Novel special high-temperature alloy wire hot rolling process

A high-temperature alloy wire and high-temperature alloy technology, applied in the field of wire material processing, can solve the problems of high production cost of special alloys, difficulty in controlling product quality, and high cost of equipment procurement, and achieve the goal of promoting manufacturing costs, improving the production environment, and increasing the number of wire drawing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

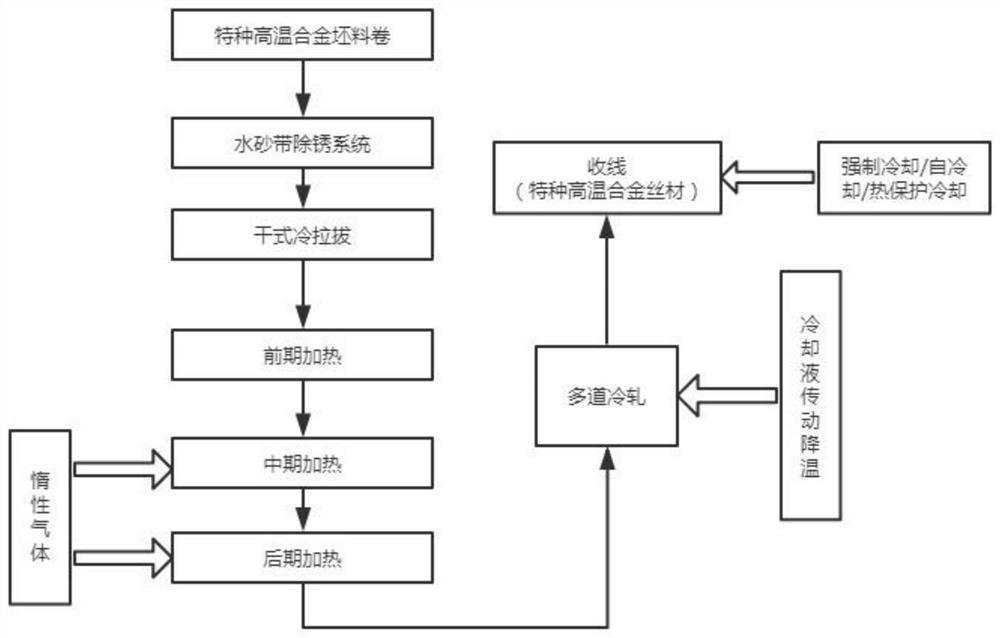

[0041] A new type of special high temperature alloy wire hot rolling process, including the following steps:

[0042] The nickel-based alloy wire blank has a specification of φ10.00mm to remove the water tape in the water tape in the defect 0.05 mm, and the dry cold pull is pulled to φ8.00mm, the tube preheating device is warmed to 350 ° C for 3 min, medium frequency electromagnetic heating The temperature is warmed to 750 ° C for 4 min, high frequency electromagnetic heating temperature rise to 930 ° C for 5 min;

[0043] Three cold rolled, the first cold rolling is a size of φ5.50mm, the second cold rolling is φ3.50mm, the third cold rolling is 2.10 mm, and the heat protection is cooled, and the speed is 15m / s. That is, a nickel-based alloy material having a specification is φ2.10 mm;

[0044] Among them, the cold drawn is composed of 4 linkage-type cold drawing machine devices;

[0045] Pre-heating and heating rate 6 ° C / s, medium heating and late heating temperature rise r...

Embodiment 2

[0049] A new type of special high temperature alloy wire hot rolling process, including the following steps:

[0050]The titanium alloy wire blank is specified from φ8.00mm to remove the water tape strip removal defect 0.03mm, after dry cold pull to φ5.00mm, tube preheating device temperature rise to 400 ° C holding 5 min, medium frequency electromagnetic heating temperature To 700 ° C for 3 min, high-frequency electromagnetic heating temperature rose to 900 ° C for 8 min;

[0051] Three cold rolled, the first cold rolling is 0.50mm, the second cold rolling is 0.00mm, the third cold rolling is 3.40mm size, the heat protection is cooled, and the wire is 15m / s. That is, the specification is a titanium alloy material φ3.40 mm;

[0052] Among them, the cold drawn is composed of 4 linkage-type cold drawing machine devices;

[0053] The pre-heating temperature rise rate is 5 ° C / s, medium heating and late heating temperature rise rate of 8 ° C / s;

[0054] The medium-frequency elec...

Embodiment 3

[0057] A new type of special high temperature alloy wire hot rolling process, including the following steps:

[0058] The nickel-based alloy wire blank has a specification of φ10.00mm to remove the water tape in the water tape in the water tape, which is 0.05mm, passed through dry cold pull to φ8.00mm, tube preheating device to heat up to 300 ° C for 10 min, medium frequency electromagnetic heating Touring to 700 ° C for 10min, high frequency electromagnetic heating temperature rise to 800 ° C for 10 min,

[0059] Three cold rolled, the first cold rolling is a size of φ5.50mm, the second cold rolling is φ3.50mm, the third cold rolling is 2.10 mm, and the heat protection is cooled, and the speed is 15m / s. That is, a nickel-based alloy material having a specification is φ2.10 mm;

[0060] Among them, the cold drawn is composed of 3 linkage-type cold drawing machine devices;

[0061] The pre-heating temperature rise rate of 5 ° C / s, medium heating and late heating temperature ris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com