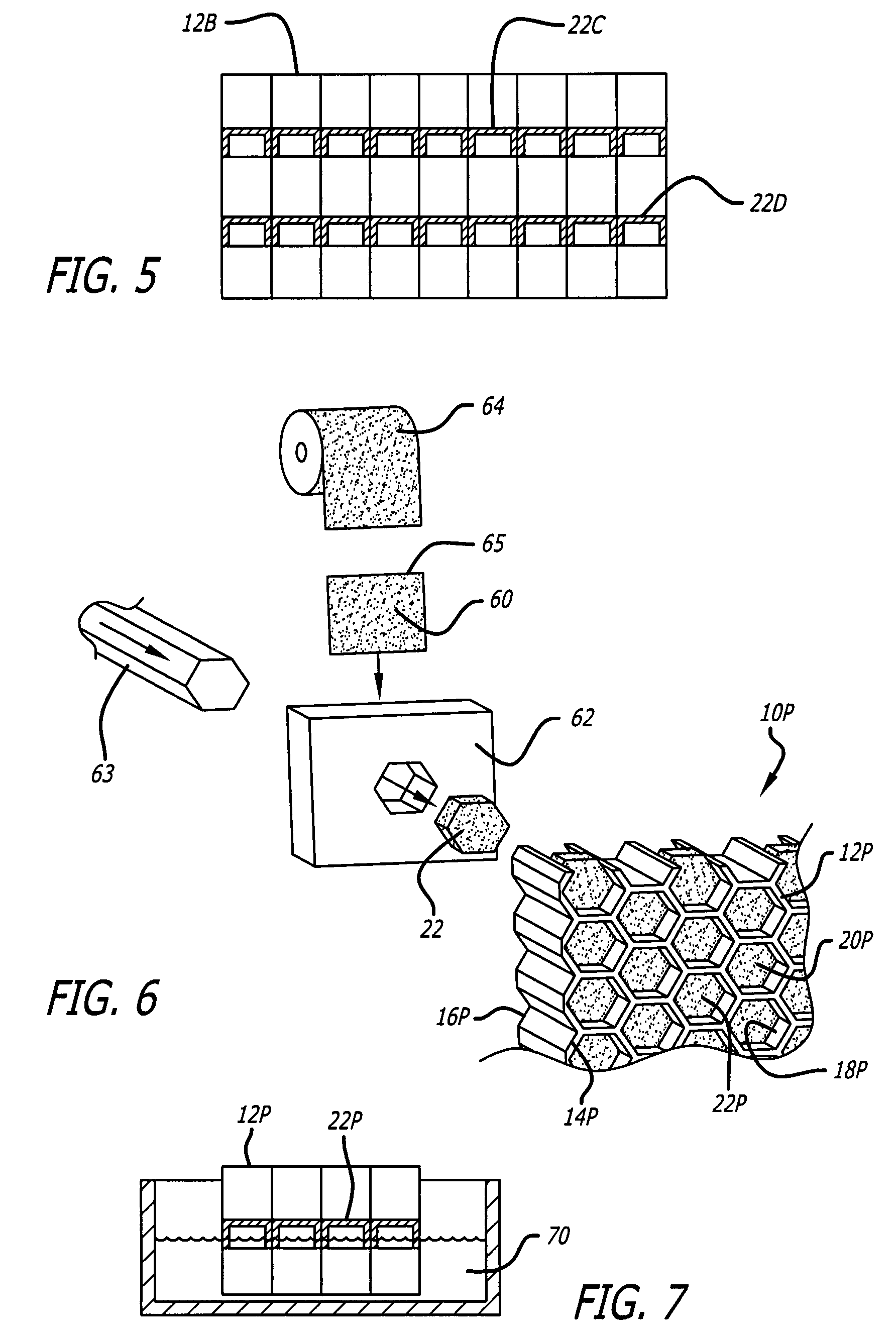

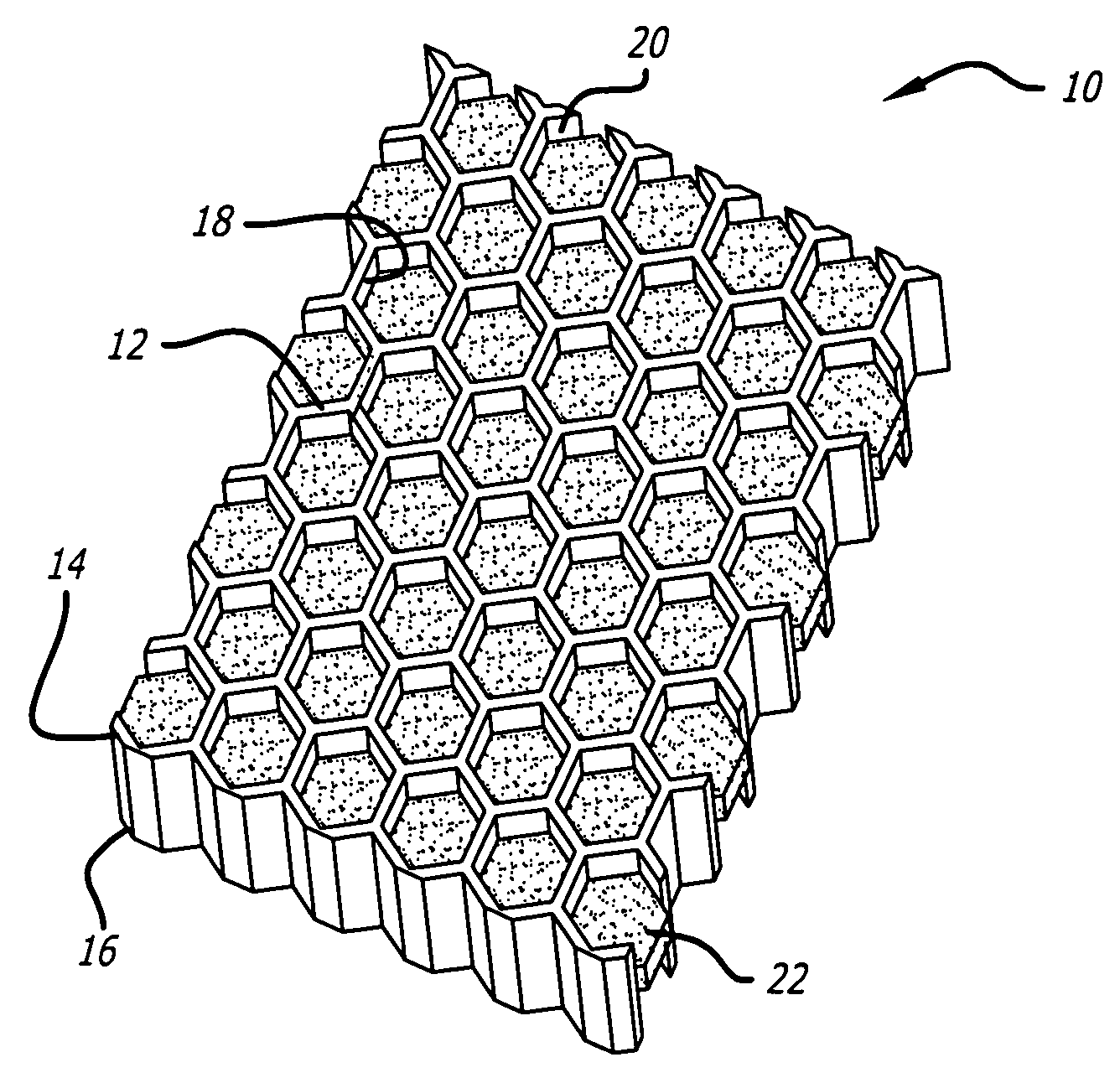

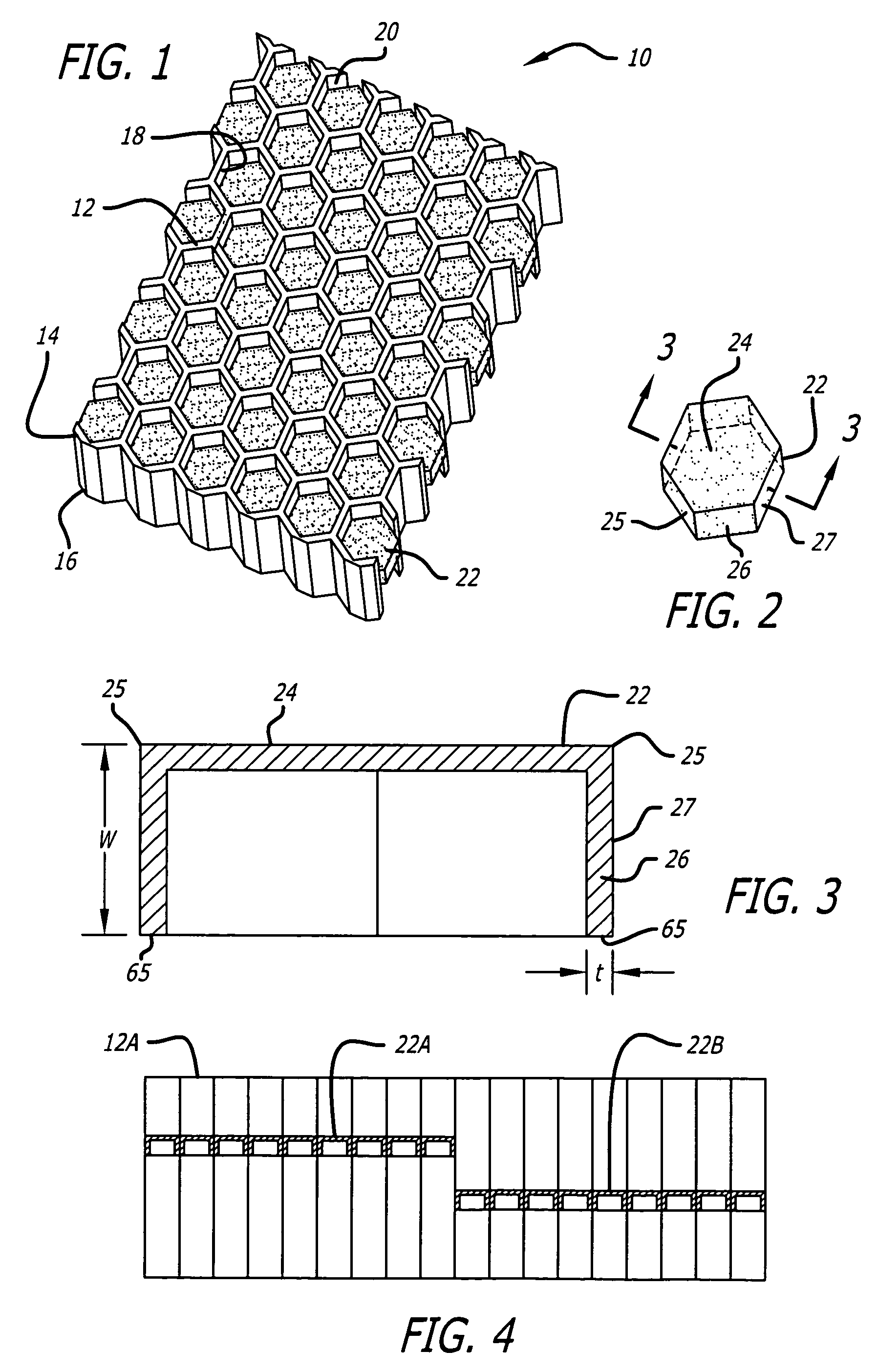

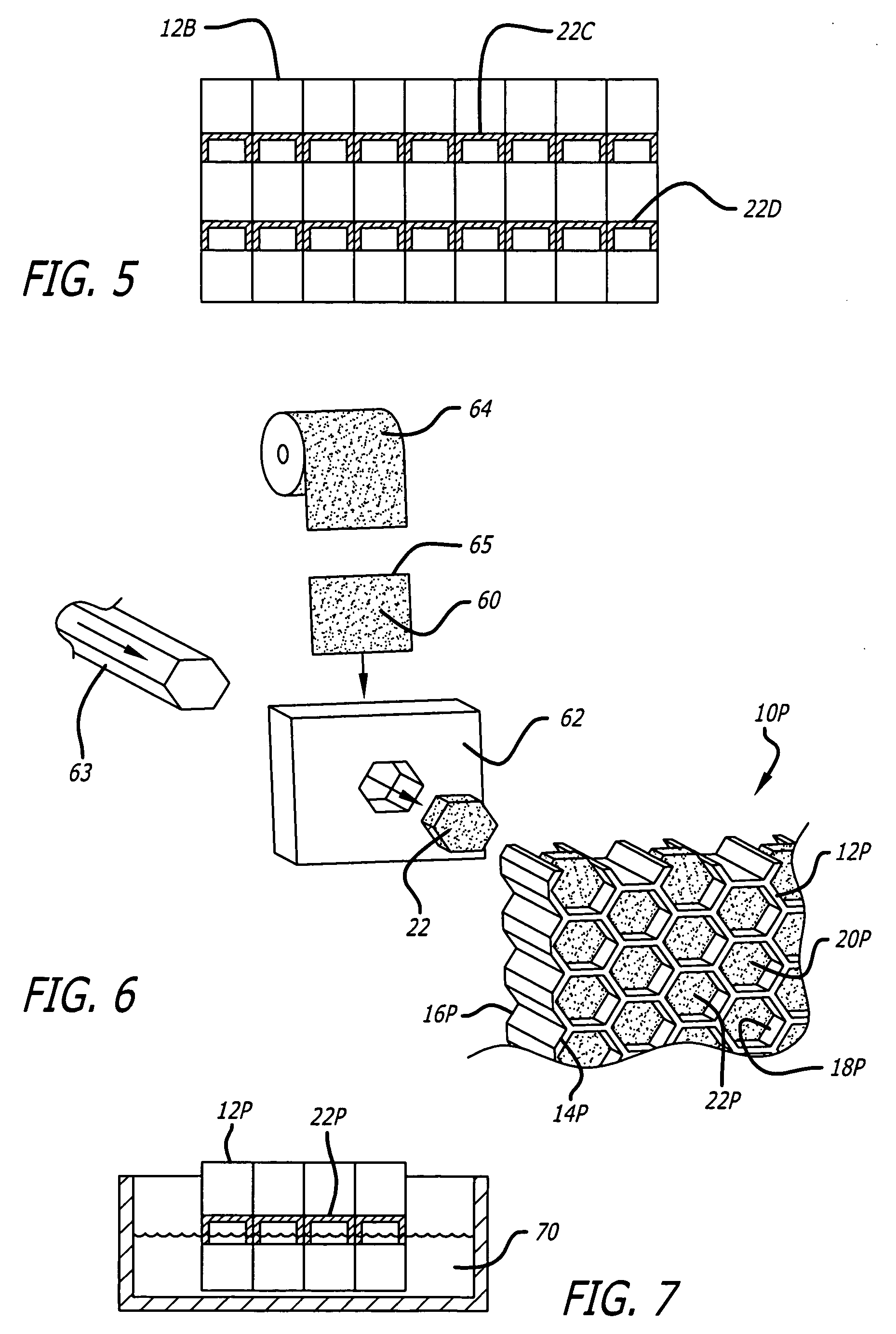

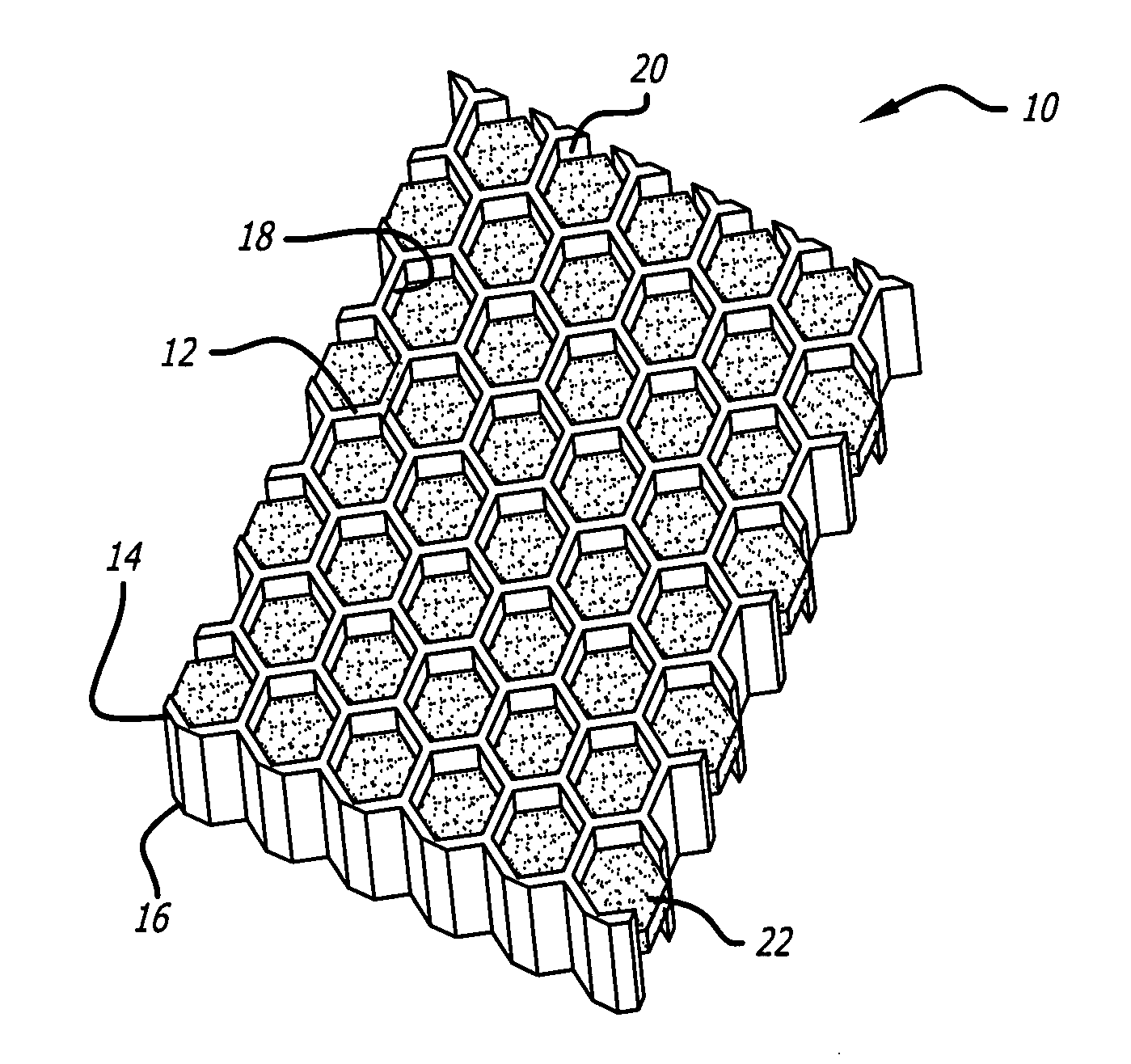

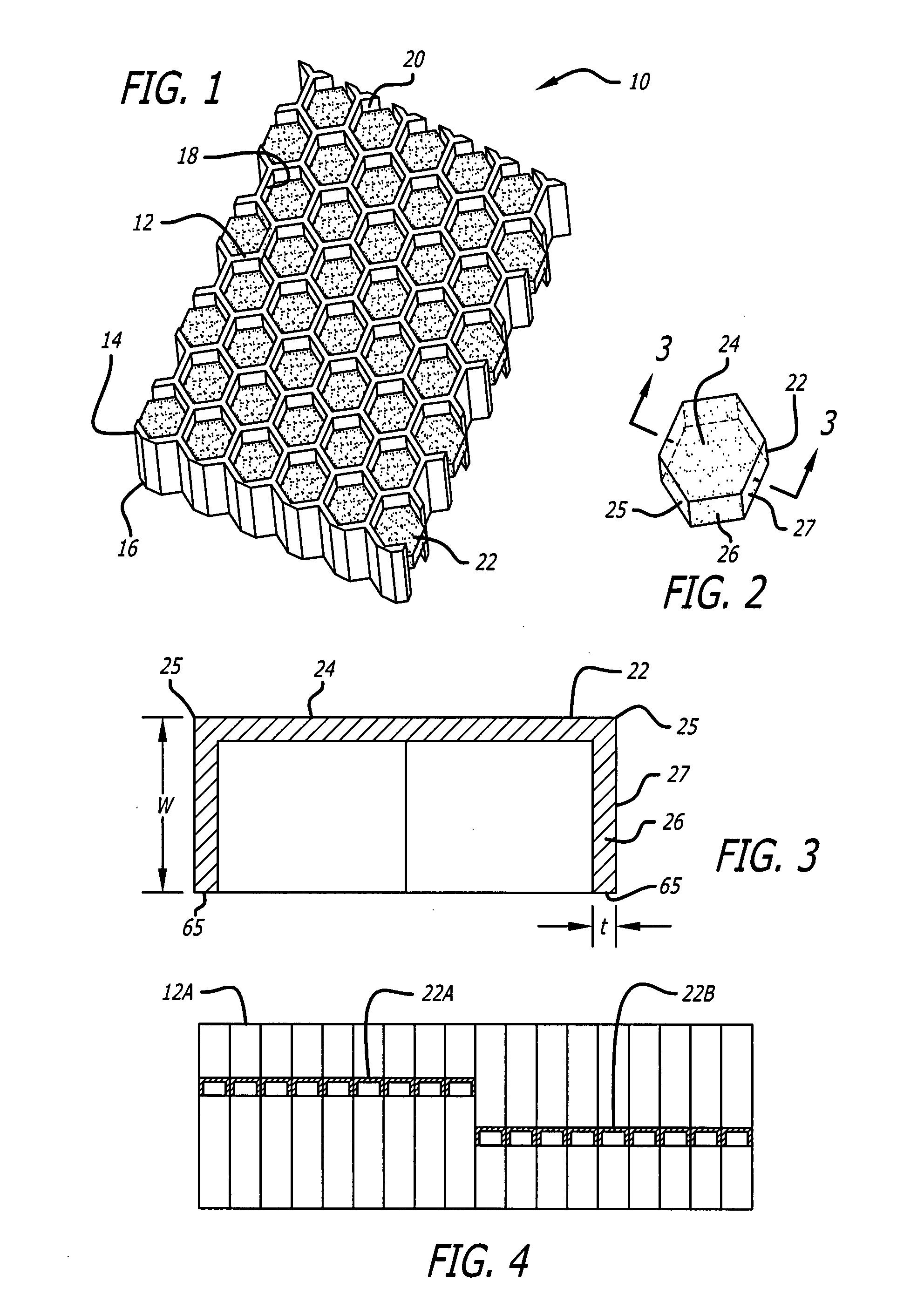

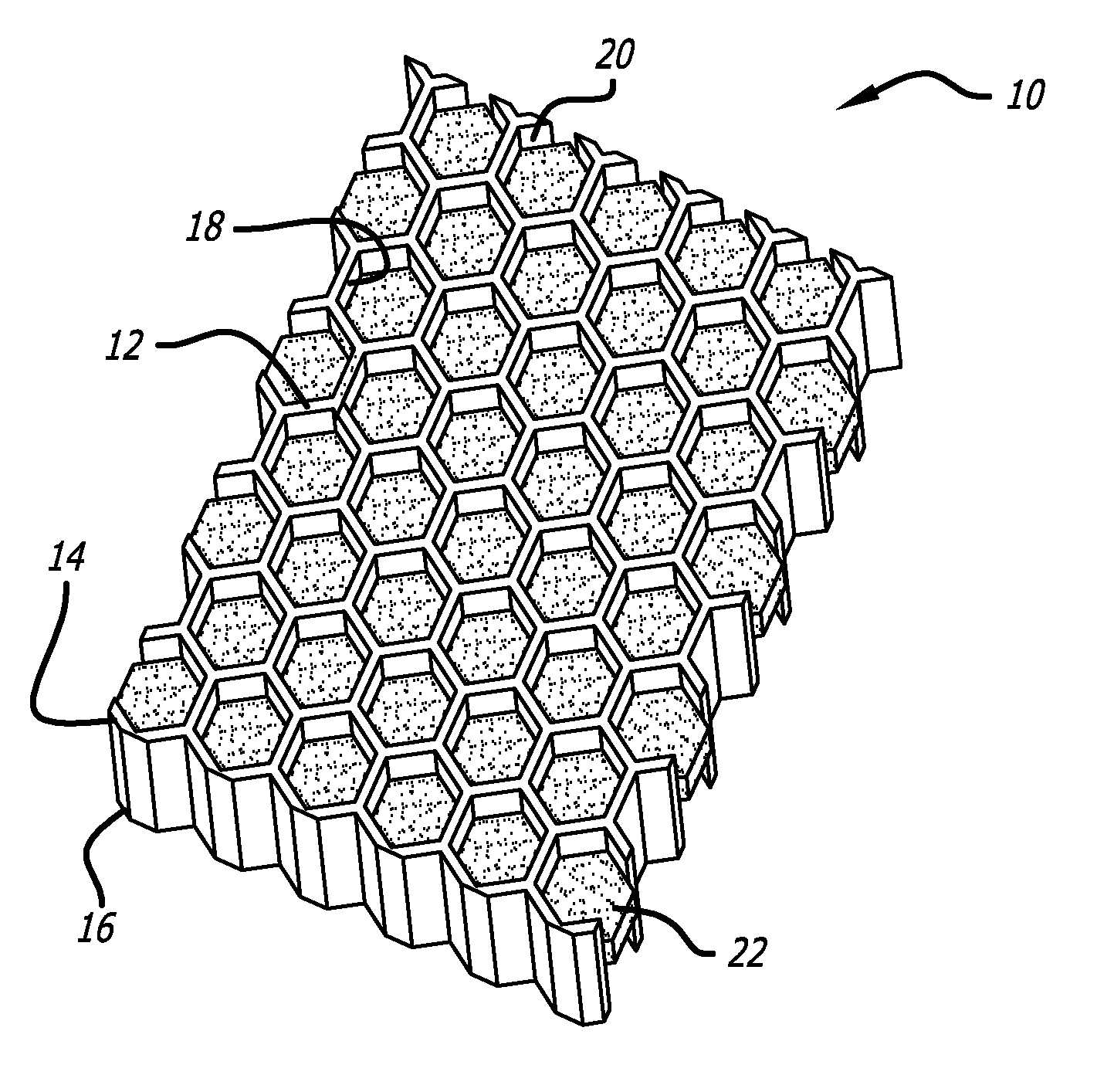

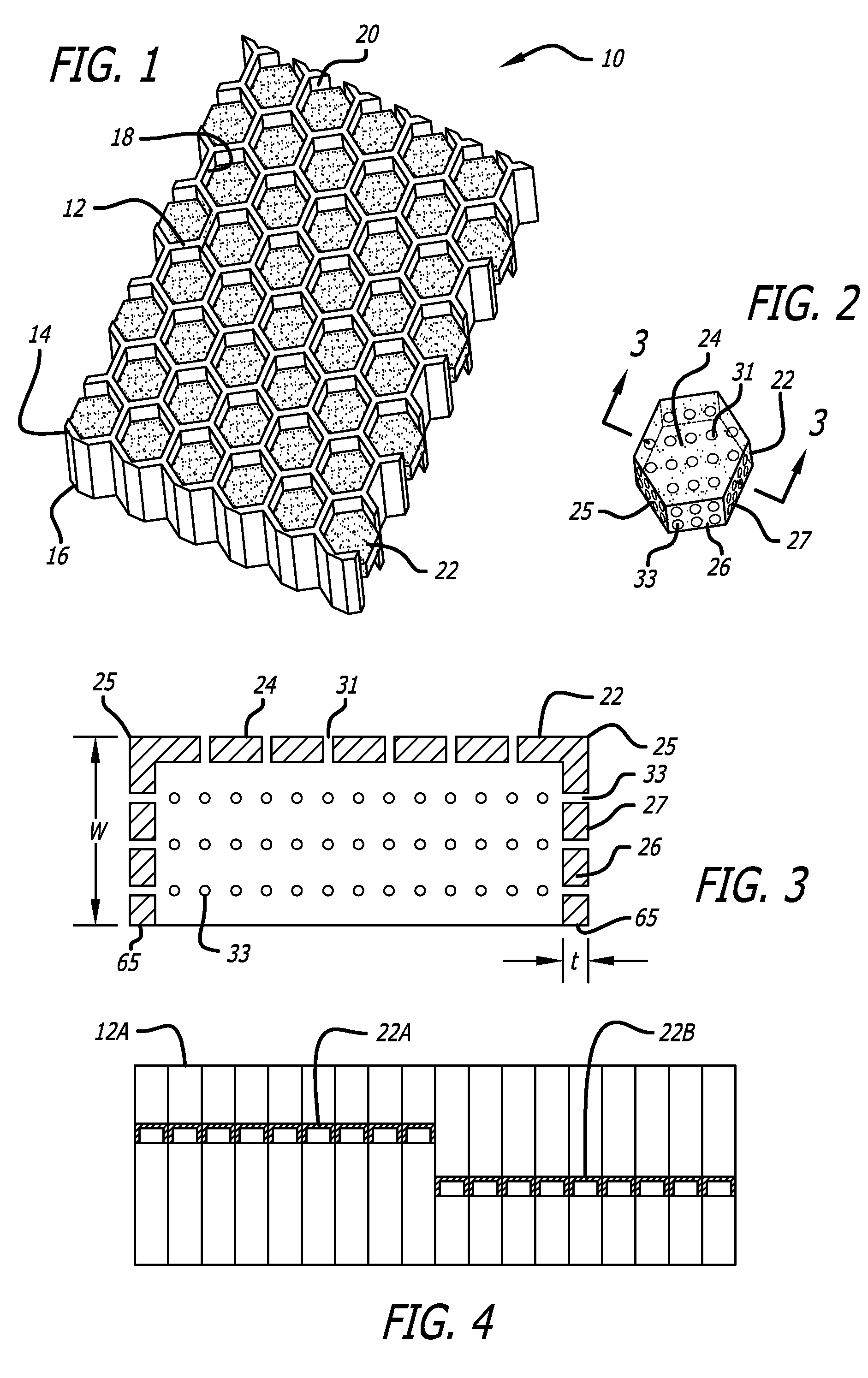

Acoustic septum cap honeycomb

Owner:HEXCEL

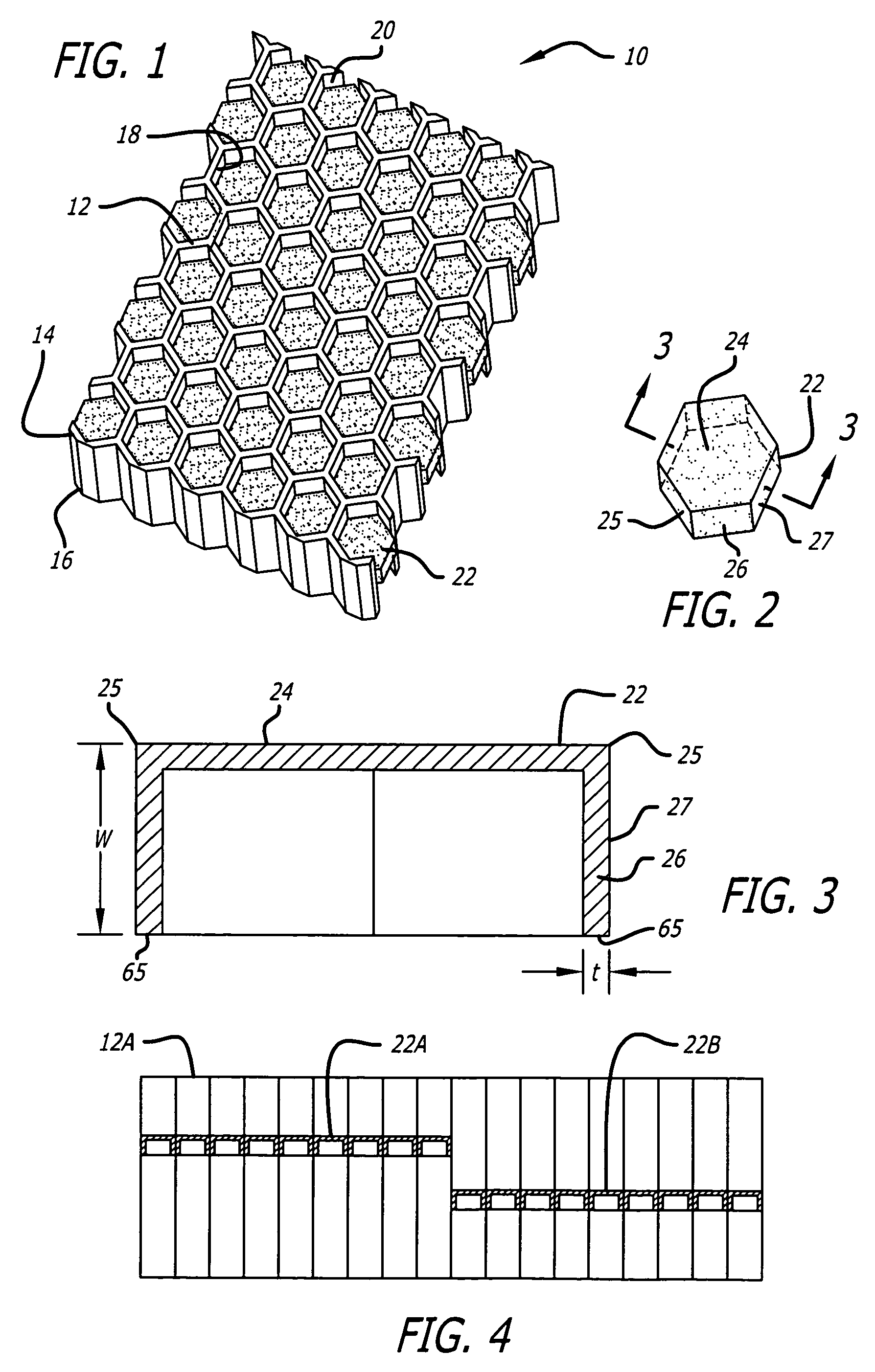

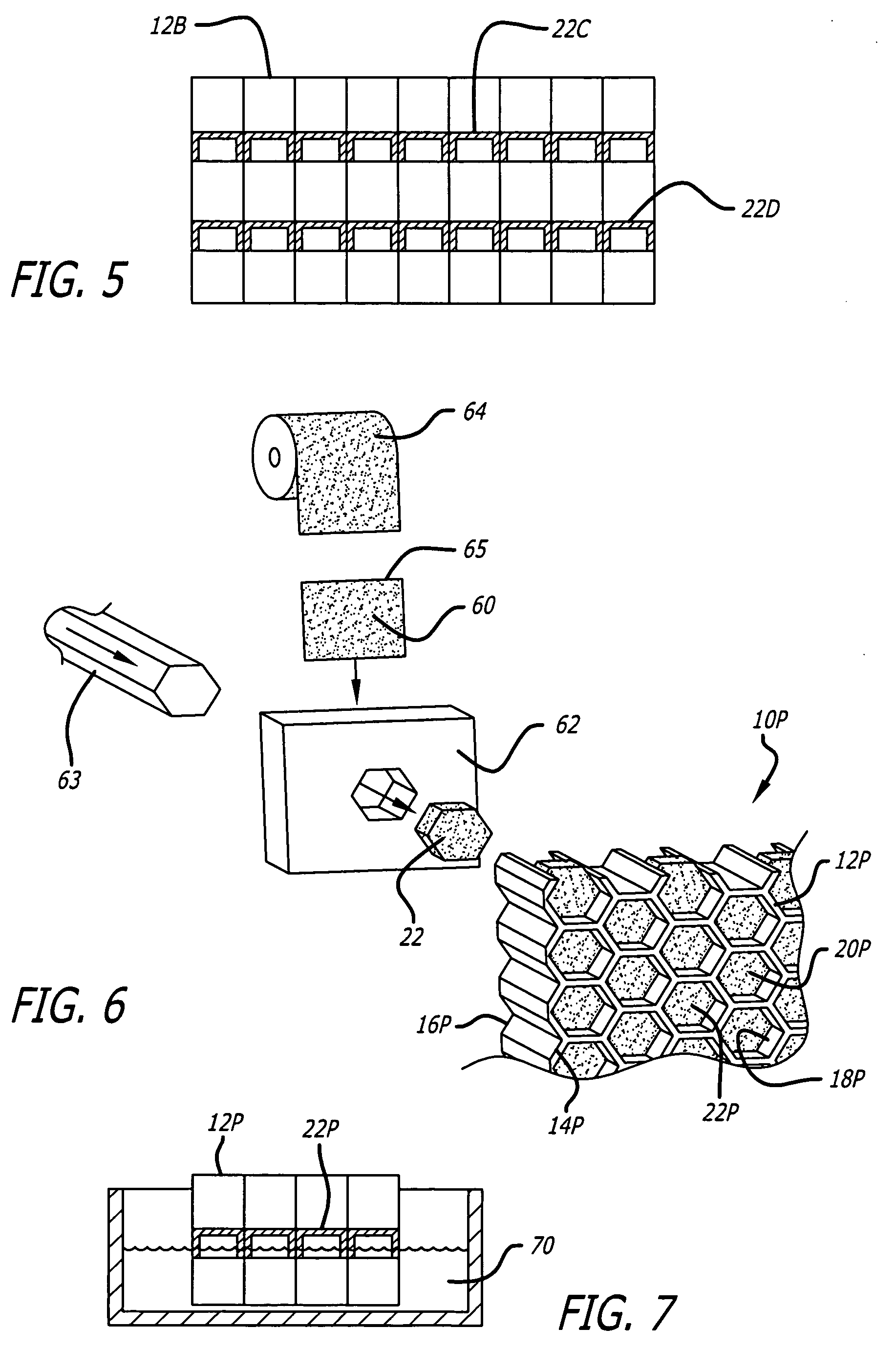

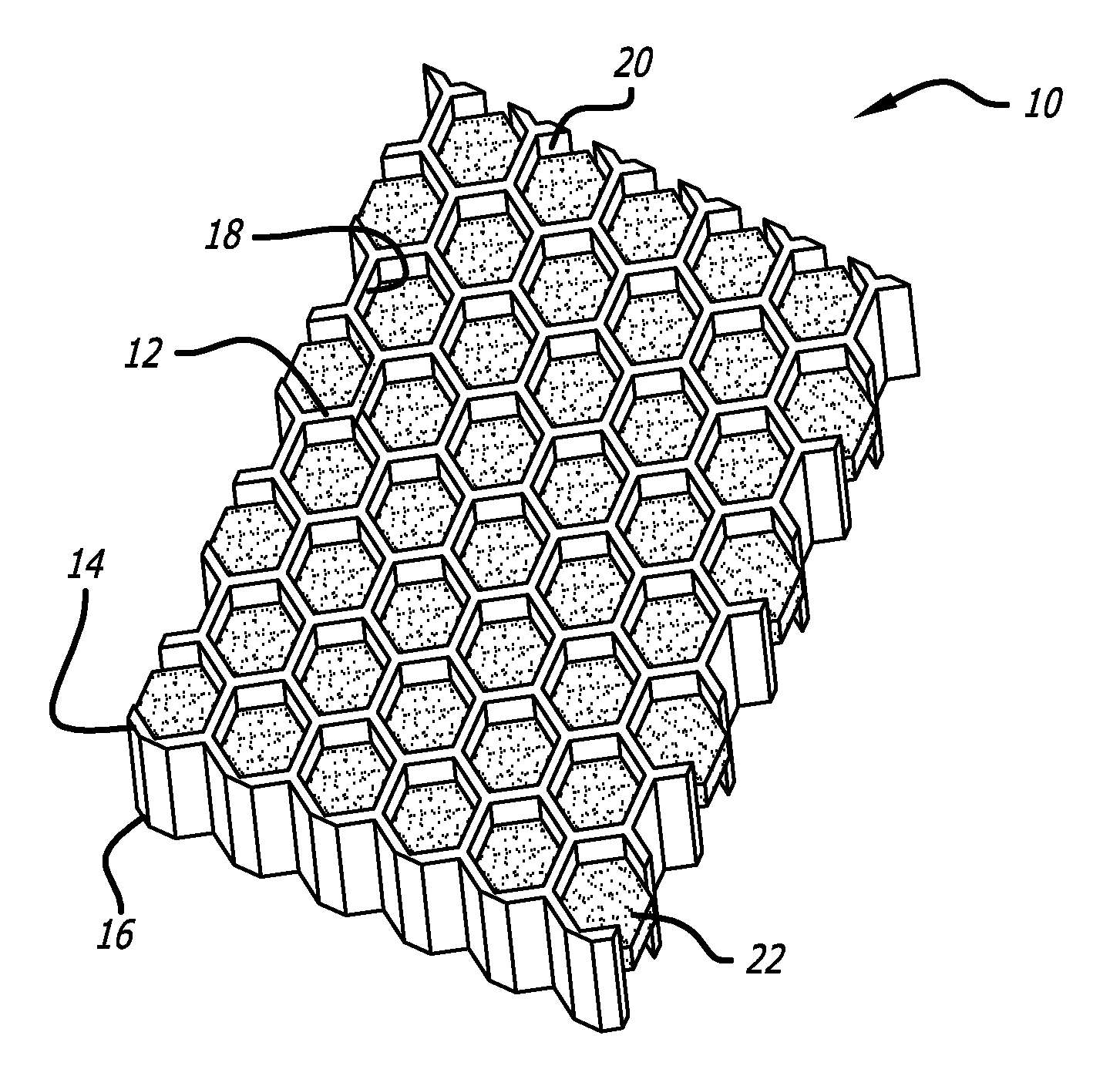

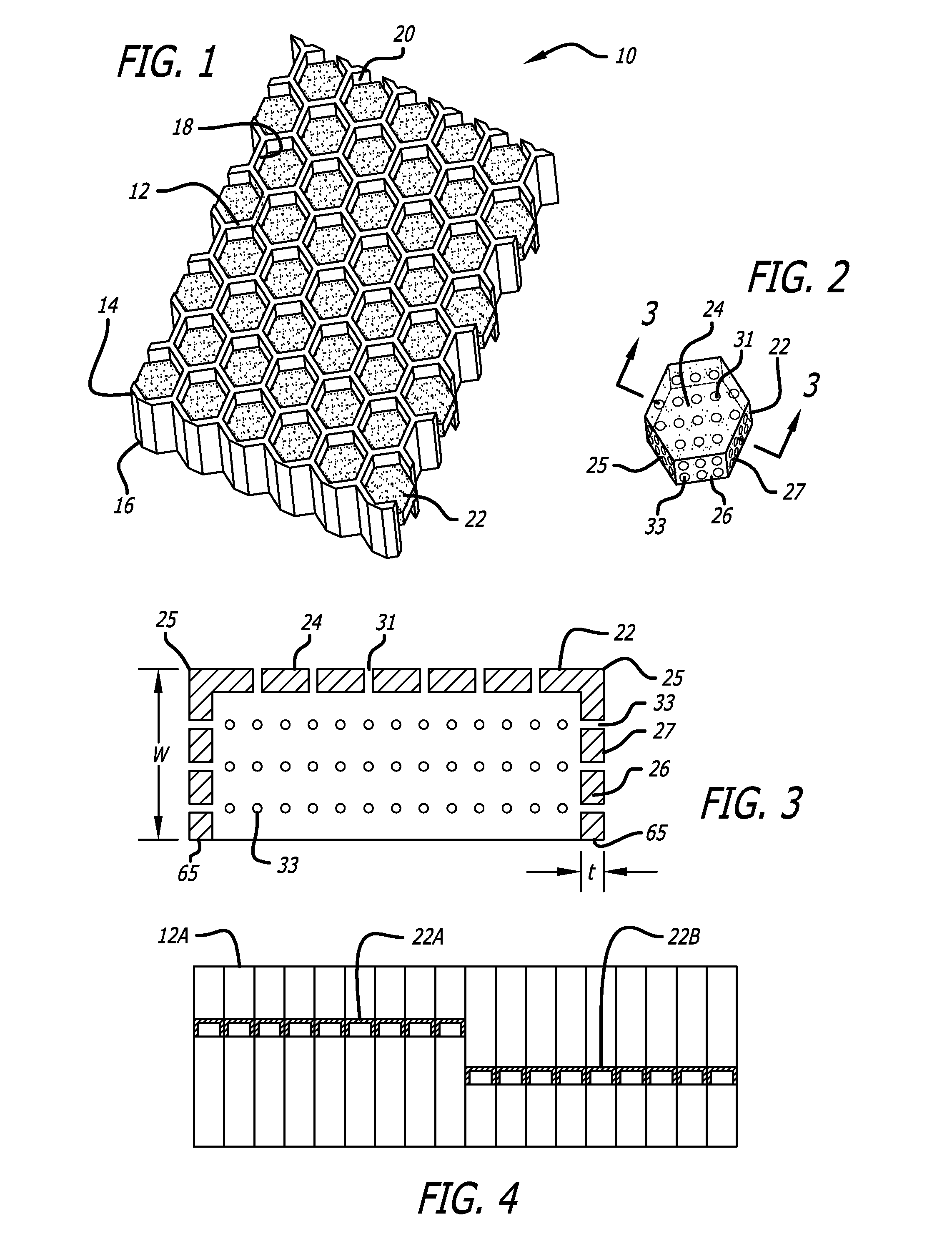

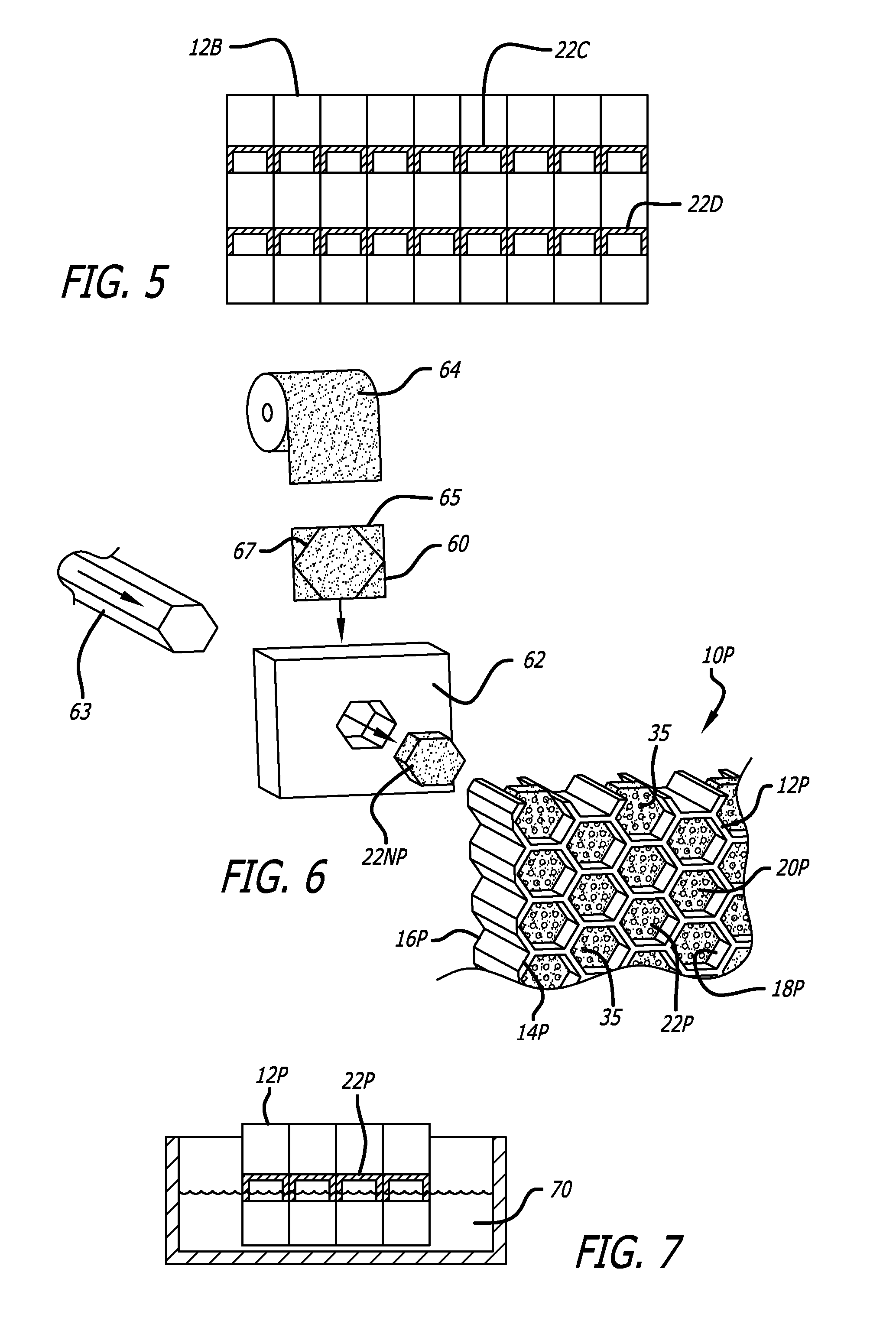

Acoustic septum cap honeycomb

An acoustic structure that includes a honeycomb having cells in which septum caps are located. The septum caps are formed from sheets of acoustic material and include a resonator portion and a flange portion. The flange portion has an anchoring surface that provides frictional engagement of the septum caps to the honeycomb cells when the caps are inserted into the honeycomb during fabrication of the acoustic structure. An adhesive is applied to the anchoring surface of the septum caps after the caps have been inserted into the honeycomb cells to provide a permanent bond.

Owner:HEXEL CORP

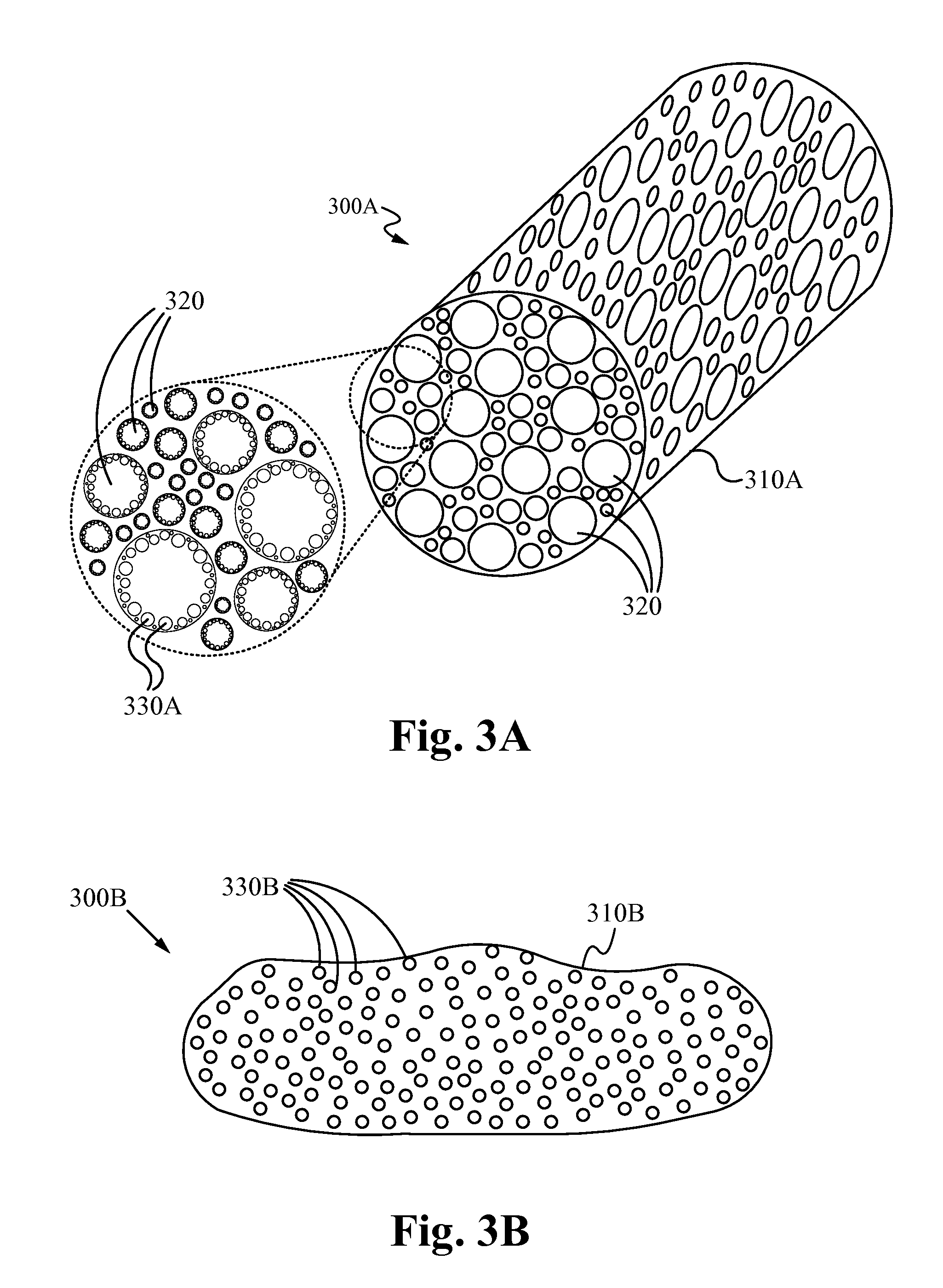

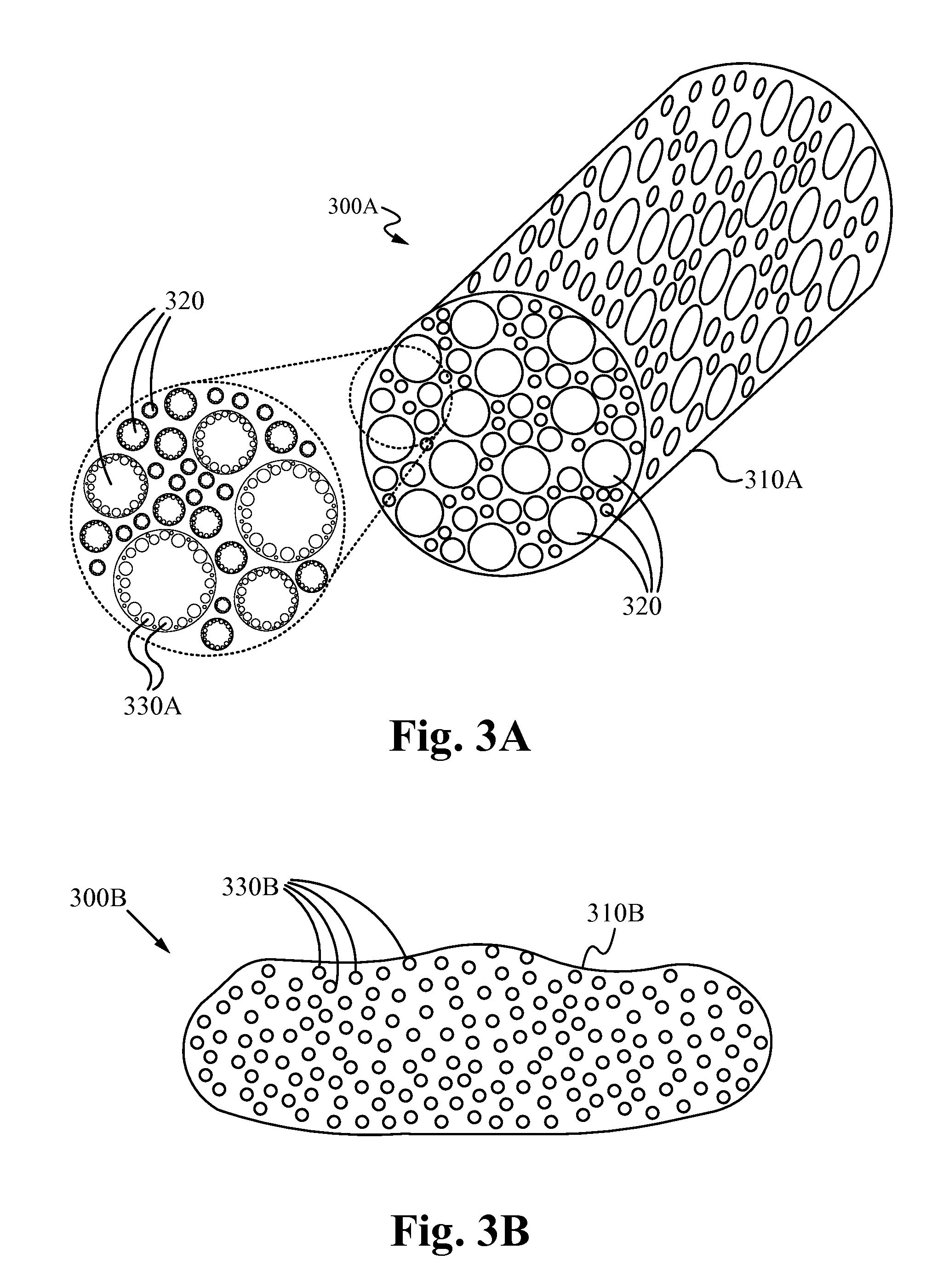

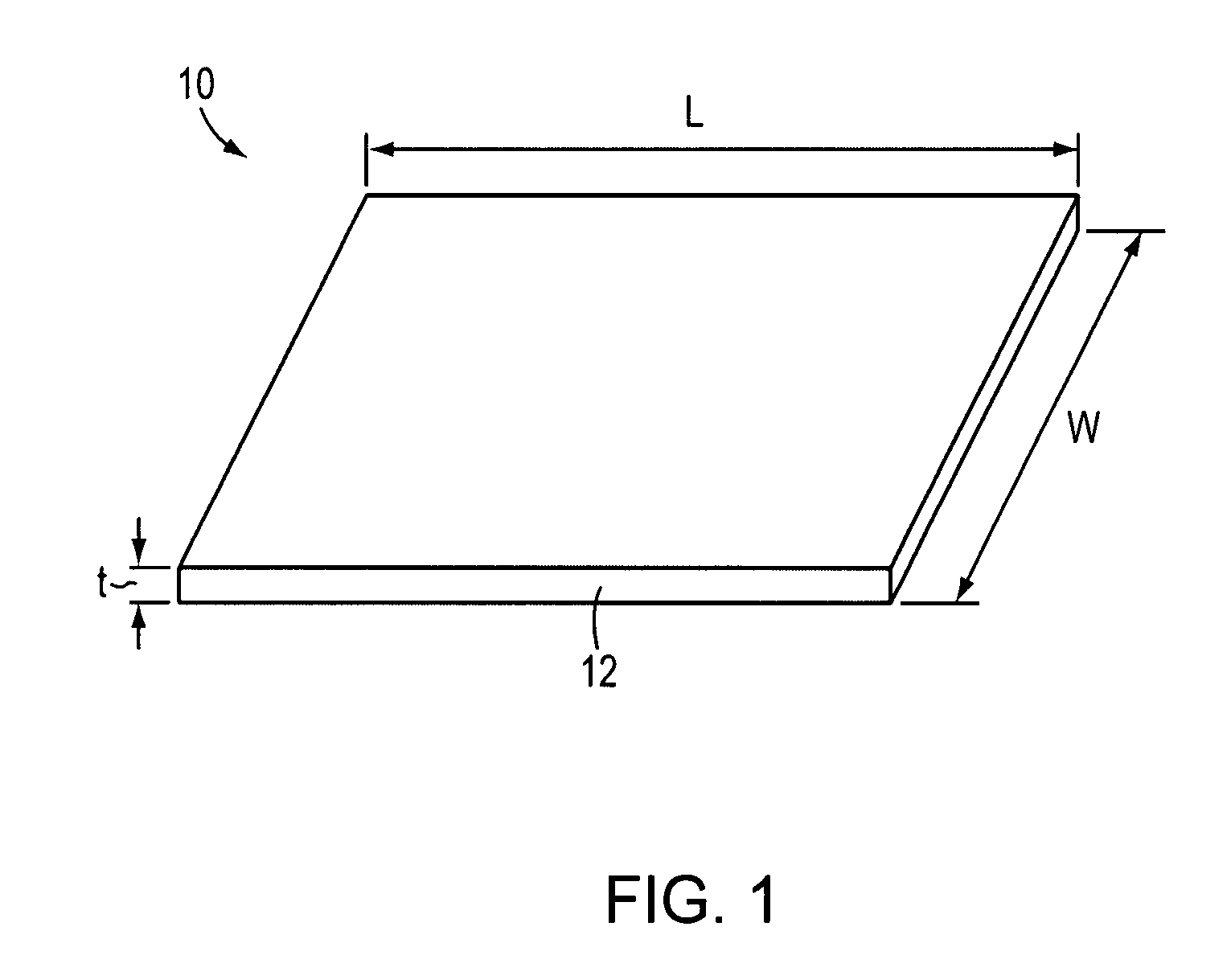

Modified fibers for use in the formation of thermoplastic fiber-reinforced composite articles and process

InactiveUS20080160302A1Secure bondingImprove mechanical propertiesGlass making apparatusOptical articlesSize compositionNanometre

A surface-modified fibrous material is provided for incorporation in a thermoplastic matrix to form a fiber-reinforced composite article. Good binding between the fibrous material and the thermoplastic matrix is achieved through the presence of finely roughened surfaces on the fibers of nanoparticles of an inorganic material. Such nanoparticles are provided from an alkaline aqueous size composition containing the nanoparticles dispersed therein (as described). The fibrous material may be provided in continuous or discontinuous form. In a preferred embodiment glass fibers are initially provided in continuous form followed by cutting into discontinuous lengths and drying with the retention of the nanoparticles on the surfaces of the fibers. The surface-roughened fibrous material is incorporated in a thermoplastic matrix as fibrous reinforcement with the application of heat whereby the thermoplastic matrix is rendered melt processable. In preferred embodiments injection or compression molding is utilized. Improved long-fiber thermoplastics also may be formed to advantage.

Owner:JOHNS MANVILLE CORP

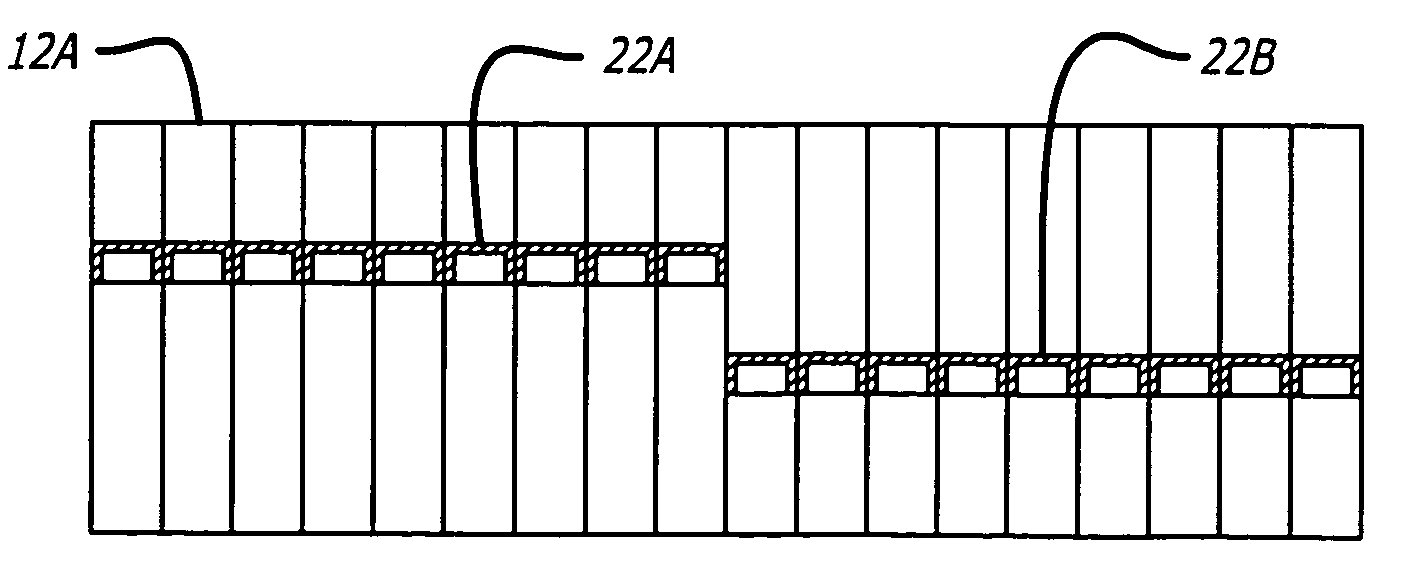

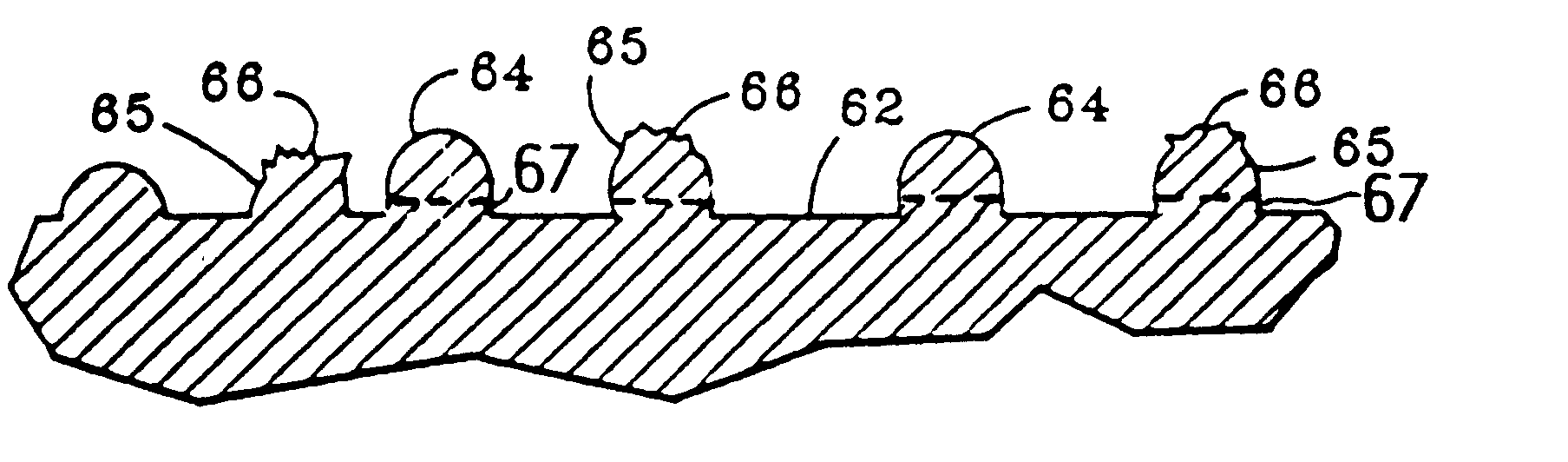

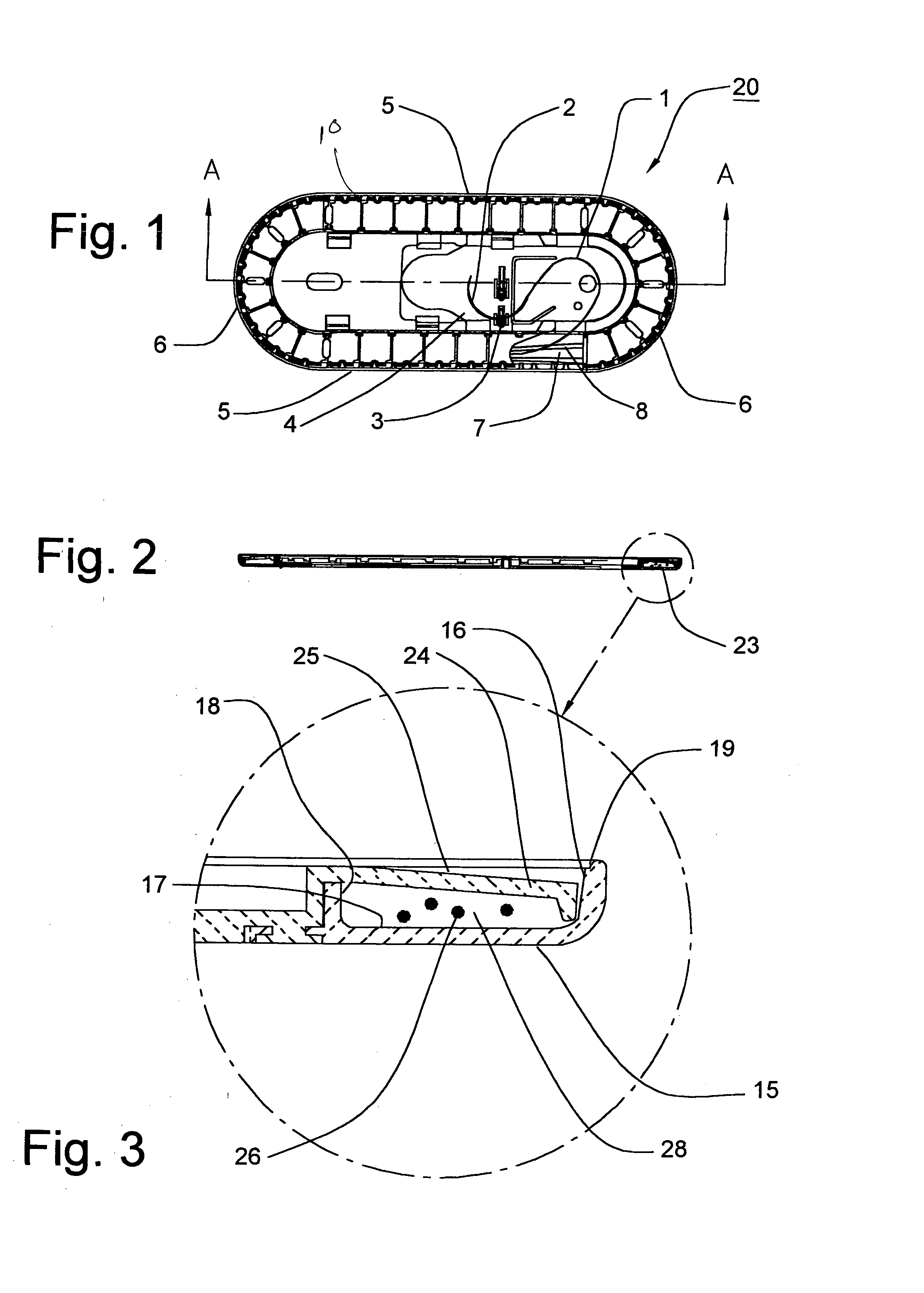

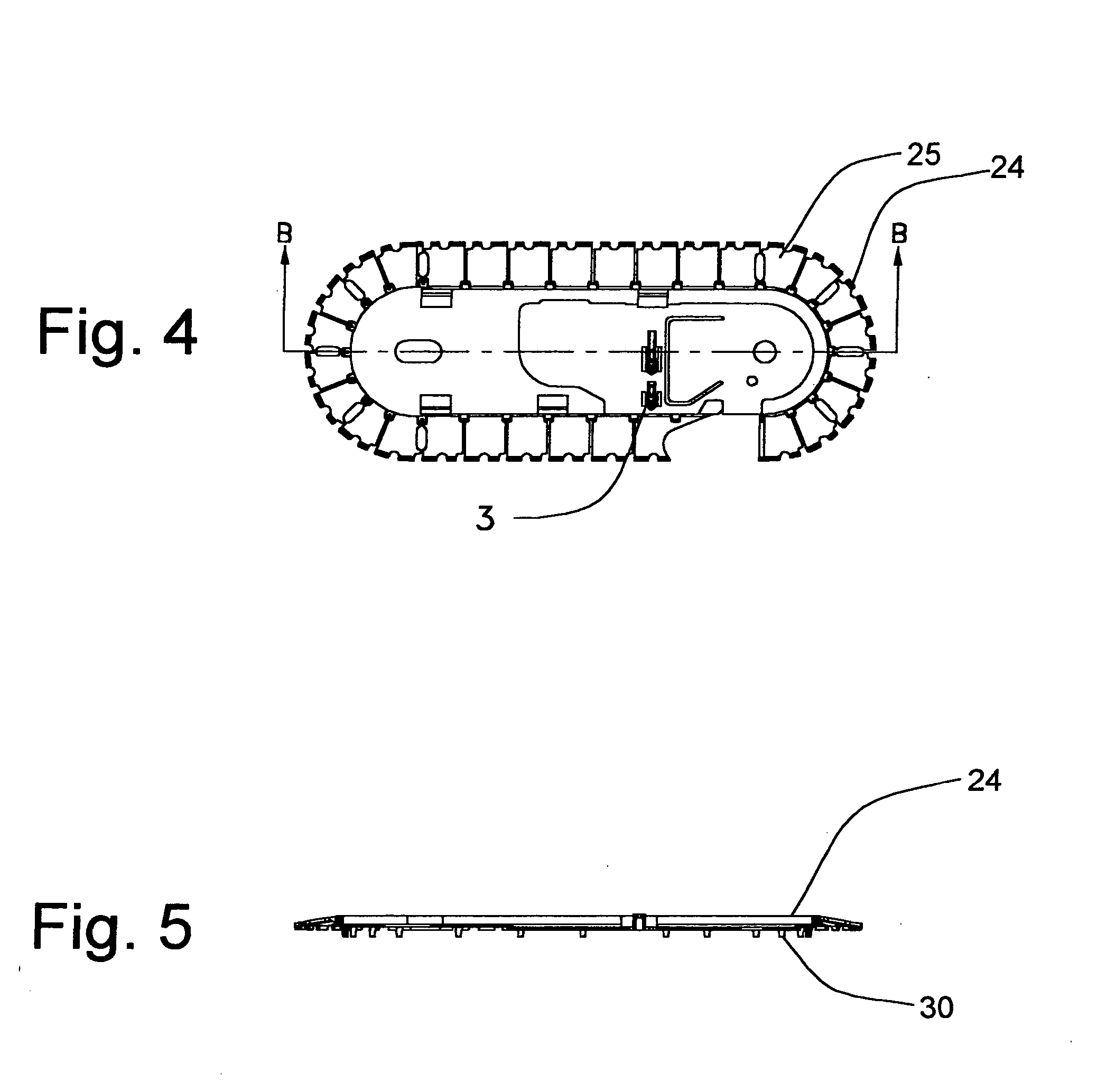

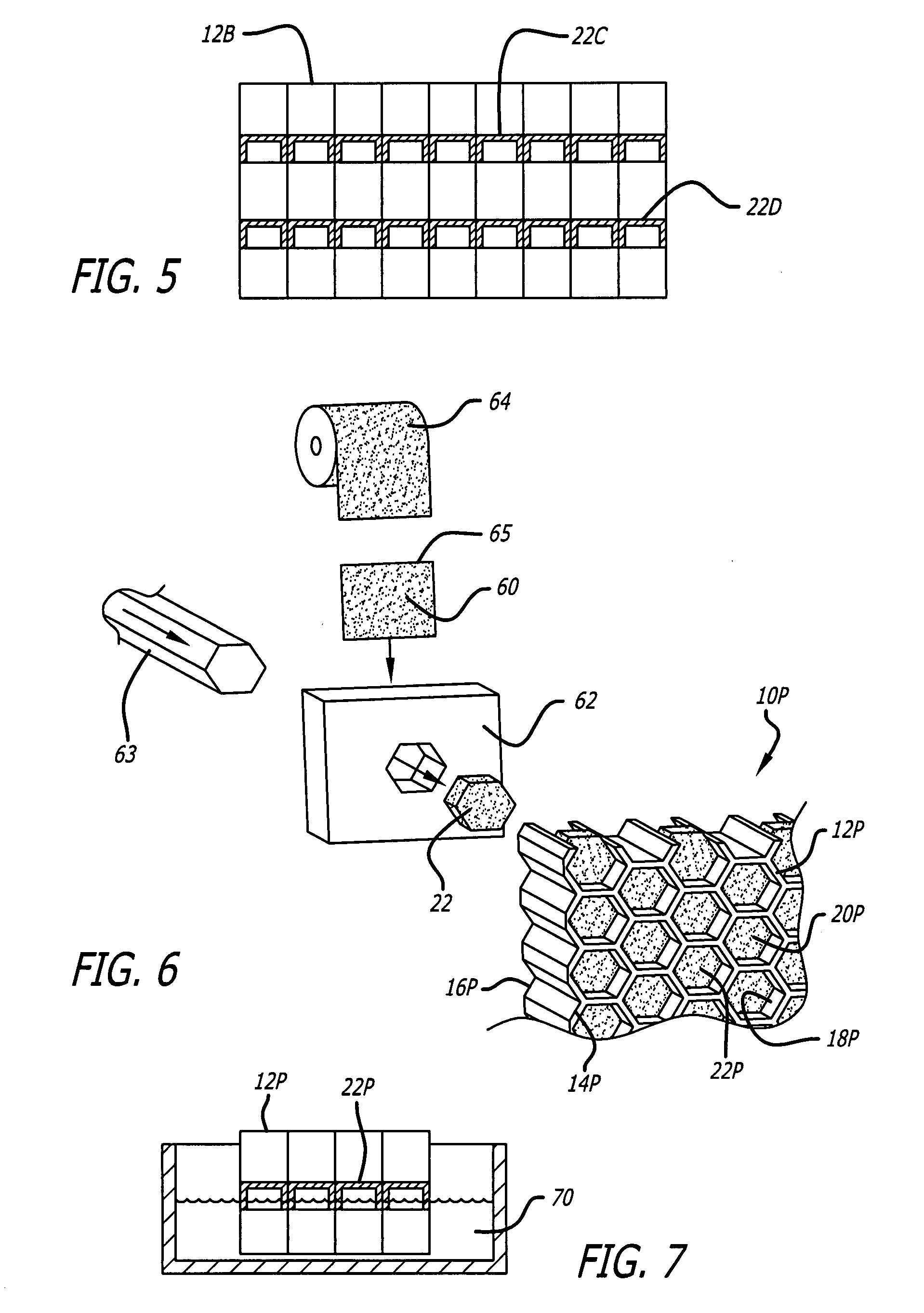

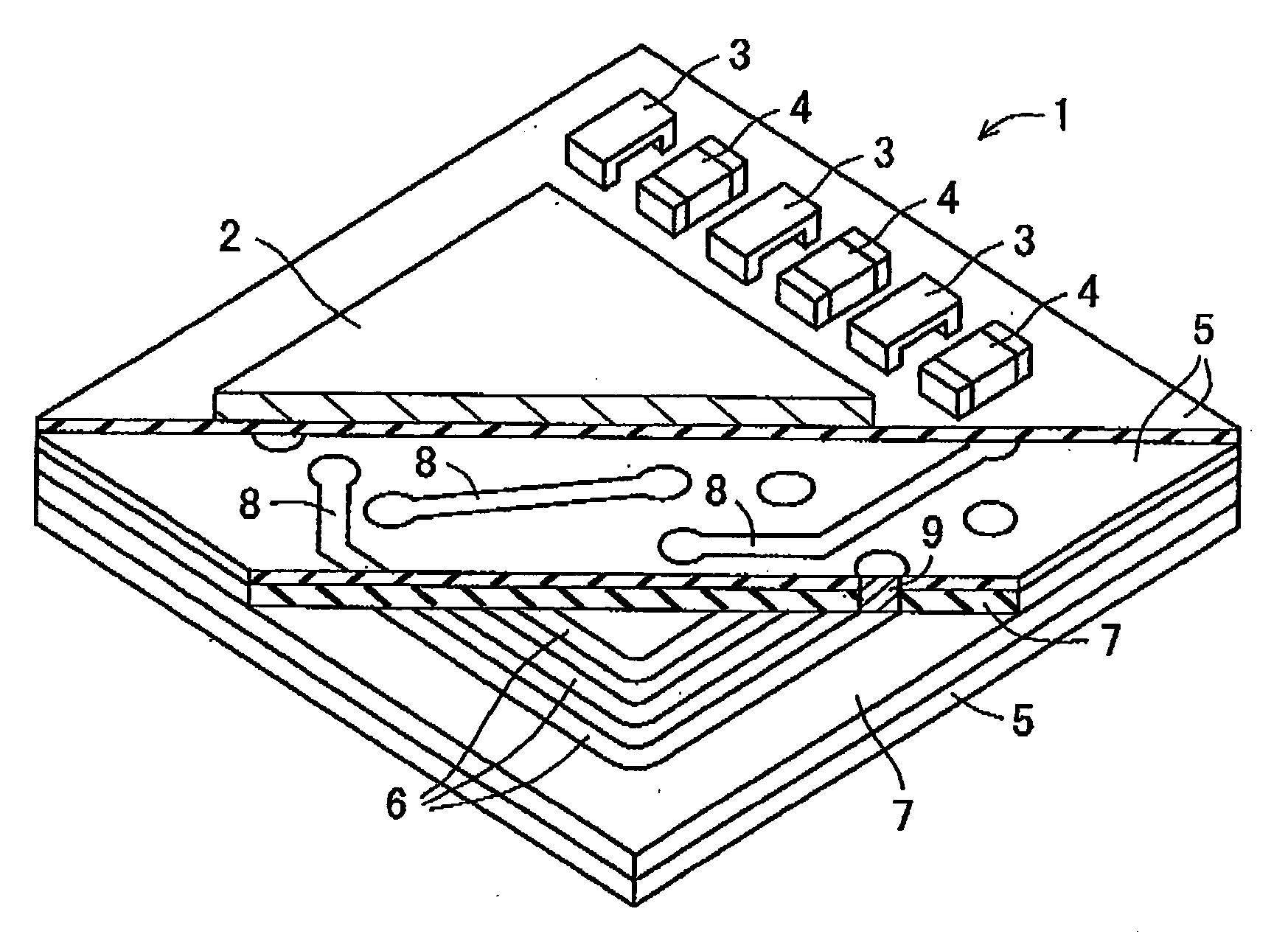

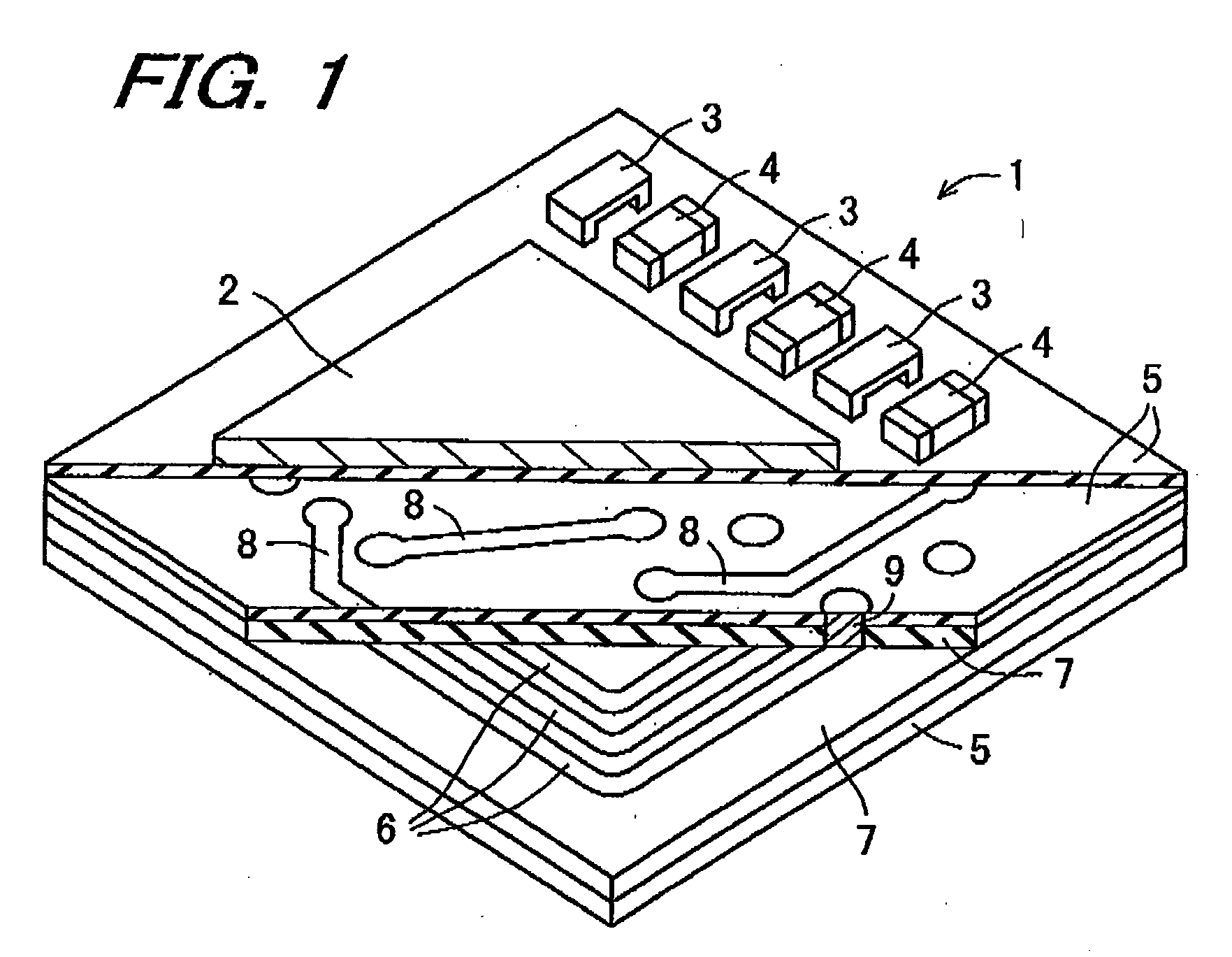

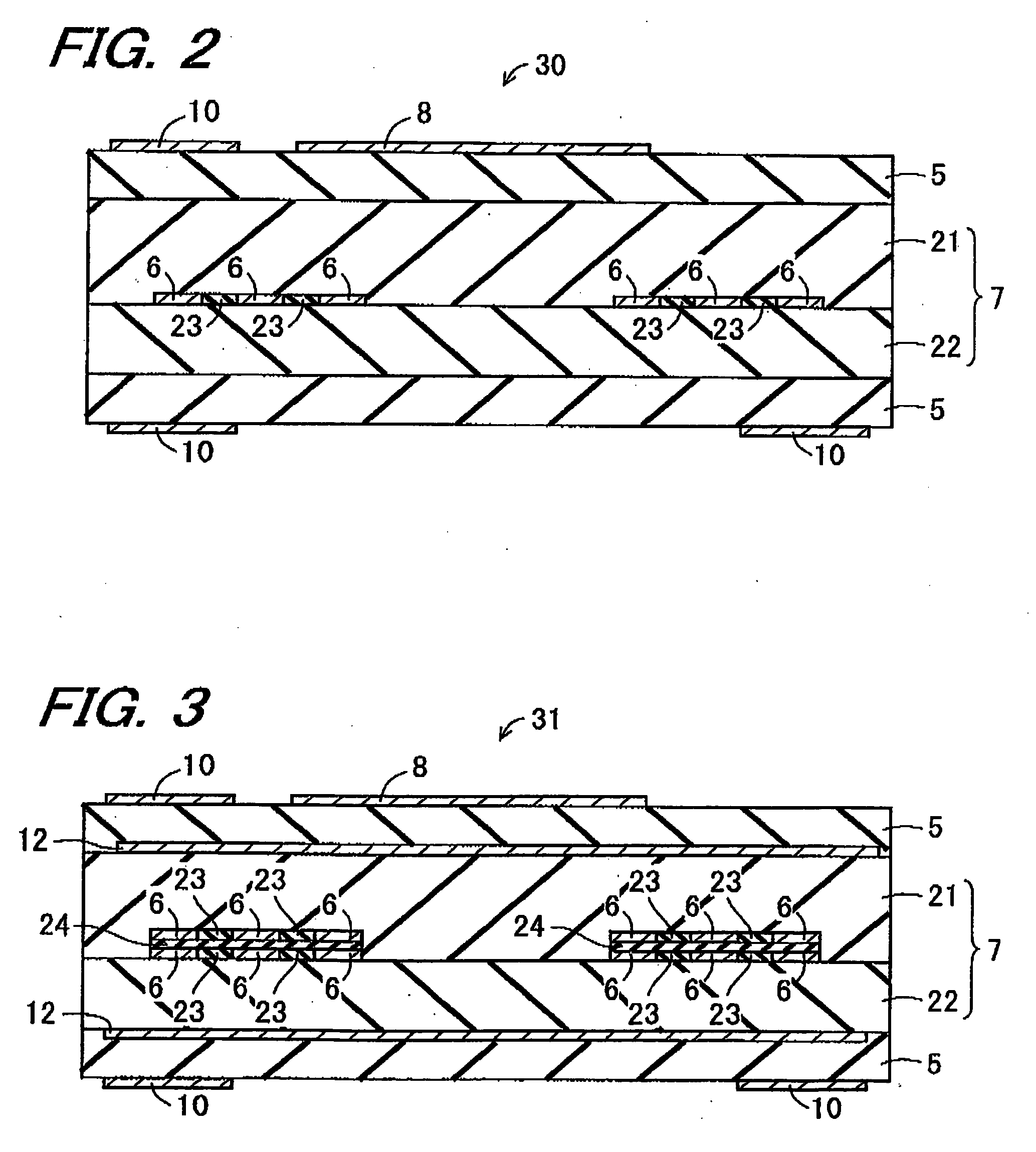

Acoustic honeycomb with perforated septum caps

ActiveUS20120037449A1Lean structureReduced flexibilityElectrical transducersRecord carriersAdhesiveEngineering

An acoustic structure that includes a honeycomb having cells in which septum caps are located. The septum caps are formed from sheets of flexible material that may be perforated before or after the material is inserted into the honeycomb. The flexible material is sufficiently flexible to allow folding into the shape of a septum cap. The flexible material is also sufficiently stiff to provide frictional engagement and locking of the septum cap to the honeycomb cell when the cap is inserted into the honeycomb during fabrication of the acoustic structure. An adhesive is applied to the septum caps after the caps have been inserted into the honeycomb cells to provide a permanent bond.

Owner:HEXCEL

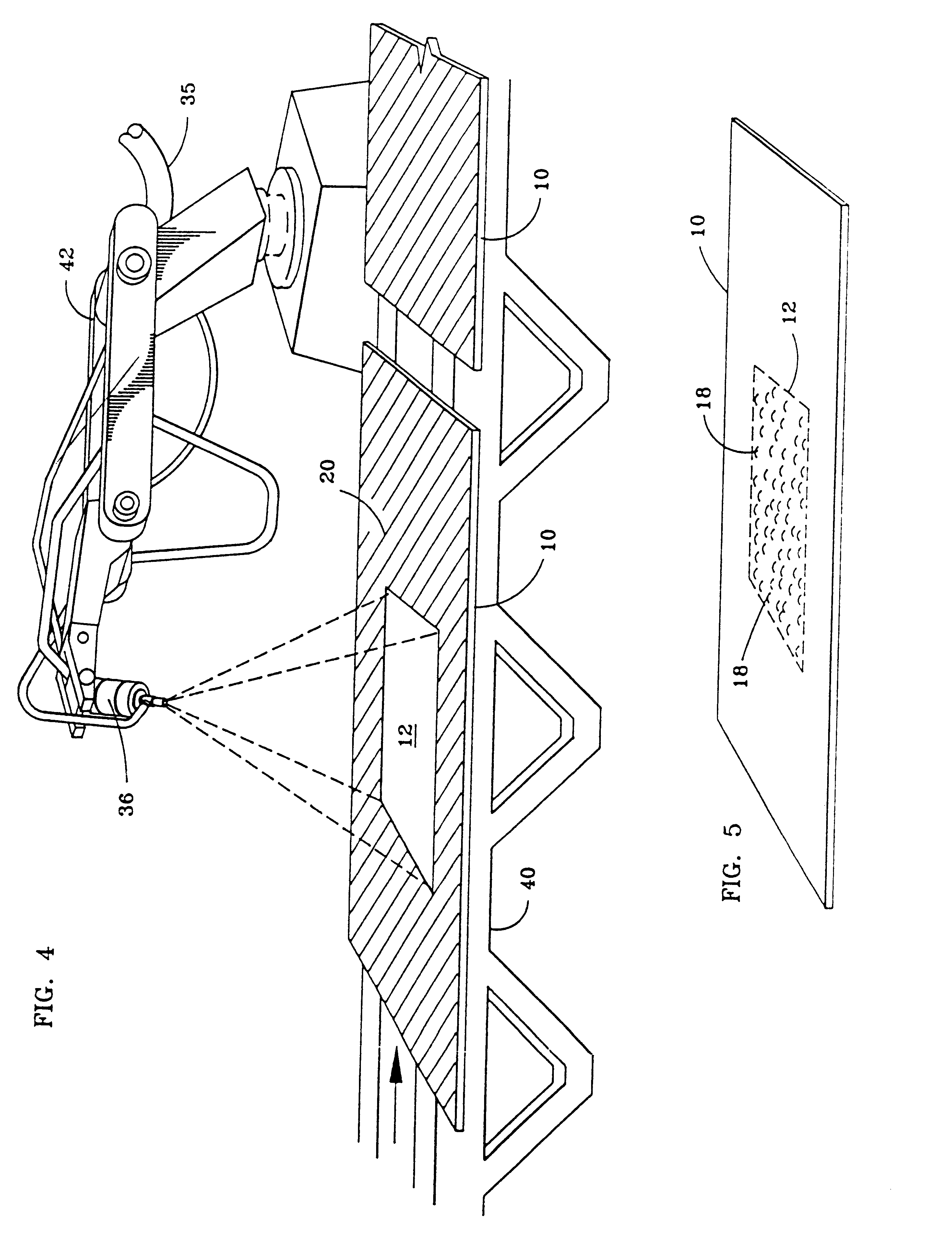

Thermoplastic products having antislip surfaces

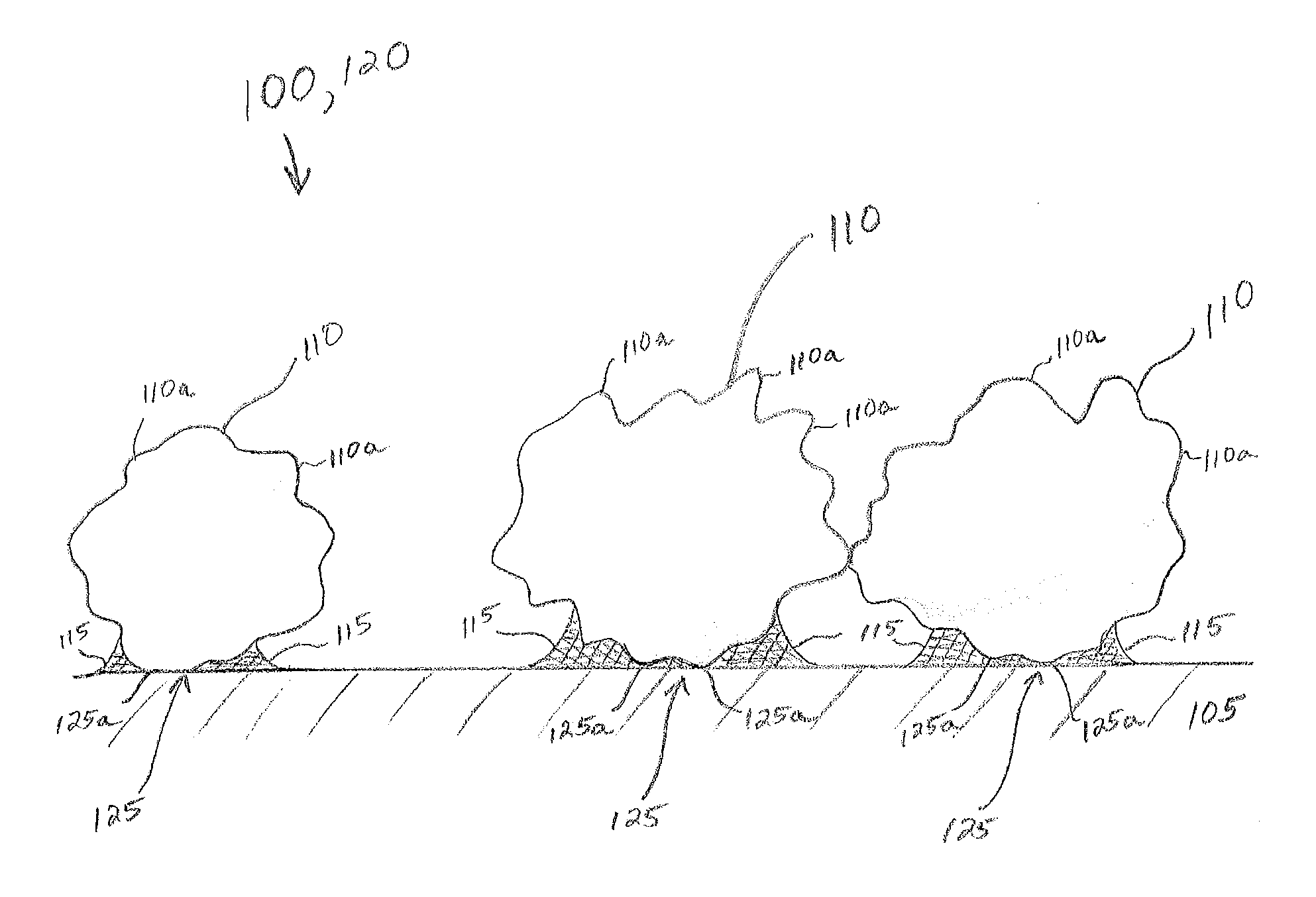

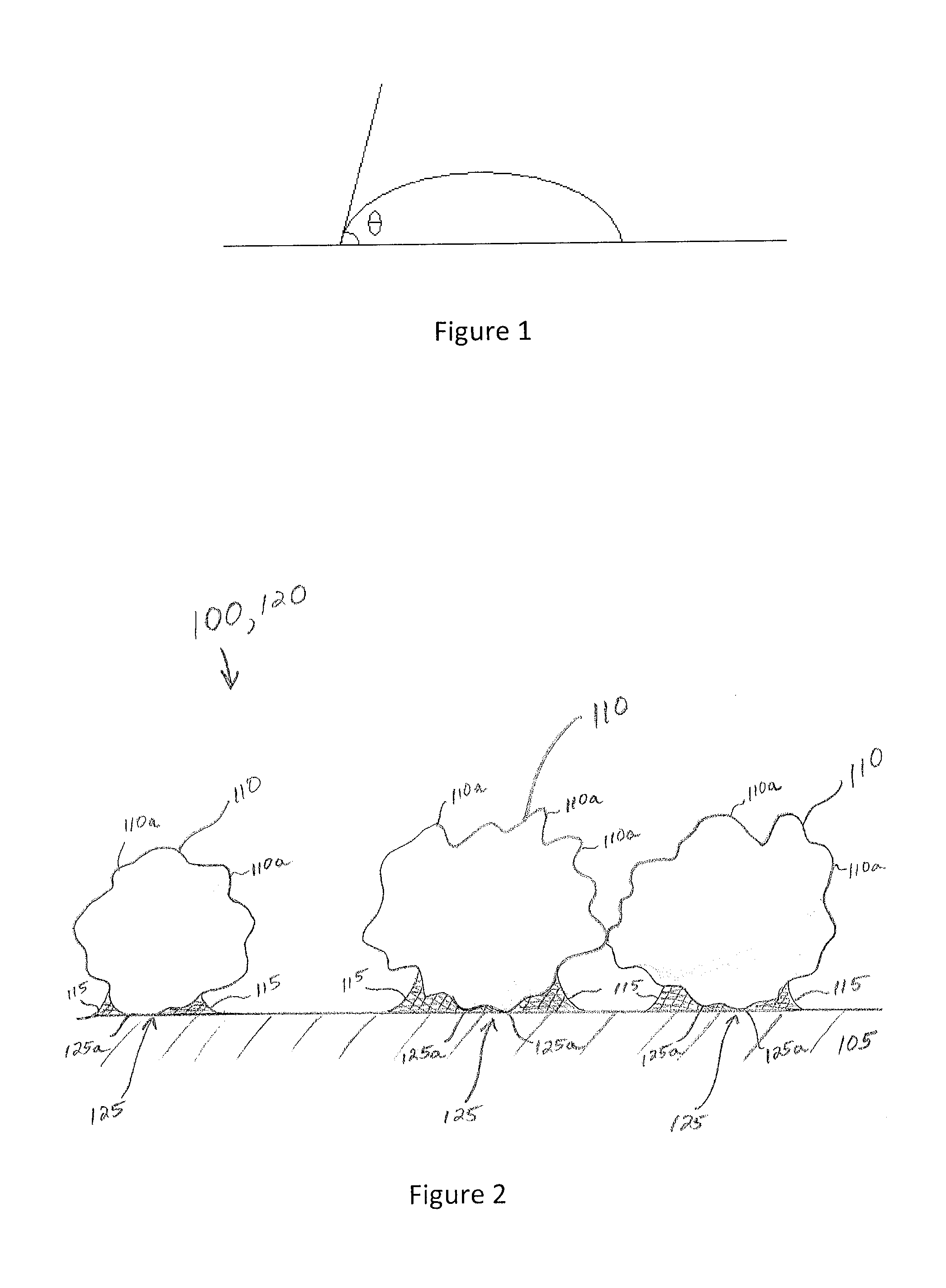

InactiveUS6509084B2Effective antislip surface propertyGood adhesion and durability and wearabilityKitchenware cleanersCleaning machinesEngineeringVolcano

Thermoplastic products such as vehicle cargo area liners, floor mats, recreational and playground equipment, cargo pallets, and wet area walking surfaces are provided with an antislip surface treatment. The antislip surface is made up of individual non-interconnected asperities of an antislip polymer material, which do not form a continuous film over the surface of the thermoplastic product. The thermoplastic product is especially made of high density polyethylene. The antislip polymer is preferably a thermoset polymer, and most particularly is a polyurea / isocyanate polymer. The antislip polymer is preferably applied by spraying, and then the product is heat treated at a temperature in the range from 100 to 200° F., or is thermoformed at a temperature in the range from 250 to 550° F. The antislip asperities are durably bonded onto the thermoplastic base material, and provide a significantly increased coefficient of friction. The asperity size, height, and hardness can be controlled by adjusting the processing conditions. The asperities may have an increased surface relief due to a so-called "moth effect" and an increased surface roughness due to cratering as a result of a so-called "volcano effect" in the process using thermoforming.

Owner:CUSTOM PLASTICS MOLDING

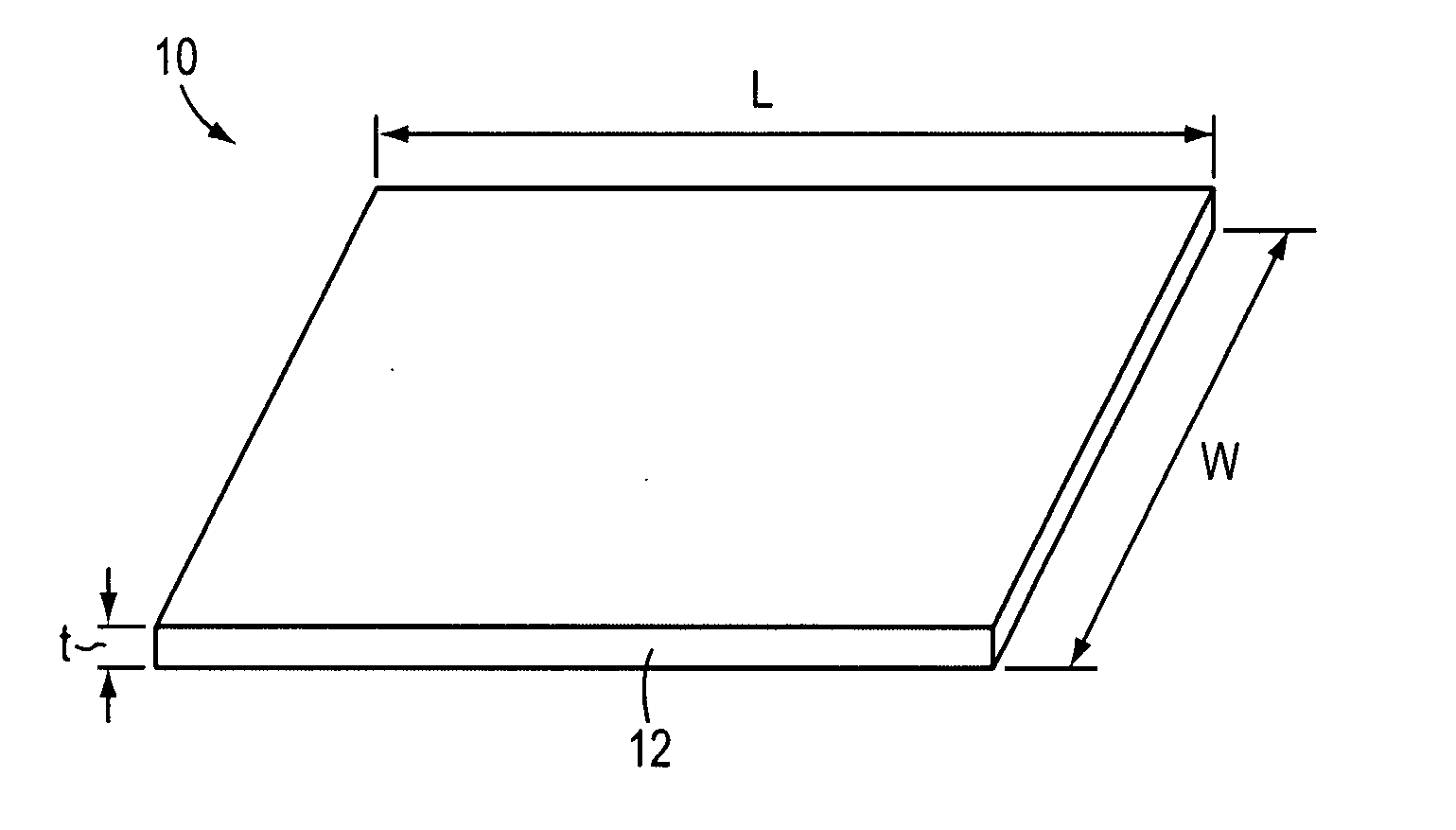

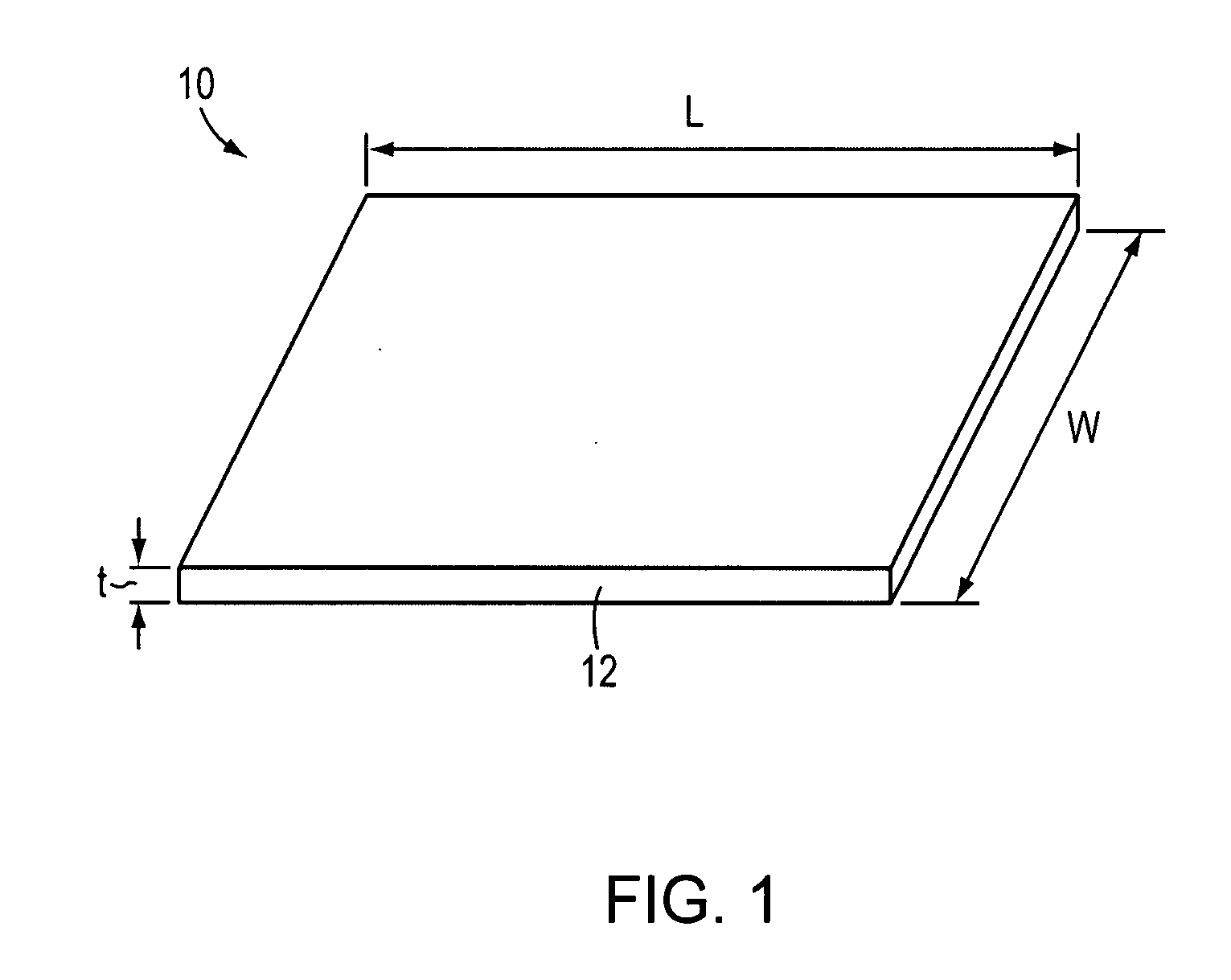

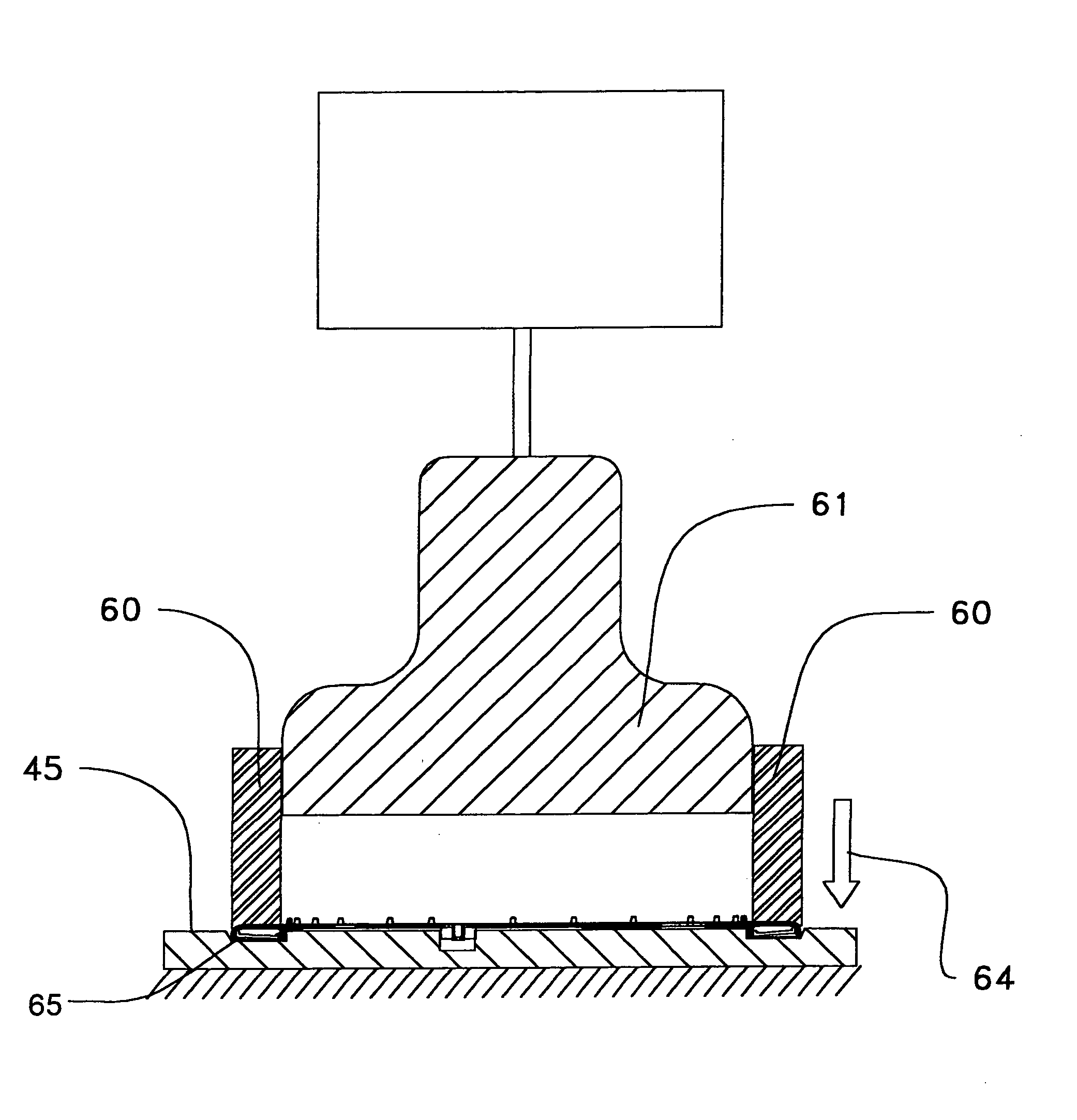

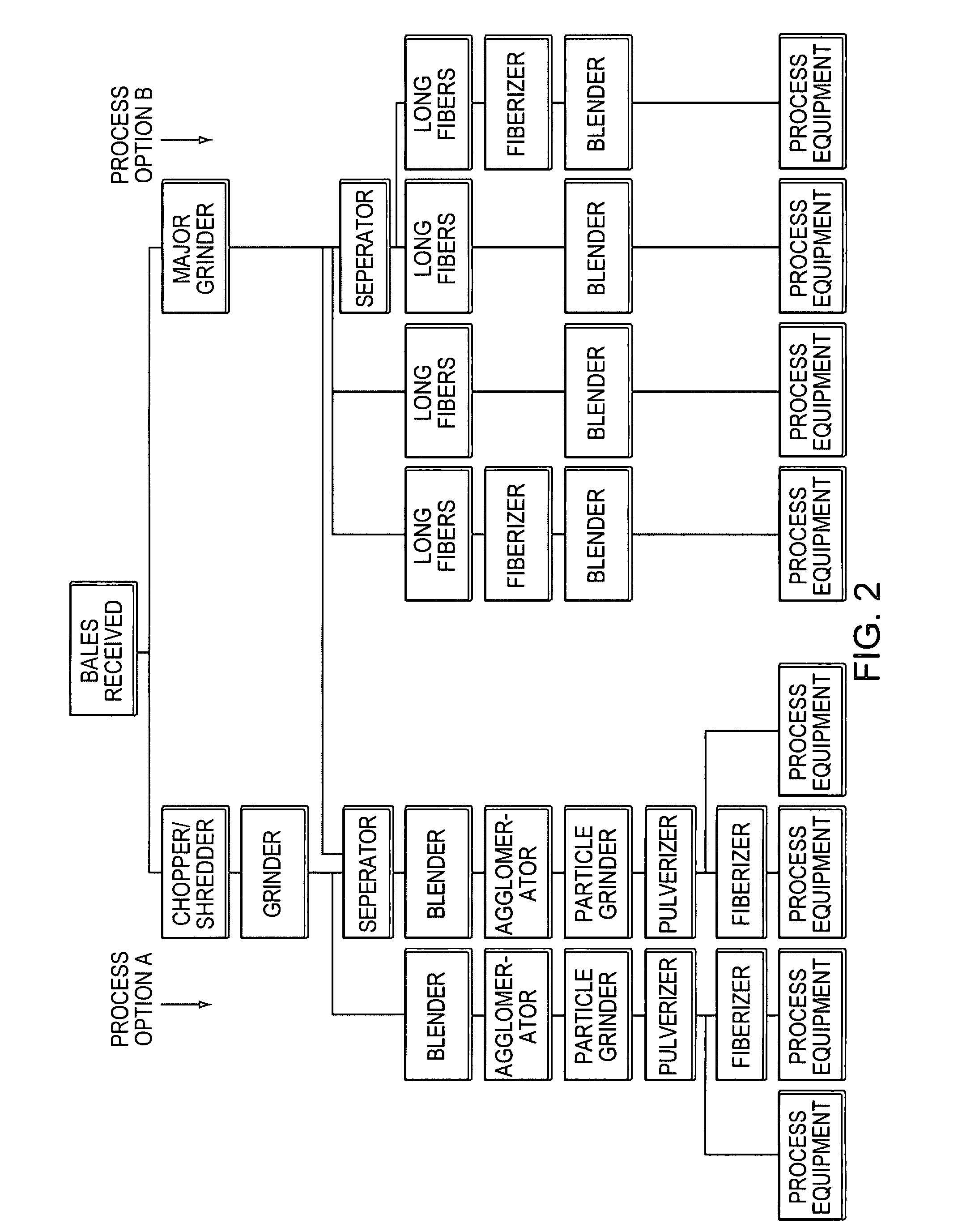

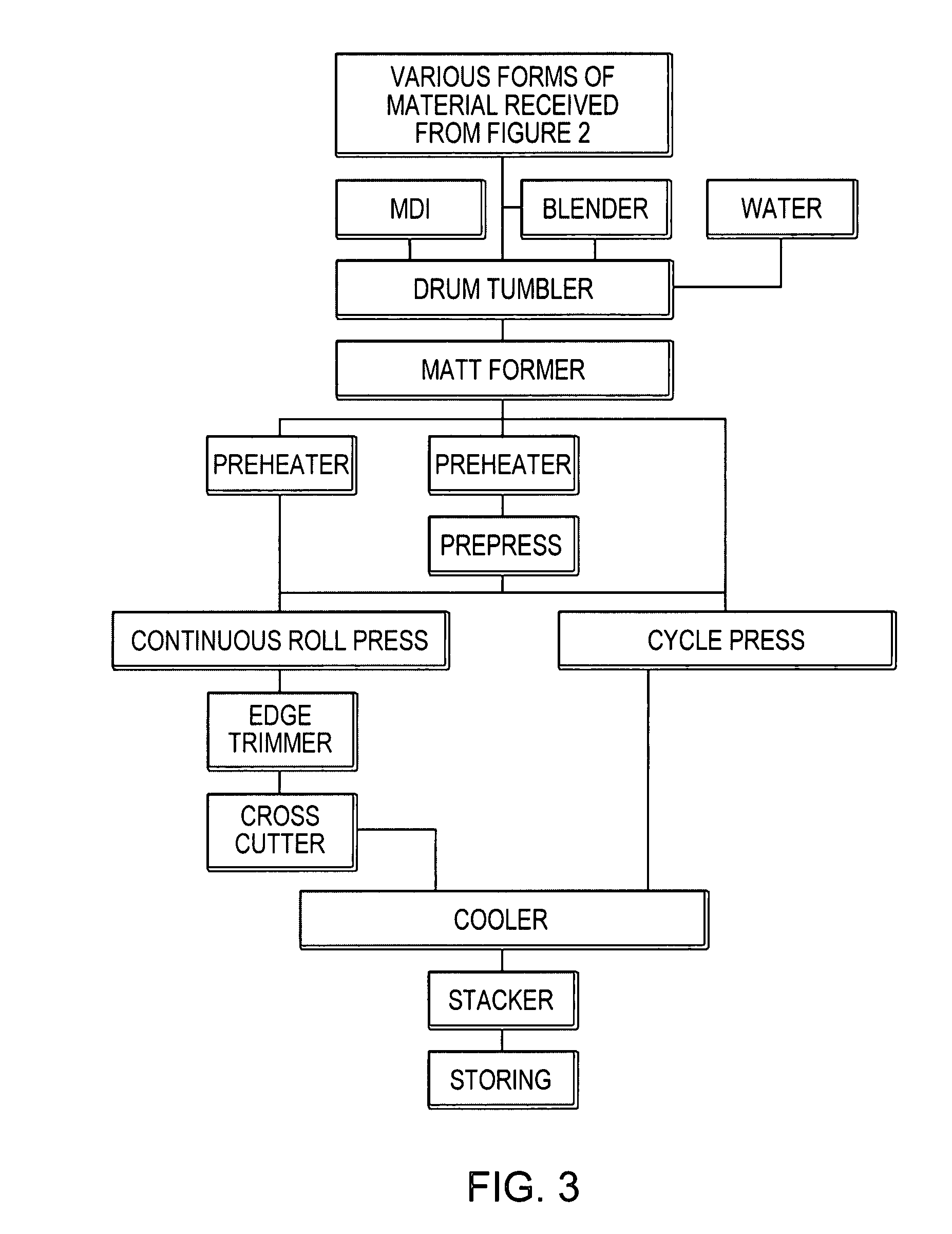

Carpet Waste Composite

A composite material is produced from carpet waste and a binding agent, in intimate association, and may also include wood fiber or chips and / or other additives. A method of manufacturing a composite material includes shredding carpet waste, coating the carpet waste with a binding agent, and subjecting the shredded, coated carpet waste to elevated heat and pressure. As an additional step, the composite material may be actively cooled to prevent deformation of the material.

Owner:MATERIAL INNOVATIONS LLC

Method for assembling a package for sutures

InactiveUS20050034431A1Quick applicationReduce manufacturing costSuture equipmentsSurgical needlesEngineeringCounterbore

A novel method and apparatus for riveting a two-piece suture tray package. A two-piece suture tray assembly is provided having a top member and a bottom member. The top member has a top and a bottom, and plurality of rivet members extending down from the bottom of the top member. The rivet members have free ends. The bottom member has a top and a flat bottom surface, and a plurality of rivet receiving openings extending therethrough. A counterbore surrounds each rivet receiving opening in the flat bottom surface. An ultrasonic riveting apparatus is provided having a clamp member with a cavity, and an ultrasonic horn member having a flat bottom moveably mounted in the cavity The assembly is mounted in the riveting apparatus and engaged by the clamp member. The flat bottom of the horn member engages the free ends of the rivet members, and when energized by an ultrasonic generator, causes the free ends of the rivet members to deform into the counterbores, such that the free ends are flat and in alignment with the bottom surface of the bottom member.

Owner:ETHICON INC

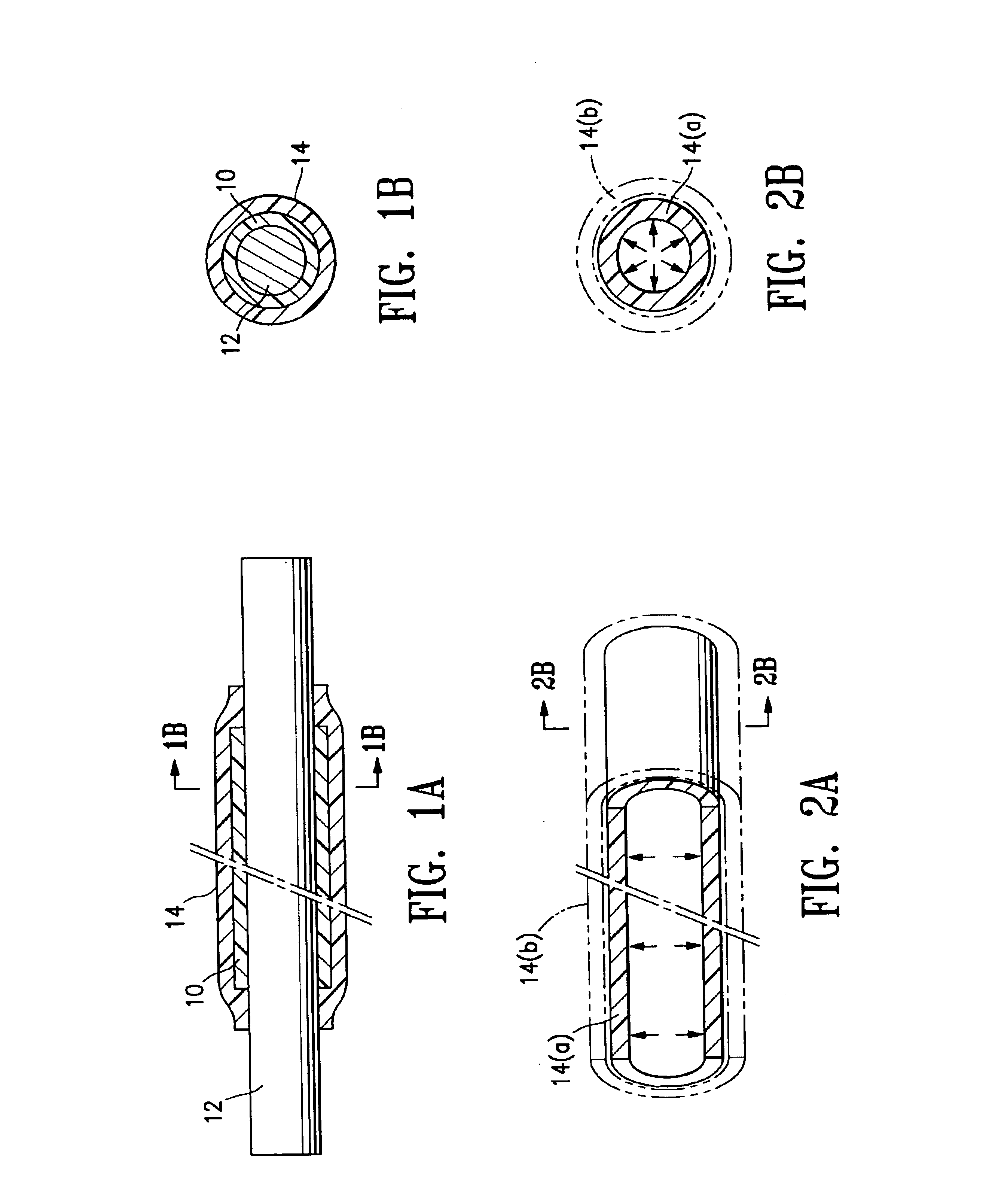

Method of making an expandable medical device formed of a compacted porous polymeric material

InactiveUS6863757B1Easy to manufactureBroaden applicationLaminationLamination apparatusCatheterMedical device

A method of making a catheter balloon or other expandable tubular medical device or component thereof formed of a compacted porous polymeric material, in which a tube of porous polymeric material is axially compacted, preferably without increasing the outer diameter of the tube, by positioning heat shrink material on the porous polymeric tube and heating the heat shrink material to decrease the length and diameter of the heat shrink material.

Owner:ABBOTT CARDIOVASCULAR

Modified discontinuous glass fibers for use in the formation of thermoplastic fiber-reinforced composite articles

InactiveUS20080160286A1Secure bondingImprove mechanical propertiesMaterial nanotechnologyLayered productsFiber-reinforced compositeMechanical property

Surface-modified discontinuous glass fibers are provided for incorporation in a thermoplastic matrix to form a fiber-reinforced composite article by injection or compression molding which displays enhanced mechanical properties, including improved tensile strength. Good binding between the discontinuous glass fibers and the thermoplastic matrix is achieved through the presence of finely roughened surfaces on the fibers of nanoparticles of an inorganic material. Such nanoparticles are provided from an alkaline aqueous size composition containing the nanoparticles dispersed therein (as described). The glass fibers are initially provided in continuous form followed by cutting into discontinuous lengths and drying with the retention of the nanoparticles on the surfaces of the fibers. Improved color in the resulting injection or compression molded thermoplastic discontinuous glass fiber-reinforced composite articles is made possible in combination with enhanced mechanical properties.

Owner:ASRAR JAWED +1

WET CHEMICAL METHOD OF FORMING STABLE PiPd DIESEL OXIDATION

InactiveUS20120214666A1Minimizing and eliminating mobilityMinimizing and eliminating and agglomerationMaterial nanotechnologyCatalyst activation/preparationNanoparticleCopper

A nano-particle comprising: an interior region comprising a mixed-metal oxide; and an exterior surface comprising a pure metal. In some embodiments, the mixed-metal oxide comprises aluminum oxide and a metallic pinning agent, such as palladium, copper, molybdenum, or cobalt. In some embodiments, the pure metal at the exterior surface is the same as the metallic pinning agent in the mixed-metal oxide in the interior region. In some embodiments, a catalytic nano-particle is bonded to the pure metal at the exterior surface. In some embodiments, the interior region and the exterior surface are formed using a plasma gun. In some embodiments, the interior region and the exterior surface are formed using a wet chemistry process. In some embodiments, the catalytic nano-particle is bonded to the pure metal using a plasma gun. In some embodiments, the catalytic nano-particle is bonded to the pure metal using a wet chemistry process.

Owner:UMICORE AG & CO KG +1

Acoustic septum cap honeycomb

An acoustic structure that includes a honeycomb having cells in which septum caps are located. The septum caps are formed from sheets of acoustic material and include a resonator portion and a flange portion. The flange portion has an anchoring surface that provides frictional engagement of the septum caps to the honeycomb cells when the caps are inserted into the honeycomb during fabrication of the acoustic structure. An adhesive is applied to the anchoring surface of the septum caps after the caps have been inserted into the honeycomb cells to provide a permanent bond.

Owner:HEXEL CORP

Acoustic septum cap honeycomb

An acoustic structure that includes a honeycomb having cells in which septum caps are located. The septum caps are formed from sheets of acoustic material and include a resonator portion and a flange portion. The flange portion has an anchoring surface that provides frictional engagement of the septum caps to the honeycomb cells when the caps are inserted into the honeycomb during fabrication of the acoustic structure. An adhesive is applied to the anchoring surface of the septum caps after the caps have been inserted into the honeycomb cells to provide a permanent bond.

Owner:HEXCEL

Dissimilar metal hermetic connector

ActiveUS6932644B1Improve bindingFirmly connectedSubstation/switching arrangement detailsContact member cases/bases manufactureThermal expansionEngineering

A hermetically sealed connector comprises an outer metallic shell having an aperture that receives a multipin-retaining, multi-metallic insert. The insert is a laminate of dissimilar metals, including a first metal extending to a first side of the insert and having a first coefficient of thermal expansion (CTE), and a second metal extending to a second side of the insert and having a second CTE different that the first CTE. A plurality of bores extend between first and second sides of the insert and contain connector pins that are hermetically sealed with the first metal of the insert by a dielectric material formed between the pins and sidewalls of the bores. A bond joint is formed between the second metal of the insert and the side of the outer metallic shell adjacent to the second side of the metallic insert.

Owner:WINCHESTER INTERCONNECT HERMETICS LLC

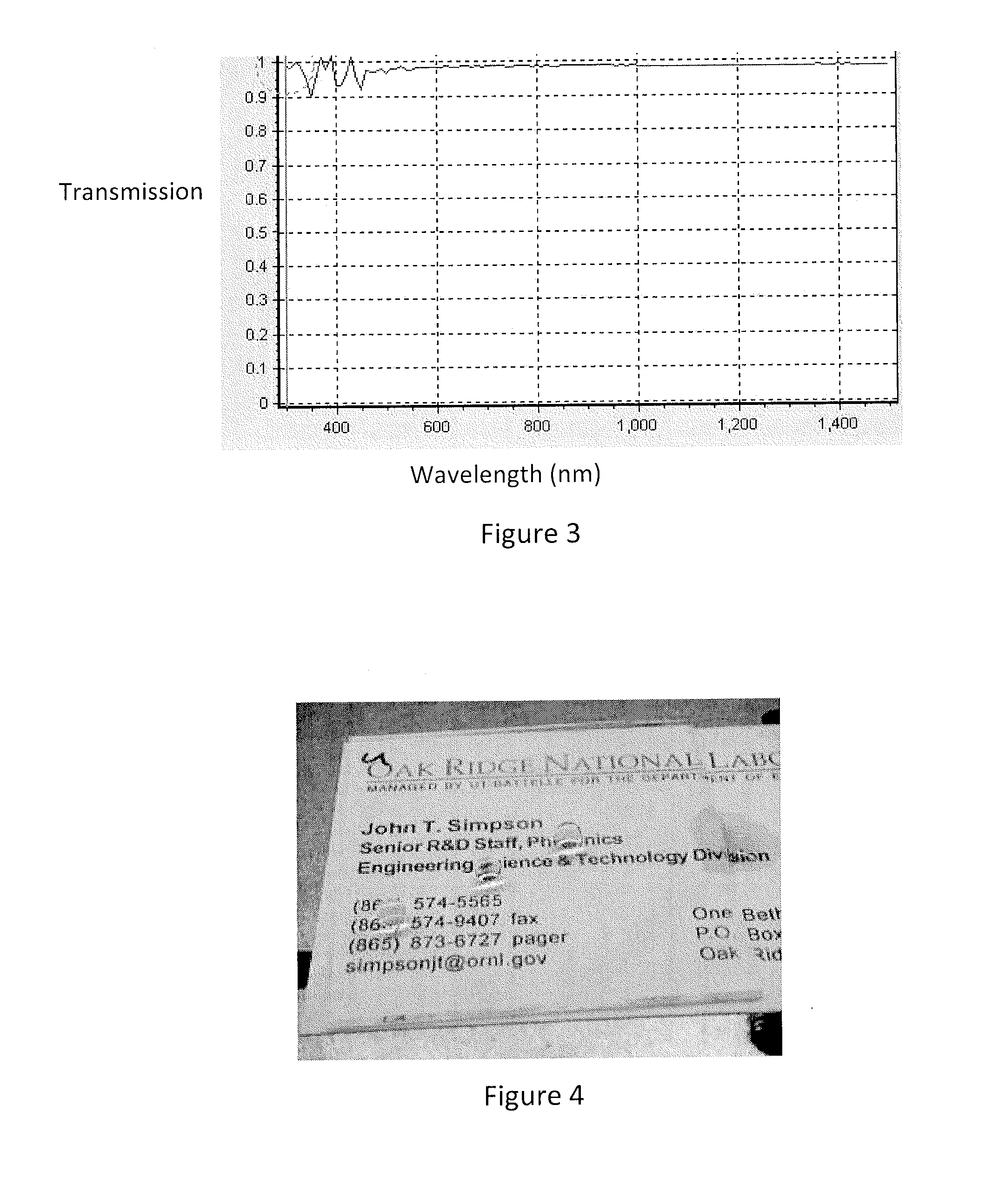

Composition for forming an optically transparent, superhydrophobic coating

ActiveUS20120107581A1Secure bondingLayered productsPolyurea/polyurethane coatingsSolventSuperhydrophobic coating

A composition for producing an optically clear, well bonded superhydrophobic coating includes a plurality of hydrophobic particles comprising an average particle size of about 200 nm or less, a binder at a binder concentration of from about 0.1 wt. % to about 0.5 wt. %, and a solvent. The hydrophobic particles may be present in the composition at a particle concentration of from about 0.1 wt. % to about 1 wt. %. An optically transparent, superhydrophobic surface includes a substrate, a plurality of hydrophobic particles having an average particle size of about 200 nm or less dispersed over the substrate, and a discontinuous binder layer bonding the hydrophobic particles to the substrate, where the hydrophobic particles and the binder layer form an optically transparent, superhydrophobic coating.

Owner:UT BATTELLE LLC

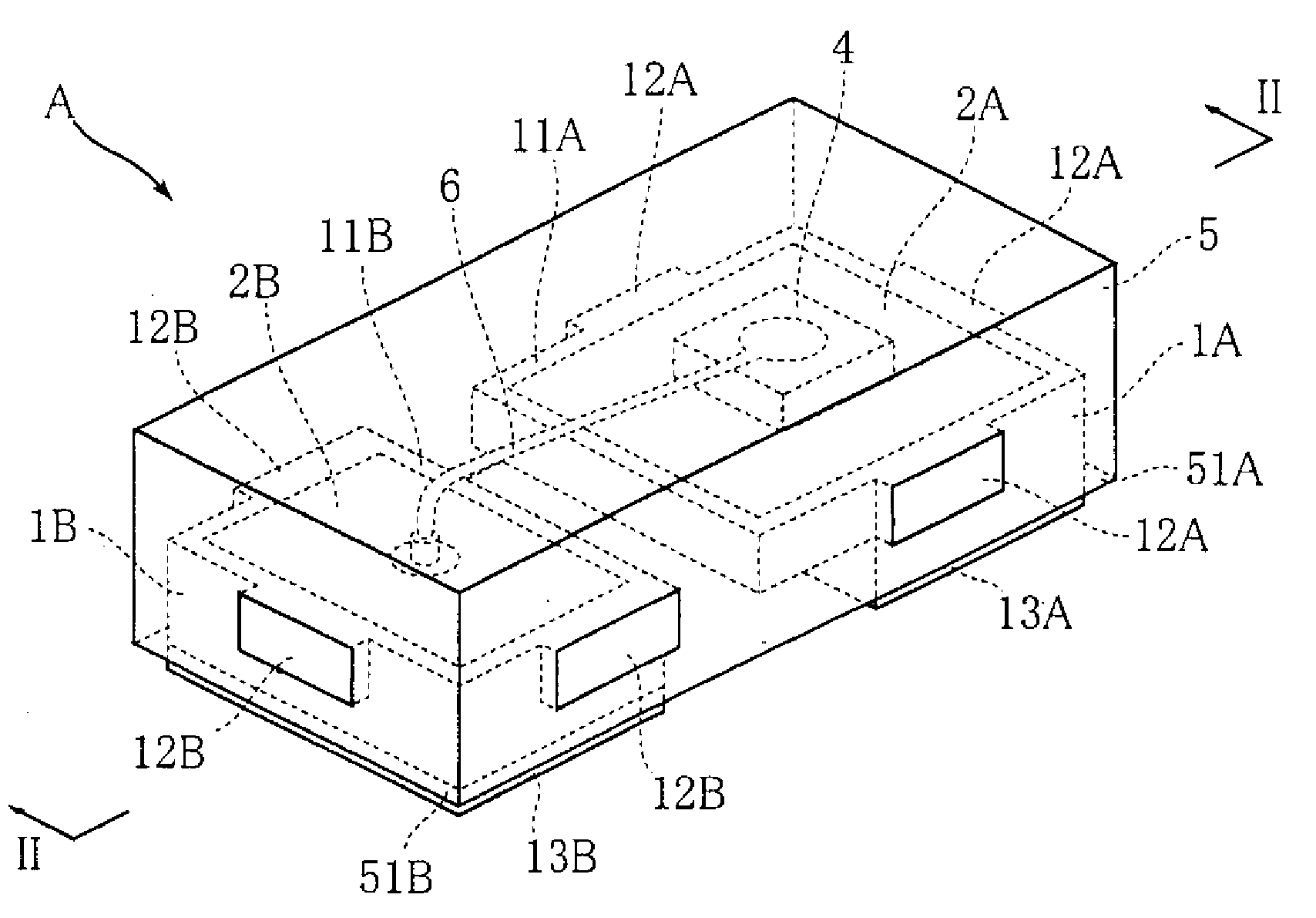

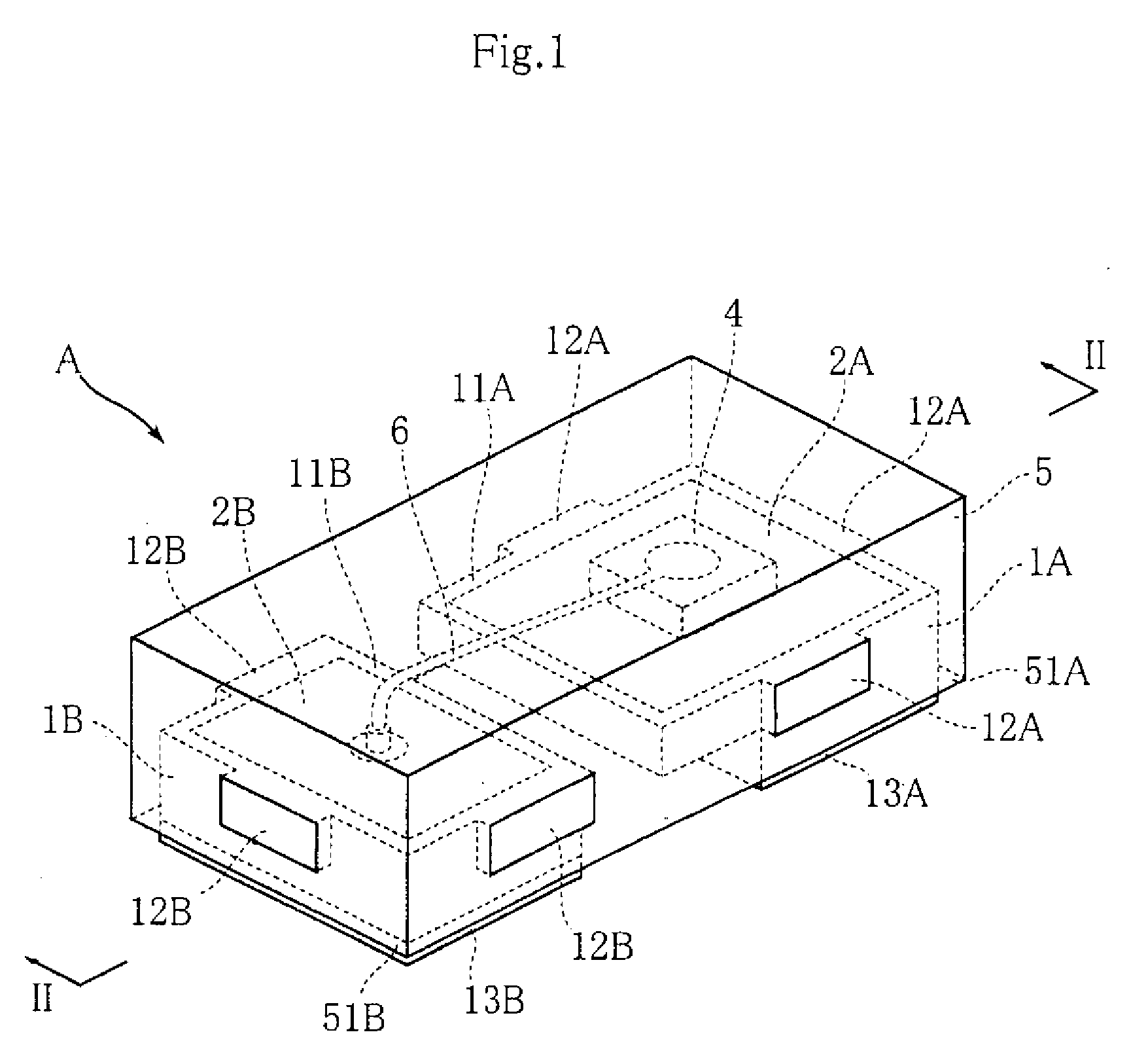

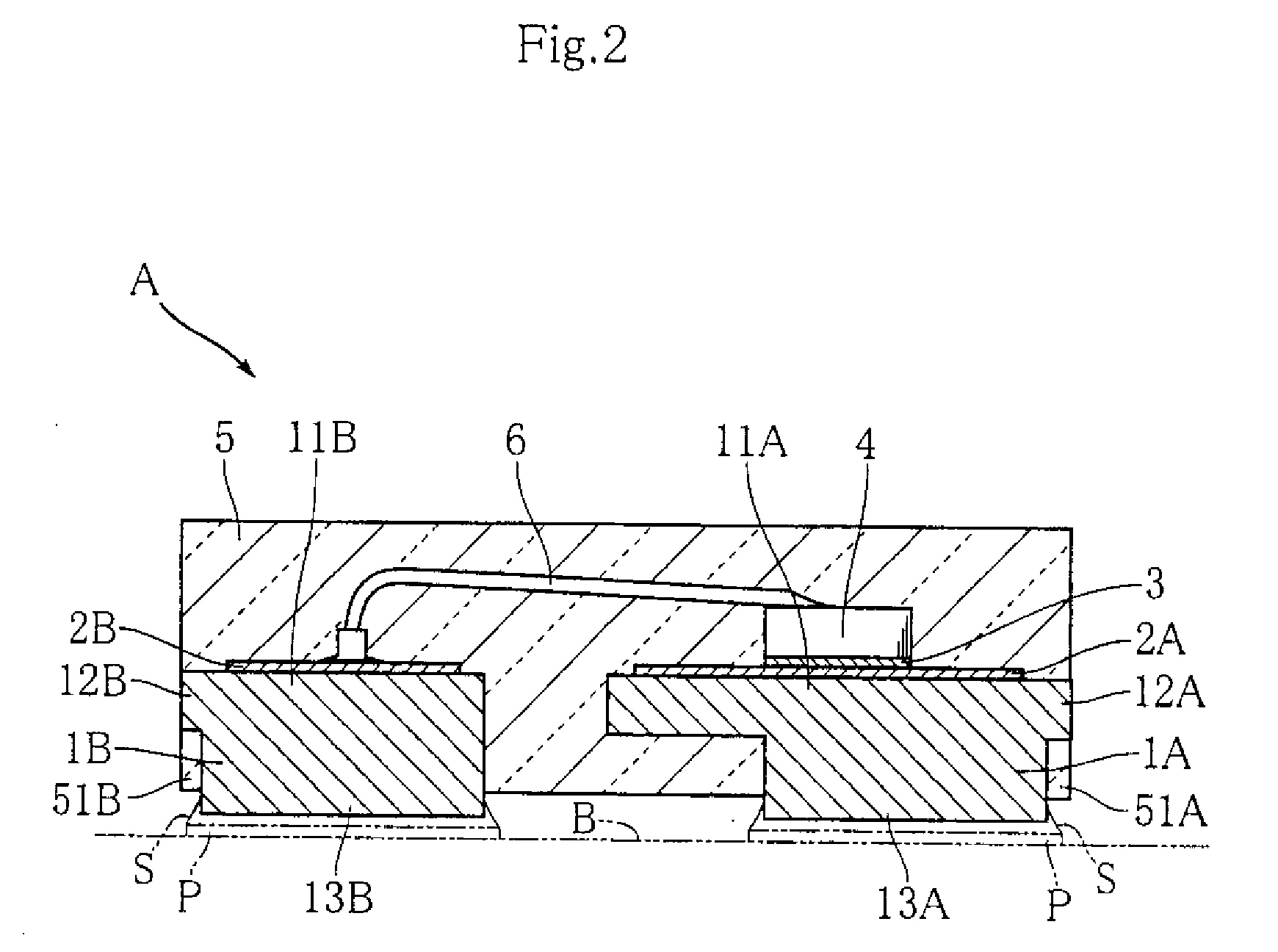

Semiconductor light emitting device

InactiveUS20100163920A1More compact in sizeImprove installation densitySolid-state devicesSemiconductor devicesIn planeLight emitting device

A semiconductor light emitting device (A) includes a resin package (5), a semiconductor light emitting element (4), a first lead (1A) and a second lead (1B). The resin package (5) has an upper surface and a bottom surface, and has translucency. The semiconductor light emitting element (4) is covered with the resin package (5) in a state where the semiconductor light emitting element faces the upper surface of the resin package (5). The first lead (1A) includes a bonding pad (11A) which supports the semiconductor light emitting element (4). The second lead (1B) is separated from the first lead (1A), and is electrically connected to the semiconductor light emitting element (4) via a wire (6). The leads (1A, 1B) have mounting terminals (13A, 13B) which are exposed from the bottom surface of the resin package (5). The mounting terminals (13A, 13B) are surrounded by the resin package (5) in an in-plane direction perpendicular to the thickness direction of the resin package.

Owner:ROHM CO LTD

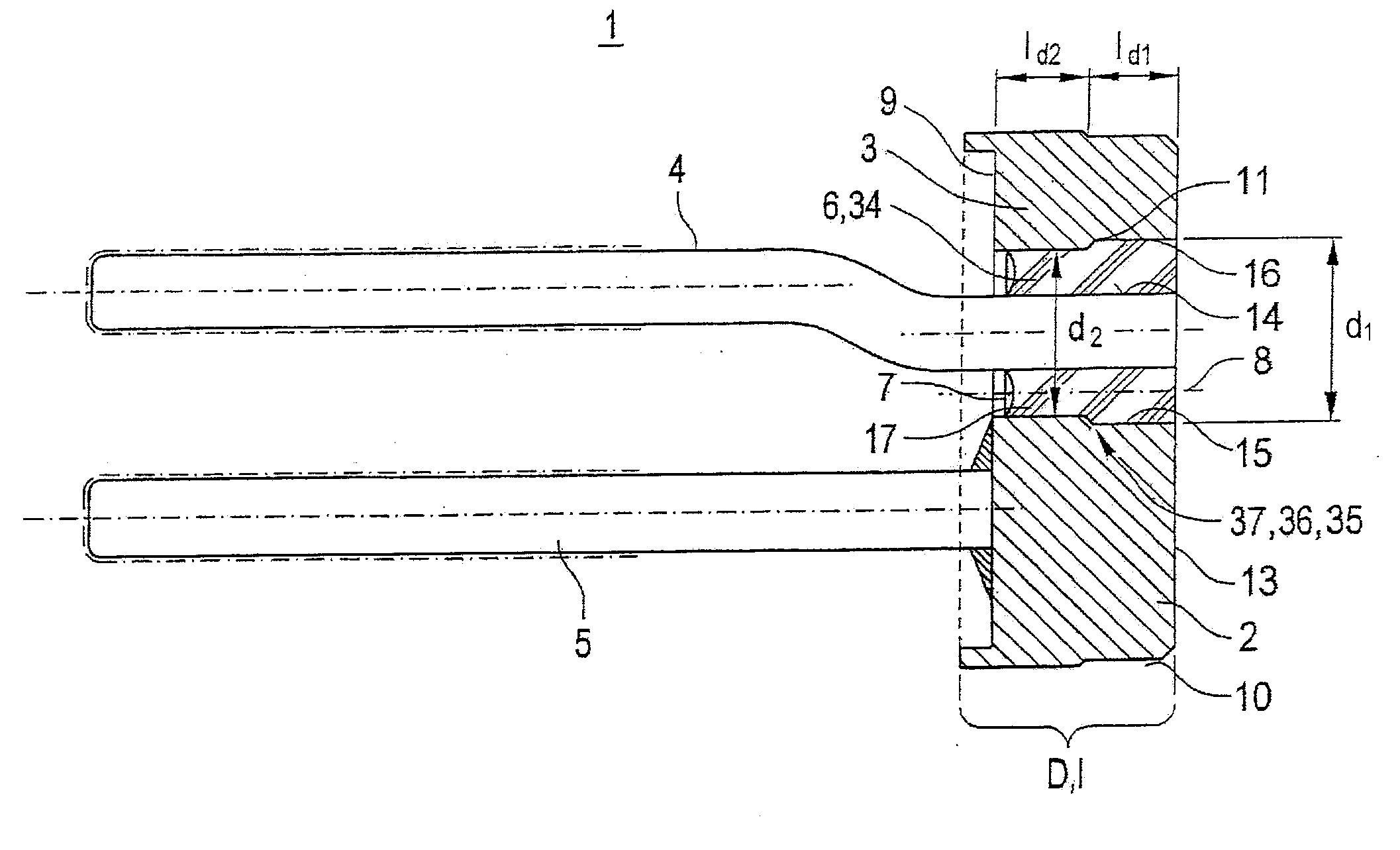

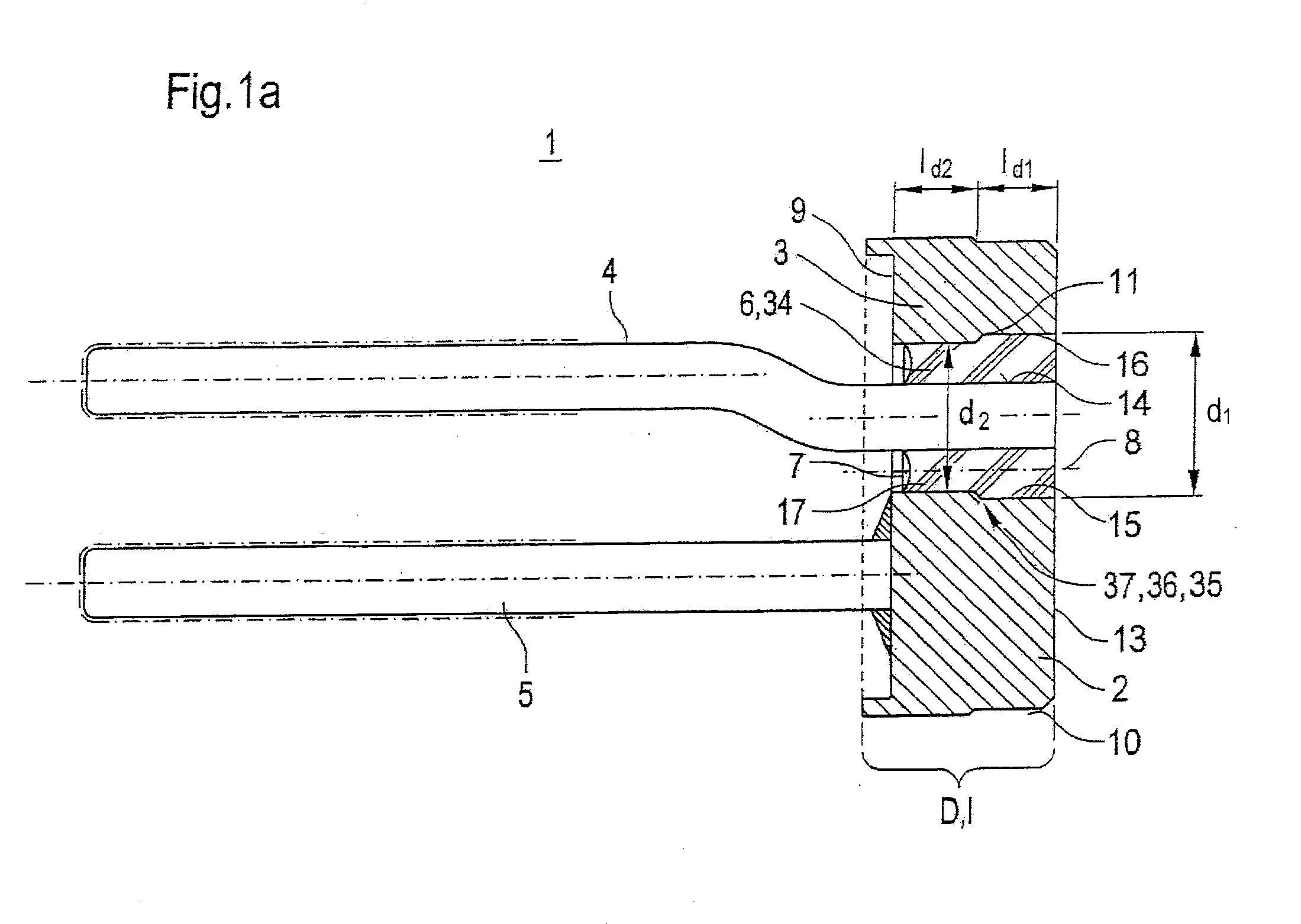

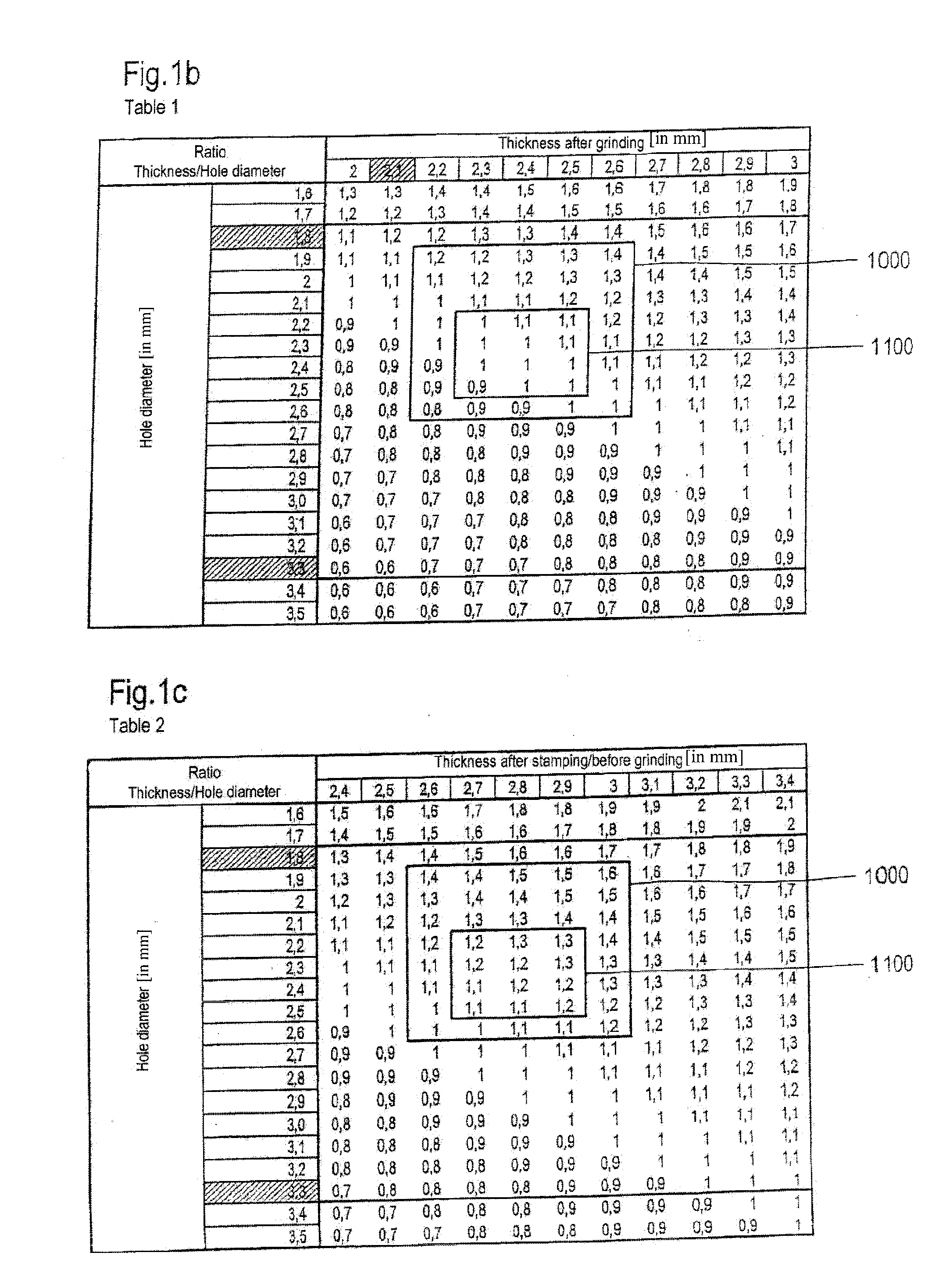

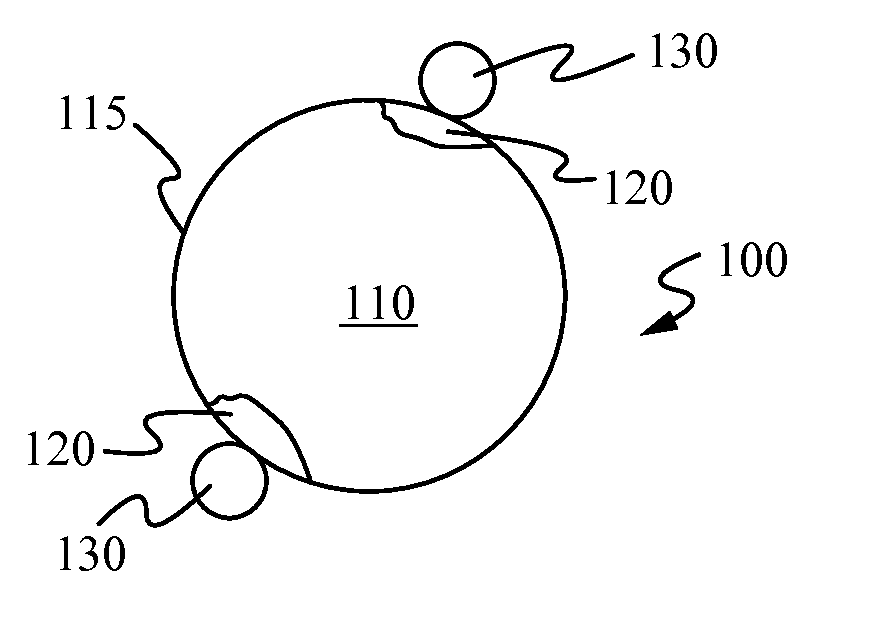

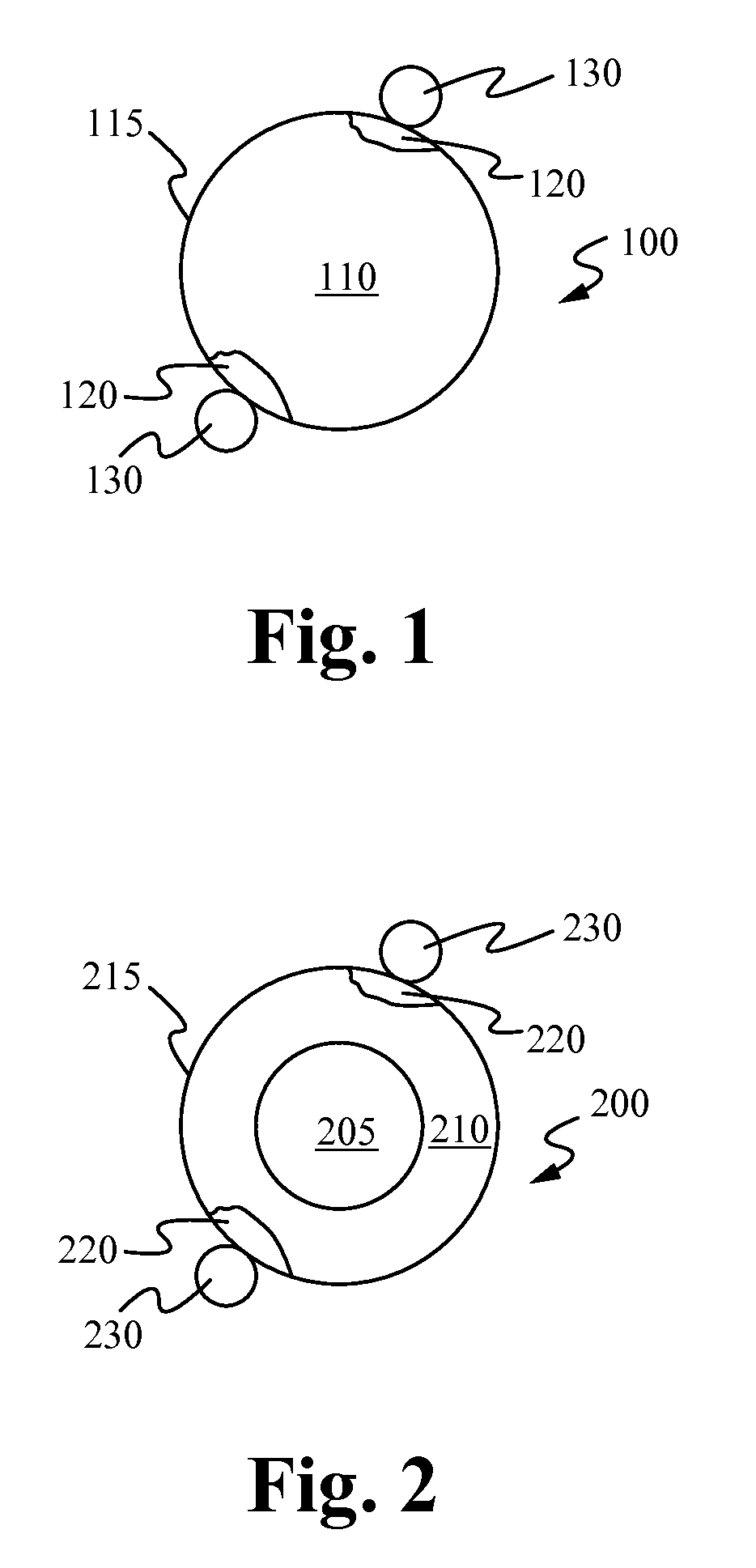

Metal-sealing material-feedthrough and utilization of the metal-sealing material feedthrough with an airbag, a belt tensioning device, and an ignition device

ActiveUS20070187934A1Improve solderabilityImprove corrosion resistanceBlasting cartridgesPedestrian/occupant safety arrangementMaximum dimensionAirbag

The present invention relates to a metal-sealing material-feedthrough for igniters of airbags or belt tensioning devices, especially glass-metal-feedthrough, including at least one metal pin which is located in a feedthrough opening in the base body in a sealing material, wherein the base body has a front side and a back side. Structure is provided between the front and the back side in order to avoid a relative movement of sealing material in the direction toward the back relative to the inside circumference of the feedthrough opening. At least the feedthrough opening is punched out of the base body. The base body is configured so that the ratio of thickness (D) of the base body to the maximum dimension of the feedthrough opening vertical to the axis direction of the feedthrough opening is in the range of between and including 0.9 to 1.6.

Owner:SCHOTT AG

Wet chemical and plasma methods of forming stable PtPd catalysts

InactiveUS8669202B2Minimizing and eliminating mobility and agglomerationArea maximizationMaterial nanotechnologyOther chemical processesCobaltInterior design

A nano-particle comprising: an interior region comprising a mixed-metal oxide; and an exterior surface comprising a pure metal. In some embodiments, the mixed-metal oxide comprises aluminum oxide and a metallic pinning agent, such as palladium, copper, molybdenum, or cobalt. In some embodiments, the pure metal at the exterior surface is the same as the metallic pinning agent in the mixed-metal oxide in the interior region. In some embodiments, a catalytic nano-particle is bonded to the pure metal at the exterior surface. In some embodiments, the interior region and the exterior surface are formed using a plasma gun. In some embodiments, the interior region and the exterior surface are formed using a wet chemistry process. In some embodiments, the catalytic nano-particle is bonded to the pure metal using a plasma gun. In some embodiments, the catalytic nano-particle is bonded to the pure metal using a wet chemistry process.

Owner:UMICORE AG & CO KG +1

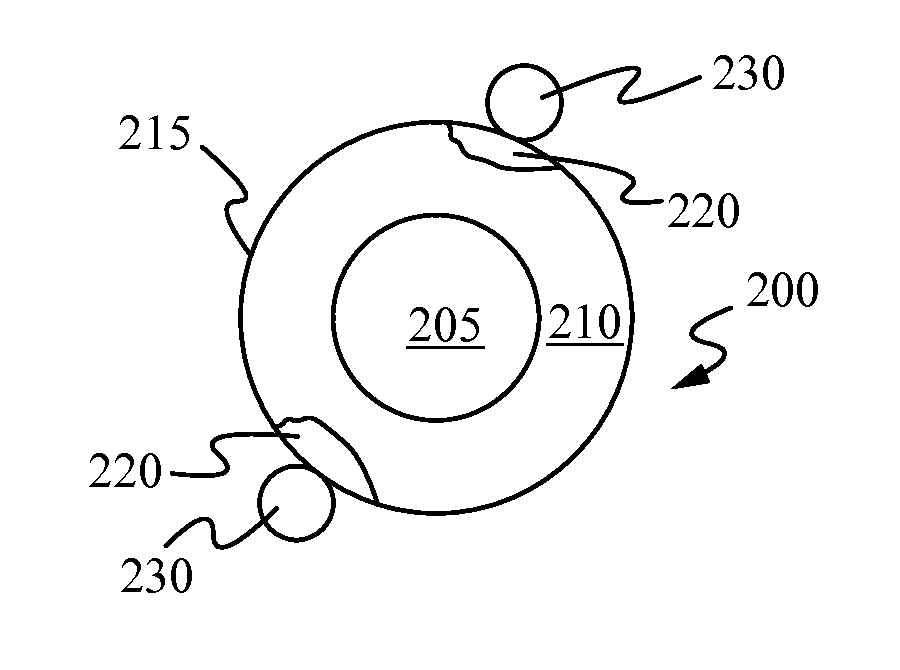

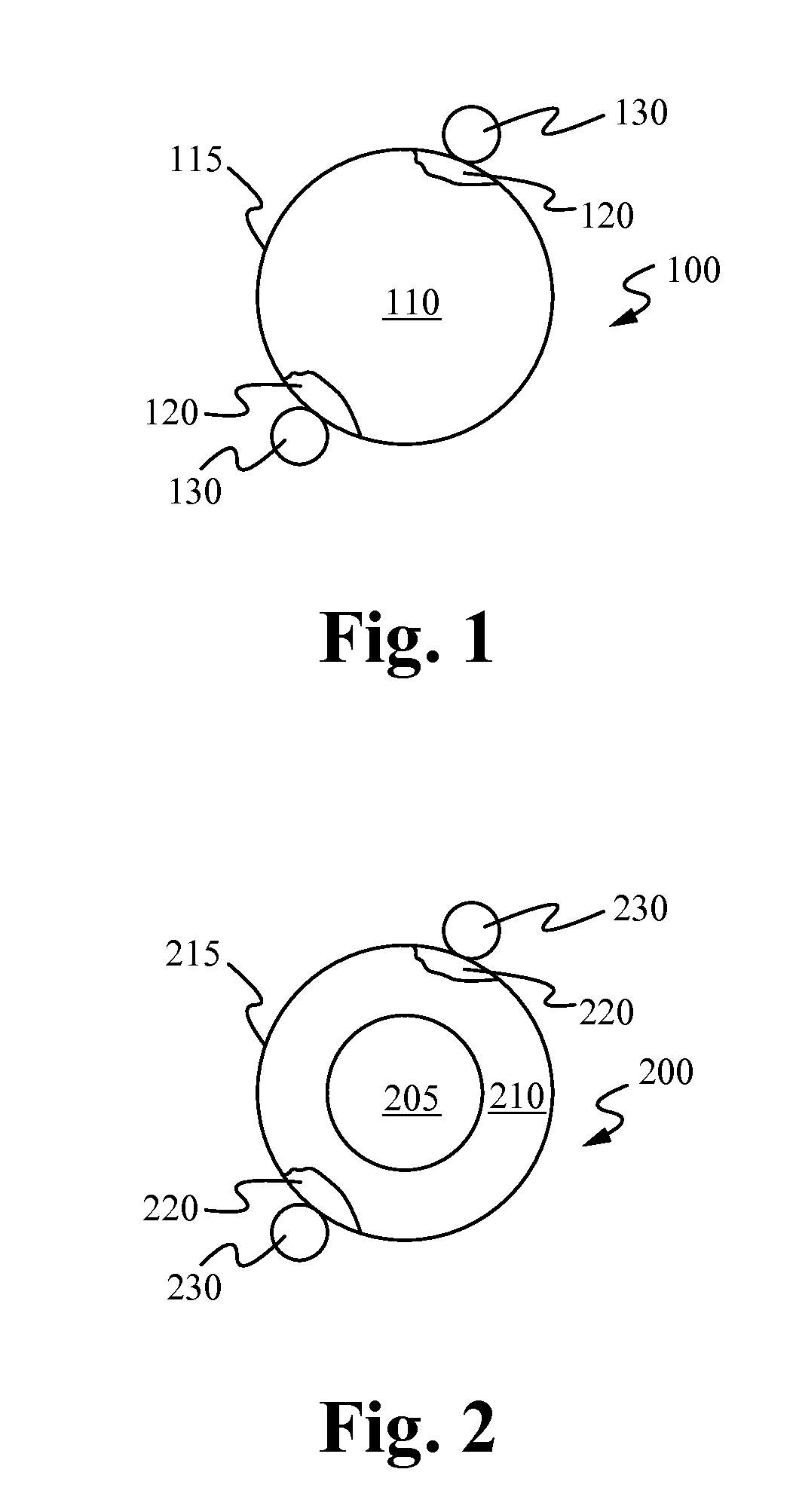

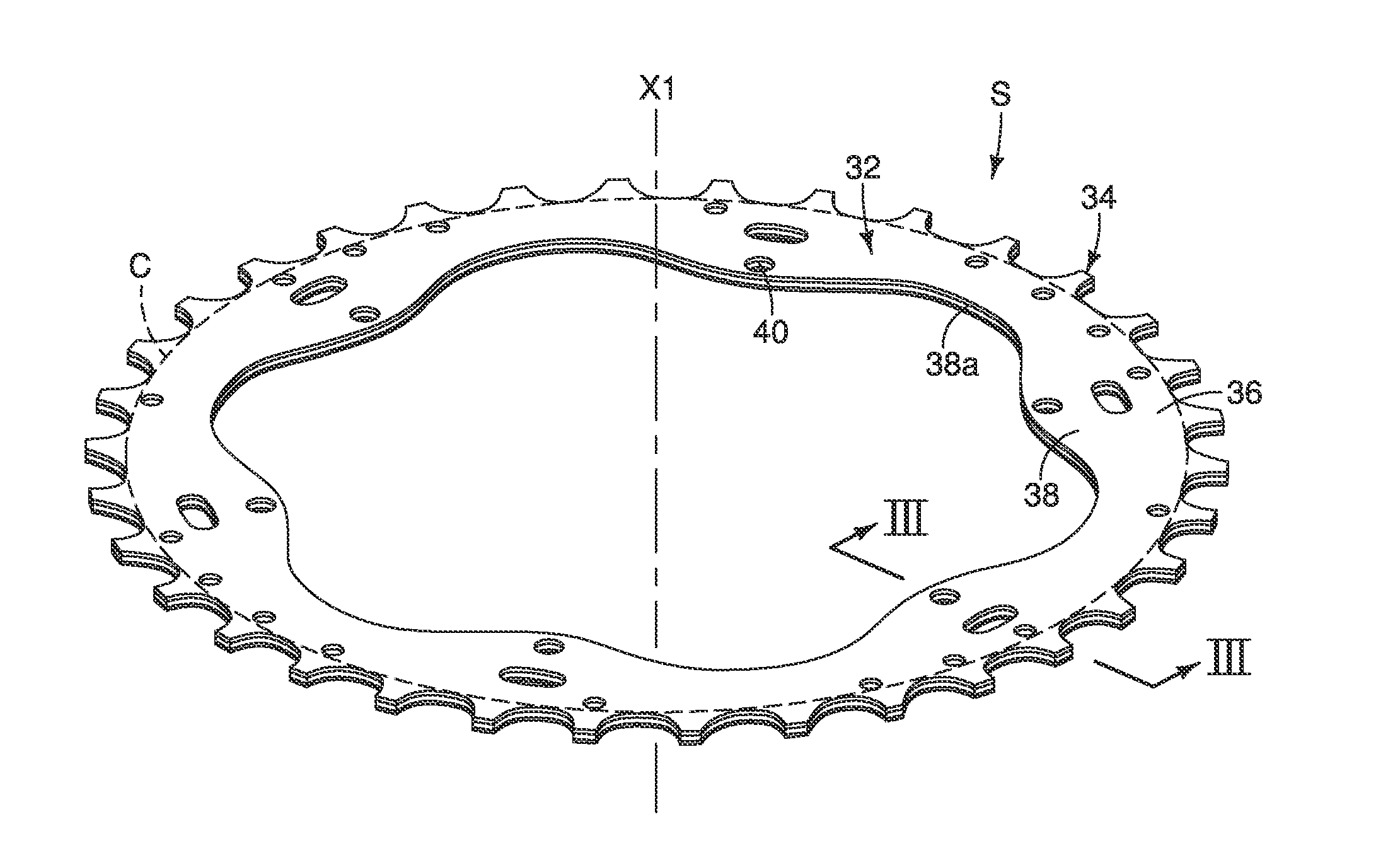

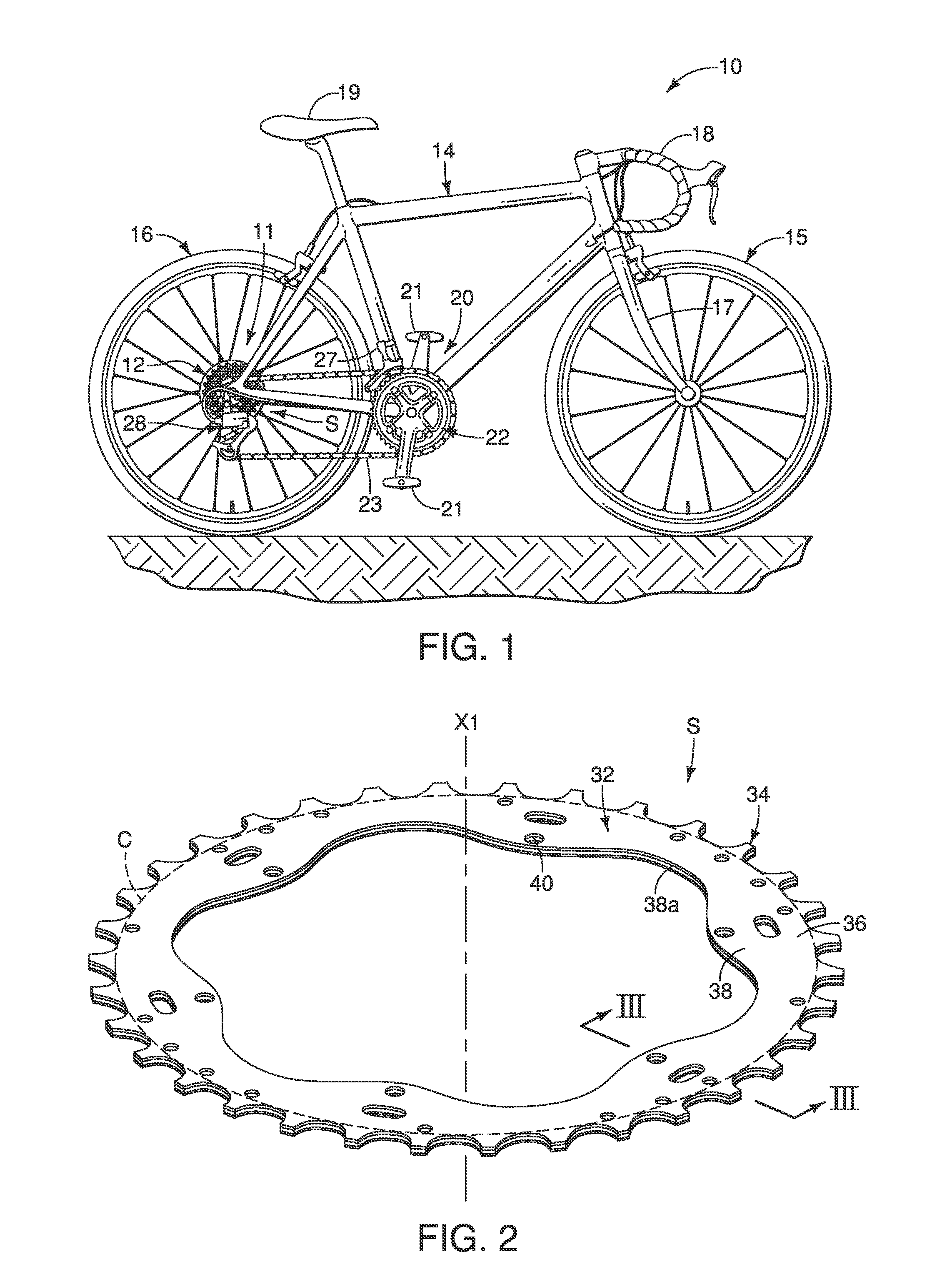

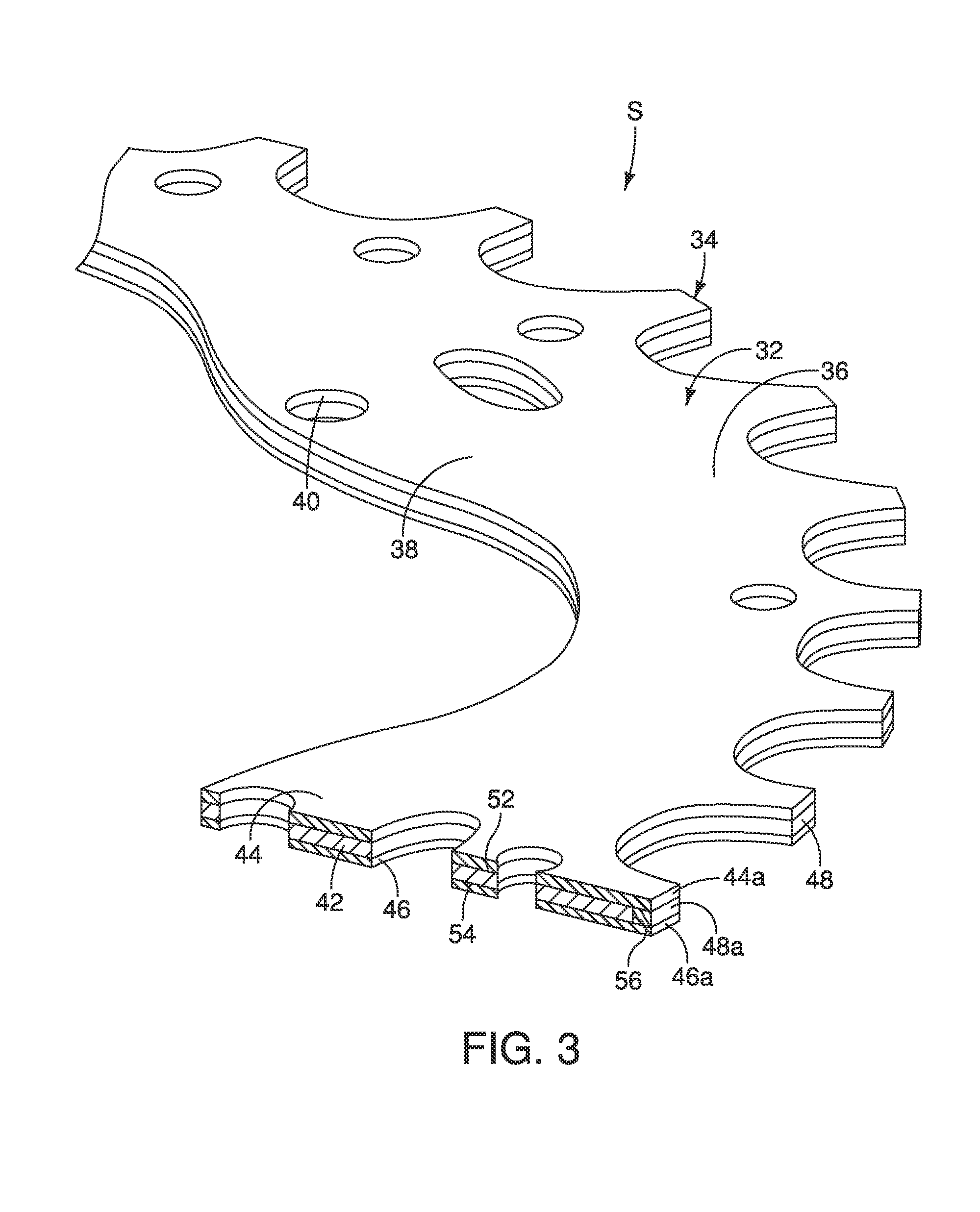

Bicycle sprocket

ActiveUS20140335987A1Rigid enoughSecure bondingChain/belt transmissionPortable liftingSpecific gravityRotational axis

A bicycle sprocket includes a sprocket body, and a plurality of sprocket teeth. At least one of the sprocket teeth includes a first layered member, a second layered member and a third layered member. The first layered member has a first axial surface and a second axial surface. The second layered member is attached to the first axial surface such that the first and second layered members overlap each other in an axial direction as viewed parallel to a rotational axis of the sprocket body. The third layered member is attached to the second axial surface such that the first and third layered members overlap each other in the axial direction as viewed parallel to the rotational axis of the sprocket body. The first layered member has a specific gravity that is less than those of the second layered member and the third layered member.

Owner:SHIMANO INC

Antistatic fabrics and anti-taser protective device

InactiveUS20060175581A1Good conductive propertyHigh wear resistanceNanoinformaticsConductive materialElectrically conductiveCarbon nanotube

The invention includes fabrics that have been dyed or finished with a dye that contains a conductive mixture of conductive organic materials, inorganic materials, metals, metal oxides, carbon and carbon nanotubes or combinations or mixtures thereof. The dye is used to finish a fabric such that it is conductive. These fabrics are useful in shielding law enforcement personnel from energy weapons discharge and in providing an electrostatic medium for personnel that work with static sensitive products. The fabrics, when appropriately grounded, dissipate the emitted charge and transmit it to ground. Additionally, the apparel has high wear resistance and is both thermally and electrically conductive yet is comfortable to wear.

Owner:MYSTICMD

Low odor, light color, disposable article construction adhesive

InactiveUS20050014891A1Improve cohesive strengthEasy to processMonocarboxylic acid ester polymer adhesivesPersonal carePolymer scienceHot melt

We have found a novel spray-on adhesive composition made from components including a high melt index polymer and a high melt tackifier that interact to produce a composition that can form a low odor, light color, non-tacky, hot melt adhesive material that can be used in disposable article manufacture. The adhesive is thermally stable at hot melt application conditions, is low in cost, is easily applied and produces high quality disposable articles.

Owner:ADHERENT LAB

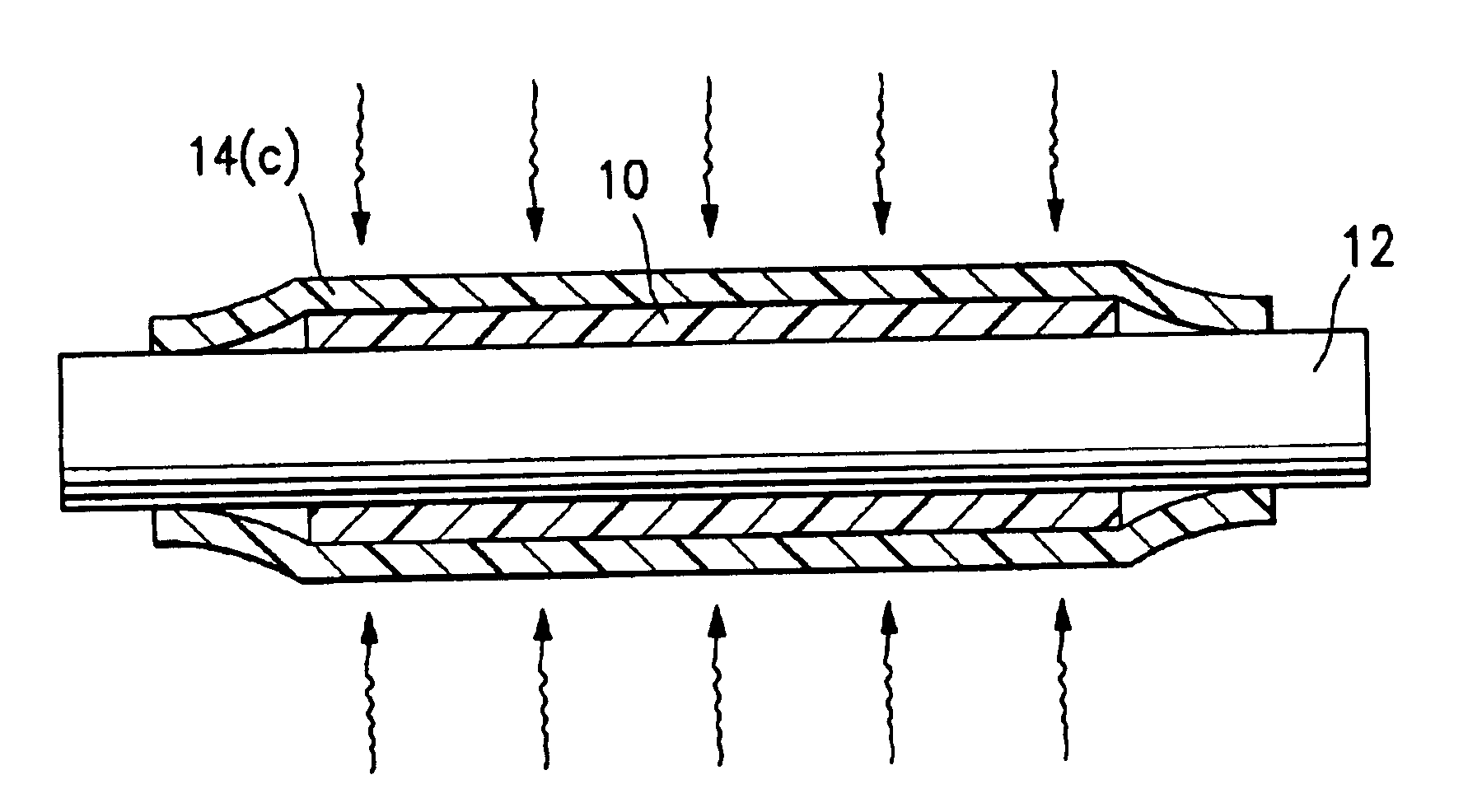

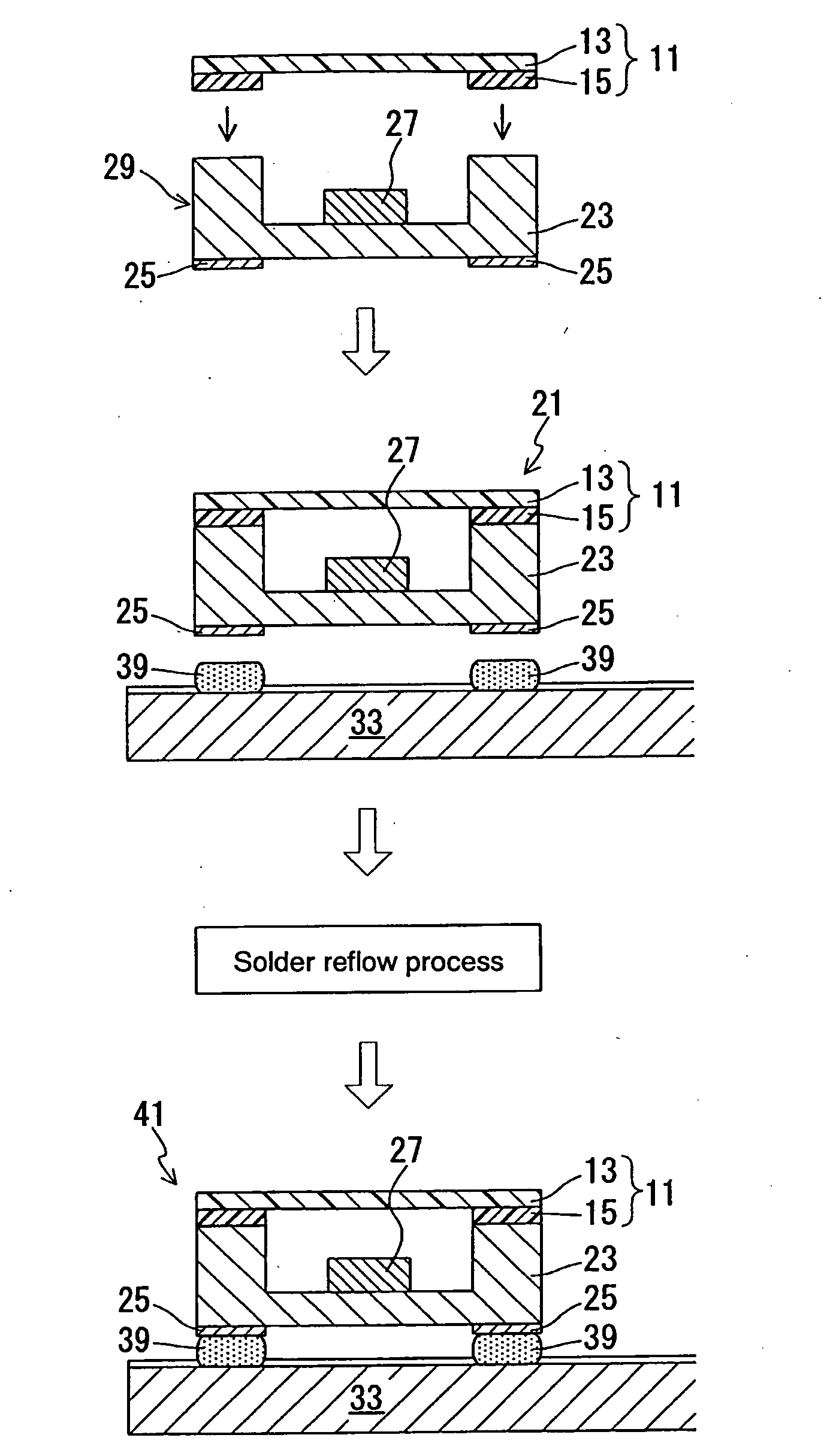

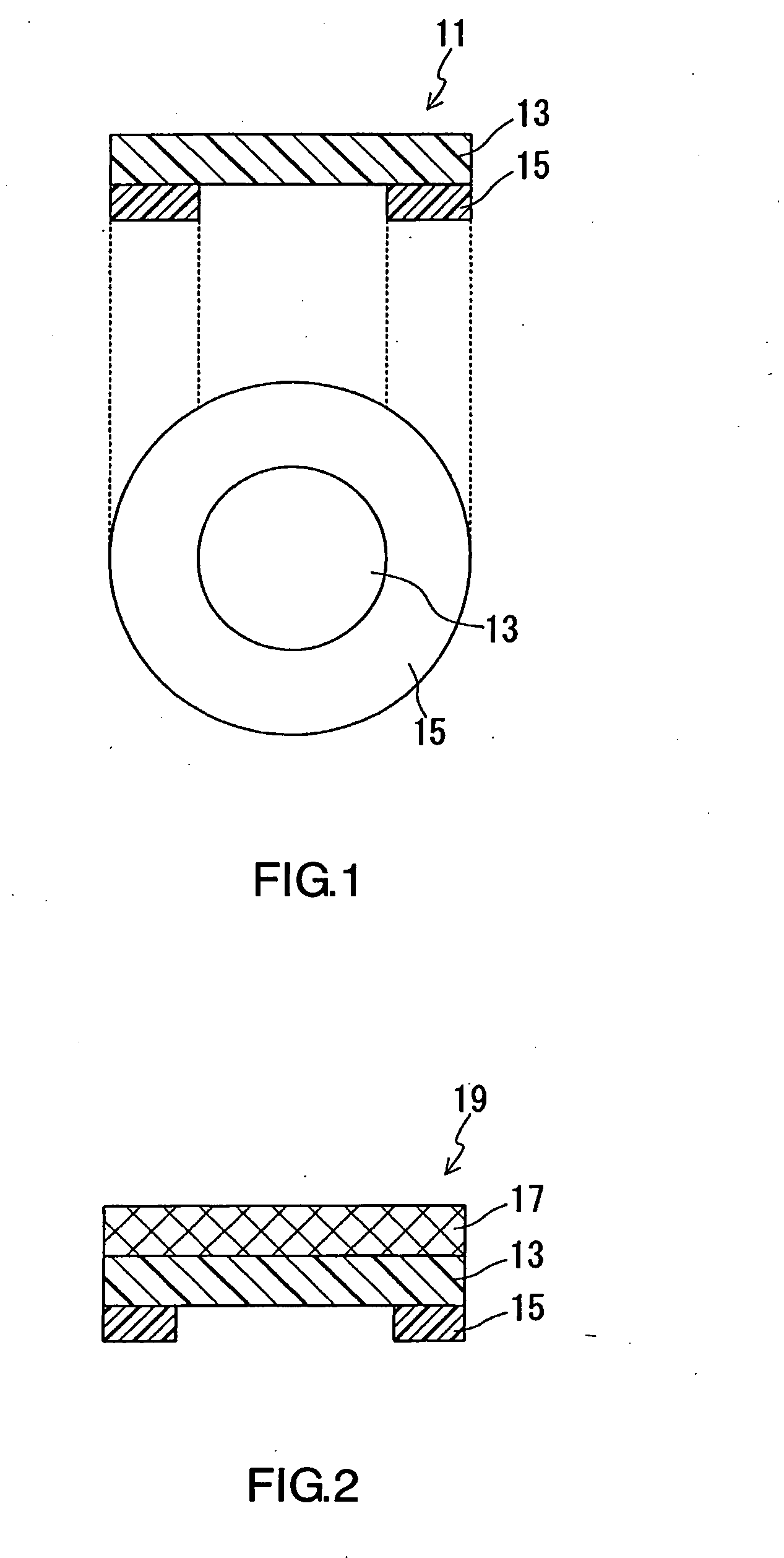

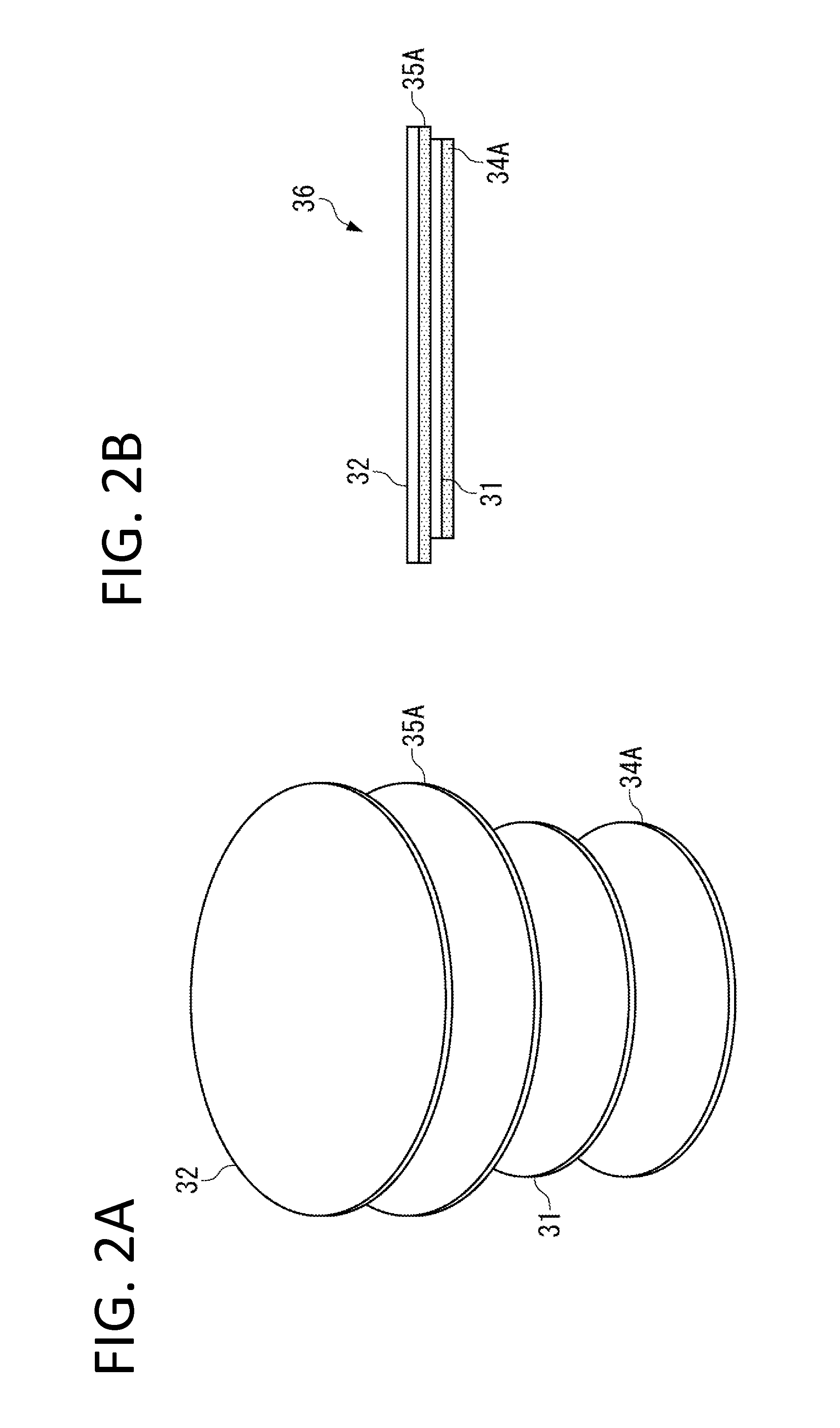

Sound-Permeable Film, Electronic Component with Sound-Permeable Film, and Method of Producing Circuit Board Having Electronic Component Mounted Thereon

ActiveUS20090268928A1Improve heat resistanceReduce in quantityPrinted circuit assemblingLoudspeaker screensForeign matterPorous membrane

A sound-permeable film (11) includes: a porous membrane (13) that contains polytetrafluoroethylene as its main component, allows sound to pass therethrough, and prevents an foreign object such as a water drop from passing therethrough; and a heat-resistant double-sided adhesive sheet (16) that is disposed on a part of at least one of main surfaces of the porous membrane (13).

Owner:NITTO DENKO CORP

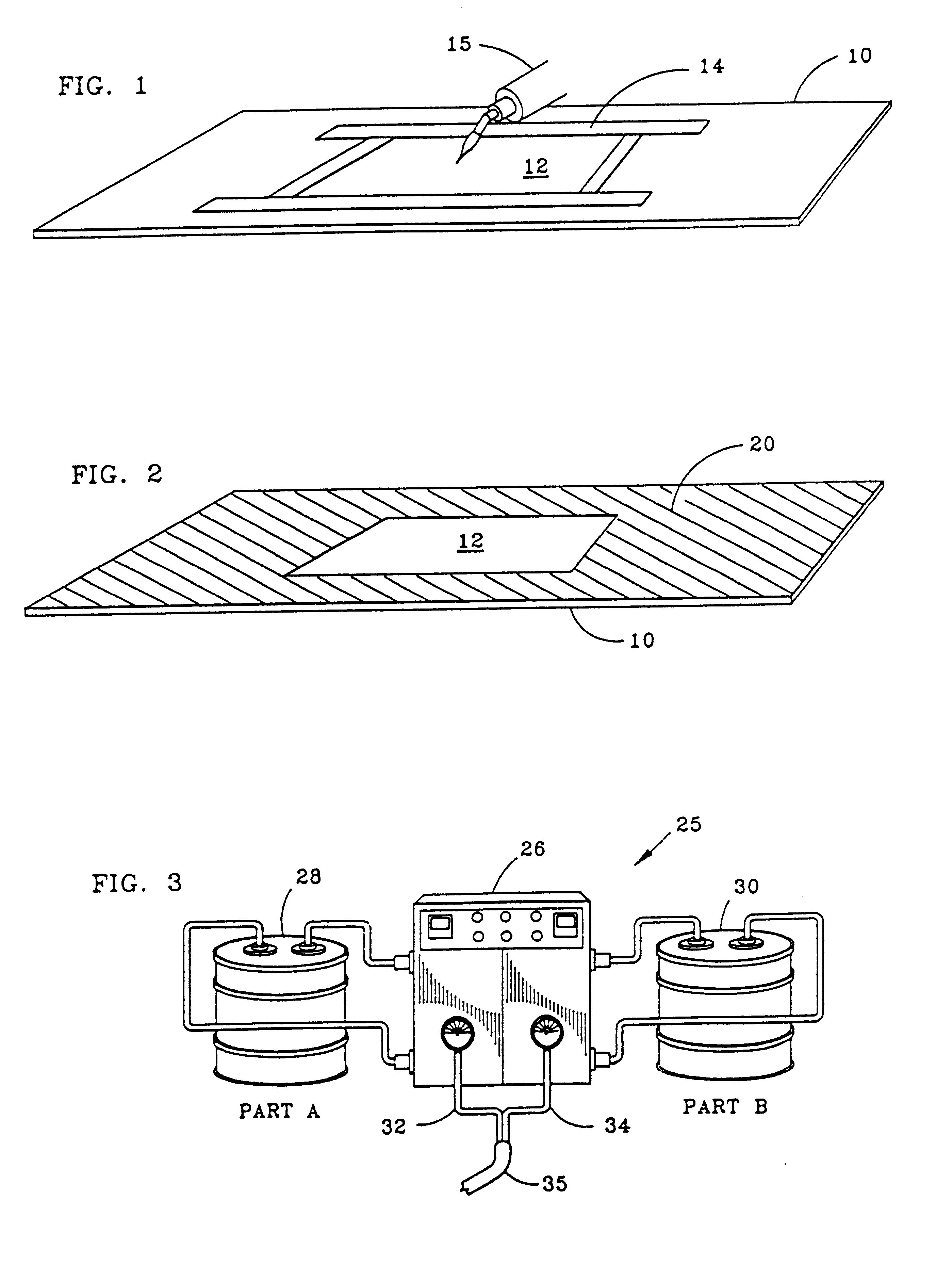

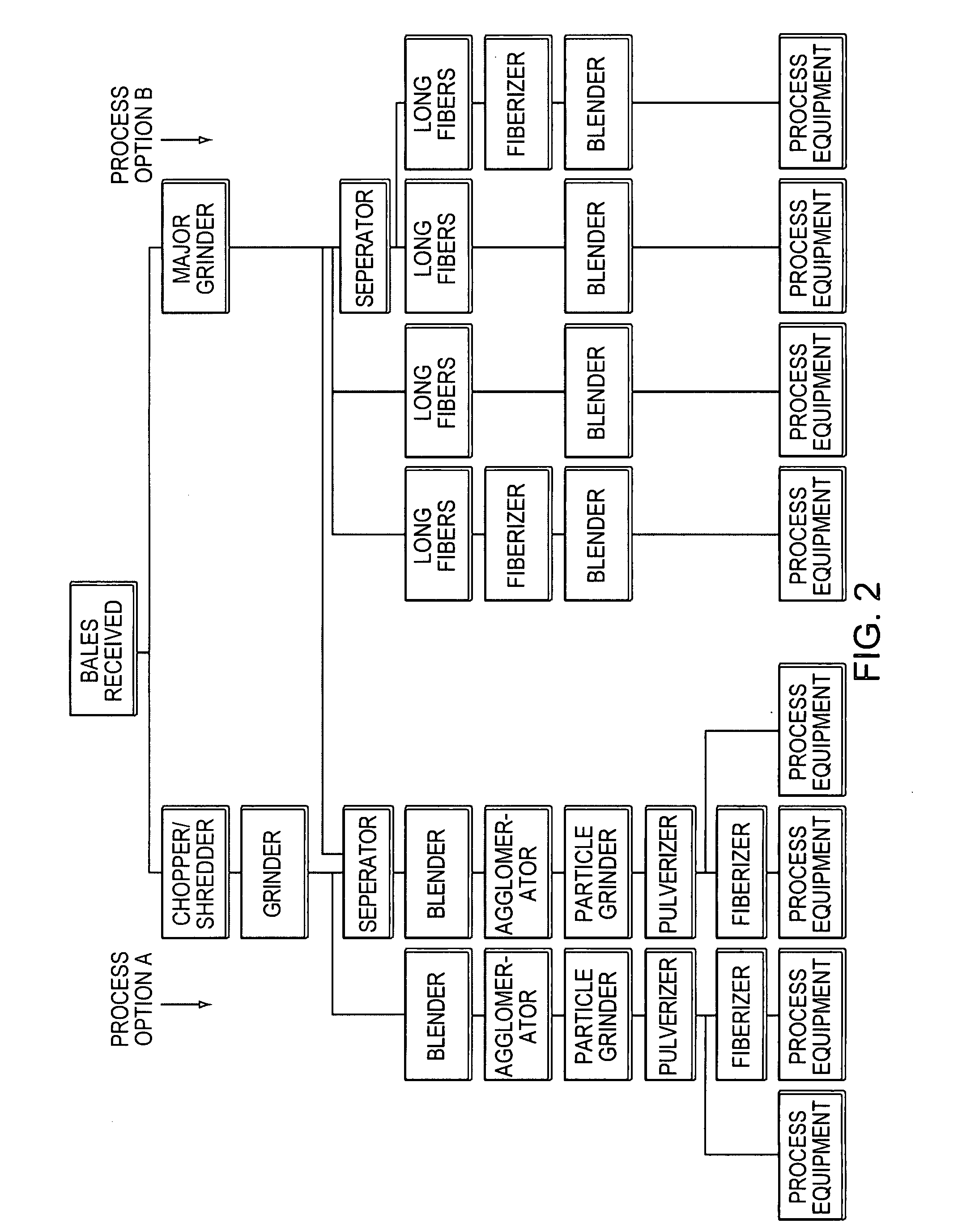

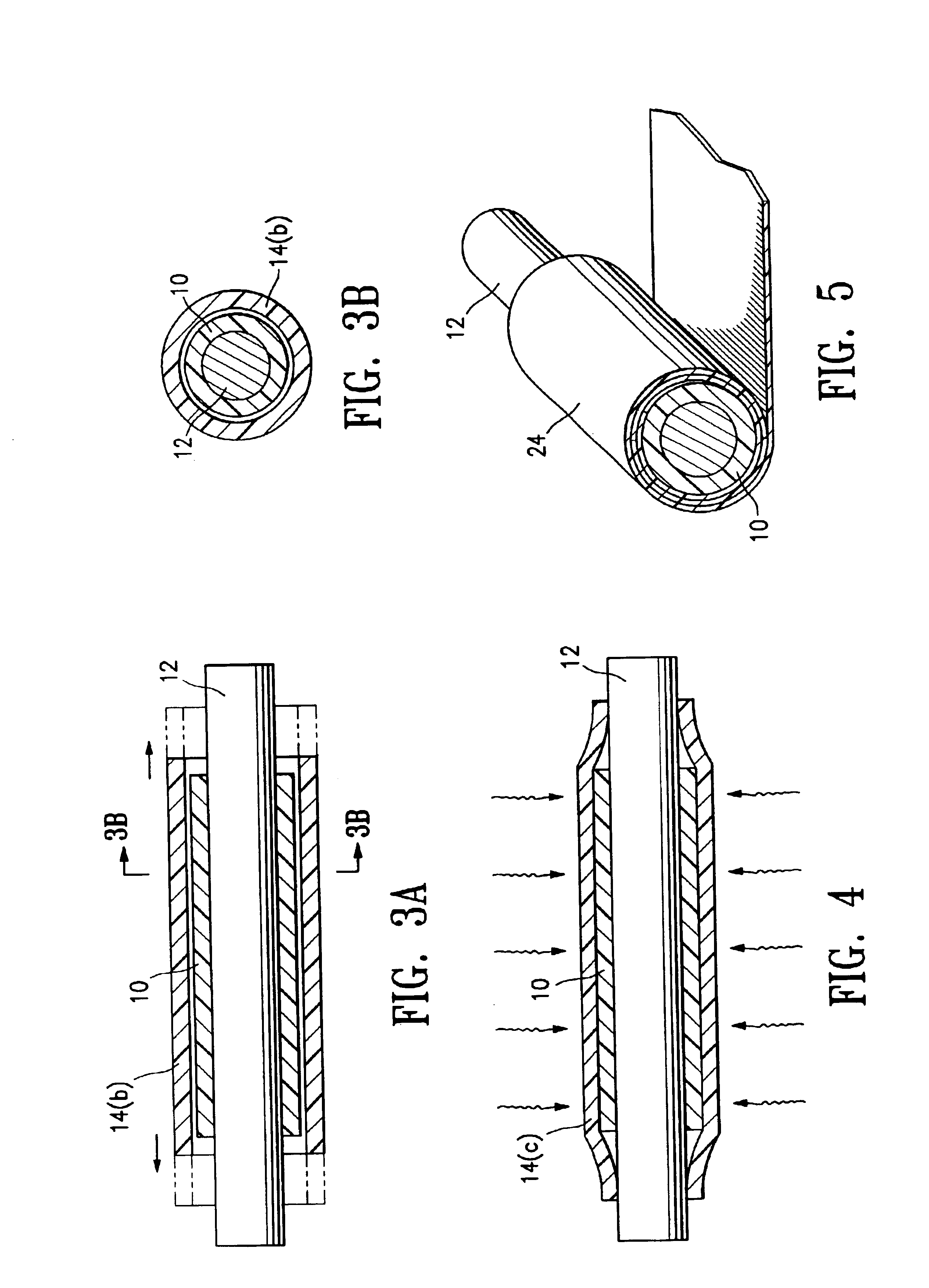

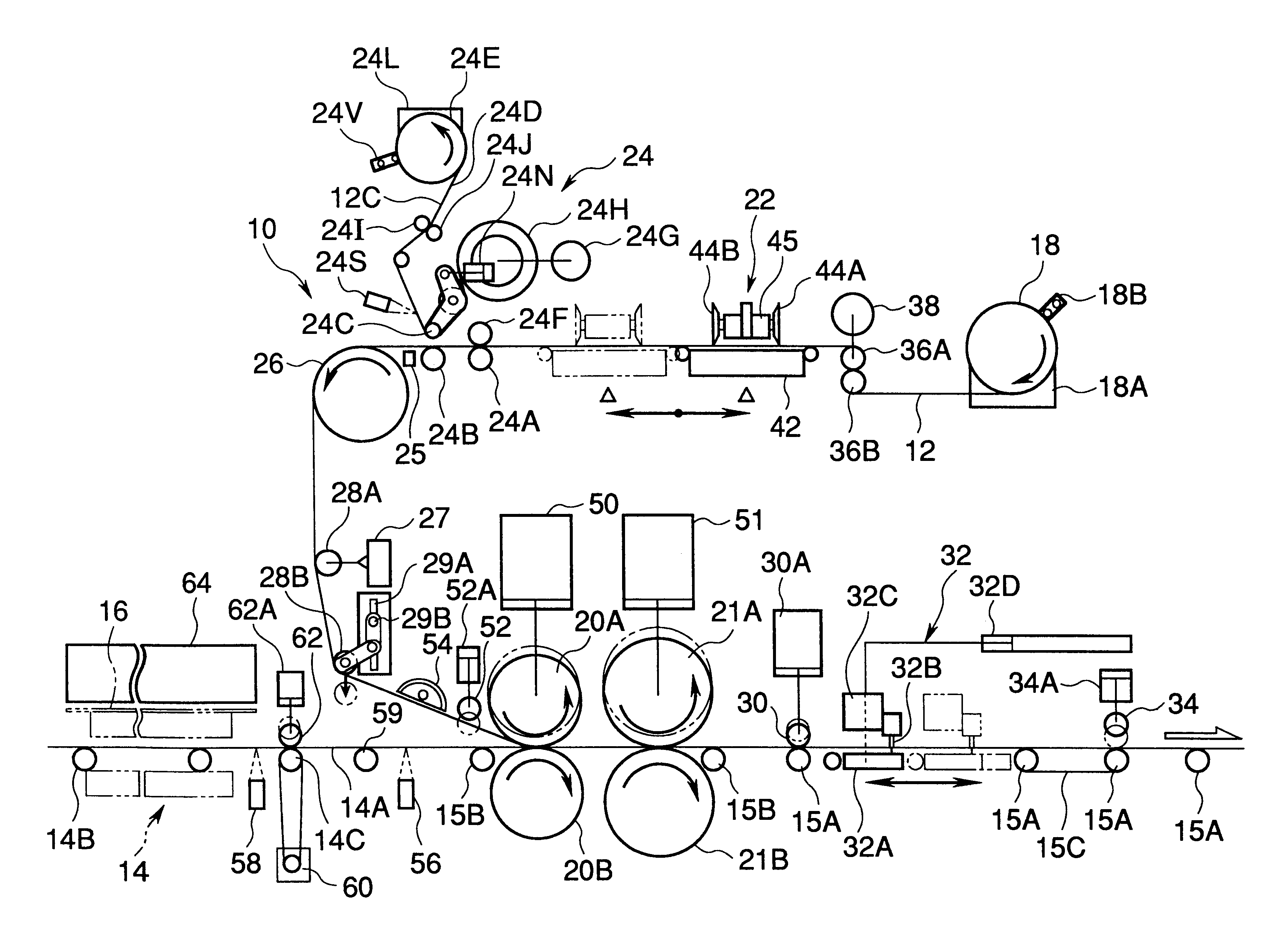

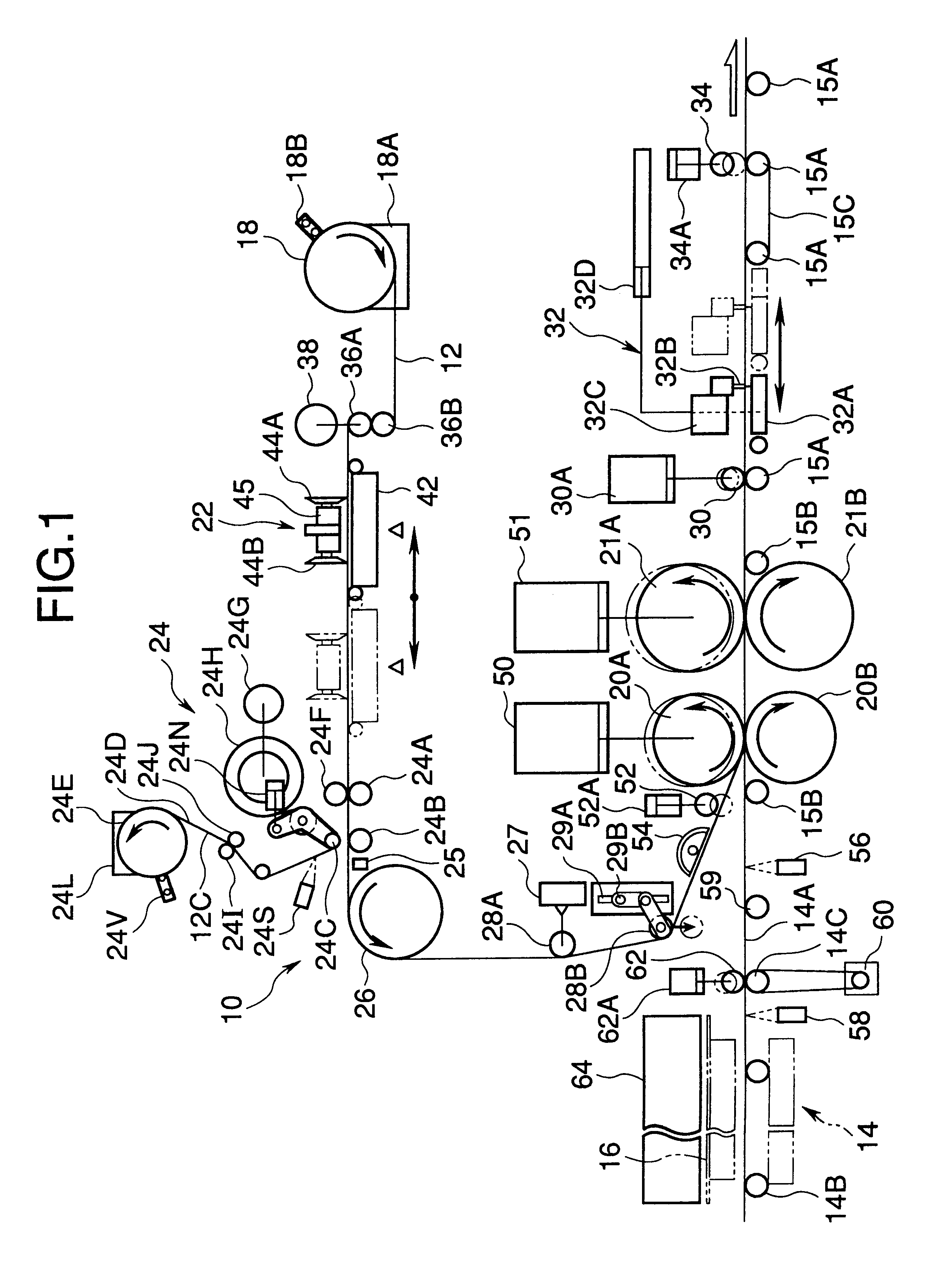

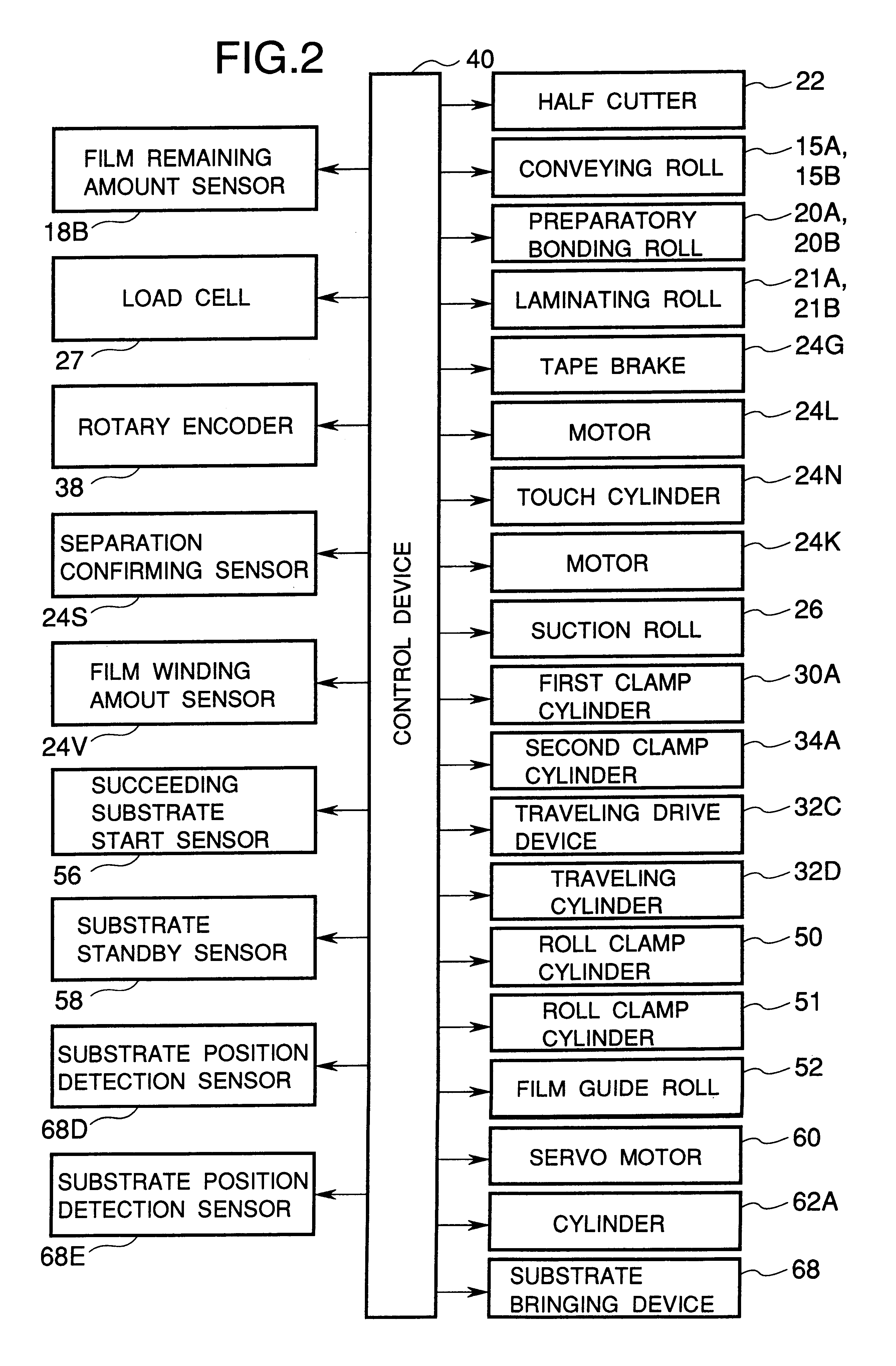

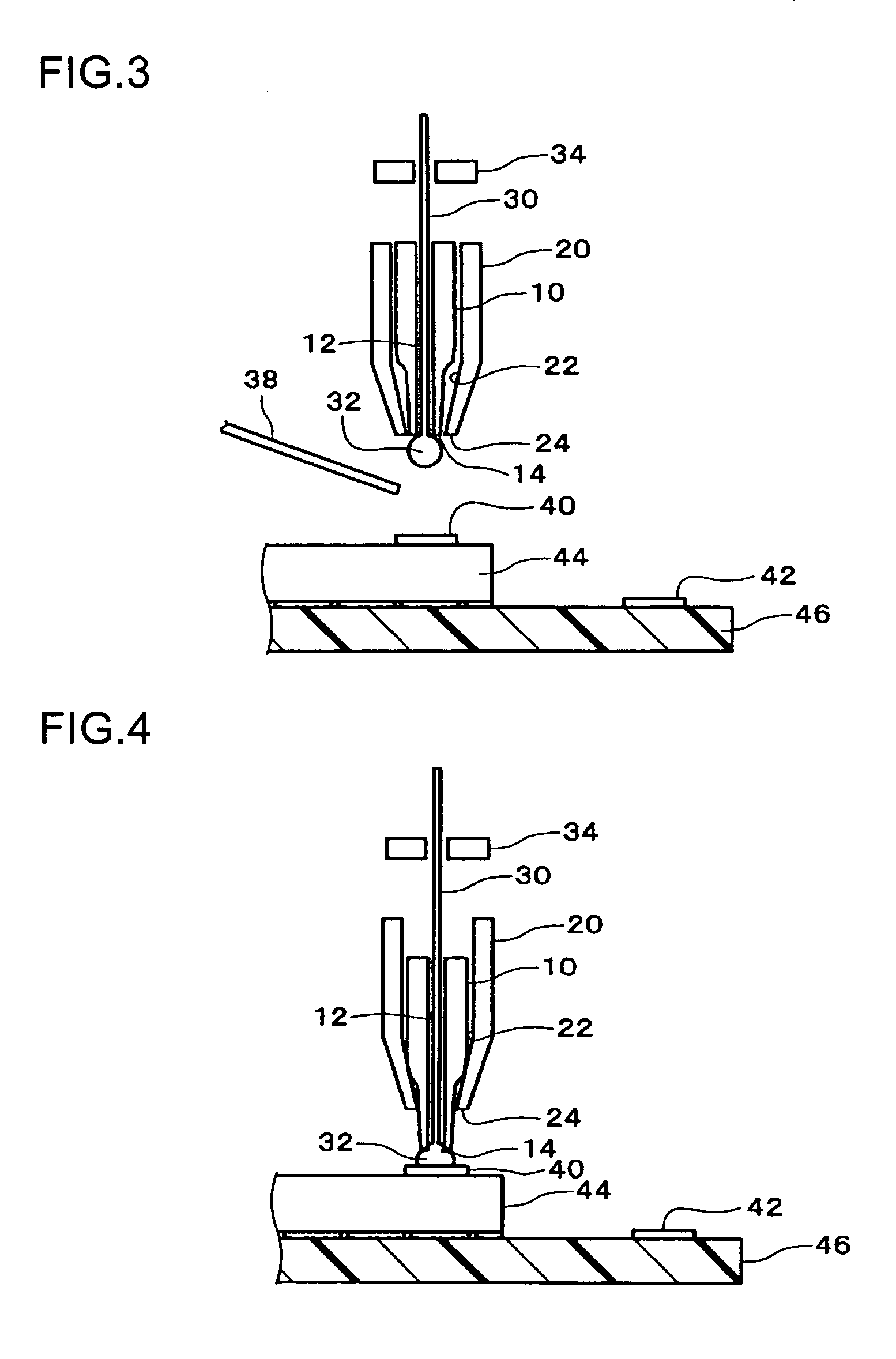

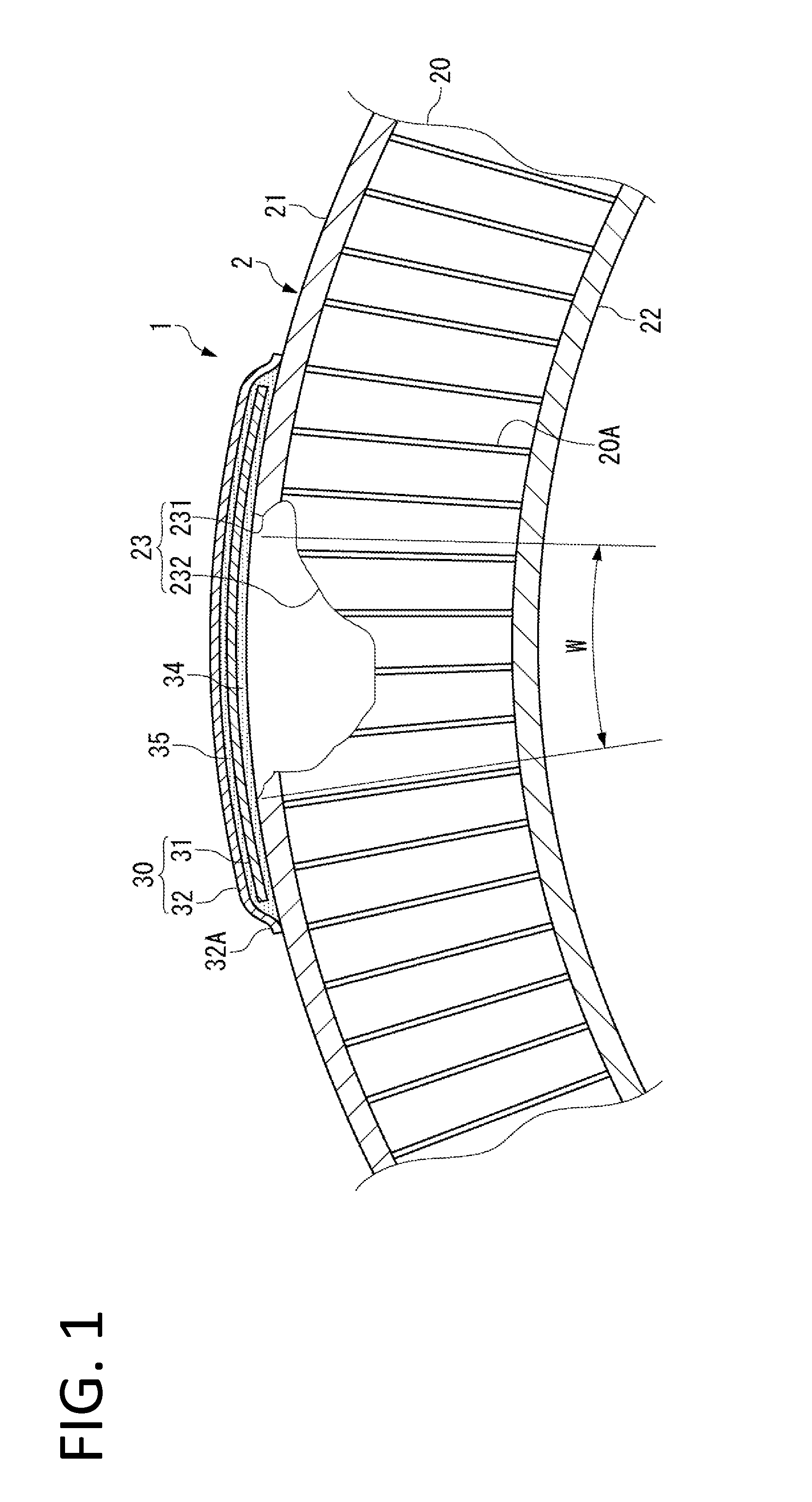

Film applying apparatus

InactiveUS6176286B1Small rangeSecure bondingMechanical working/deformationLamination ancillary operationsSheet filmEngineering

A film applying apparatus 10 is provided with preparatory bonding rolls 20A, 20B and laminating rolls 21A, 21B, and a laminated film 12 wound out from a film roll 18 and a substrate 16 conveyed by a substrate conveying device 14 pass between these rolls and pressure bonding is performed. Diameter of the preparatory bonding rolls 20A, 20B is made smaller than diameter of the laminating rolls 21A, 21B and range of elastic deformable area S1 at the roll surface at grasping starting of the substrate and the laminated film 12 by the preparatory bonding rolls 20A, 20B is made small thereby range of generating, air holding or the like is limited to small.

Owner:SOMAR CORP

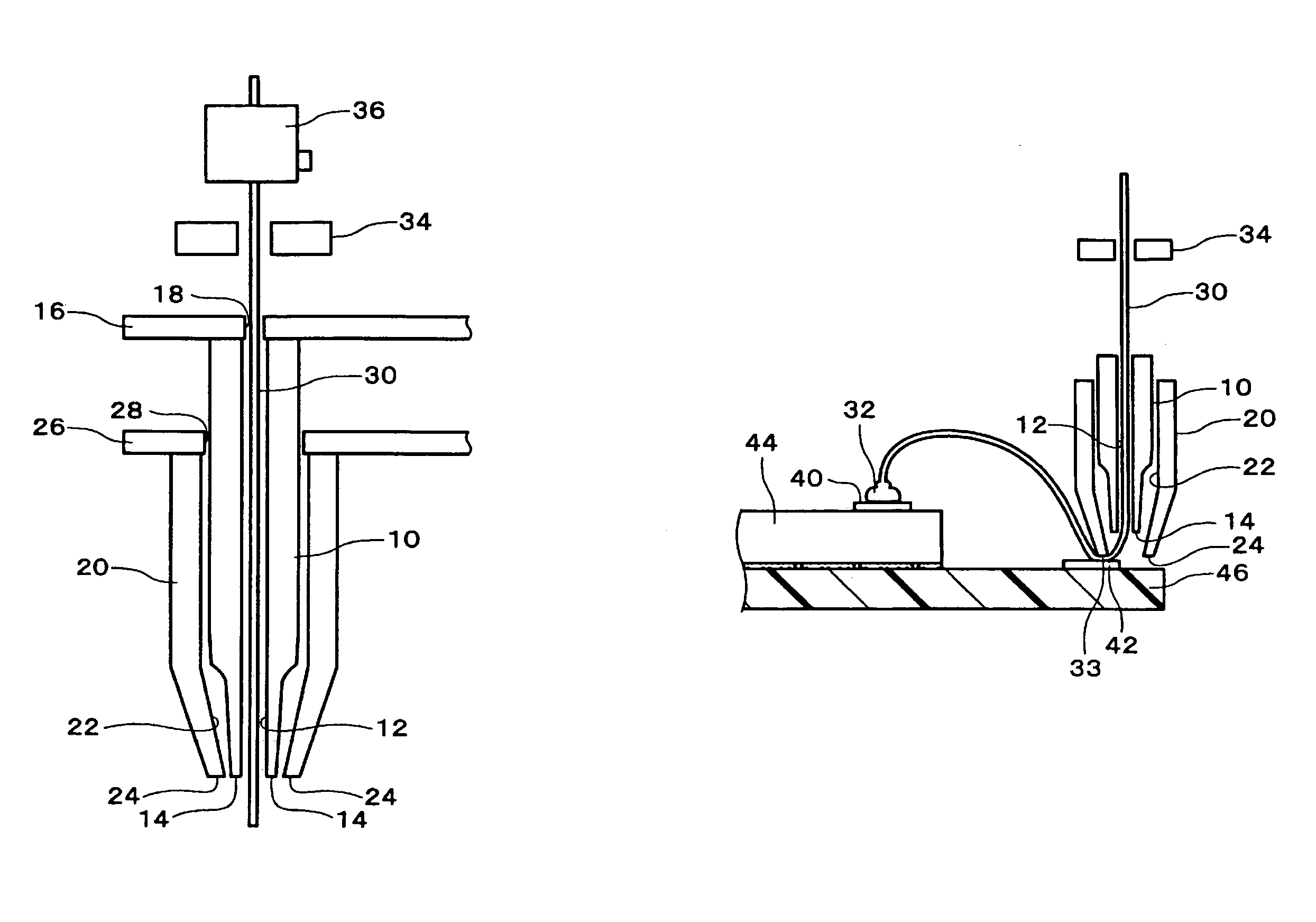

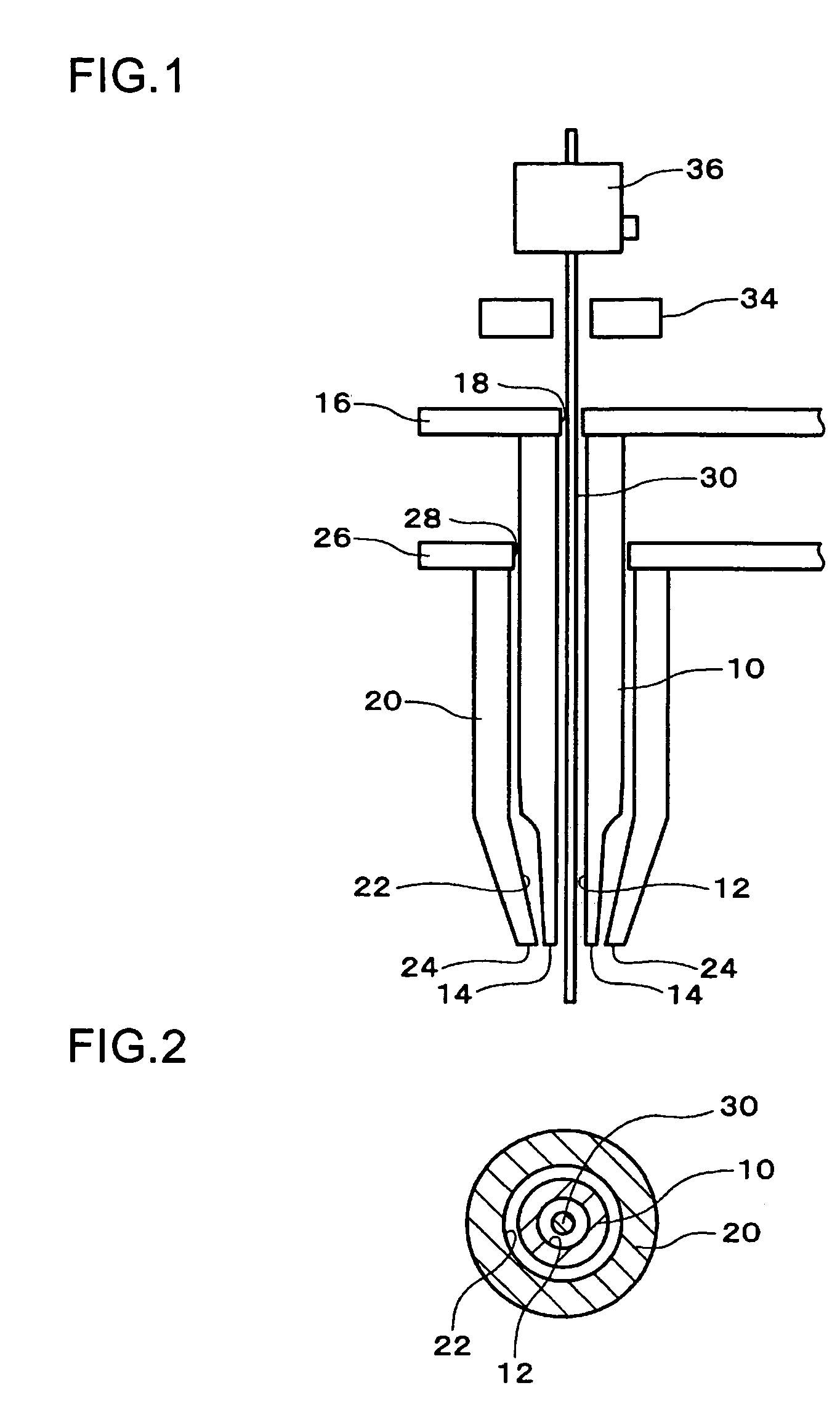

Wire bonding method and wire bonding apparatus

InactiveUS7017794B2Width of the open end sectionBonding failure can be eliminatedWelding/cutting auxillary devicesSolid-state devicesLead bondingBonding process

A highly reliable bonding process is provided. The wire bonding method includes: (a) bonding a tip portion of a wire to a first electrode by pressing an open end section of a first hole of a first tool against the tip portion of the wire that is passed through the first hole and protrudes outside the first hole, and (b) bonding a part of a section of the wire that is lead out from the first electrode to a second electrode. The first tool is passed through a second hole of a second tool. The width of an open end section of the second hole is formed greater than the width of the open end section of the first hole. The step (b) is conducted by pressing the open end section of the second hole against the part of the wire.

Owner:SEIKO EPSON CORP

Carpet waste composite

Owner:MATERIAL INNOVATIONS LLC

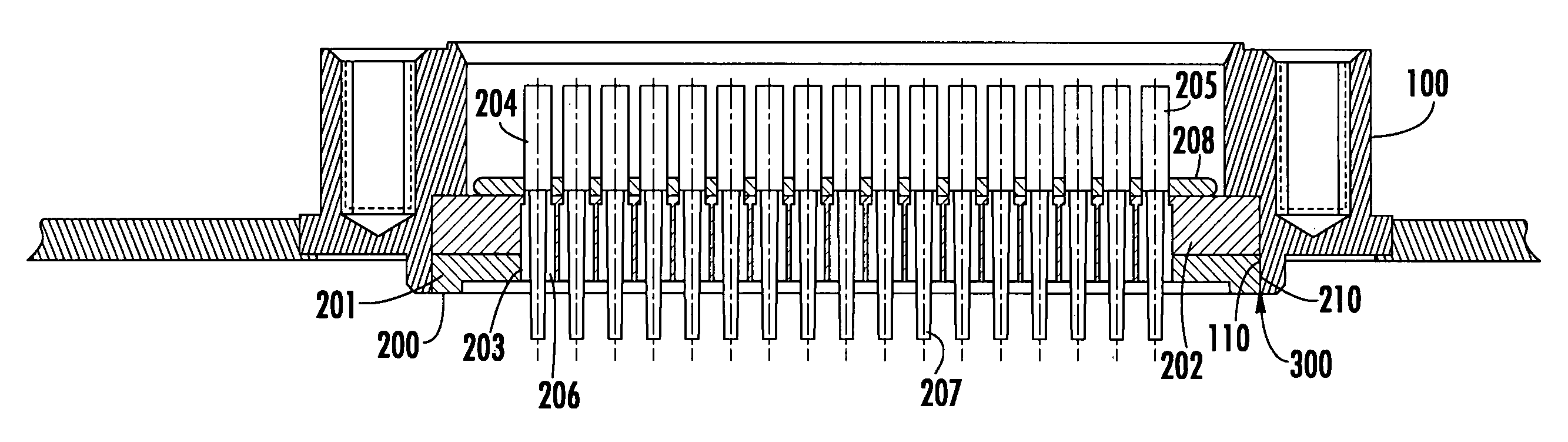

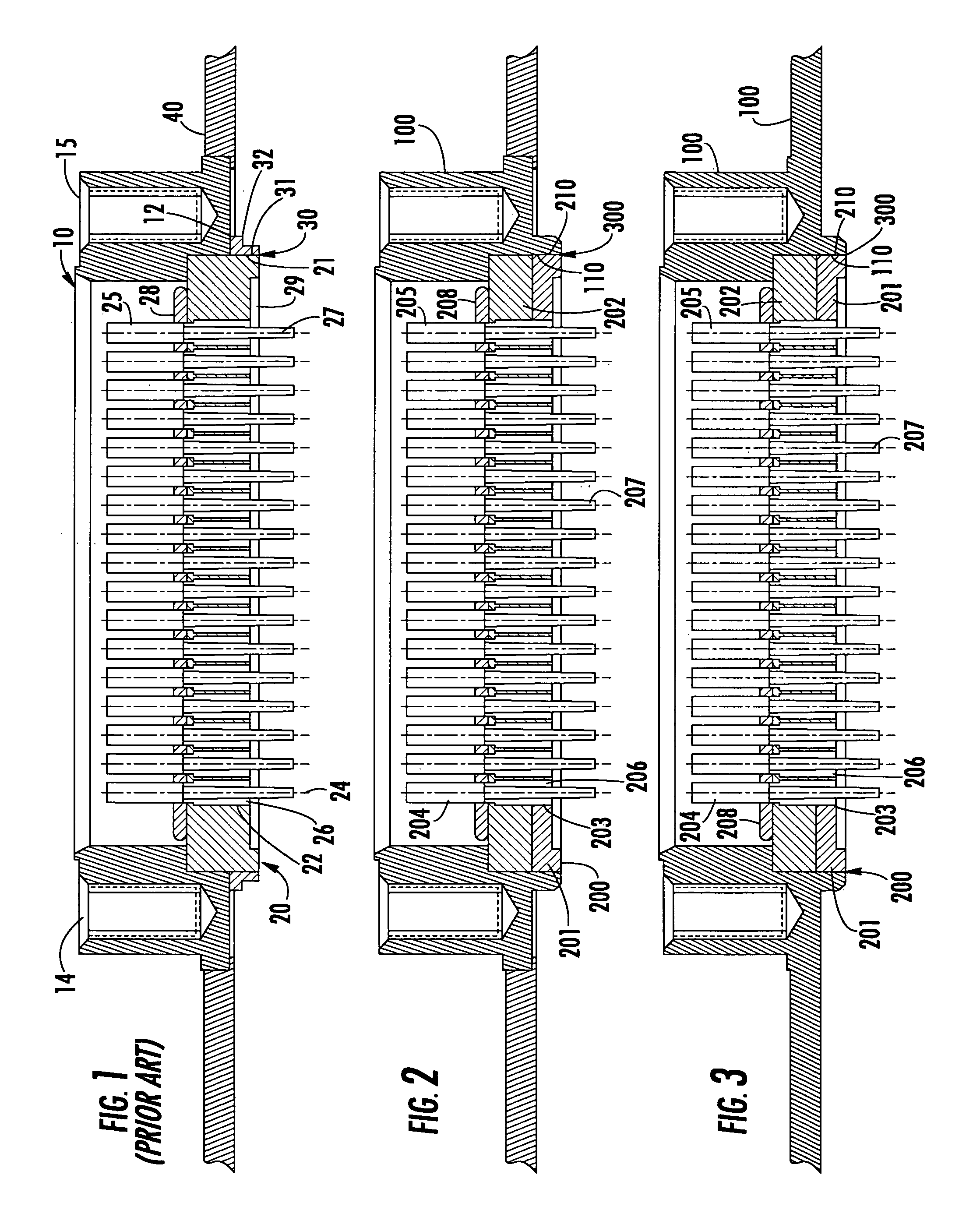

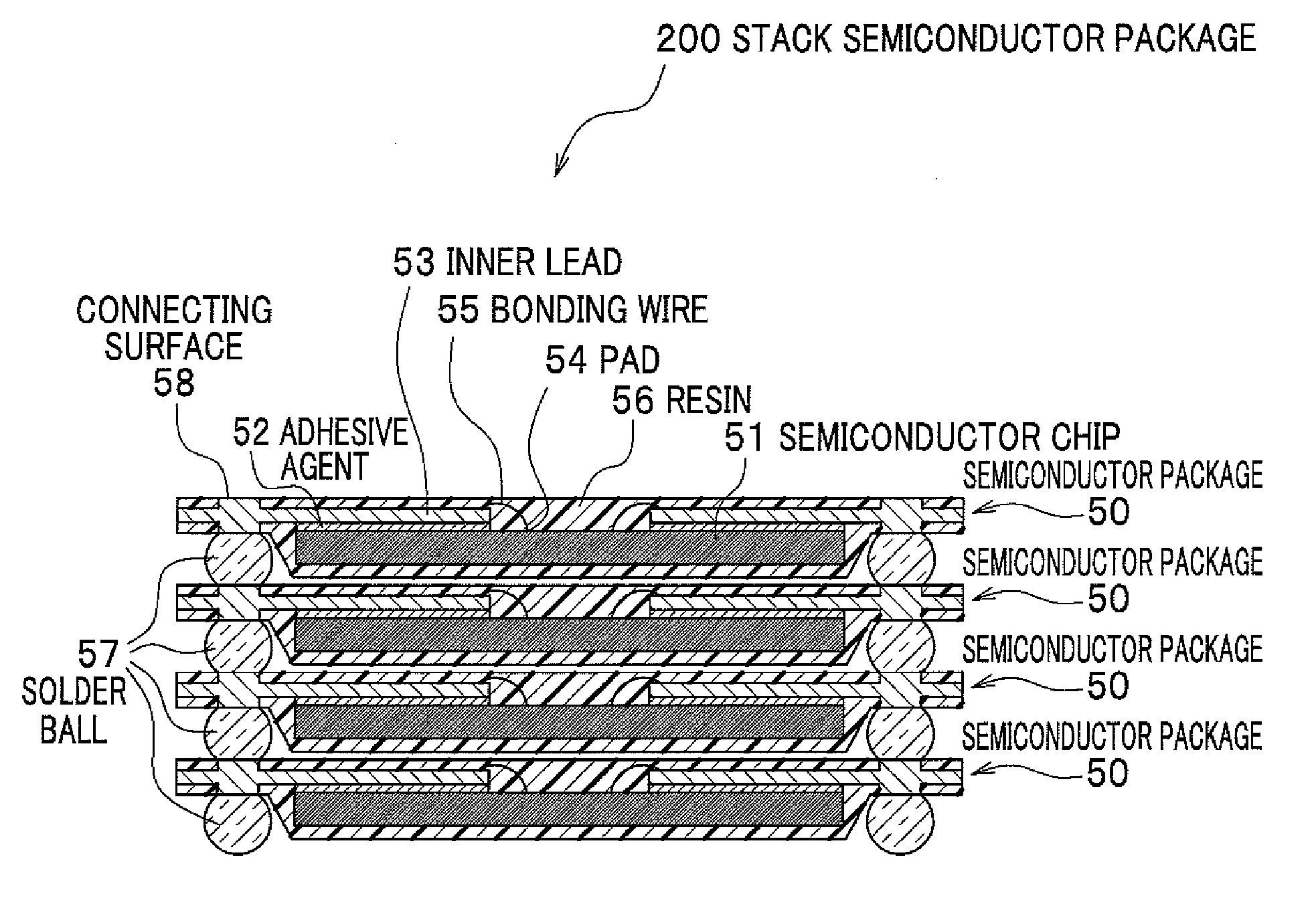

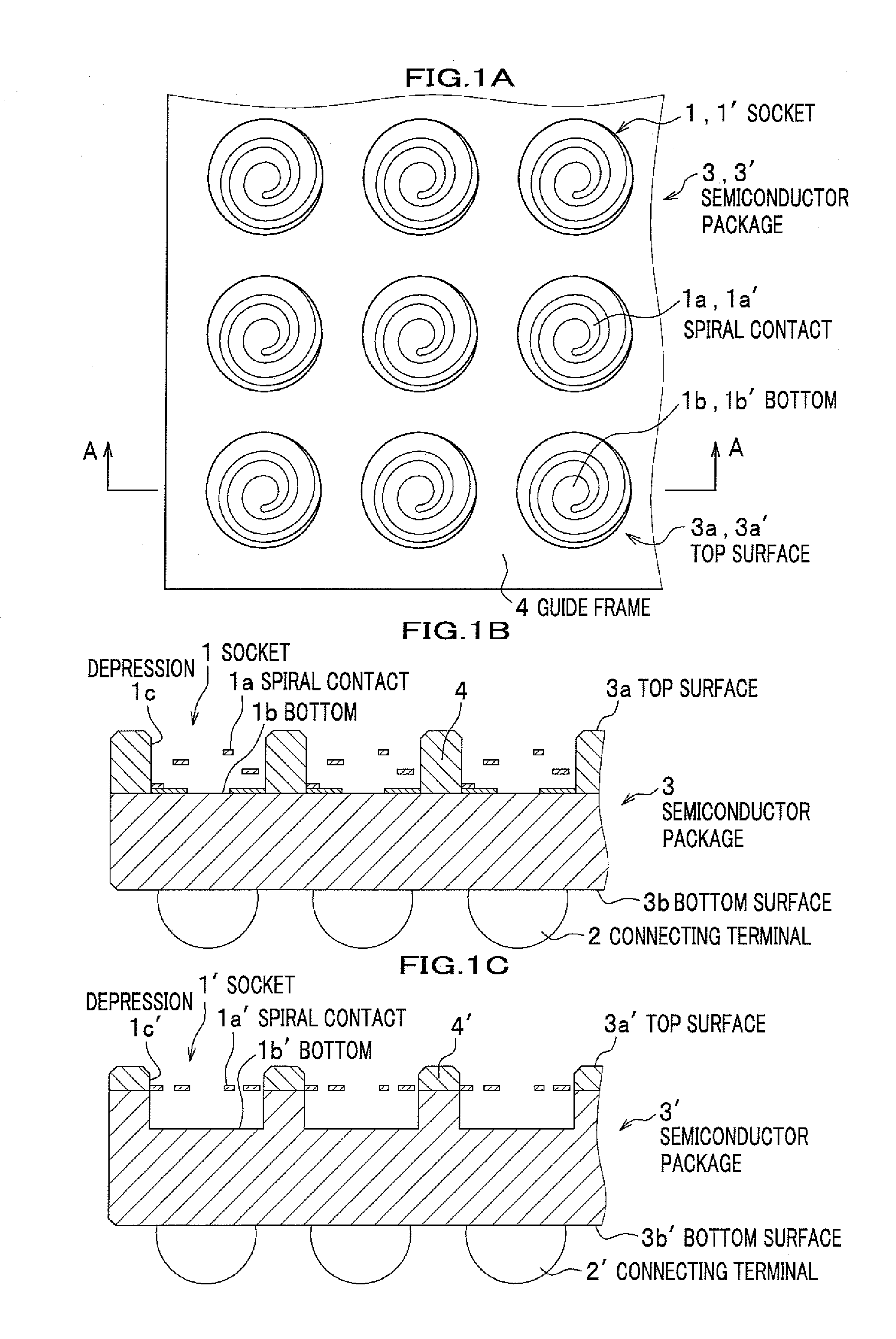

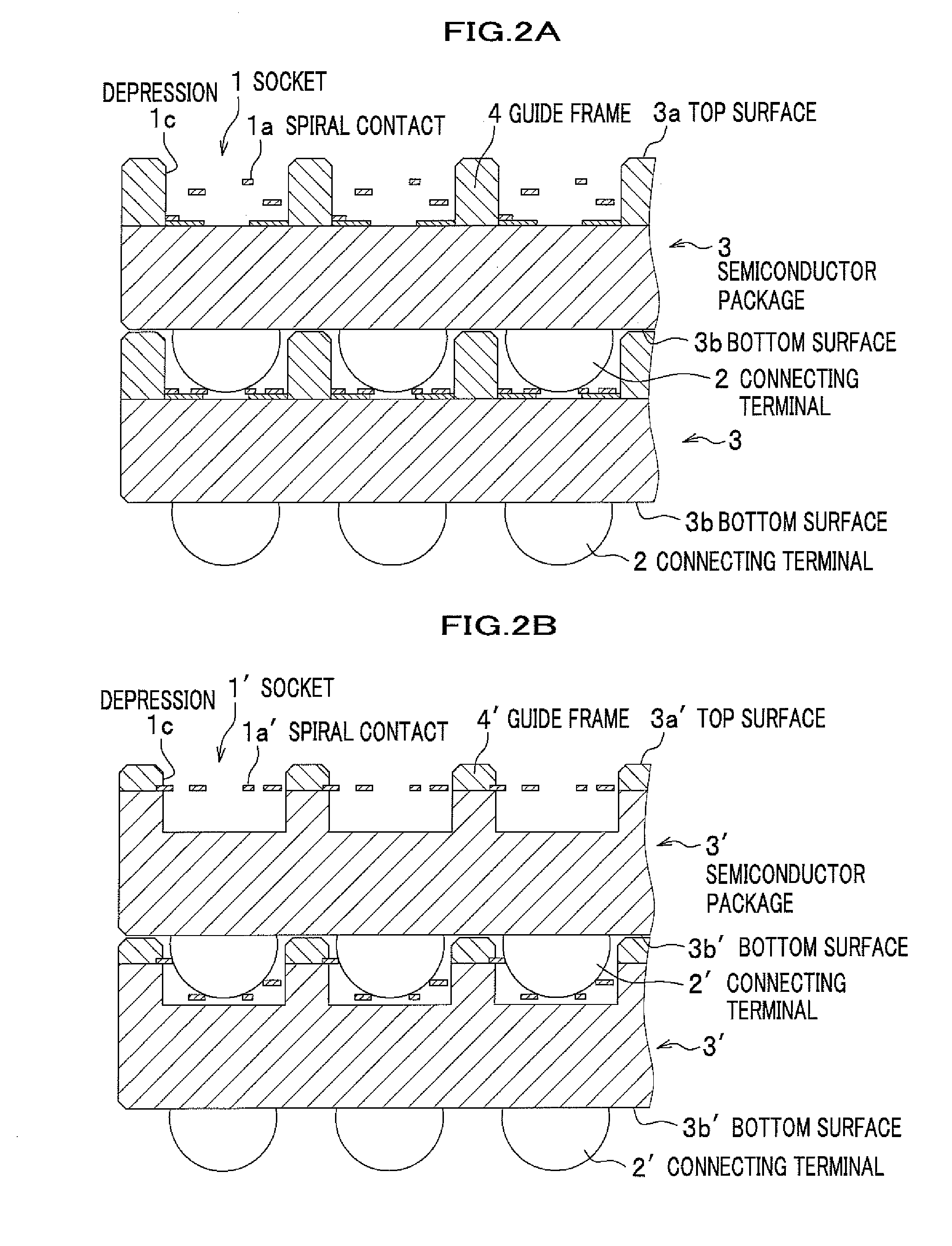

Semiconductor Package Having Socket Function, Semiconductor Module, Electronic Circuit Module and Circuit Board with Socket

InactiveUS20090067135A1Easy to measureSecure bondingElectric discharge tubesSemiconductor/solid-state device detailsSemiconductor packageEngineering

Disclosed is a semiconductor package 3 including a socket 1 which is formed on the top surface 3a for enabling electrical conductivity and a connecting terminal 2 which is formed on the bottom surface 3b for enabling electrical conductivity. The socket 1a has a depressed shape, and a spiral contact 1 is formed in the depression 1c. An electronic circuit module is constructed by mounting and electrically connecting a semiconductor module wherein a plurality of semiconductor packages 3 is stacked on a circuit board. A circuit board with sockets is constructed by mounting a socket board on a circuit board.

Owner:APOLLOWAVE CORP

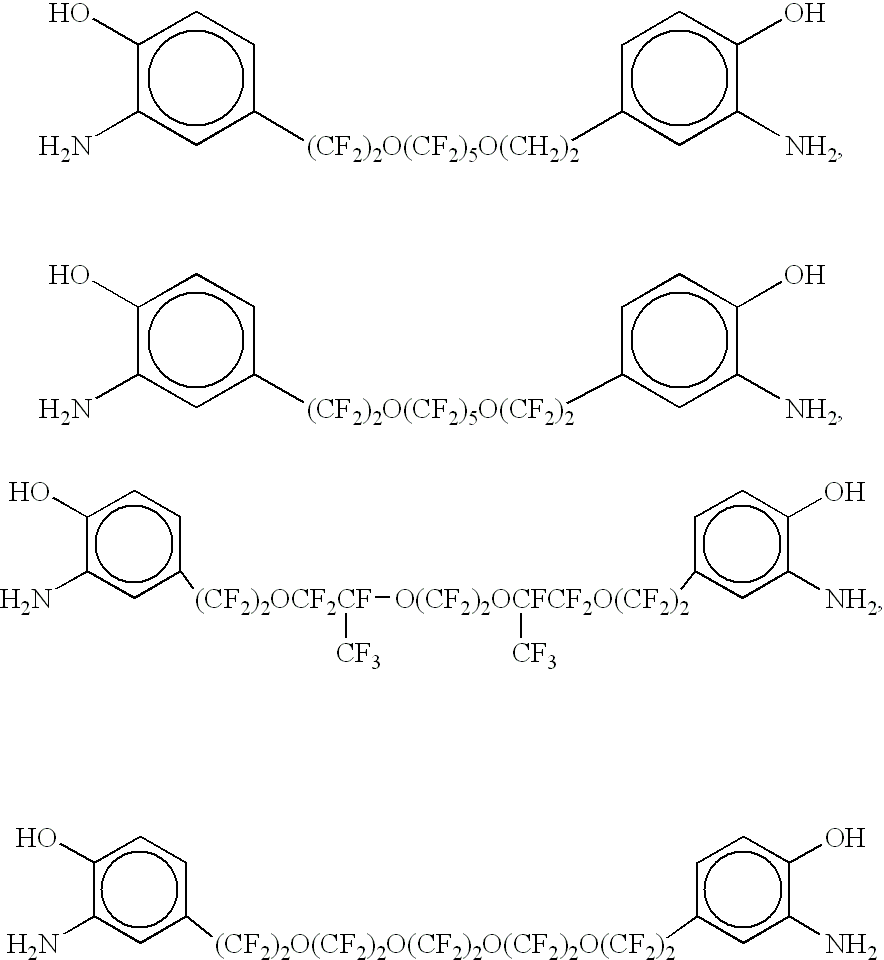

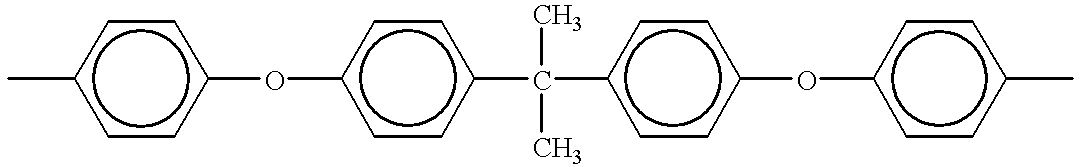

Thermoresistance adhesive and semiconductor device using the same

InactiveUS6372859B1Sufficient adhesivenessSecure bondingSemiconductor/solid-state device detailsSolid-state devicesImideAdhesive

A thermoresistance adhesive which does not dissolve in the sealer-composing resins at the sealer molding temperature and is capable of providing a semiconductor chip / lead frame adhesive strength under shear of 1 N / 4 mm2 or greater, and including, for example, amide, imide, ester or ether linkage is suited for use in producing thermoresistance adhesive solutions and thermoresistance resin pastes, and the semiconductor chips, lead frames, films, etc., made by using such an adhesive are suited for providing low-cost semiconductor devices.

Owner:HITACHI CHEM CO LTD

Acoustic honeycomb with perforated septum caps

ActiveUS8413761B2Lean structureReduced flexibilityElectrical transducersRecord carriersAdhesiveEngineering

An acoustic structure that includes a honeycomb having cells in which septum caps are located. The septum caps are formed from sheets of flexible material that may be perforated before or after the material is inserted into the honeycomb. The flexible material is sufficiently flexible to allow folding into the shape of a septum cap. The flexible material is also sufficiently stiff to provide frictional engagement and locking of the septum cap to the honeycomb cell when the cap is inserted into the honeycomb during fabrication of the acoustic structure. An adhesive is applied to the septum caps after the caps have been inserted into the honeycomb cells to provide a permanent bond.

Owner:HEXCEL

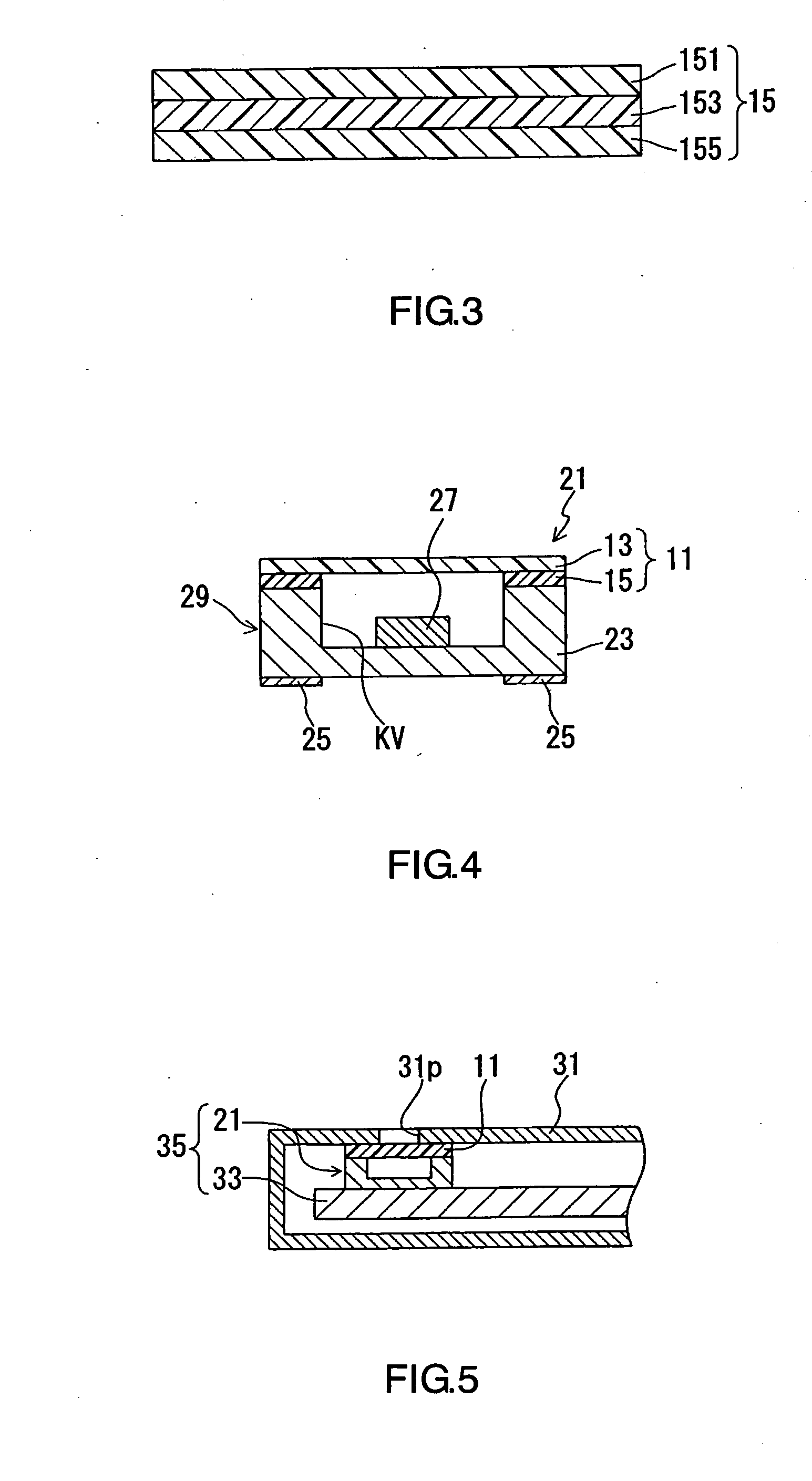

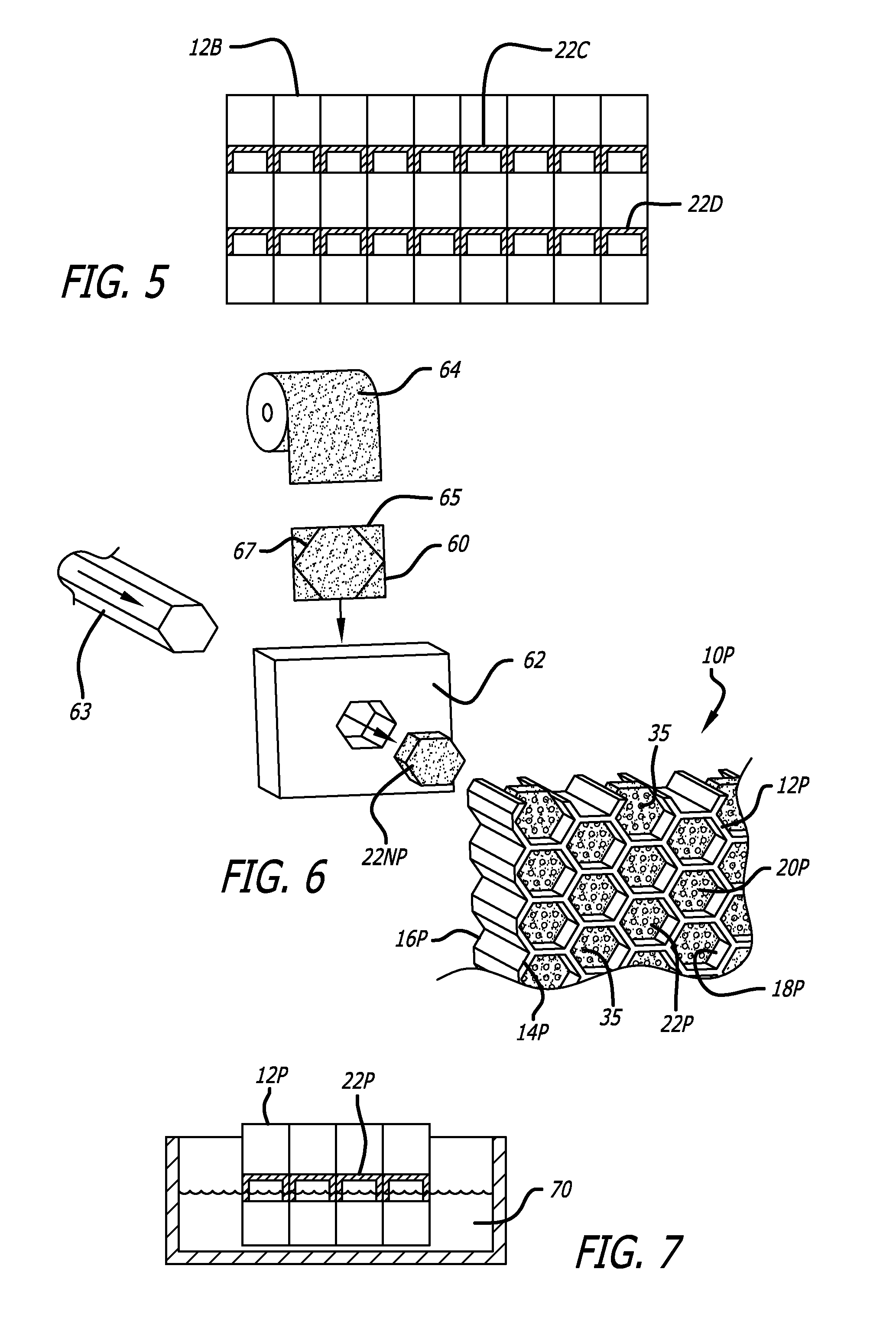

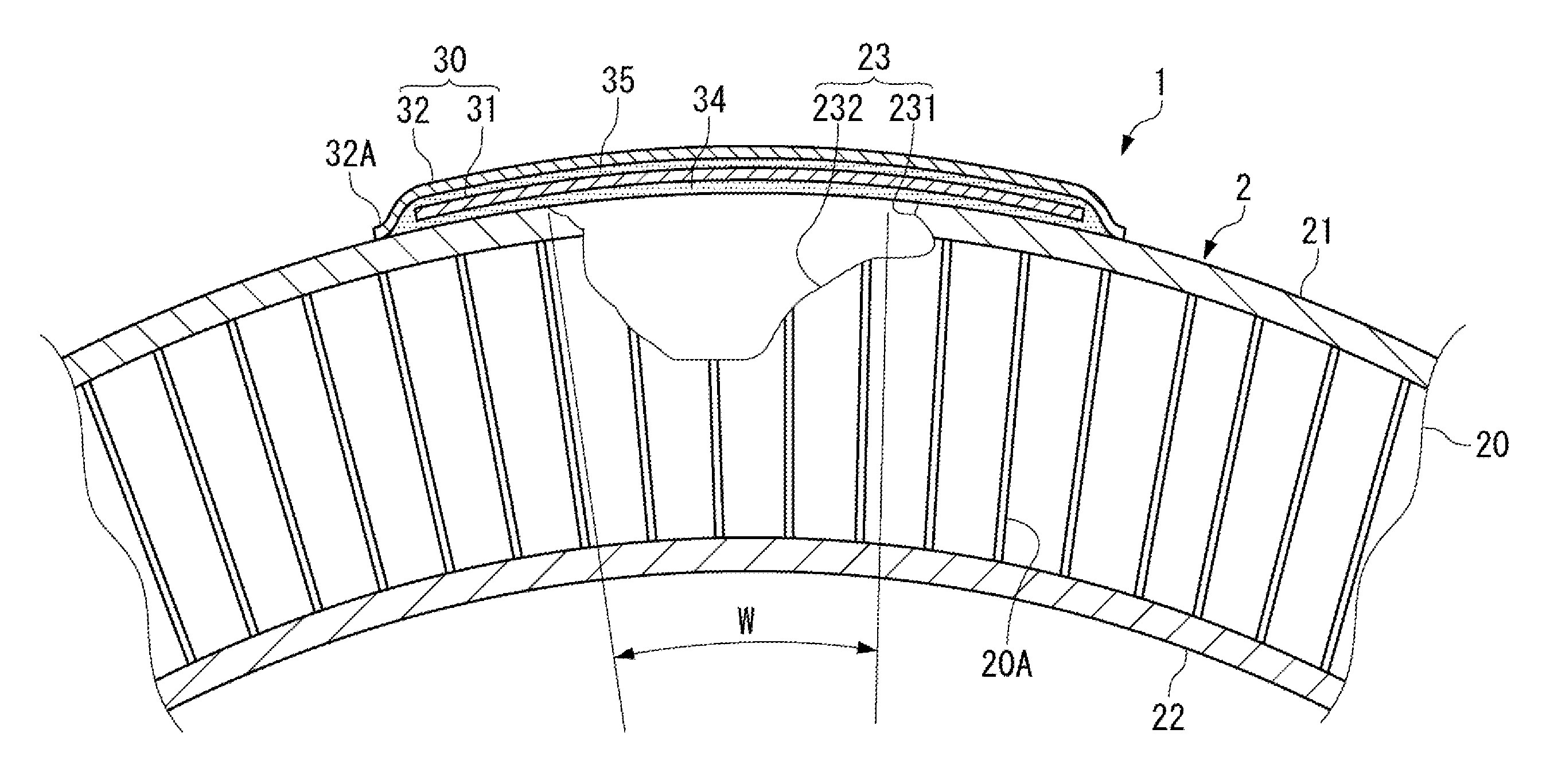

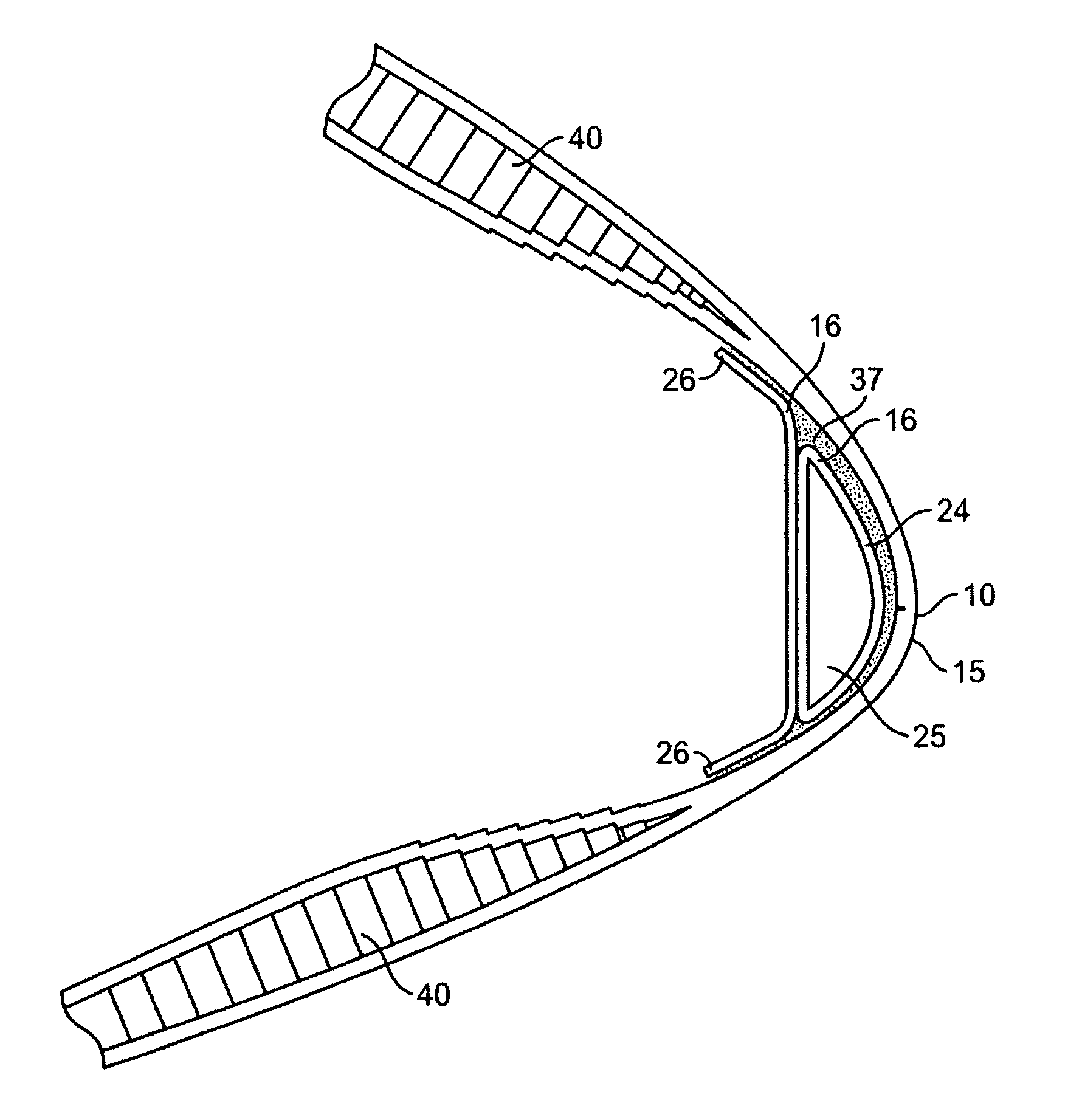

Repair method of repair target portion, and repaired product obtained from repairing

ActiveUS20140295124A1Plate thickness becomes thinnerOut-of-plane stiffnessLamination ancillary operationsLaminationFiberOut of plane

The present invention relates to a repair method using a pre-cured repairing patch, and a repaired product obtained from repairing using the repairing patch, and the present invention securely bonds a repairing patch, where an out-of-plane stiffness is required, to a repair target. In order to cover a repair target portion 23 formed in an outer panel 2 with a repairing patch 30, and bond the repairing patch 30 to a repair target, repairing plates 31, 32 that are formed of fibers and thermosetting resin, and pre-cured before repairing are used as the repairing patch 30, and a laminating step S4 of laminating the repairing plates 31, 32, and a bonding step S7 of bonding the repairing plates 31, 32 to each other are performed.

Owner:MITSUBISHI AIRCRAFT

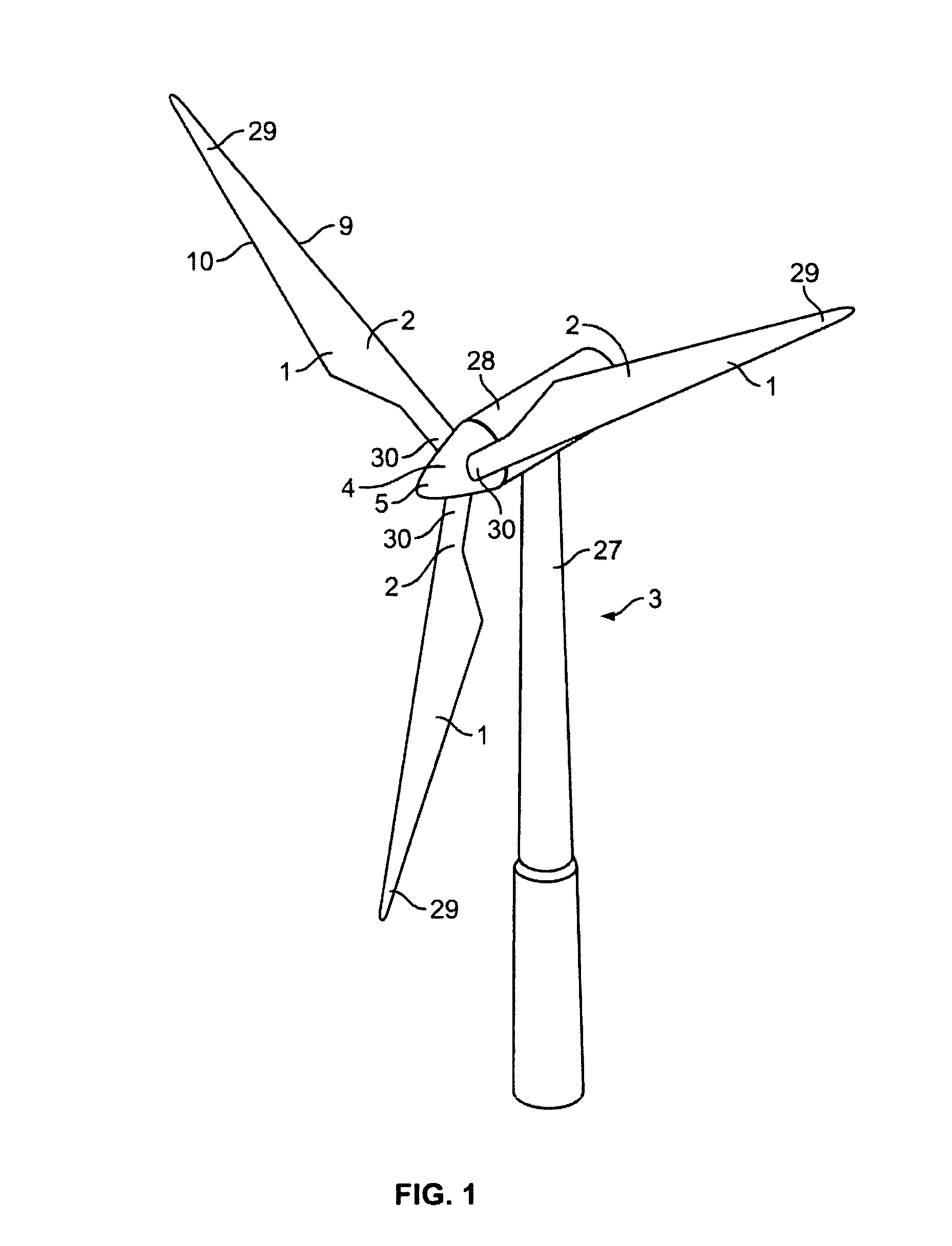

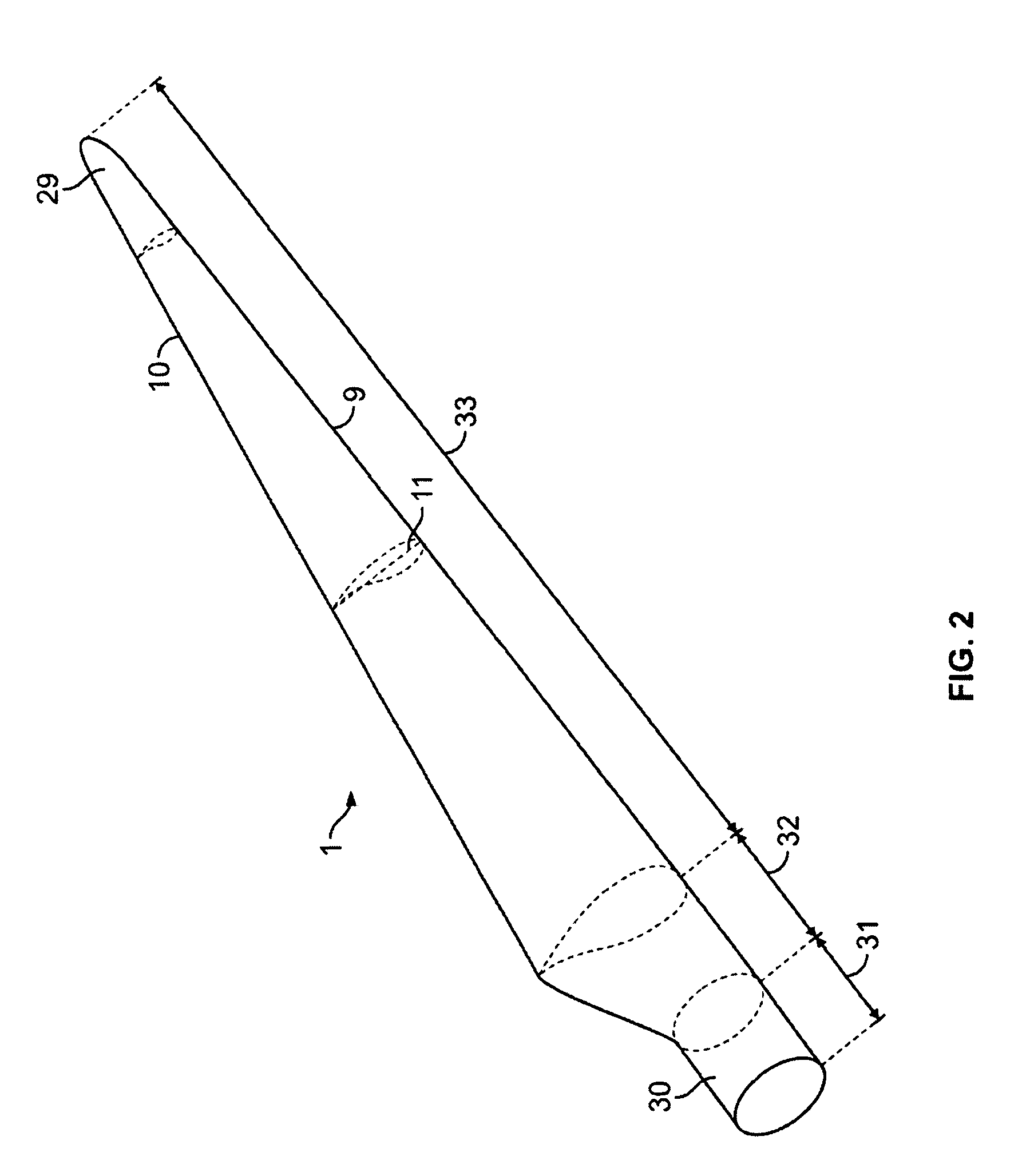

Wind turbine blade for a rotor of a wind turbine

ActiveUS20130108455A1Reduce the amount requiredReduce riskPropellersRotary propellersLeading edgeTurbine blade

A wind turbine blade comprises a profiled contour having a pressure side and a suction side, a leading edge and a trailing edge with a chord extending between the leading edge and the trailing edge. The profiled contour generating a lift when being impacted by an incident airflow is formed by a hollow shell body. The hollow shell body is formed by at least a first shell body part and a second shell body part, which are mutually connected at least at the trailing edge and / or the leading edge. An edge stiffener is arranged within the hollow shell body at a first part of the edges, a first surface part of the edge stiffener being connected to an inner side of the first shell body part, and a second surface part of the edge stiffener being connected to an inner side of the second shell body part.

Owner:LM GLASSFIBER

Ferrite material and ceramic substrate

InactiveUS20070085121A1Reduce stressSecure bondingSemiconductor/solid-state device detailsPrinted circuit aspectsCeramic substrateFerric

A low-temperature firable ceramic substrate having formed in its inside a ferrite layer with a coil embedded therein is provided. The ferrite layer has a composition of 63 to 73% by mass of Fe2O3, 5 to 10% by mass of CuO, 5 to 12% by mass of NiO, and 10 to 23% by mass of ZnO. Even if firing is performed at a lower temperature than ever, it is possible to obtain a ferrite layer which is excellent in sintered density and magnetic permeability.

Owner:KYOCERA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com