Shrink tunnel

A technology of shrinking channel and shrinking medium, which is applied in the direction of wrapping paper shrinking, wrapping, wrapping paper, etc., and can solve problems such as defective packaging, uneven drainage area of hot air 40, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

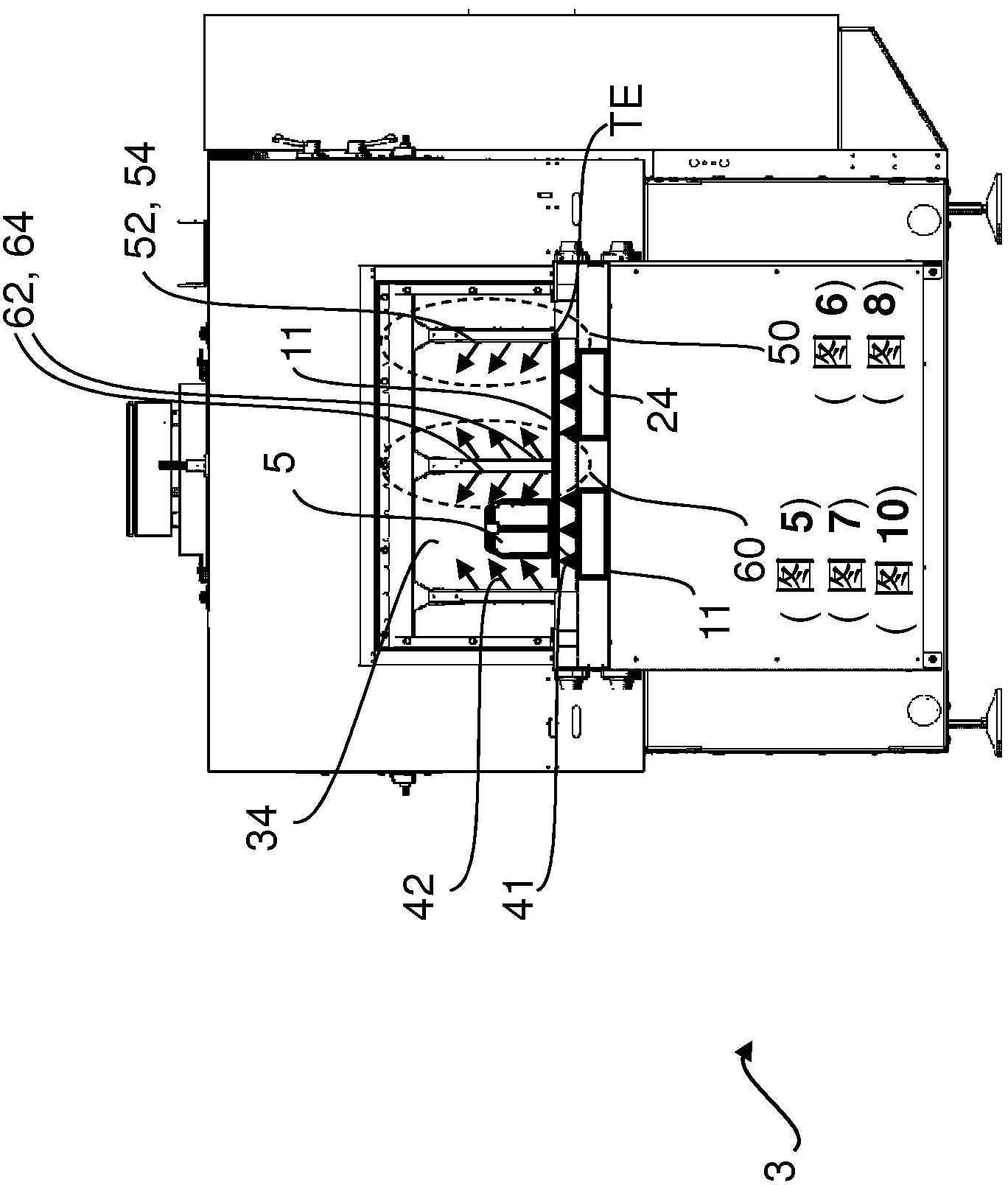

[0041] The same reference numerals are used for identical or functionally identical elements of the invention. Furthermore, for reasons of clarity, only the reference signs required for the description of the respective figure are shown in the individual figures. The embodiments shown are merely examples of how the device according to the invention and the method according to the invention are designed and are not intended to represent a closed limitation.

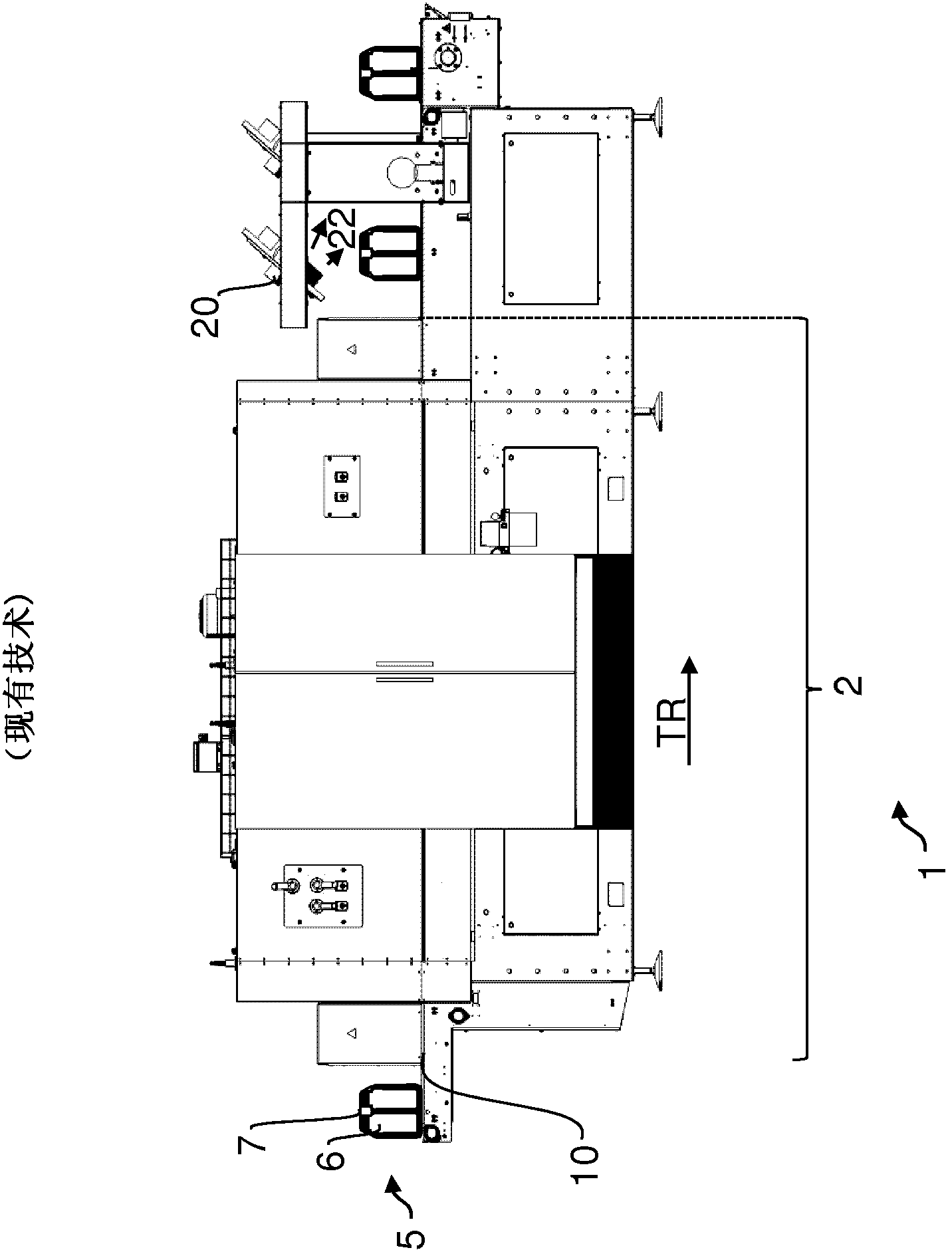

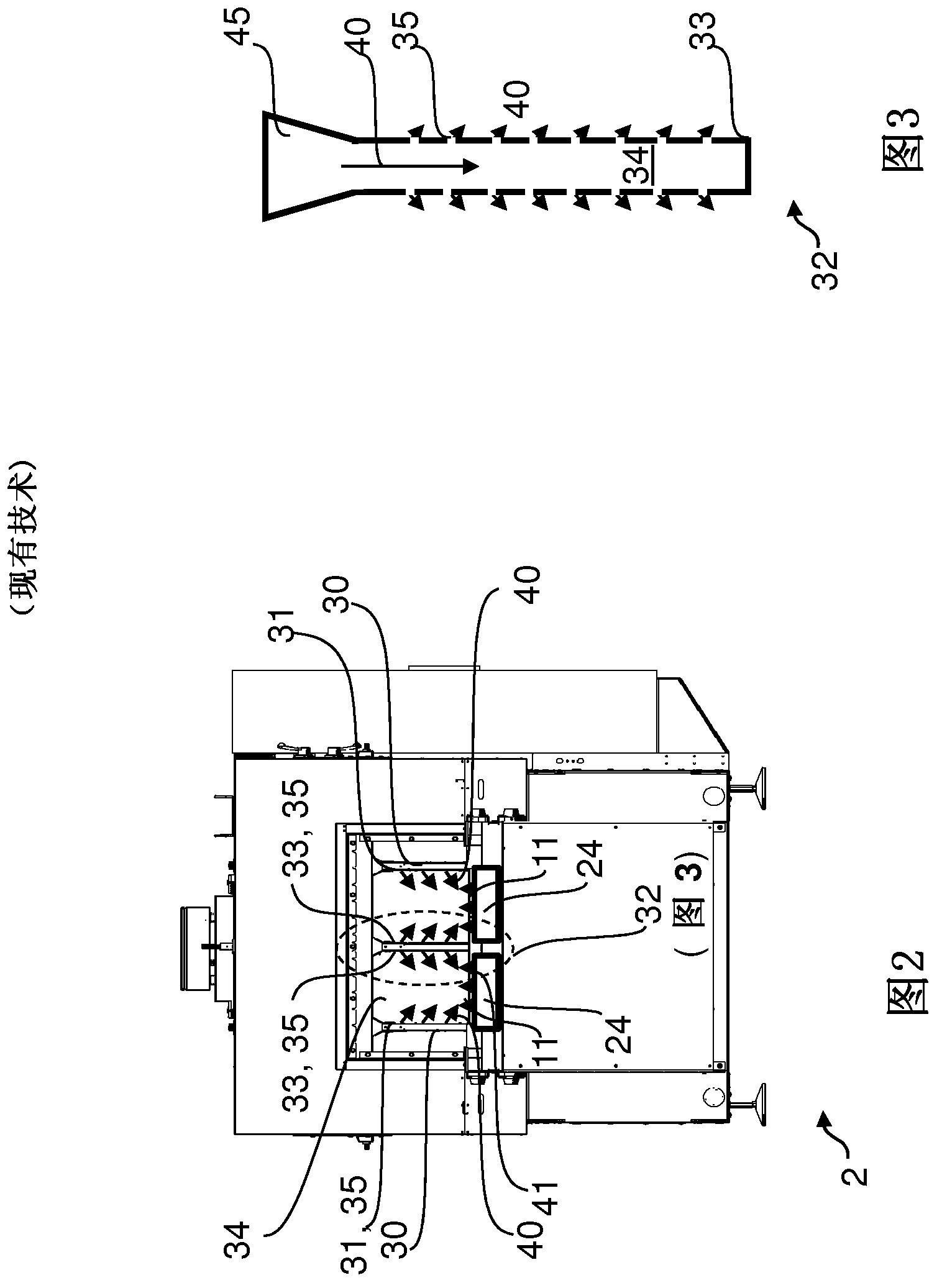

[0042] Figures 1 to 3 It has been introduced in the prior art.

[0043] Figure 4 A sectional view of the constriction channel 3 with an inner cylinder wall 60 modified according to the invention and an outer cylinder wall 50 modified according to the invention is shown. The shrink tunnel 3 comprises two conveying tracks 11 for the bundles 5 of articles. A hot air generator 24 is arranged below the transport plane TE. Hot air 41 is used as a shrinking medium and is directed upwards through the conveying plane towards...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com