Patents

Literature

50results about How to "Running slow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

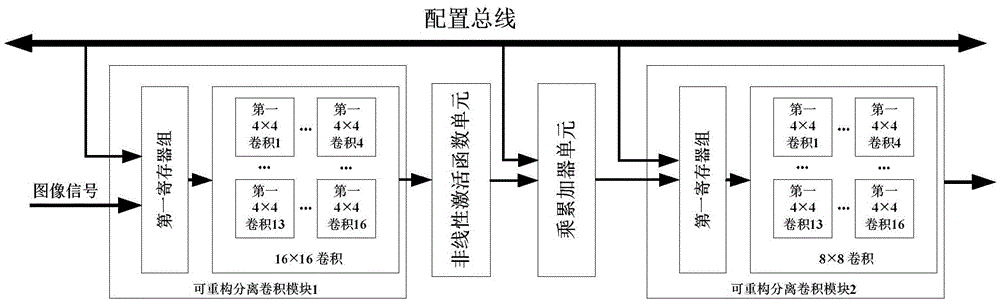

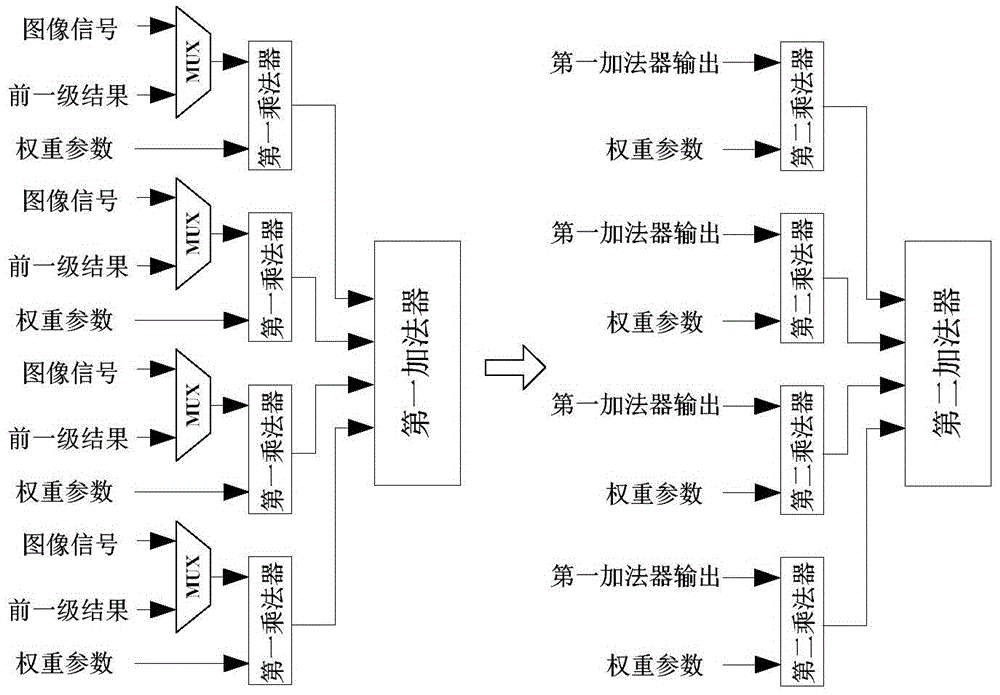

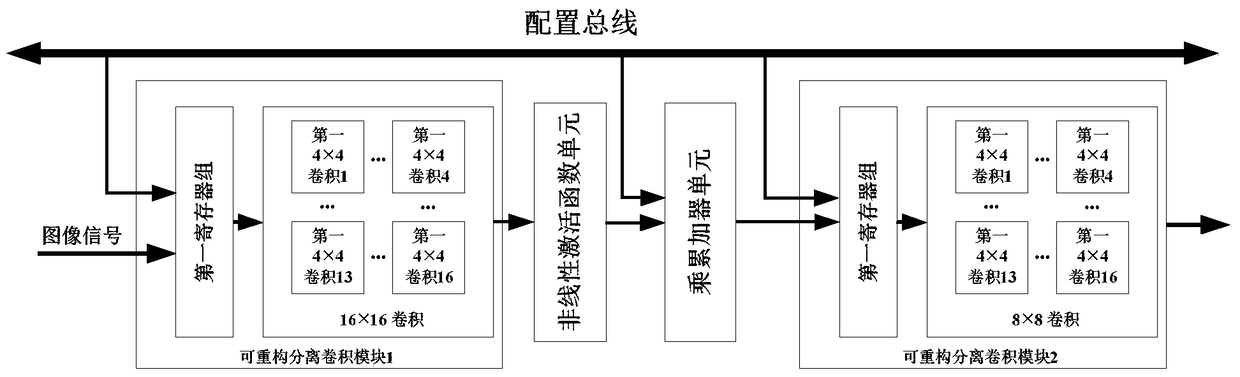

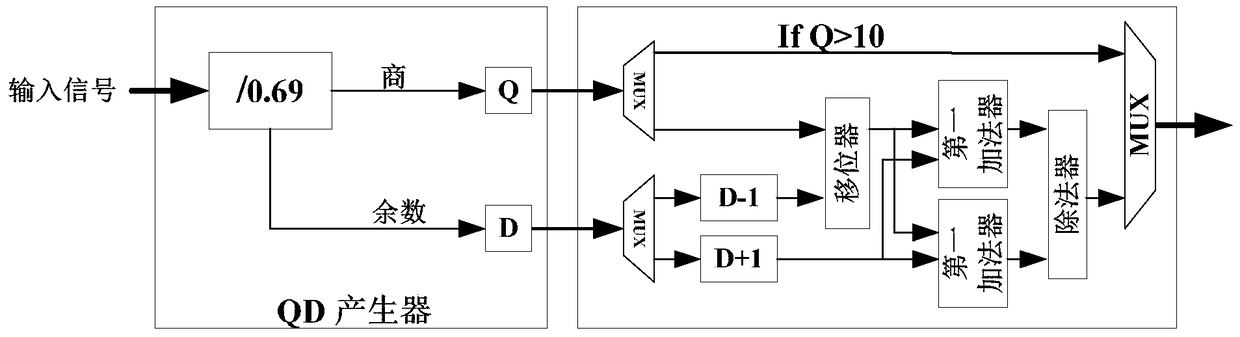

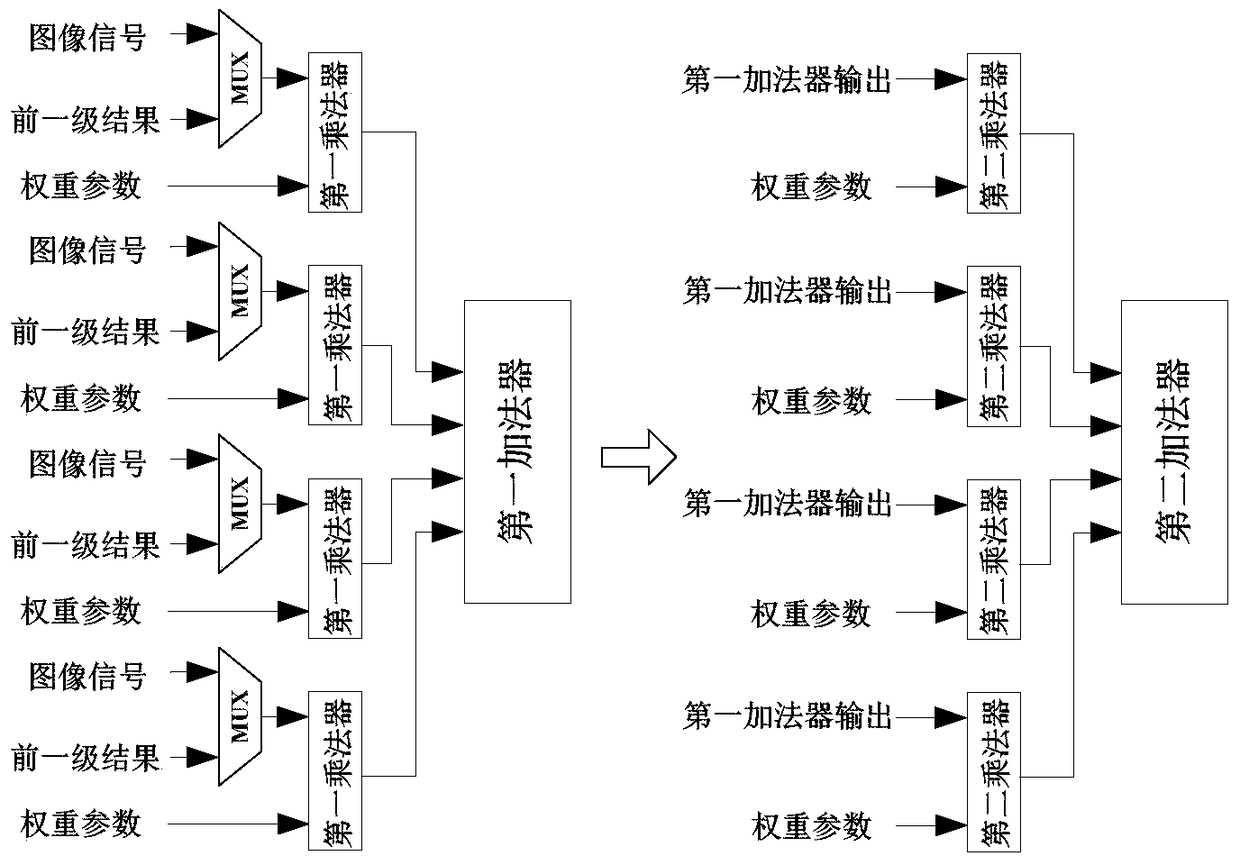

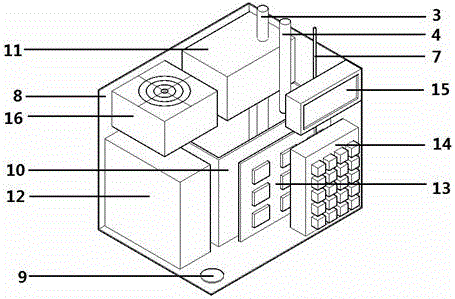

Convolution network arithmetic unit, reconfigurable convolution neural network processor and image de-noising method of reconfigurable convolution neural network processor

ActiveCN105681628AReduce consumptionReduce the number of convolutionsTelevision system detailsColor signal processing circuitsComputer architectureResource consumption

The invention discloses a convolution network arithmetic unit, a reconfigurable convolution neural network processor and an image de-noising method of the reconfigurable convolution neural network processor. The reconfigurable convolution neural network processor comprises a bus interface, a preprocessing unit, a reconfigurable hardware controller, an SRAM, an SRAM control module, an input caching module, an output caching module, a memory, a data memory controller and the convolution network arithmetic unit. The processor is featured by few resources and rapid speed and can be applicable to common convolution neural network architecture. According to the unit, the processor and the method provided by the invention, convolution neural networks can be realized; the processing speed is rapid; transplanting is liable to be carried out; the resource consumption is little; an image or a video polluted by raindrops and dusts can be recovered; and raindrop and dust removing operations can be taken as preprocessing operations for providing help in follow-up image identification or classification.

Owner:XI AN JIAOTONG UNIV

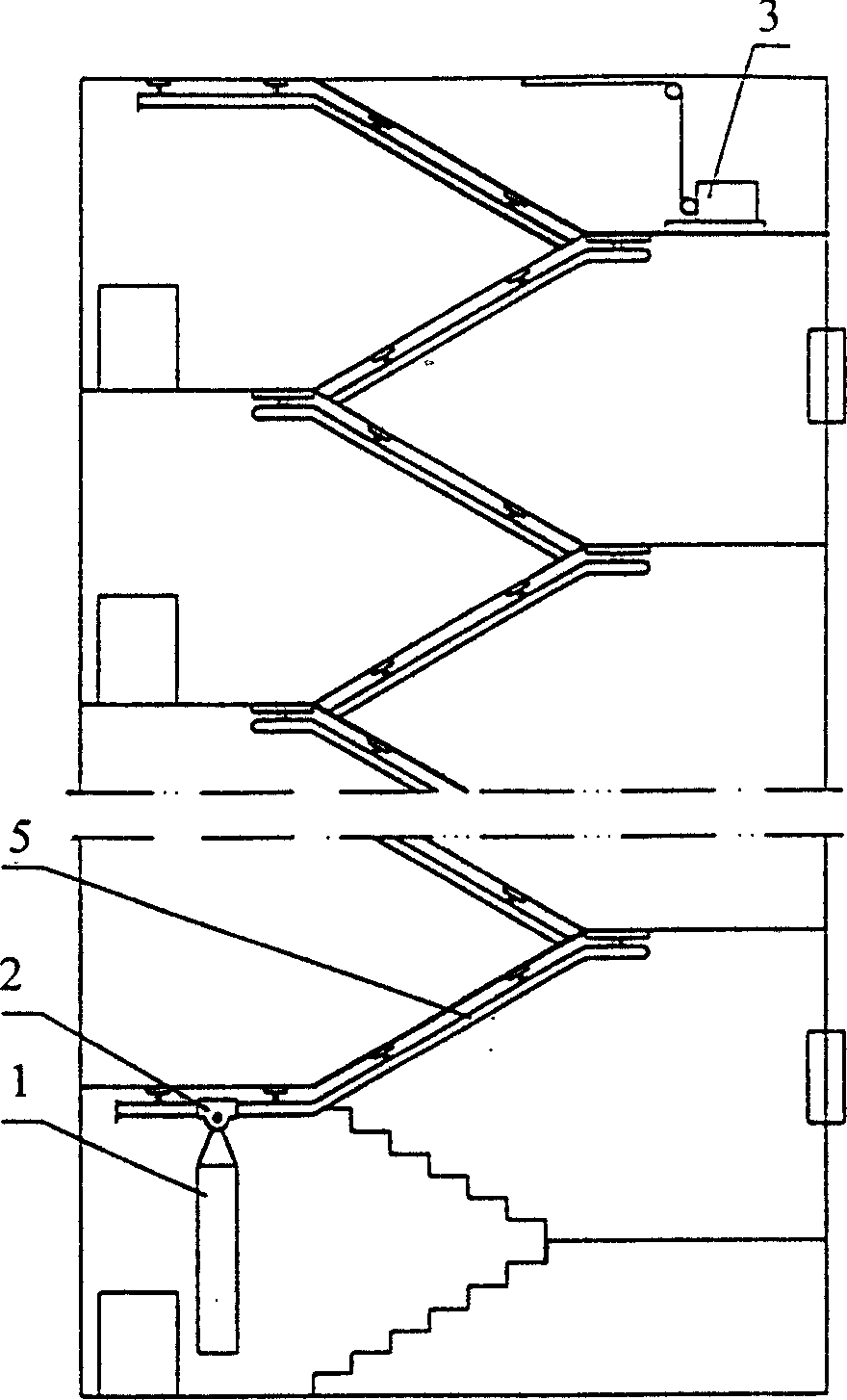

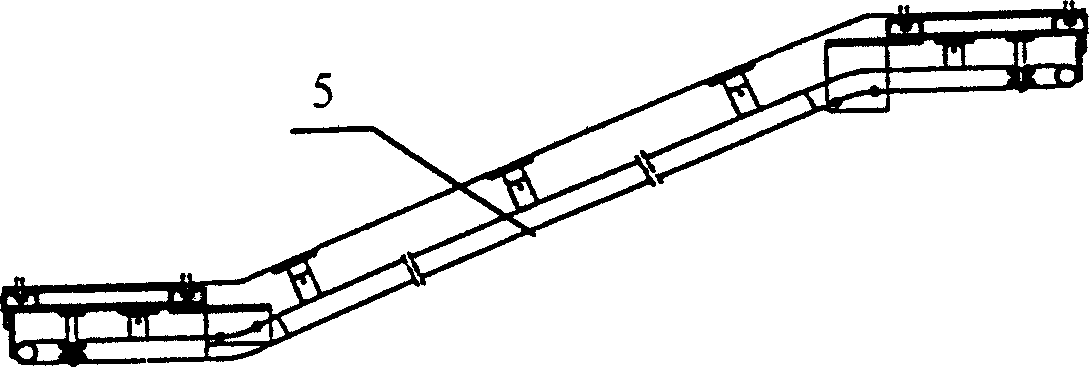

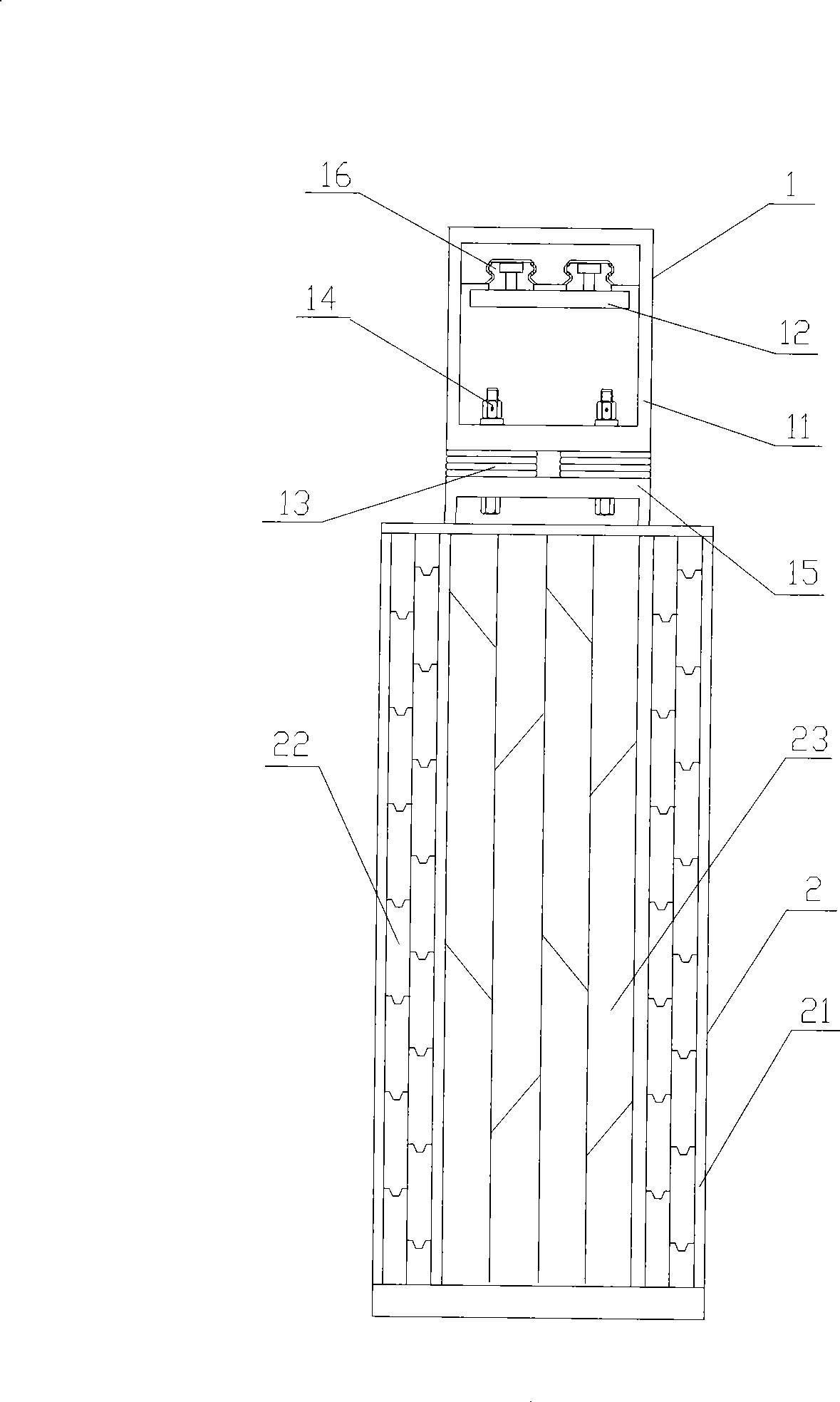

Safety elevator for multi-layer building

The prsent invention discloses a multistoried domestic building staircase safety elevator which is installed according to multistoried domestic building staircase, variable-frequency speed regulated and controlled by computer. It mainly includes passenger-carrying device, suspended mechanism, traction drive device, control system and spiral guideway. Said invention also provides their assembly scheme and construction method and steps. Said invention elevator is safe and reliable, and its cost is low.

Owner:南京理工科技园股份有限公司

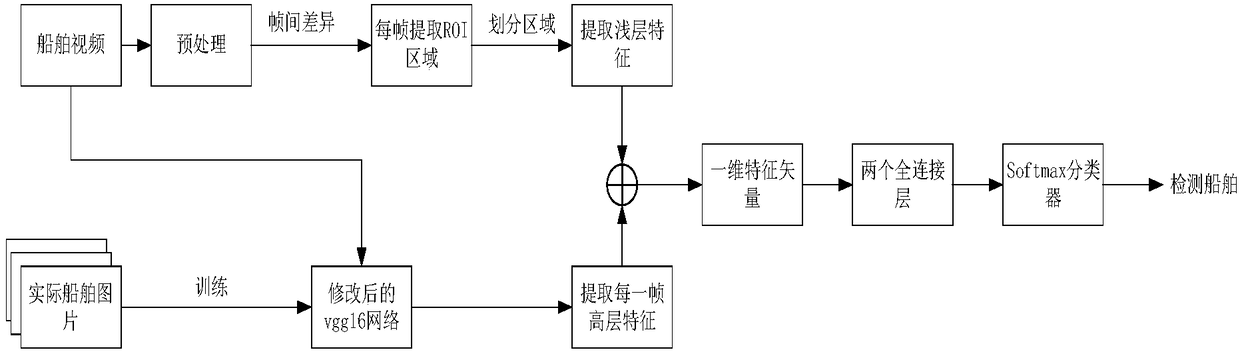

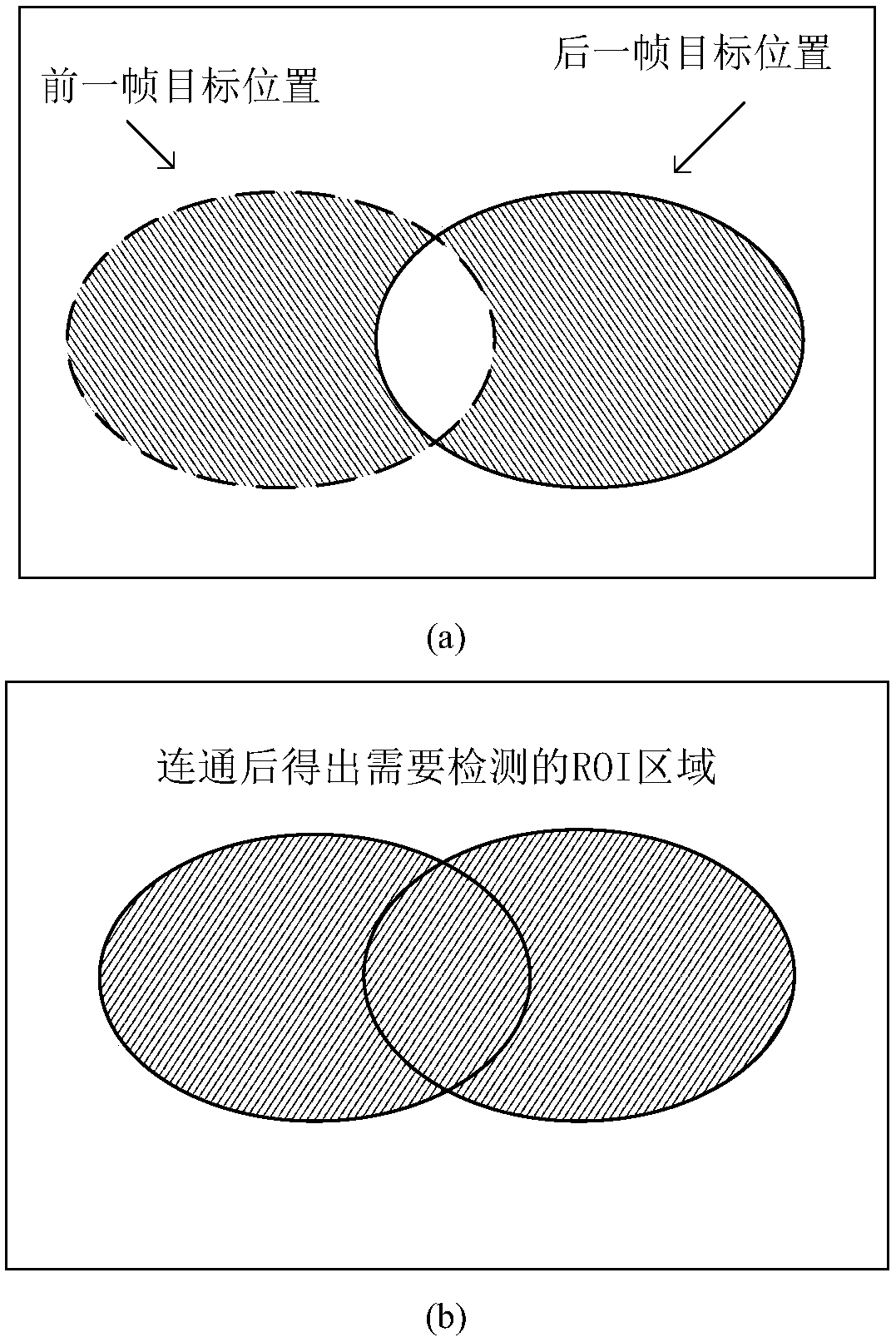

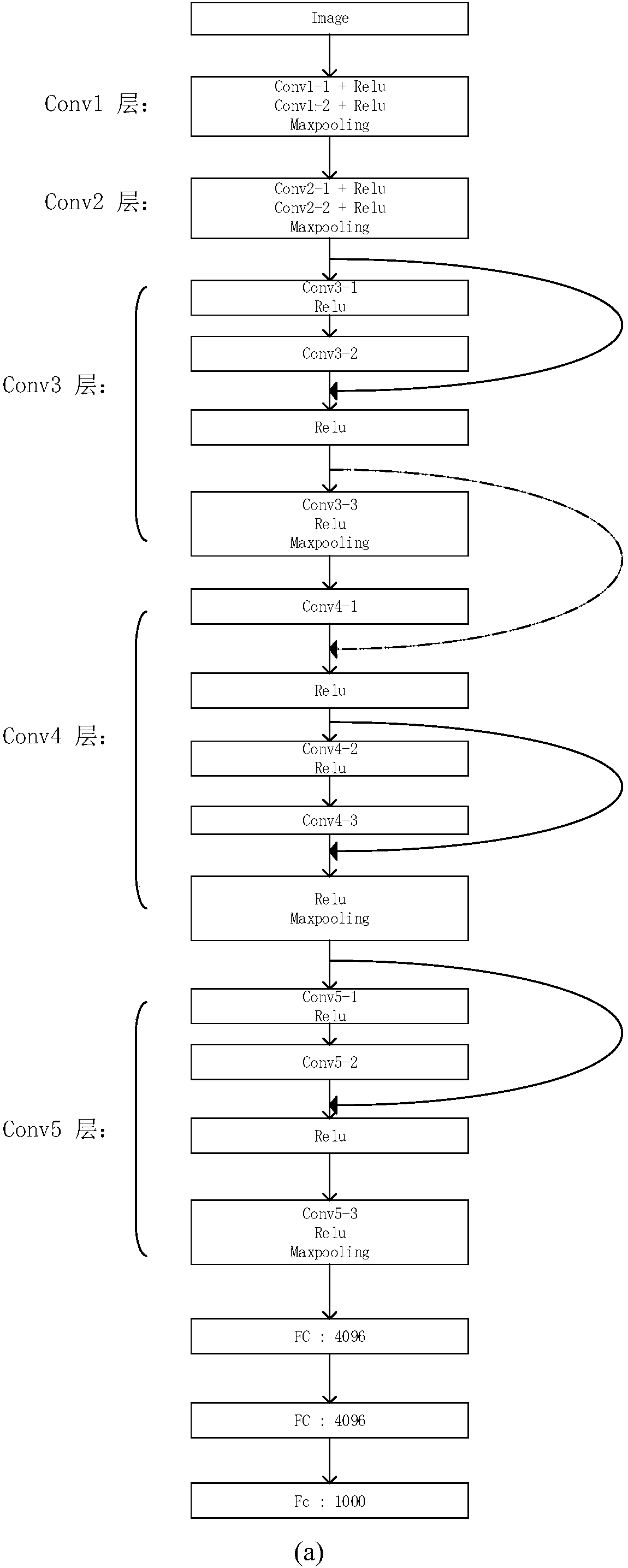

Inter-frame difference and convolutional neural network fusion-based ship video detection method

InactiveCN108229319ARunning slowSmall frame-to-frame differencesCharacter and pattern recognitionNeural architecturesSaliency mapInter frame

The invention discloses an inter-frame difference and convolutional neural network fusion-based ship video detection method. The method comprises the four parts of preprocessing a video; obtaining anROI of each frame and extracting low layer features; obtaining high layer features of each frame of image by using a modified VGG16 network; and predicting a ship saliency map of the ROI of each frameand extracting a ship target. A relationship between continuous video frames is fully utilized; the interference of a background is reduced; a moving ship is accurately located; a ship moving regionis obtained; and compared with ship image saliency detection only using the low layer features, the method not only can be directly applied to the ship video detection but also reduces the situation of incomplete ship detection, has higher adaptability to a complex inland river moving ship scene, has higher detection precision, solves the problem of inaccurate inland river ship target saliency detection, and has extremely high practical application values.

Owner:NANJING UNIV

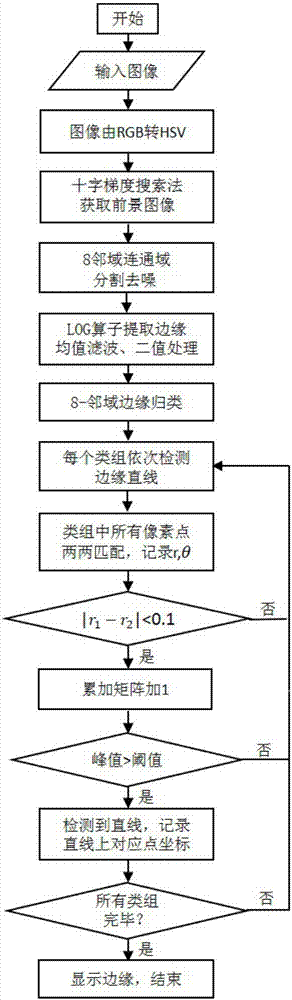

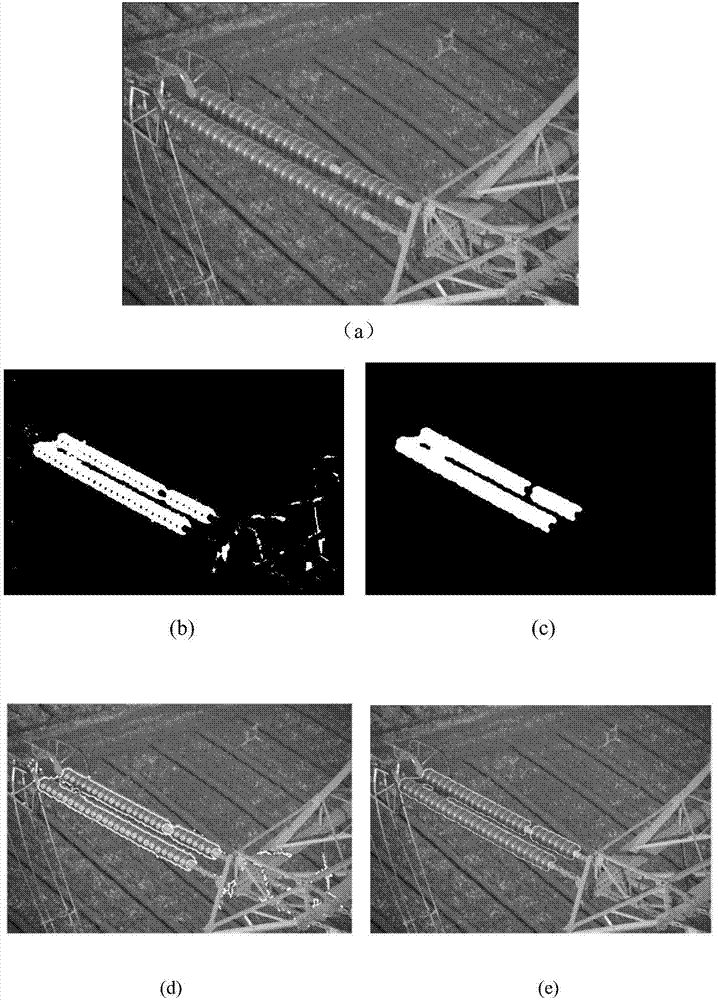

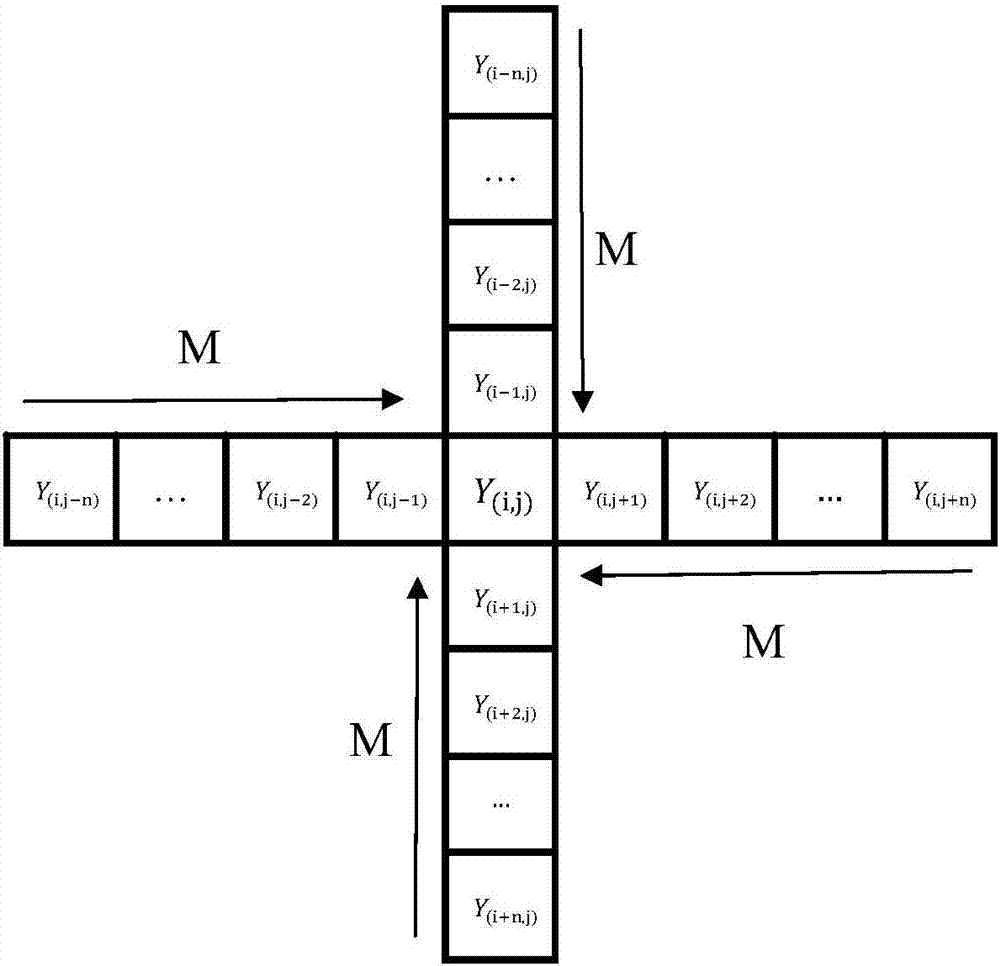

Unmanned aerial vehicle visual detection method for high-voltage line insulators

InactiveCN107492094AImprove accuracyRunning slowImage enhancementImage analysisPattern recognitionEdge extraction

The invention discloses an unmanned aerial vehicle visual detection method for high-voltage line insulators. The method comprises the following steps of: obtaining a high-voltage line insulator image; converting the high-voltage line insulator image from an RGB model to an HSV model; detecting a brightness component of the HSV model by adoption of a cross gradient search method, and obtaining a direction gradient and a spatial brightness similarity so as to generate a foreground image; carrying out connected domain segmentation on the foreground image by adoption of a 8-neighborhood connected domain segmentation method so as to obtain an insulator connected domain image; carrying out edge extraction on the insulation connected domain image by adoption of an LOG operator so as to obtain edge information of the image; carrying out 8-neighborhood edge classification on an image edge point by adoption of a 8-neighborhood edge tracking method; for pixel class groups obtained through the 8-neighborhood edge classification, carrying out edge linear detection on the groups, and displaying a recognized insulator profile. According to the method, complete insulator connected domain images can be obtained, so that the insulation recognition correctness is effectively improved, the operation speed is effectively improved and the calculation complexity is reduced.

Owner:CHANGAN UNIV

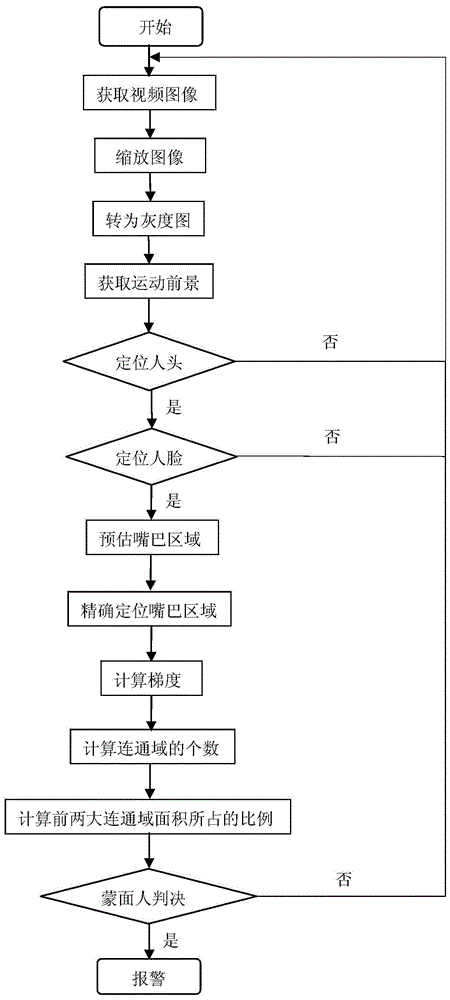

Dual-mode masked man event automatic detection method based on video characteristic statistics

ActiveCN105678213AWaste of human resourcesRun fastCharacter and pattern recognitionMouth regionTime processing

The invention provides a dual-mode masked man event automatic detection method based on video characteristic statistics. The dual-mode masked man event automatic detection method comprises the steps of: zooming a video frame and converting the video frame into a grayscale image after acquiring a source video image, acquiring a maximum object motion foreground rectangular frame, positioning a head region coarsely, acquiring face position information, then estimating a mouth region within the obtained face range, cutting the mouth region to narrow a range, calculating a gradient map, primarily judging whether a person is a masked man through calculating number of connected domains on the basis of the obtained gradient map, and calculating proportion of the areas of the top two connected domains for further judging whether the person is a masked man. The dual-mode masked man event automatic detection method based on video characteristic statistics does not have specific requirements for a video scene, is simple and efficient in the calculation method, can perform real-time processing, can be applied to real-time investigation and case solving, saves suspicious masked man information, and can provide first-hand information for evidence collection after a crime is committed.

Owner:SOUTH CHINA UNIV OF TECH

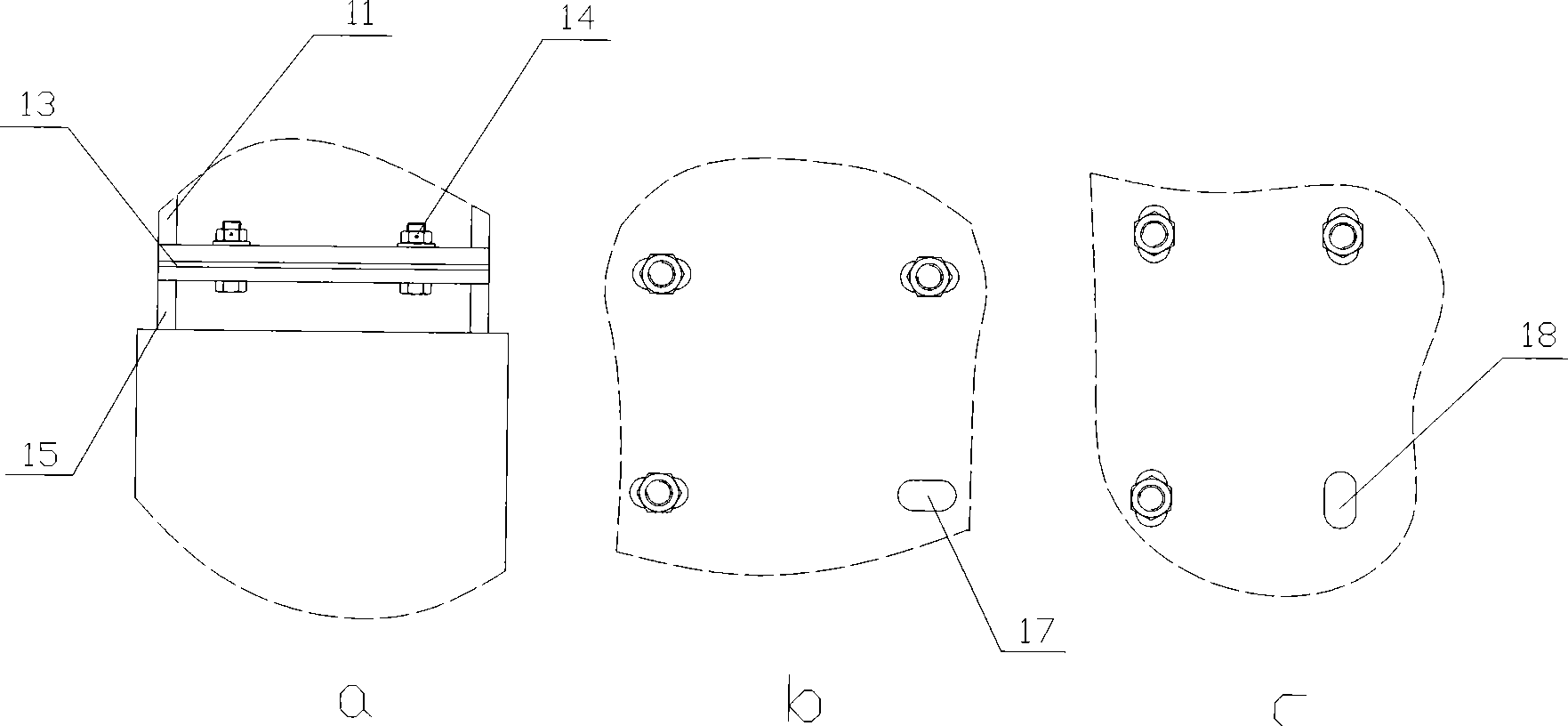

Radiation-retarding door body structure and mounting method thereof

InactiveCN101469596ASave steel plate material and transportationNo leakage hazardRadiation protectionLayered productsSteel platesEngineering

The present invention provides a radiation protection door structure which includes: door hanging device including hanging upper frame, guide way, fixed bolt and hanging lower frame; a groove that coordinates with the guide way is set on the upper end-face of the hanging upper frame and a circular hole is set on the lower end-face; a circular hole is set on the upper end-face of the hanging lower frame; the fixed bolt locks by passing through circular hole on lower end-face of the hanging upper frame and circular hole on the upper end-face of the hanging lower frame; the door includes: van-type frame, lead layer and boron containing polyethylene layer; the inner layer of the door is boron containing polyethylene layer, outer layer is lead layer and the outside of the lead layer is covered by van-type frame. The advantages are: a great volume of steel plate material and transport, hoisting cost is saved.

Owner:BLUESTAR BEIJING CHEM MACHINERY

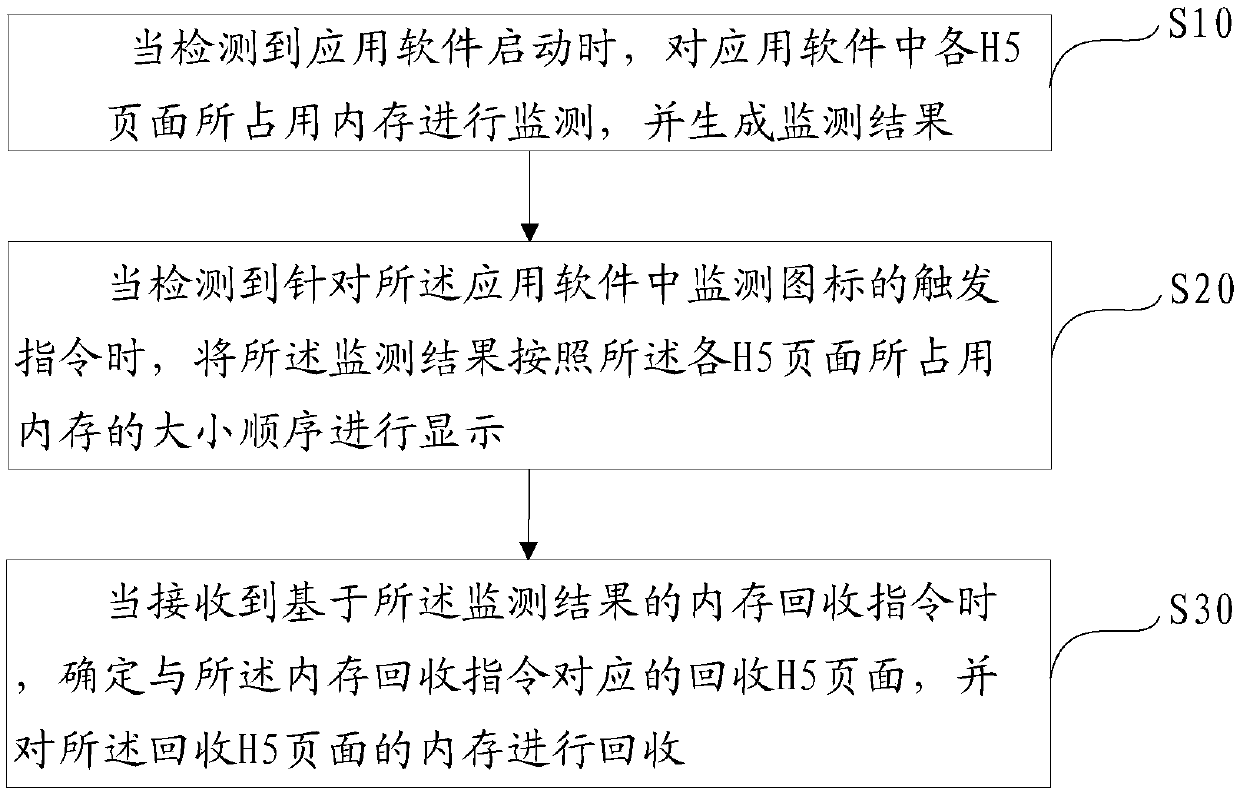

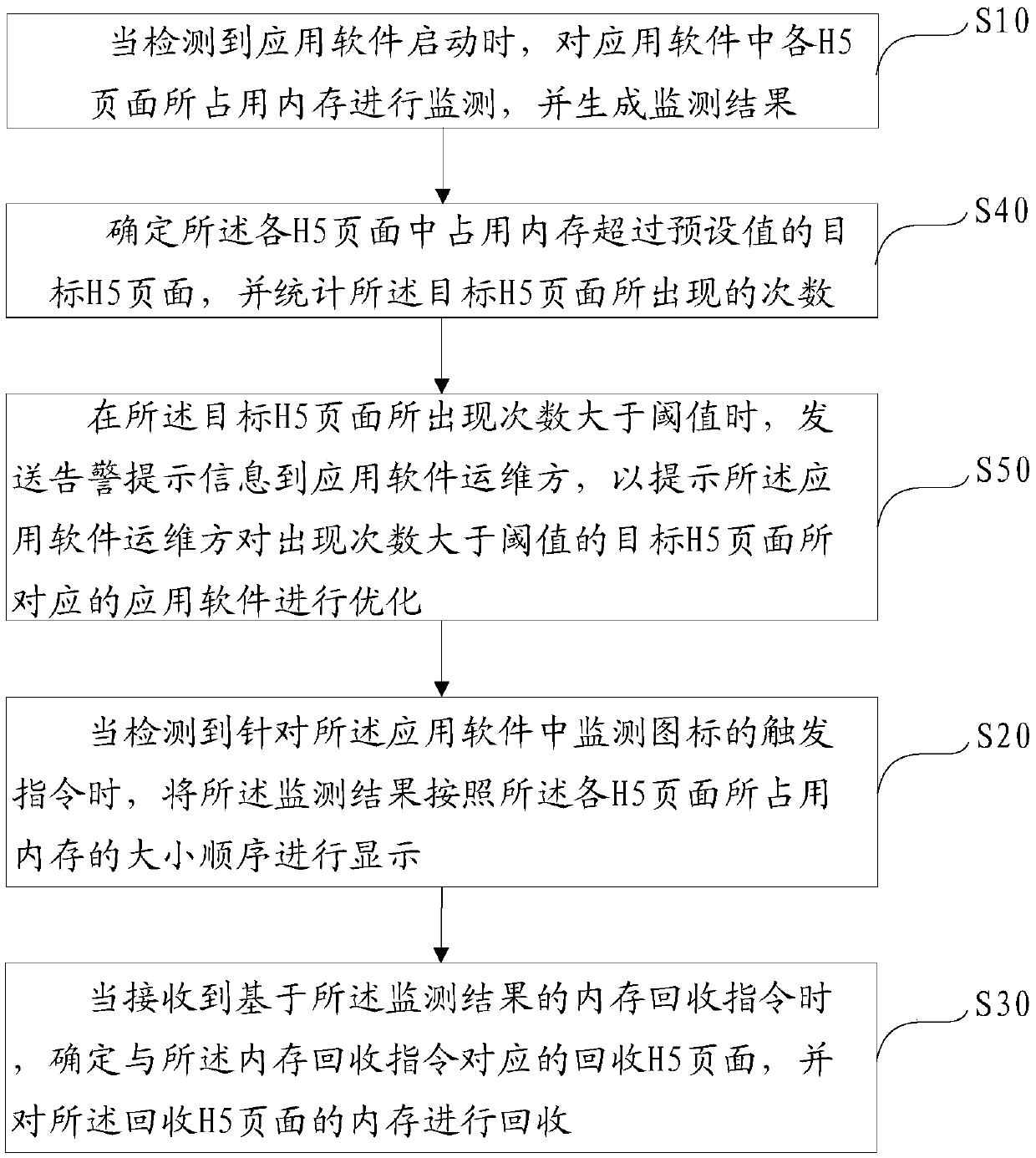

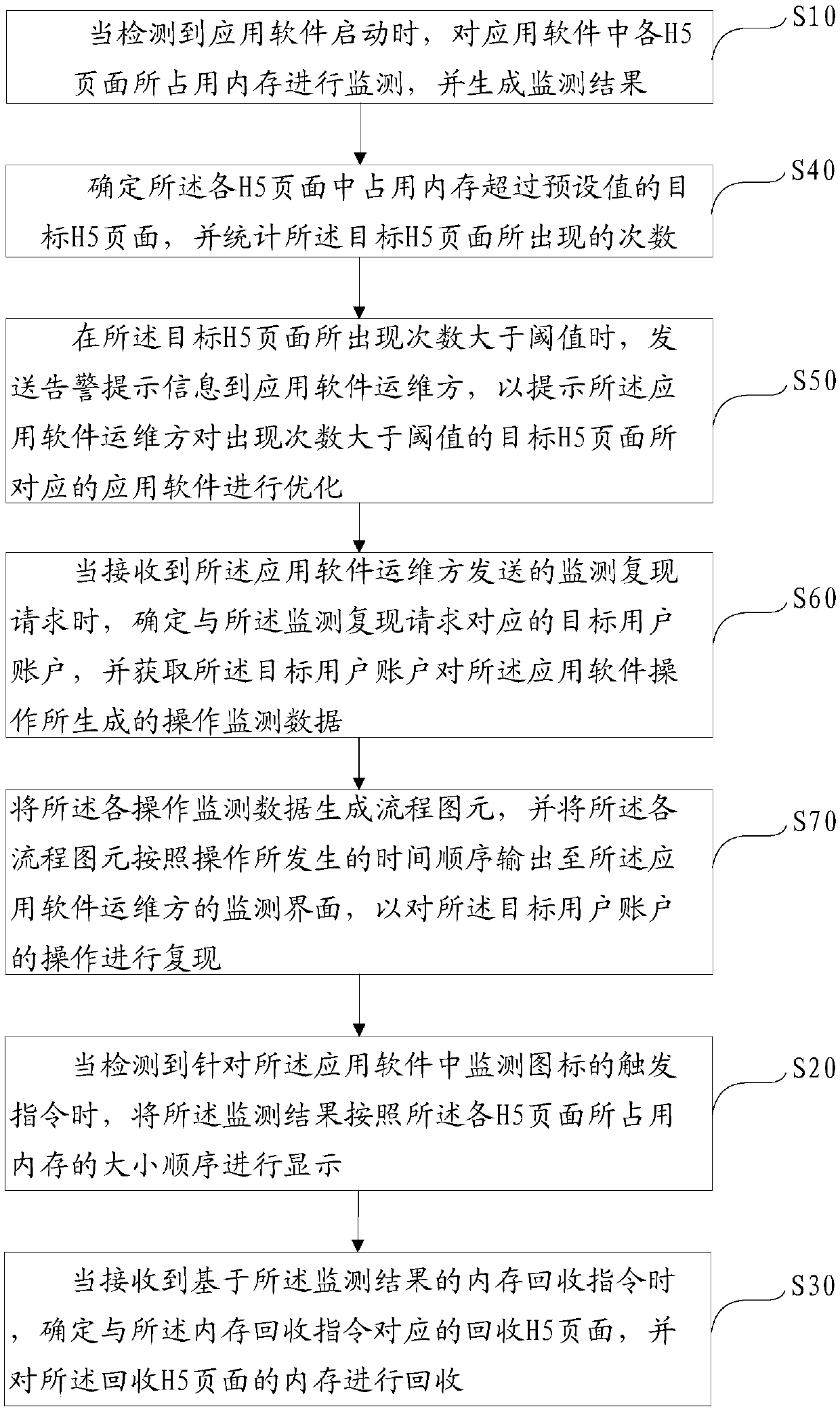

H5 page memory occupation monitoring method, device and equipment and readable storage medium

PendingCN109726069AGuaranteed uptimeRunning slowHardware monitoringComputer hardwareMemory footprint

The invention discloses an H5 page memory occupation monitoring method, device and equipment and a readable storage medium, and the method comprises the steps: when detecting that application softwareis started, monitoring the memory occupied by each H5 page in the application software, and generating a monitoring result; When a trigger instruction aiming at a monitoring icon in the application software is detected, displaying the monitoring result according to the size sequence of a memory occupied by each H5 page; And when a memory recovery instruction based on the monitoring result at theterminal side is received, determining a recovery H5 page corresponding to the memory recovery instruction, and recovering the memory of the recovery H5 page. According to the scheme, the memory occupation conditions of all the H5 pages in the application software are automatically monitored, the monitoring result can be checked, the H5 pages needing to be recycled are selected, the occupied memory is recycled, the situation that due to memory occupation, the running speed of the application software is low, and the application software breaks down is avoided, and the running of the application software is smoother.

Owner:PINGAN PUHUI ENTERPRISE MANAGEMENT CO LTD

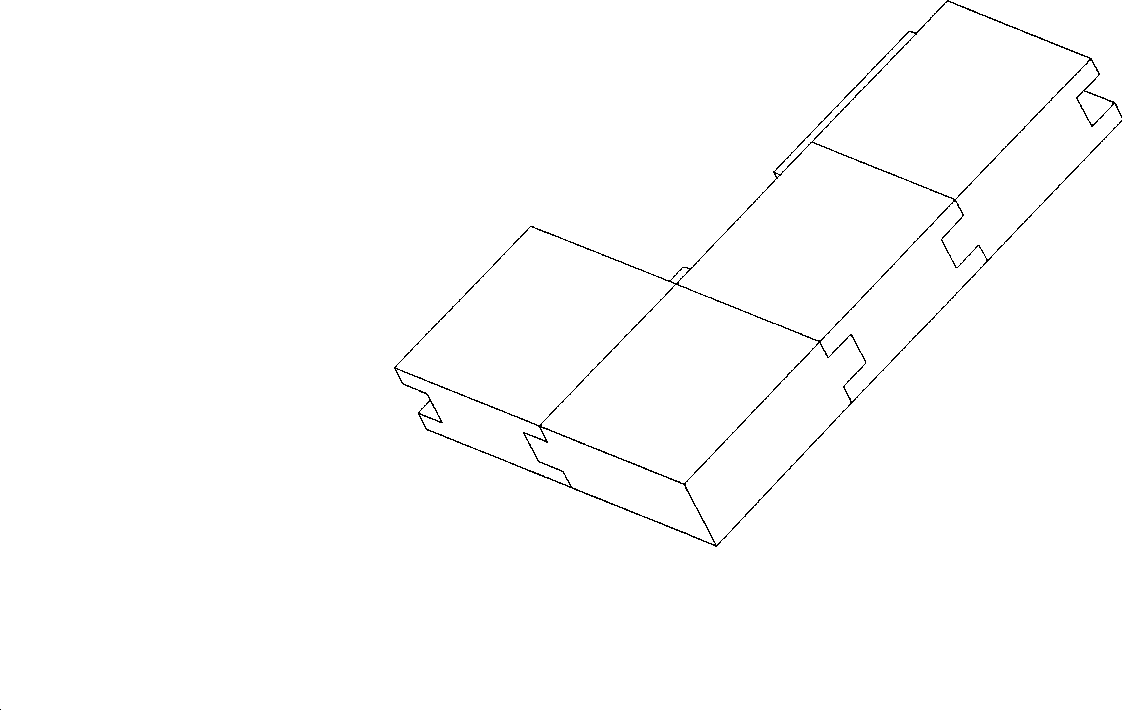

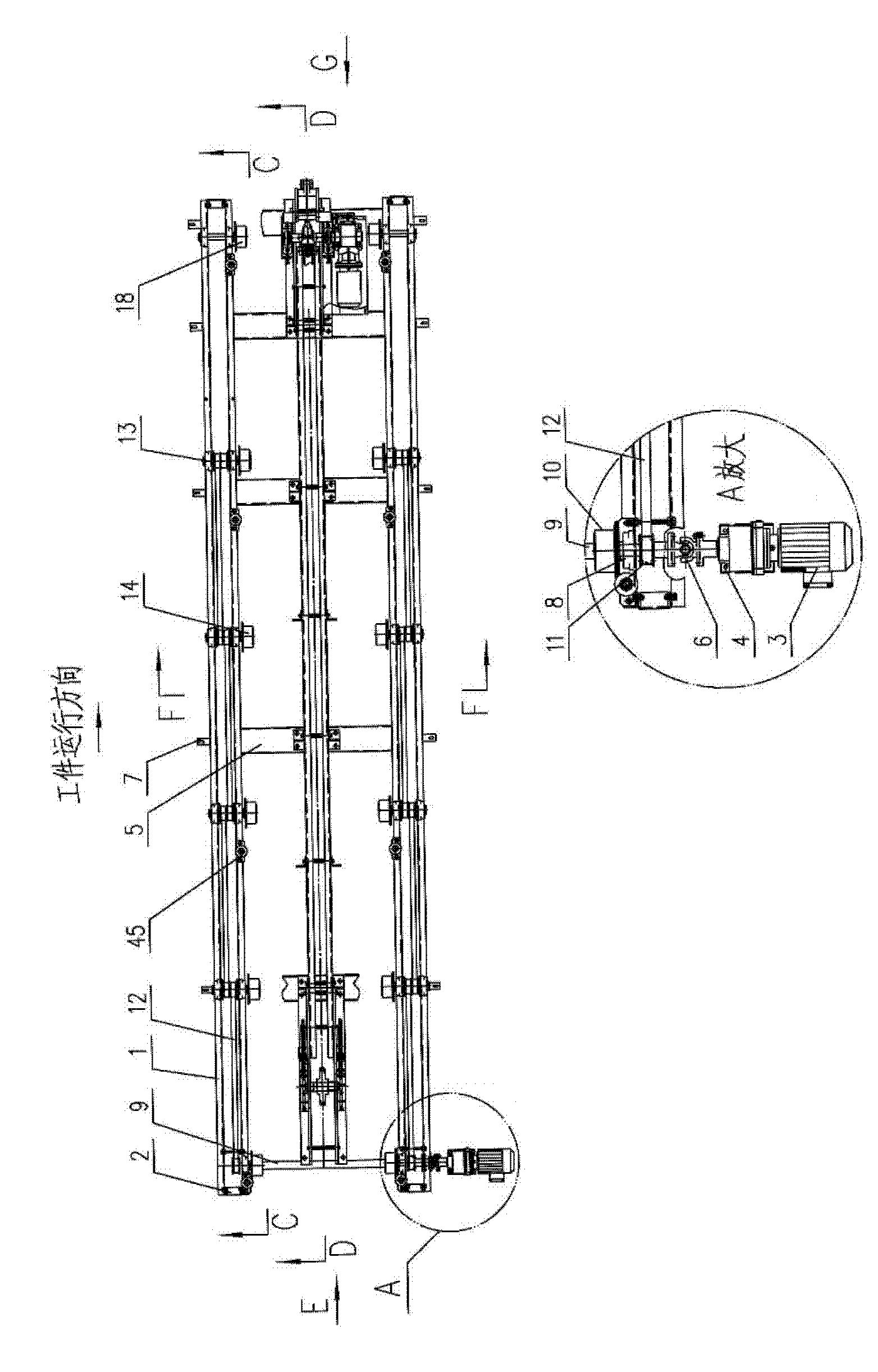

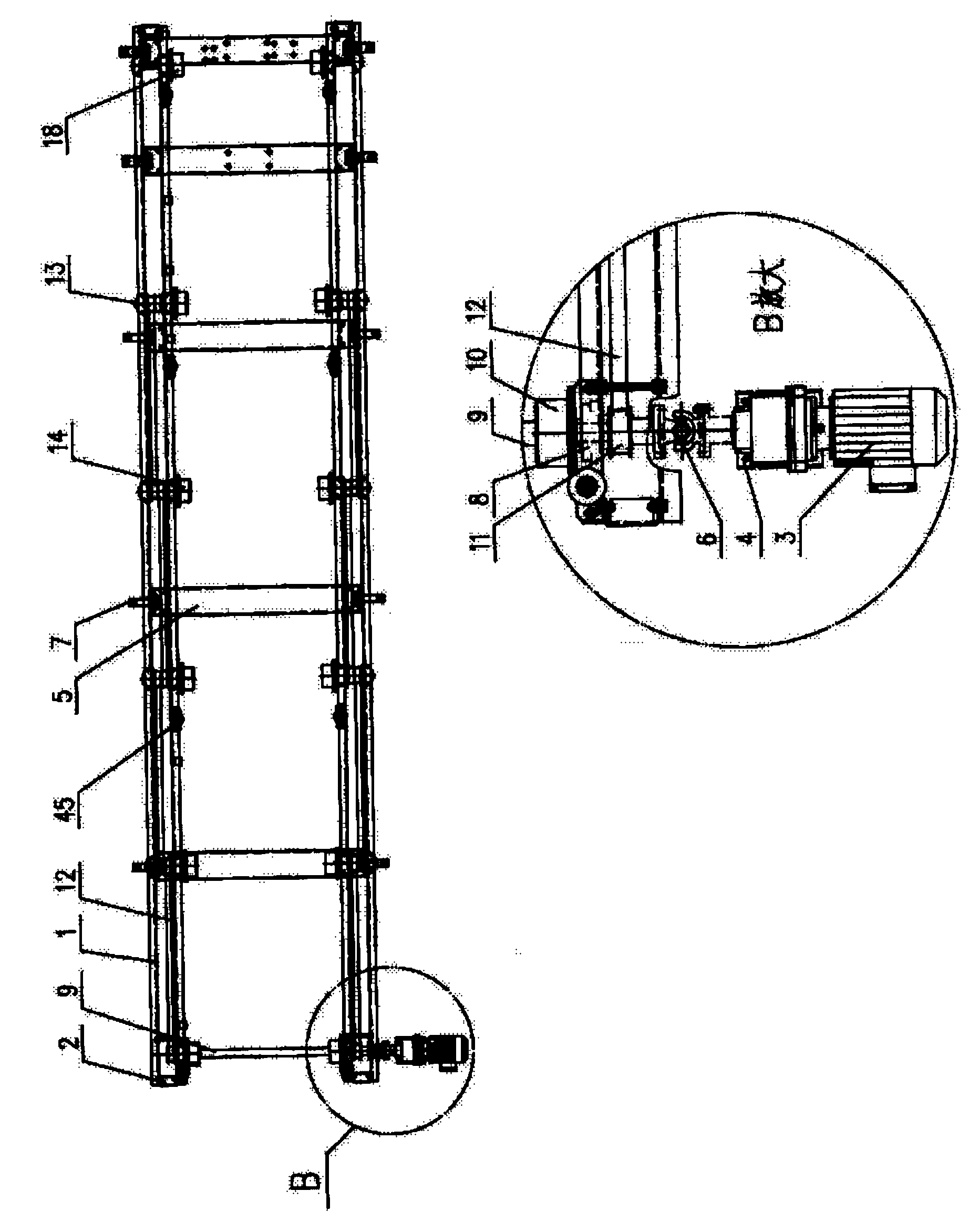

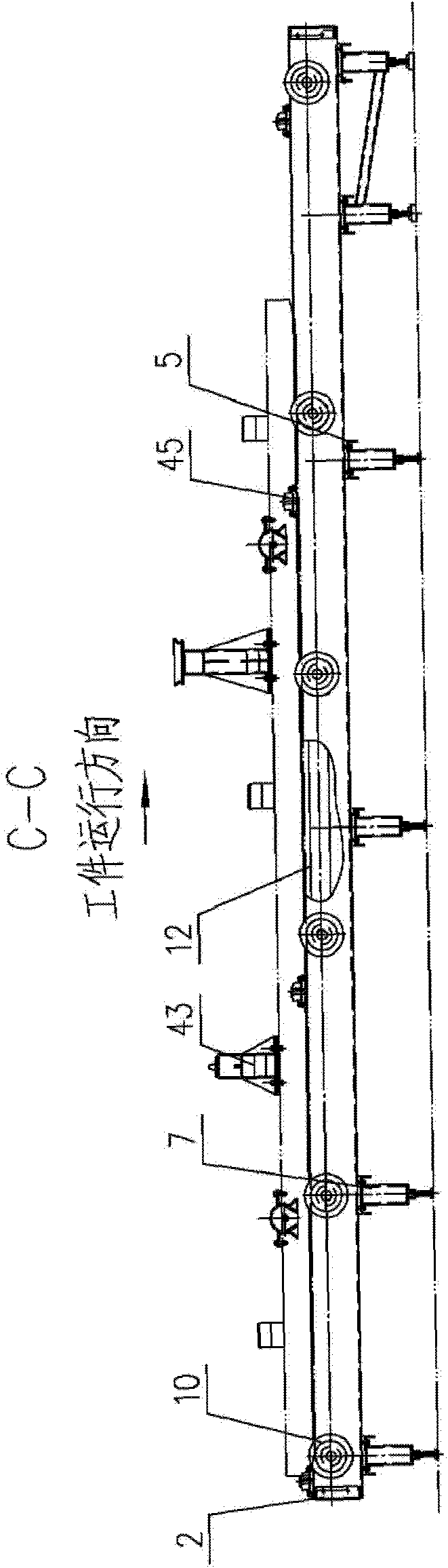

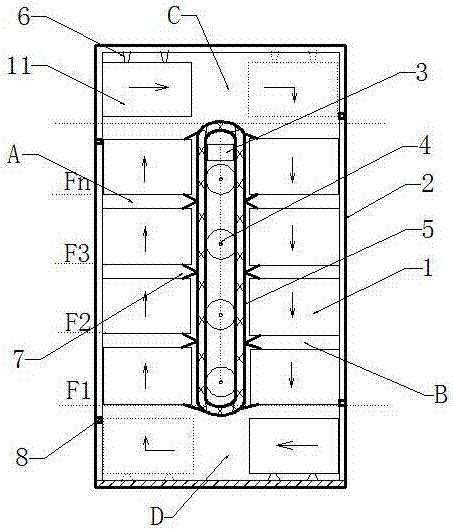

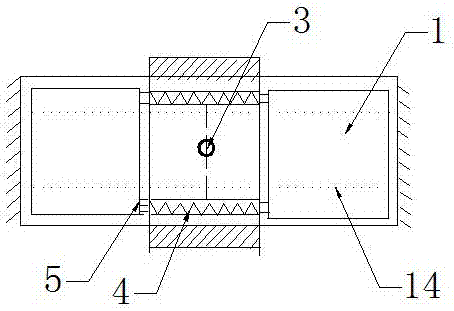

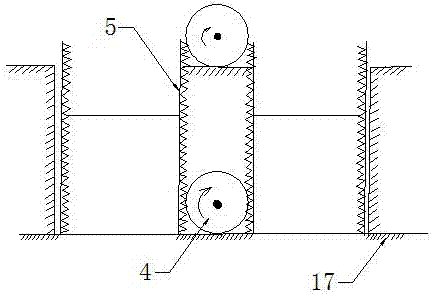

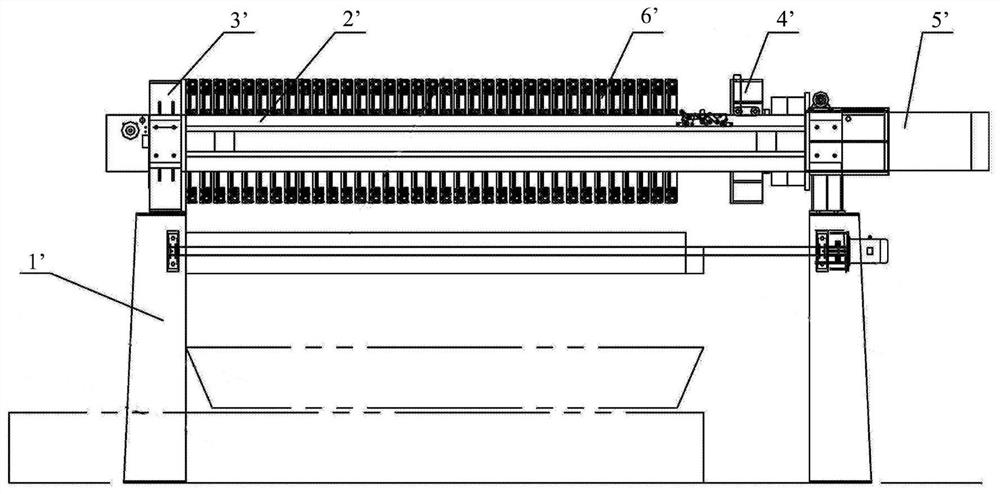

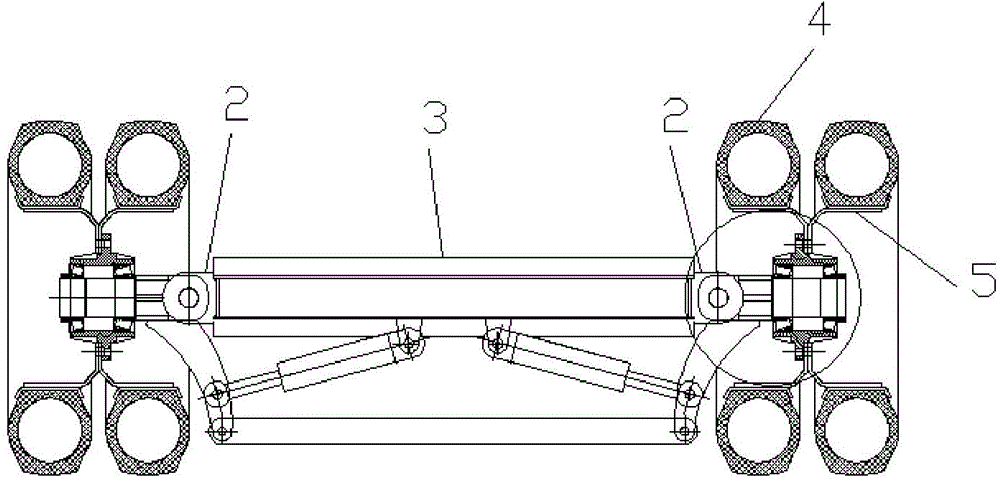

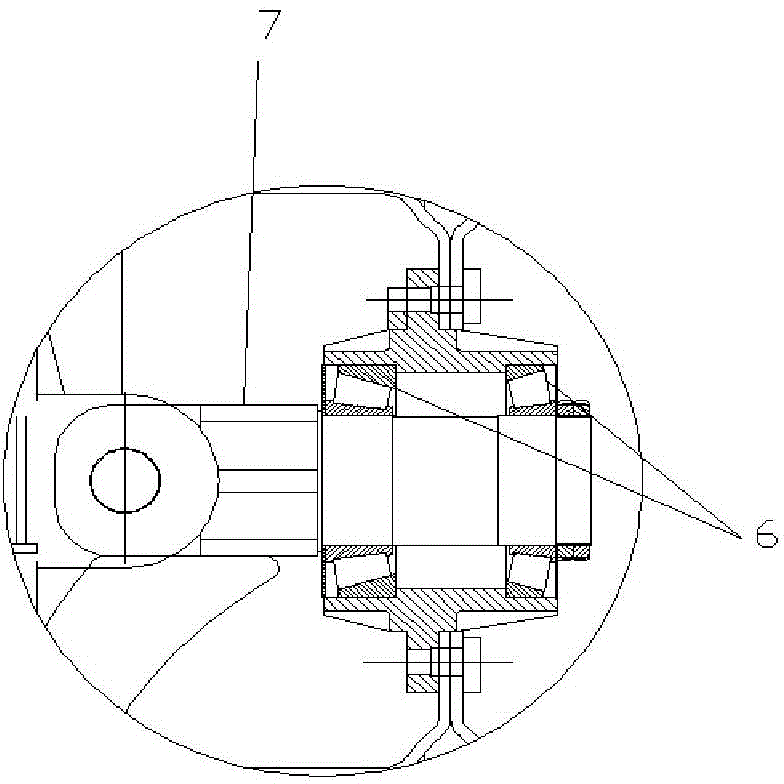

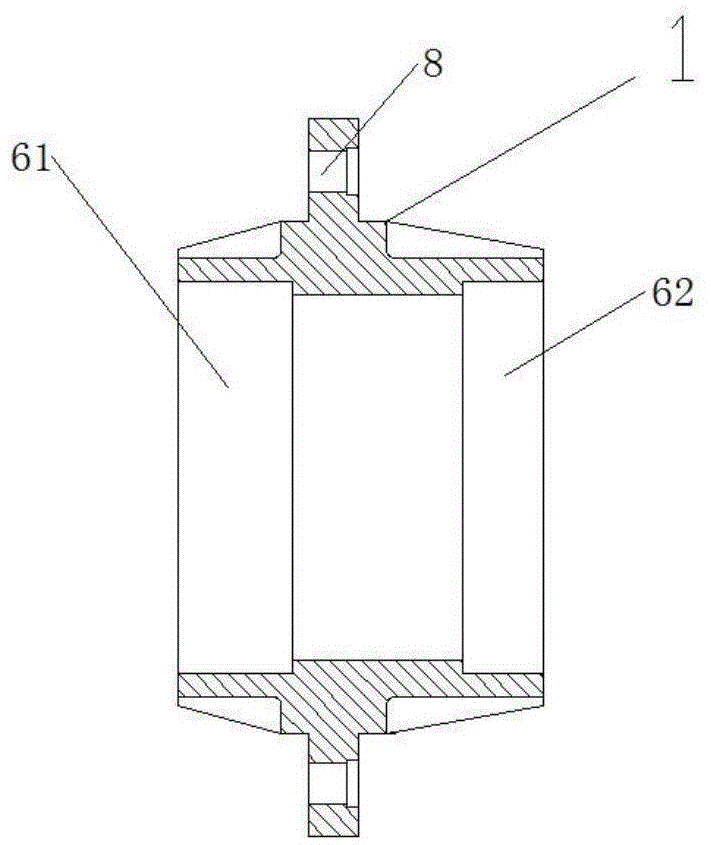

Chain-type boosting inlet roller machine for oscillating bar conveyer

ActiveCN101850900APrevent slippingReduce frictional resistanceConveyorsConveyor partsLow speedUniversal joint

The invention relates to a chain-type boosting inlet roller machine for an oscillating bar conveyer. The roller machine consists of a frame, a speed reducing motor, a universal joint, and a long roller component, a short roller component and a free roller component which are used for supporting and conveying a runner, wherein a roller is supported in a plummer block on the frame; an adjustable support leg is fixed to the lower part of the frame; a chain-type boosting mechanism consists of a tensioning section, a driving section and a middle section which are linked with one another through a chain; the chain is provided with a push head and runs in a groove track of each section; a sledge body which bears a workpiece is supported on the roller; the chain is driven by the speed reducing motor in the driving section; the push head pushes a sledge body cross beam to move forward and be jointed with the oscillating bar, so that the roller machine starts running. Since the chain runs stably at a low speed without impact, the jointing reliability and stability of the sledge body and the oscillating bar are high. An oscillating arm of a positioning mechanism is driven by a cylinder so as to block and position the sledge body. The roller machine is characterized by full chain transmission process, no sliding of the sledge body in the roller machine, low running speed, stability, little impact and shock, high reliability and capacity of more than or equal to 60 JPH.

Owner:AUTOMOTIVE ENG CORP +1

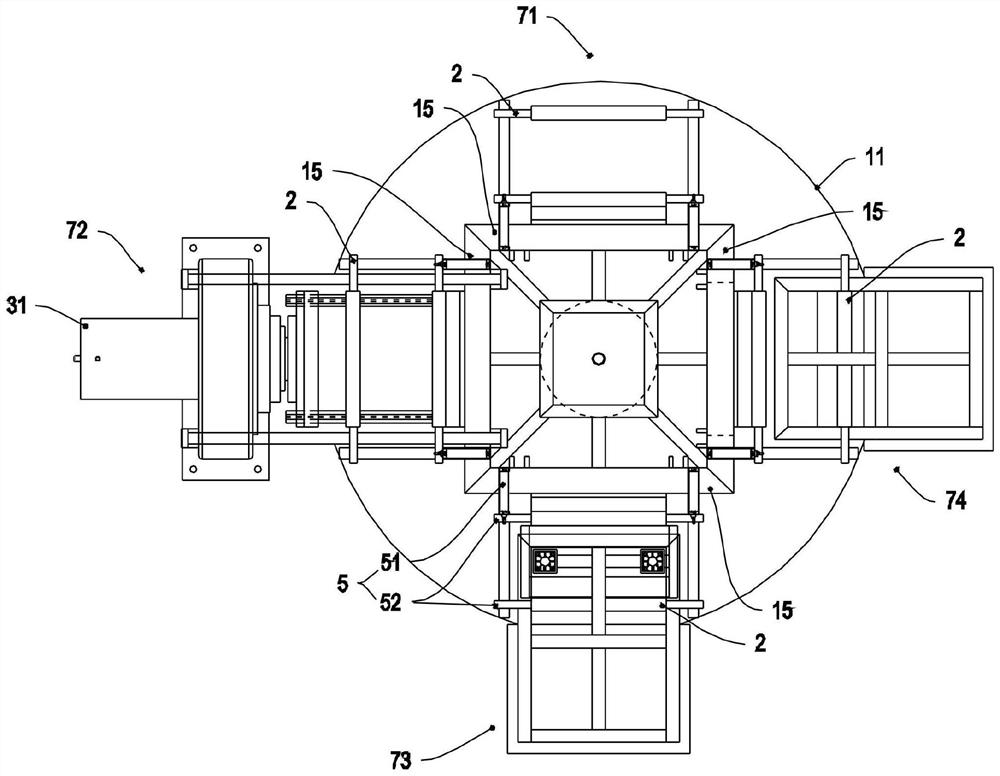

Intelligent elevator capable of driving plurality of lift cars to move circularly by utilizing gears

PendingCN107311012AIncrease passenger capacityImprove space utilizationBuilding liftsSynchronous motorCar driving

The invention provides an intelligent elevator capable of driving a plurality of lift cars to move circularly by utilizing gears. The intelligent elevator comprises lift cars, guide rails, a shaft, a synchronous motor set, a gear set, a lift car driving mechanism, a lift car reversing driving mechanism and a lift car storage region, wherein a supporting framework is arranged in the middle of the shaft and is used for bearing the synchronous motor set, the gear set, the lift car driving mechanism and the like; the inner part of the shaft is divided into a lift car ascending region, a lift car descending region, a top reversing region and a bottom reversing region; the intelligent elevator is characterized in that the lift cars further comprises a reversing lift car; a hook and an unhooking mechanism are arranged between the lift cars and the lift car driving mechanism; and the intelligent elevator is further provided with a central controller, and a first position sensor, a second position sensor, a lift car door control device, a delaying relay and the like. According to the intelligent elevator provided by the invention, a product combines software and hardware and the operation time and retention time of the elevator can be strictly controlled so that the utilization rate of the elevator is greatly improved.

Owner:张博飞

Novel smashing and grinding technology and equipment

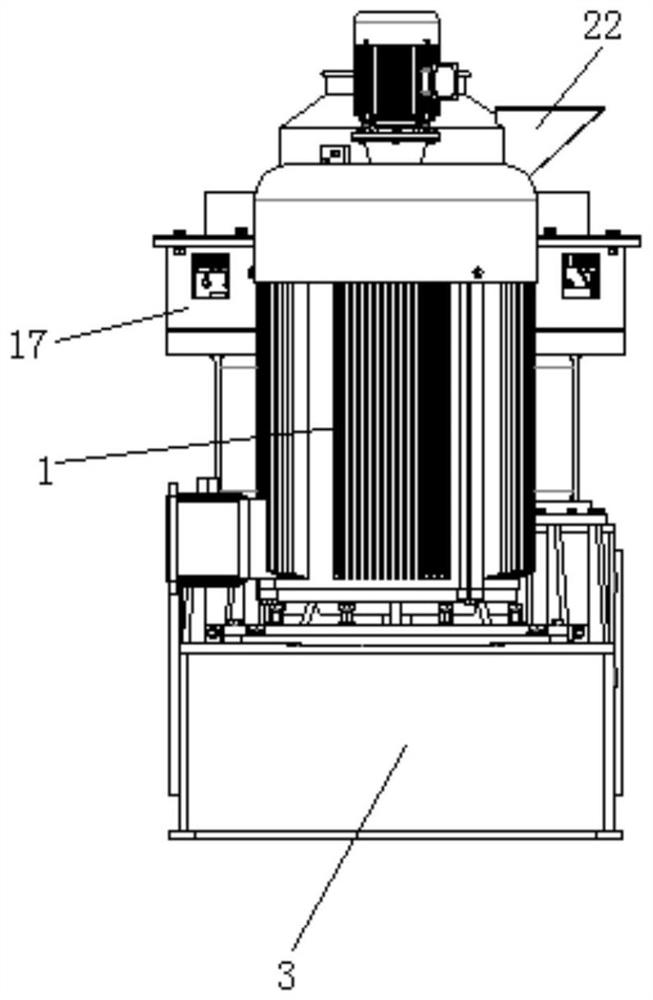

InactiveCN103252275ARealize the processing methodRealize the integration of crushing and grindingGrain treatmentsDynamic balanceEngineering

The invention discloses novel smashing and grinding equipment which comprises a stander, at least two working plates and a thrust mechanism, and the novel smashing and grinding equipment is characterized in that one of at least two working plates is used as a fixing plate and is fixed on the stander, and the other working plates are used as movable plates; all the working plates are arranged in an adjacent manner, and a smashing cavity is formed between every two adjacent working plates, and an opening degree is formed; each smashing cavity is provided with an inlet and an outlet; the size of the opening degree of each smashing cavity is changed along with the change of a relative position between every two adjacent working plates; the thrust mechanism is fixed on the stander or is fixed between the stander and each movable plate; and the thrust mechanism is connected with or separated from the movable plates. Compared with conventional smashing grinding equipment, the novel smashing and grinding equipment has the advantages that straight thrust uniformly acts on the fixing plate and the movable plates of the smashing cavities, so that respective particles of the materials can adaptively reach mechanical dynamic balance under stress, and the particles are smashed by relatively uniform squeezing force; and due to the smashing of the materials, a processing method for replacing grinding by smashing is really realized.

Owner:杨建勋 +2

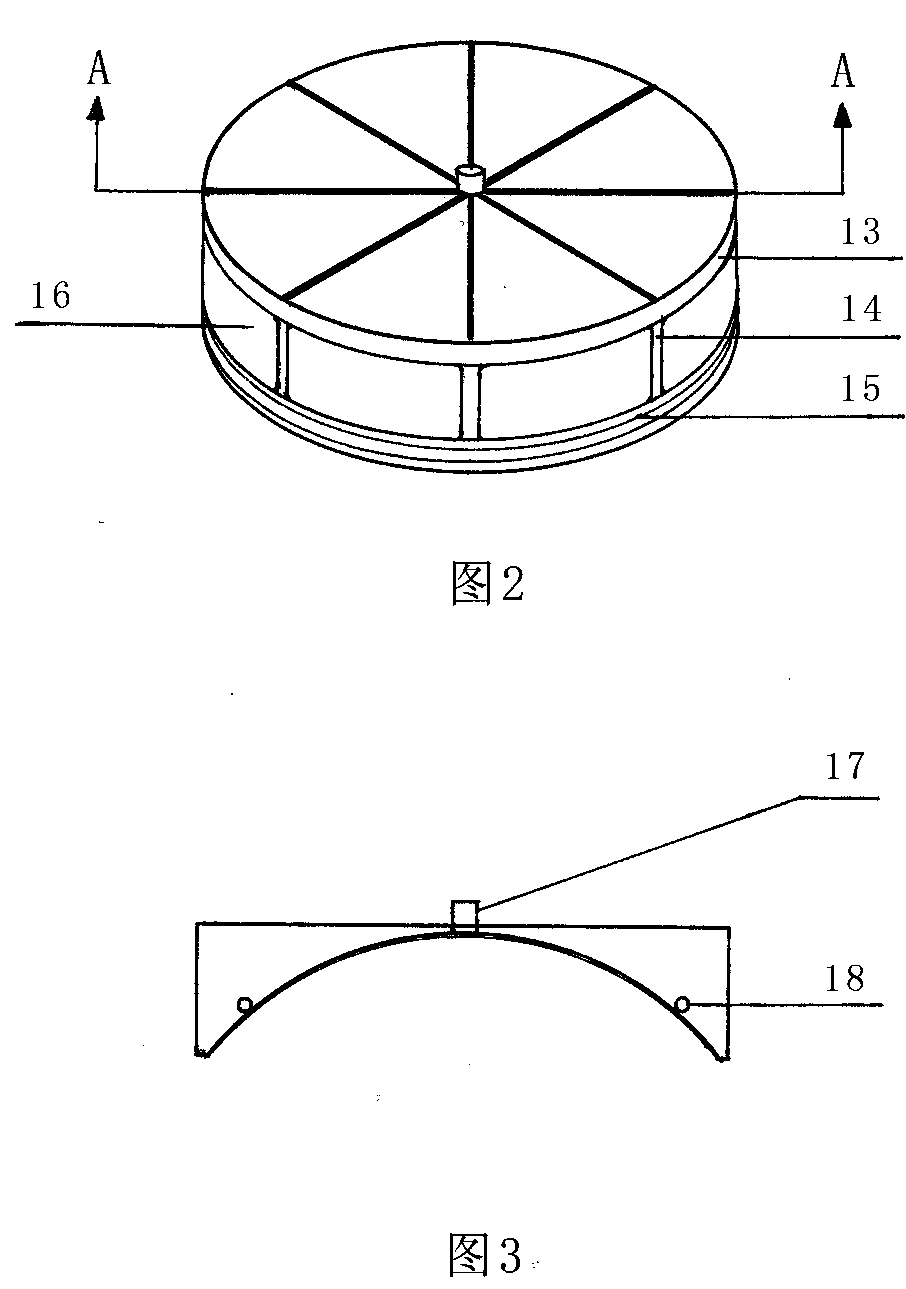

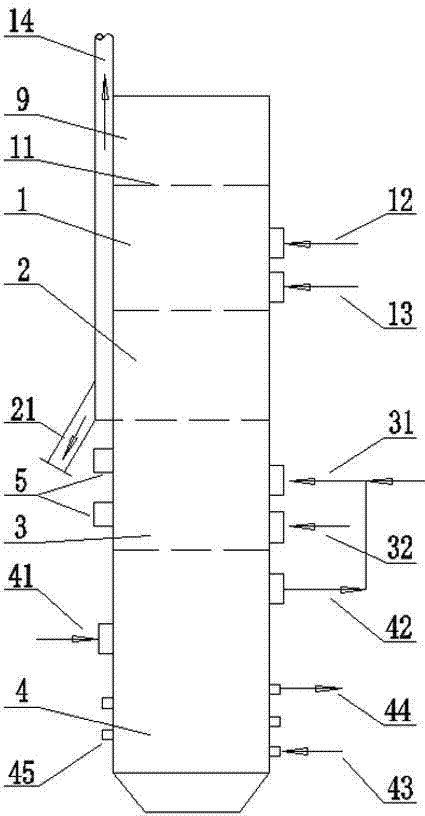

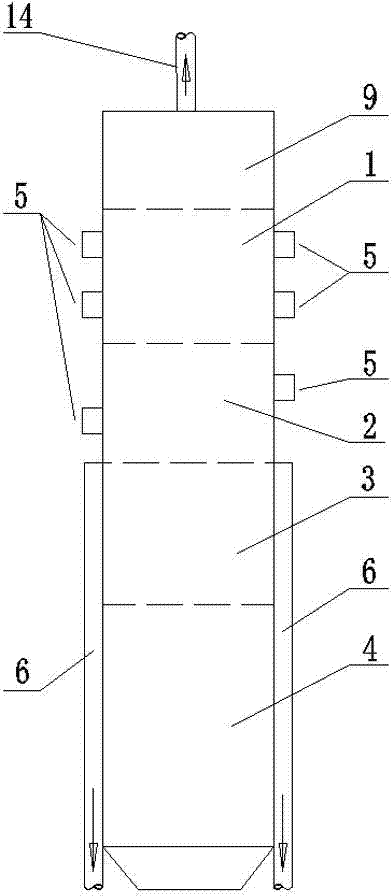

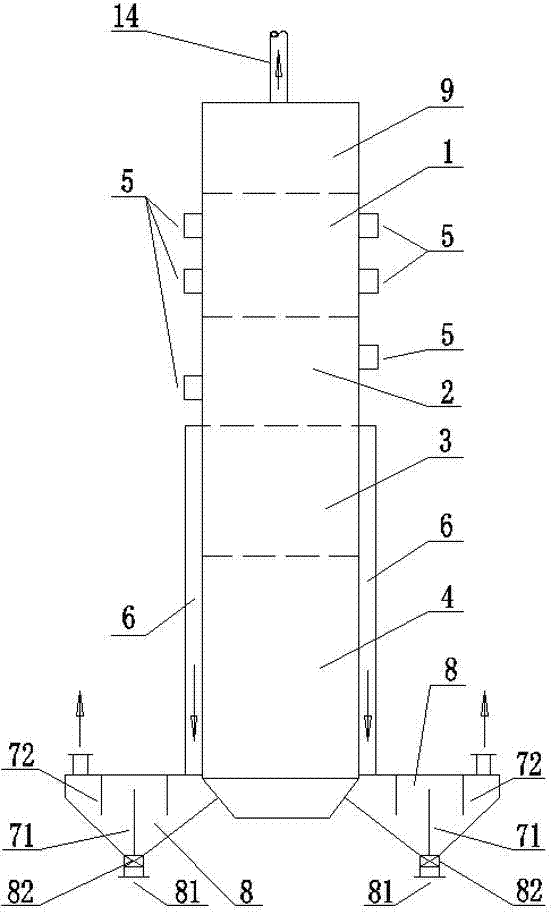

Vacuum-energy-storage-type launching catapult for fixed-wing aircraft

The invention relates to a vacuum-energy-storage-type launching catapult for a fixed-wing aircraft. The vacuum-energy-storage-type launching catapult is formed through sequentially connecting an electric winch, a trailer wagon, a speed transformation, a cable winding pulley, a large-diameter piston, a large-caliber vacuum cylinder, an oil pump, an oil storage tank and the like. The electric winch draws the piston to slowly rise to an upper dead point from a lower dead point under the deceleration of the speed transformation, so as to enable the interior of the vacuum cylinder to reach a completely-vacuum state and complete energy storage; the piston enables the trailer wagon to drive the aircraft to rapidly advance and launch through the acceleration of the speed transformation under the propulsion of atmospheric pressure and self-gravity, so as to complete catapult. Data related to specific embodiments of the invention are as follows: the catapult traction distance is 99 meters, the constant net traction force is 31.4 tons, the energy storage power is 600kw, the energy storage time is 60 seconds, the minimum requirements of a power supply on power is 800kw, the power consumption for catapult of one aircraft is lower than 20 kilowatt-hours, the gross weight of the catapult is lighter than 60 tons, and a system main body, i.e., the large-caliber vacuum cylinder has the height of 126 meters and the volume of 465 cubic meters. The vacuum-energy-storage-type launching catapult has the most principal features of uniformity in acceleration, little heat generation, low energy consumption, electrification, light weight and few systems.

Owner:王振川

Vacuum energy storage fixed-wing aircraft take-off catapult

The invention relates to a vacuum-energy-storage-type launching catapult for a fixed-wing aircraft. The vacuum-energy-storage-type launching catapult is formed through sequentially connecting an electric winch, a trailer wagon, a speed transformation, a cable winding pulley, a large-diameter piston, a large-caliber vacuum cylinder, an oil pump, an oil storage tank and the like. The electric winch draws the piston to slowly rise to an upper dead point from a lower dead point under the deceleration of the speed transformation, so as to enable the interior of the vacuum cylinder to reach a completely-vacuum state and complete energy storage; the piston enables the trailer wagon to drive the aircraft to rapidly advance and launch through the acceleration of the speed transformation under the propulsion of atmospheric pressure and self-gravity, so as to complete catapult. Data related to specific embodiments of the invention are as follows: the catapult traction distance is 99 meters, the constant net traction force is 31.4 tons, the energy storage power is 600kw, the energy storage time is 60 seconds, the minimum requirements of a power supply on power is 800kw, the power consumption for catapult of one aircraft is lower than 20 kilowatt-hours, the gross weight of the catapult is lighter than 60 tons, and a system main body, i.e., the large-caliber vacuum cylinder has the height of 126 meters and the volume of 465 cubic meters. The vacuum-energy-storage-type launching catapult has the most principal features of uniformity in acceleration, little heat generation, low energy consumption, electrification, light weight and few systems.

Owner:王振川

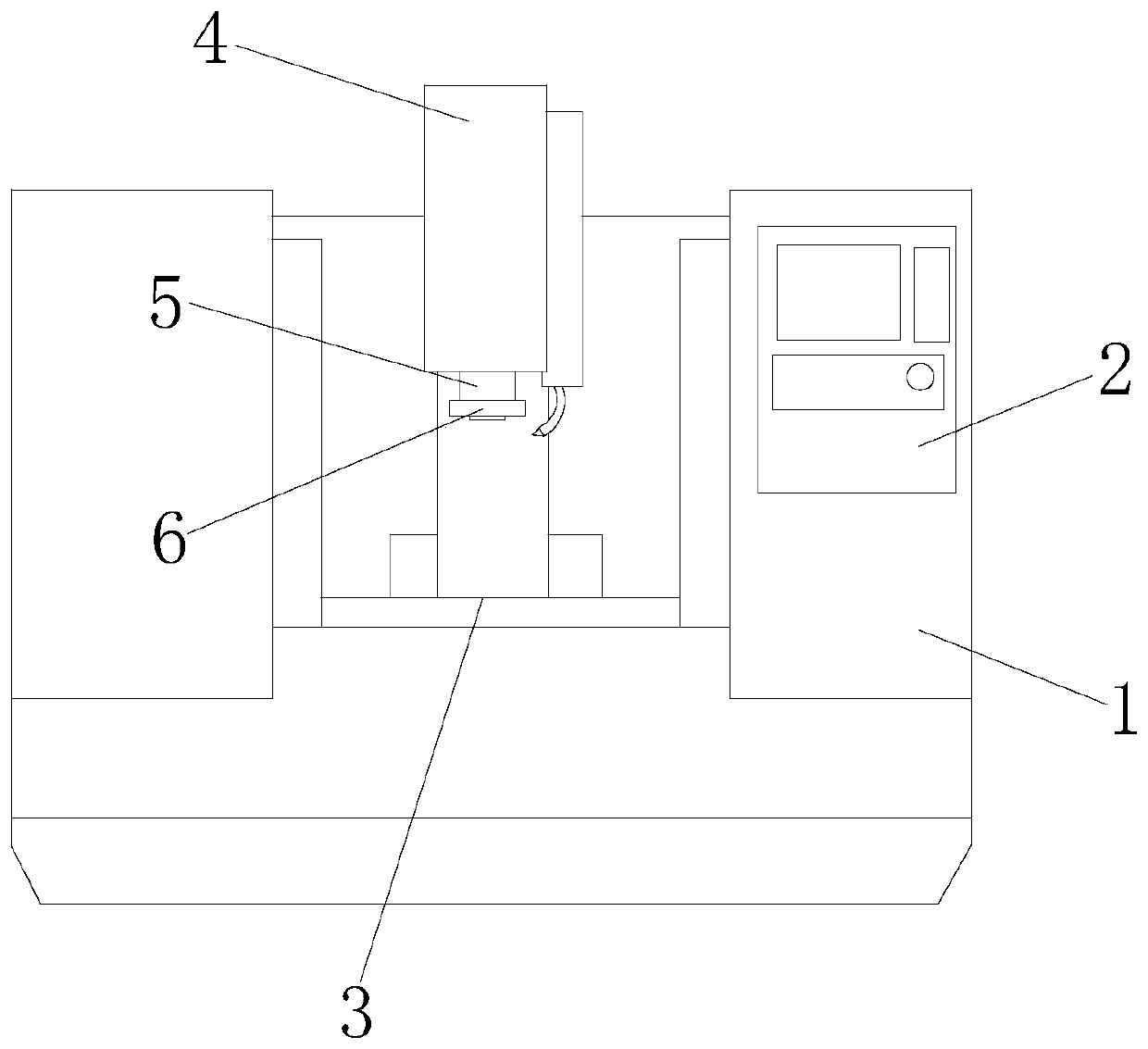

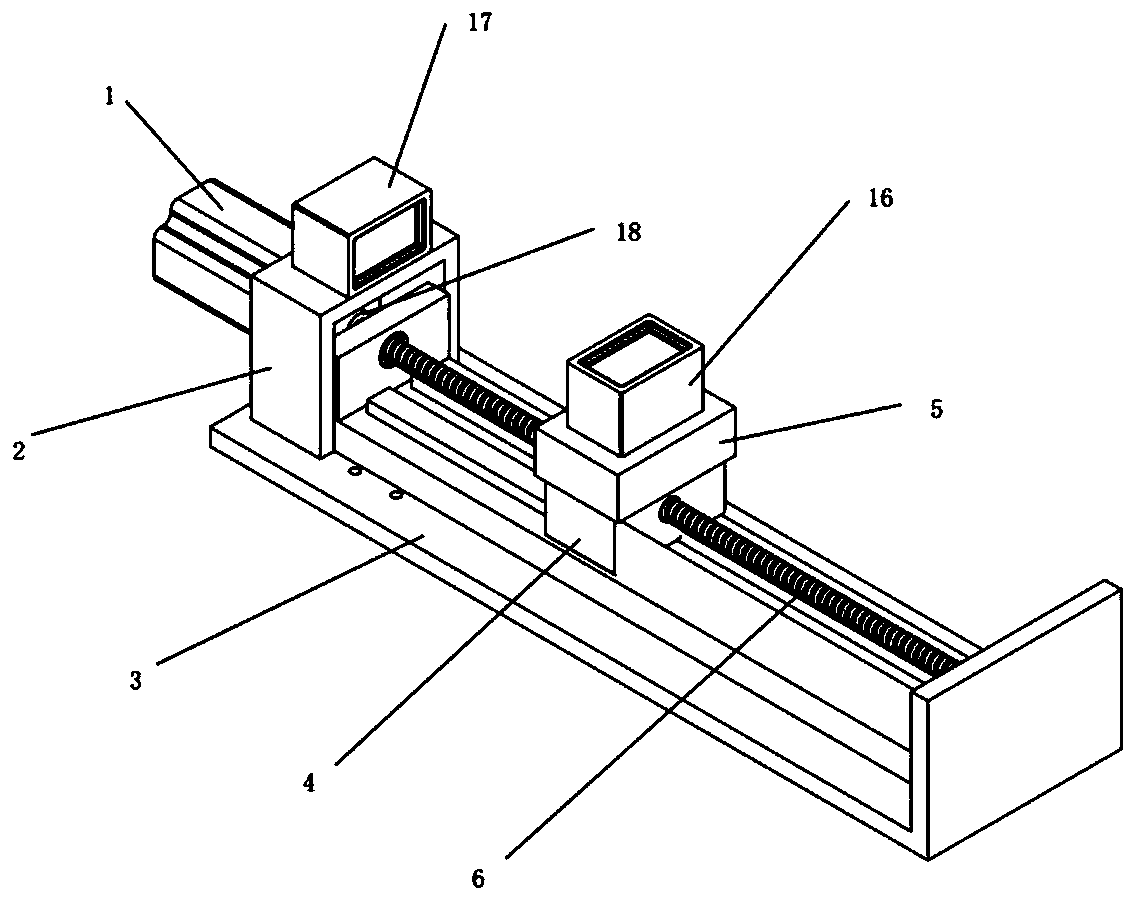

Numerical control metal cutting machine tool

ActiveCN111113136AOptimize dataRunning slowMaintainance and safety accessoriesNumerical controlProcess engineering

The invention discloses a numerical control metal cutting machine tool. The numerical control metal cutting machine tool structurally comprises an equipment main body, a controller, a workbench, a stand column, a machine head and a scale cleaning device. The numerical control metal cutting machine tool has the beneficial effects that oil dirt left on the surface of the machine head due to long-term operation is further scraped through scale scraping mechanisms so as to prevent the situation that the machine head operates at a low speed due to thickened oil dirt and a rotating fault occurs to the machine head of equipment under the opposed impact action of high-speed operation; an antimagnetic structure is used for eliminating thermal magnetization generated from high-speed rotating to thesurface of the machine head and adsorbing metal scraps produced during operation; the antimagnetic structure is used for adsorption treatment on the metal scraps, so that data errors occurring in thecutting process due to excess metal scraps adhering to the machine head is avoided.

Owner:江苏中智自动化股份有限公司

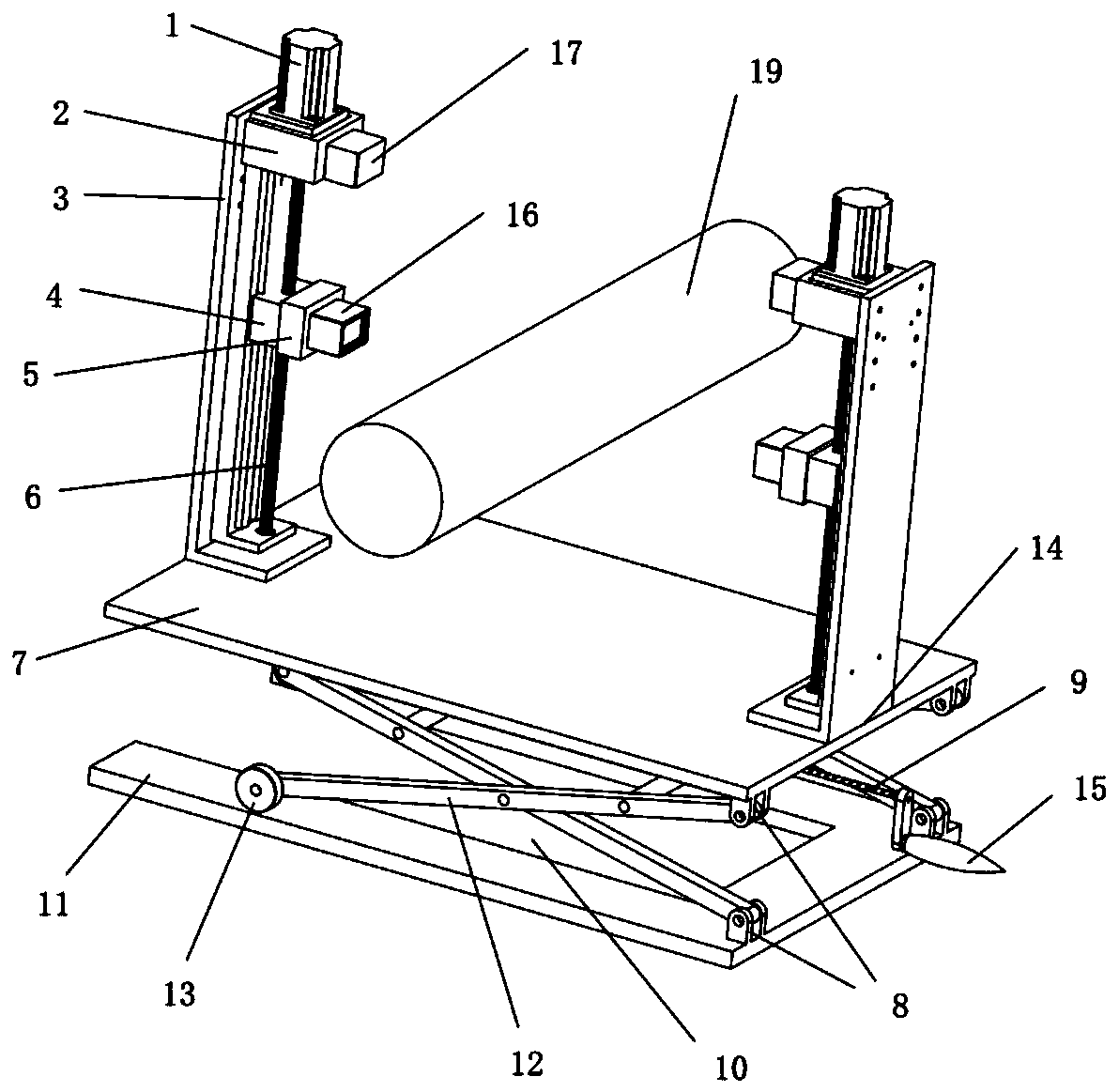

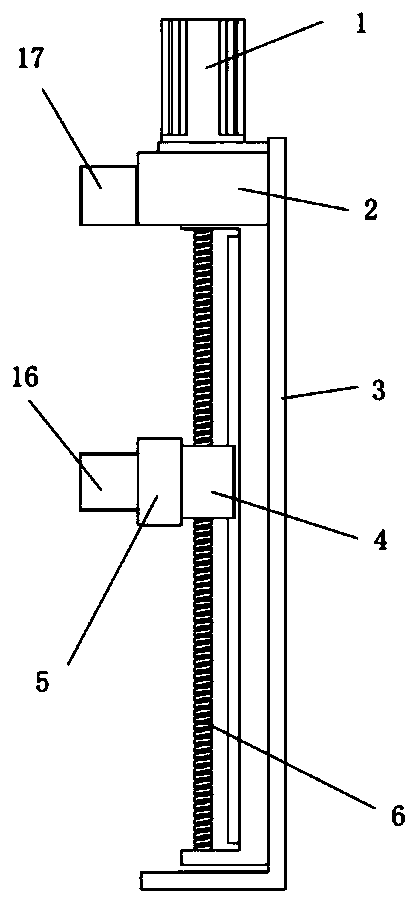

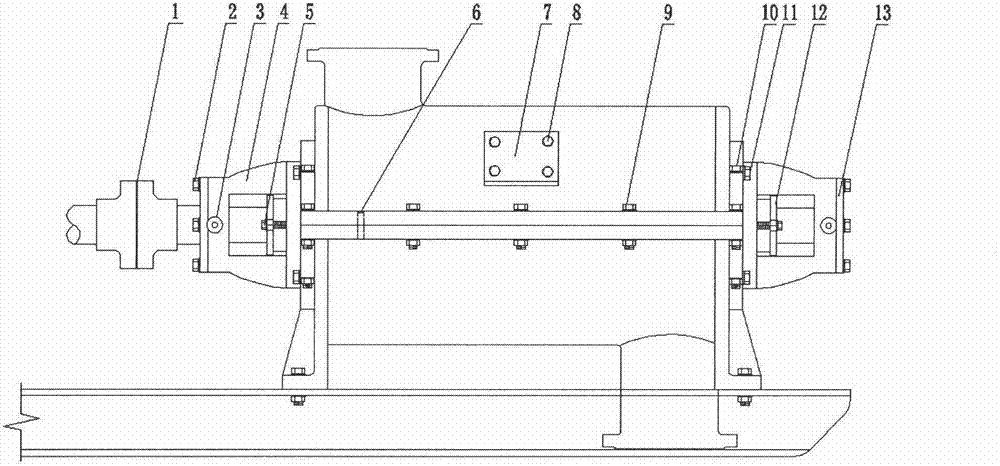

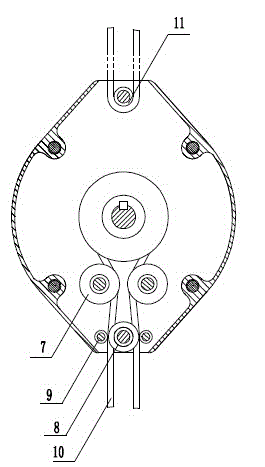

Non-contact measuring equipment for radial deformation of submarine cable

ActiveCN110132156ARunning slowGuaranteed sampling timeMaterial strength using tensile/compressive forcesUsing optical meansBall screwMultiple sensor

The invention discloses non-contact measuring equipment for radial deformation of a submarine cable, which belongs to the field of submarine device testing and is used for scanning the contour of thesubmarine cable and accurately measuring the radial deformation of the submarine cable. The non-contact measuring equipment comprises a lifting table and two sets of identical scanning devices, wherein each set of scanning device comprises a fixed plate, a guide rail, a driving device and two sensors; the two sets of identical scanning devices are symmetrically arranged on both sides of the lifting table to realize full contour scanning of a submarine cable to be measured; the lifting table can be adjusted according to the position of the submarine cable in an experiment in order to adapt to the experimental environment; the driving device can output a relatively low revolving speed to ensure adequate scanning time; and a ball screw guide rail can meet the requirement of experimental accuracy in a relatively economical way. The contour of the submarine cable is scanned through the cooperation of multiple sensors, so that the radial deformation of the submarine cable is measured accurately, which is of great significance to the stiffness analysis of the submarine cable.

Owner:DALIAN UNIV OF TECH

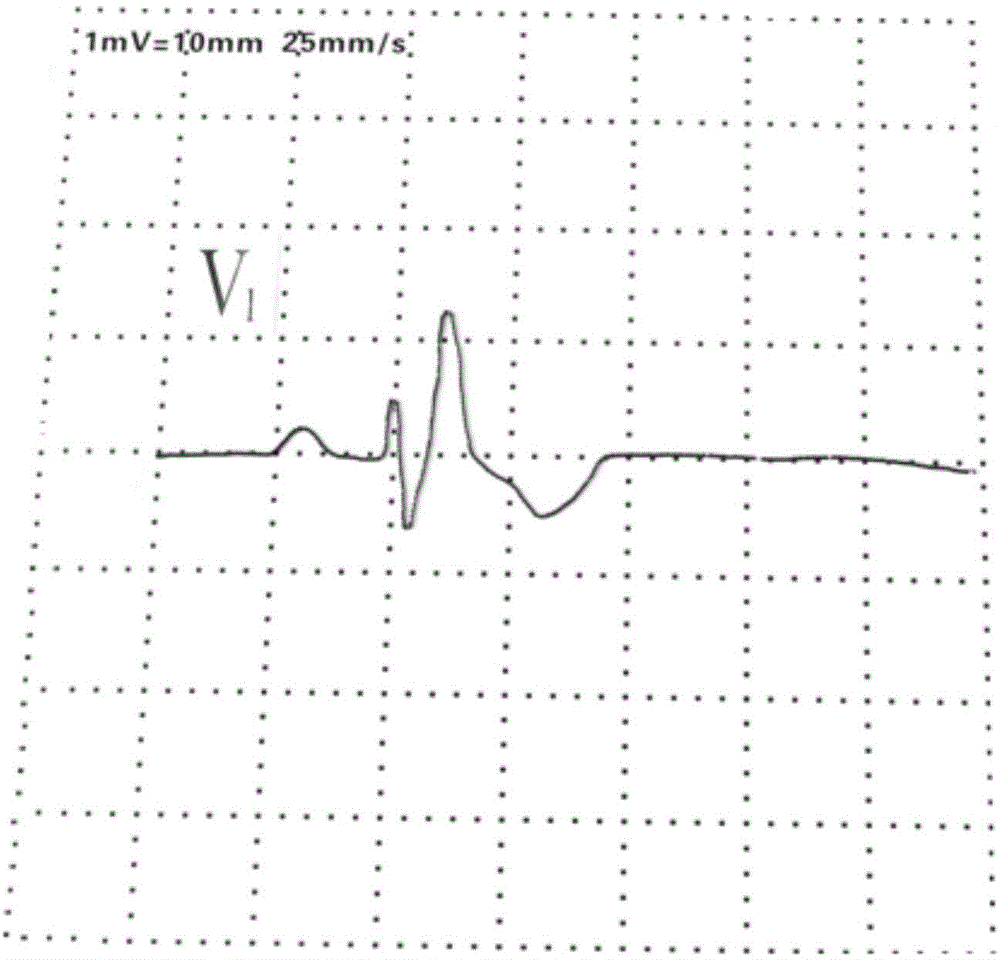

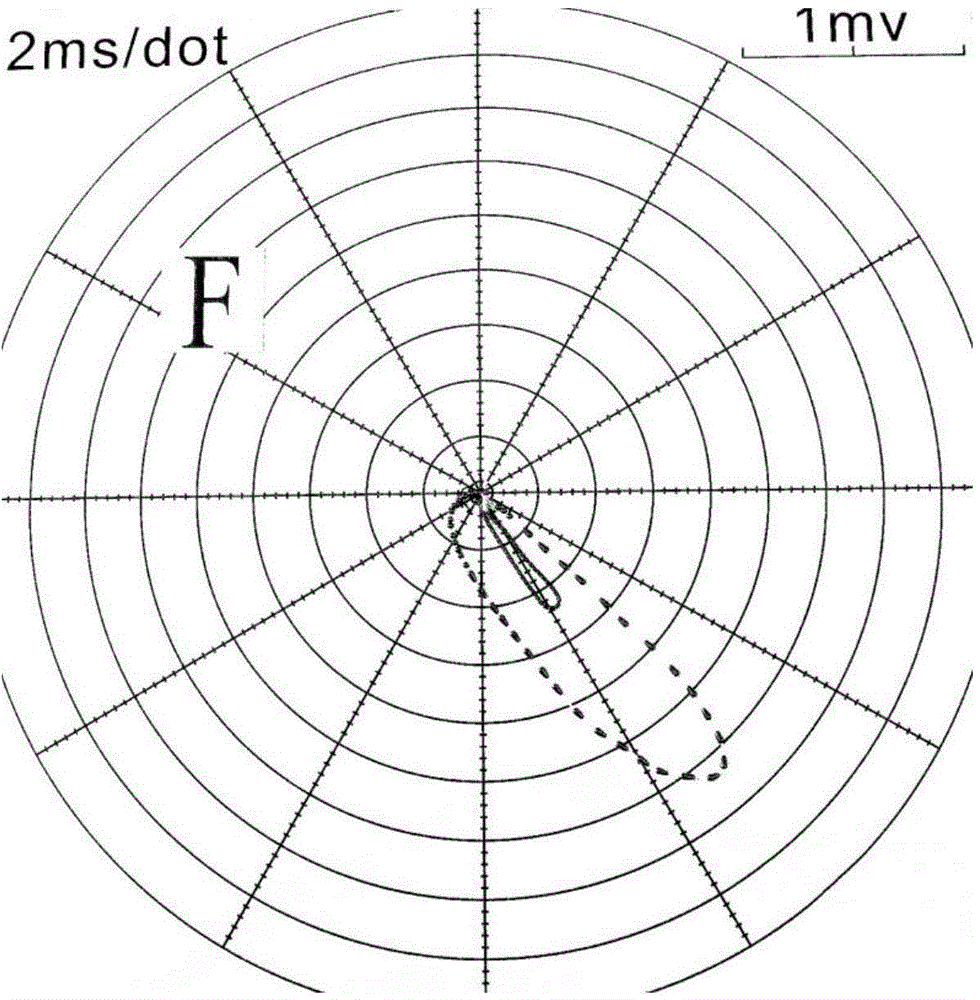

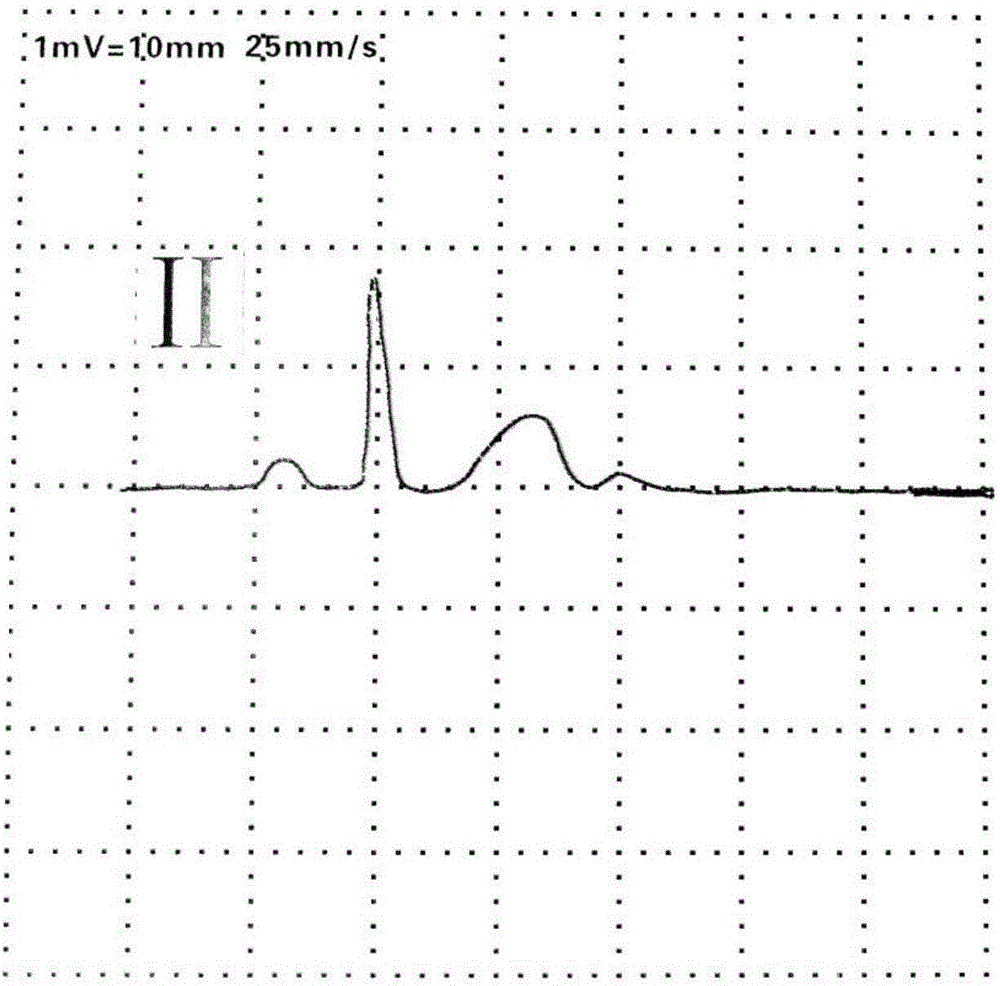

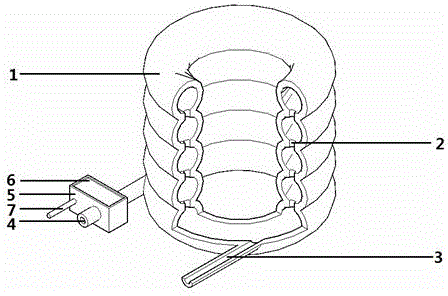

Electrocardiogram and vector cardiogram experiment operating panel

InactiveCN104835398AInnovating Experimental Teaching ContentInnovation methodEducational modelsGraphicsMagnetic bead

The present invention discloses an electrocardiogram and vector cardiogram experiment operating panel. The electrocardiogram and vector cardiogram experiment operating panel comprises an iron operating panel body, an electrocardiogram operation surface is arranged on the right side of the operating panel body, and the square scales used for measuring the electrocardiogram time and amplitude are arranged on the electrocardiogram operation surface. The magnetic line segments which can be bent flexibly and are used for the simulation operation of the electrocardiogram normal graphs, the electrocardiogram abnormal graphs or the conventional 12-lead electrocardiographs are arranged on the electrocardiogram operation surface, and are formed by connecting a plurality of hollow small magnetic pipes in series via the flexible lines. A vector cardiogram operation surface is arranged on the backside of the operating panel body, and the concentric scales used for recording the electrocardiogram vector loop amplitudes, the magnetic stripes which can be bent flexibly and are used for the QRS vector loop operation and the magnetic line segments used for the P vector loop and T vector loop operation are arranged on the vector cardiogram operation surface. The magnetic strips are formed by connecting a plurality of hollow magnetic spheres and magnetic beads in series by the flexible lines, and the head ends and the tails ends of the magnetic strips are all magnetic spheres.

Owner:HANGZHOU NORMAL UNIVERSITY

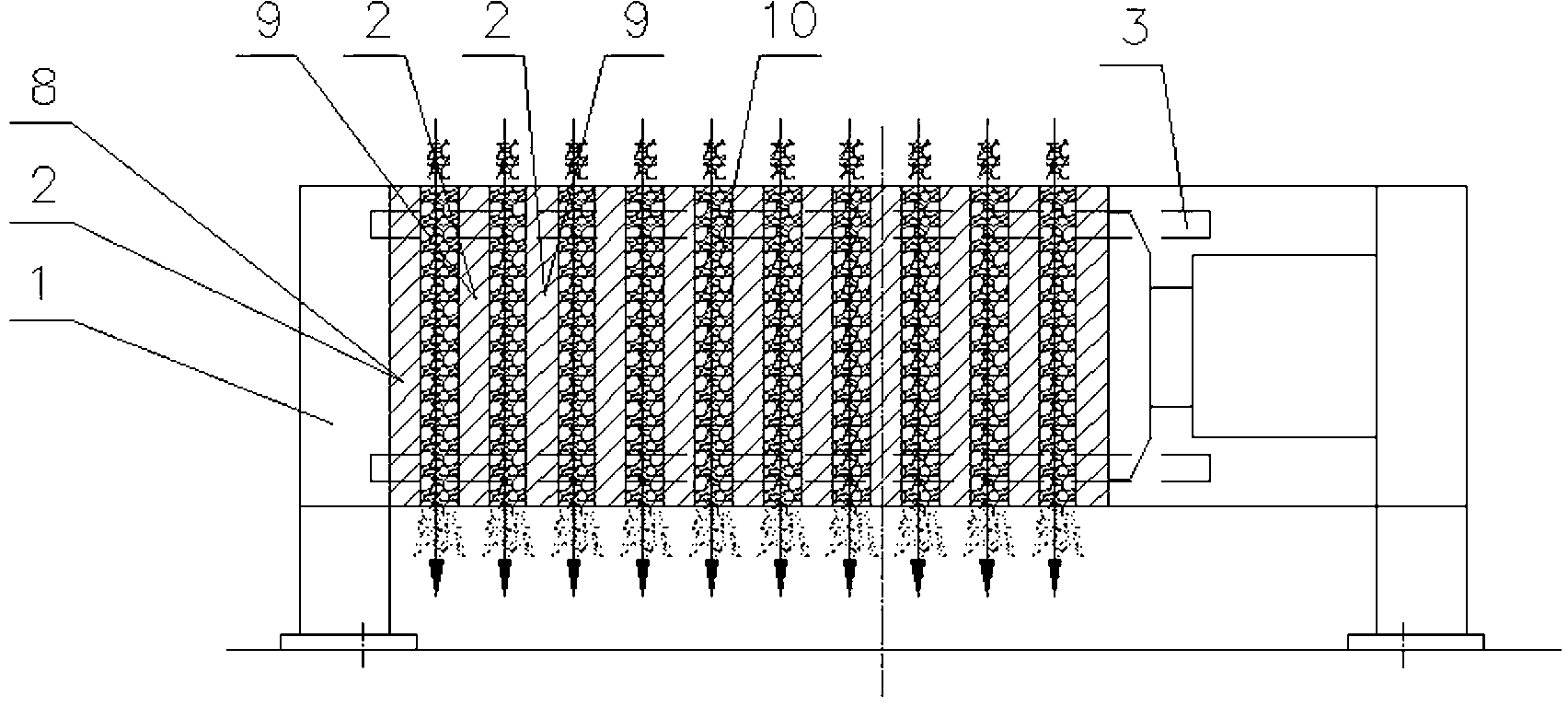

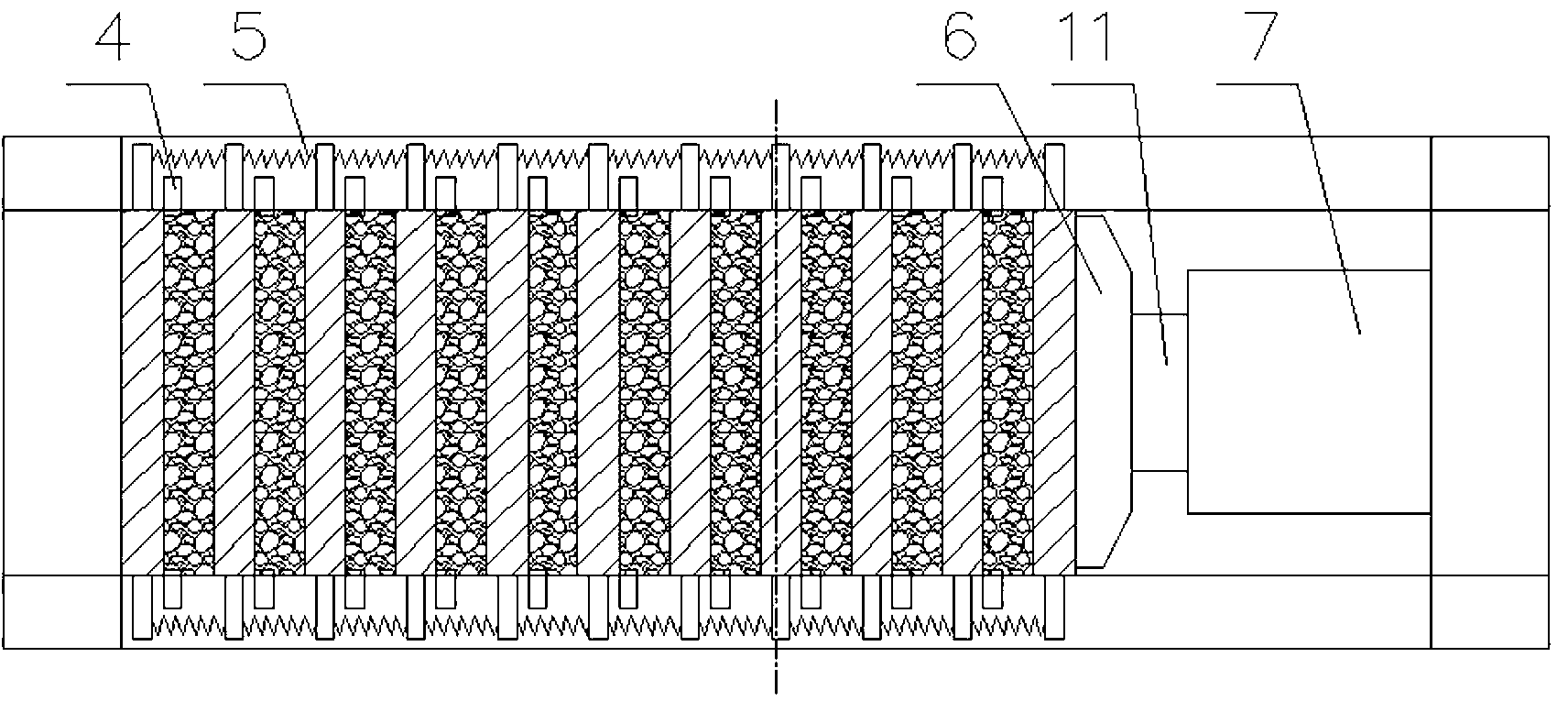

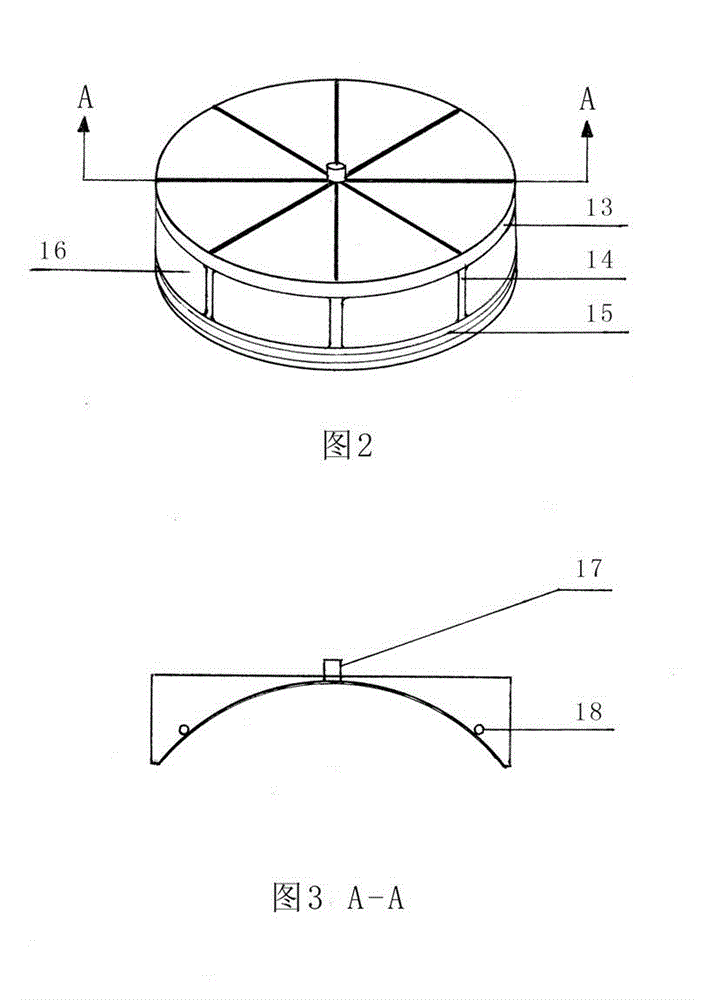

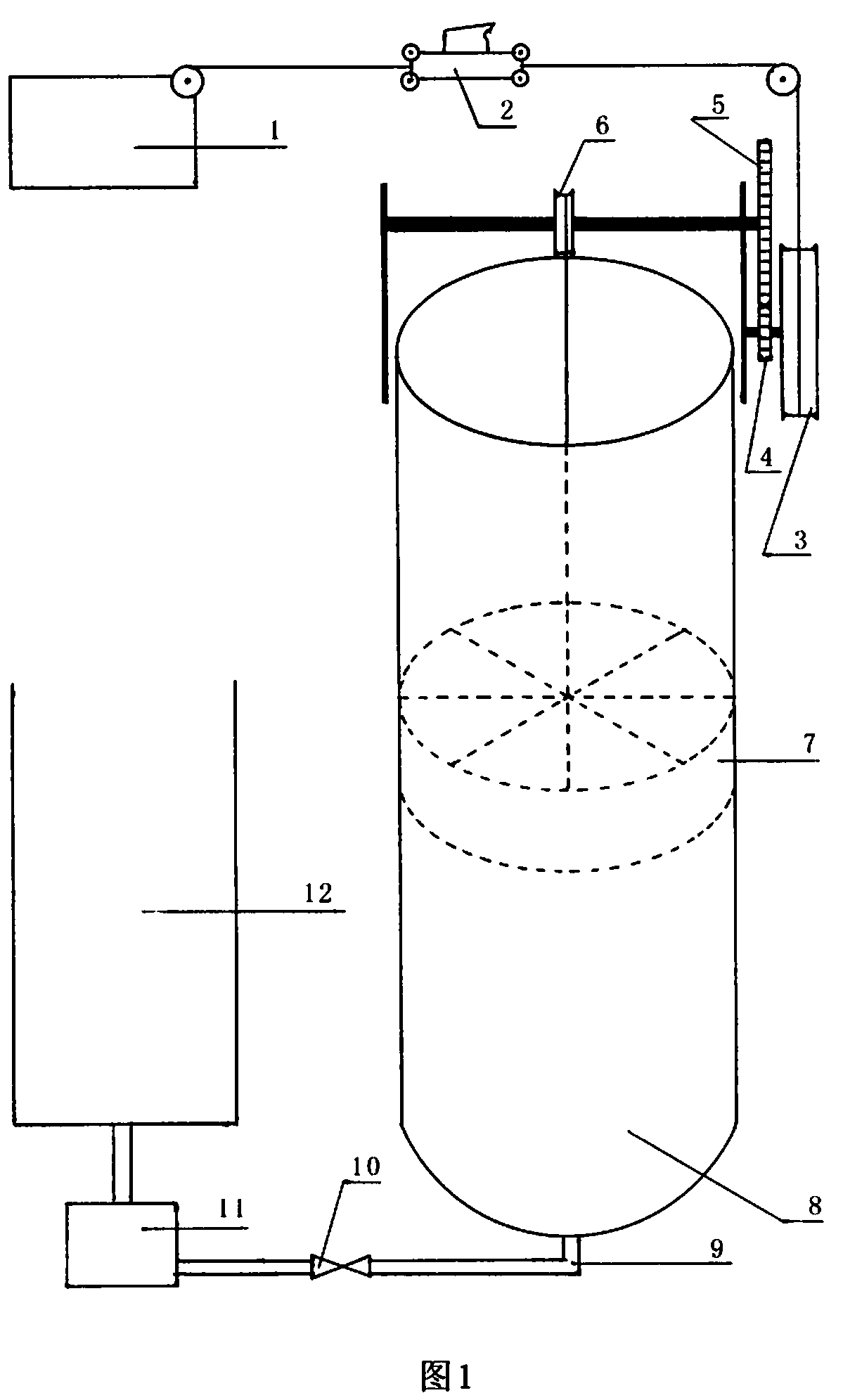

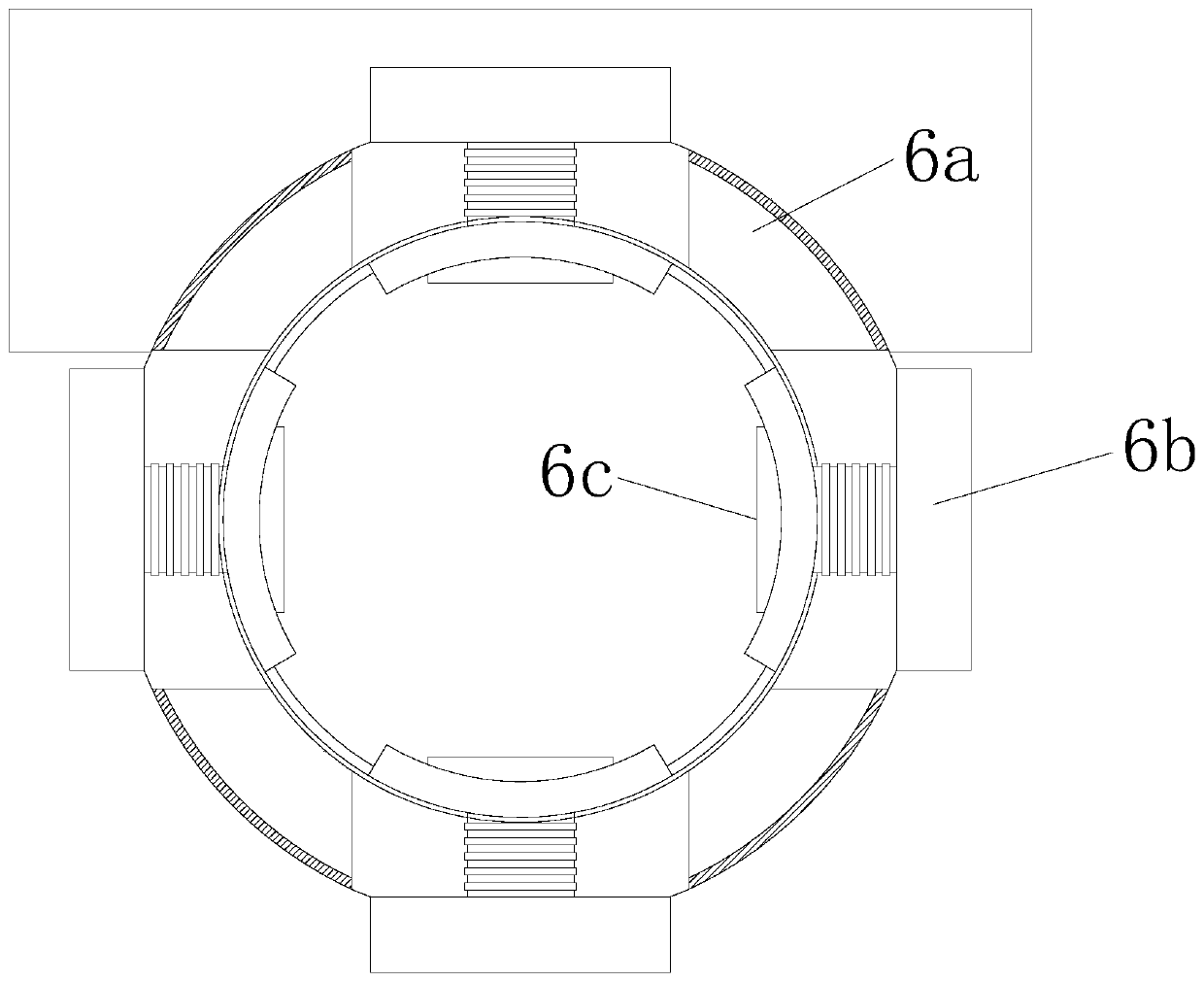

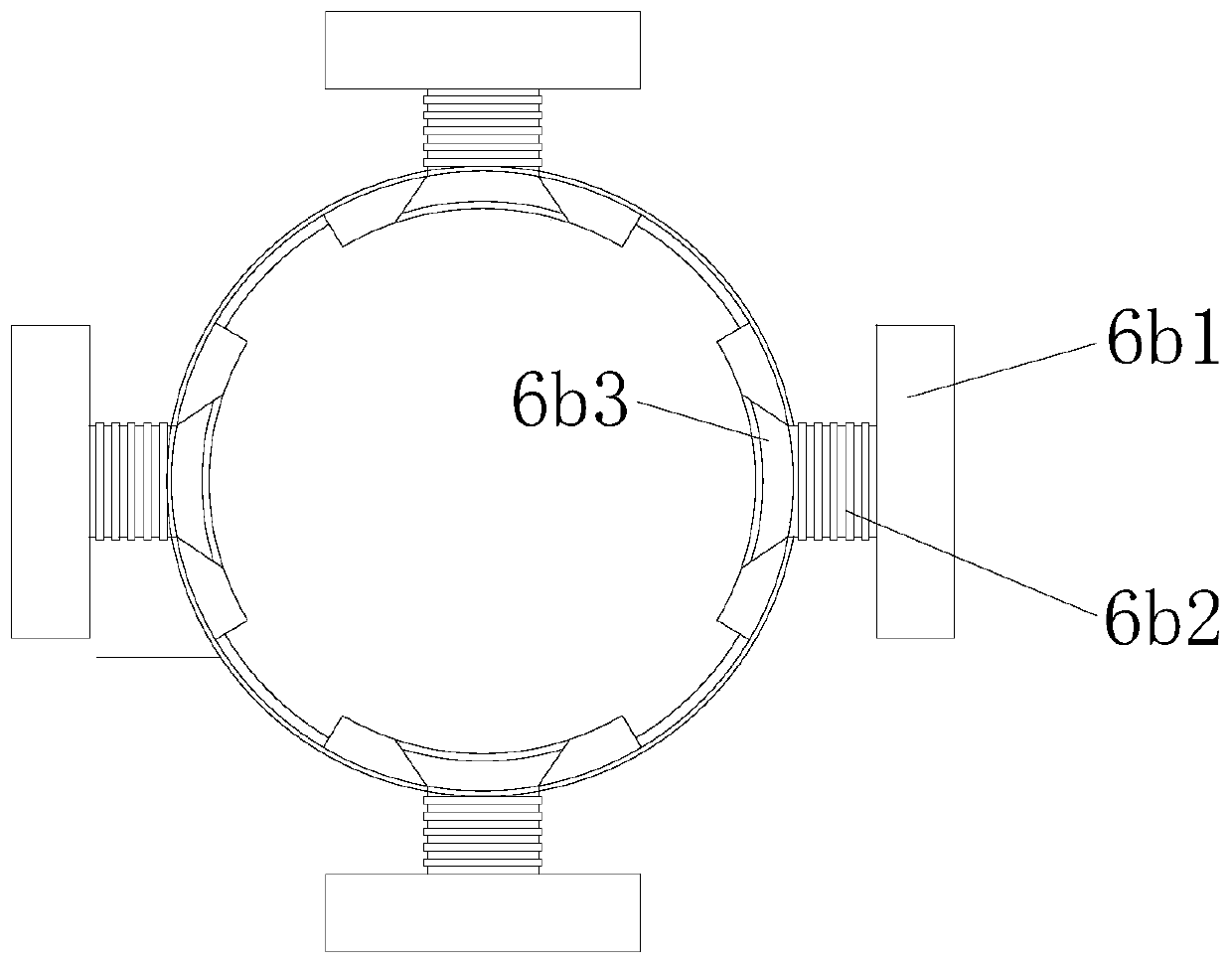

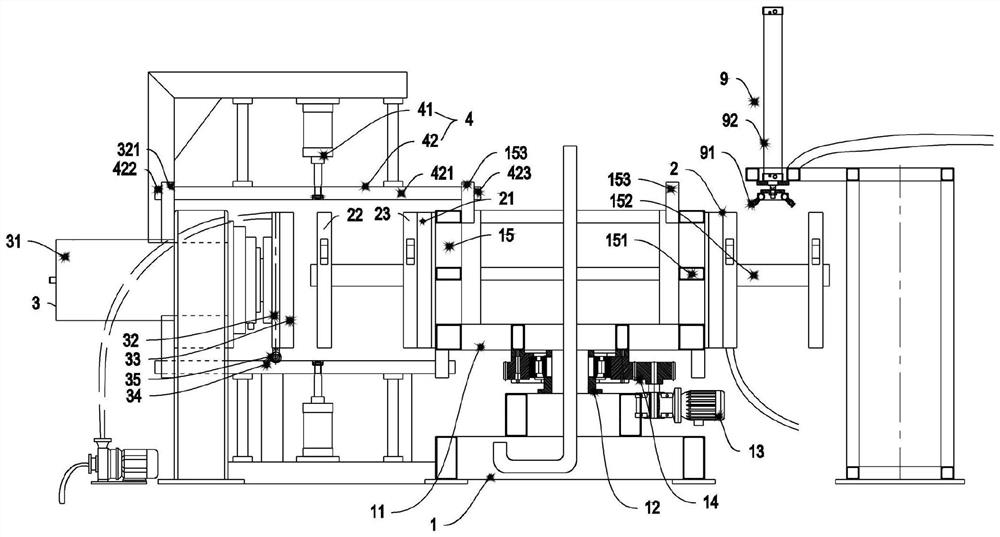

Vertical rotary multi-station diaphragm filter press

PendingCN112044127AShorten the lengthReduced footprintFiltration separationFilter pressControl theory

The invention provides a vertical rotary multi-station diaphragm filter press. The vertical rotary multi-station diaphragm filter press comprises a main rack and a rotary rack; the rotary rack can rotate on the main rack around a connecting bearing of the rotary rack and the main rack; a plurality of plate group fixing frames are arranged on the rotary rack in the circumferential direction, and afilter plate group is mounted on each plate group fixing frame; each filter plate group at least comprises a pressure stop plate and a first diaphragm filter plate, and the first diaphragm filter plate can reciprocate on the plate group fixing frame towards the direction of the pressure stop plate; and at least one set of pushing and pressing device is arranged on the outer side of the rotary rack. The pushing and pressing device comprises an oil cylinder, and an output rod of the oil cylinder is connected with a pushing and pressing plate; the pushing and pressing plate can be driven by the oil cylinder to do telescopic reciprocating translation towards the direction of the rotary rack; and the pushing and pressing plate can move to abut against the filter plate group corresponding to thepushing and pressing plate in position, so that the pushing and pressing plate, the first diaphragm filter plate and the pressure stop plate are combined in sequence to form a filter cavity. A multi-station rotary working structure is adopted, multiple stations rotate synchronously, synchronous operation is achieved, and the beneficial effects of being efficient, capable of saving time and labor,capable of saving space and the like are achieved.

Owner:佛山市绿星环保科技有限公司

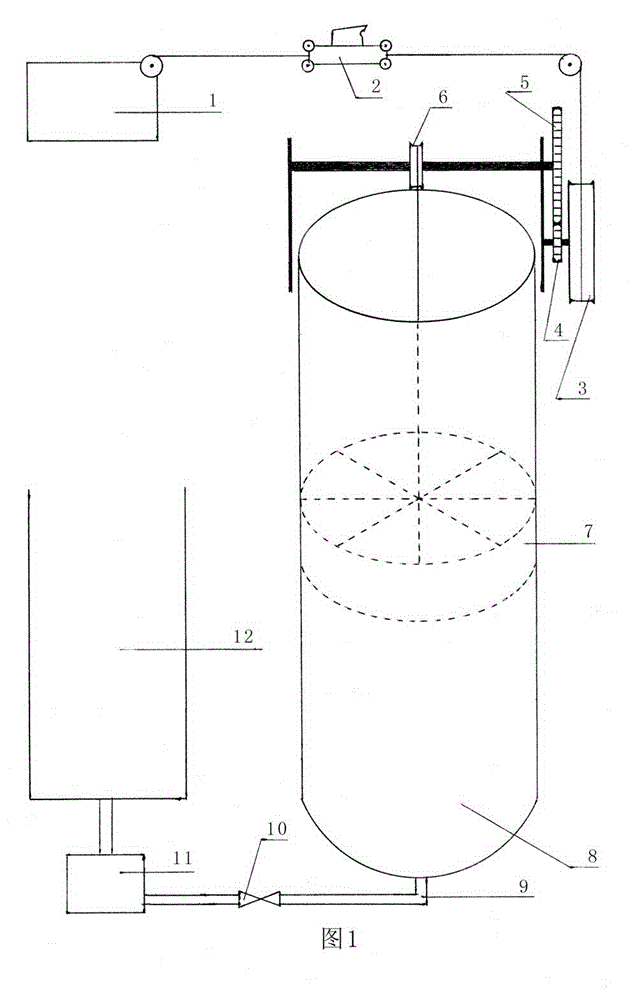

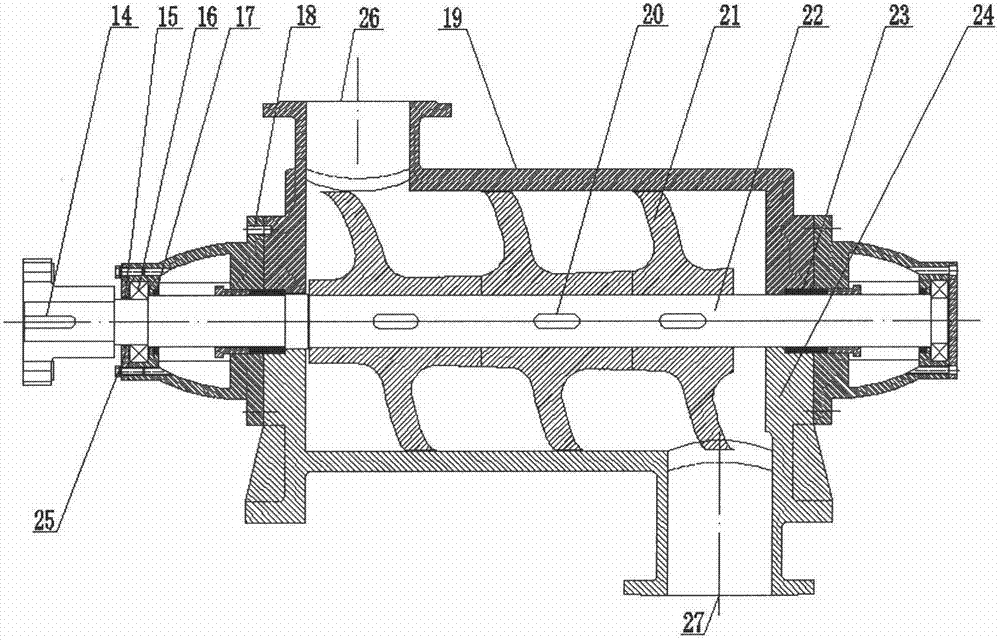

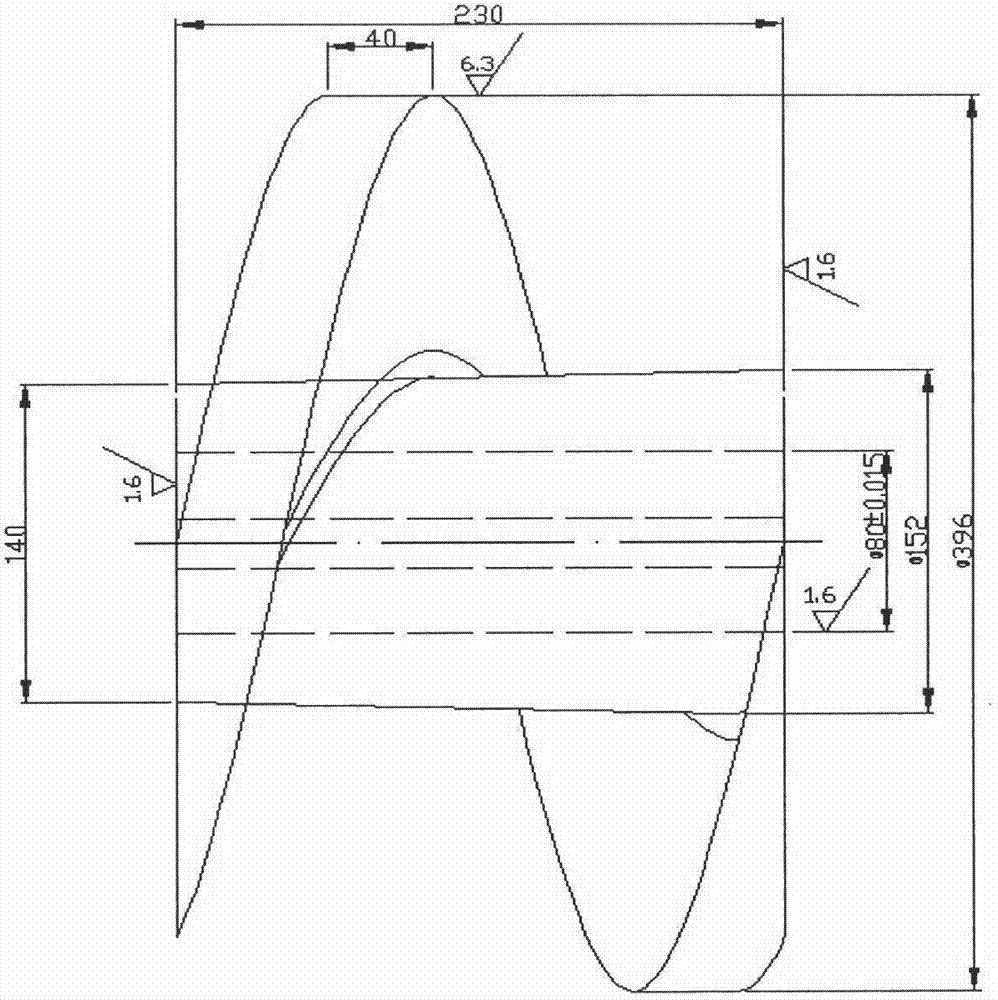

Slurry filling pump with flow rate control function

InactiveCN103206382ASimple structureEasy to processAxial flow pumpsNon-positive displacement fluid enginesImpellerHigh concentration

Disclosed is a slurry filling pump with a flow rate control function. A main pump core is a spiral body with a varying pitch, a varying root diameter and an equal outer diameter and comprises three or a plurality of different spiral impellers (21) which are mounted on a transmission shaft (22) and are sleeved in a cylinder space (pump shell) formed by an upper pump body (19) and a lower pump body (24), a feed port (26) is arranged at one end of the upper pump body, a discharge port (27) is arranged at the other end of the lower pump body, the inner wall of the pump shell is closely matched with the periphery of the pump core to form a sealed wedge-shaped spiral space, and the wedge-shaped spiral space is naturally communicated with the feed port (26) and the discharge port (27). When the transmission shaft (22) is driven to continuously run forwards, the wedge-shaped spiral space can continuously reduce and generate positive pressure, media entering the spiral space are dragged, pushed and conveyed under the action of the pressure, the viscous force of the media and friction force, and the working principle is more suitable for conveying slurry with high concentration, viscosity and coarse aggregate content.

Owner:济南友龙建筑安装有限公司

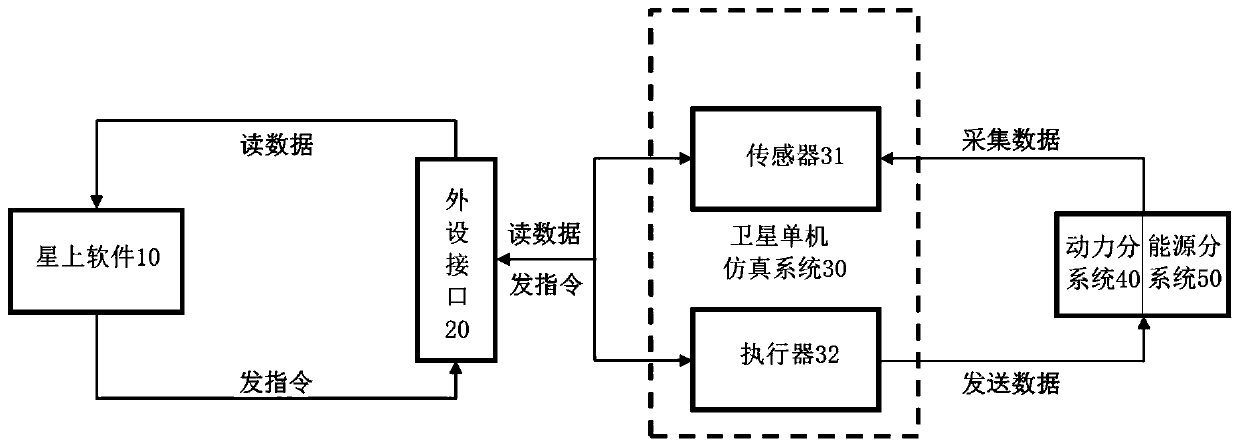

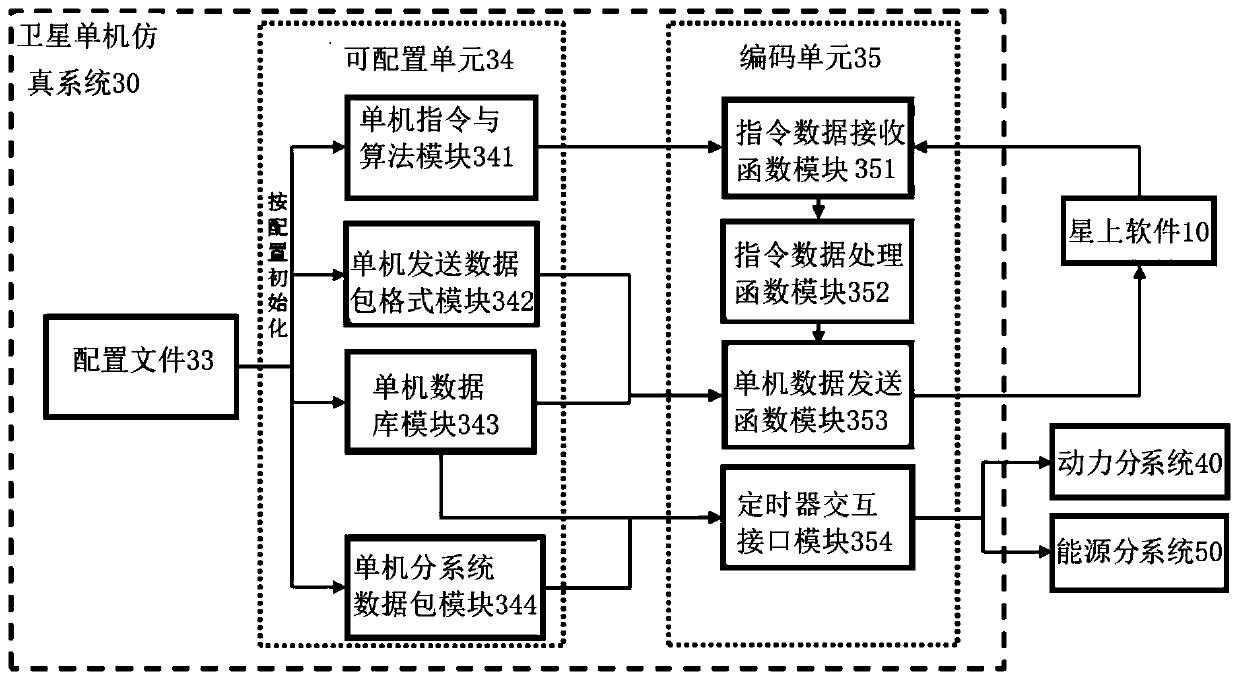

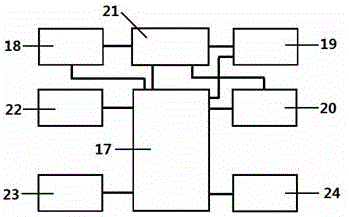

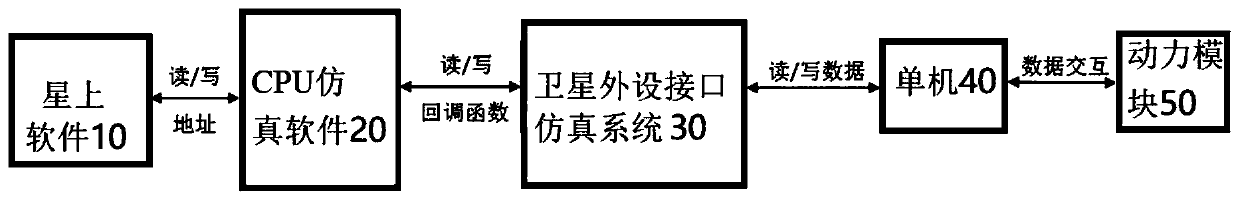

Satellite stand-alone simulation system and method

ActiveCN110687825ASolve the generalization problem of fault simulationSolve the modularization problem of stand-alone simulationSimulator controlModelSimData operations

The invention provides a satellite stand-alone simulation system and method. The satellite stand-alone simulation system is disclosed. The satellite stand-alone simulation system is connected with on-satellite software, a power subsystem and an energy subsystem. The satellite stand-alone simulation system simulates a satellite stand-alone for modeling. The satellite stand-alone comprises a sensorand an actuator. The satellite stand-alone simulation system models the satellite stand-alone as data reading operation or data writing operation. And corresponding data processing is performed according to an algorithm set by an instruction. The satellite stand-alone simulation system comprises a configurable unit, a coding unit and a configuration file. A design parameter and generated data in the configurable unit are initialized according to the configuration file. An instruction action in the coding unit is fixed as a function through a code, and the function sends, receives or processesthe generated data.

Owner:INNOVATION ACAD FOR MICROSATELLITES OF CAS +1

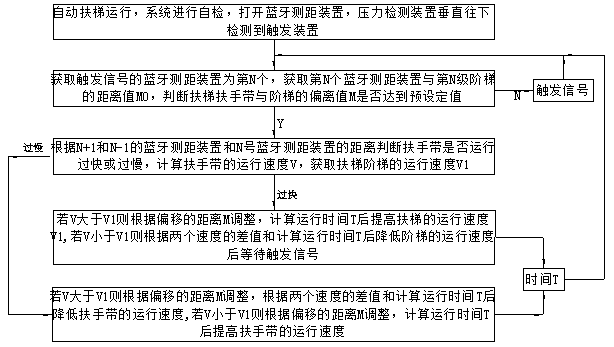

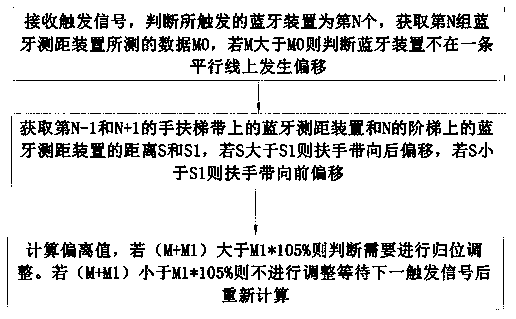

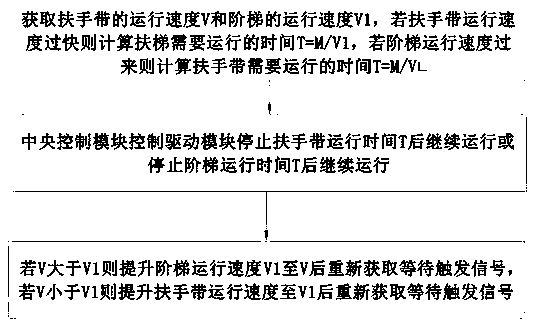

Synchronous operation control system and control method for hand strap of escalator and ladder

InactiveCN108715394ARun fastRunning fast or handrail running too slowEscalatorsControl systemEngineering

The invention relates to a synchronous operation control system and control method for a hand strap of an escalator and a ladder. The synchronous operation control system comprises Bluetooth ranging devices, detection triggering devices, central control modules, operation speed detecting devices and driving modules which are arranged on the hand strap of the escalator and the ladder. Whether the hand strap operates too fast or not or operates too slowly or not is judged by calculating the distance between the hand strap and the ladder and judging a deviation value of the hand strap, and the speed of the ladder and the speed of the hand strap achieve the consistency through adjustment.

Owner:BEIHAI HESI TECH

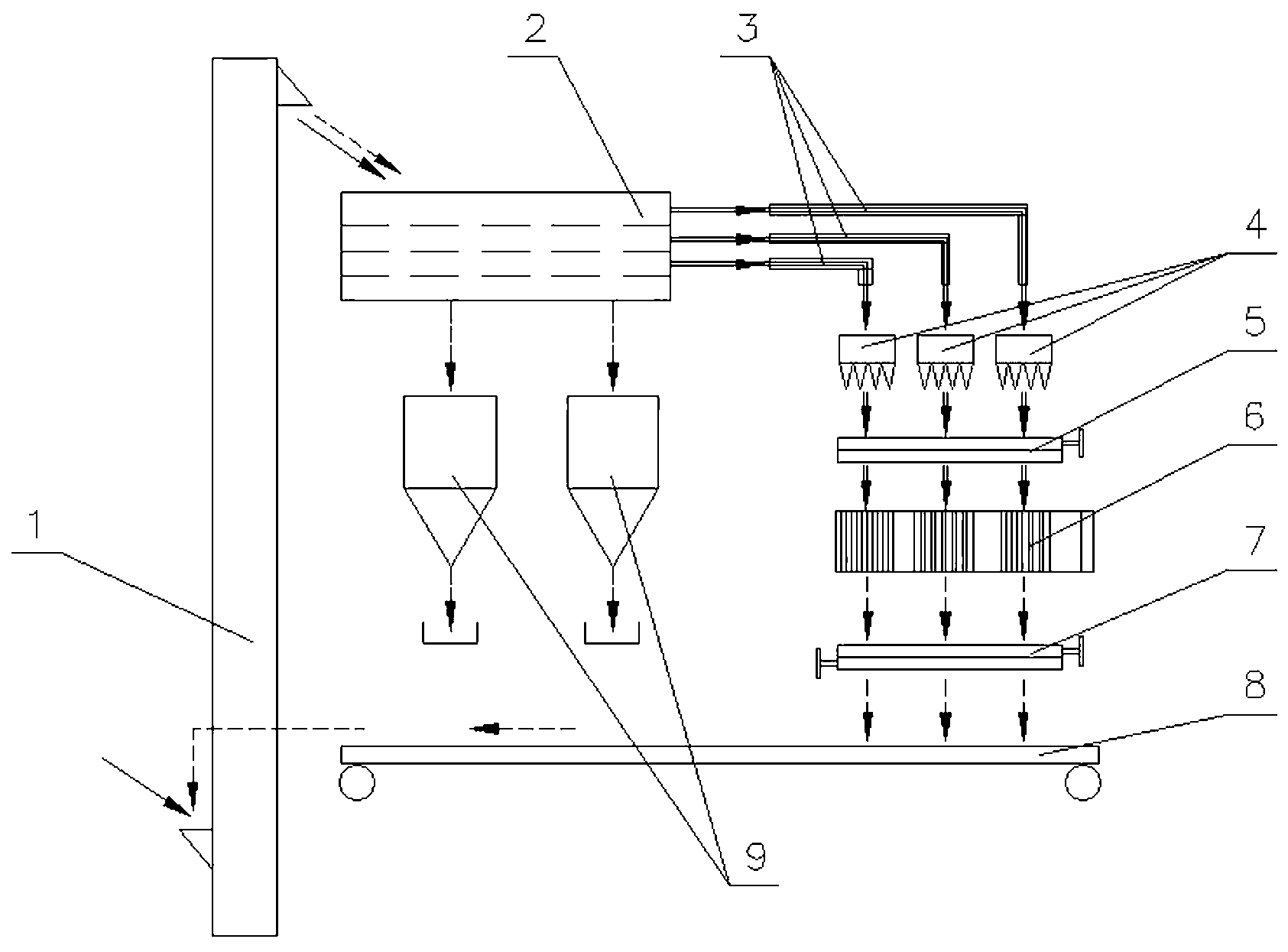

Small-particle four-section moving bed dry distillation furnace with hydrogen-enriched environment and dry distillation method of small-particle four-section moving bed dry distillation furnace

ActiveCN104726116AReduce the amount of dustReduce the chance of frictionCoke quenchingDirect heating destructive distillationChemistryProcess engineering

The invention discloses a small-particle four-section moving bed dry distillation furnace with a hydrogen-enriched environment and a dry distillation method of the small-particle four-section moving bed dry distillation furnace. According to the dry distillation furnace, a feeding hole is formed in the upper part of a drying and preheating section, an upper air inlet and a lower air inlet are respectively formed in the middle side and lower side of the drying and preheating section, and an air outlet is formed in the end, far away from the upper air inlet, of the drying and preheating section; the drying and preheating section is vertically communicated with a dry distillation section through a sealing section; a medium-temperature air inlet is formed in the middle side of the dry distillation section, a high-temperature air inlet is formed in the lower side of the dry distillation section, and an oil gas outlet communicated with an oil gas recovery system arranged on the outer wall of the dry distillation section is formed in the medium-upper side of the dry distillation section; a cold coal gas inlet is formed in the middle side of a cooling section, a coal gas outlet is formed in the upper side of the cooling section, a water inlet is formed in the lower side of the cooling section, and a water outlet is formed in the middle side of the cooling section; and the cooling section is provided with a cooling heat exchanger communicated with the water inlet and the water outlet. The dry distillation method comprises the steps of drying and preheating; sealing; carrying out dry distillation; and cooling. The small-particle four-section moving bed dry distillation furnace with the hydrogen-enriched environment has the characteristics that the power consumption is low, the energy utilization rate and oil yield are high, the quality of an oil product is good, the dust content of oil gas is low, and the utilization rate of resources is high.

Owner:QUJING ZHONGYI FINE CHEMICAL INDUSTRY CO LTD

A convolutional network operation unit, a reconfigurable convolutional neural network processor, and a method for implementing image denoising processing

ActiveCN105681628BImprove performanceIncrease flexibilityTelevision system detailsColor signal processing circuitsImage denoisingResource consumption

Owner:XI AN JIAOTONG UNIV

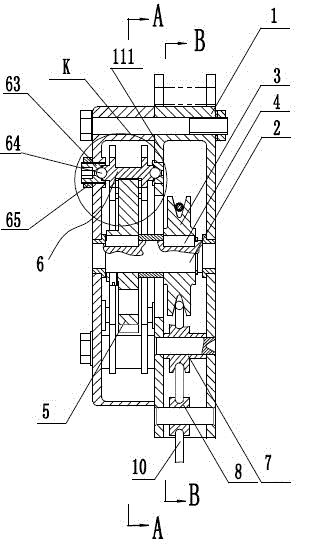

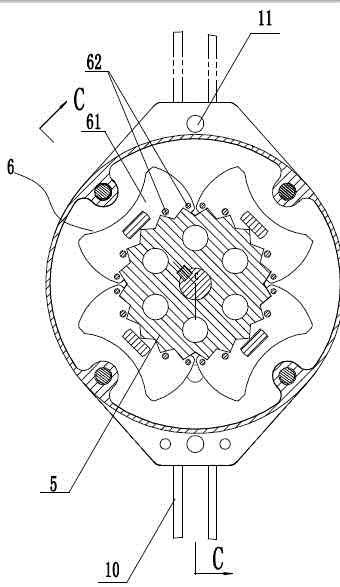

High-altitude descent control device

The invention relates to a rescue and escape device, and in particular relates to a high-altitude descent control device, which is mainly used when a person is required to urgently descend in a high-rise or other high-altitude situations, and required to fall safely at a certain speed. The high-altitude descent control device comprises a shell, a grooved pulley in the shell, a shaft, a rope arranged in a grooved wheel groove, and is characterized in that more than one set of descending mechanism is arranged in the shell; and each set of descending mechanism mainly comprises a pointed gear and more than one balancing point rack which is engaged with the pointed gear. The high-altitude descent control device is simple in structure, safe and reliable, enables the descending speed to be stabilized in a safety value, and is a high-altitude descent control device with a novel structure.

Owner:裘伟江

Newborn Conditioning Device for Cesarean Section

A post-cesarean postpartum neonatal conditioning device, the main part of the simulated birth canal is a hollow simulated shape made of silica gel, the chambers inside the simulated shape are connected by water guide holes, and the simulated shape is provided with water inlet pipes and water outlet pipes , and connected to the main engine by the water inlet pipe and the water outlet pipe, an intelligent pressure monitoring valve is provided on the water outlet pipe, and an electric control valve, a pressure sensor and a temperature sensor are arranged inside the intelligent pressure monitoring valve; the advantages of the present invention are: safe, reliable, clean It is hygienic, easy to operate, and highly practical, and can greatly reduce the labor intensity of medical workers.

Owner:JIANGXI NORMAL UNIV

Distribution system for trade order data information centralized management

InactiveCN112506296AImprove efficiencyAvoid imprecisionFinanceParticular environment based servicesTouchscreenData acquisition module

The invention discloses a distribution system for trade order data information centralized management, which comprises a box body, a casing and a microprocessor, a touch screen is arranged above the box body, an operation panel is arranged on one side wall of the box body, and a sliding box is arranged in the middle of the box body. The beneficial effect is that the circuit board, the data acquisition module, the information module and the intelligent module are arranged. A memory module, a microprocessor and a wifi module can automatically collect and transmit the system, inaccurate system data caused by low webpage operation speed is avoided, the use efficiency of the trade order data information centralized management distribution system is improved, and secondly, the interior of the system can be ventilated and cooled by arranging a cooling fan and a radiator, Slow operation of the distribution system due to high internal temperature caused by long-time operation of the system is avoided, and the use requirement of the trade order data information centralized management distribution system is met.

Owner:广州依琪信息科技有限公司

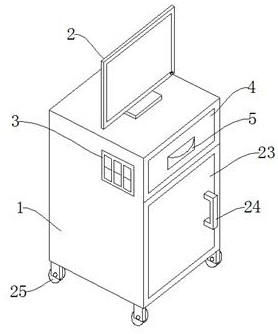

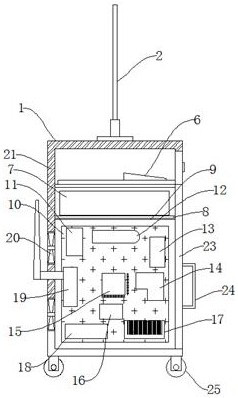

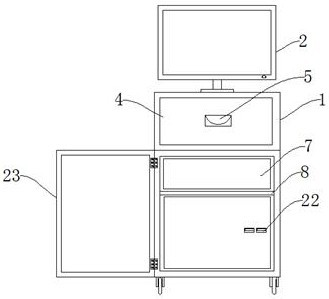

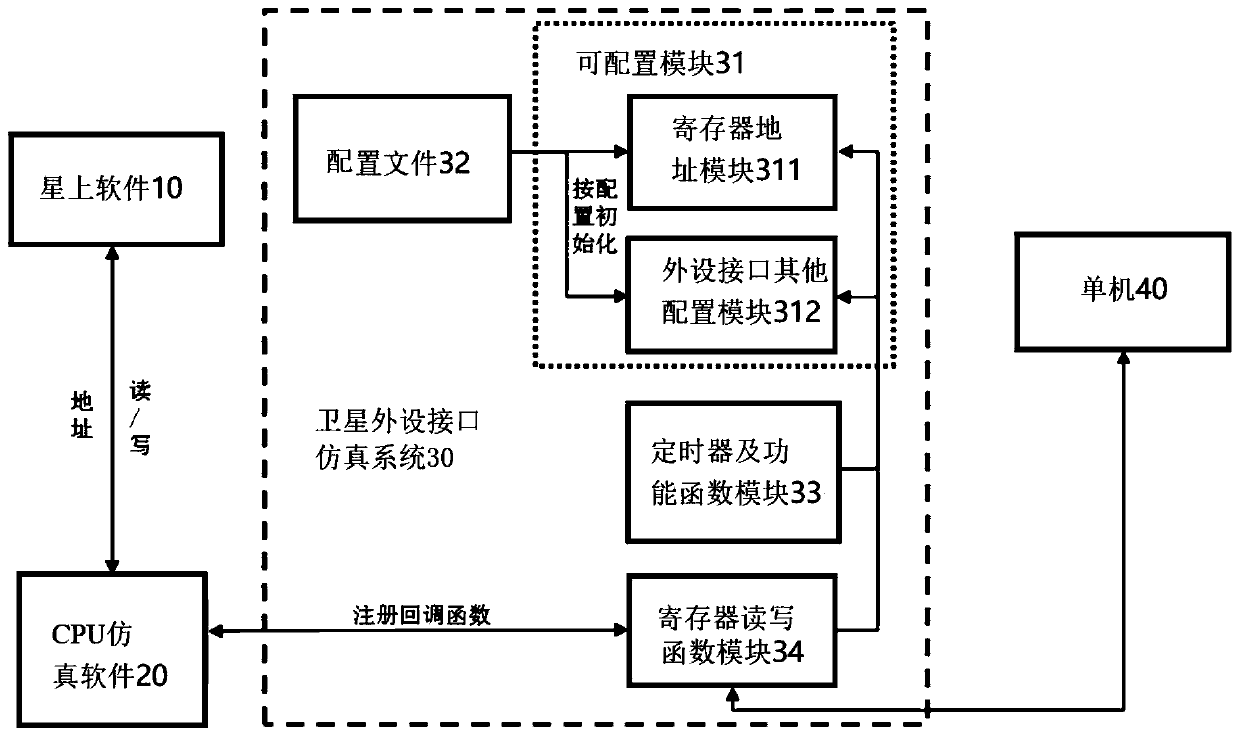

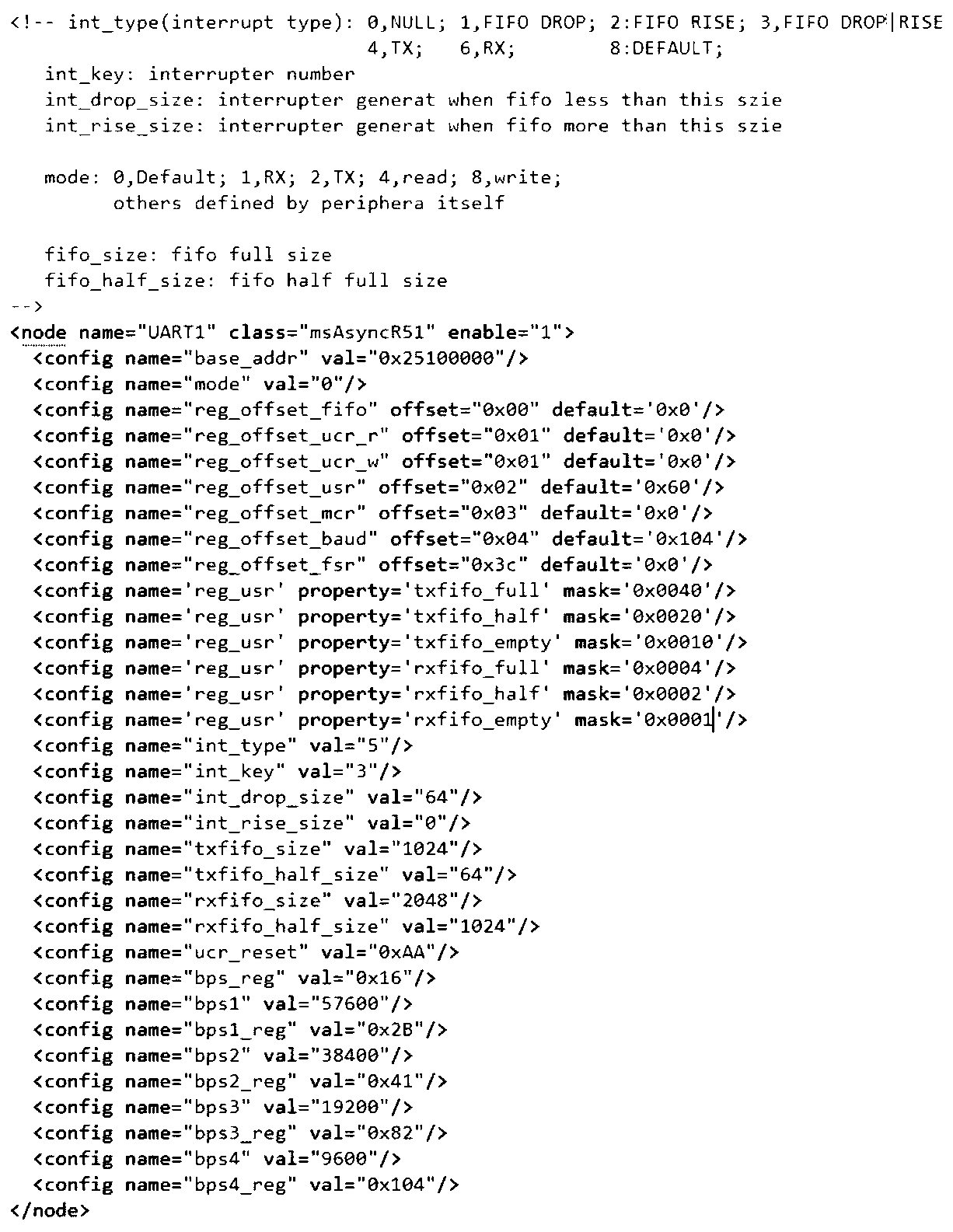

Satellite peripheral interface simulation system and method

ActiveCN110674579ASolve the generalization problemSolving Simulation Modularity ProblemsDesign optimisation/simulationPeripheralEngineering

The invention provides a satellite peripheral interface simulation system and method. Satellite-borne software and CPU simulation software, the satellite peripheral interface simulation system, a single machine and a power module are connected in sequence. The satellite-borne software, the CPU simulation software and the power module are external software, and the single machine is a fixed codingmodule. The satellite peripheral interface simulation system realizes a corresponding reading function and a corresponding writing function of the register according to an address. The satellite peripheral interface simulation system comprises a configurable module and a configuration file, the configurable module comprises a register address module and other peripheral interface configuration modules, the register address module is used for storing register addresses, and the other peripheral interface configuration modules are used for storing related design parameters. The configuration file is respectively connected with the register address module and other configuration modules of the peripheral interface, and the configuration file is used for initializing the register address module and other configuration modules of the peripheral interface according to configuration.

Owner:INNOVATION ACAD FOR MICROSATELLITES OF CAS +1

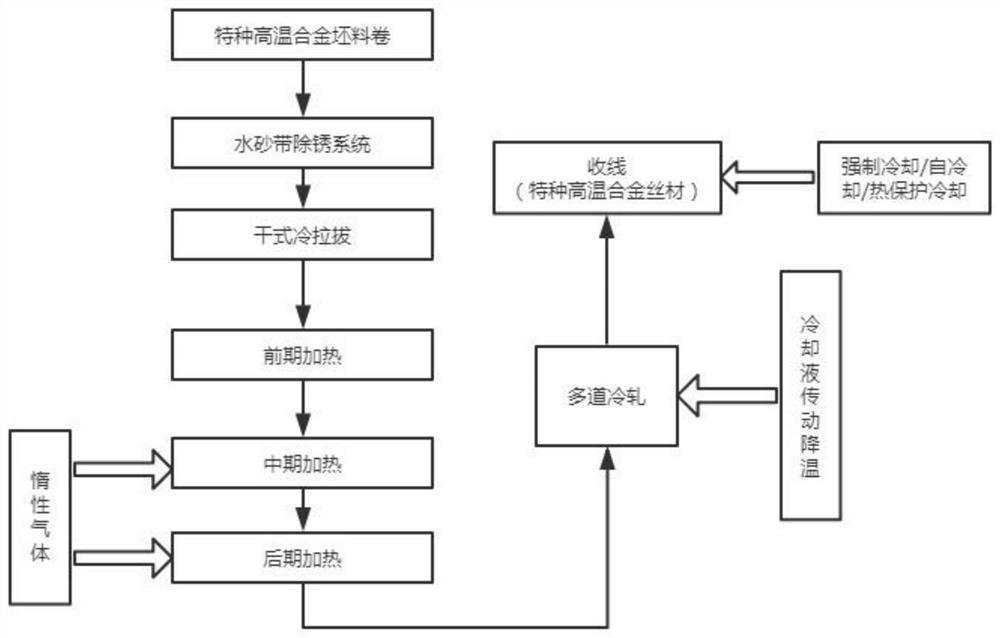

Novel special high-temperature alloy wire hot rolling process

The invention discloses a novel special high-temperature alloy wire hot rolling process, and belongs to the technical field of wire processing. The process comprises the following steps that S1, a special high-temperature alloy bar is subjected to surface pretreatment, and a wire with the specification of phi 8.00-4.00 mm is formed through cold drawing; and S2, the wire obtained in step S1 is sequentially subjected to early-stage heating, middle-stage heating and later-stage heating treatment, then cold rolling is carried out multiple times, cooling is carried out in the cold rolling process, and after the wire is subjected to cold rolling to a certain specification, wire winding is carried out to obtain the novel special high-temperature alloy wire. The process provided by the invention is high in production efficiency, low in process control difficulty, excellent in product quality and low in manufacturing cost.

Owner:陕西鼎益科技有限公司

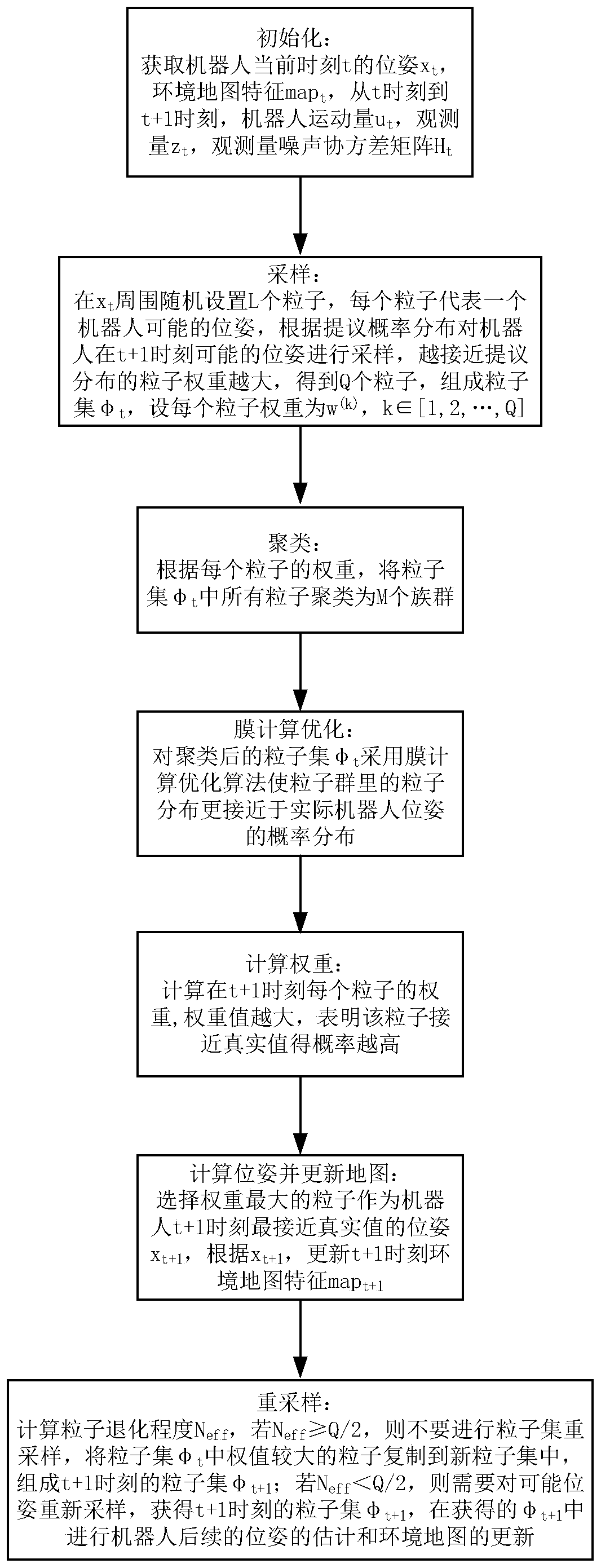

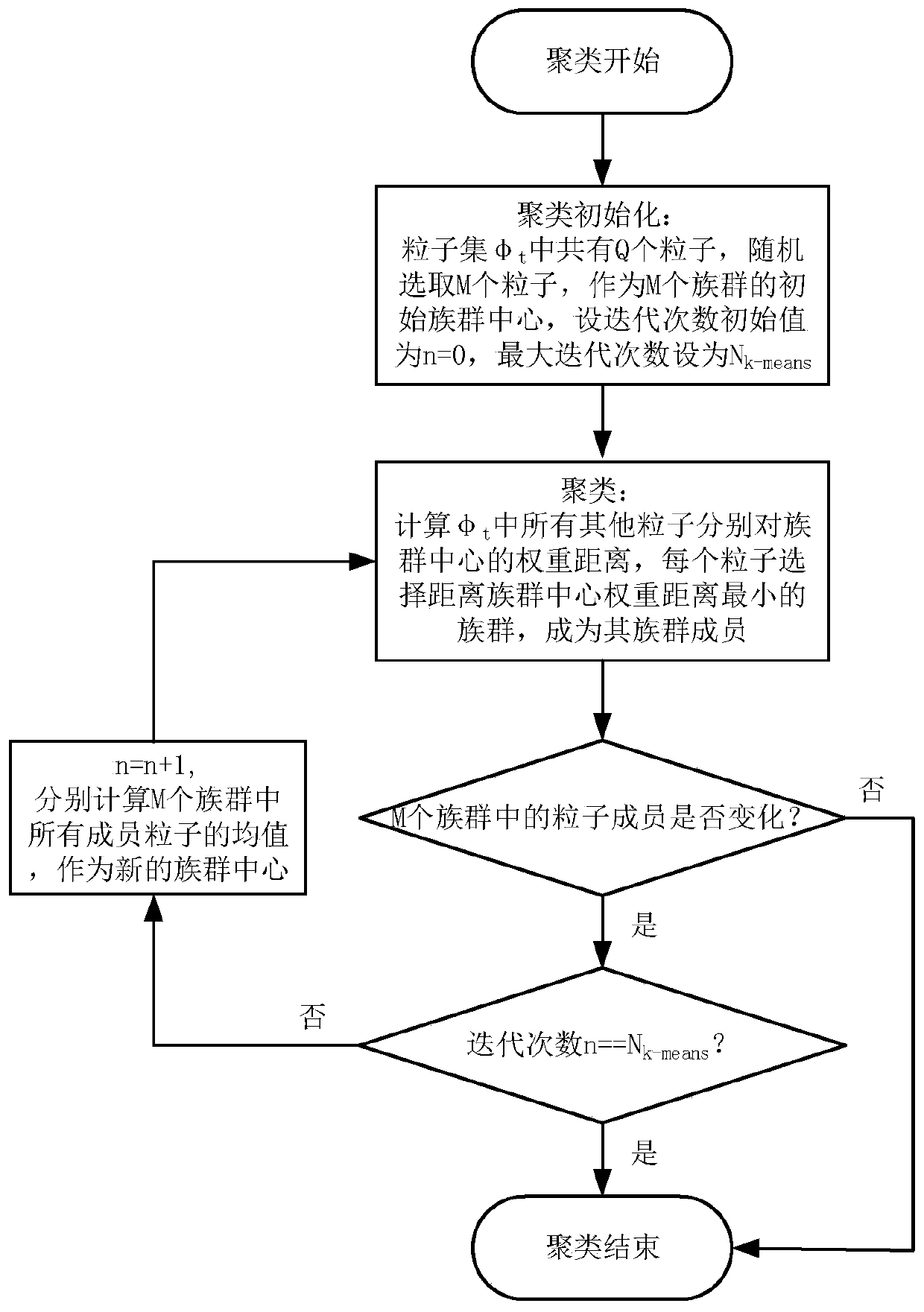

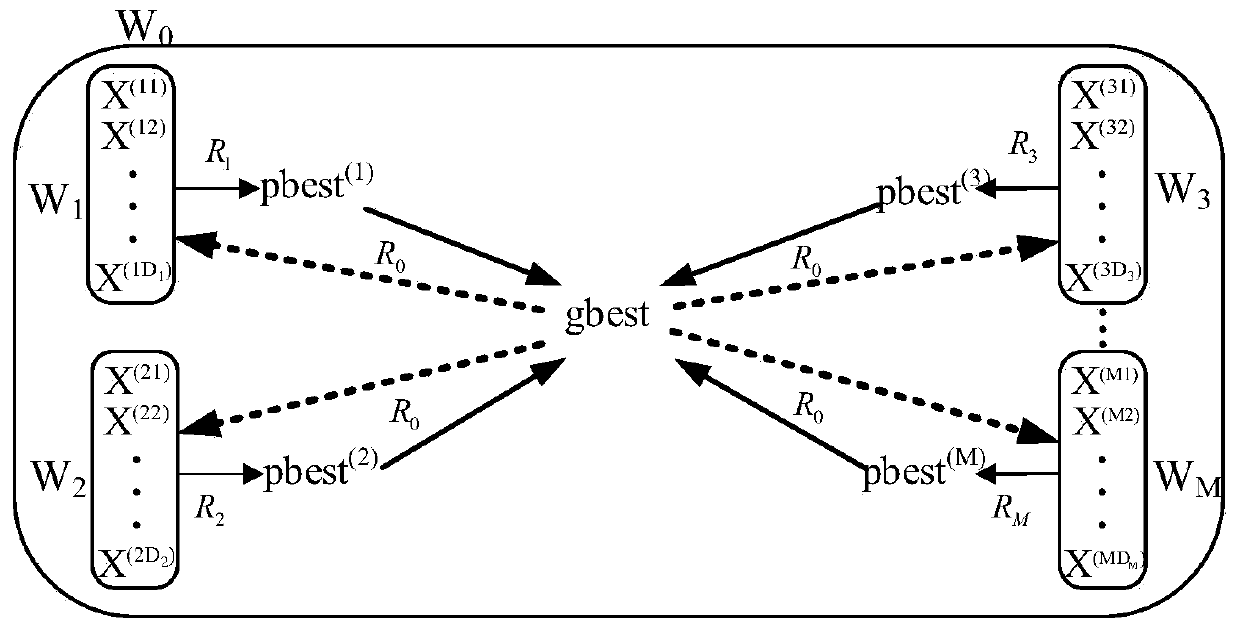

Improved FastSLAM algorithm based on clustering and membrane calculation

ActiveCN110598804ARunning slowLow efficiencyNavigational calculation instrumentsCharacter and pattern recognitionAlgorithmSelf positioning

The invention discloses an improved FastSLAM algorithm based on clustering and membrane calculation, and the algorithm comprises a series of processes: initialization, sampling, clustering, membrane calculation optimization, weight calculation, pose calculation, map updating and resampling, and the functions of robot quick self-positioning and environment map construction are achieved. According to the method, a particle set is preprocessed by using a clustering method; the high parallelism of an algorithm is optimized by using membrane calculation; the particle searching speed is increased, the searching range is enlarged, the particle degeneration condition is relieved, the diversity of particles is guaranteed, the particles are promoted to be distributed near the real pose more quickly,and the robot positioning and mapping precision and speed are effectively improved.

Owner:ANHUI UNIV OF SCI & TECH

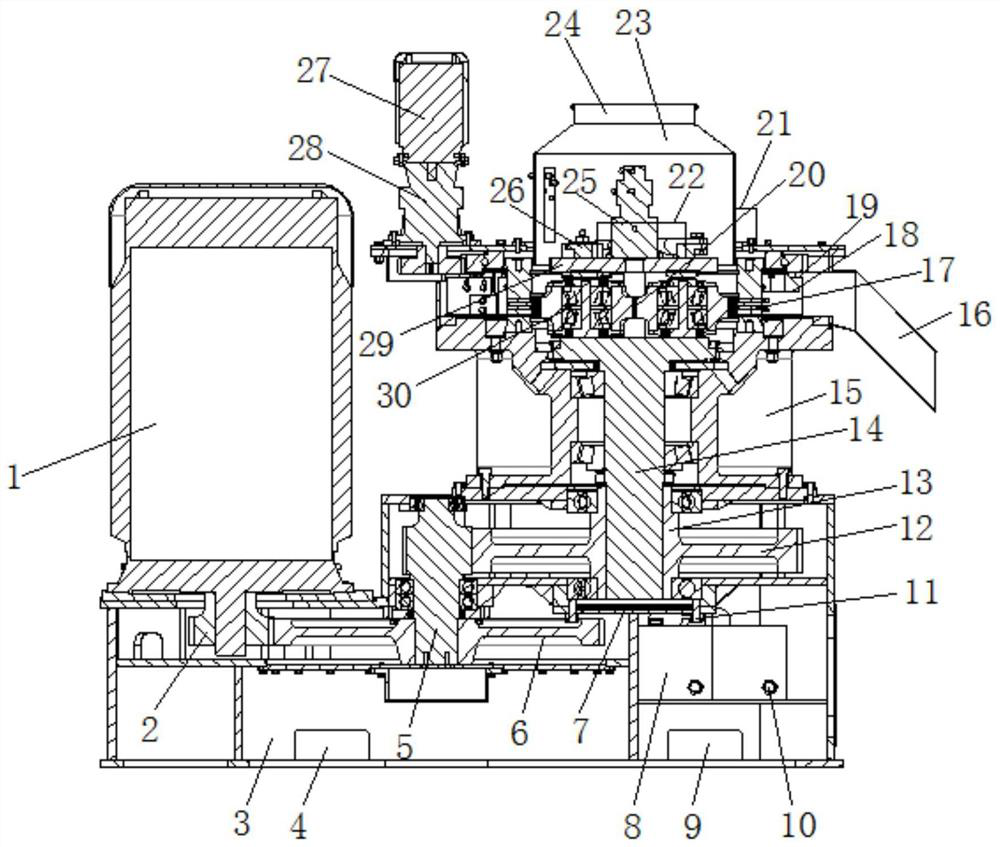

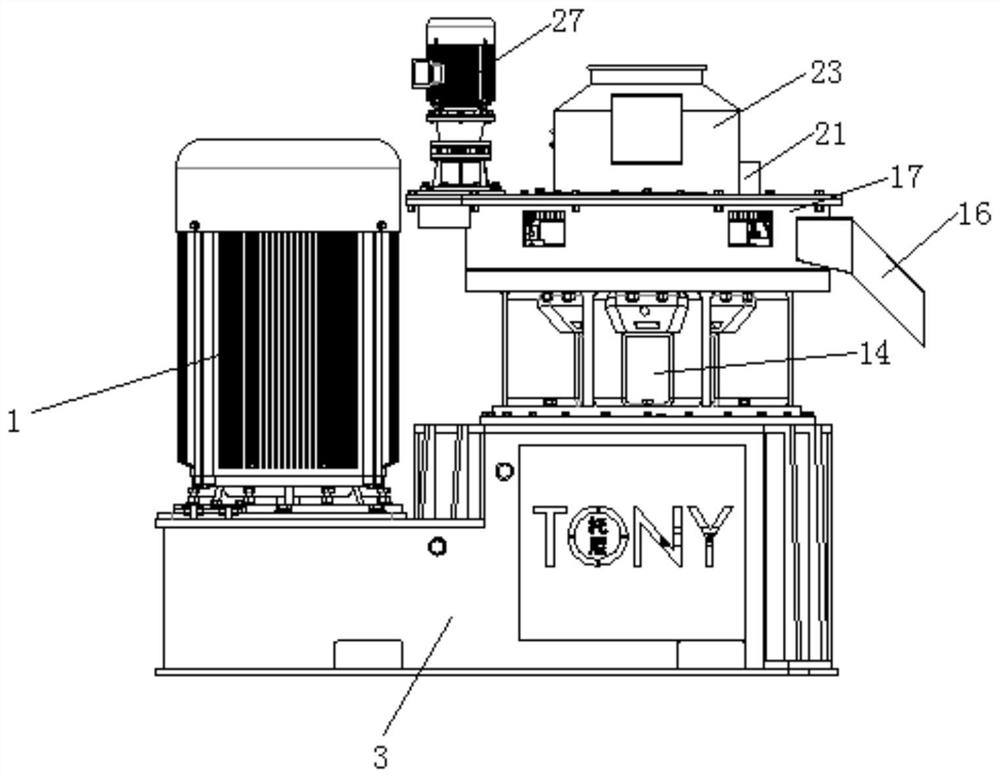

Bull gear transmission vertical type ring die granulator

InactiveCN111889029ACompact structureRun smoothlyFeeding-stuffGranulation by pressingElectric machineryGear drive

The invention discloses a bull gear transmission vertical type ring die granulator. The granulator comprises a vertical motor, a gear box, a material stirring motor and a granulation chamber, a vertical motor is fixed on one side of the upper surface of the gear box through a bolt, a first small gear in the gear box is positioned below the vertical motor, the first small gear and a rotating shafton the vertical motor realize coaxial rotation, a first large gear is rotationally mounted on one side of the first small gear through meshing, the first big gear is located in the center of the interior of the gear box, a sealing cover is arranged on the lower portion, close to the first large gear, of the front surface of the gear box, a second large gear is located on the inclined upper portionof the side, deviating from the vertical motor, of the first large gear, a main shaft is installed on the second large gear, a main shaft bearing is fixed to the bottom of the main shaft, and a bearing chamber is located above the gear box. Gear loss can be reduced, the transmission efficiency is high, the operation cost is low, and the service life is long.

Owner:山东托尼环保科技有限公司

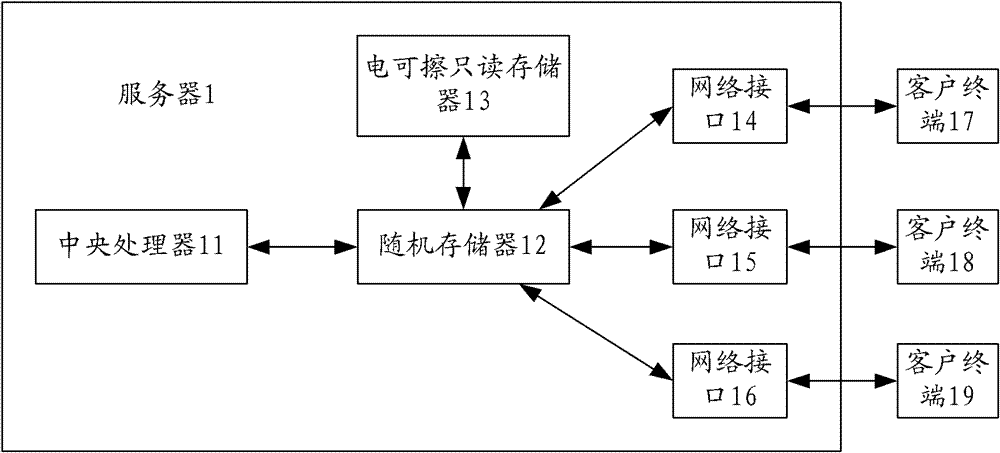

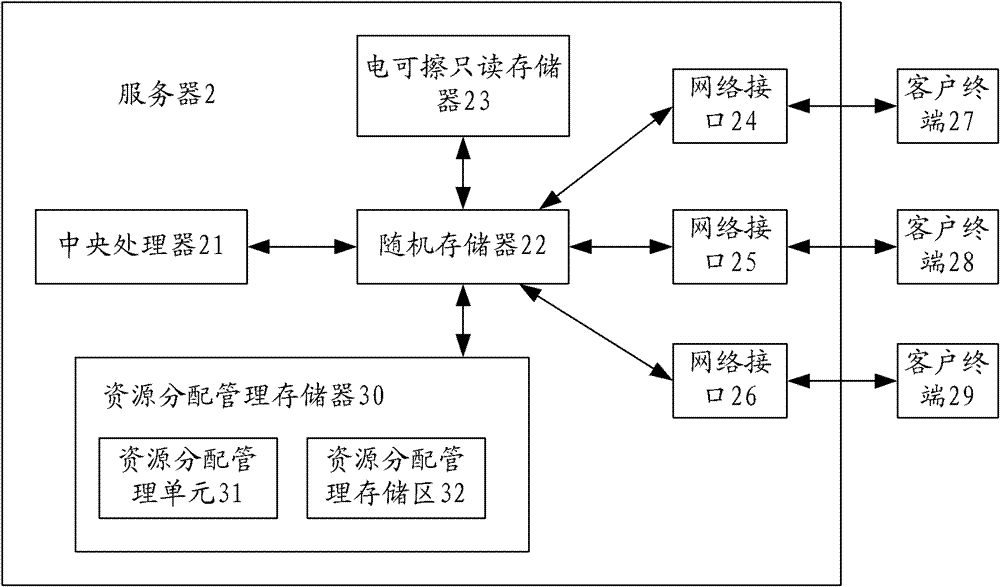

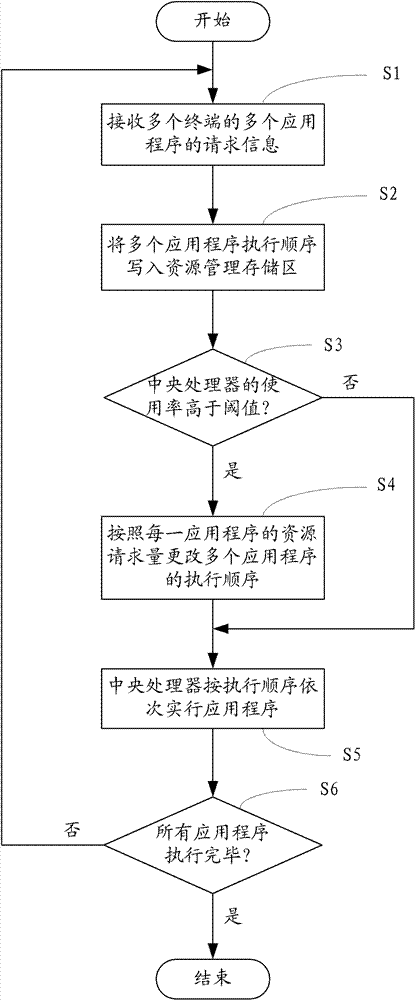

Computer system and working method thereof

A computer system and operating method thereof are provided. The computer system comprises a central processing unit (21) and a random access memory (22). The random access memory (22) is provided with a resource allocating management storage region (32) for storing execution sequence of the central processing unit executing an application program, and a resource allocating management unit (31) for dynamically changing the execution sequence according to request amount of resource occupied by a plurality of application programs, wherein the execution sequence is such that the execution priority level of an application program with a small request amount of resource is higher than the execution priority level of an application program with a large request amount of resource. The method comprises the following steps: the resource allocating management unit (31) receives information on request amount of resource sent from a plurality of application programs; writes an execution sequence of the plurality of application programs into the resource allocating management storage region (32); the resource allocating management unit (31) dynamically changes the execution sequence according to request amount of resource occupied by the application programs; and the central processing unit (21) executes the application programs according to the execution sequence.

Owner:ZHUHAI HOTDOOR TECH CO LTD

Front hub on front steering axle

Owner:郑之松

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com