Non-contact measuring equipment for radial deformation of submarine cable

A non-contact, radial deformation technology, applied in the direction of measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve the problems of lack of measurement of radial deformation of flexible pipes, measurement difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and implementation process.

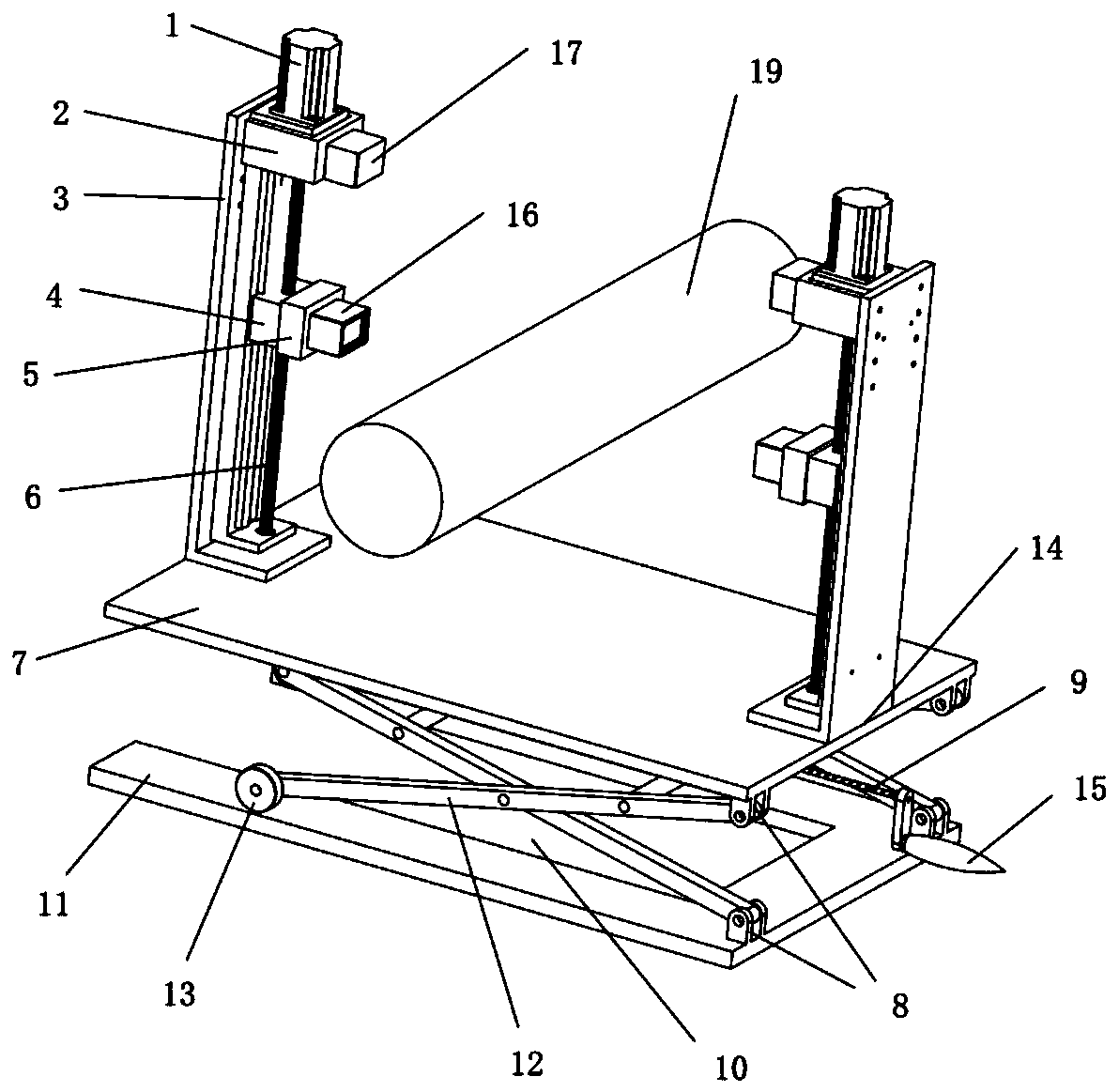

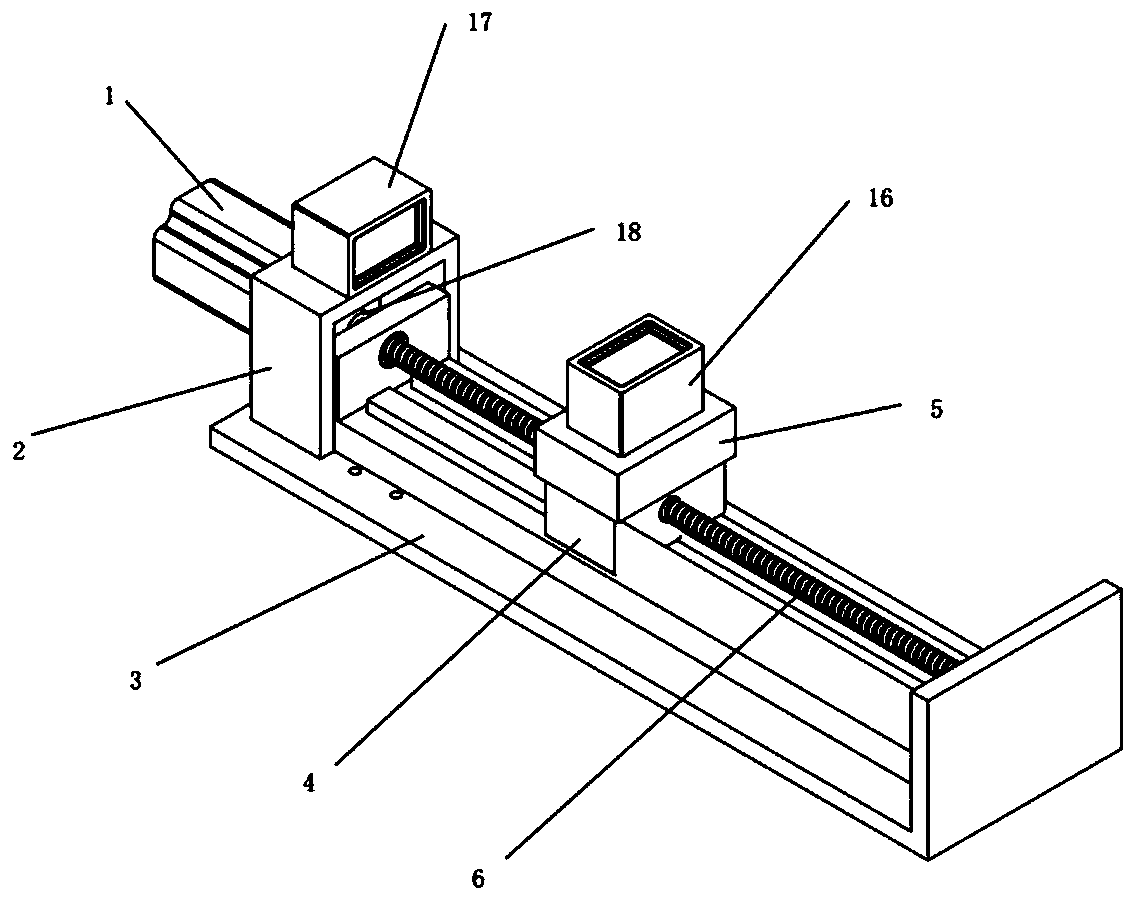

[0026] Such as figure 1 , figure 2 As shown, a non-contact measuring device for the radial deformation of a submarine cable includes a fixed plate 3, a guide rail 6, a sensor A 17, and a sensor B 16.

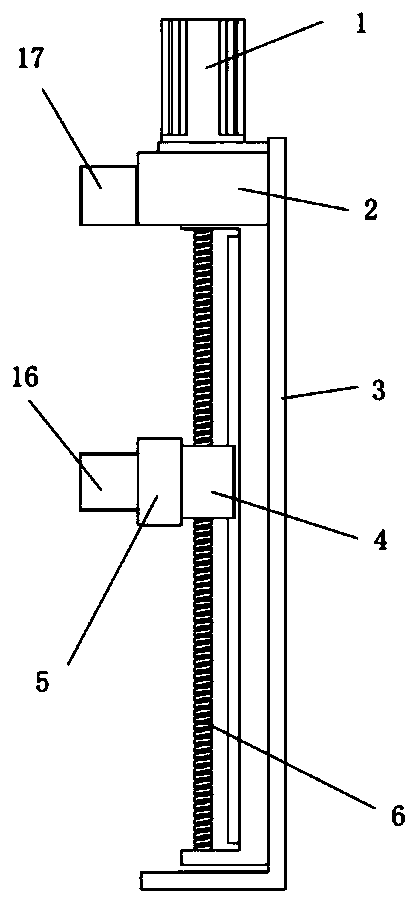

[0027] The fixed plate 3 is L-shaped, and the L-shaped long side is fastened with screws to install the guide rail 6 and the grooved plate 2, the sensor A17 is fixed on the top of the grooved plate 2 and installed vertically, and the laser irradiation direction is vertically directed downward to the sensor B16; The slide block 4 is installed on the guide rail 6, and the slide block 4 is connected with the sensor B16 through a connecting plate 5. Meanwhile, the sensor B16 is installed horizontally, and the laser irradiation direction is horizontally directed to the submarine cable 19 to be tested.

[0028] The guide rail 6 of this device is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com