Water-gas cooling spraying nozzle assembly for roller

A technology of cooling nozzles and water vapor, applied in the direction of rolls, metal rolling, spray devices, etc., can solve the problems of poor cooling effect, high equipment power, low cooling capacity, etc., to achieve compact structure, simple processing, and improved cooling efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

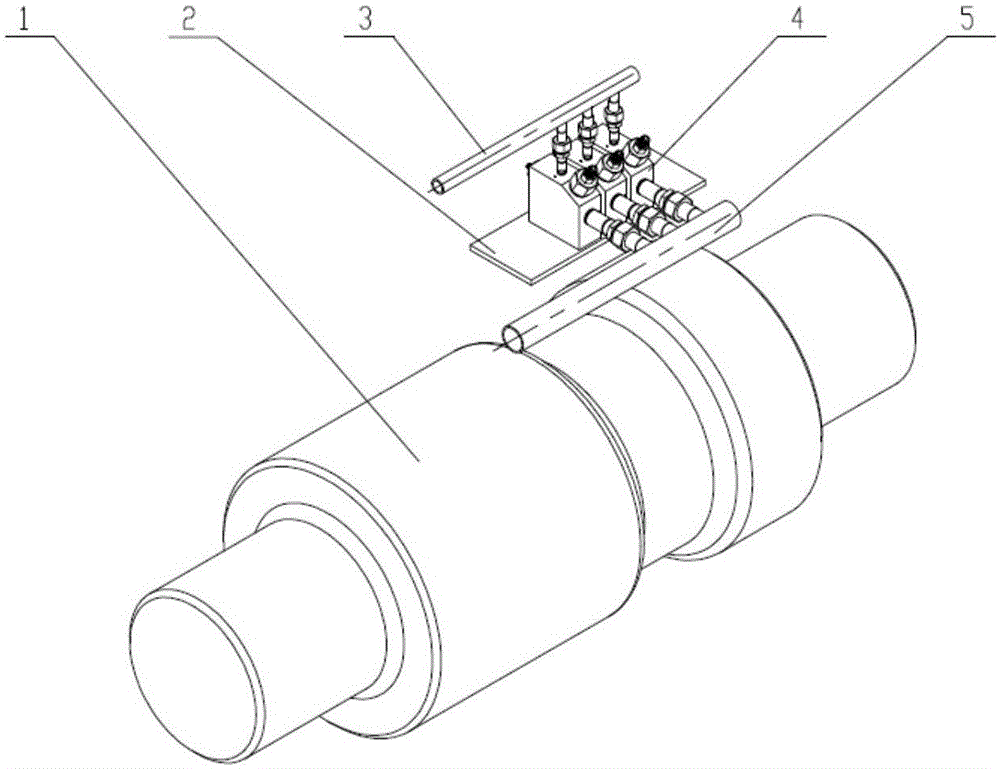

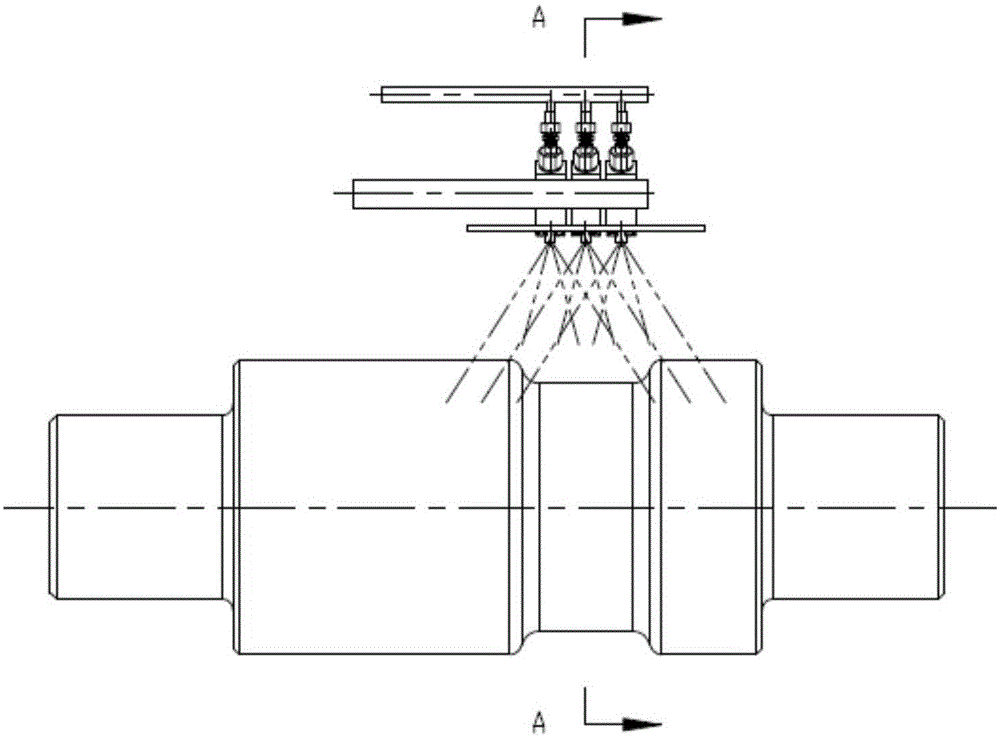

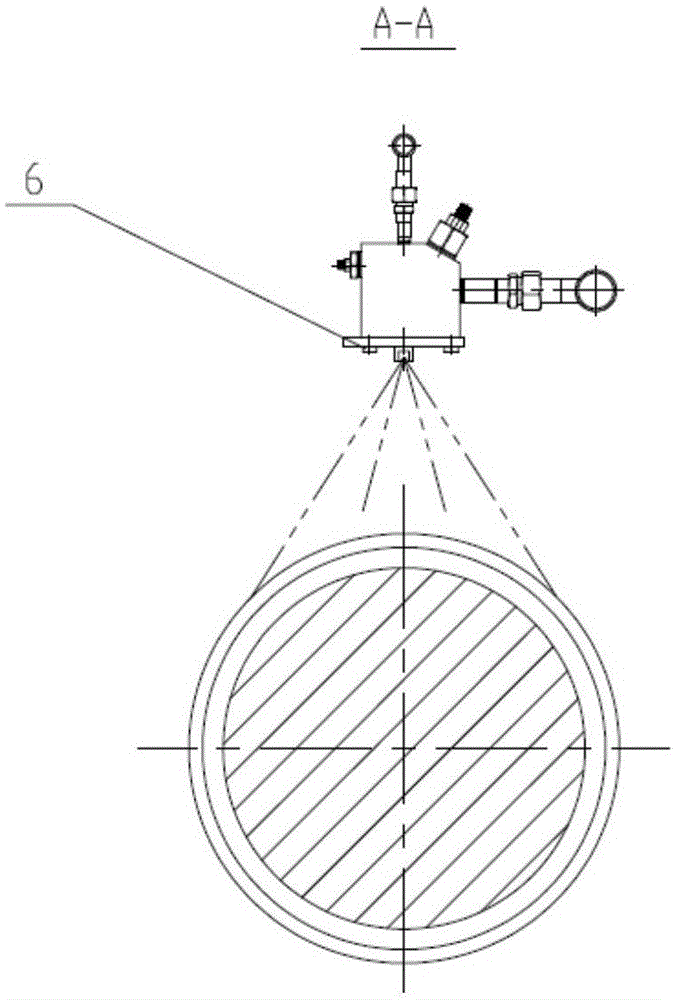

[0020] figure 1 , figure 2 and image 3 In , the on-site installation arrangement of the roll water-air cooling nozzle assembly 4 is illustrated. The roll water-air cooling nozzle assembly 4 is installed and fixed on the support bottom plate 2 through the connecting piece 6 . During on-site installation and arrangement, the exit direction of the water-air nozzle 20 on the roll water-air cooling nozzle assembly 4 faces the high-temperature cooling area of the roll 1 . According to the actual size of the high-temperature cooling area of the roll 1 on site, different numbers of roll water-air cooling nozzle assemblies 4 can be configured.

[0021] From Figure 4 It can be seen from the figure that the roll water-air cooling nozzle assembly 4 includes a valve body 7 , an air inlet pipe 9 , a water inlet pipe 15 , and a water-air nozzle 20 . The compressed air pipeline 3 is connected with the intake pipe 9, and the compressed air is input to the valve body 7, and the comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com