Shrink tunnel

A tunneling and heat shrinking technology, which is applied in the direction of wrapping paper shrinkage, packaging, wrapping paper, etc., can solve the problems of not getting jet flow, achieve the effect of optimizing mechanical properties and appearance properties, and minimizing energy costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

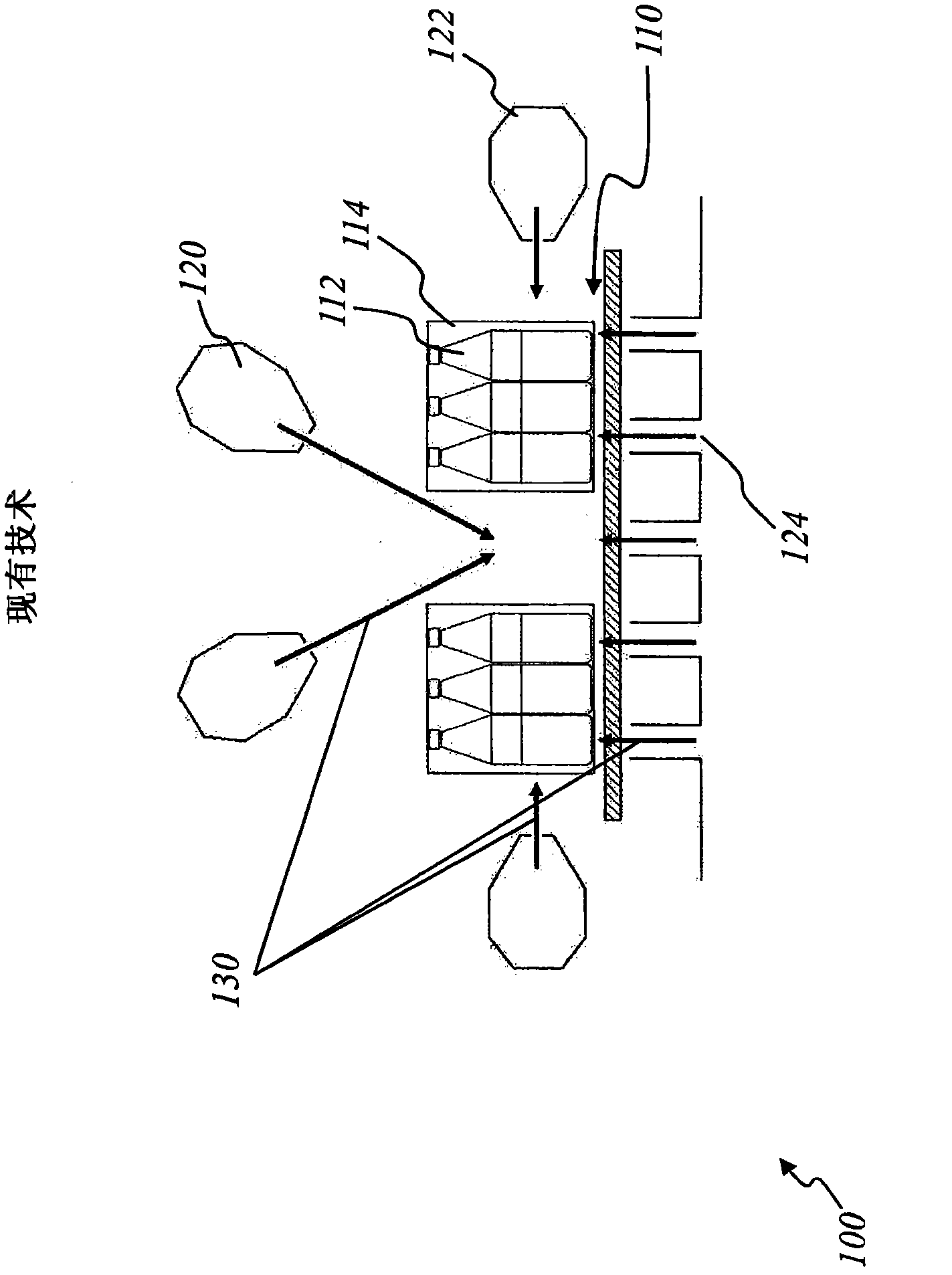

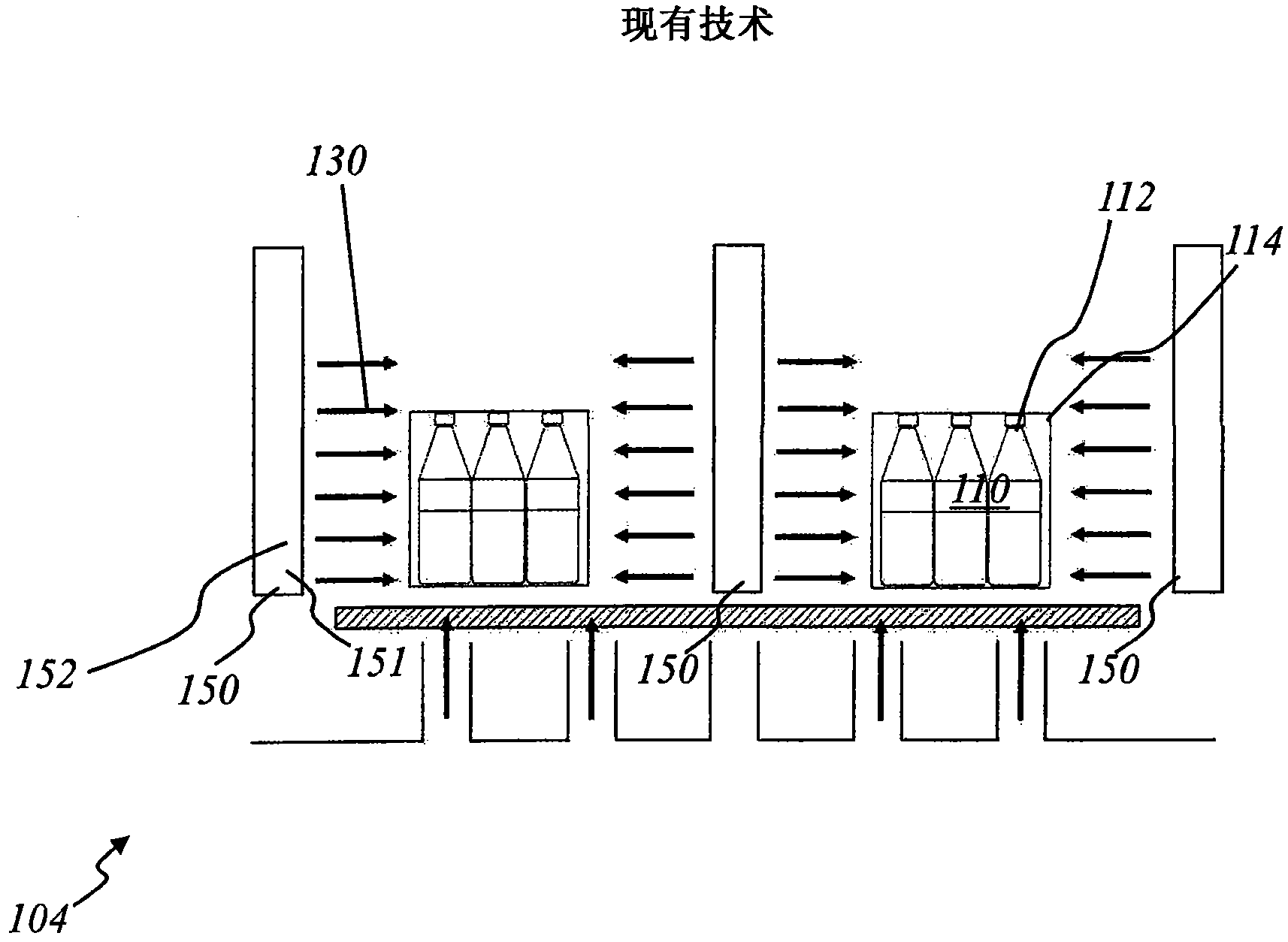

[0056] figure 1 and figure 2 It has been described in detail in the prior art.

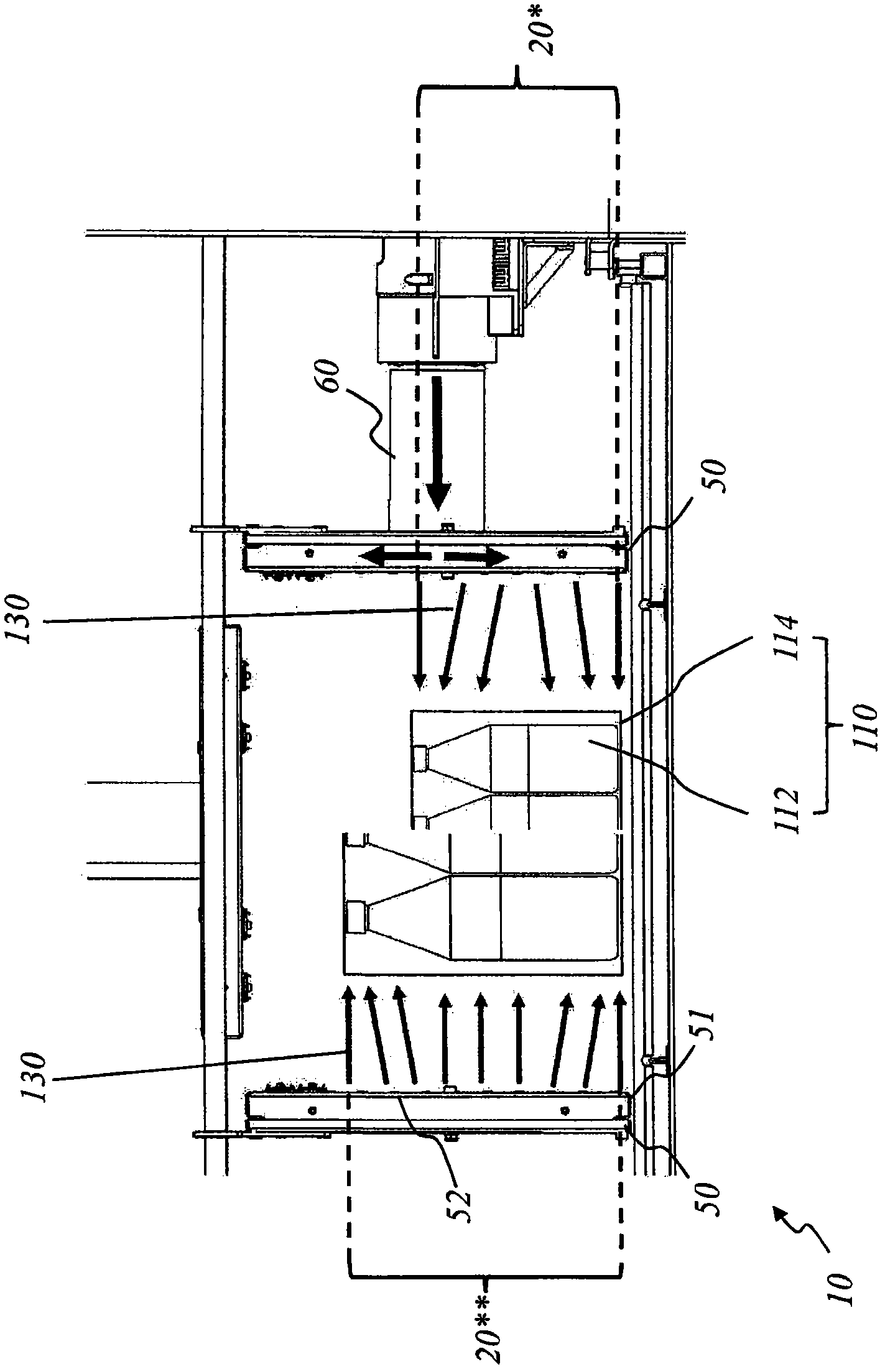

[0057] image 3 A schematic diagram of a constriction tunnel 10 according to the invention using ventilation shaft wall technology with variable air supply is shown. also, image 3 The relative adjustability of the nozzle rows with respect to each other is also shown.

[0058] The shrink tunnel 10 has at least one ventilation shaft 50 . The at least one ventilation shaft 50 is a hollow wall, for example made of metal, with at least one ventilation shaft wall 51 having nozzle openings 52 at least substantially over the entire length of the height of the constriction tunnel 10 . In general, the shrink tunnel 10 has two ventilation shafts 50 arranged parallel to one another and parallel and perpendicular to the goods transport section, wherein the ventilation shaft walls 51 are arranged in such a way that the nozzle openings 52 point towards the shrink tunnel 10 internal. Hot air or hot air 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com