Chain-type boosting inlet roller machine for oscillating bar conveyer

A conveyor and roller bed technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of reduced friction between the bottom surface of the skid and the surface of the rollers, occupied takt time, dripping, etc., saving waiting time, reducing frictional resistance, small impact and vibration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

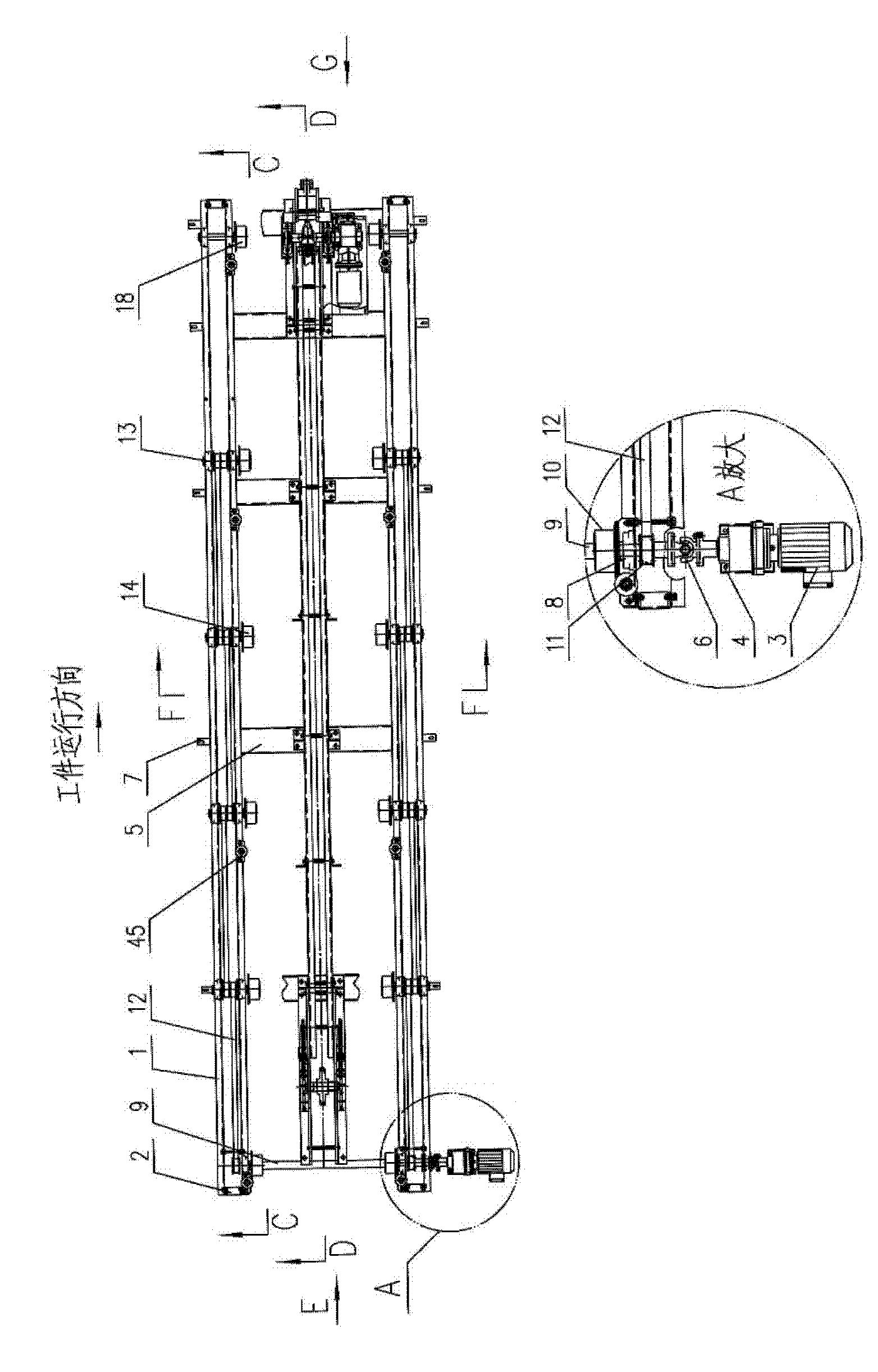

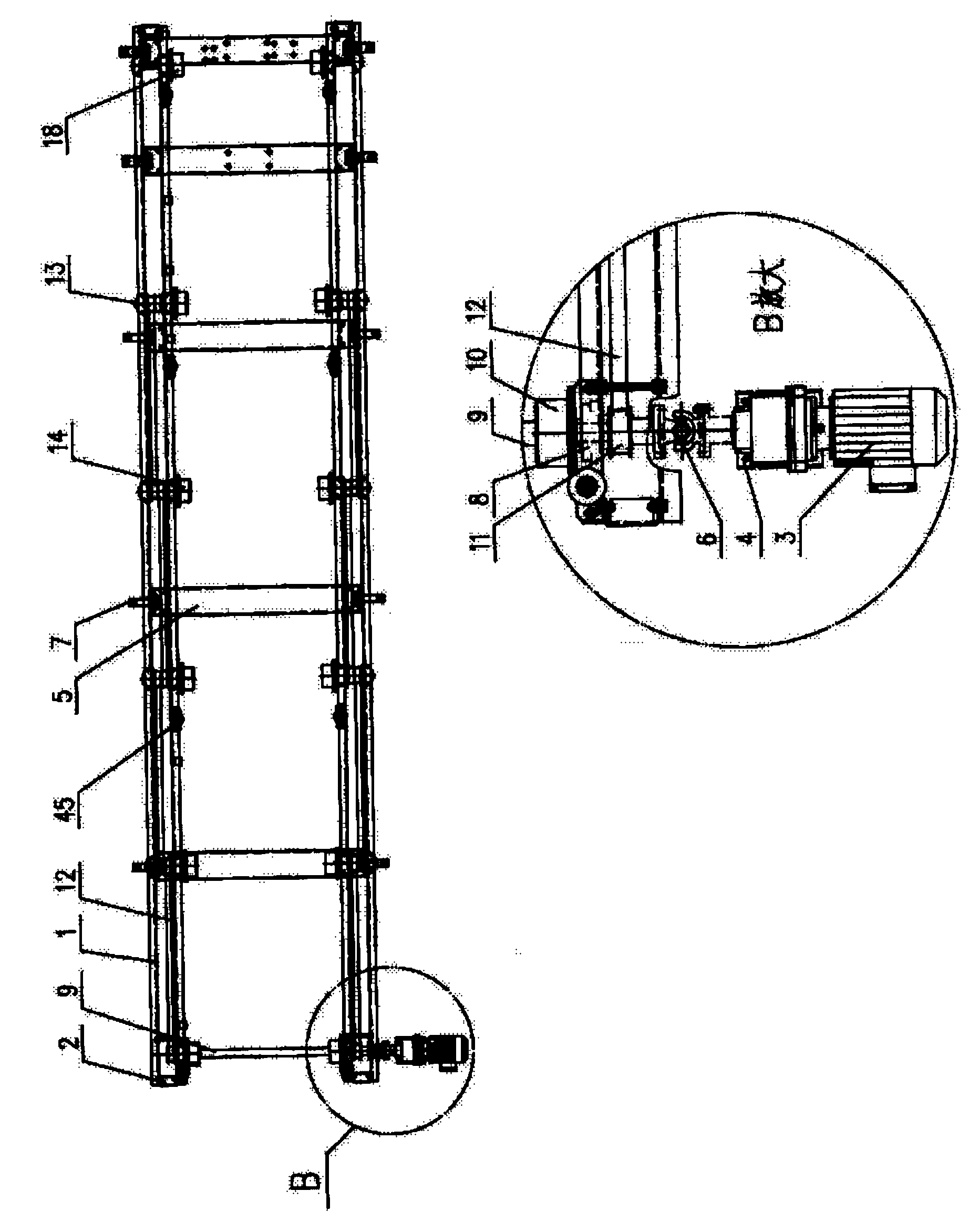

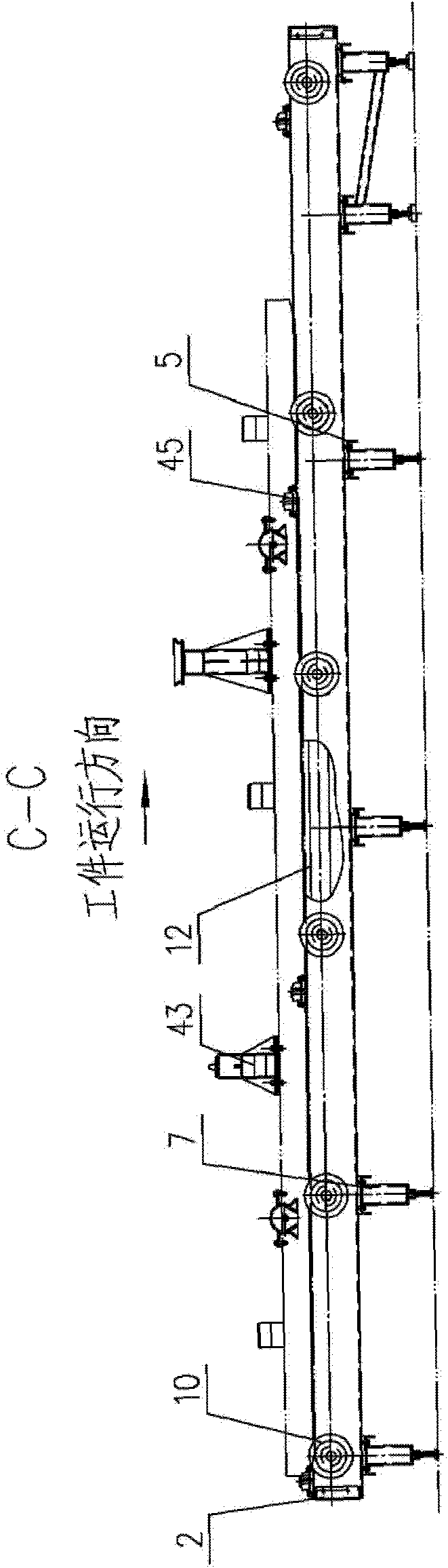

[0010] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS: In order to further understand the content, characteristics and effects of the present invention, the following embodiments are exemplified and described in detail with the accompanying drawings as follows, please refer to Figure 1-Figure 9 .

[0011] The chain-type booster inlet roller bed used for the swing bar conveyor includes a roller bed, a booster mechanism and a positioning mechanism, and is characterized in that: figure 1 , figure 2 Shown: The present invention consists of a roller bed with a separate assembly structure, a chain booster mechanism with an assembled frame structure, and a pneumatic positioning mechanism.

[0012] like Figure 3-Figure 5 , Figure 9 Shown: the tumbler with separate assembly structure is mainly composed of tumbler U-shaped plate 1, end plate 2, tumbler gear motor 3, motor bracket 4, fixed leg beam 5, universal joint 6, fixed leg 7. A belt seat bearing 8, composed of long roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com