Slurry filling pump with flow rate control function

A technology for filling pumps and thick slurry, which is applied in the direction of axial flow pumps, pumps, non-variable pumps, etc., which can solve the problems of wearing pipelines and filling drillings, etc., and achieves easy processing and manufacturing, convenient installation and use, and simple equipment structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

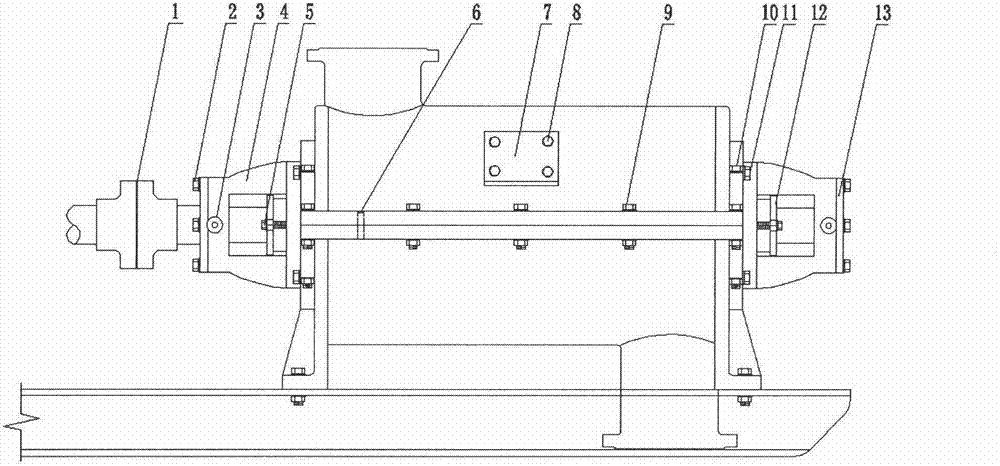

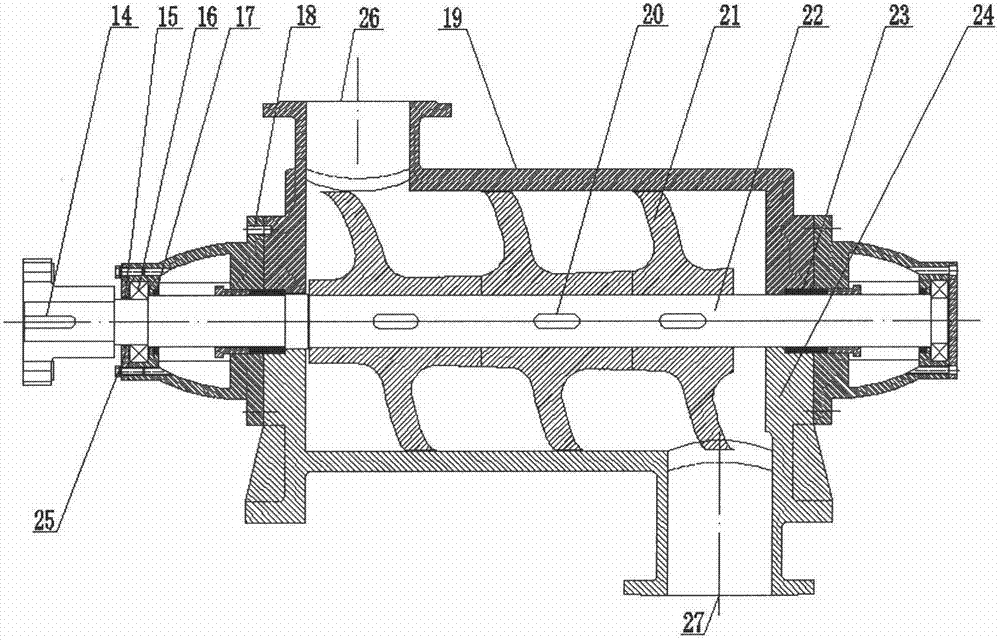

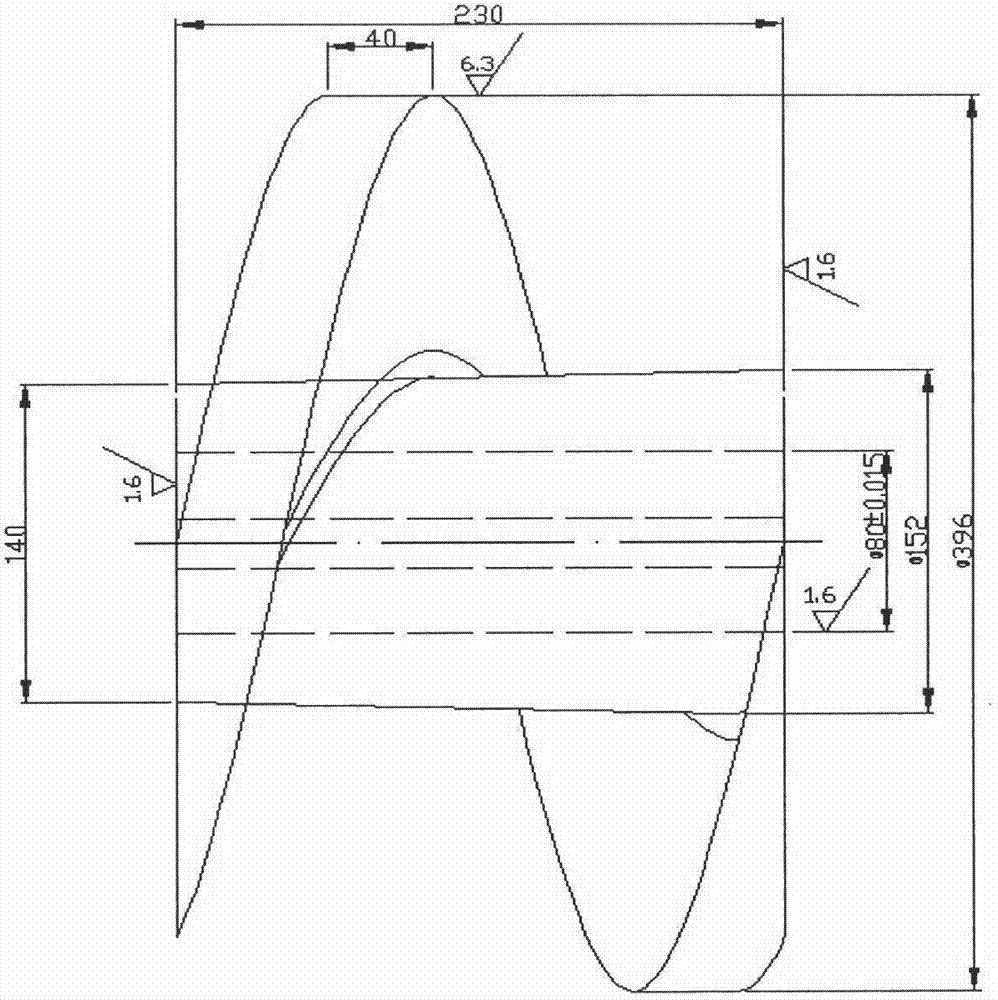

[0023] In the accompanying drawings, the main components of the thick slurry filling pump are the pump core and the pump casing. The pump core of this embodiment is composed of three helical impellers (21). The pump core composed of more than three or more helical impellers can transport the filling slurry with a longer distance and a higher pressure. It should be pointed out that no matter the pump core is composed of several helical impellers, the dimensions of each helical impeller are different. This is because the pitch of the pump core gradually changes from large to small, and the root diameter gradually changes from small to large, and its changing law is similar to a parabolic trajectory, which is a major factor in generating the delivery capacity. The pump core composed of three or more helical impellers (21) is assembled on the transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com