Patents

Literature

57 results about "Shrink tunnel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

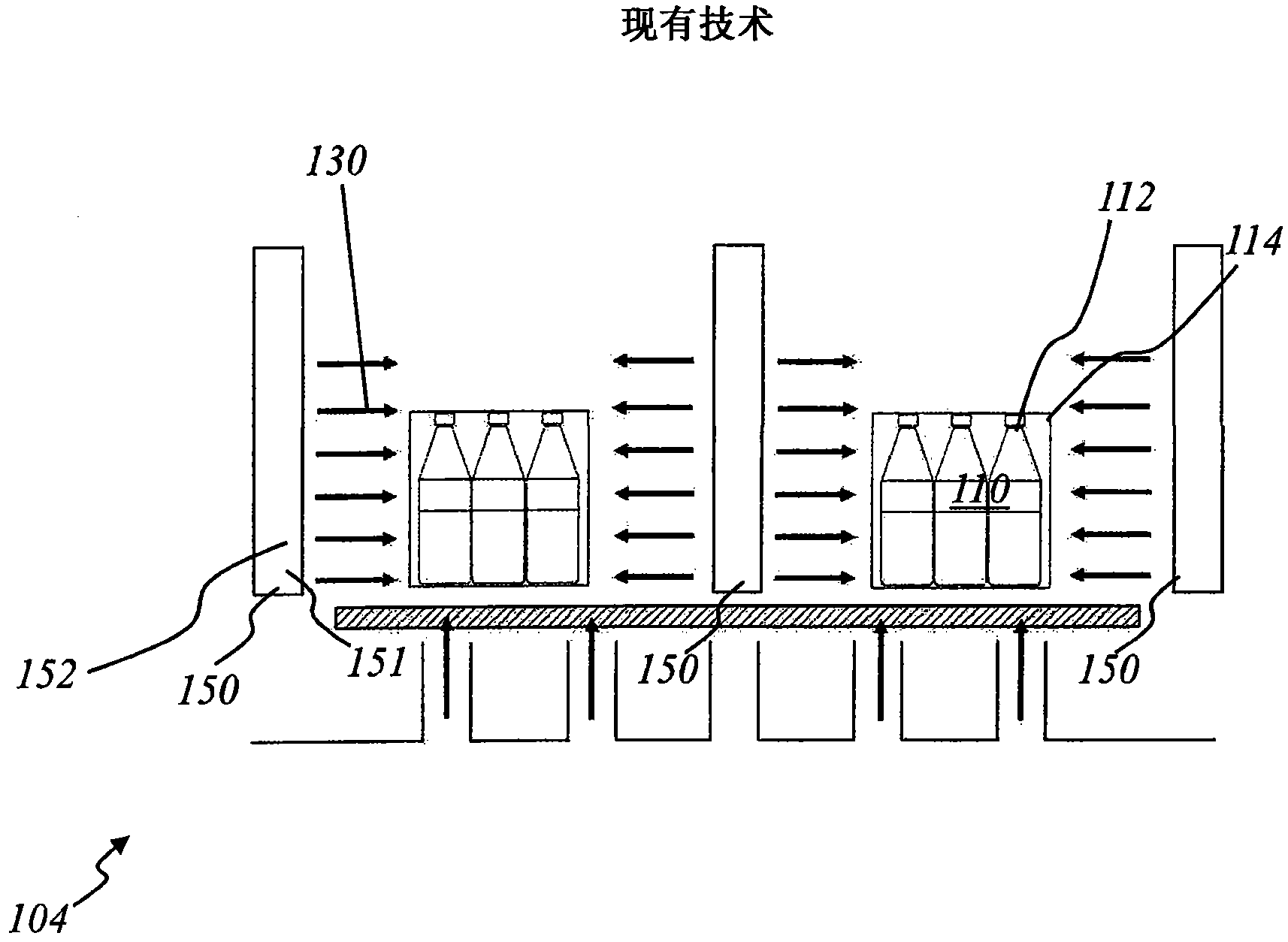

A shrink tunnel or heat tunnel is a heated tunnel mounted over or around a conveyor system. Items (such as packaging) have shrink film loosely applied; with heat, the film shrinks to fit snugly around the wrapped object.

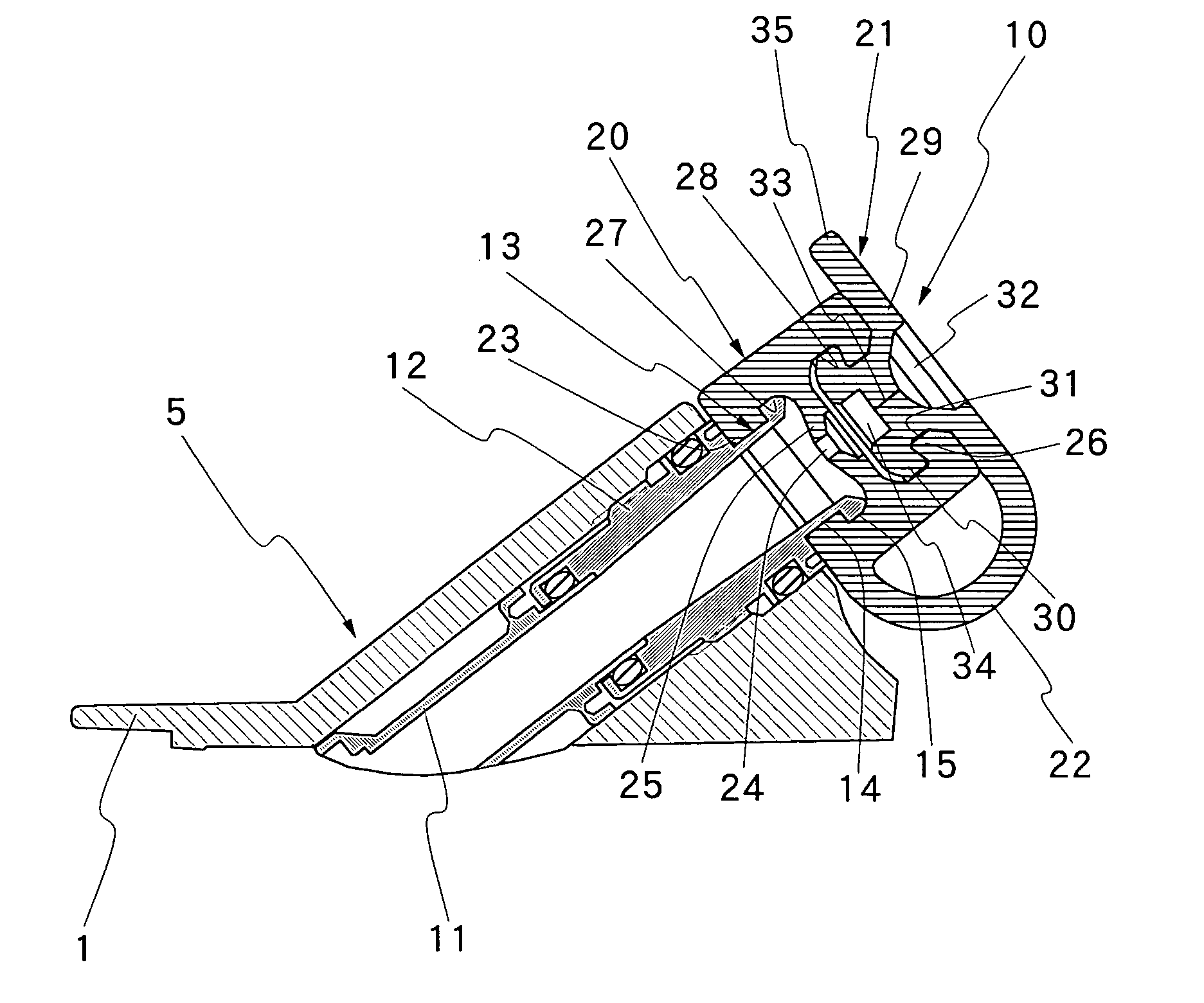

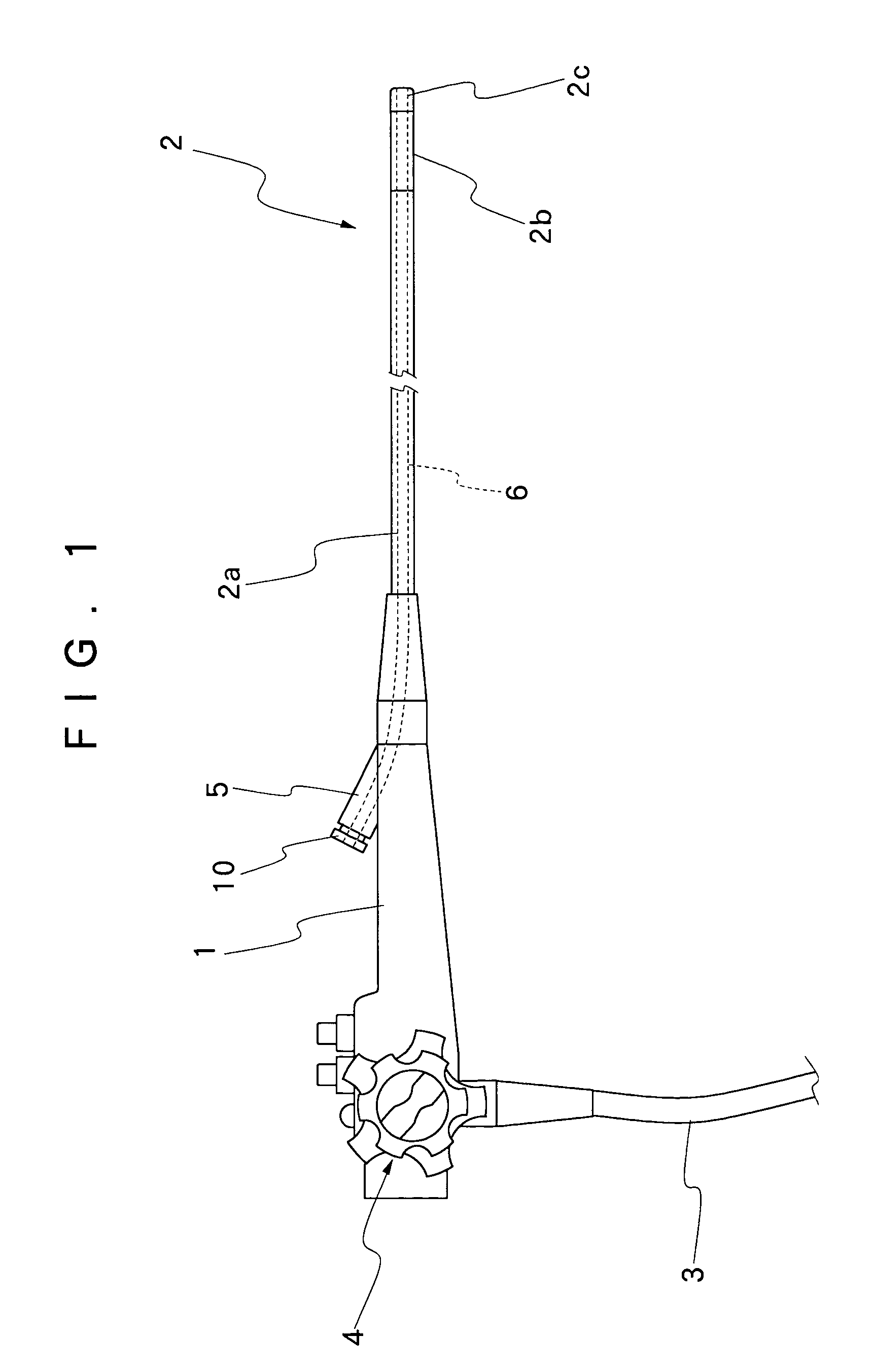

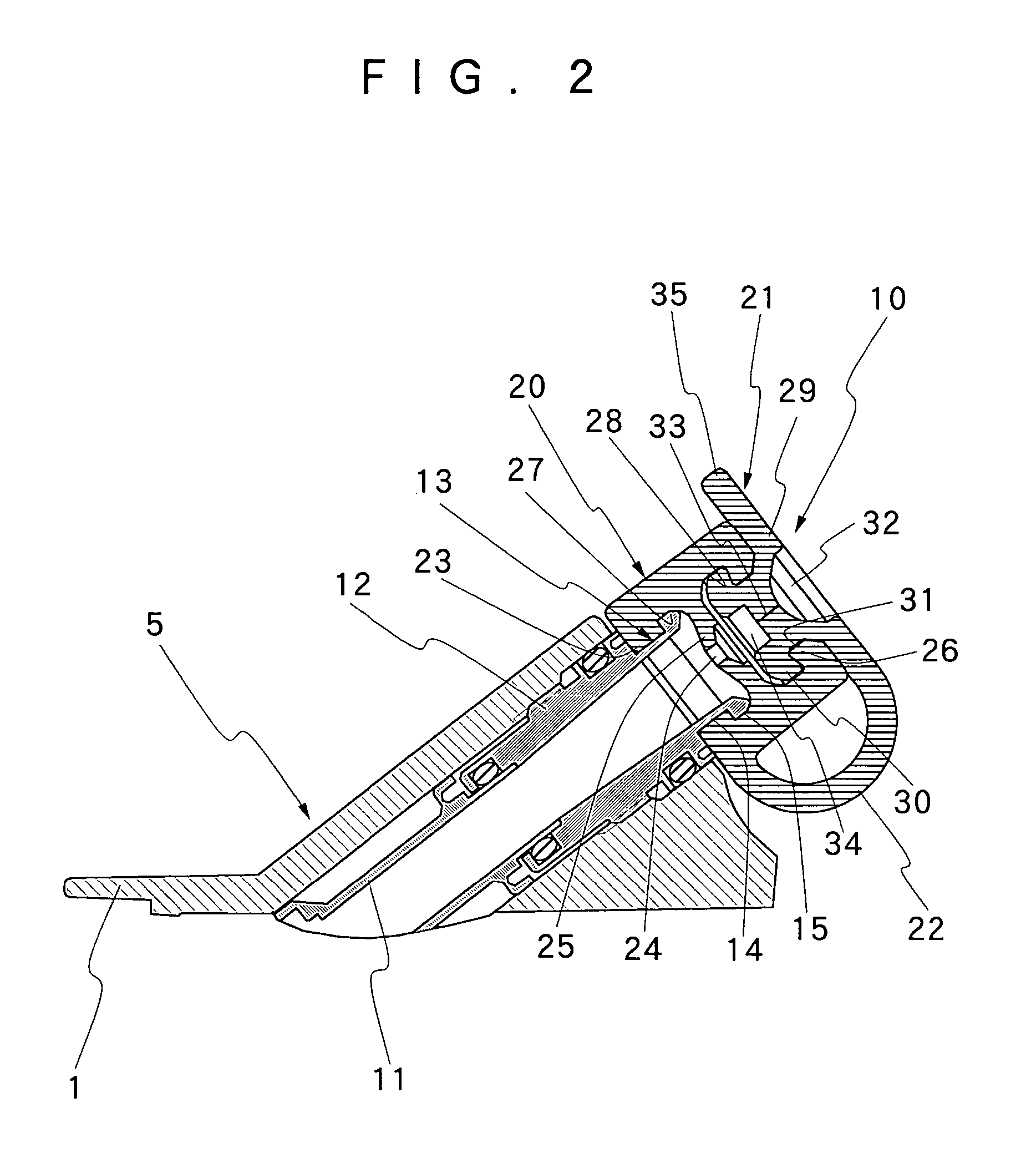

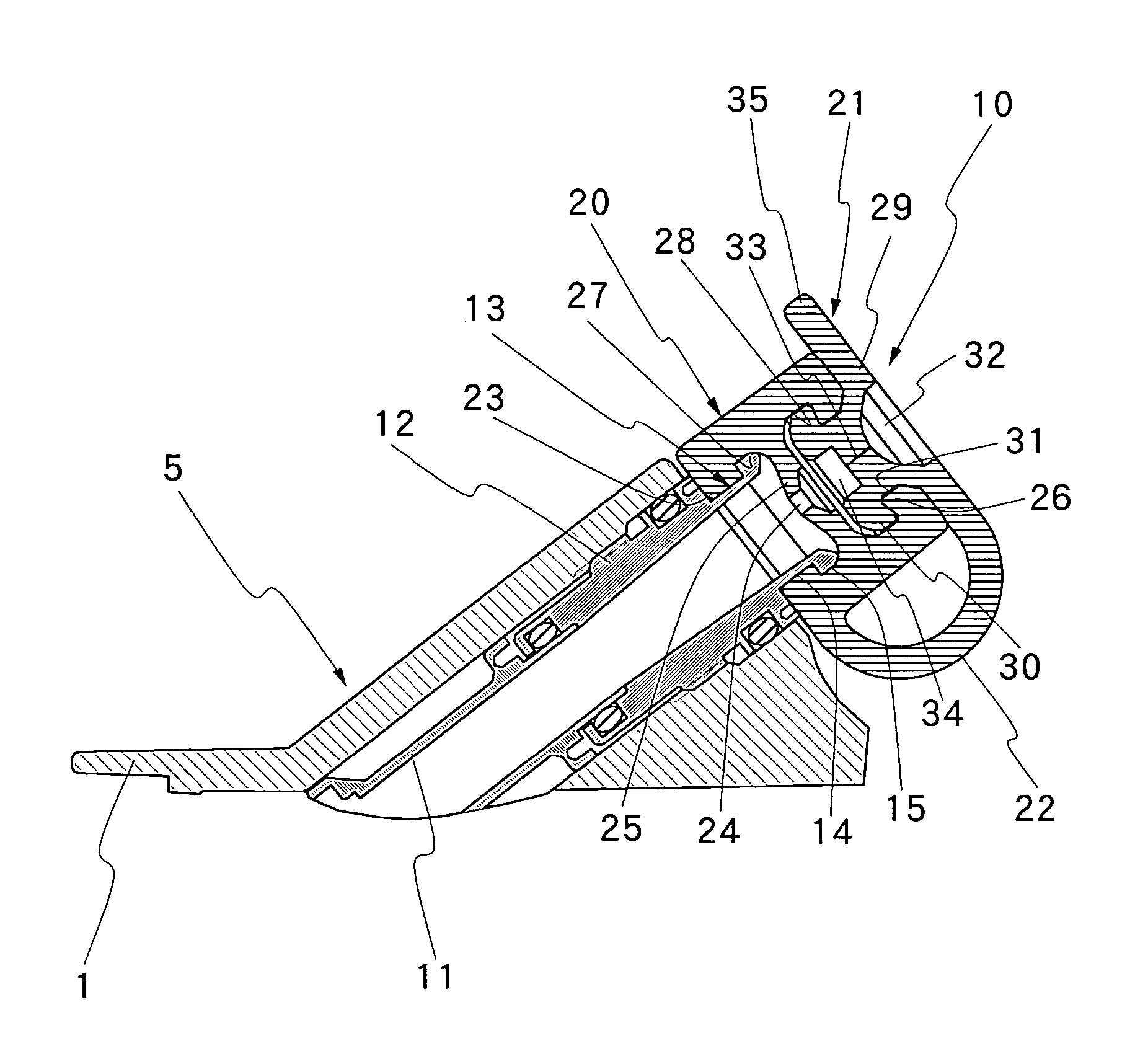

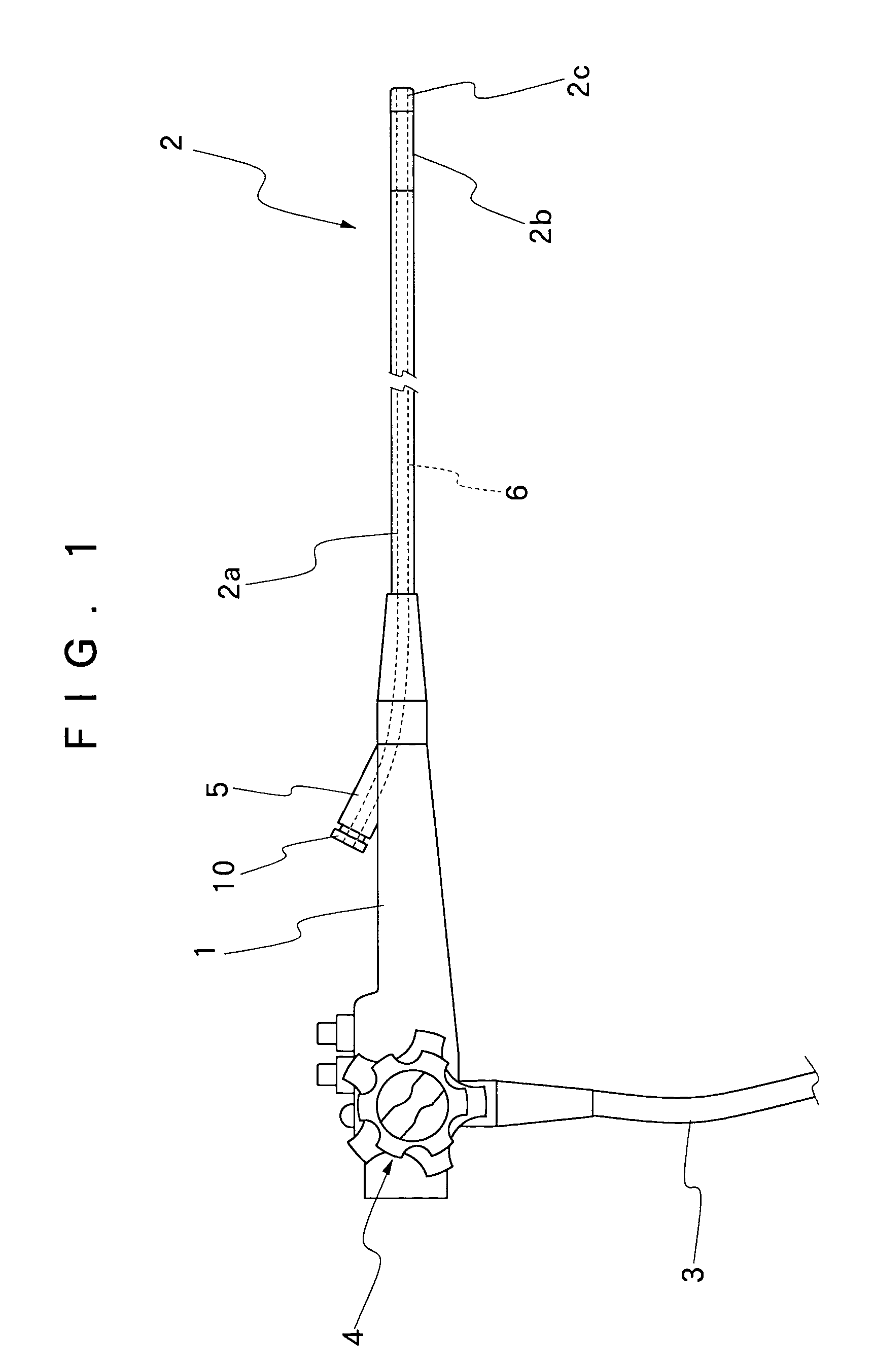

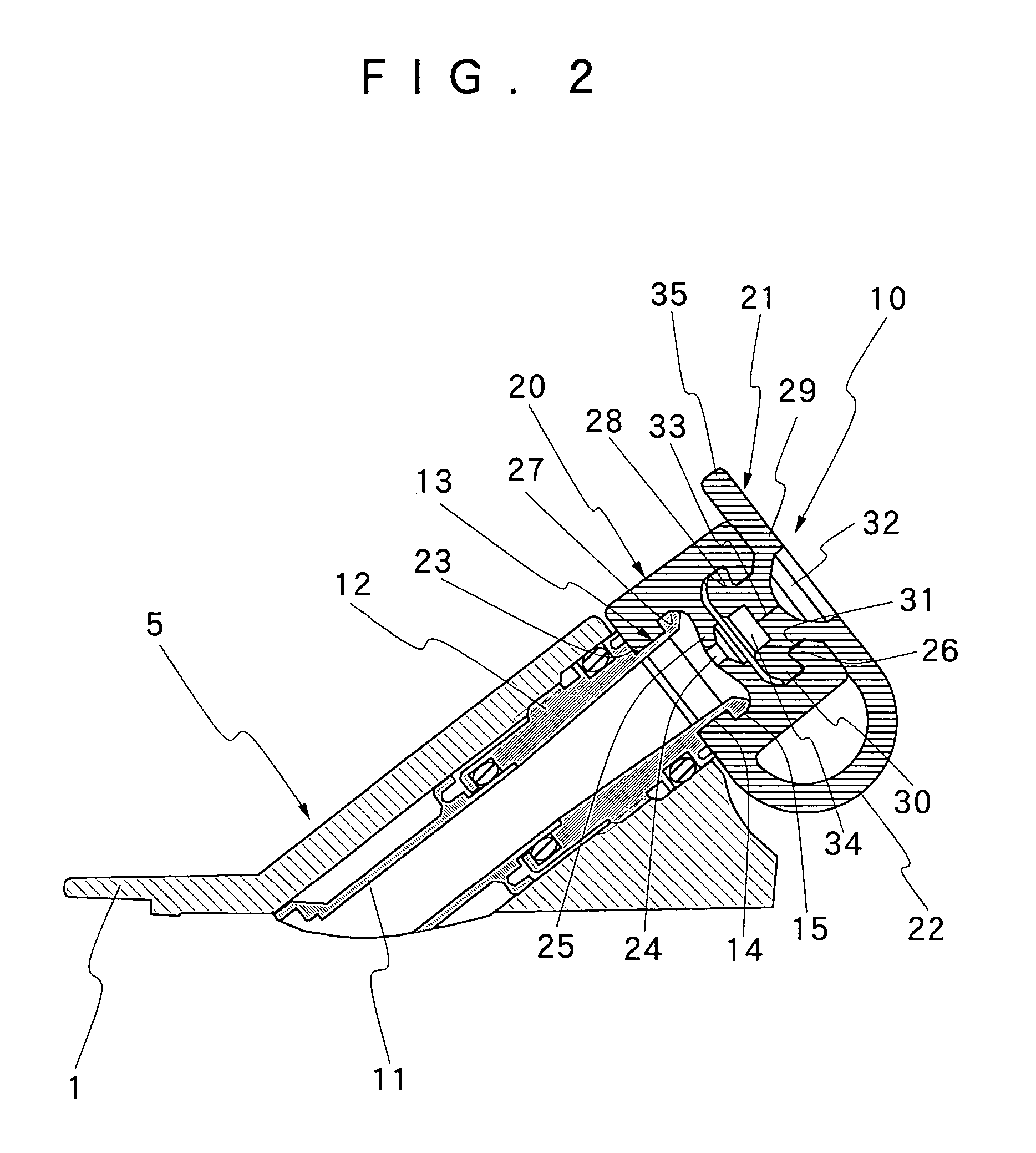

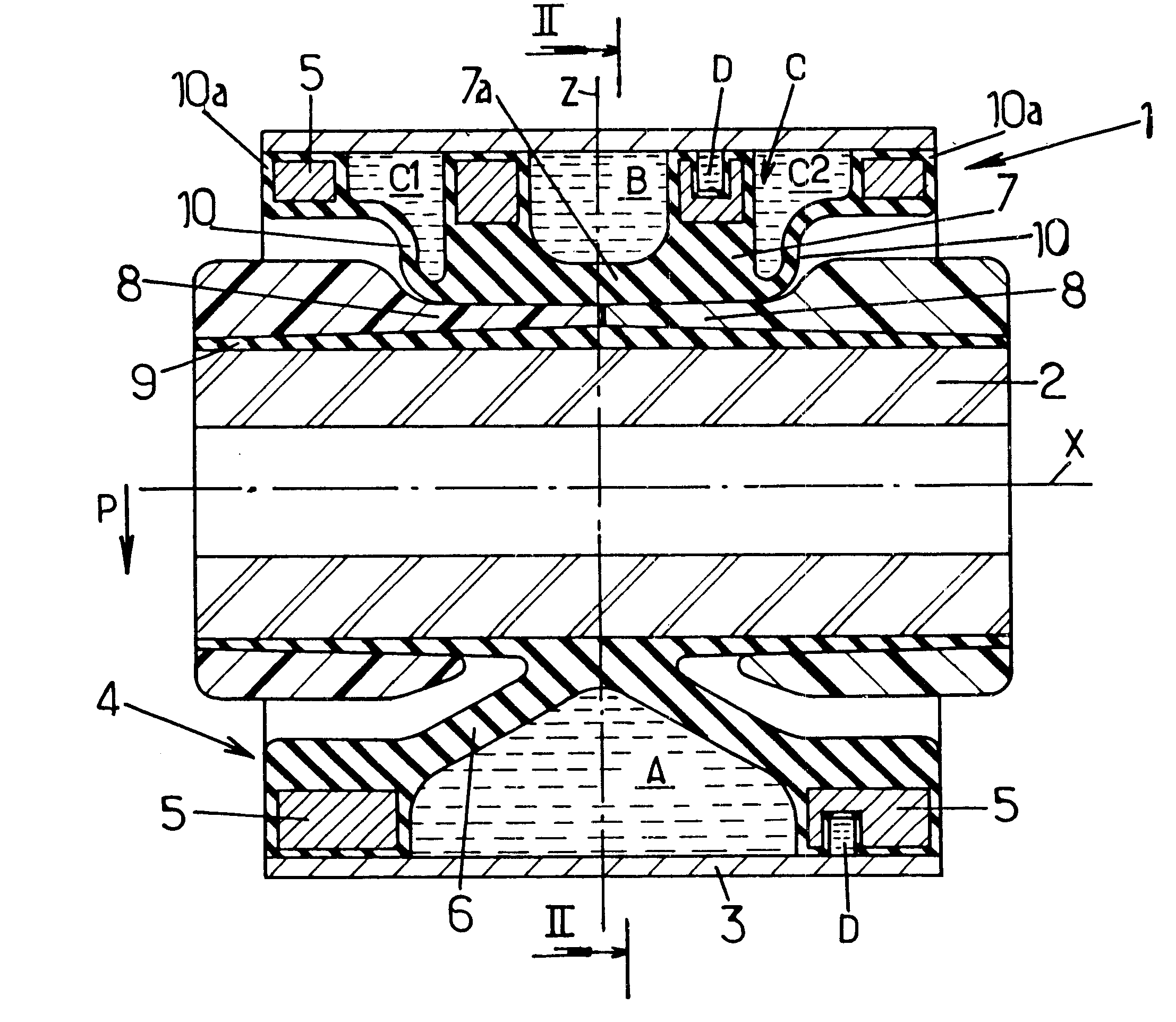

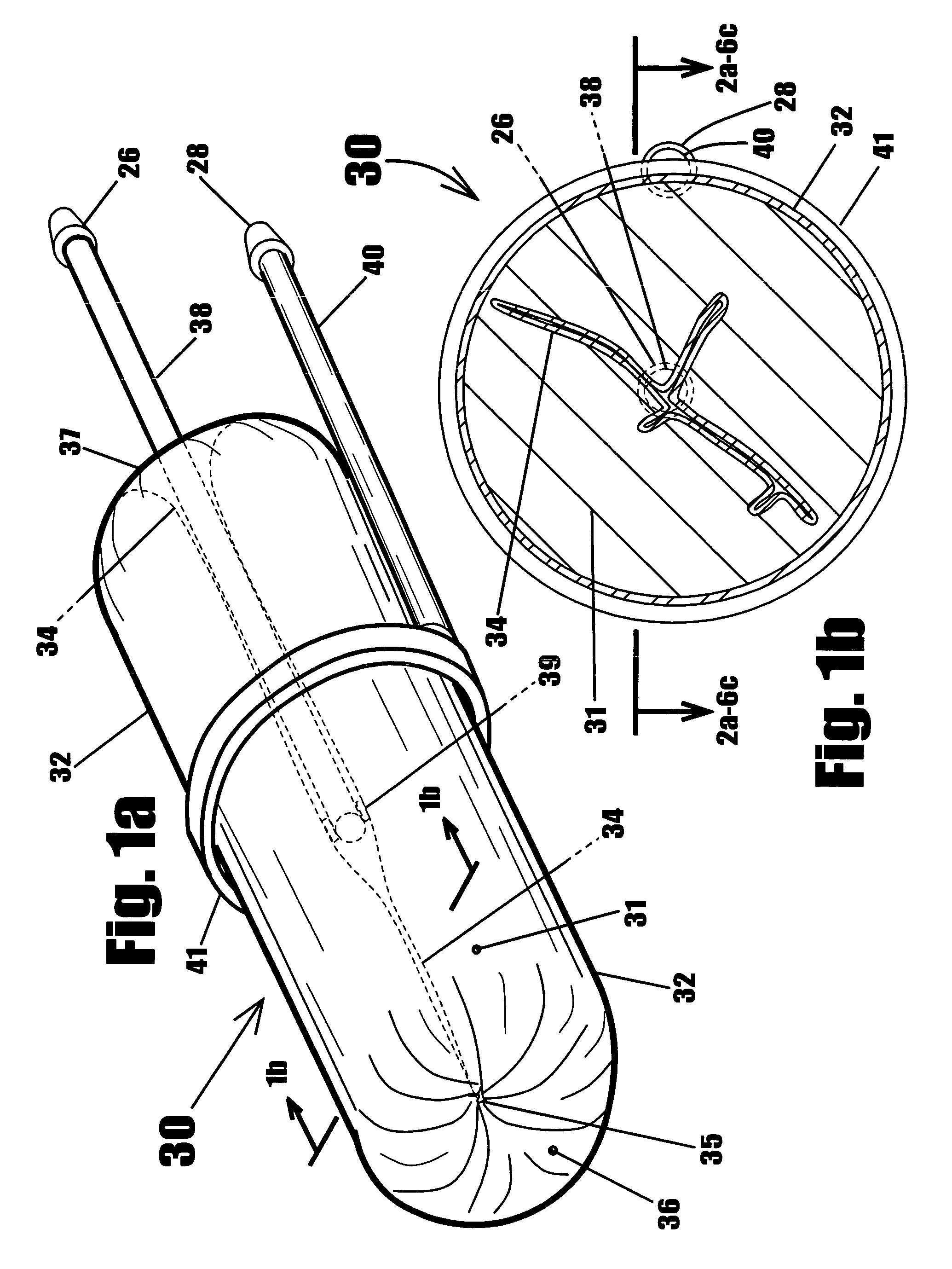

Valved plug for endoscopic biopsy channel

InactiveUS20040167379A1Suppress degradations in hermetical tightness of a slitImprove stabilityInfusion devicesSurgeryMouth pieceEngineering

A valved plug to be fitted on a mouth piece at an inlet opening of an endoscopic biopsy channel. The plug as a whole is formed of a resilient material, and has, at the opposite ends of a foldable connecting strip or string, a generally tubular main body portion which is provided with a constricted portion in its axial passage, and a valved nesting piece which is adapted to be detachably coupled with the main body portion and provided with a normally closed slit valve axially in an aligned position relative to the constricted passage on the side of the main body portion. The main body portion is provided with an inward interlocking projection of a predetermined thickness at its outer end, for tight interlocking engagement with an interlocking groove which is provided on the side of the nesting piece in such a way as to grip the interlocking projection tightly in a compressed state.

Owner:FUJI PHOTO OPTICAL CO LTD

Valved plug for endoscopic biopsy channel

InactiveUS7226411B2Suppress degradations in hermetical tightness of a slitImprove stabilityInfusion syringesInfusion devicesMouth pieceEngineering

Owner:FUJI PHOTO OPTICAL CO LTD

Hot melt adhesives for roll-applied labels

ActiveUS20100112250A1Plastic/resin/waxes insulatorsSynthetic resin layered productsPolyesterTriethylene glycol

Disclosed are hot-melt adhesives prepared from polyesters containing 1,4-cyclohexane-dicarboxylic acid as a diacid component and a diol component containing at least two diols chosen from 1,4-cyclohexanedimethanol, triethylene glycol, and diethylene glycol. These adhesives set up rapidly within a well-defined temperature window. The hot-melt adhesives can be used in a variety of applications, but are especially suited as seaming adhesives for roll-applied labels. These adhesives have melting temperatures and crystallization properties that allow their application at temperatures cool enough to prevent curling and premature shrinkage of the shrink label during seaming, and yet produce strong label seams that can withstand the elevated temperatures of a shrink tunnel without sacrificing line speed. Also disclosed are labeled containers and a process for applying a roll-on, shrink label to a container using the hot-melt adhesives of the invention.

Owner:EASTMAN CHEM CO

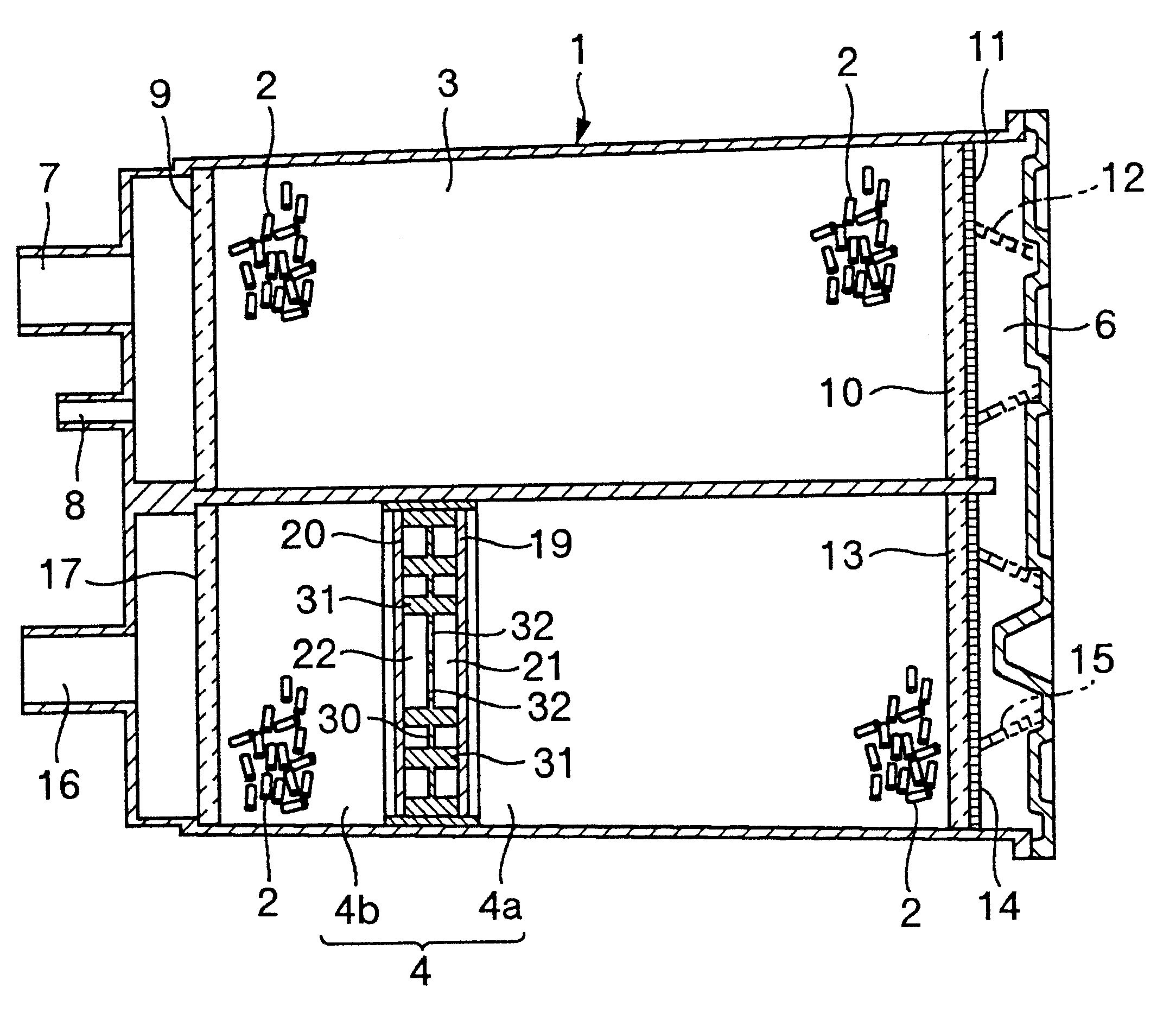

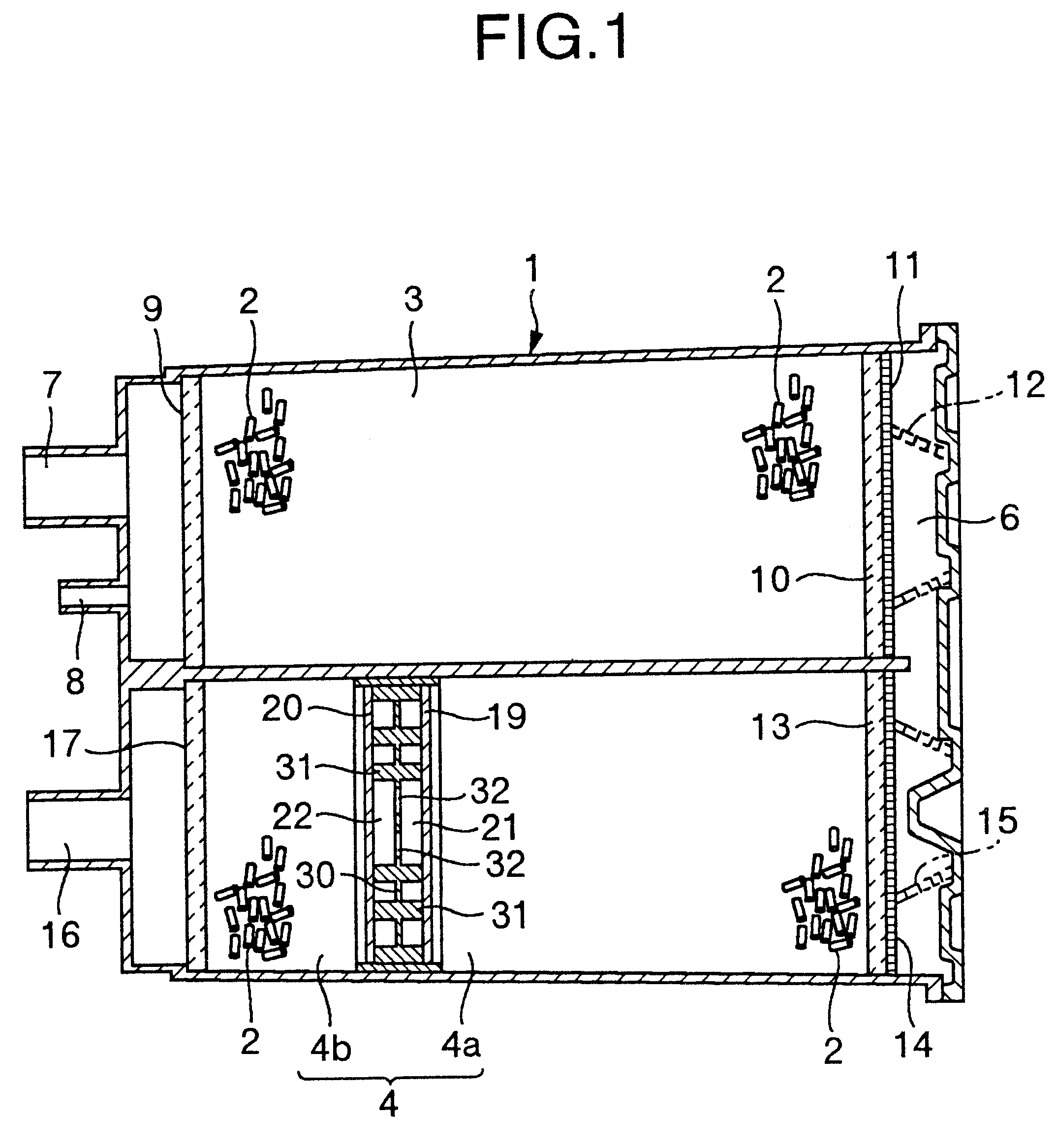

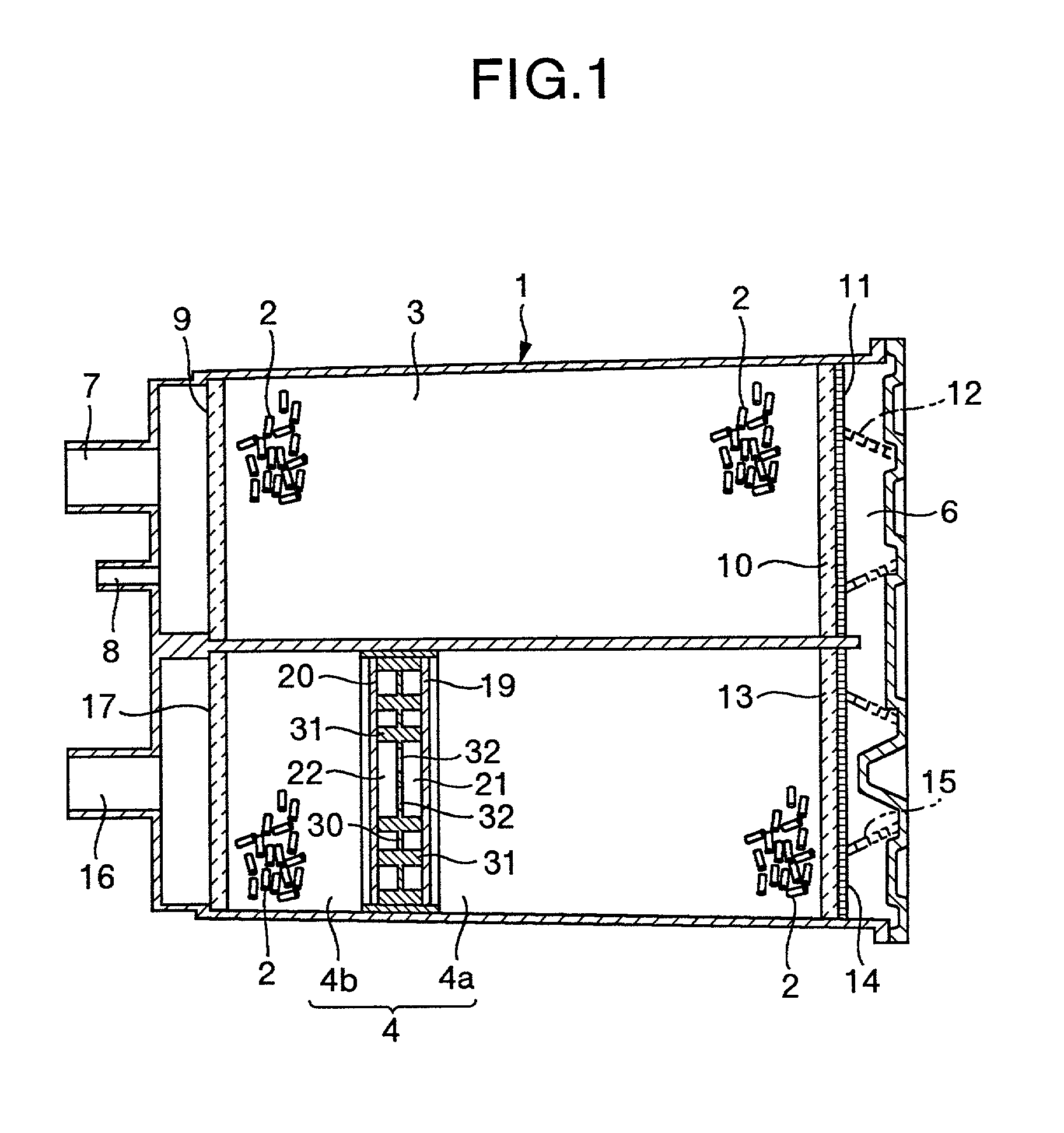

Canister

In order to aim at shortening the time of refueling by maintaining the function of prevention of discharge of vapor, similar to that of a conventional canister in the case of other than refueling during resting of an engine while the flow resistance in the canister becomes smaller during refueling, there is provided a canister in which a plate is vertically arranged in a chamber charged therein with absorbent in the canister, and filter support pins are projected from opposite surfaces of the plate while filters are arranged at the tip end faces of the filter support pins, and in which a plurality of constriction passages are formed being arranged in a horizontal direction only in the upper part of the plate.

Owner:AISAN IND CO LTD

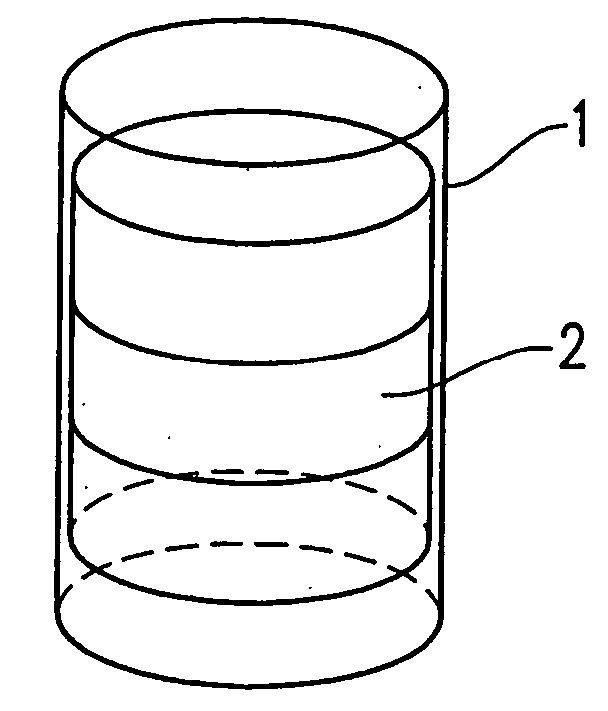

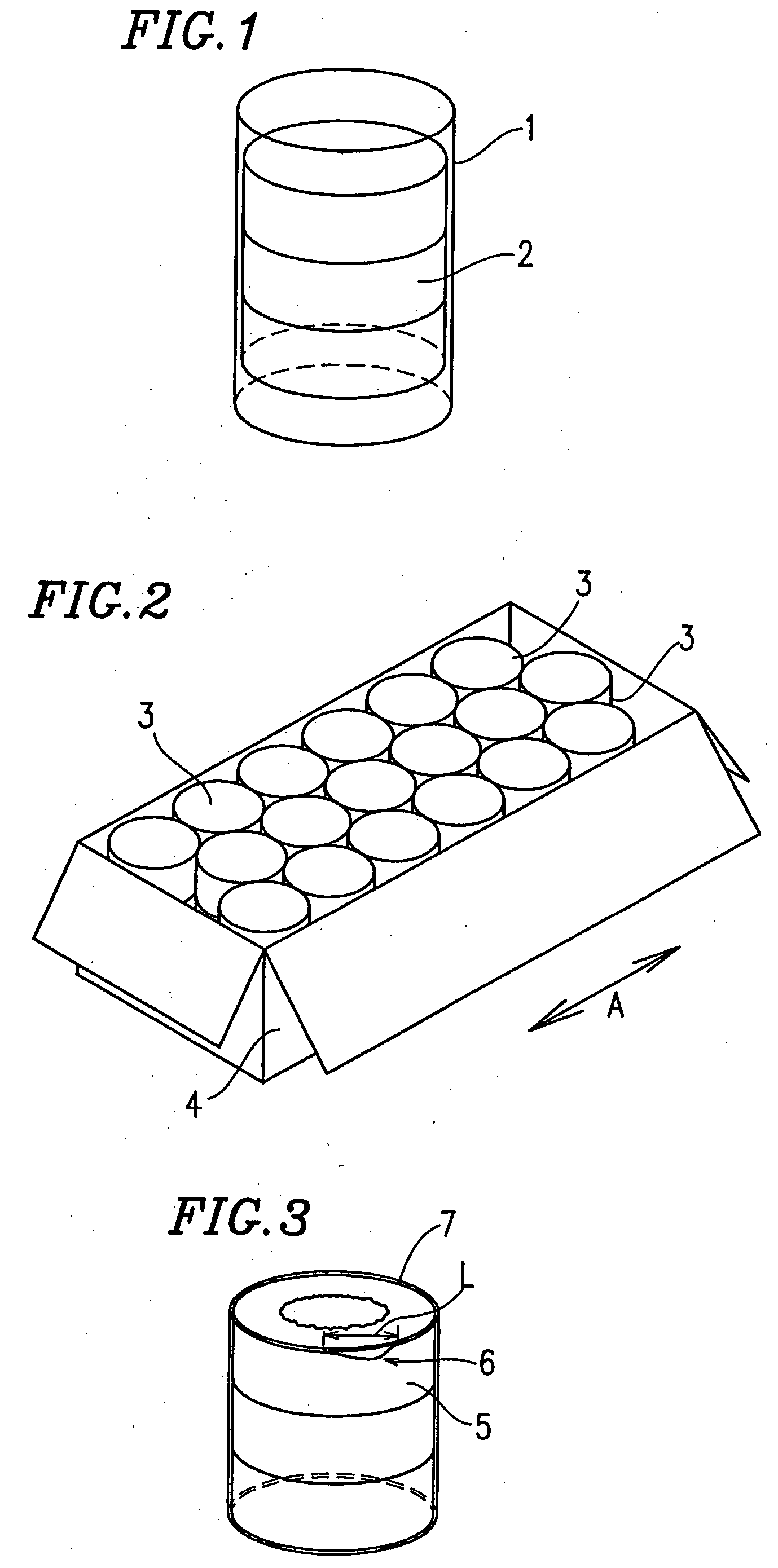

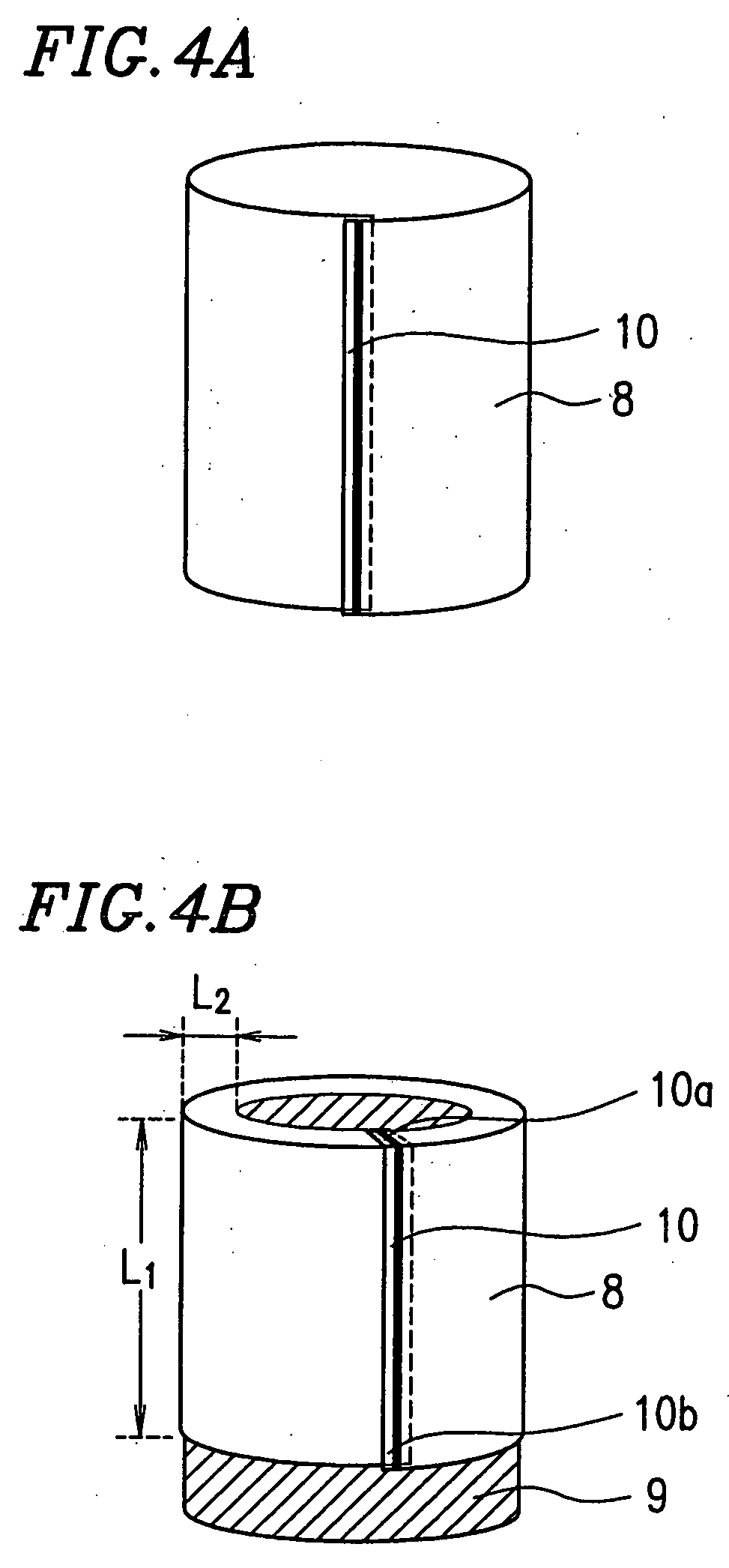

Heat shrinkable polyester film

InactiveUS20050196563A1Improve seismic performanceHigh adhesive retentionEnvelopes/bags making machineryLayered productsPolyesterPolymer science

A heat shrinkable polyester film of the present invention has a transverse tear defect percentage of about 20% or less as determined in the following vibration test: the film is rolled into a tubular shape, two of its opposite edges bonded together, and then the tubular film is placed around a vertical stack (total weight: 660 g) of three food container cans each having a diameter of 72 mm and a height of 55 mm; the can stack with the tubular film placed therearound is passed through a shrink tunnel to shrink the tubular film onto the can stack; a total of 18 packs of such can stacks are placed into a cardboard box having a length of 455 mm, a width of 230 mm and a height of 165 mm (6 packs in the length direction by 3 packs in the width direction), and the cardboard box is sealed; the cardboard box is vibrated along the width direction for 30 min by a stroke of 50 mm and at a vibration rate of 180 reciprocations / min, after which the transverse tearage of the tubular film is visually observed; and the transverse tear defect percentage (%) is determined based on the number of defective packs per 18 packs, wherein the defective pack is any pack having a tear flaw of 30 mm or longer along a can periphery. The heat shrinkable polyester film of the present invention has a good shock resistance during shipping especially under low temperatures, with a good finish after shrinkage and a sufficient solvent adhesiveness. Thus, the heat shrinkable polyester film of the present invention is suitable for use in a multi-packaging label for packaging, inter alia, a stack of cans.

Owner:ITO HIDEKI +4

Canister

In order to aim at shortening the time of refueling by maintaining the function of prevention of discharge of vapor, similar to that of a conventional canister in the case of other than refueling during resting of an engine while the flow resistance in the canister becomes smaller during refueling, there is provided a canister in which a plate is vertically arranged in a chamber charged therein with absorbent in the canister, and filter support pins are projected from opposite surfaces of the plate while filters are arranged at the tip end faces of the filter support pins, and in which a plurality of constriction passages are formed being arranged in a horizontal direction only in the upper part of the plate.

Owner:AISAN IND CO LTD

Aromatic-aliphatic polyester hot melt adhesives for roll-applied labels

Disclosed are hot-melt adhesives prepared from aromatic-aliphatic polyesters containing terephthalic acid in combination with adipic acid, glutaric acid, or a mixture thereof, as diacid components and a diol component containing 1,4-butanediol, 1,6-hexanediol, or a combination thereof. These adhesives set up rapidly within a well-defined temperature window. The hot-melt adhesives can be used in a variety of applications, but are especially suited as seaming adhesives for roll-applied labels. These adhesives have melting temperatures and crystallization properties that allow their application at temperatures cool enough to prevent curling and premature shrinkage of the shrink label during seaming, and yet produce strong label seams that can withstand the elevated temperatures of a shrink tunnel without sacrificing line speed. Also disclosed are labeled containers and a process for applying a roll-on, shrink label to a container using the hot-melt adhesives of the invention.

Owner:EASTMAN CHEM CO

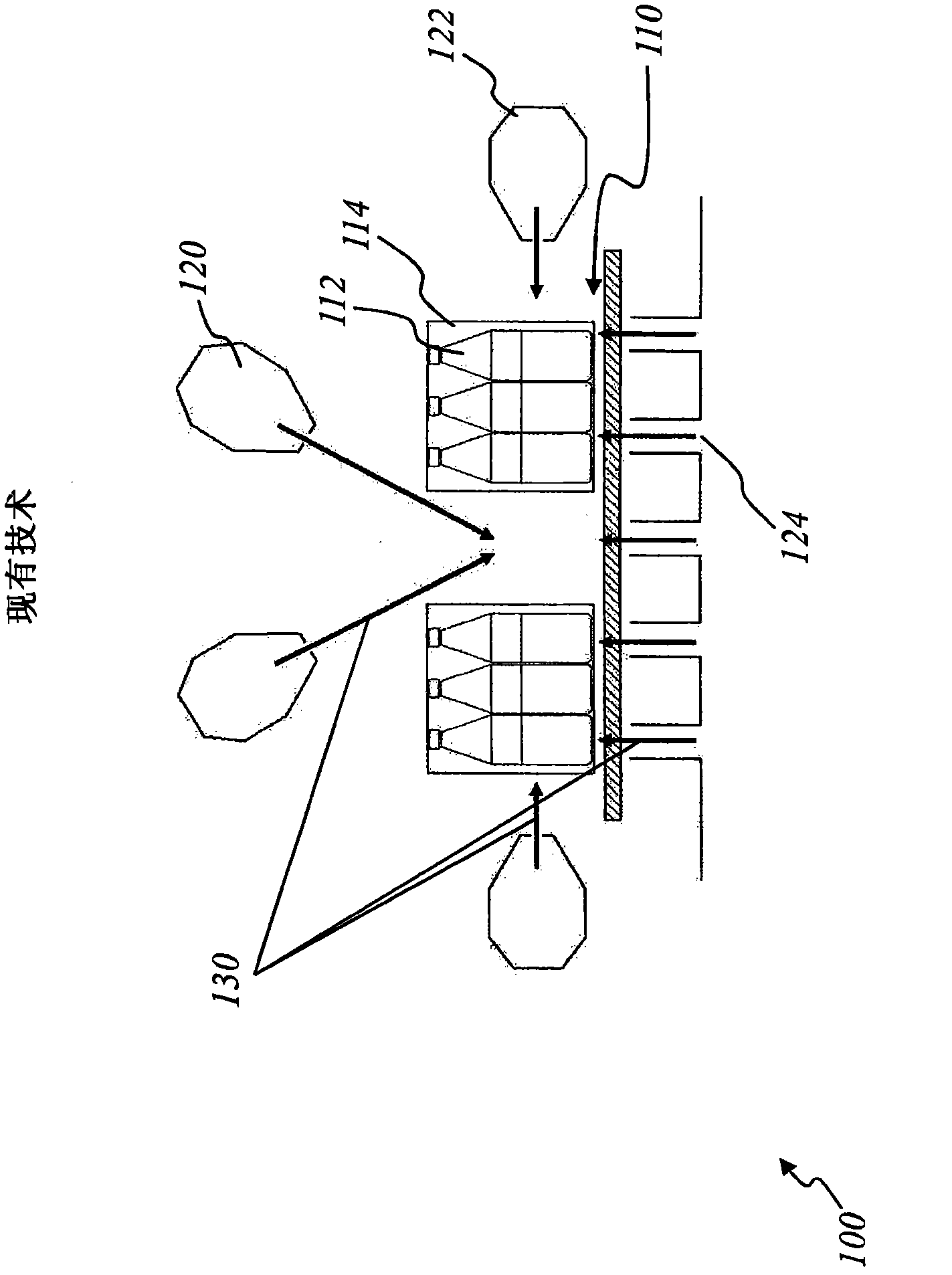

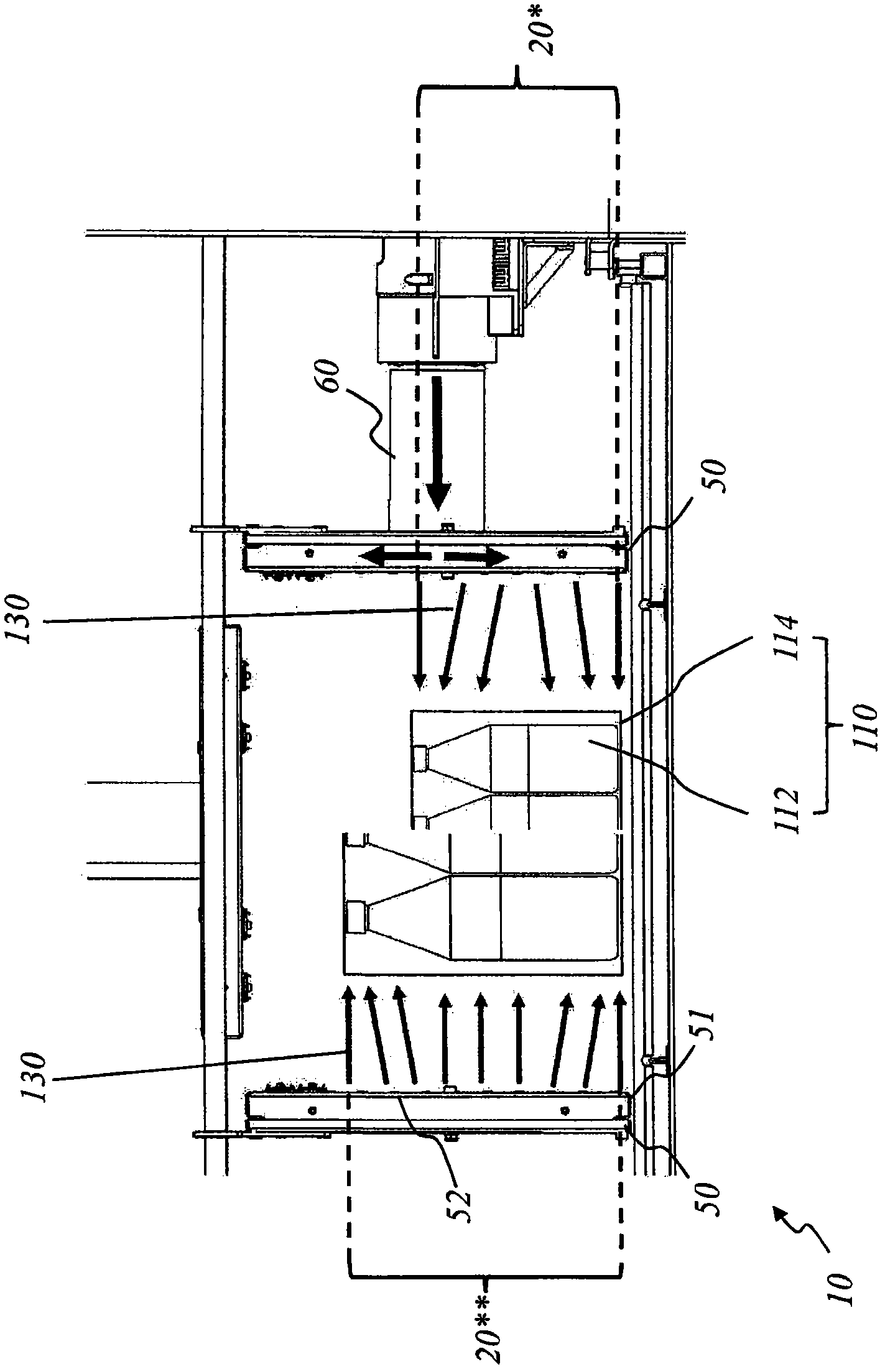

Shrink tunnel

InactiveCN102050243ALow costExcellent mechanical propertiesWrappers shrinkageGreek letter betaSpray nozzle

The invention provides a shrink tunnel (10) for the heat shrink of a film surrounding articles (112), which is preferably used for the heat shrink of a film of a container (110).The shrink tunnel comprises at least one transportation section for the articles (112), at least one ventilation shaft (50) and at least one mechanism (60) for conveying the airflow (130) to the ventilation shaft.The ventilation shaft is equipped with at least one shaft wall (51) equipped with a plurality of jet nozzles (52) directed to the articles.The airflow is introduced into the interior of the shrink tunnel through the jet nozzles.The shaft wall is equipped with an adjusting unit for adjusting the quantity or a flow angle (beta) of the airflow in the interior of the shrink tunnel.The invention is to provide a setting or adjustment of the hot-air nozzles in a shrink tunnel, which allows a simple and rapid adaptation to the articles to be packaged.

Owner:KRONES AG

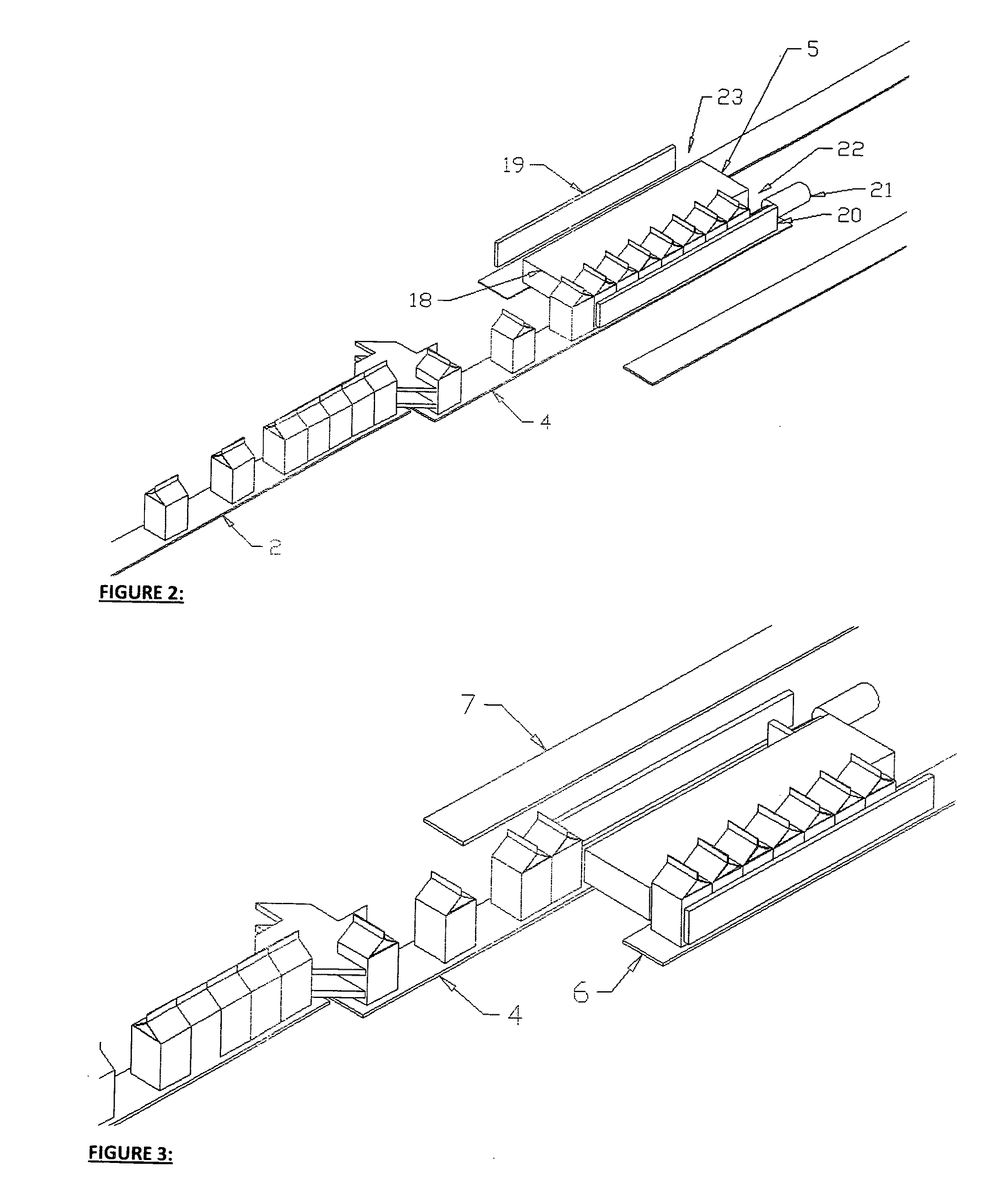

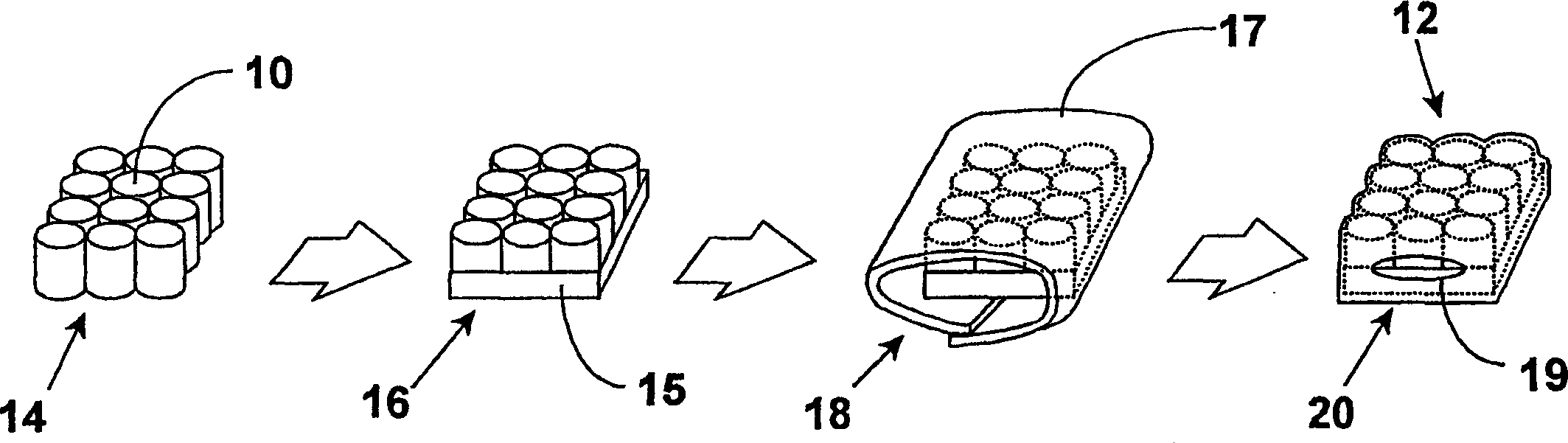

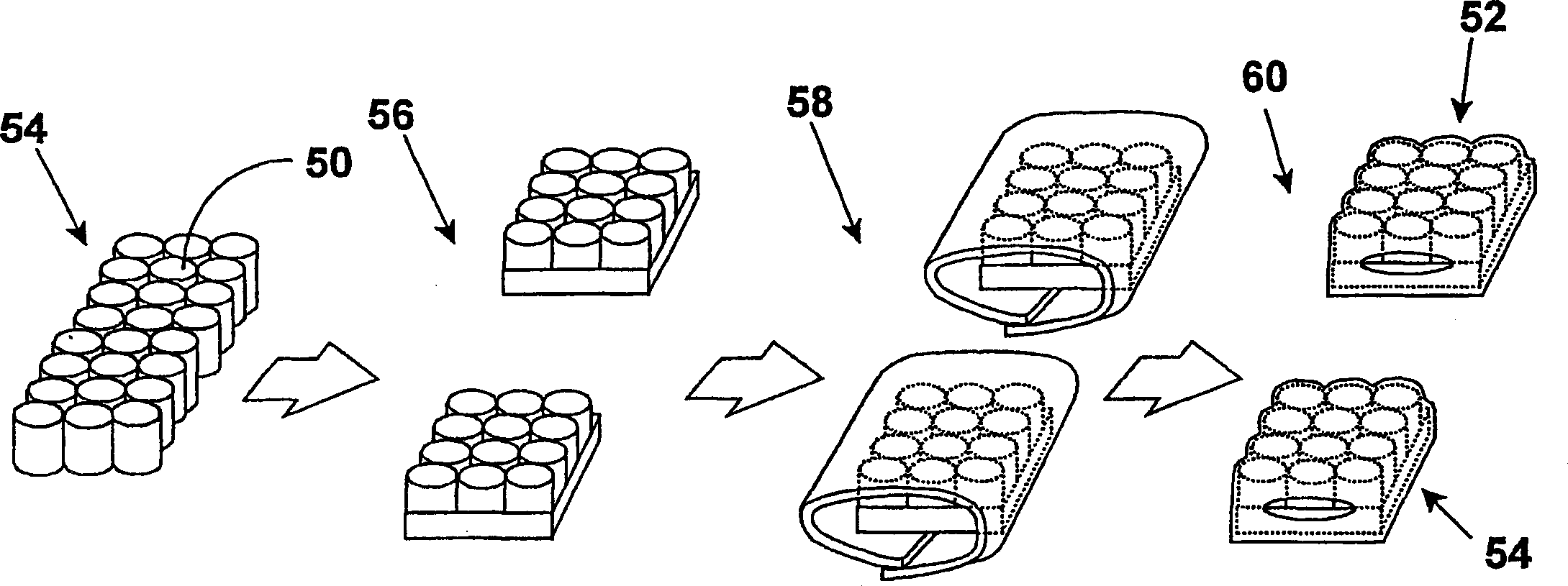

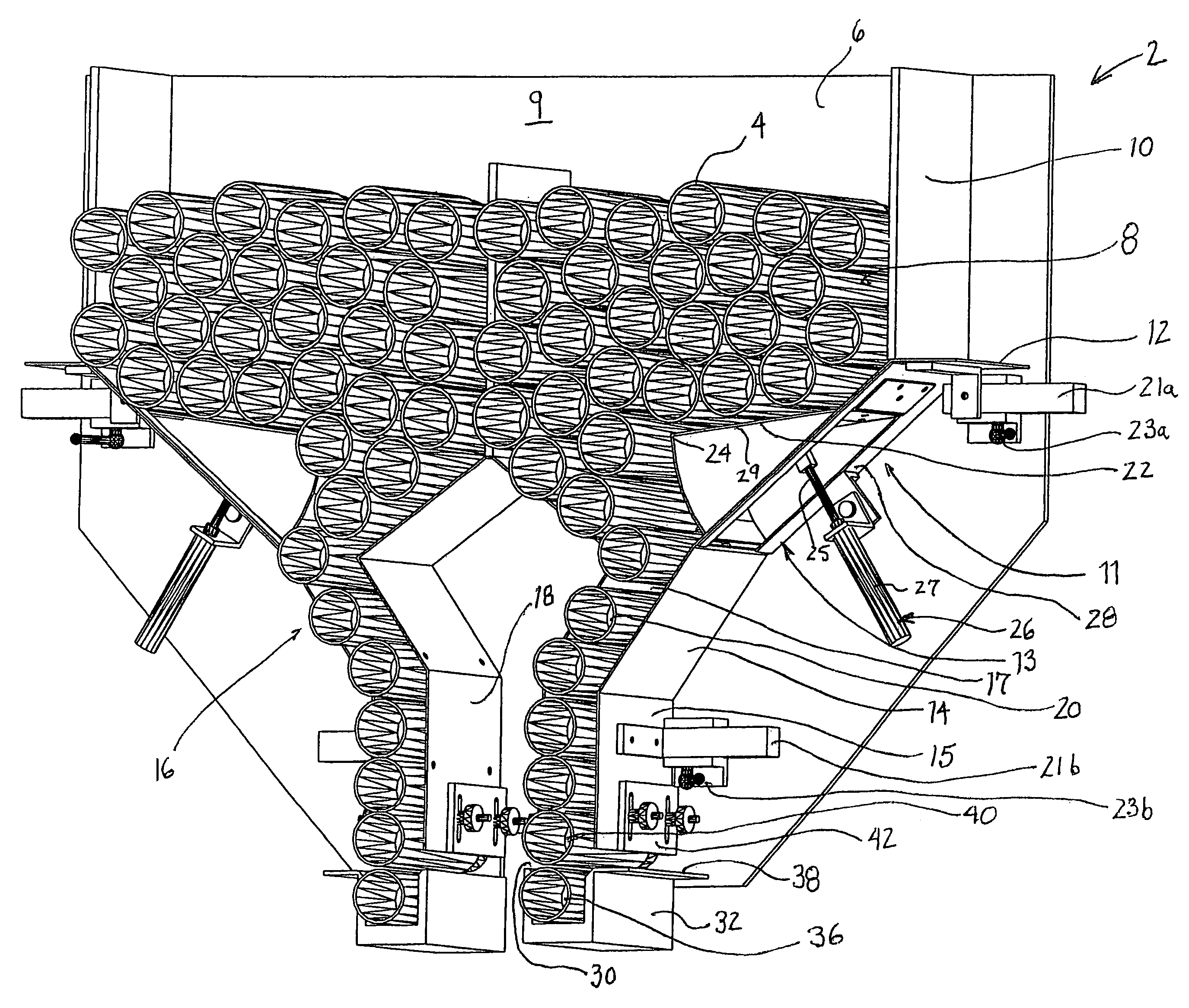

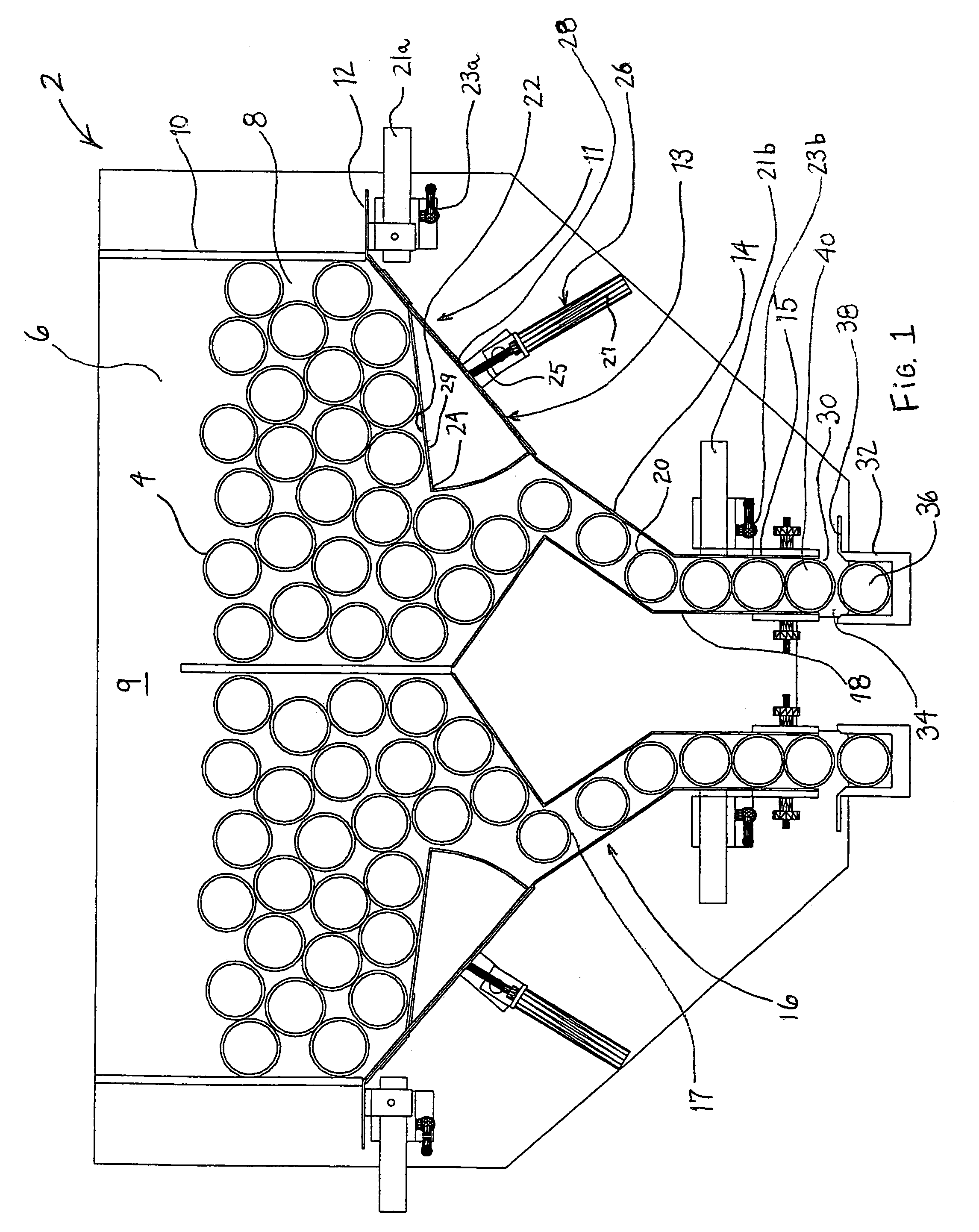

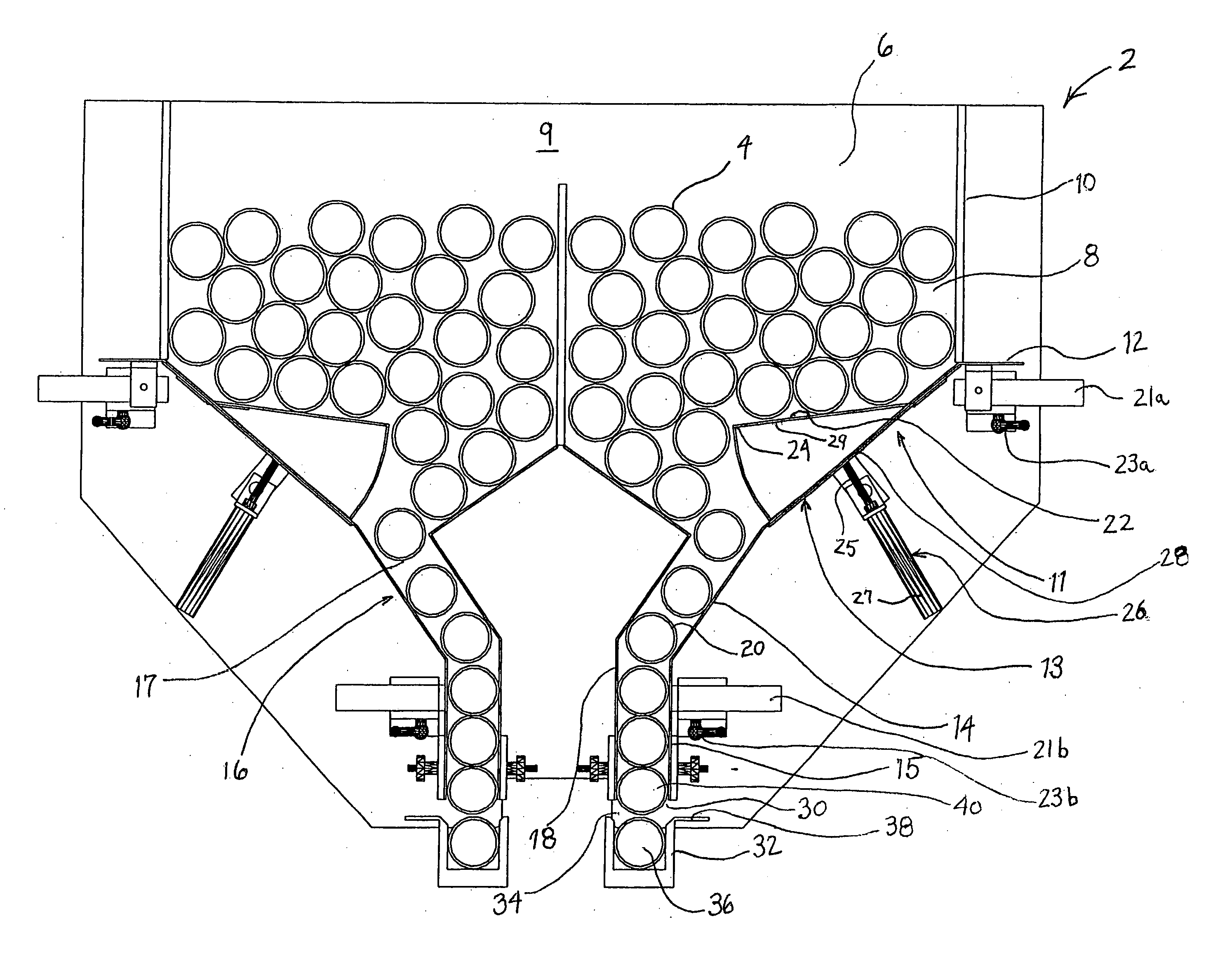

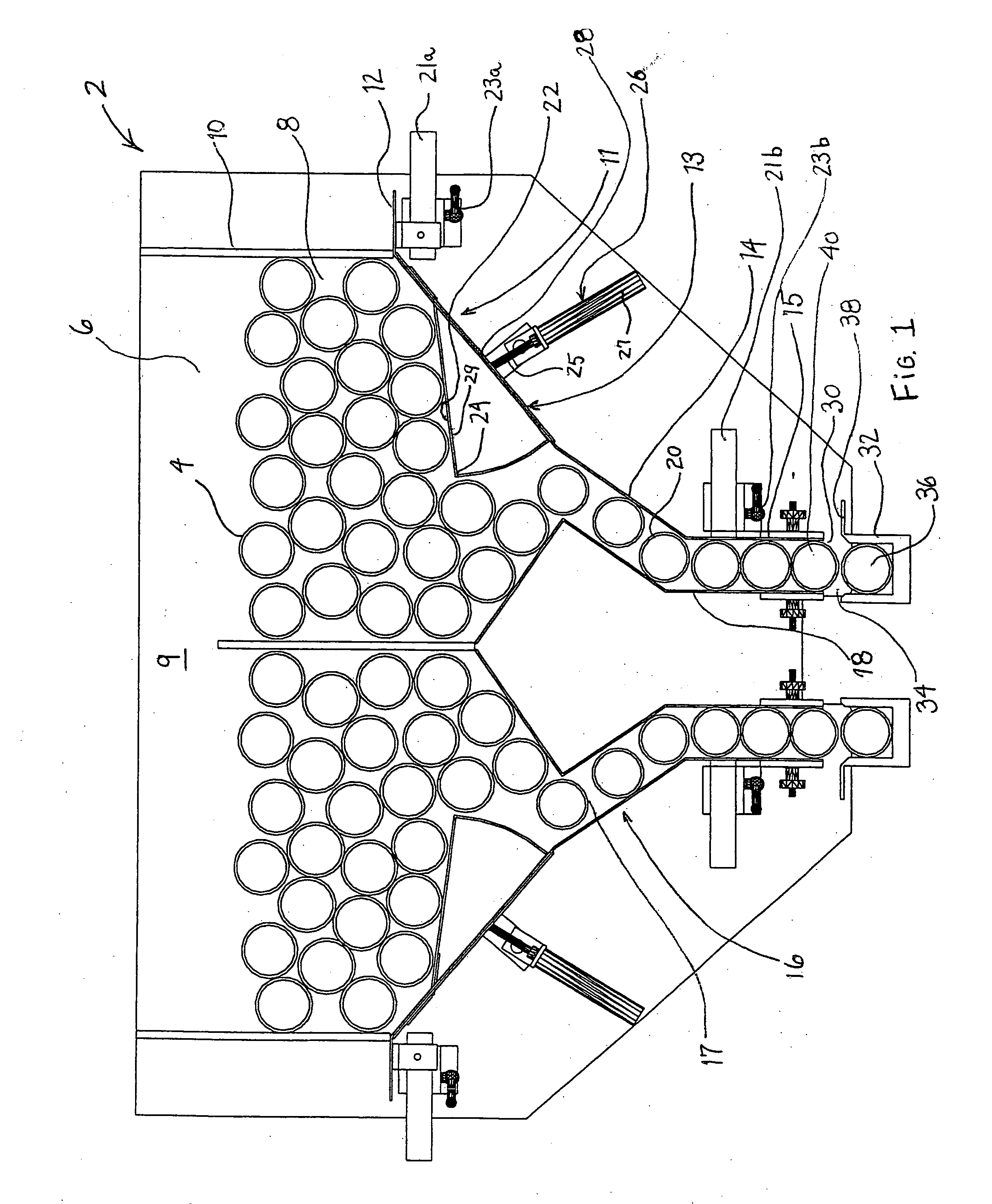

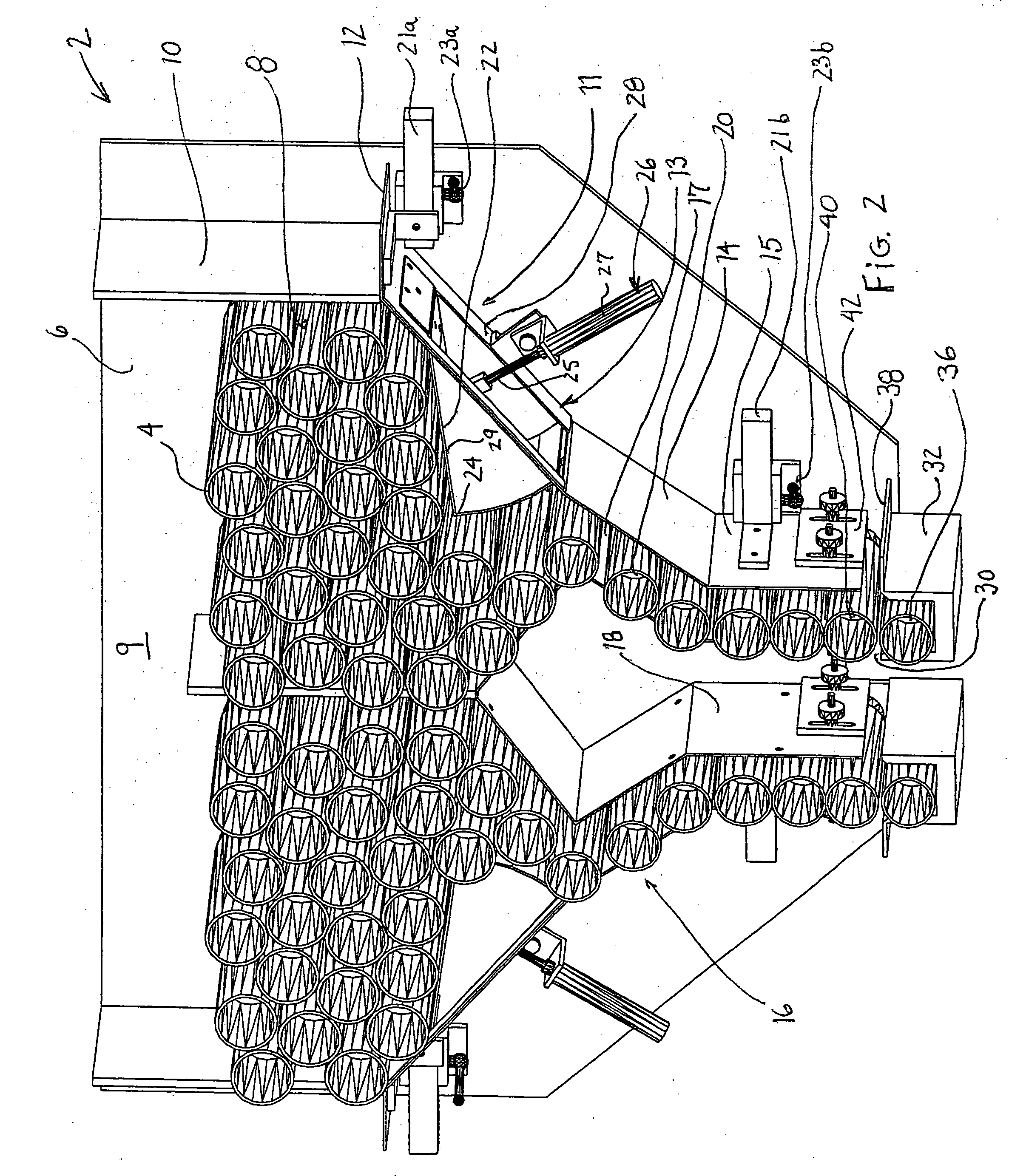

Film wrapping gable containers

This invention is directed to film wrapped and heat shrunk bundles of gabled containers to form bundles that can be stacked on pallets and not be constrained by the gables in determining the size of the bundles. This is accomplished by nesting the gable containers on a conveyor on their side. The nesting of the gable containers on their side provides a stable structure that can be moved on a conveyor to be film wrapped. After film wrapping, the containers are conveyed to a heat shrink tunnel to form bundles of gable containers that can be placed on a pallet.

Owner:CERF ALAIN

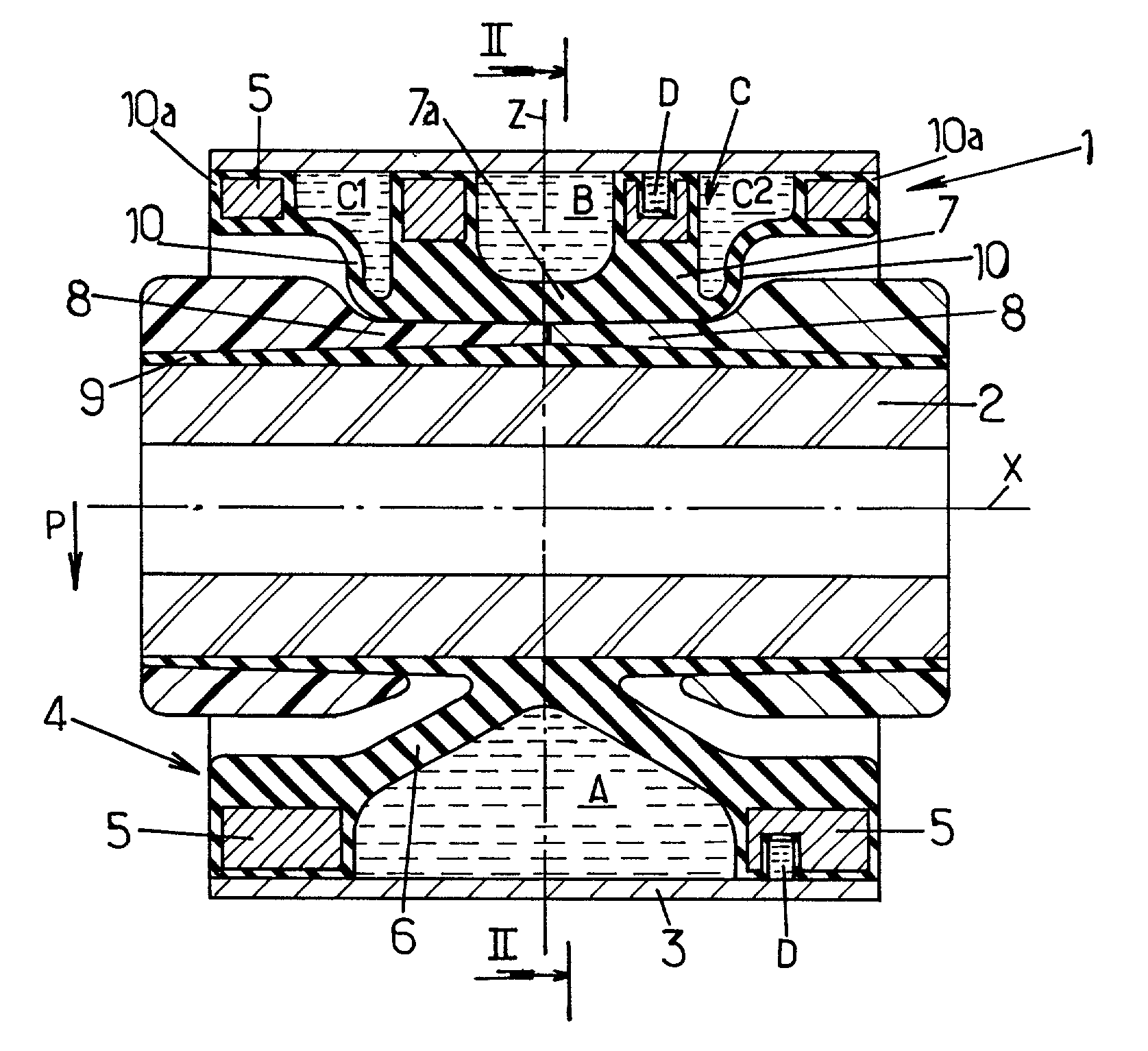

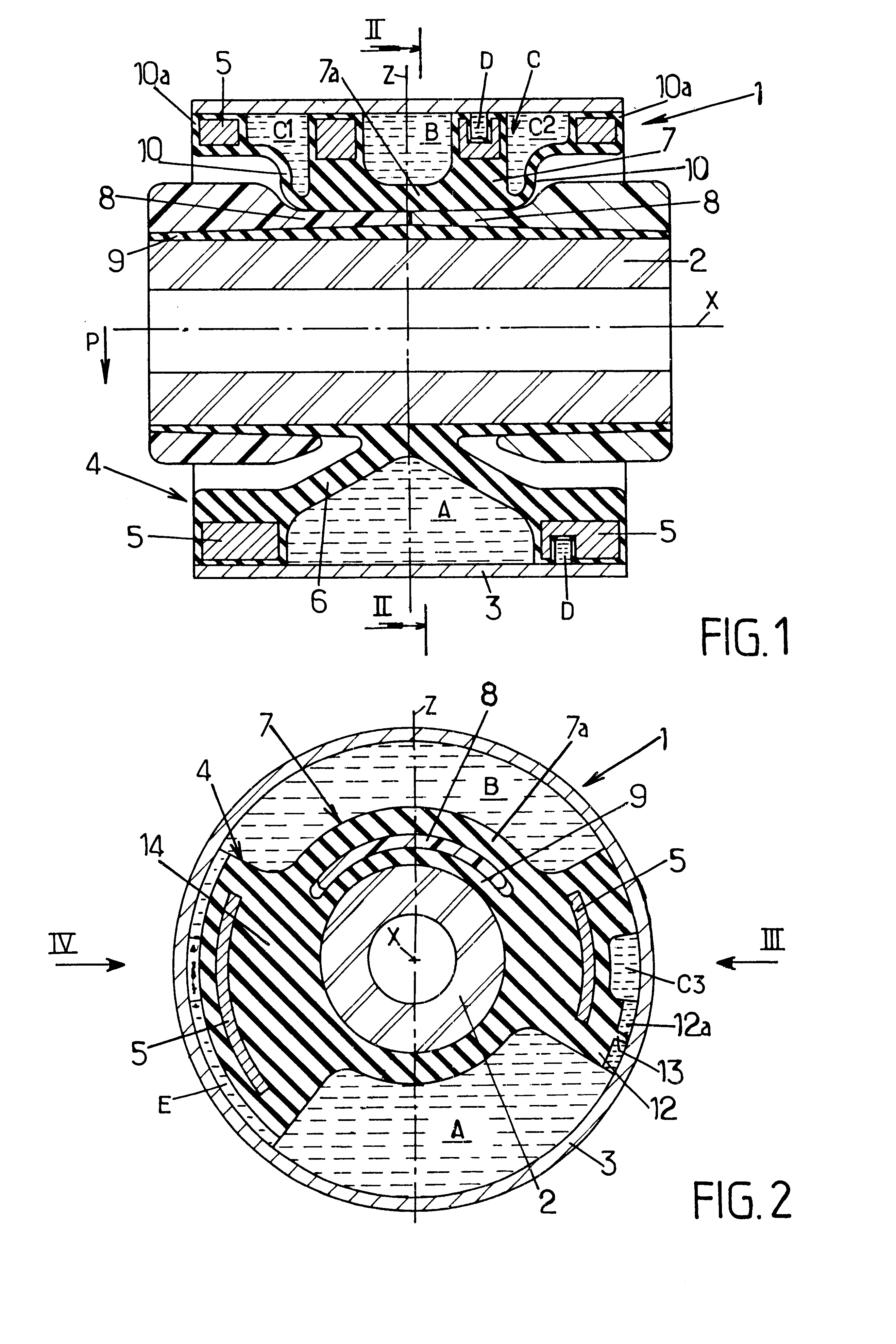

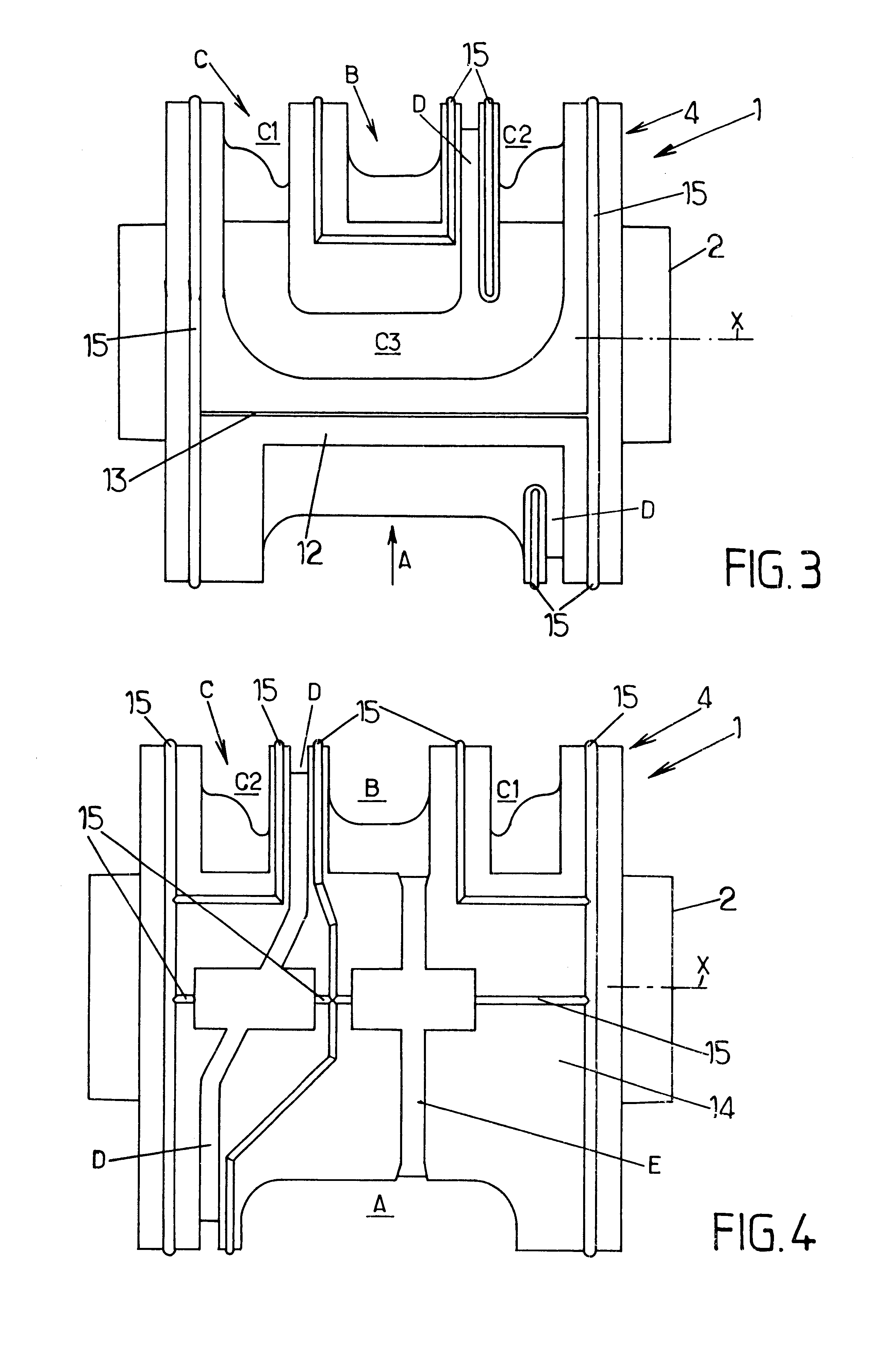

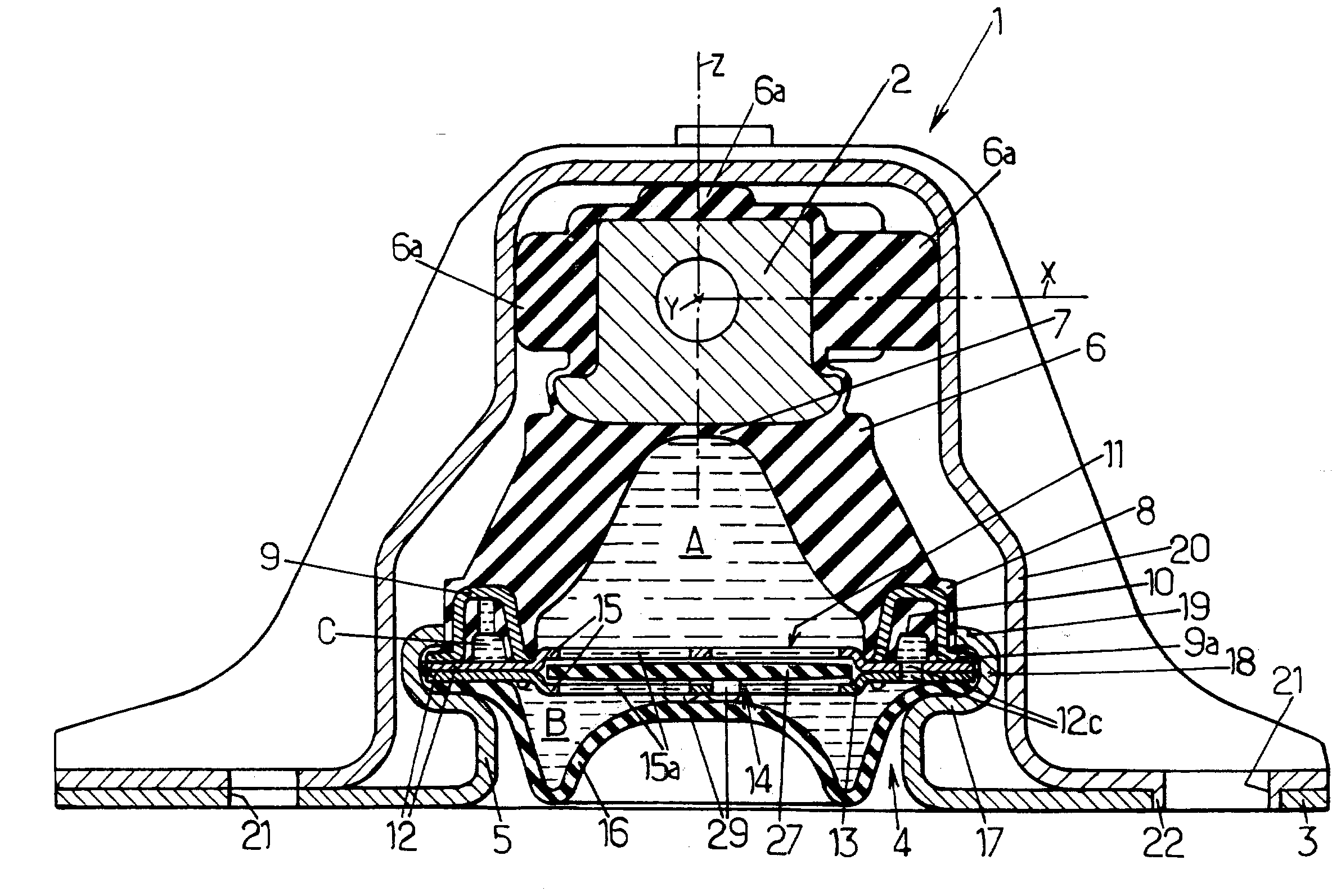

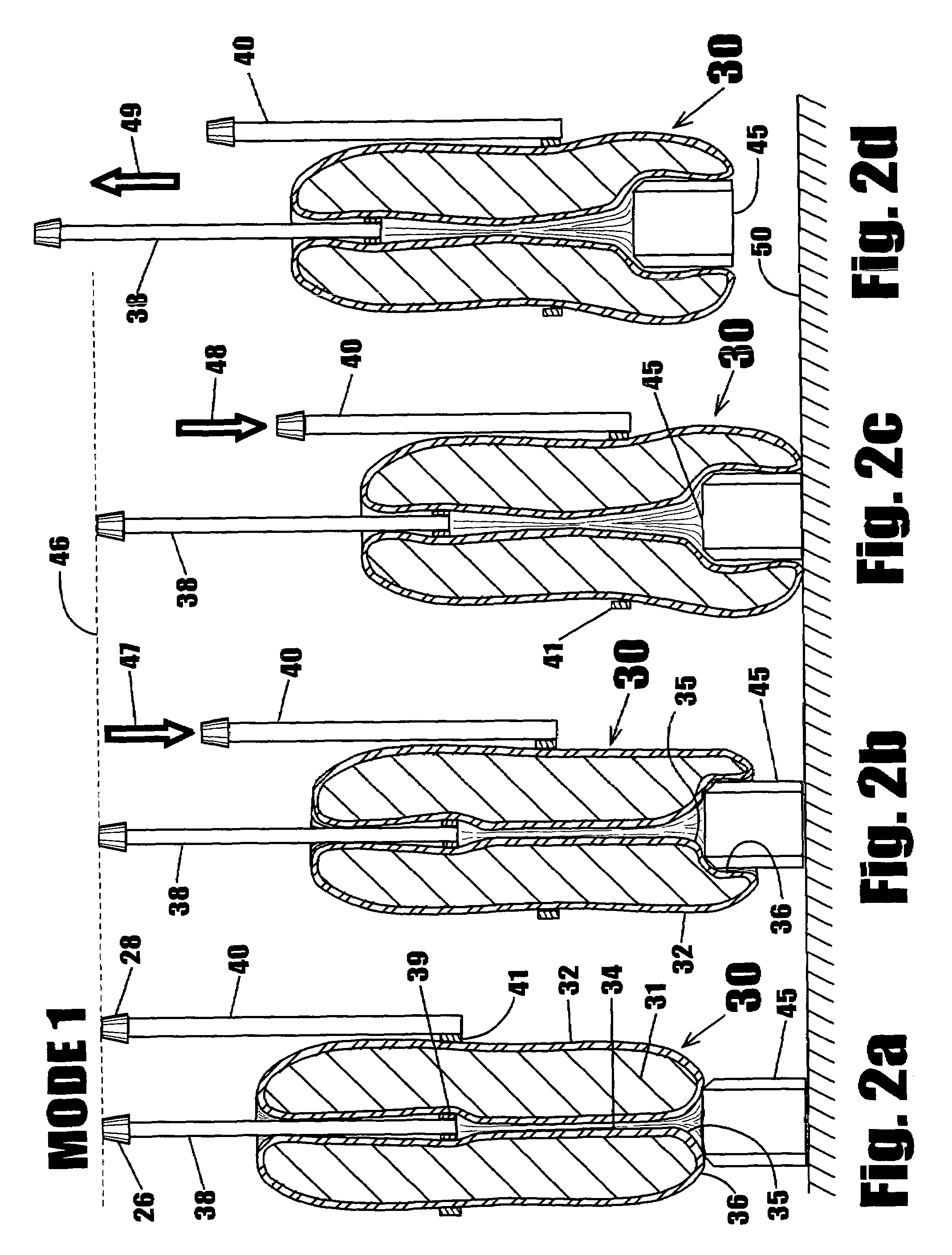

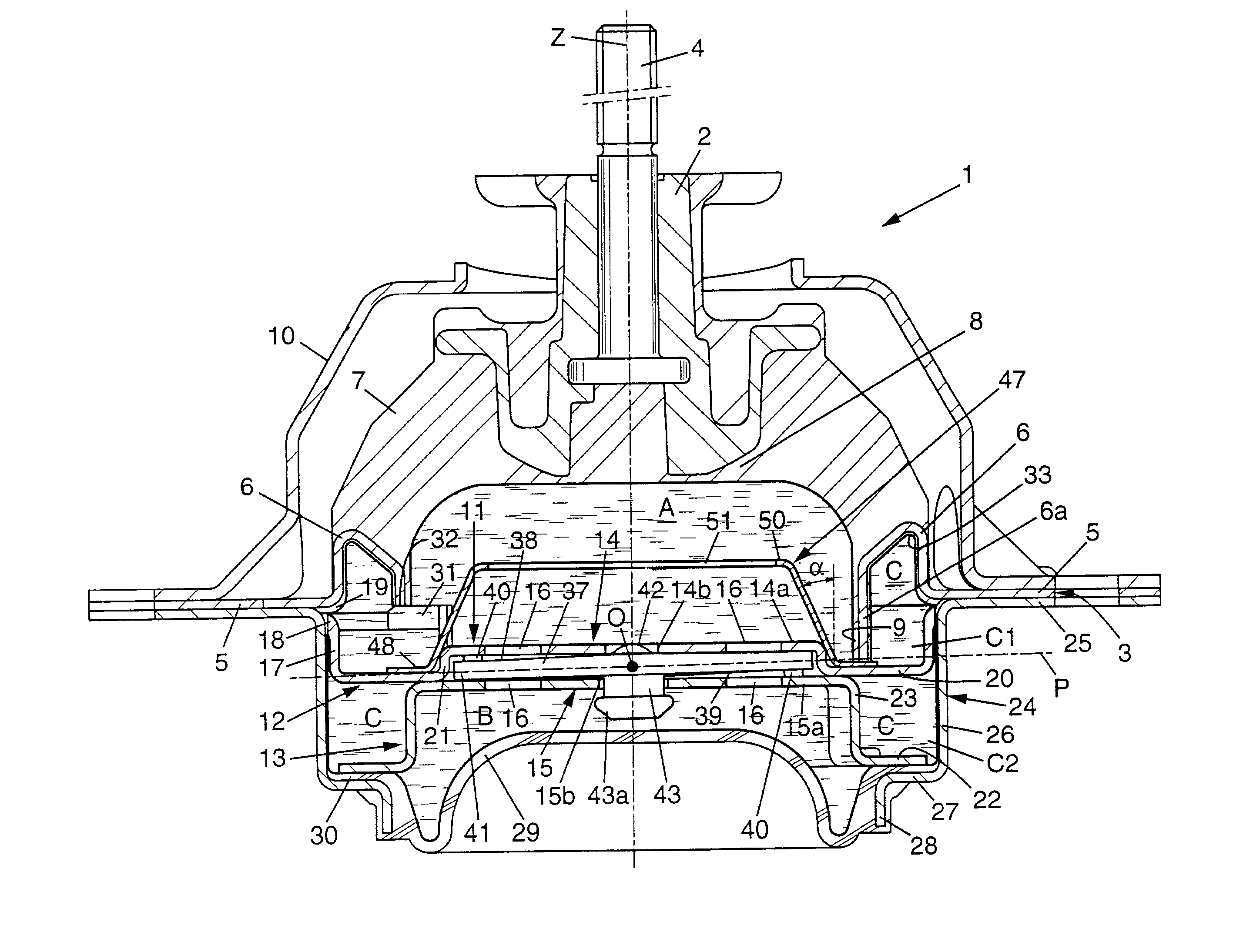

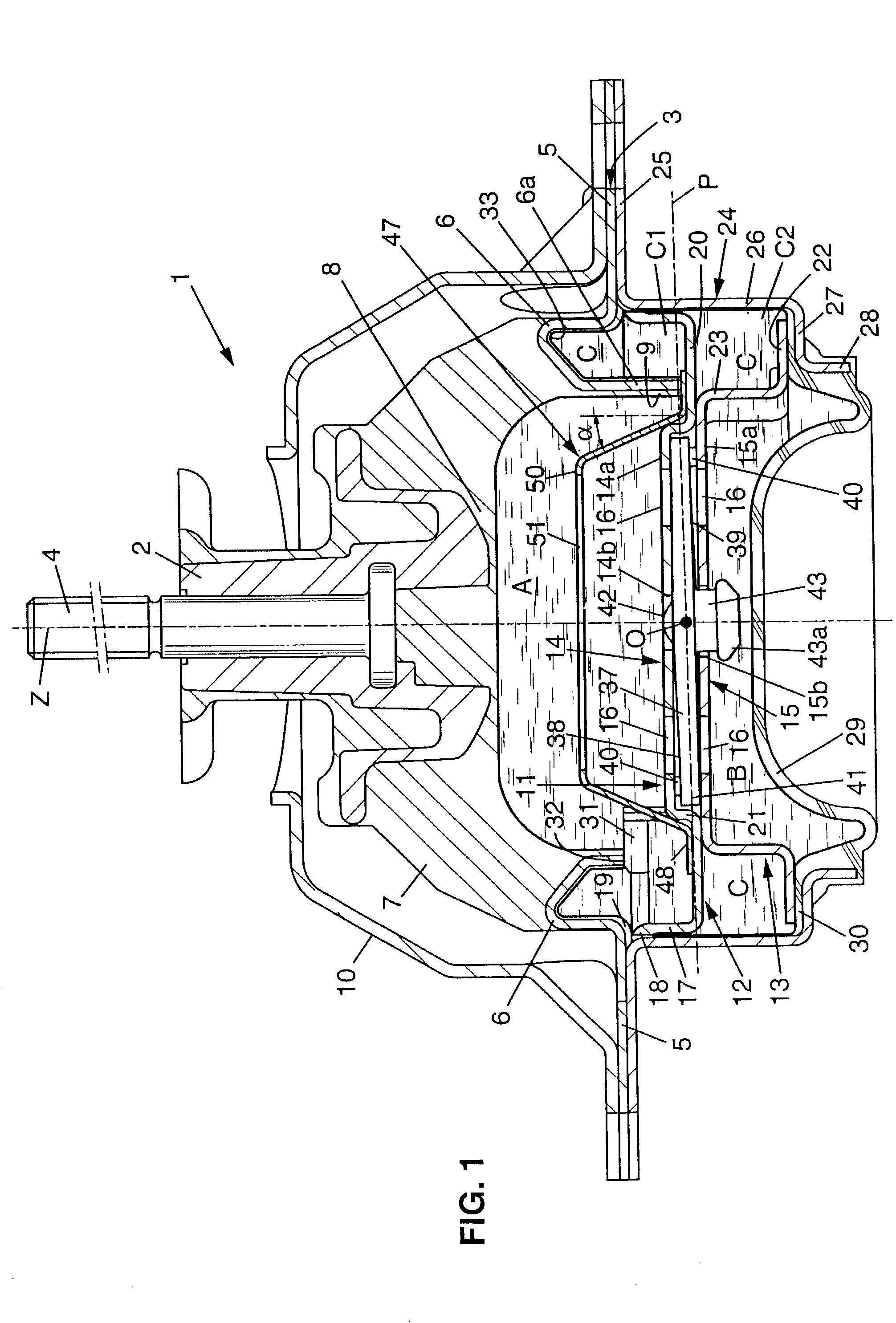

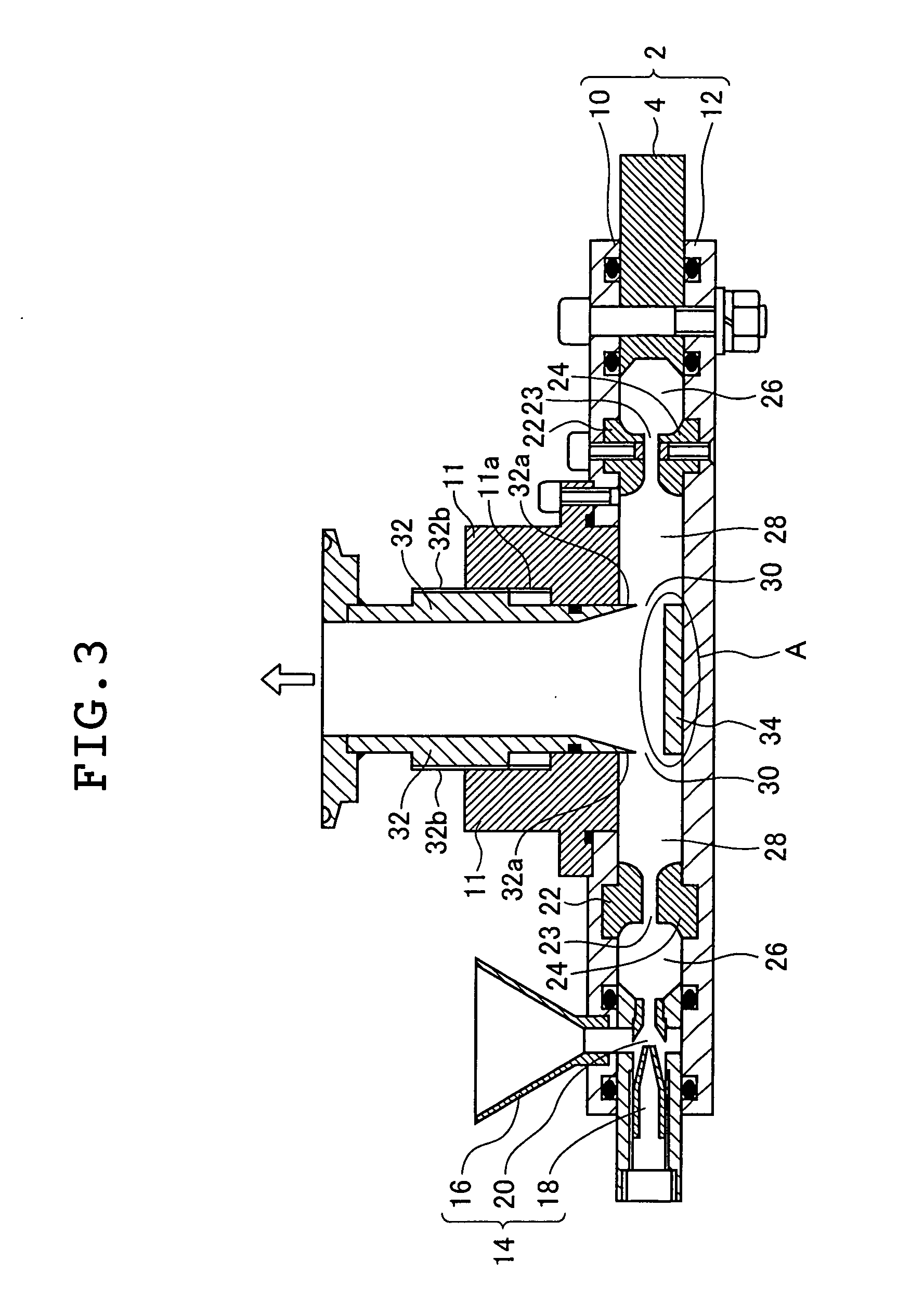

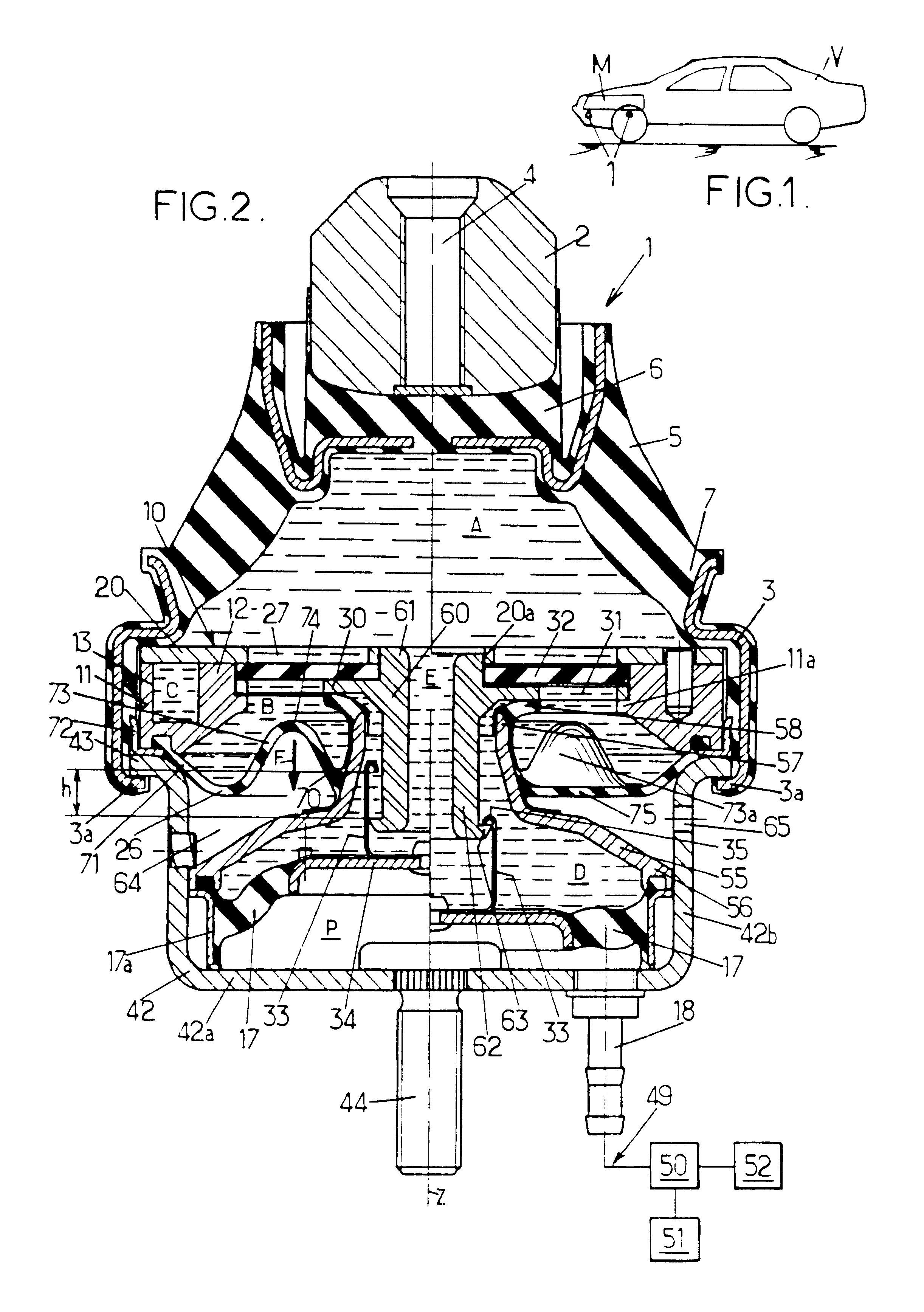

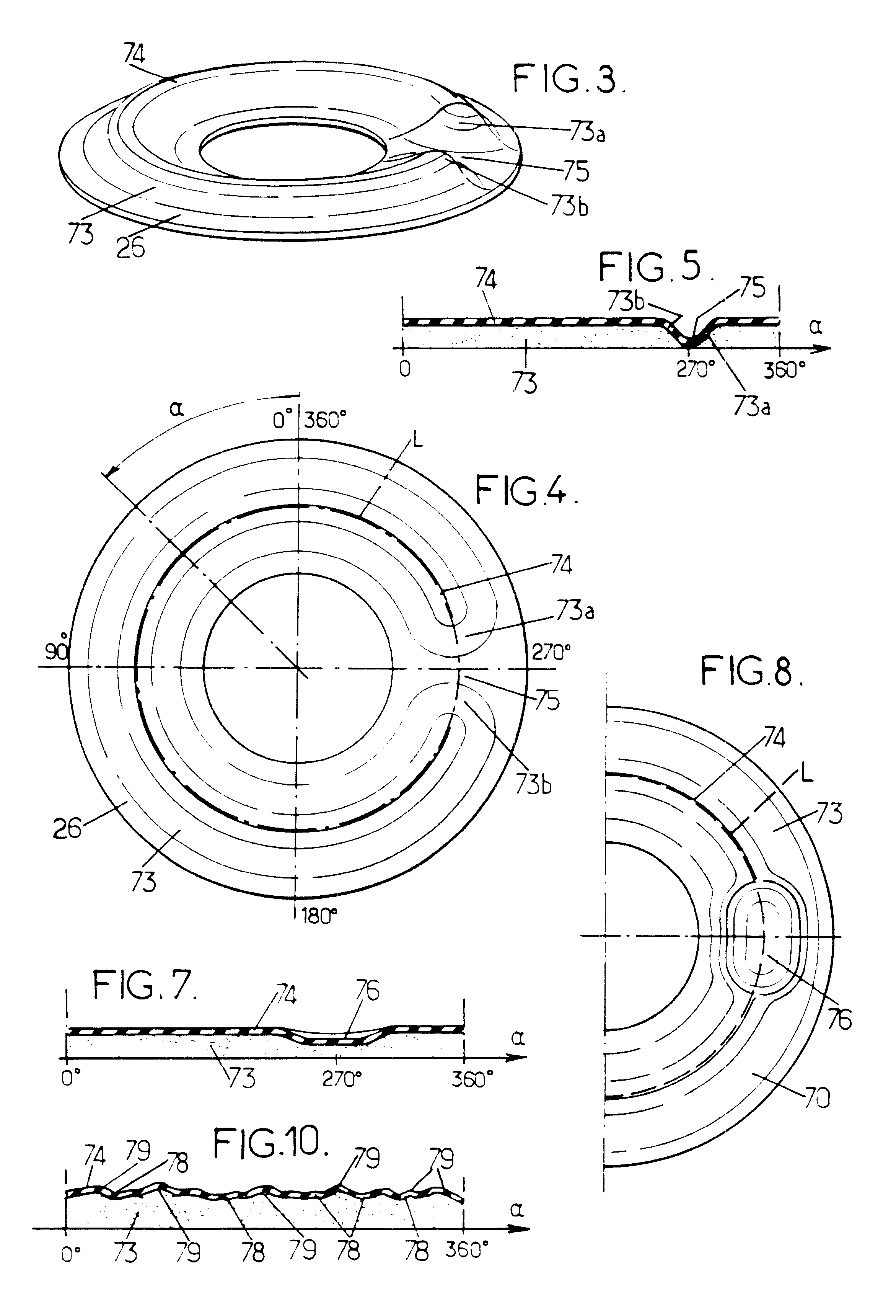

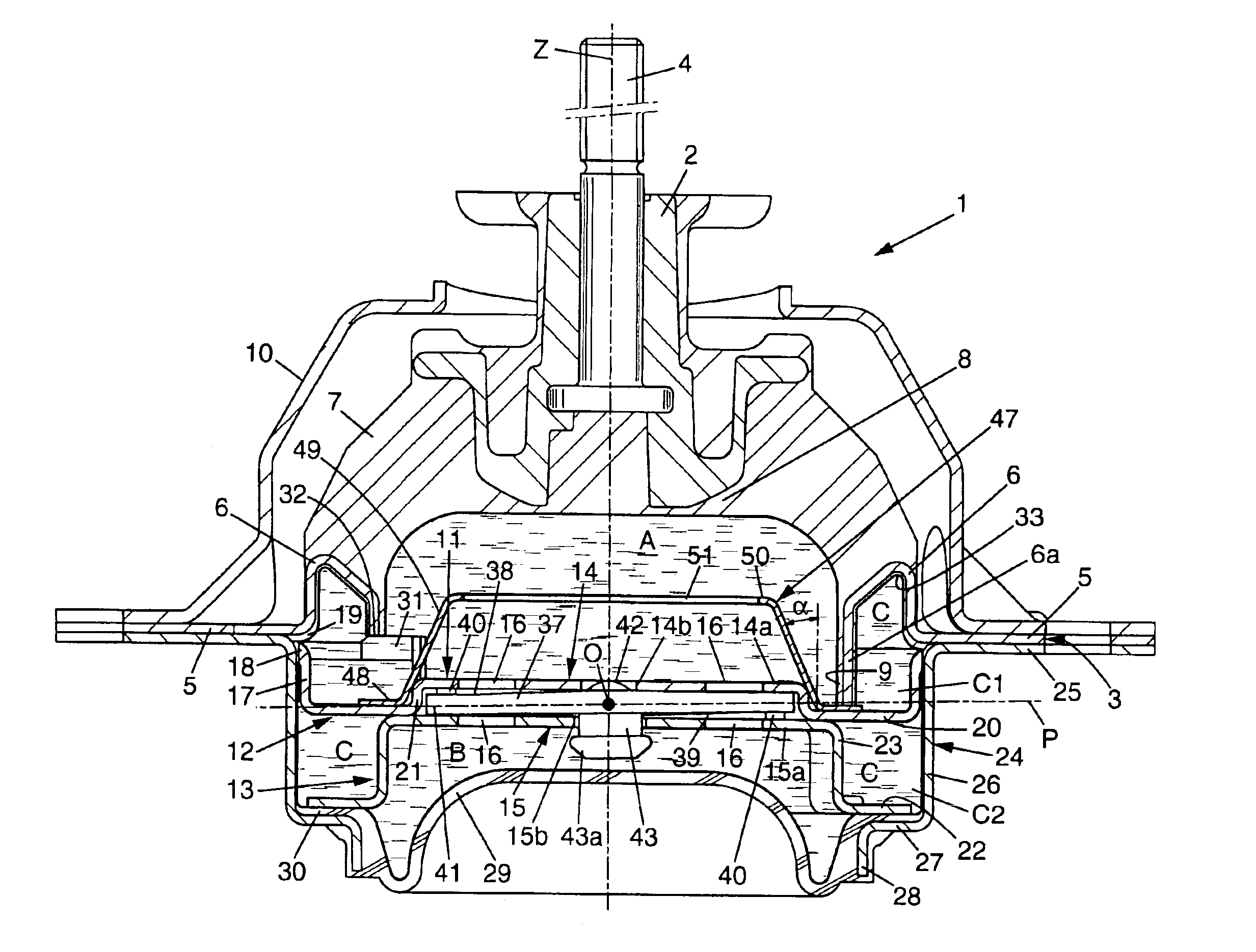

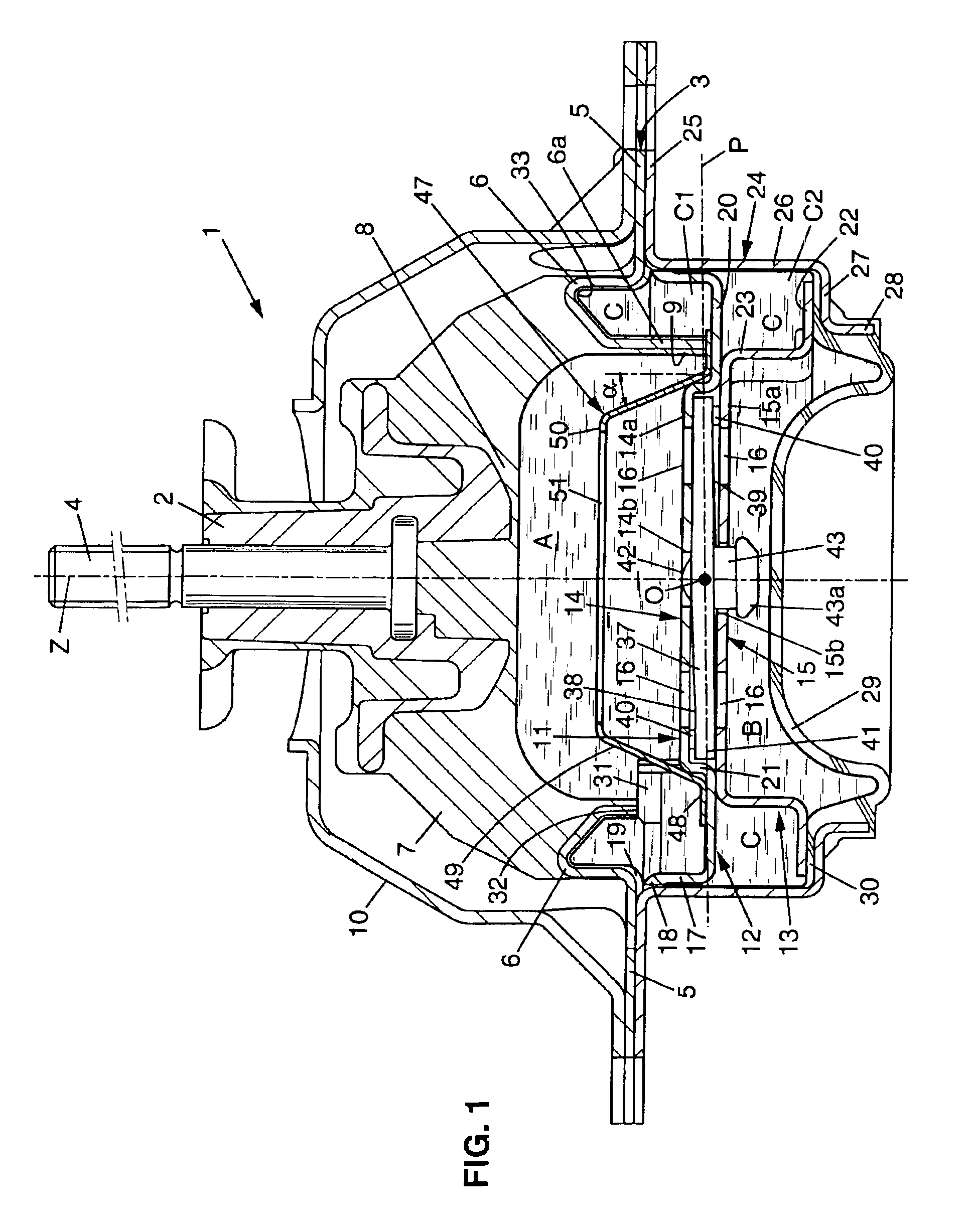

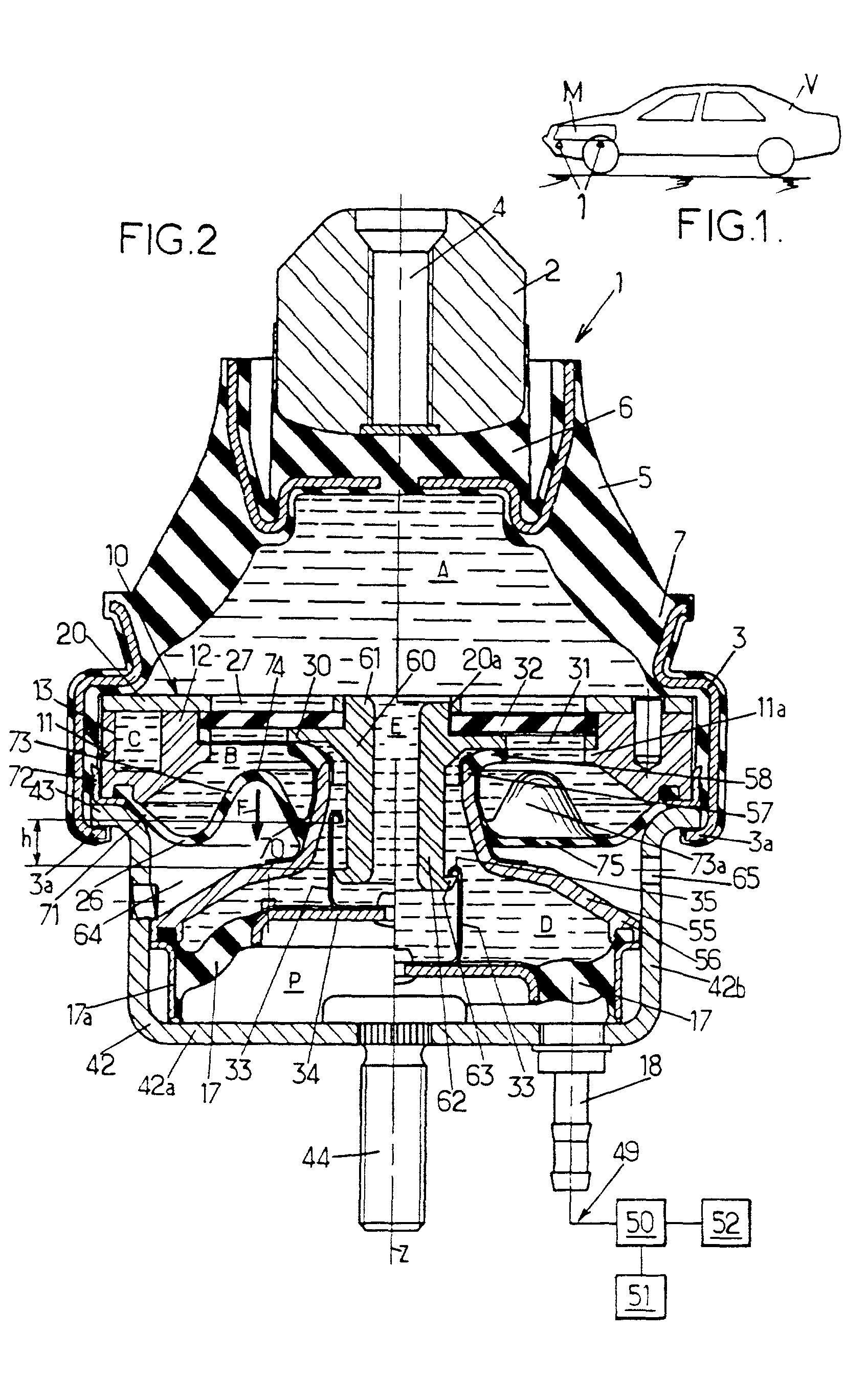

Hydraulic antivibration sleeve

A hydraulic antivibration sleeve comprising two constrictive strength members interconnected by an elastomer body which defines first and second diametrically opposite working chambers and a side compensation chamber. The two working chambers communicate with each other via a constricted passage, while the compensation chamber communicates with the first working chamber only via another constricted passage. The elastomer wall which defines the second working chamber is free and is not in contact with the inner strength member except in a certain range of values for the radial static load supported by the sleeve: this provides two different modes of operation depending on the value of said static load.

Owner:HUTCHINSON SA

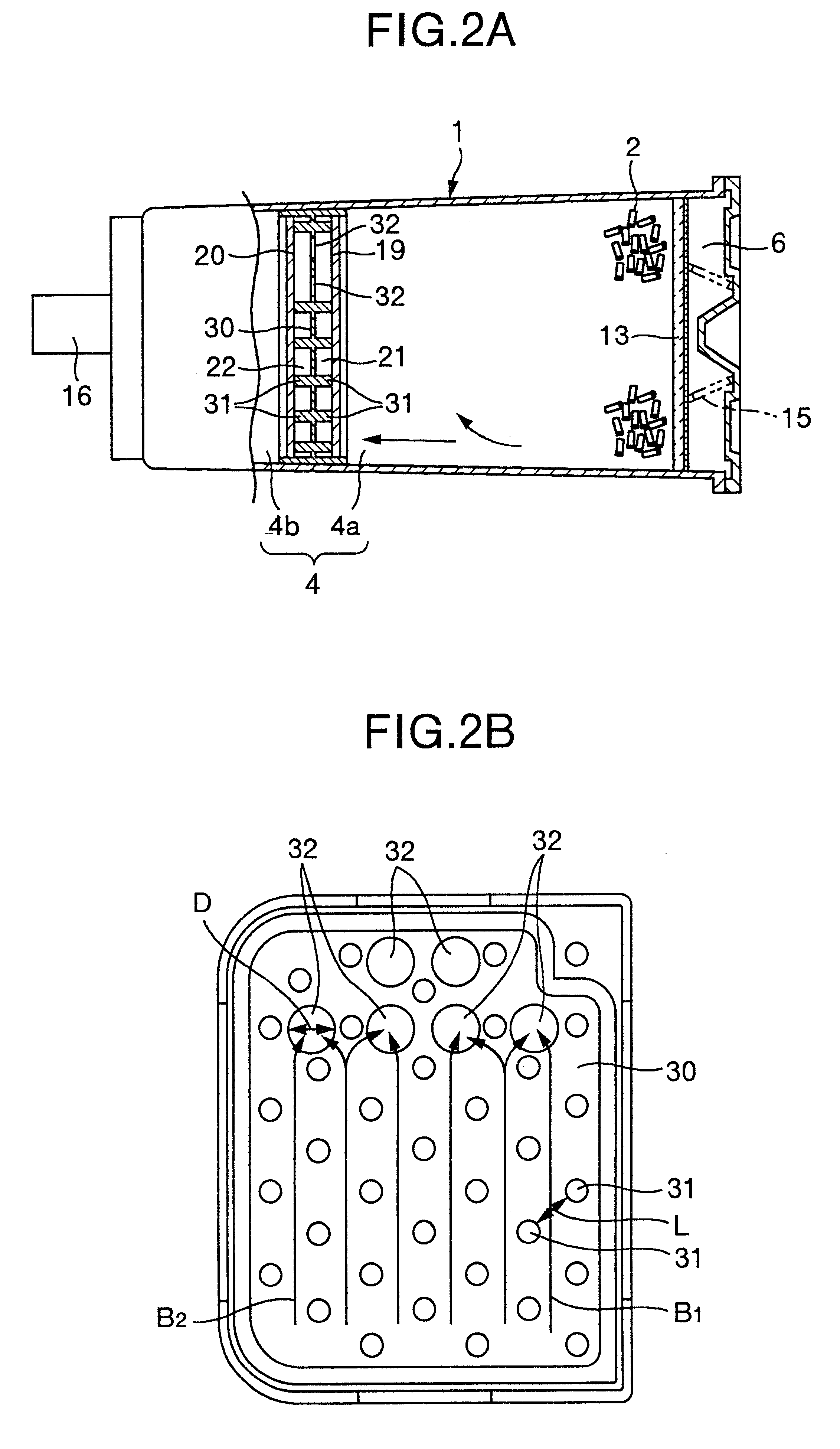

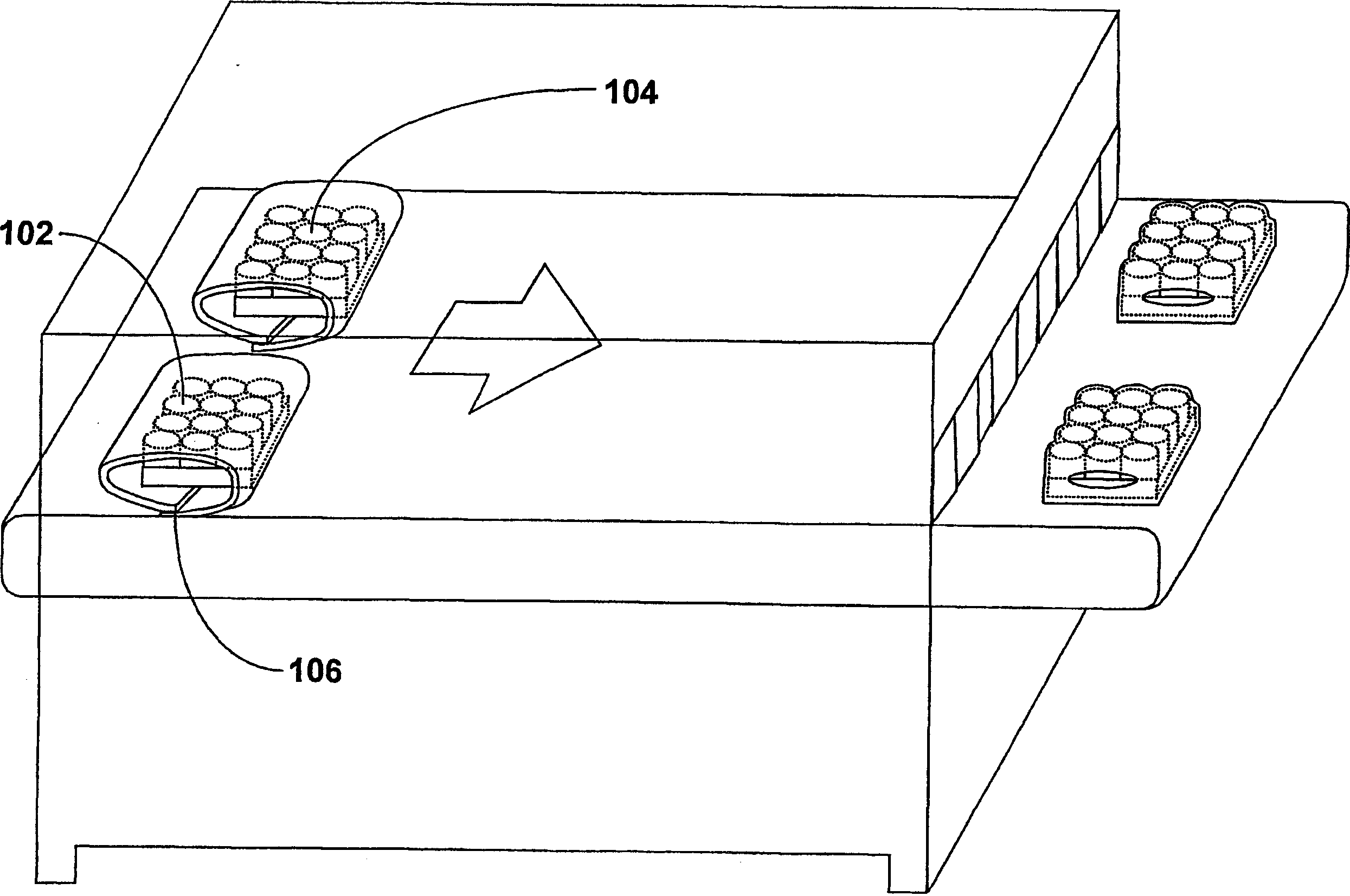

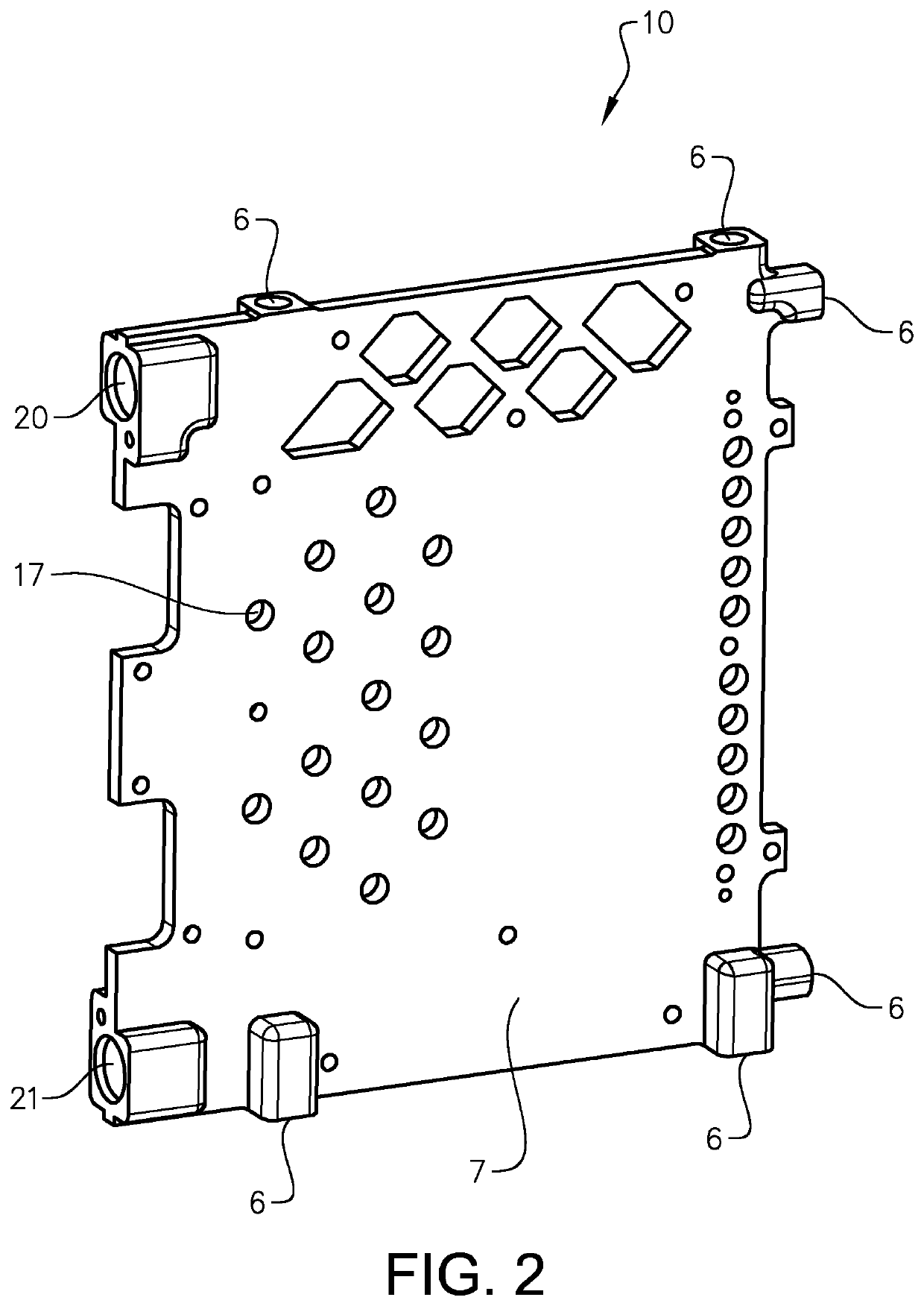

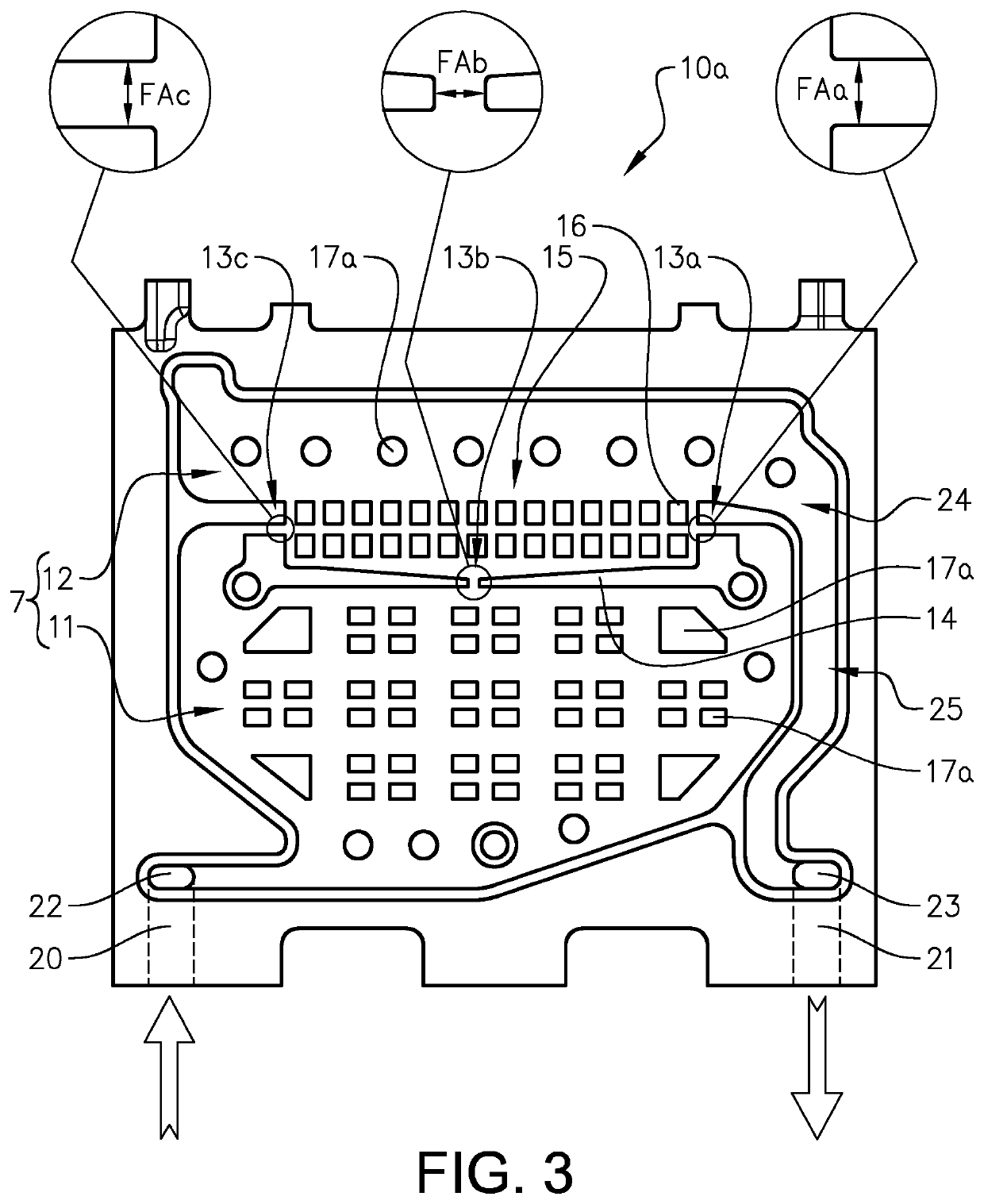

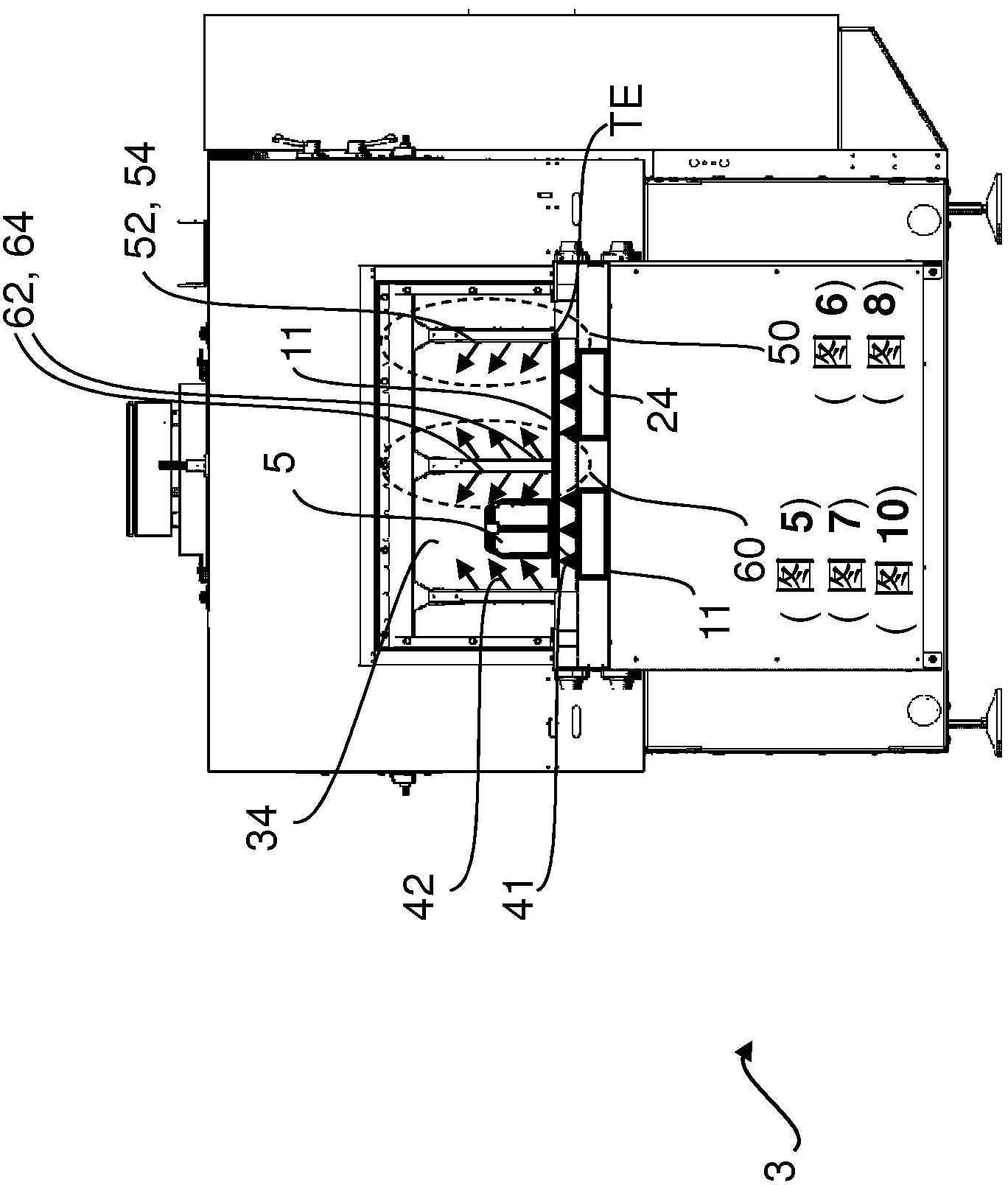

Adaptable packaging machine heat shrink tunnel

A shrink tunnel (100) for use with packaging machines utilizing heat shrinkable film (17). Air plenums (158, 160, 162, 164) positioned in the shrink tunnel (100) accurately direct heat at laterally opposed ends (188, 190, 198, 200, 202, 204, 206, 208, 212, 214, 218, 220) of film wrapped packages (192, 194, 196, 210, 216, 222) to shrink film into a bullseye (19). The air plenums (158, 160, 162, 164) are adjustable to accommodate different size packages or a differing number of lanes of operation. Interior air plenums (160, 162) are inserted between packages in lanes of a multiple lane packaging machine so that the laterally opposed ends of all packages have hot air directed at them.

Owner:GISTERS KAJATE

Hydraulic antivibration sleeve

A hydraulic antivibration sleeve comprising two constrictive strength members interconnected by an elastomer body which defines first and second diametrically opposite working chambers and a side compensation chamber. The two working chambers communicate with each other via a constricted passage, while the compensation chamber communicates with the first working chamber only via another constricted passage. The elastomer wall which defines the second working chamber is free and is not in contact with the inner strength member except in a certain range of values for the radial static load supported by the sleeve: this provides two different modes of operation depending on the value of said static load.

Owner:HUTCHINSON SA

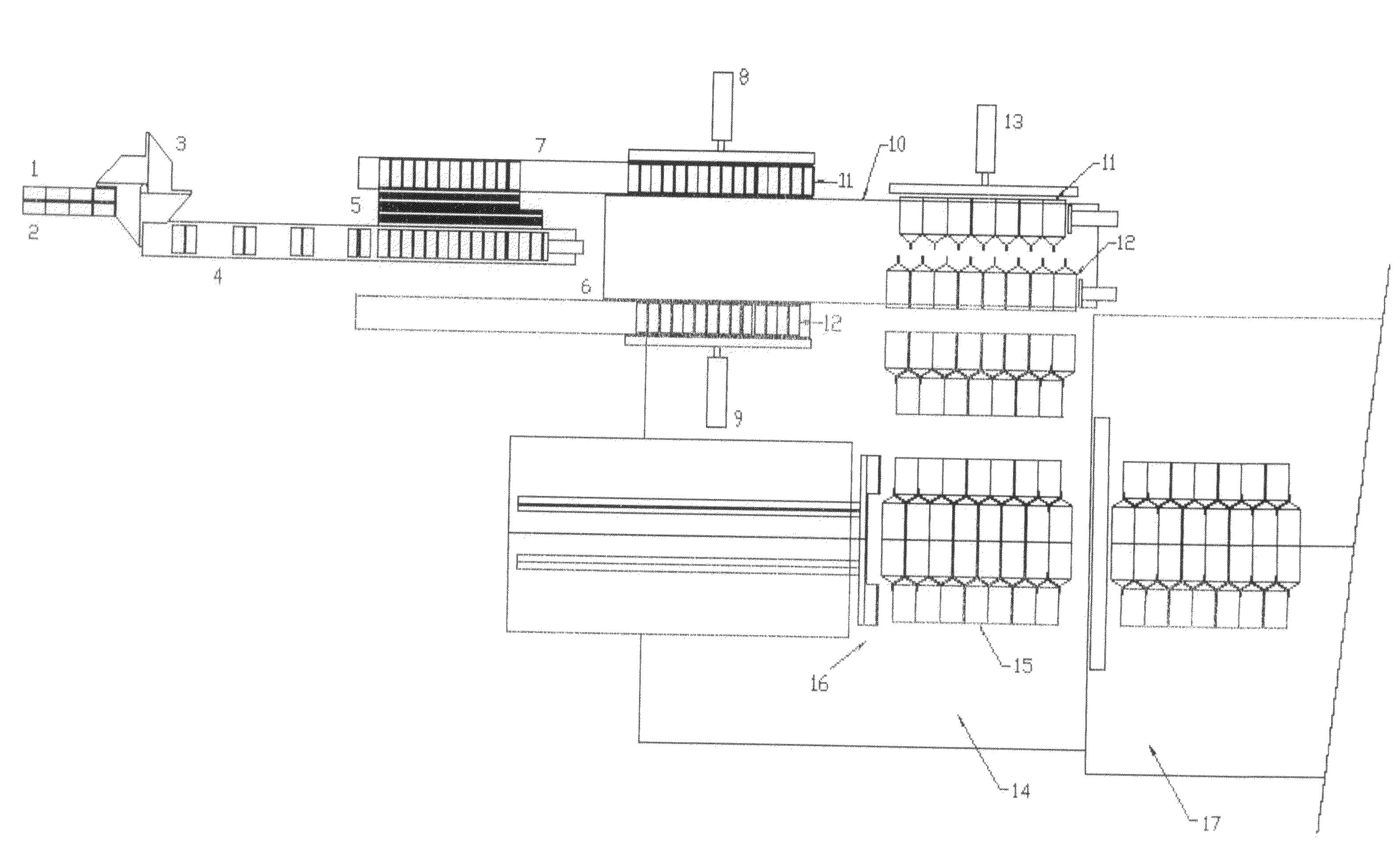

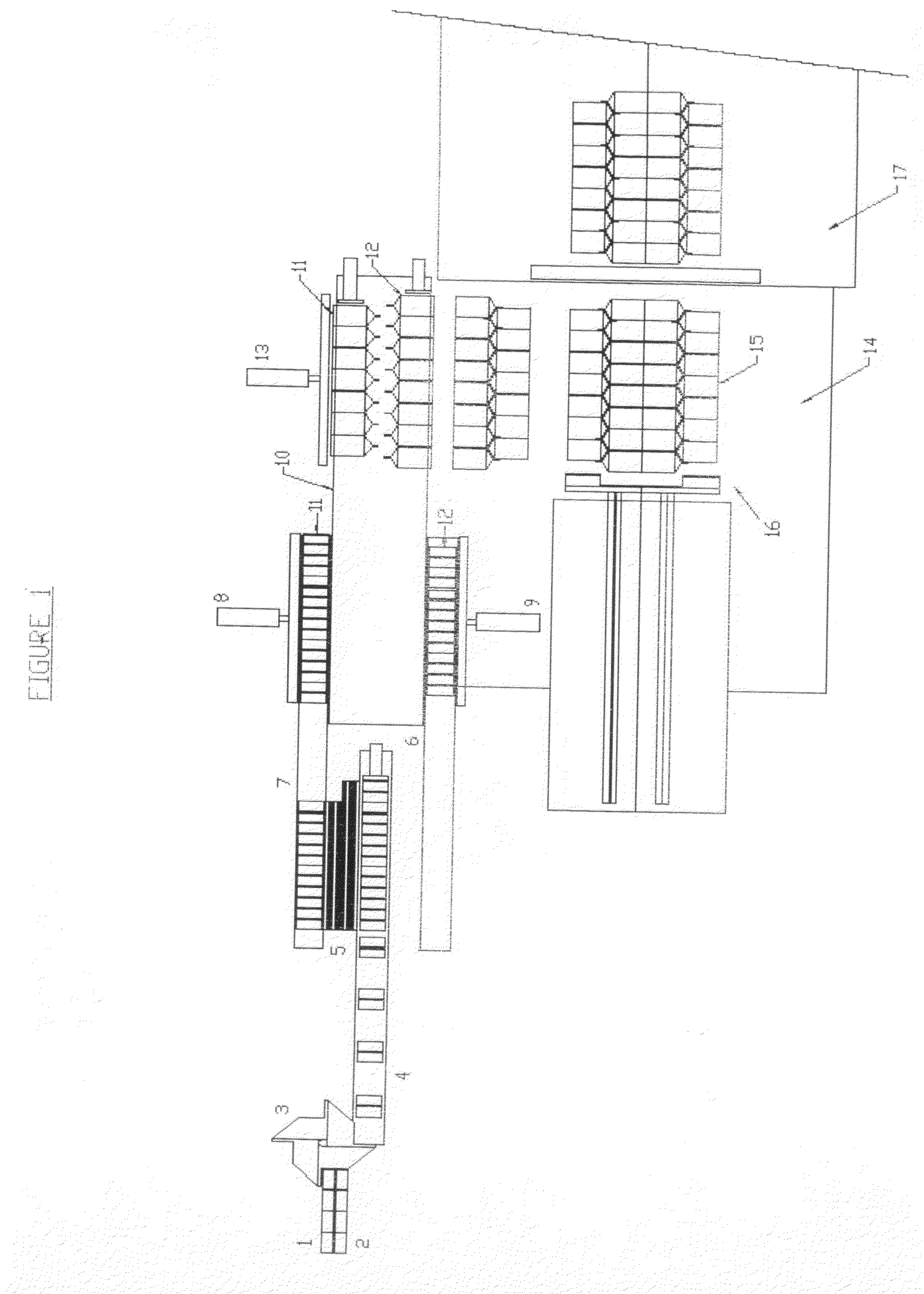

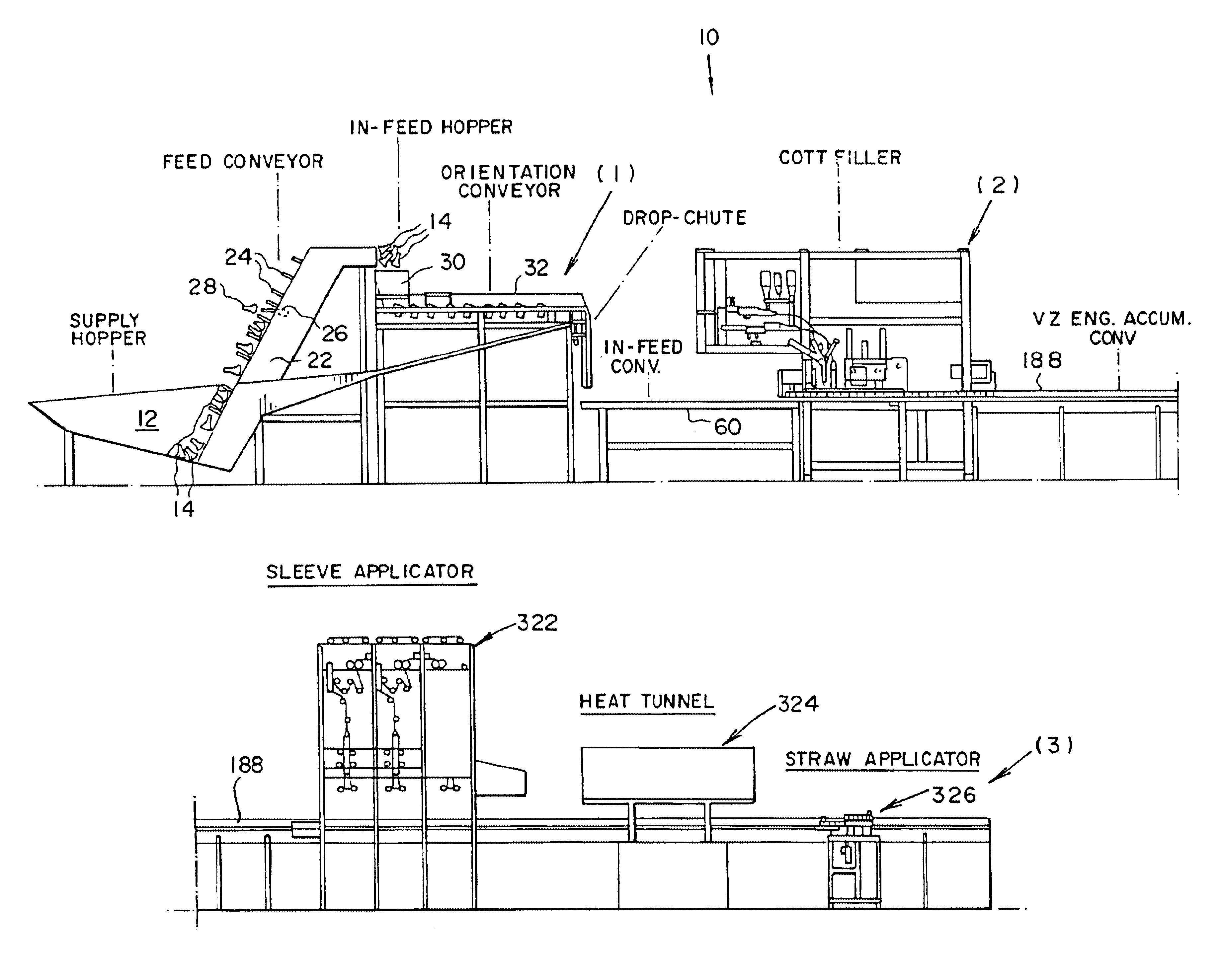

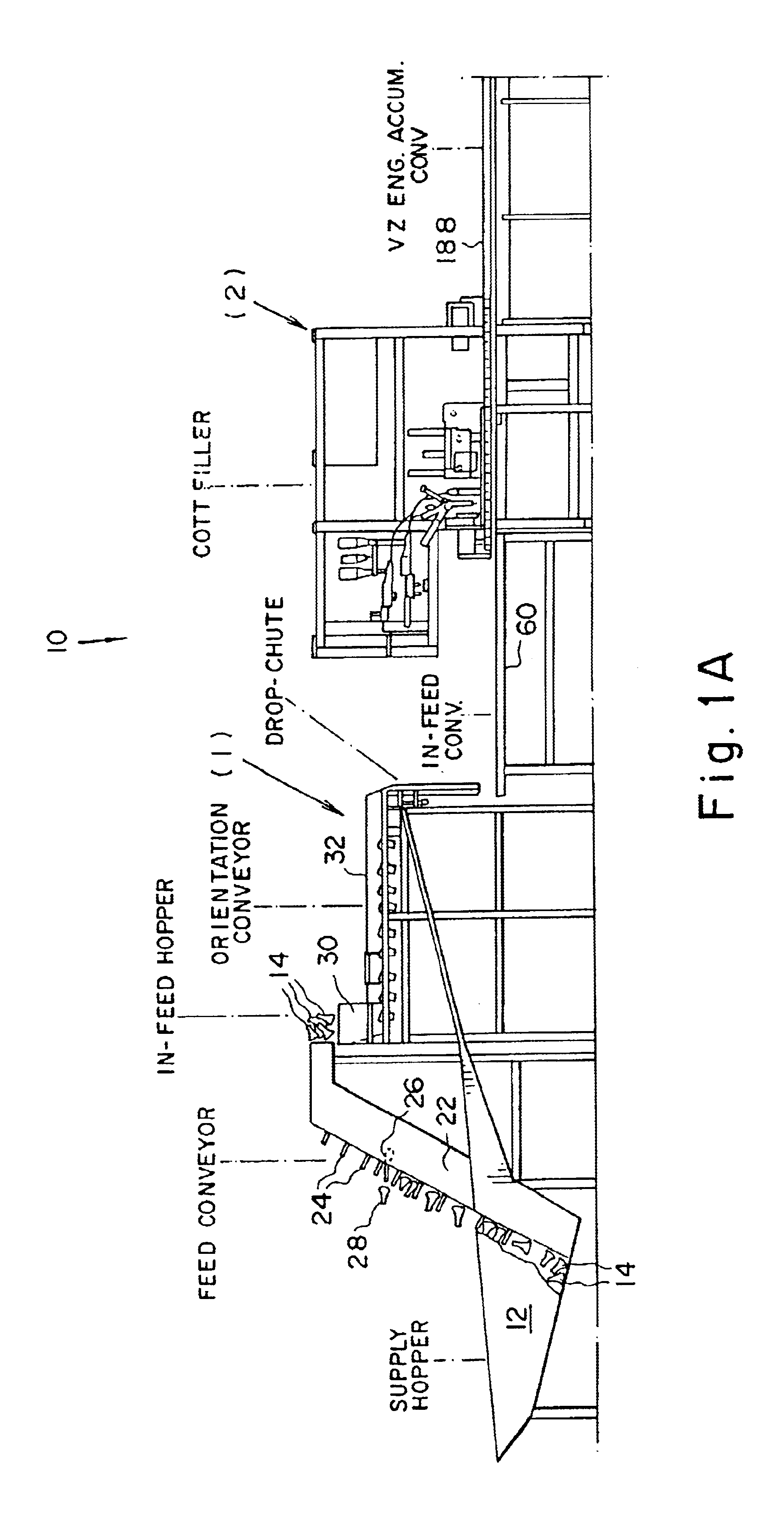

System and apparatus for an automated container filling production line

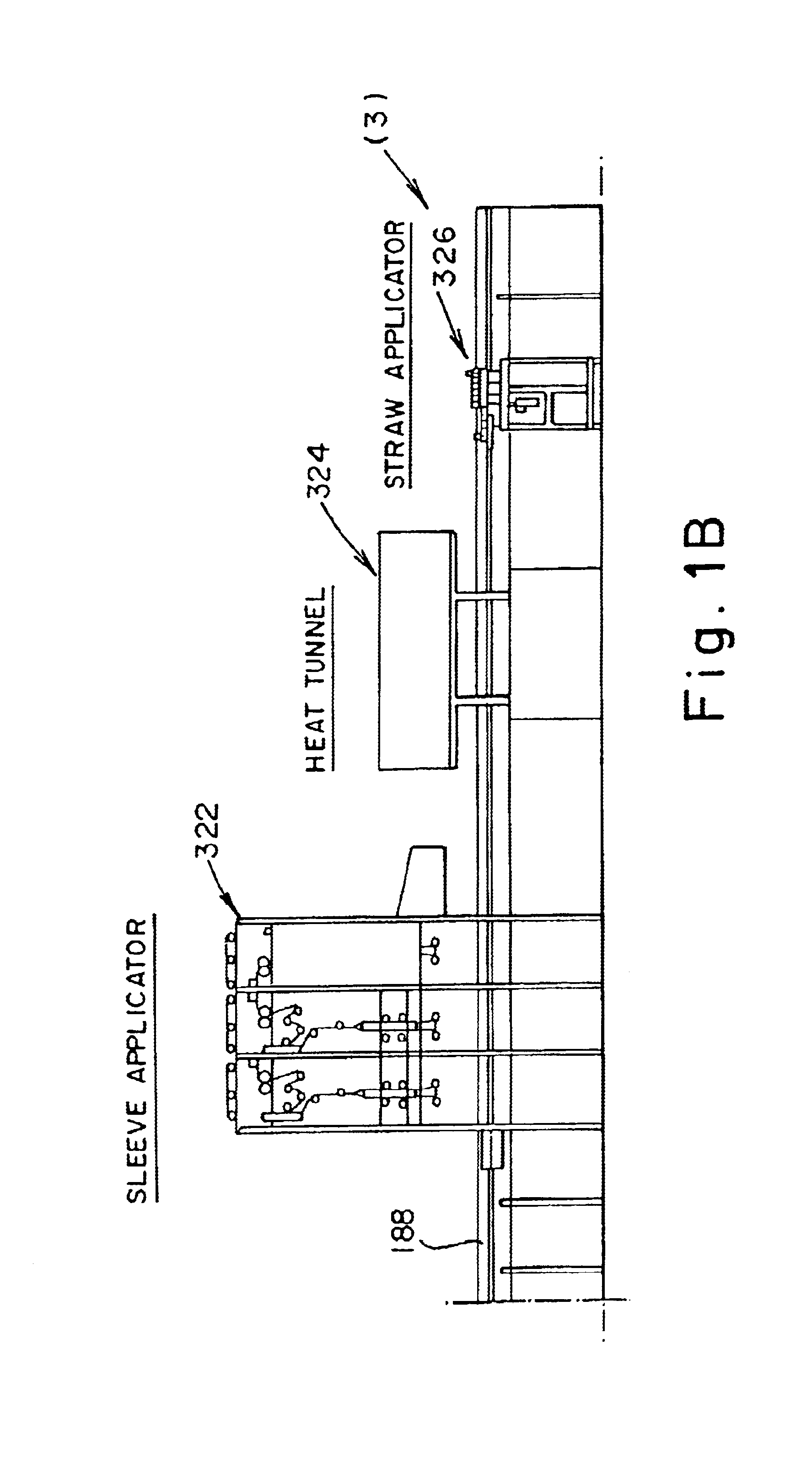

An automated container production line or automatically removing, orienting, filling, sealing and providing a label and applying a straw to the outside of the labeled container is provided which utilizes a novel orienting conveyor for receiving unoriented containers from a supply bin and orienting the containers for a plurality or novel short production lines having a positioning screw conveyor which intermittently starts and stops the advancement of the containers as groups of containers in which various groups of containers are simultaneously filled, sealed, inspected and then subsequently transported to a sleeving device for adding labels, a heat shrink tunnel for fastening the sleeve to the container and then to a novel straw applicator for subsequently attaching a straw to the outside of the container. The novel automated container filling, sealing and inspecting production line includes a computer program for controlling the production line in conjunction with various sensor devices for determining whether the containers are properly aligned, properly filled, properly sealed and completed in accordance with the highest quality control standards to not only assure product quality but also assure that containers not meeting specifications are removed from the production line and not processed further.

Owner:DE CARDENAS GILBERT L +1

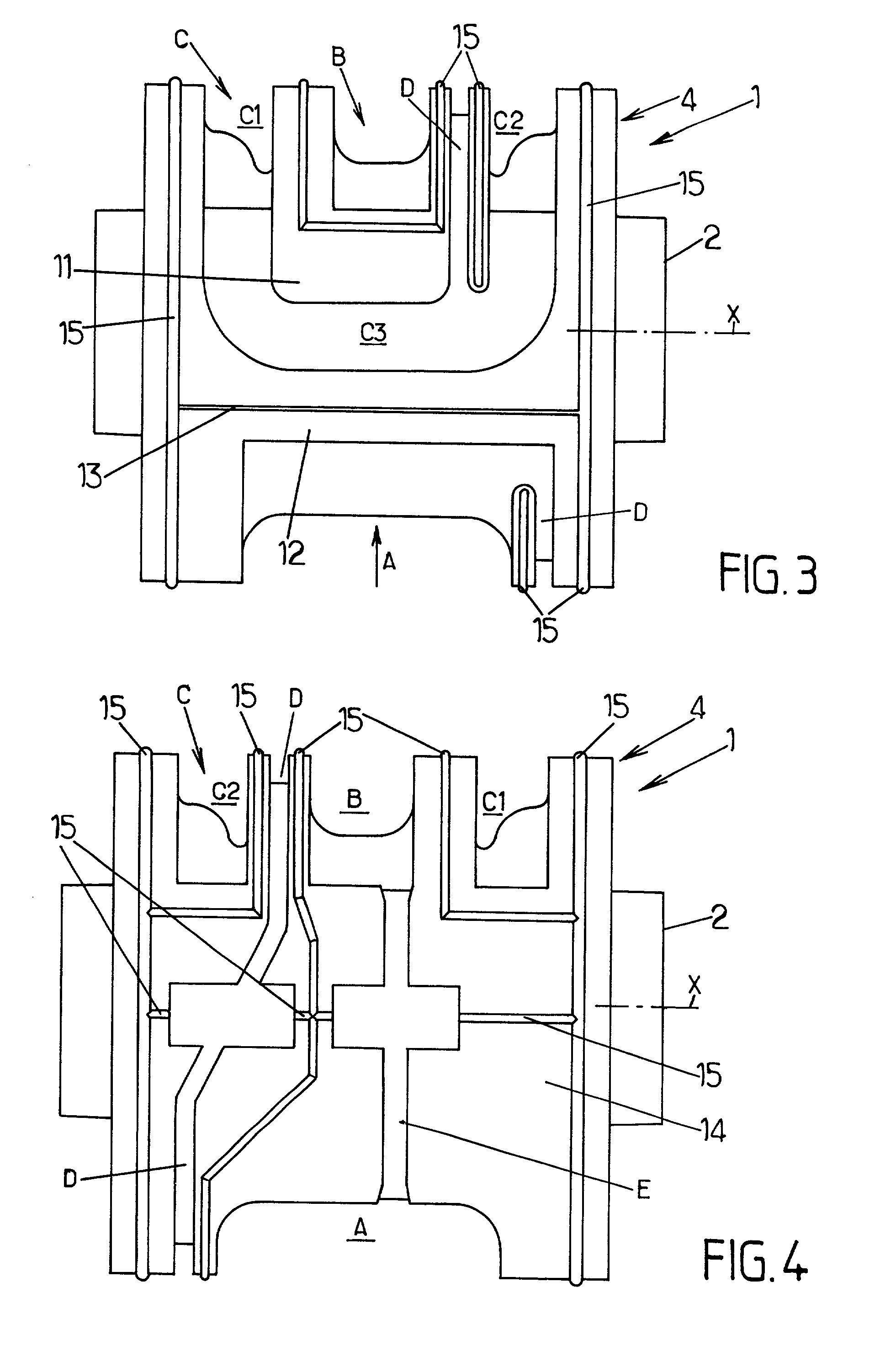

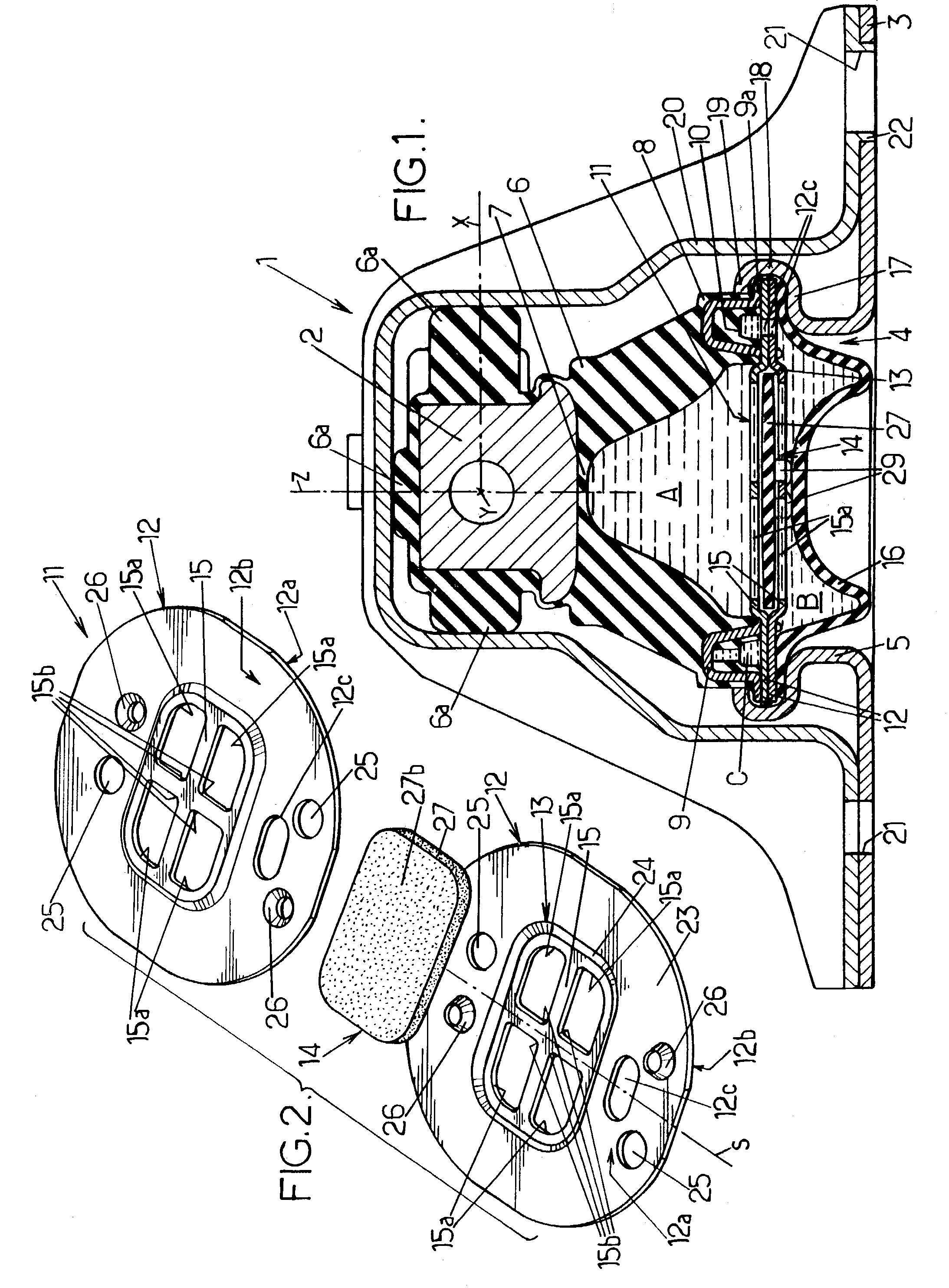

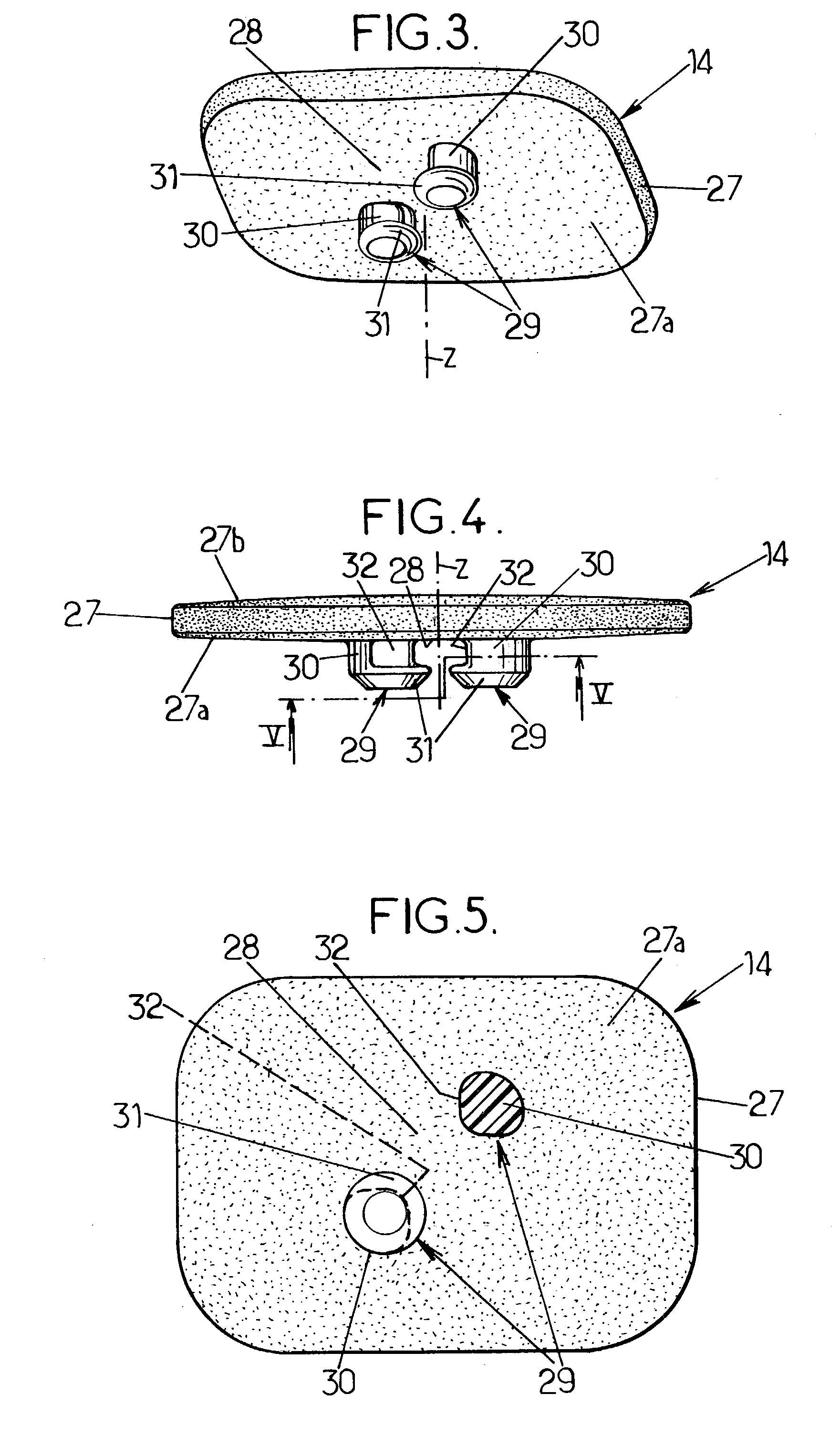

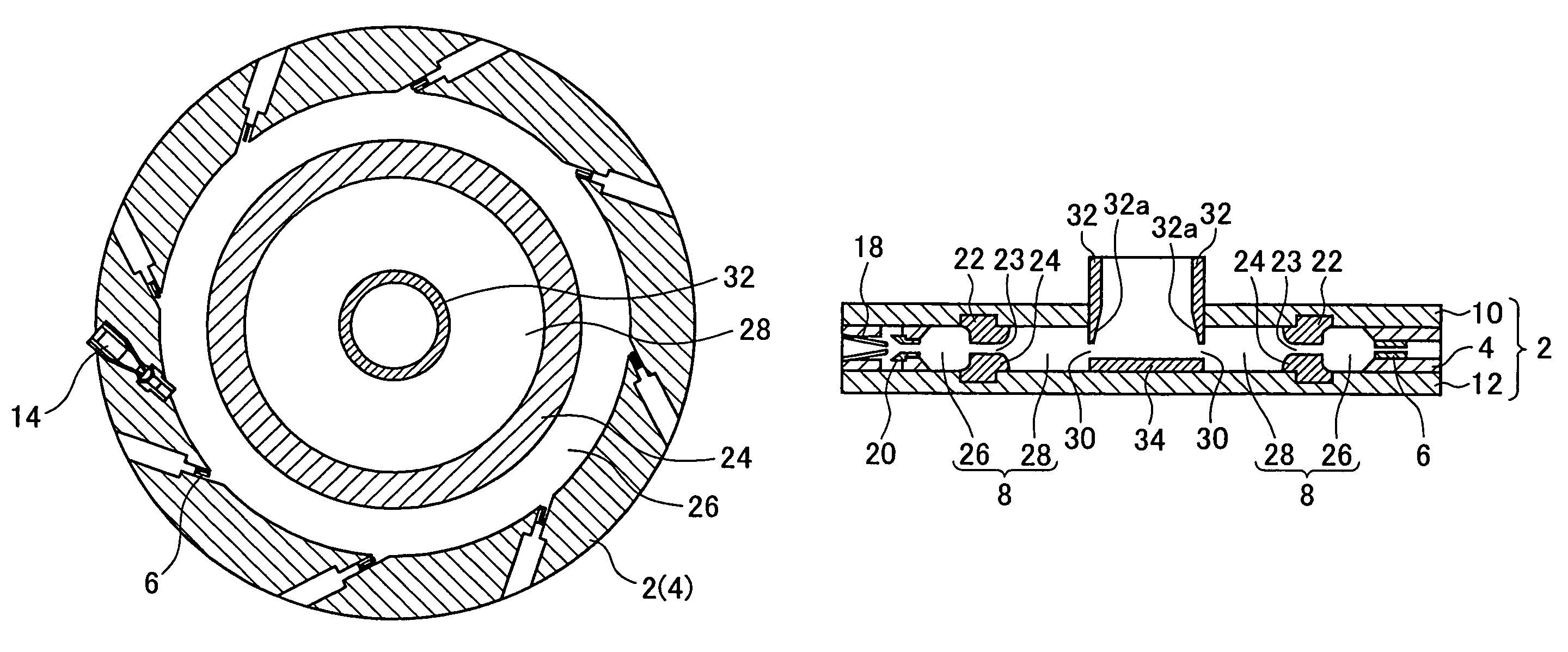

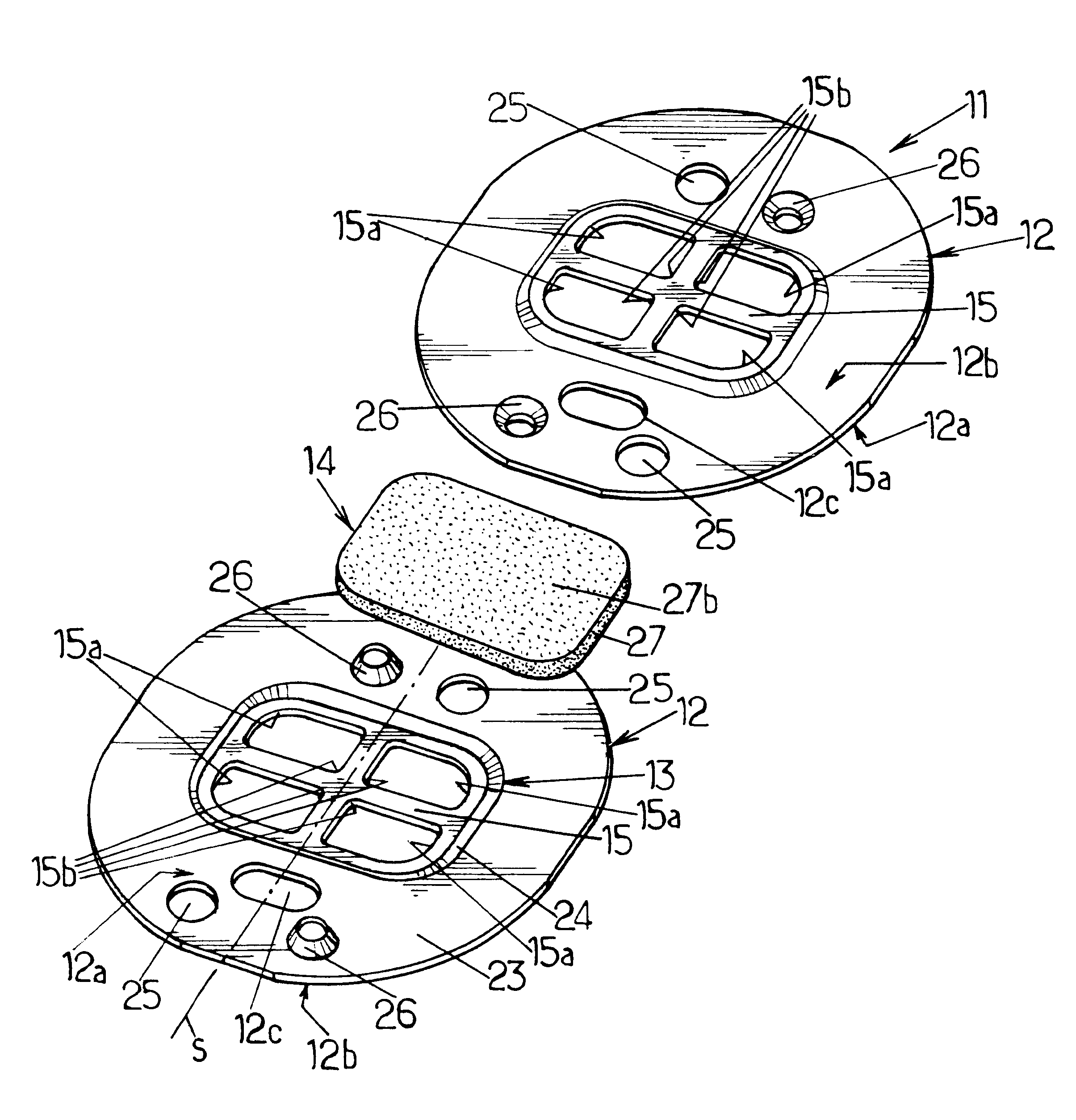

Hydraulic vibration-damping support including a clip-on decoupling flap

InactiveUS20030080482A1Precise positioningEasy to manufactureMachine framesLiquid springsElastomerGrating

A hydraulic vibration-damping support comprising two strength members interconnected by an elastomer body which defines a working chamber communicating with a compensation chamber via a constricted passage. The two hydraulic chambers are separated from each other by a rigid partition formed by two gratings disposed one on the other, and a decoupling flap is mounted with a small amount of clearance between the gratings. The decoupling flap is provided with two catches that are clipped onto one of the gratings.

Owner:HUTCHINSON SA

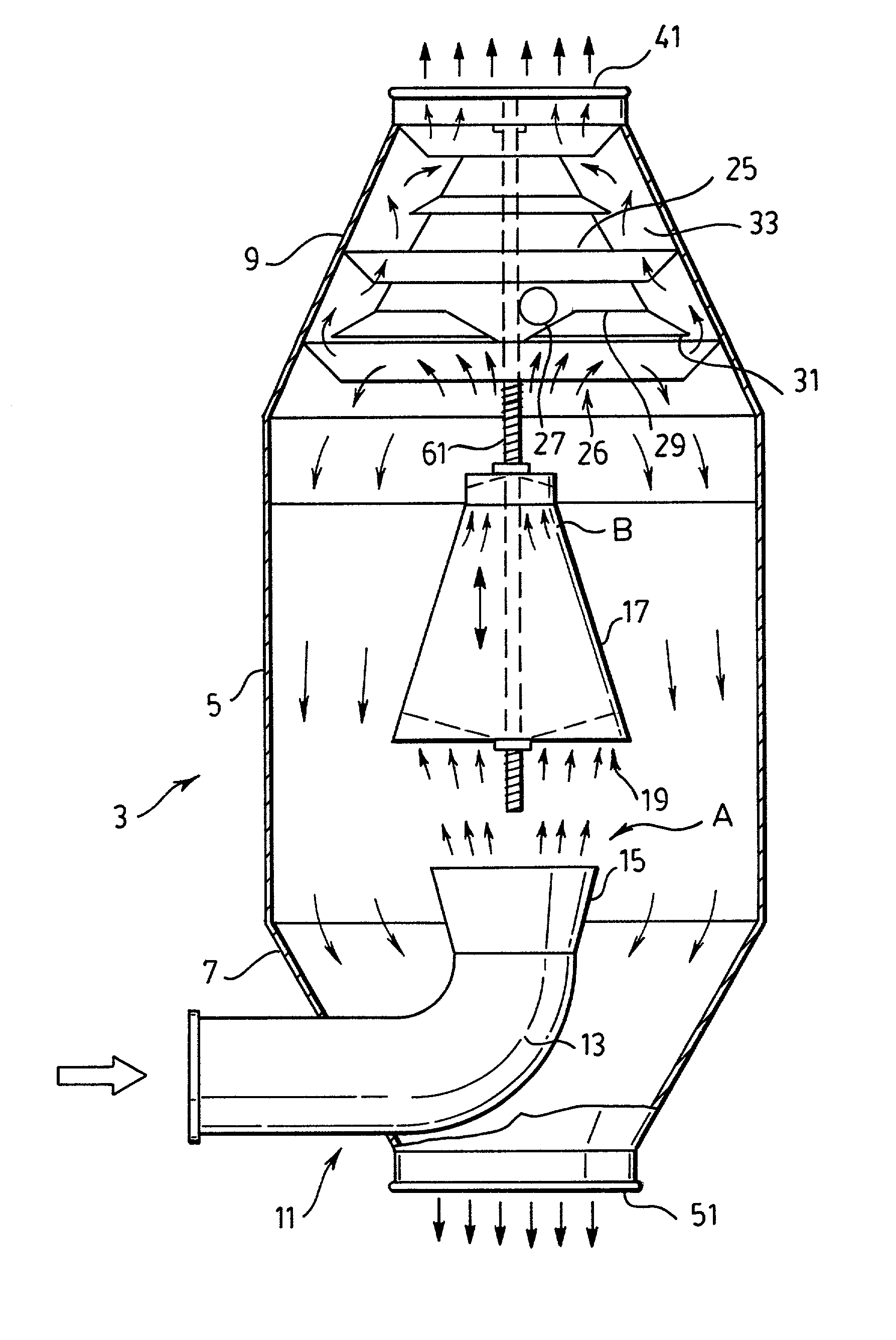

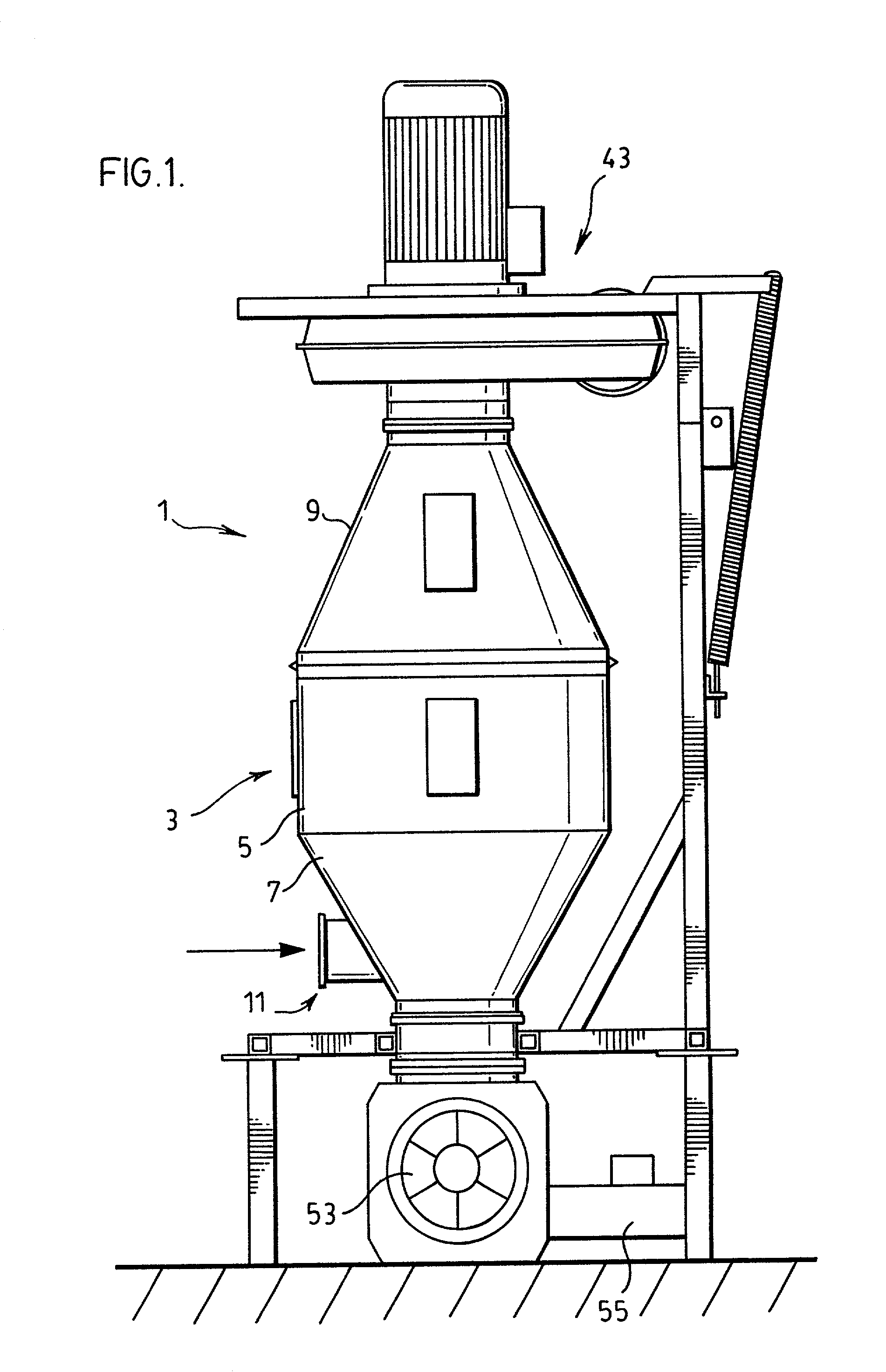

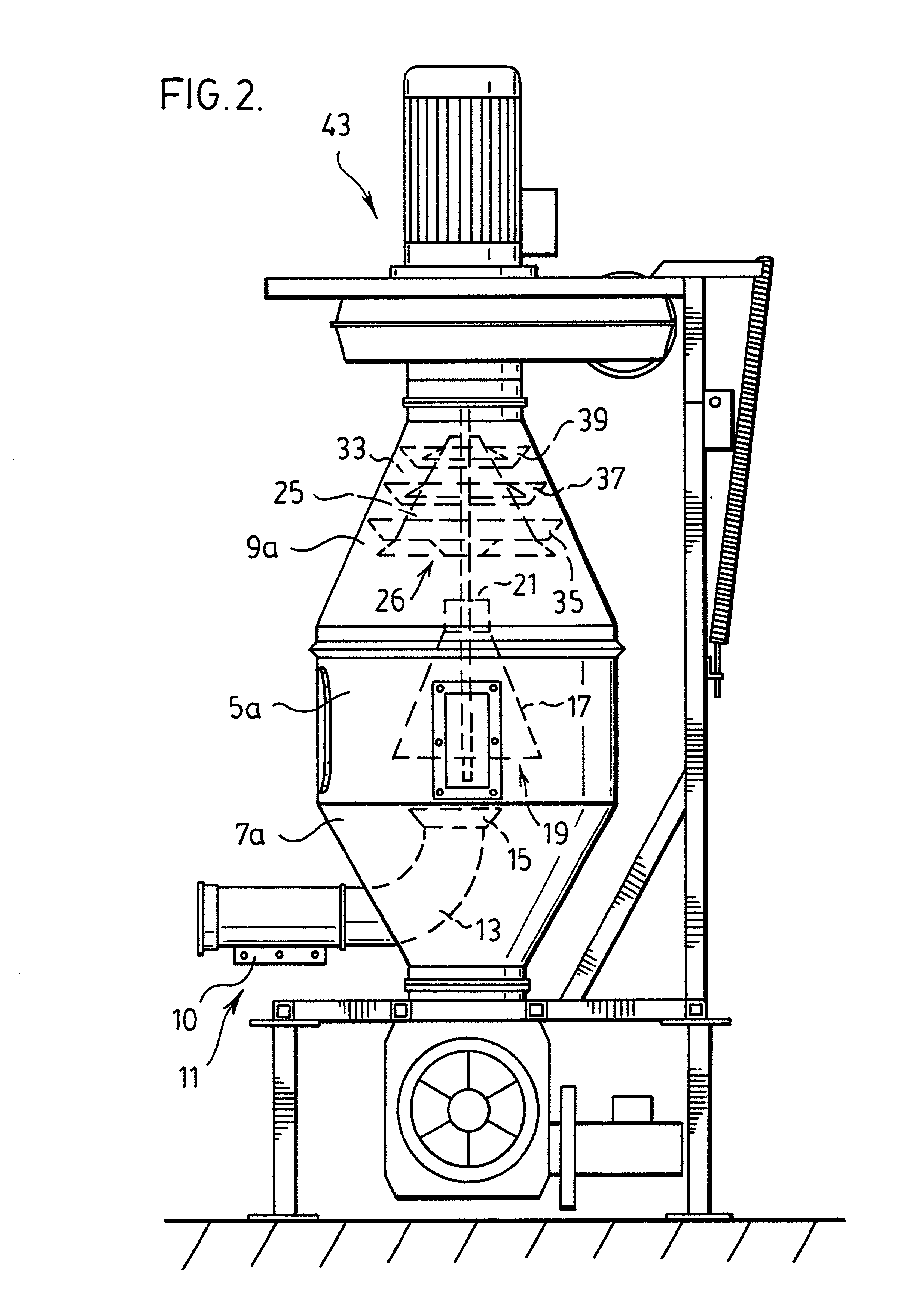

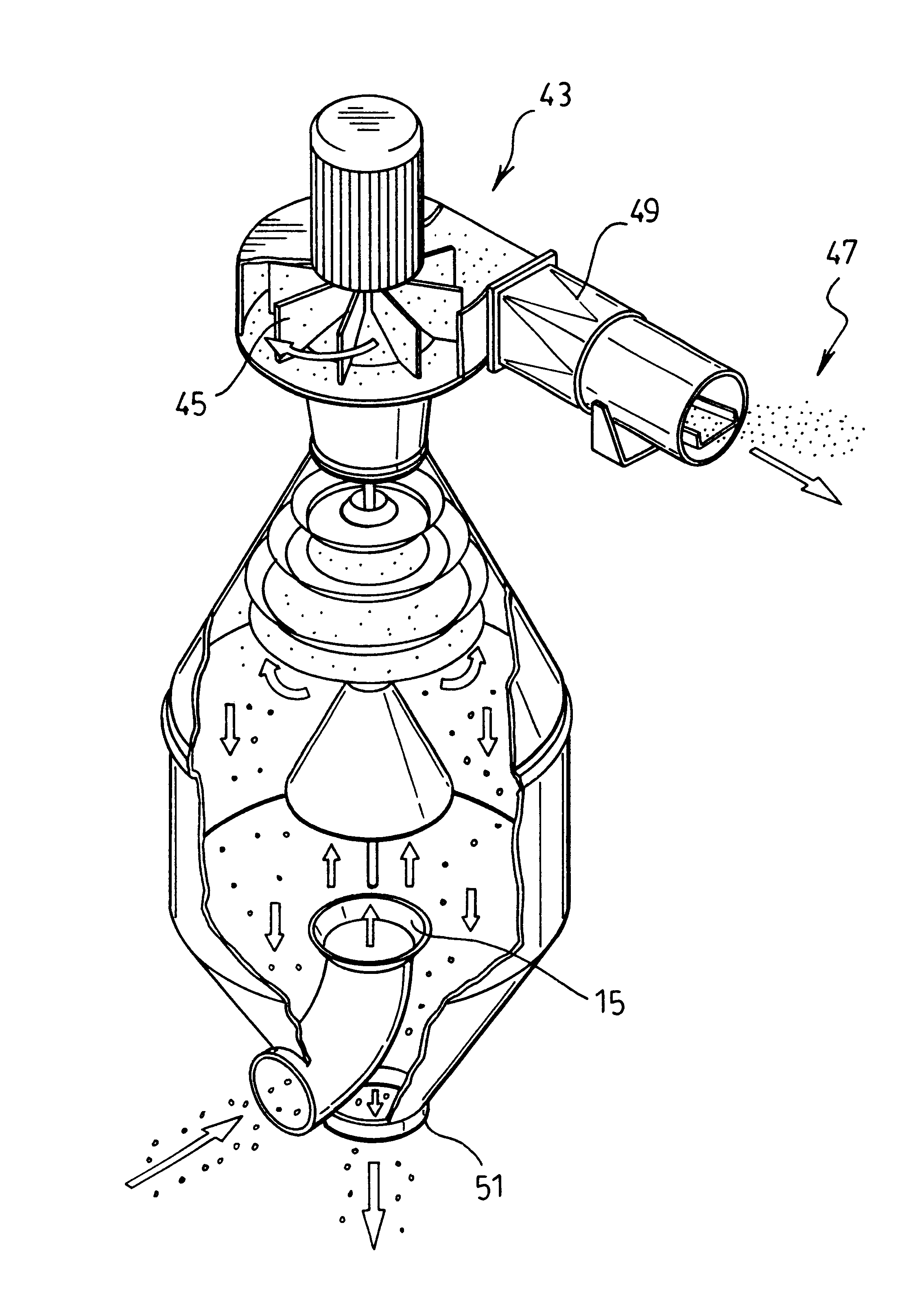

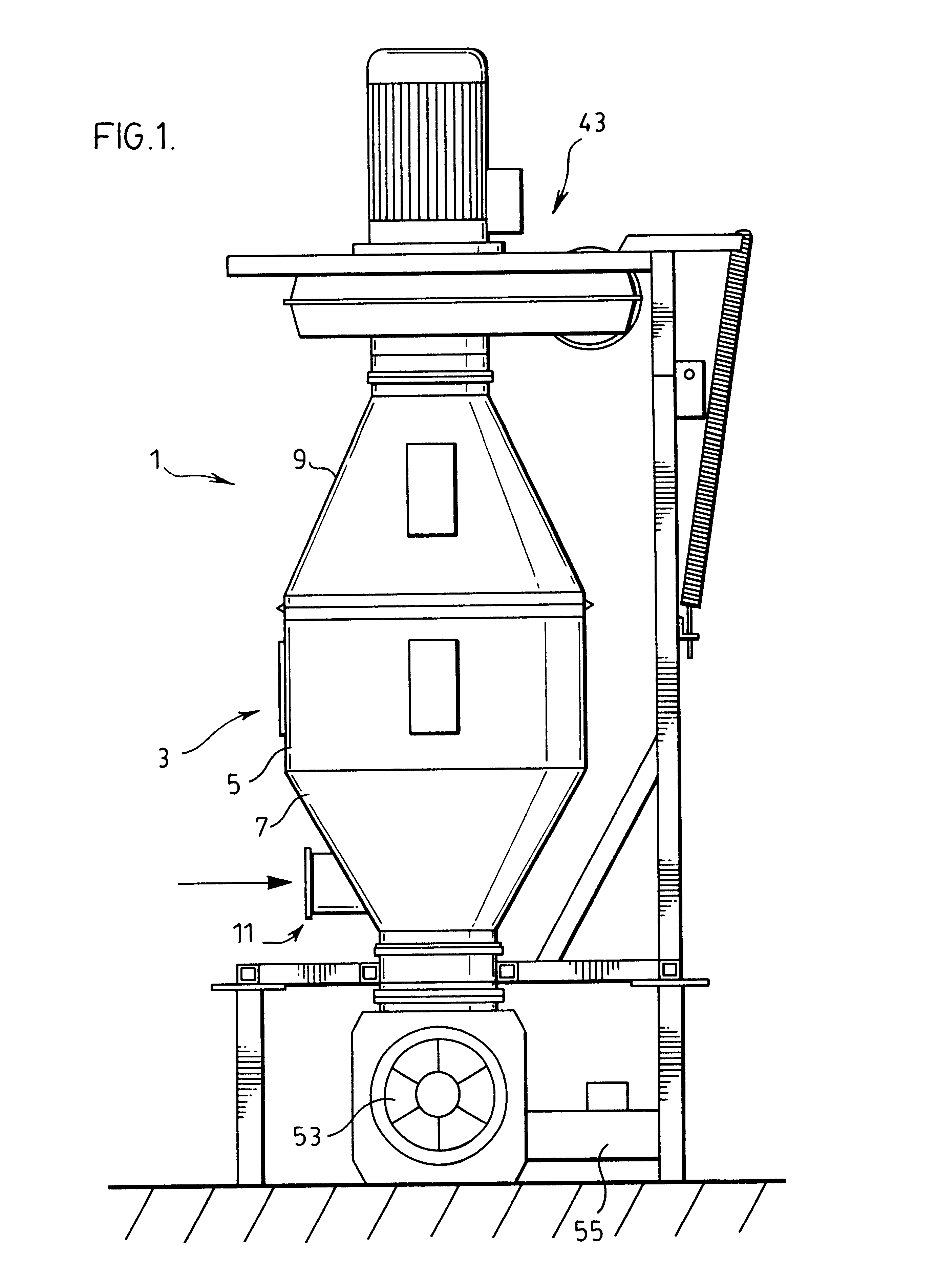

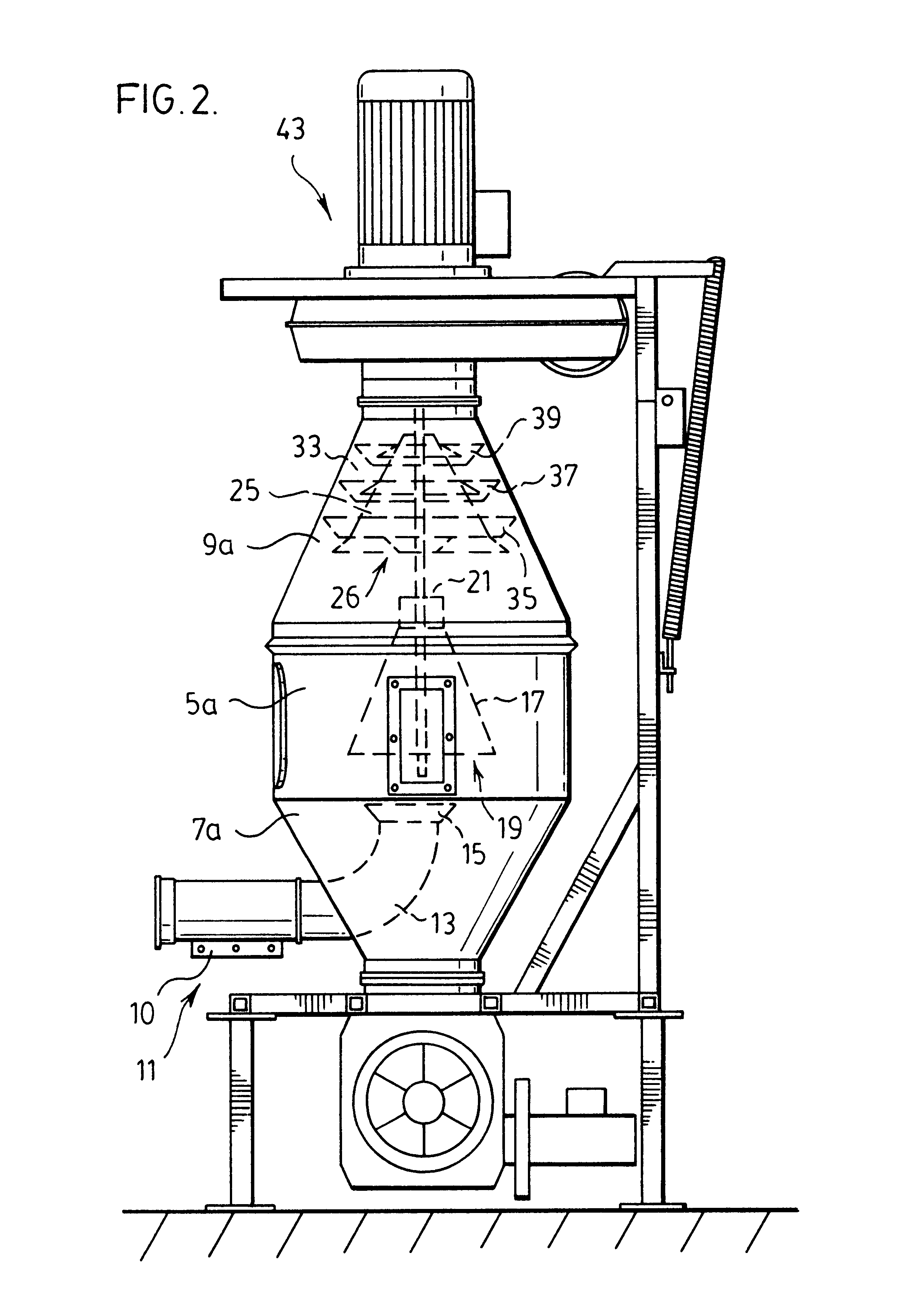

Method apparatus for separating unwanted matter from granular material

In a method of separating unwanted fine matter from heavier granular matter a flow of the material is produced under vacuum firstly through alternating expansion and contraction passages and then against impact surfaces to cause multiple redirections of the material and separation of the heavier granular material from the material flow.

Owner:VAN OIRSCHOT FRANK

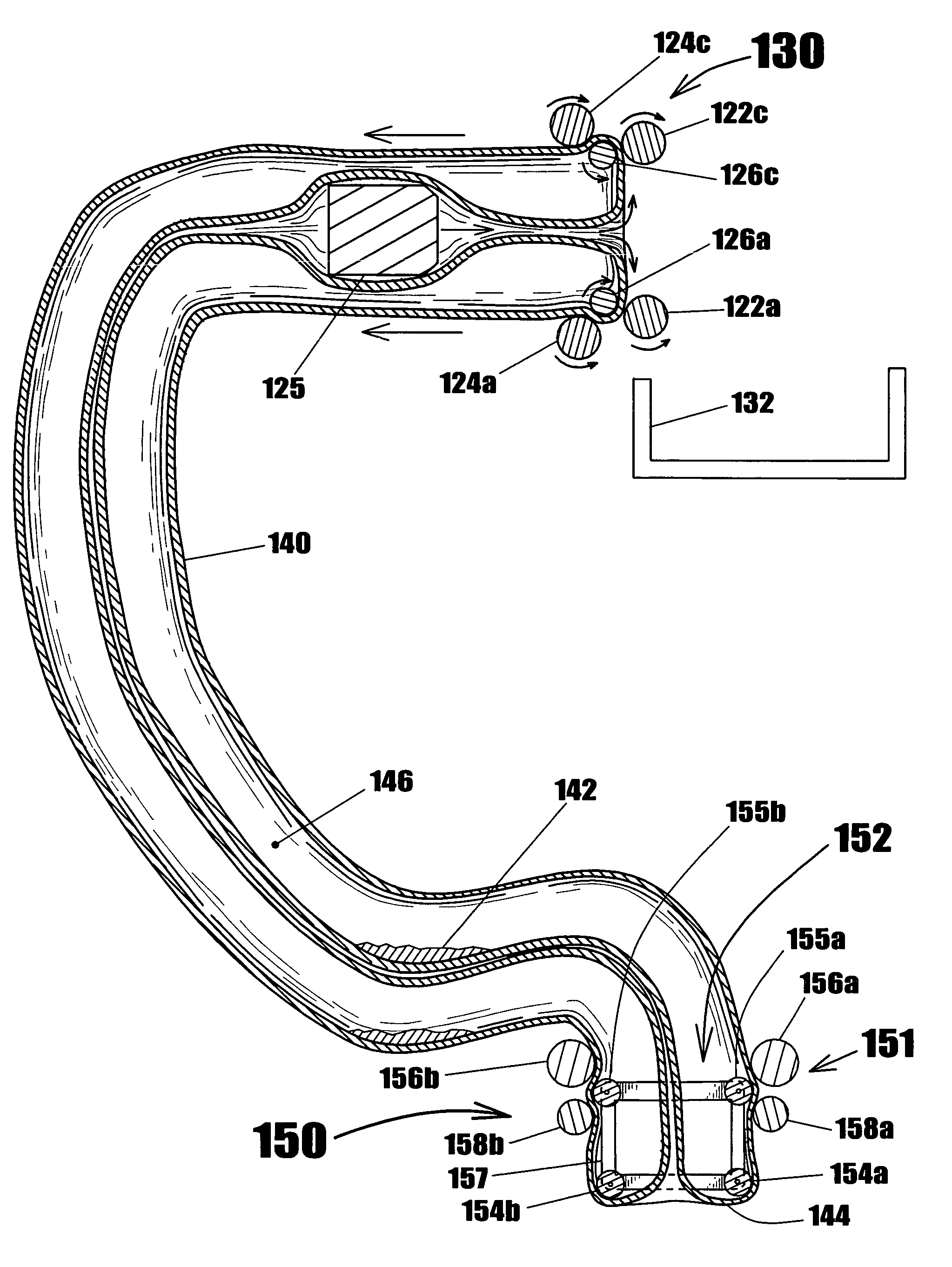

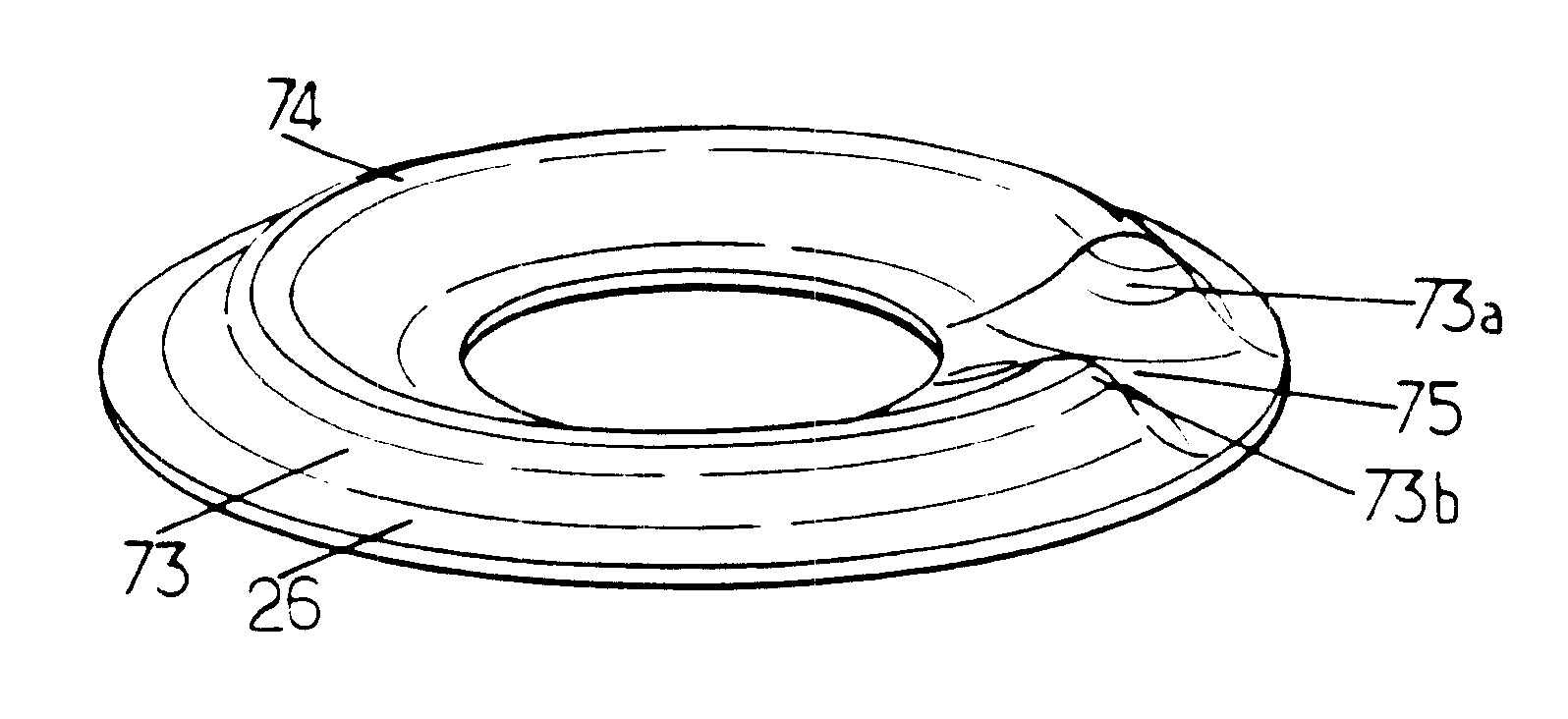

Torus-shaped conveyer and gripper

Owner:RAGNER GARY DEAN +1

Method apparatus for separating unwanted matter from granular material

In a method of separating unwanted fine matter from heavier granular matter a flow of the material is produced under vacuum firstly through alternating expansion and contraction passages and then against impact surfaces to cause multiple redirections of the material and separation of the heavier granular material from the material flow.

Owner:VAN OIRSCHOT FRANK

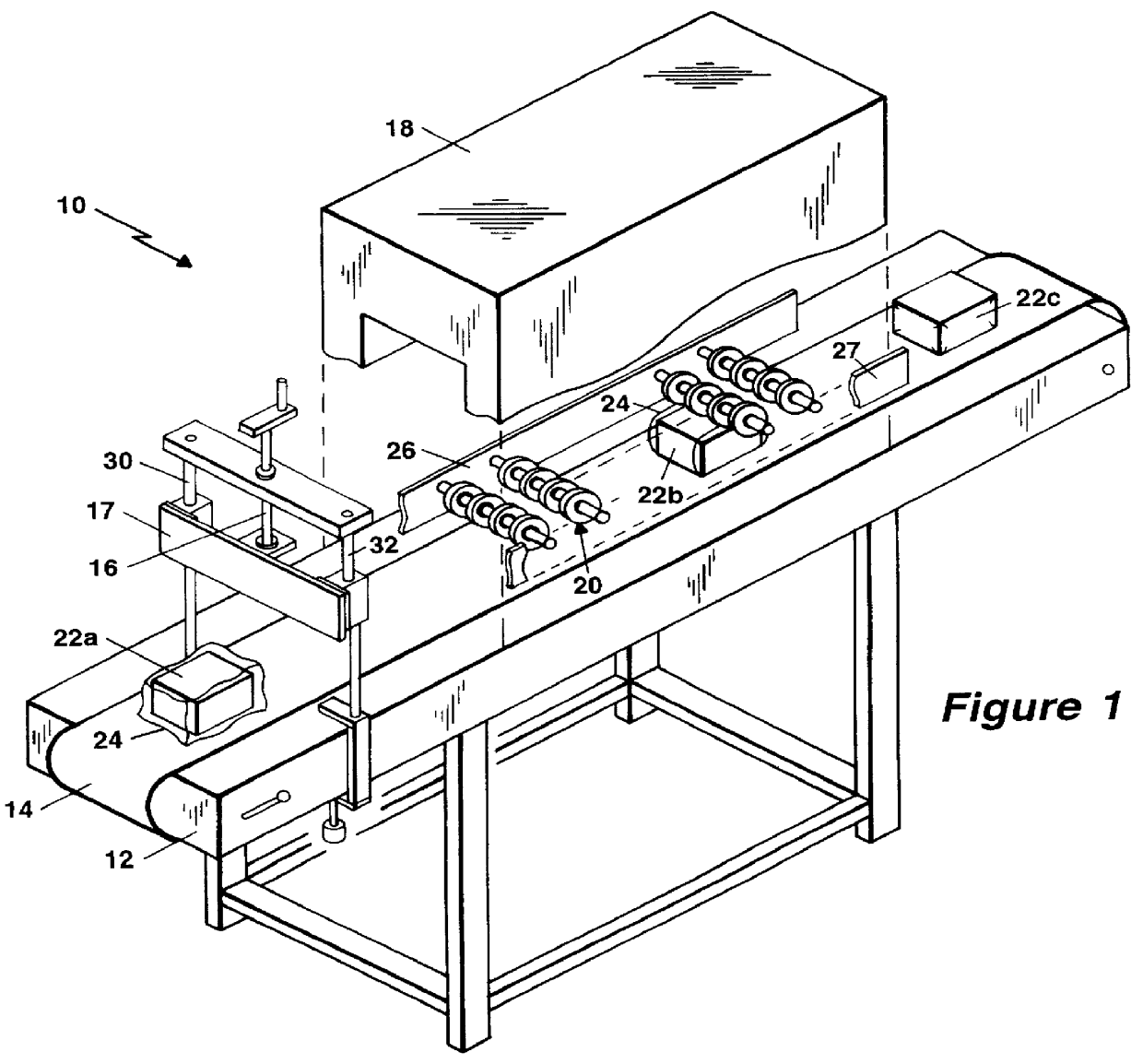

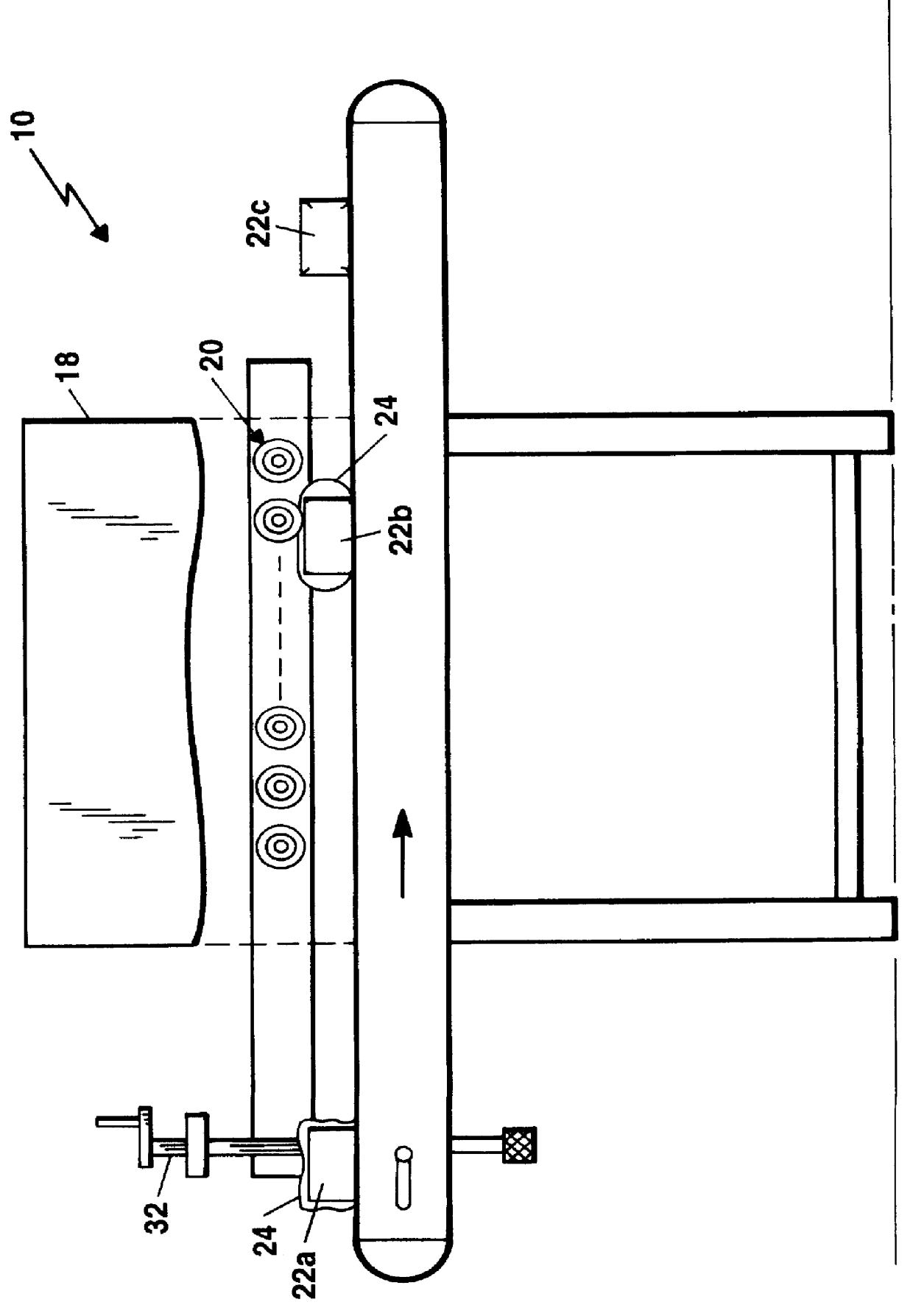

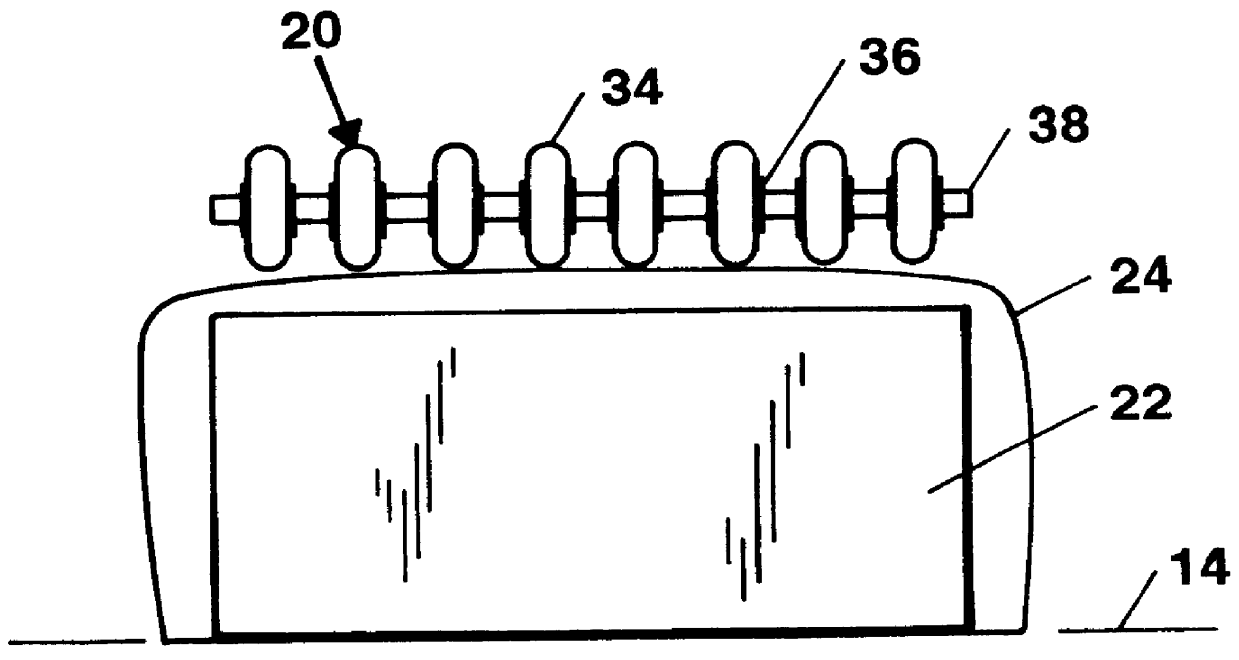

Method and apparatus for controlling shrinkage of a thin film

InactiveUS6158199AEasy to adaptWrappers shrinkageThermal conductivityElectrical and Electronics engineering

An apparatus and method for controlling the size and shape of a shrink film envelope around an article or a package to prevent the formation of wrinkles and bunching of the film when it shrinks. The apparatus comprises a hot air shrink tunnel having a conveyor for moving the article on packages through the tunnel. An assembly is position within the tunnel a preadjusted distance away from the article forming a fixed boundary to which the film envelope expands and is restricted, causing the air within the film envelope to be directed to areas around the article to keep the film from touching the article until the film shrinks. The assembly comprises material of low thermal conductivity such as a plurality of wooden wheels for contacting the film envelope.

Owner:EMERY III CELEVATORON W +1

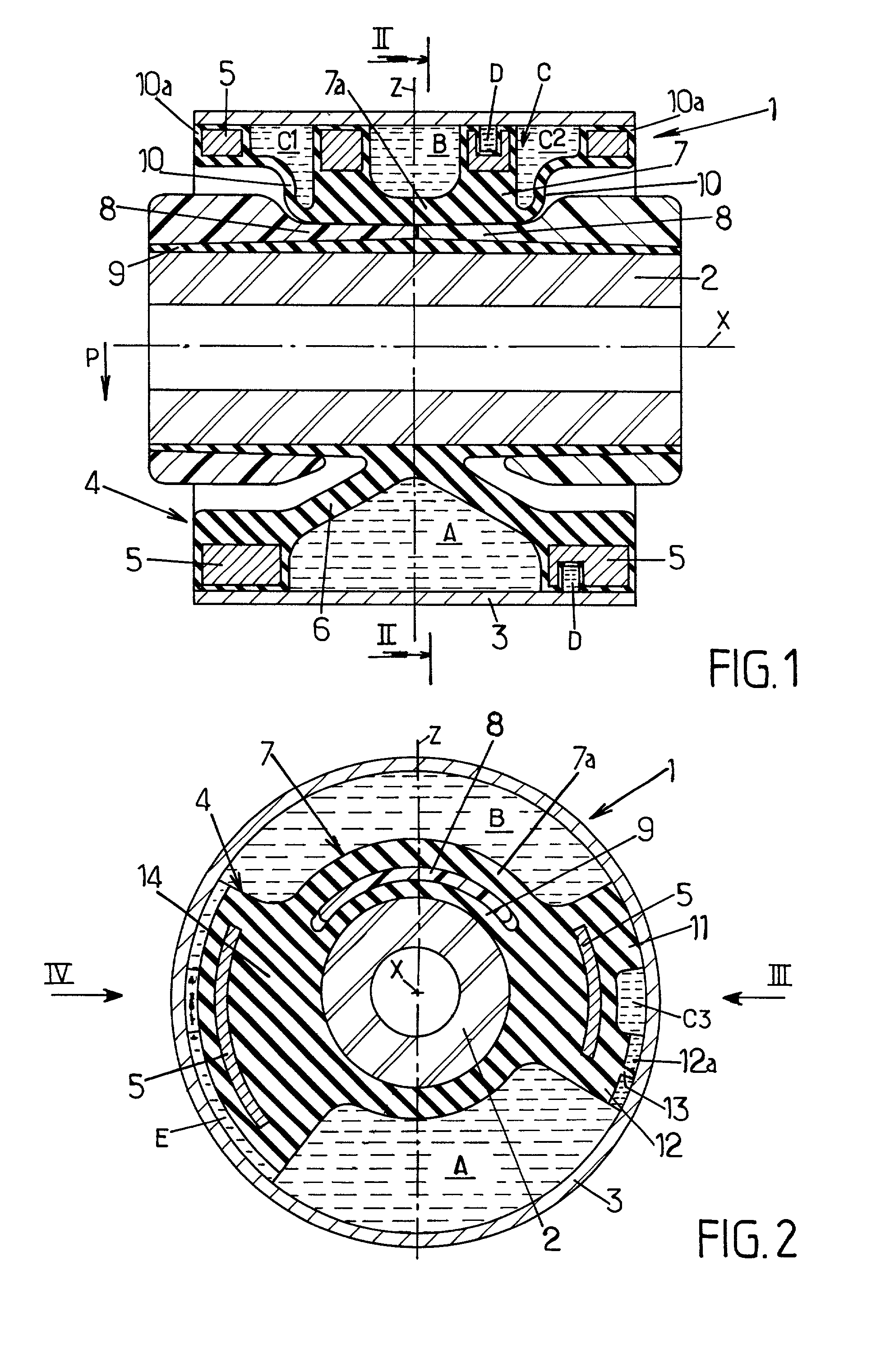

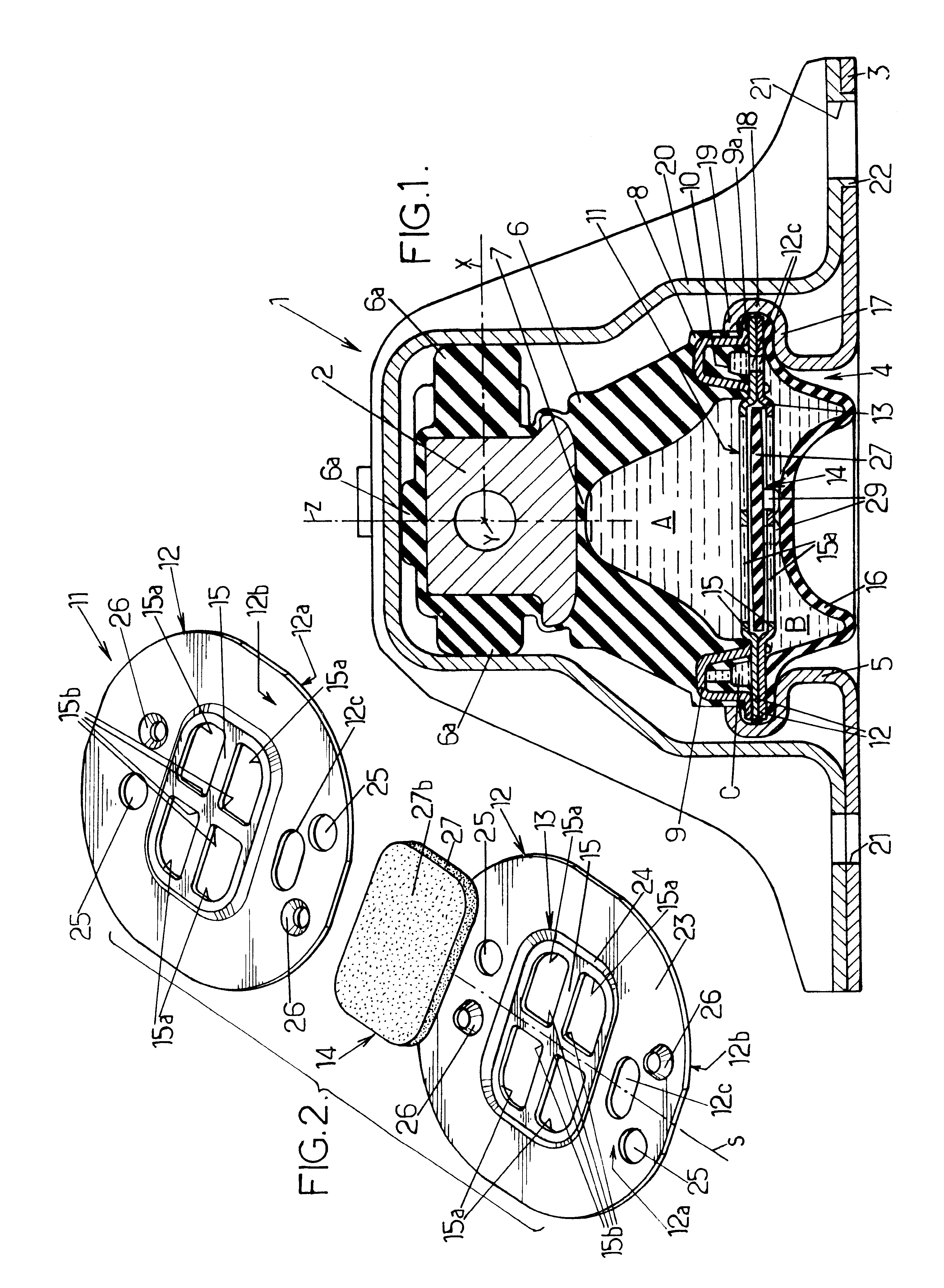

Hydraulic vibration-damping support

InactiveUS20030038414A1Mitigate such drawbackLightweight and inexpensiveMachine framesLiquid springsElastomerMetal forming

A hydraulic vibration-damping support comprising two strength members interconnected by an elastomer body defining in part a working chamber filled with liquid, said working chamber communicating via a constricted passage with a compensation chamber separated from said working chamber by a rigid partition. The constricted passage is made up of two stages defined by two pieces of sheet metal forming the rigid partition.

Owner:HUTCHINSON SA

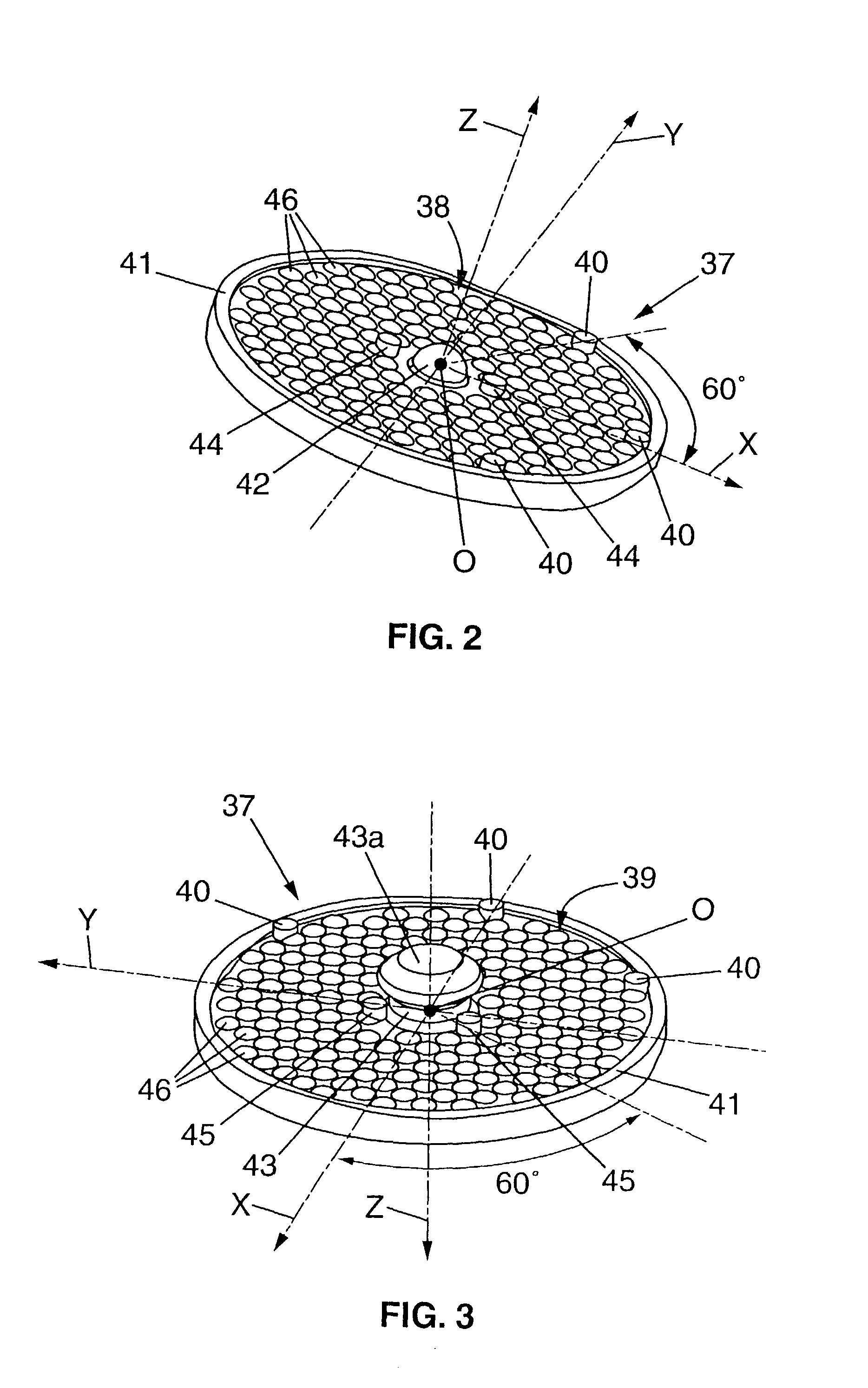

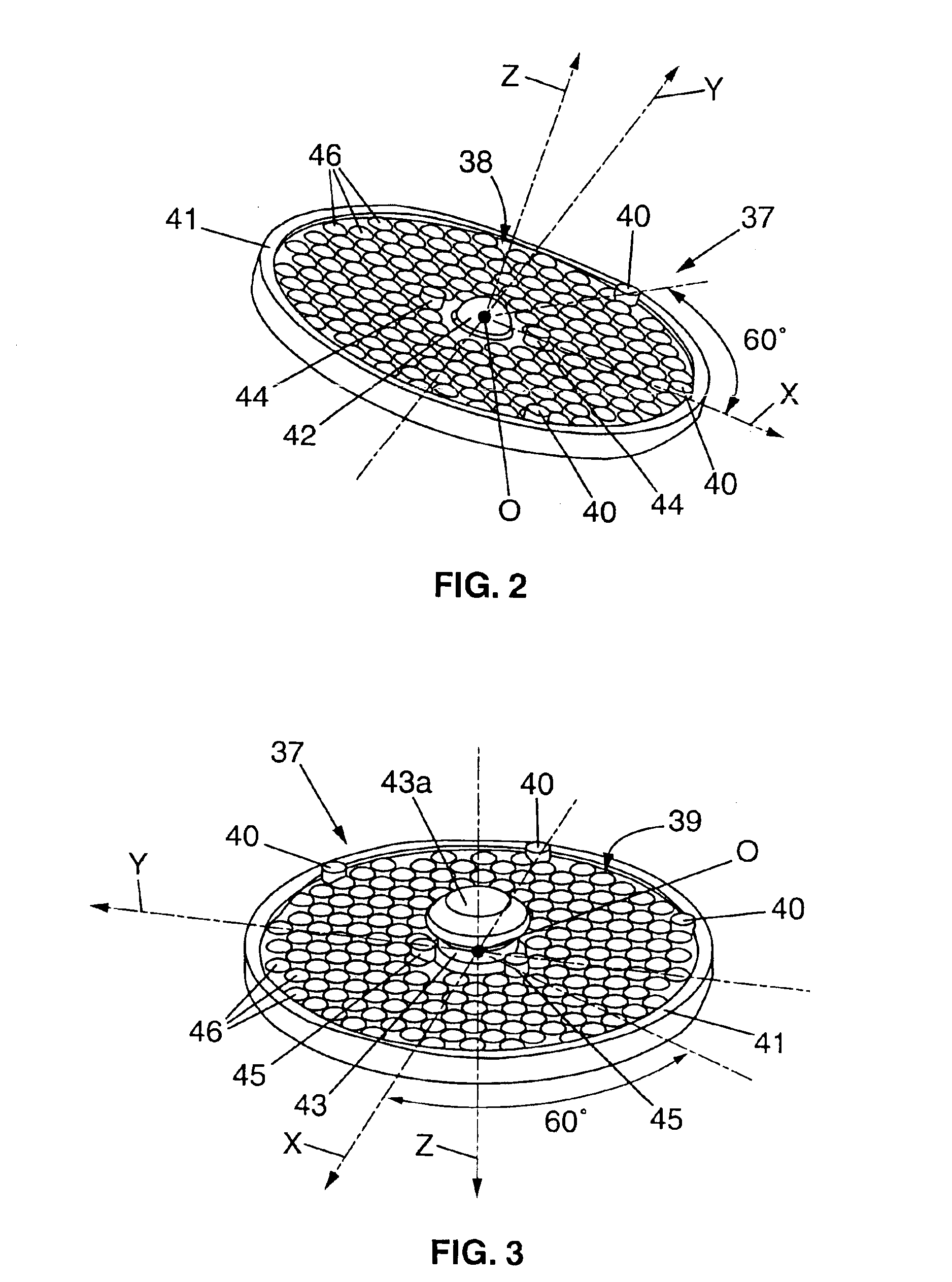

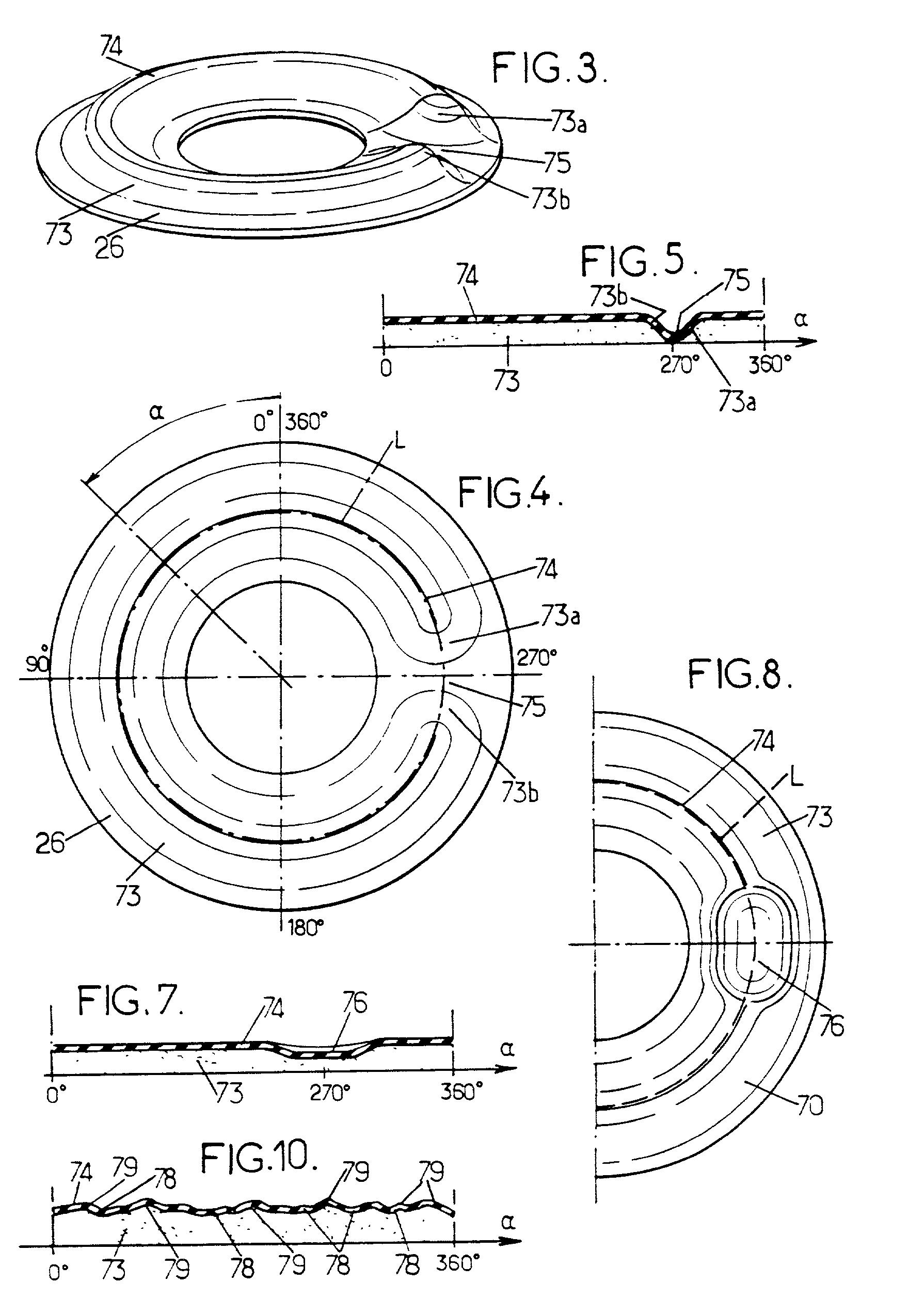

Jet mill

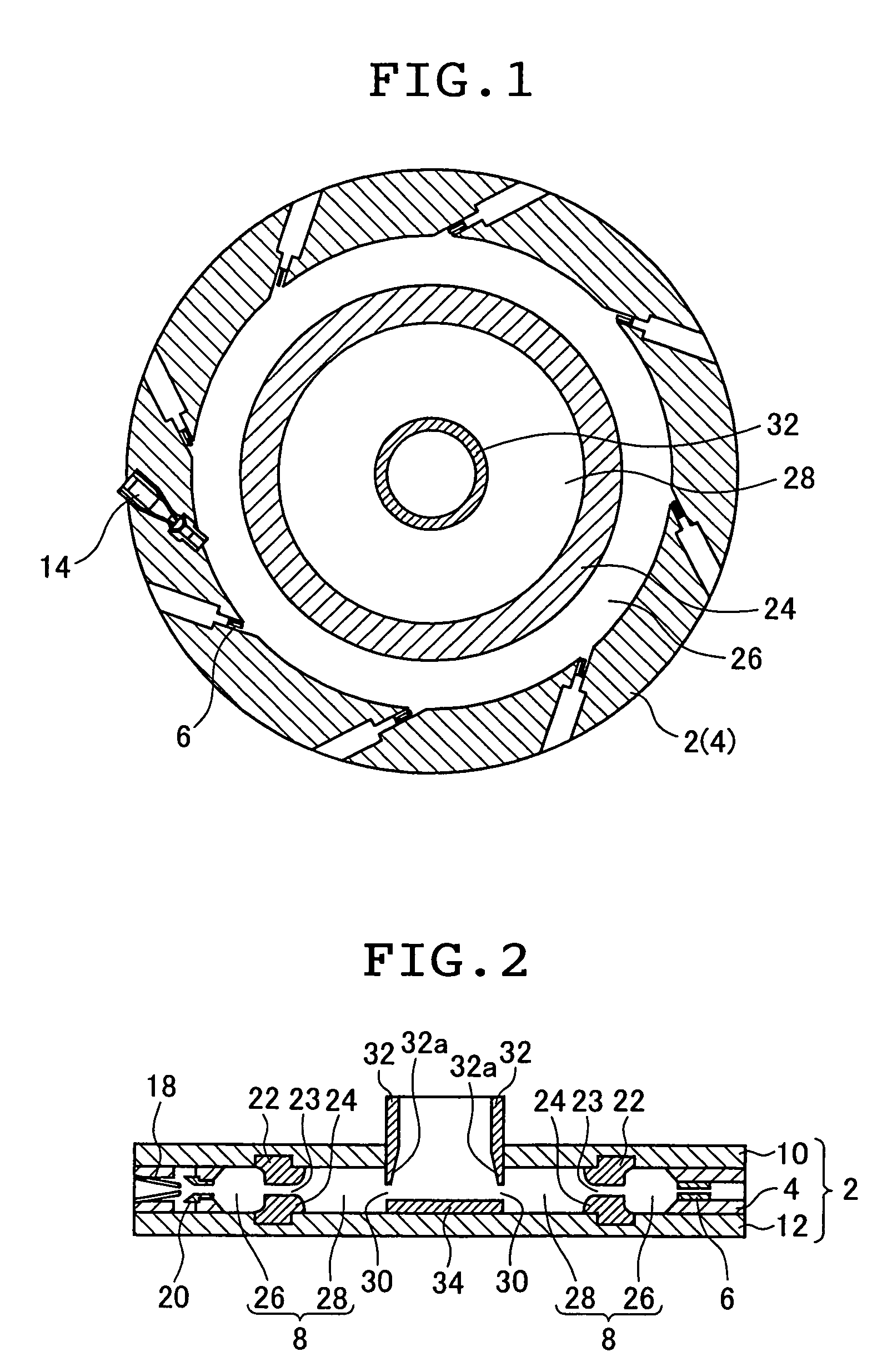

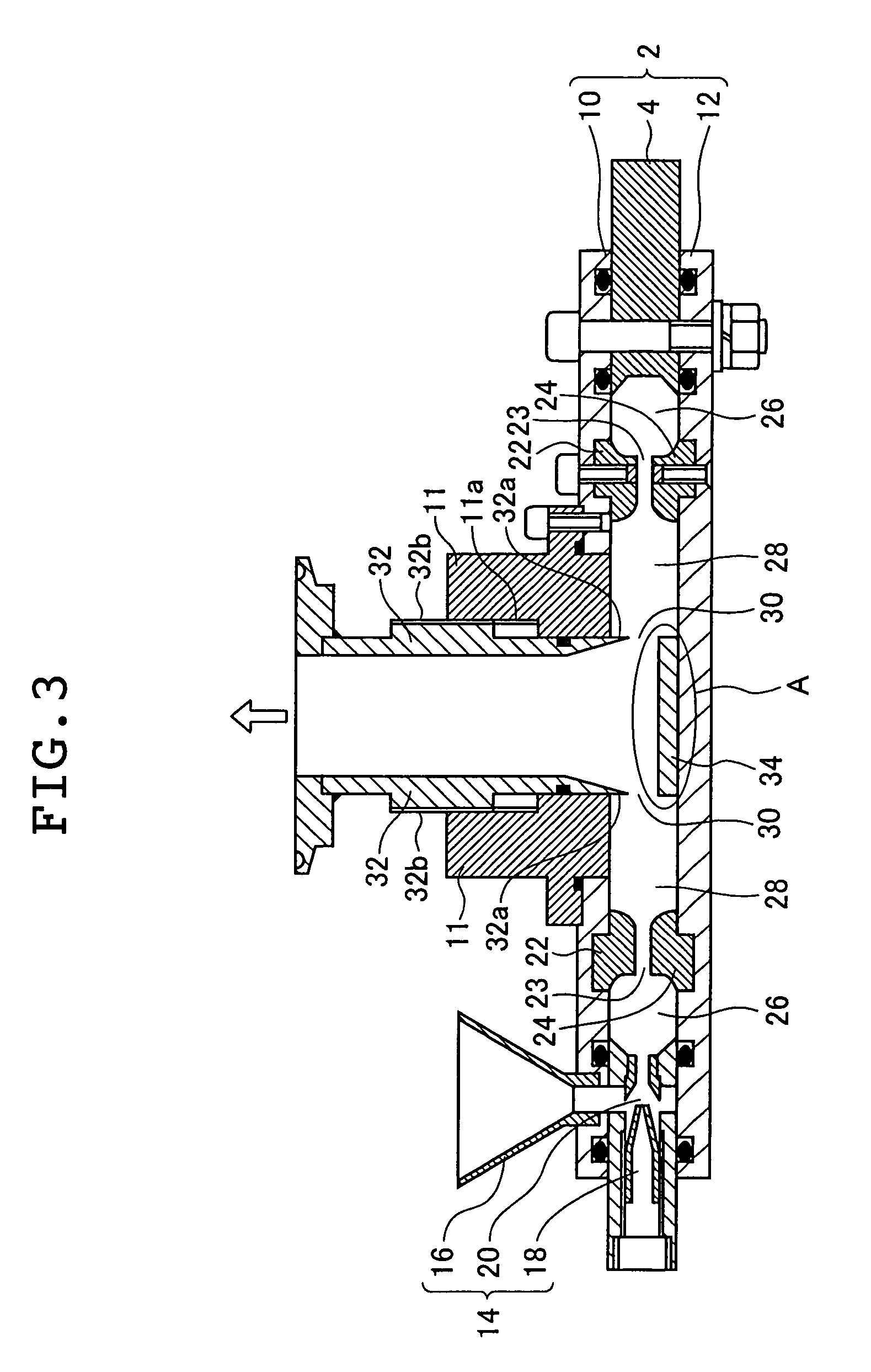

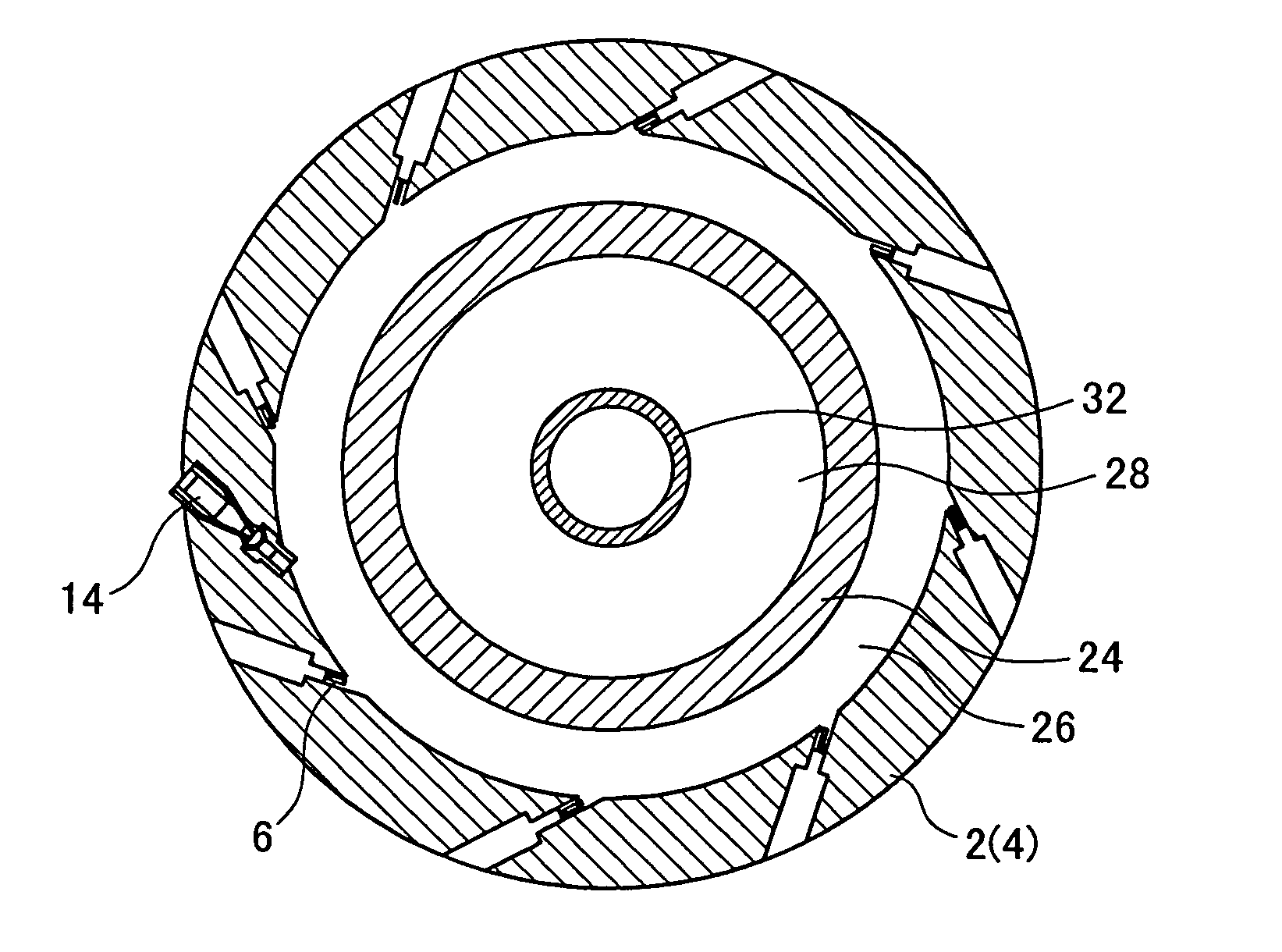

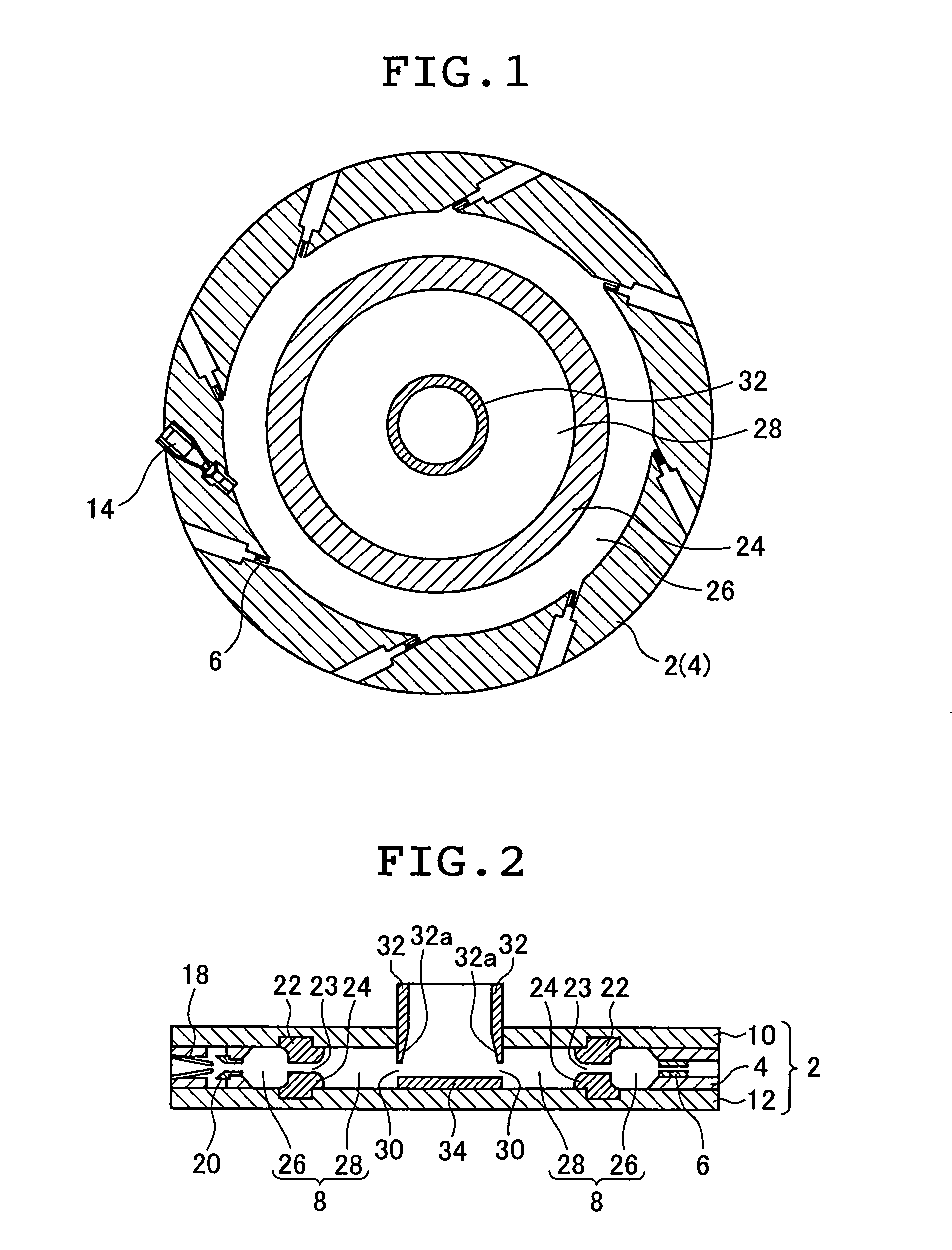

ActiveUS7258290B2Simple configurationEasy can be separated and reassembledGas current separationGrain millingJet millAirflow

A jet mill has a disk-shaped hollow part in the interior of the mill body. The hollow part is divided into an annular grinding zone for grinding a material by high-speed swirling air flows supplied through plural air nozzles and an annular classifying zone provided inside the grinding zone and communicated to an exit space for classifying the ground material by the swirling air flows in the grinding zone. An annular first constricted passageway is arranged between the grinding zone and the classifying zone to thereby divide and communicate them, and preferably an annular second constricted passageway between the classifying zone and the inside exit thereof. Accordingly, a jet mill realizing a high classification precision for a desired particle size of ground material with a narrow size distribution and having a simple inner configuration to allow easy cleaning before and after operation can be provided.

Owner:NISSHIN ENG

Jet mill

ActiveUS20050051649A1Simple configurationEasy to separateGas current separationGrain millingJet millAirflow

A jet mill has a disk-shaped hollow part in the interior of the mill body. The hollow part is divided into an annular grinding zone for grinding a material by high-speed swirling air flows supplied through plural air nozzles and an annular classifying zone provided inside the grinding zone and communicated to an exit space for classifying the ground material by the swirling air flows in the grinding zone. An annular first constricted passageway is arranged between the grinding zone and the classifying zone to thereby divide and communicate them, and preferably an annular second constricted passageway between the classifying zone and the inside exit thereof. Accordingly, a jet mill realizing a high classification precision for a desired particle size of ground material with a narrow size distribution and having a simple inner configuration to allow easy cleaning before and after operation can be provided.

Owner:NISSHIN ENG

Hydraulic vibration-damping support including a clip-on decoupling flap

InactiveUS6676117B2Mitigate such drawbackPrecise positioningMachine framesLiquid springsElastomerGrating

A hydraulic vibration-damping support comprising two strength members interconnected by an elastomer body which defines a working chamber communicating with a compensation chamber via a constricted passage. The two hydraulic chambers are separated from each other by a rigid partition formed by two gratings disposed one on the other, and a decoupling flap is mounted with a small amount of clearance between the gratings. The decoupling flap is provided with two catches that are clipped onto one of the gratings.

Owner:HUTCHINSON SA

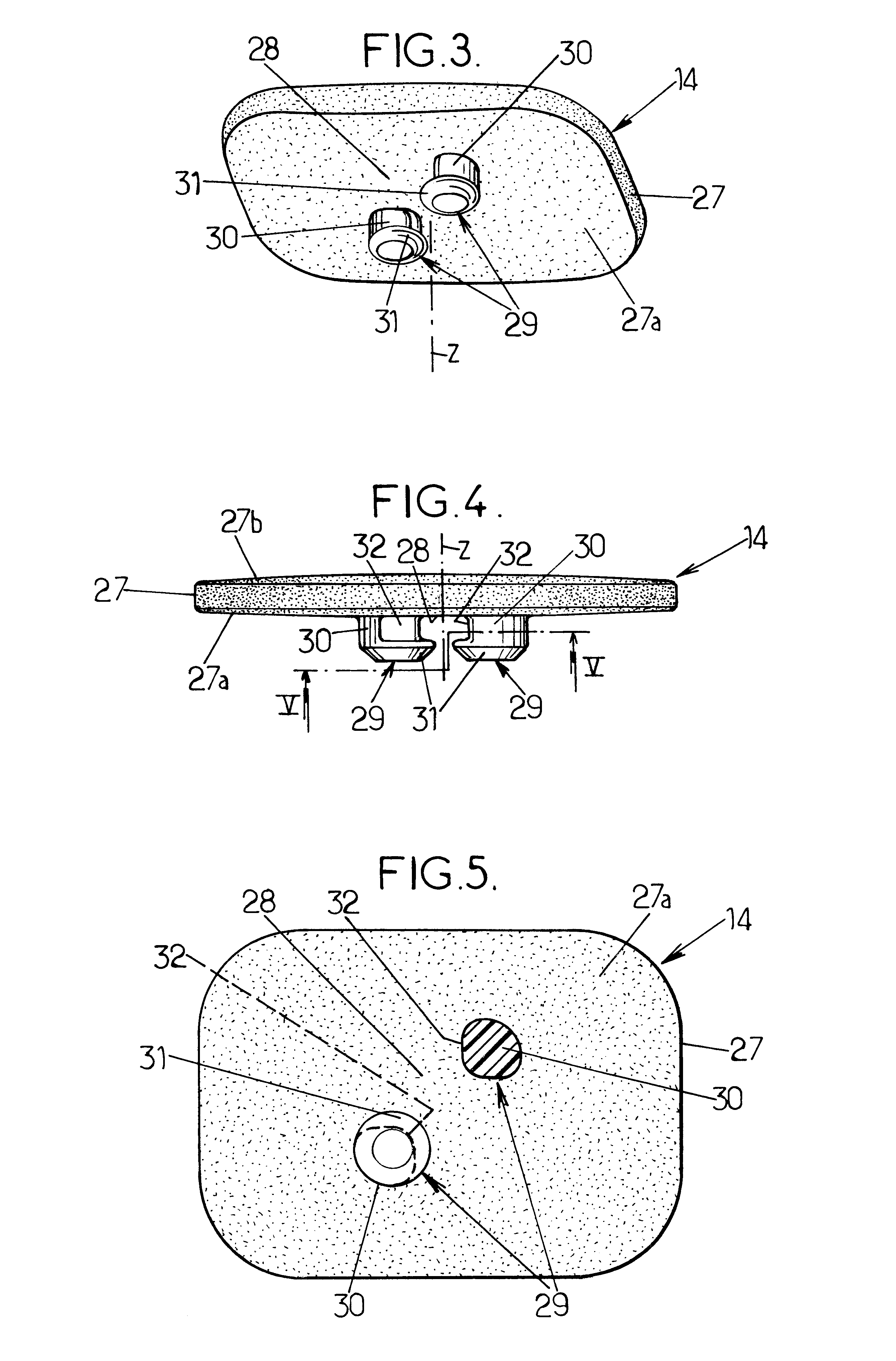

Hydraulic antivibration support

InactiveUS6601835B2Mitigate such drawbackReduce stiffnessMachine framesLiquid springsElastomerEngineering

The hydraulic antivibration support comprises two strength members interconnected by an elastomer body defining part of a liquid-filled working chamber which communicates via a constricted passage with a compensation chamber that is separated from said working chamber by a rigid partition. The compensation chamber is defined by an annular bellows presenting an annular fold which projects into the compensation chamber and which is of a shape that does not present circular symmetry.

Owner:HUTCHINSON SA

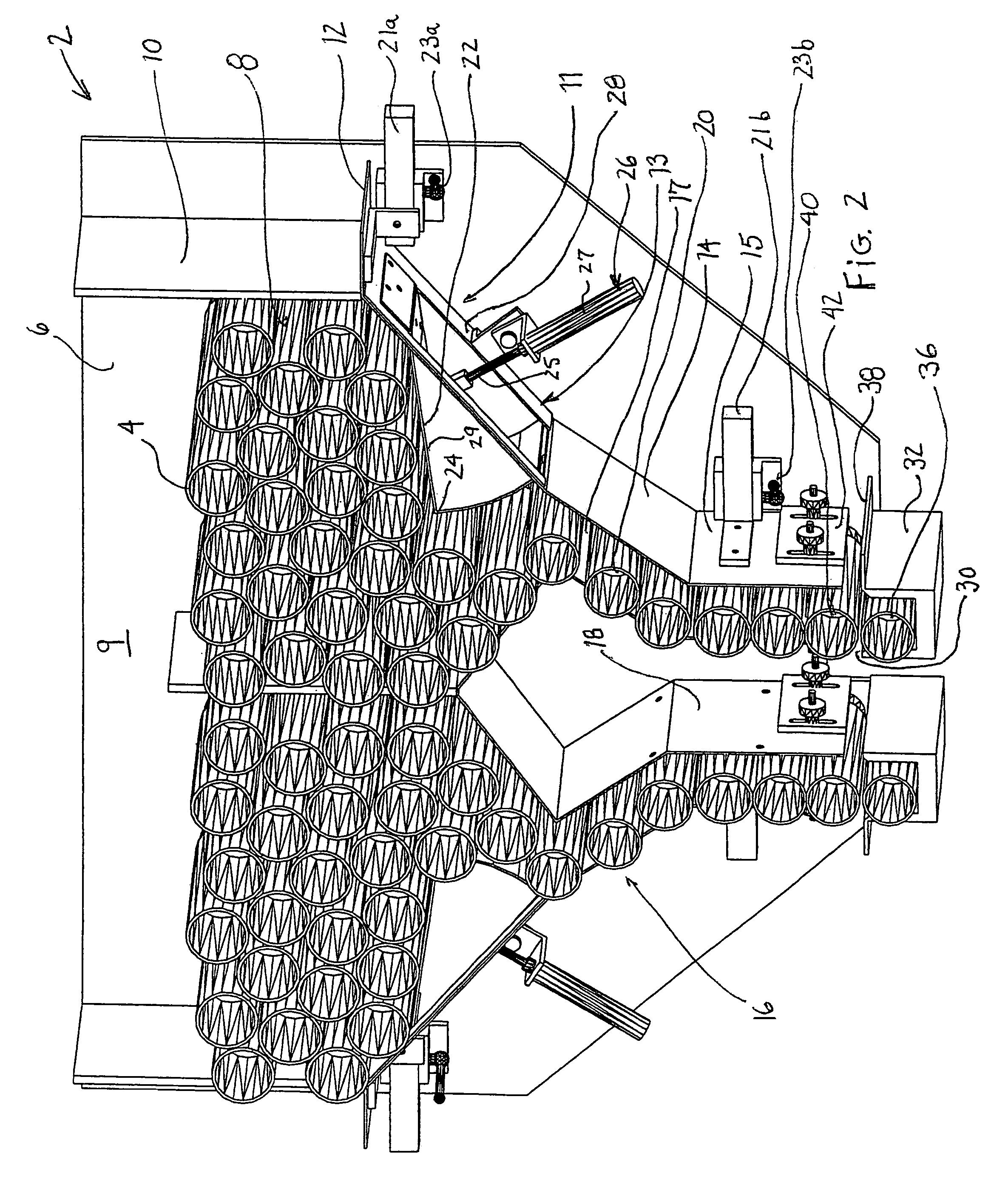

Tube dispensing magazine device and method

ActiveUS7415815B2Reduce static pressurePrevent egressRacksCoin-freed apparatus detailsGravity feedShrink tunnel

A magazine and tube dispensing method is provided. The magazine includes a receiving compartment for temporarily receiving unfilled tubes intended for filling with a flowable product, the compartment being formed with a movable outer rail wall. A gate assembly downstream from the receiving compartment includes a constriction passageway formed between a lateral inner wall and a lateral member wall allowing downward gravity feed of tubes only in a single file. The lateral member wall is movable in a direction toward or away from the lateral inner wall and integrally movable as a member of the outer rail wall, thereby adjusting a cross-sectional dimension of the passageway to accommodate processing of different diameter tubes.

Owner:CONOPCO INC D B A UNILEVER

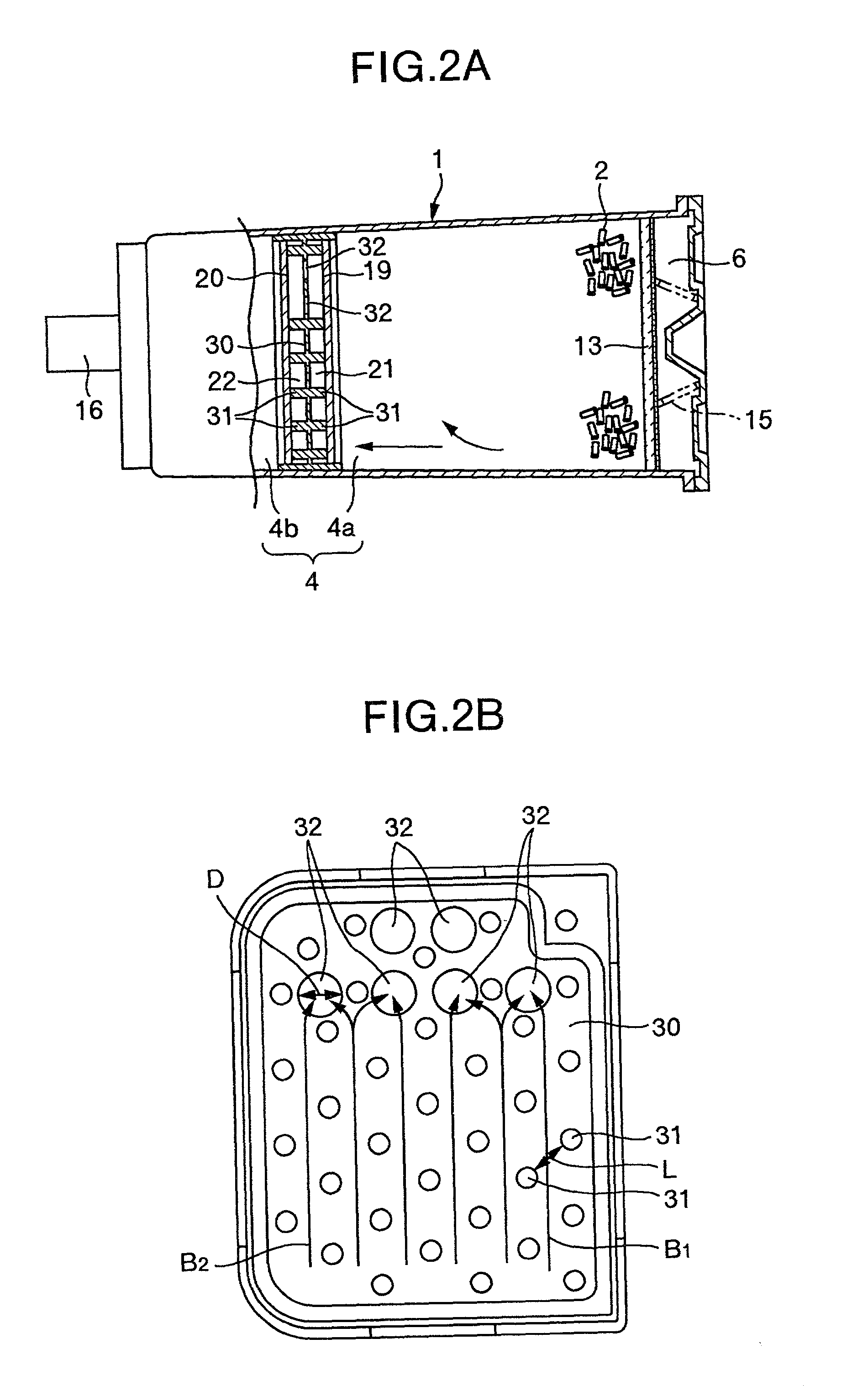

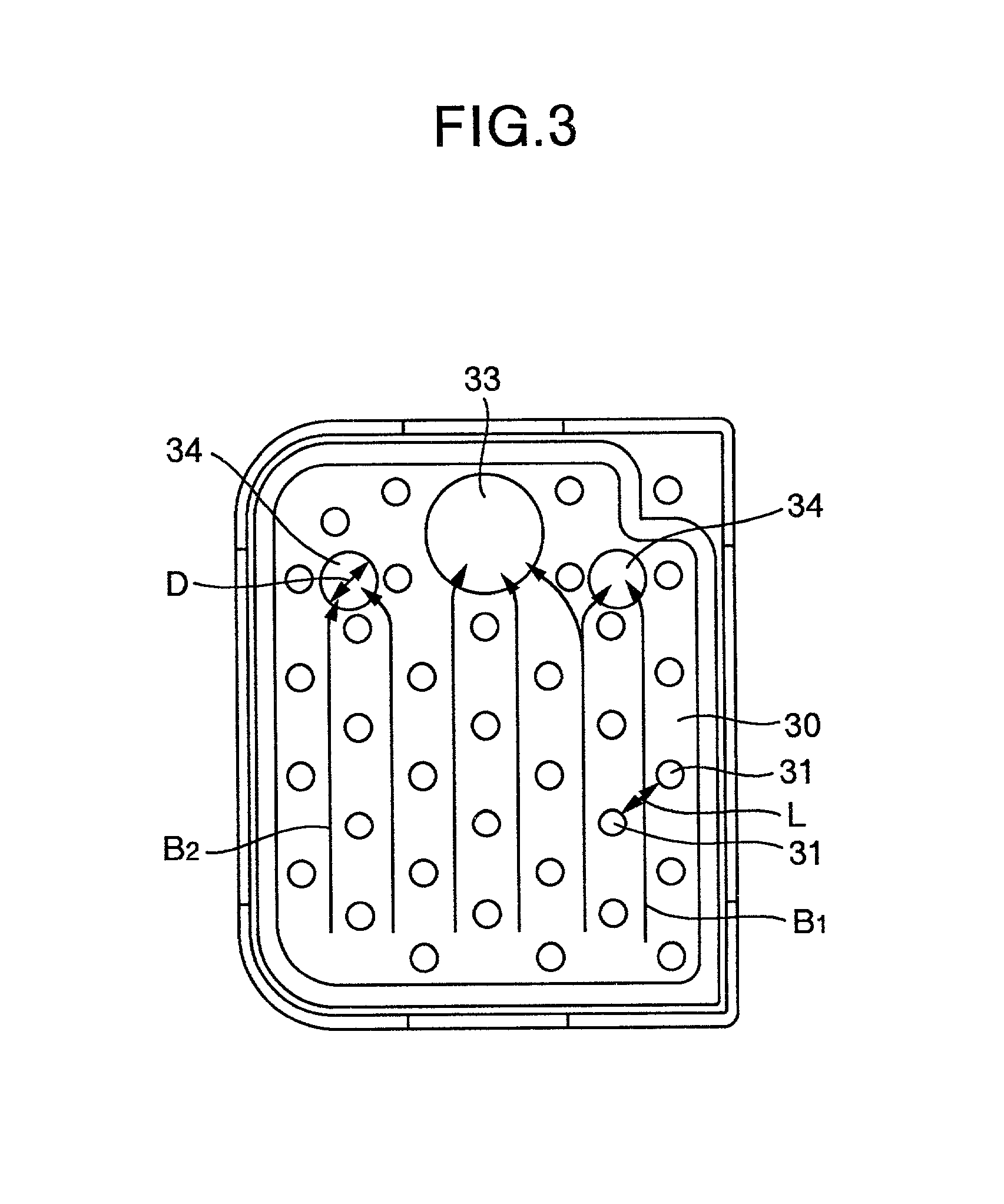

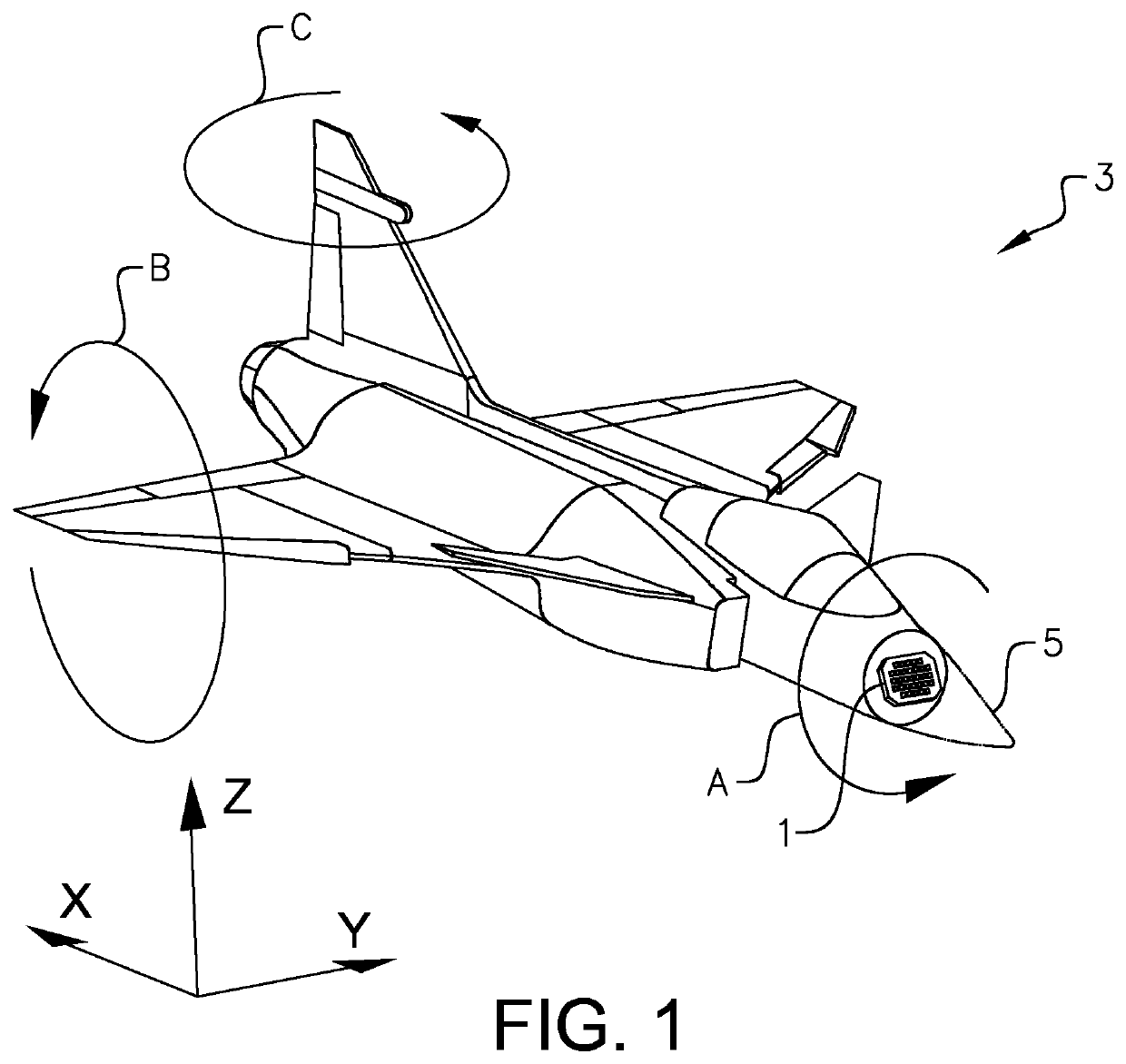

Cooling device with evenly distributed and directed cooling effect for high heat flux and deaeration functionality

ActiveUS20190368827A1Quality improvementImprove thermal performanceSpacing meansAdditive manufacturing apparatusCooling chamberCooling effect

A cooling device for providing cooling capability of adjacent structures comprises a hollow chamber, an inlet and a chamber outlet, wherein the inlet, the chamber and the chamber outlet are configured such that fluid flow may enter via the inlet, pass through the chamber, and exit via the chamber outlet. The chamber is divided into a distribution chamber and a cooling chamber by a partitioning member, wherein the inlet is fluidly connected to the distribution chamber and the chamber outlet is fluidly connected to the cooling chamber. The partitioning member comprises at least a first and a second constriction passage, wherein the first constriction passage has a first predefined cross sectional flow area and the second constriction passage has a second predefined cross sectional flow area. The sizes of the predefined at least first and second cross sectional flow areas of the at least first and second constriction passages are controllable, whereby the distribution of fluid flow from the distribution chamber to the cooling chamber via the respective constriction passage is controllable.

Owner:SAAB AB

Tube dispensing magazine device and method

ActiveUS20070023445A1Prevent egressReduce static pressureRacksCoin-freed apparatus detailsGravity feedShrink tunnel

A magazine and tube dispensing method is provided. The magazine includes a receiving compartment for temporarily receiving unfilled tubes intended for filling with a flowable product, the compartment being formed with a movable outer rail wall. A gate assembly downstream from the receiving compartment includes a constriction passageway formed between a lateral inner wall and a lateral member wall allowing downward gravity feed of tubes only in a single file. The lateral member wall is movable in a direction toward or away from the lateral inner wall and integrally movable as a member of the outer rail wall, thereby adjusting a cross-sectional dimension of the passageway to accommodate processing of different diameter tubes.

Owner:CONOPCO INC D B A UNILEVER

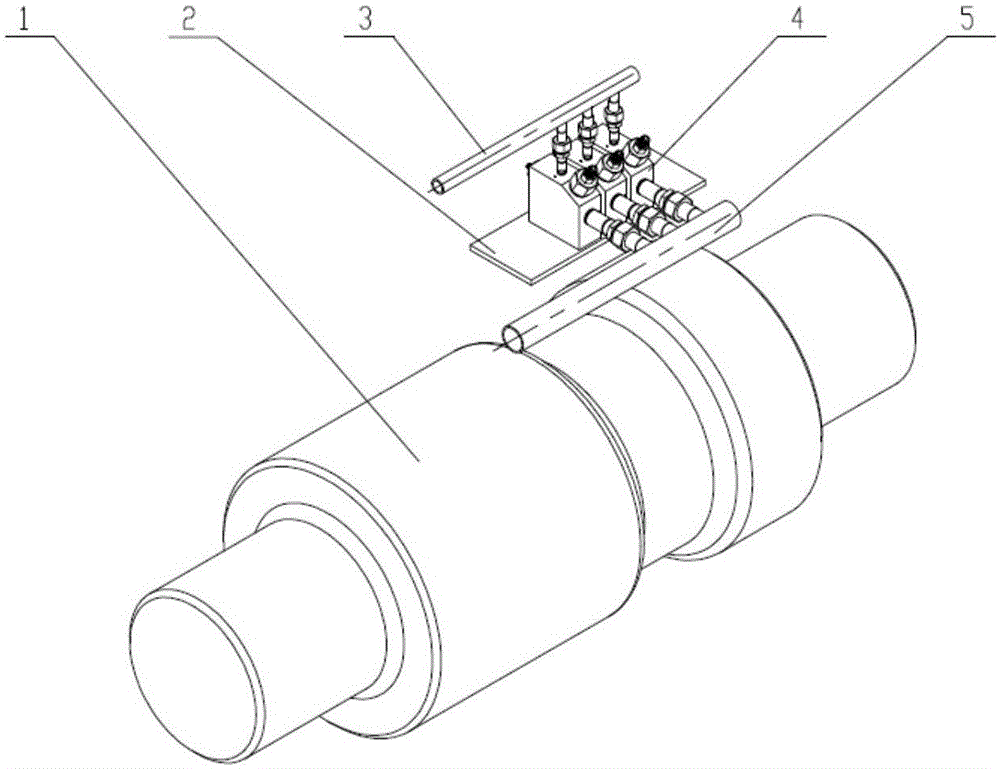

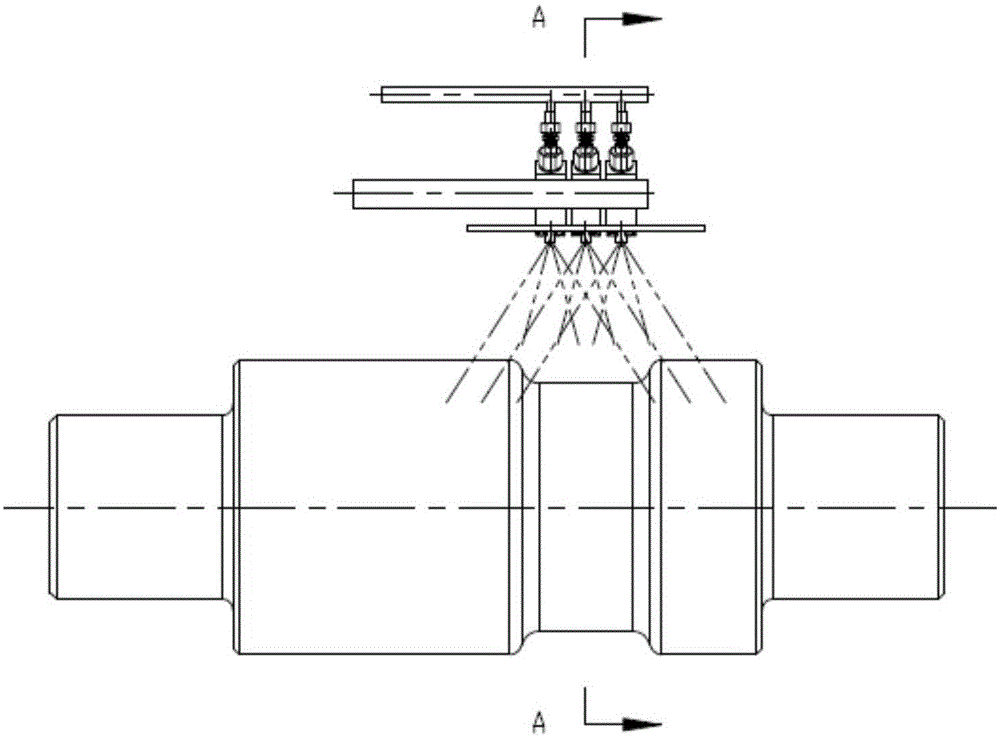

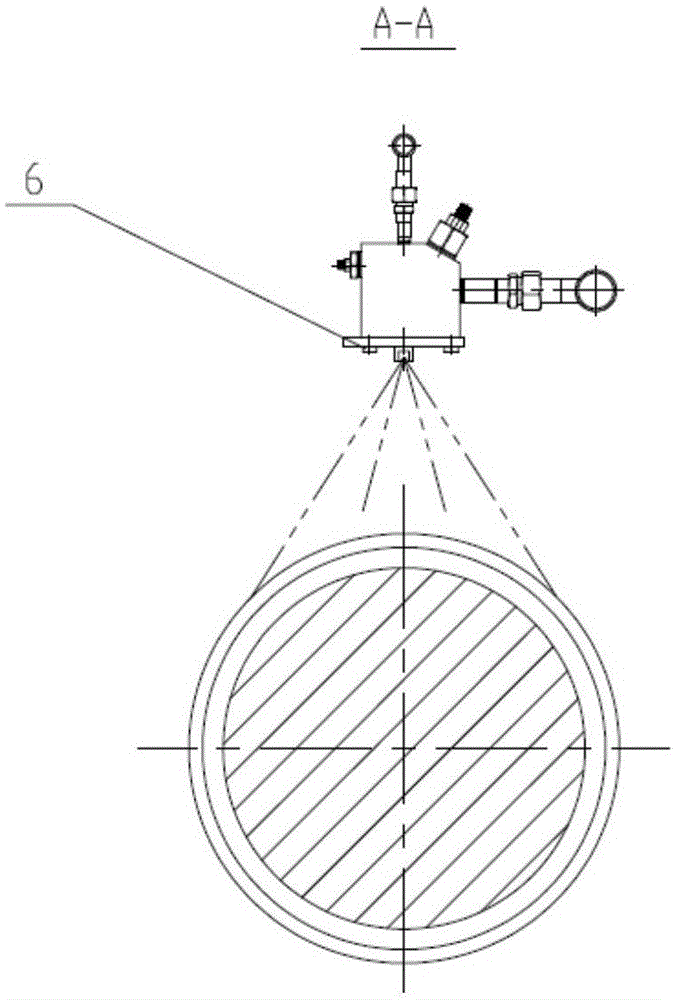

Water-gas cooling spraying nozzle assembly for roller

InactiveCN105080974AImprove cooling efficiencyExtended service lifeRollsLiquid spraying apparatusInlet channelWater vapor

The invention discloses a water-gas cooling spraying nozzle assembly for a roller. The water-gas cooling spraying nozzle assembly comprises a valve body, an air inlet and a water inlet are formed in the valve body, an air inlet pipe is installed in the air inlet, and a water inlet pipe is installed in the water inlet; the air inlet pipe is communicated with a water-air mixing channel through an air inlet channel and an air inlet shrinking channel, and the water inlet pipe is communicated with the water-air mixing channel through a water inlet channel and a water inlet guide channel; and a water-air outlet is formed in the tail end of the water-air mixing channel, and a water-air spraying nozzle is arranged on the water-air outlet. According to the water-gas cooling spraying nozzle assembly for the roller, water vapor on the surface of a rolling groove of the roller can be blown away through compressed air, circulation of water and air on the surface of the rolling groove of the roller is improved, the cooling efficiency of the roller is improved, and the service life of the roller is prolonged; the requirement of the spraying nozzle assembly for the cooling water pressure is not high; and due to the fact that the pressure of the compressed air is larger than that of cooling water, the pressure of the cooling water of locality in the water-air mixing channel can be increased by adjusting the pressure of the compressed air, and the cooling effect is improved.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Hydraulic vibration-damping support

A hydraulic vibration-damping support comprising two strength members interconnected by an elastomer body defining in part a working chamber filled with liquid, said working chamber communicating via a constricted passage with a compensation chamber separated from said working chamber by a rigid partition. The constricted passage is made up of two stages defined by two pieces of sheet metal forming the rigid partition.

Owner:HUTCHINSON SA

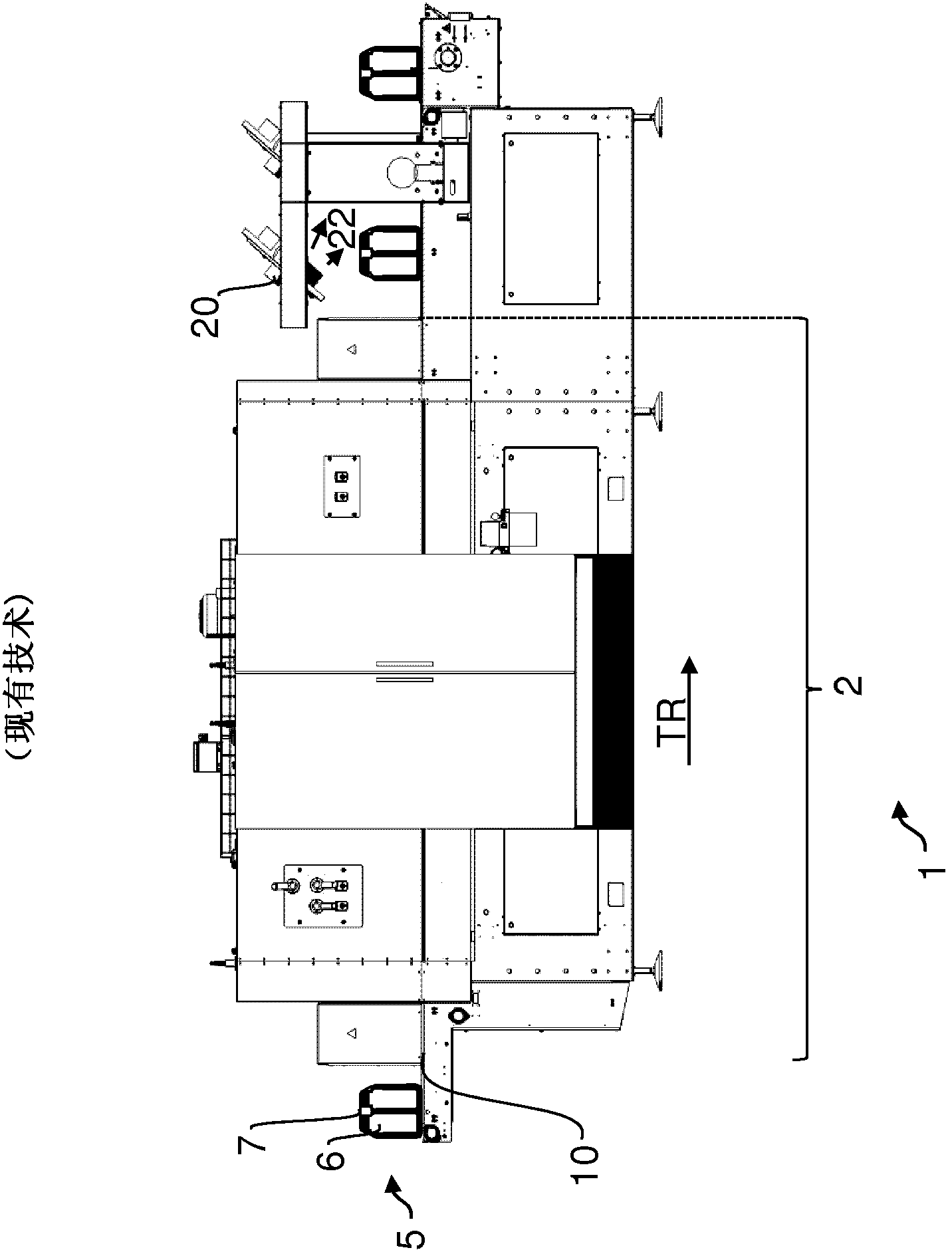

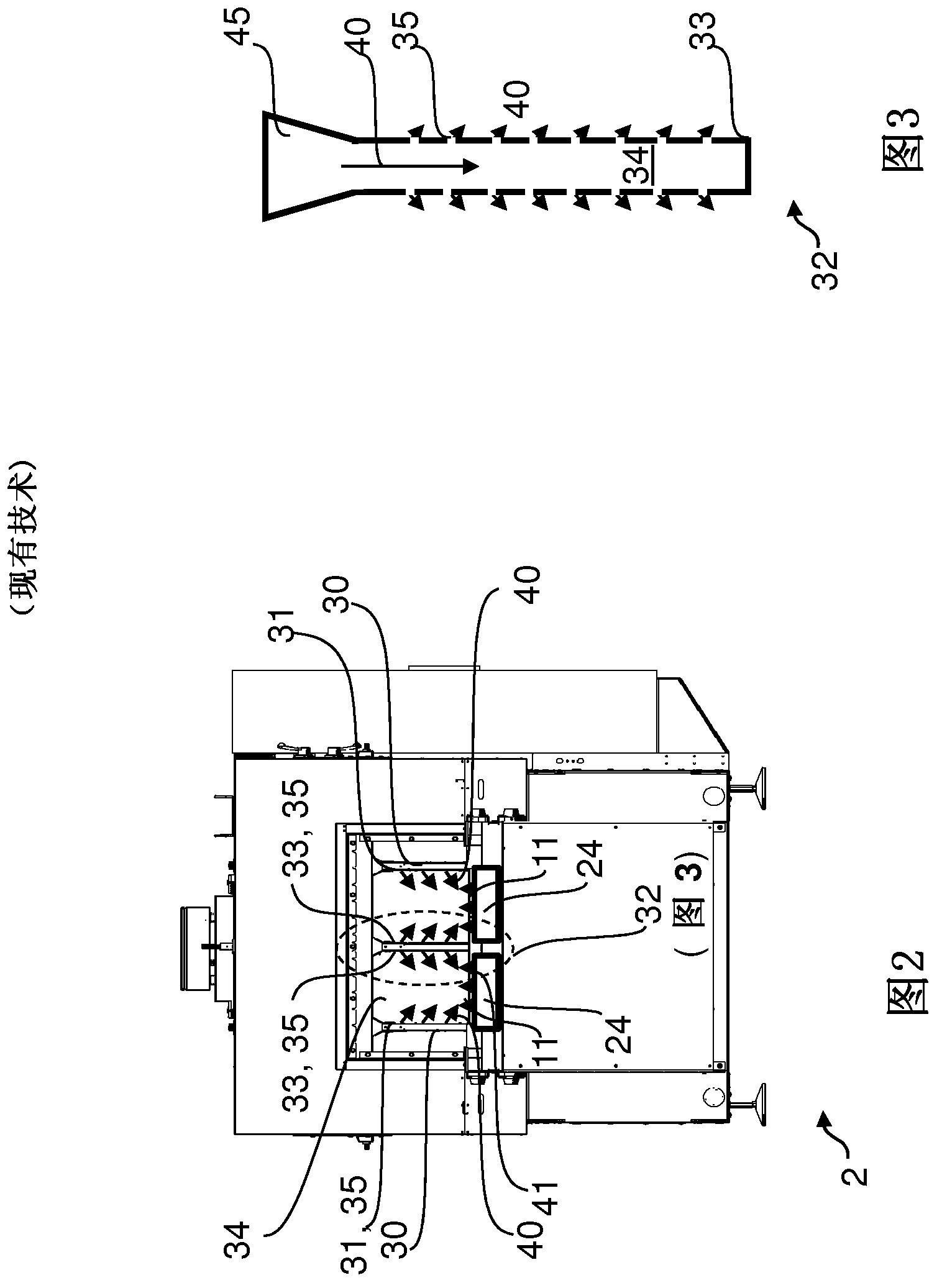

Shrink tunnel

ActiveCN102910321APrevent or reduce eddy current formationPromotes even distributionWrappers shrinkageEngineeringAir blower

The present invention relates to a shrink tunnel for enabling a packaging material wrapping article aggregation to shrink, and a method for enabling a packing material wrapping goods aggregation to shrink. The shrink channel comprises: at least one conveyor belt used for articles wrapped in the packaging material; and at least two shaft walls arranged on both sides with respect to the conveyor belt, shrink medium is guided to the shrink film of the wrapped articles through these shaft walls. The shrink medium is generated by means of a fan (for example, by means of a hot-air blower), and is introduced into the shaft walls from above. The shrink medium is introduced into the shrink tunnel, through nozzle openings arranged in the side surface of the shaft walls perpendicular to the conveyor belt. According to the present invention, the shaft walls include at least one deflecting device used for the shrink medium. Flow directions of the shrink medium are reversed by the deflecting device. The shrink tunnel of the present invention has a favorable flow direction, in order to circumvent the disadvantages of known arrangement schemes.

Owner:KRONES AG

Hydraulic antivibration support

InactiveUS20020149145A1Reduce stiffnessIncrease workloadMachine framesLiquid springsElastomerEngineering

The hydraulic antivibration support comprises two strength members interconnected by an elastomer body defining part of a liquid-filled working chamber which communicates via a constricted passage with a compensation chamber that is separated from said working chamber by a rigid partition. The compensation chamber is defined by an annular bellows presenting an annular fold which projects into the compensation chamber and which is of a shape that does not present circular symmetry.

Owner:HUTCHINSON SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com