Vertical rotary multi-station diaphragm filter press

A diaphragm filter press, vertical rotation technology, applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of increasing filter plates, difficult transportation of equipment, increasing filter chambers, etc., to reduce length and The effect of occupying an area, saving the area, and improving the efficiency of the filter press

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

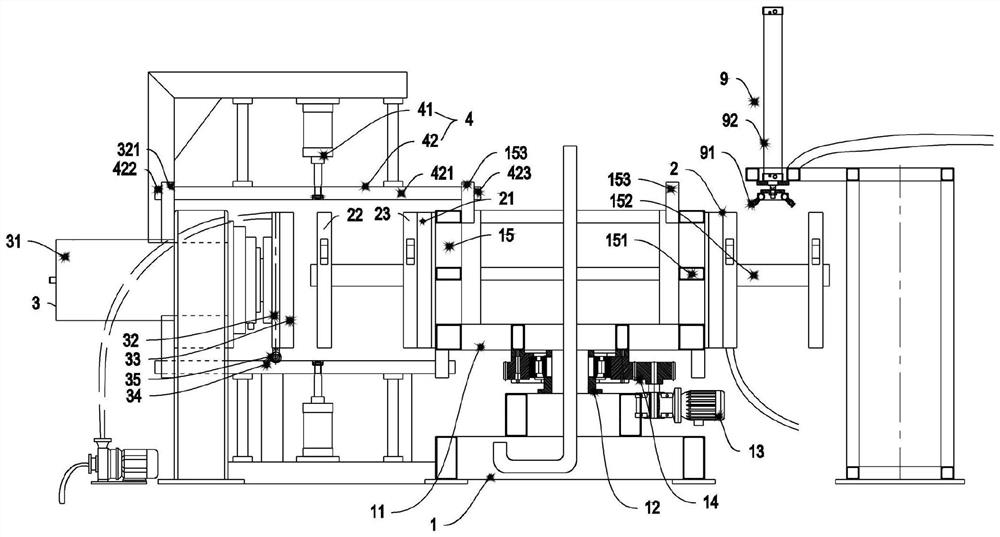

[0051] Such as Figure 2~3 As shown, a vertical rotary 4-station diaphragm filter press includes:

[0052] Main frame 1, rotating frame 11. The rotating frame 11 is connected on the main frame 1 through a bearing 12 . The main frame 1 is also provided with a rotary drive motor 13 and a transmission gear set 14 for driving the rotary frame 11 , the output end of the rotary drive motor 13 is connected with the rotary frame 11 through the transmission gear set 14 . The rotating frame 11 can rotate along the axis of the bearing 12 .

[0053] The rotating frame 11 is provided with 4 plate group fixing frames 15 and 4 groups of filter plate groups 2 equally divided along the circumferential direction, and the 4 groups of filter plate groups 2 are arranged on the 4 plate group fixing frames 15 in a one-to-one correspondence, and Four groups of filter plate groups can be displaced sequentially with the rotation of the rotating frame 11. Each plate group fixing frame 15 includes a ...

Embodiment 2

[0069] The difference between this embodiment and embodiment 1 is:

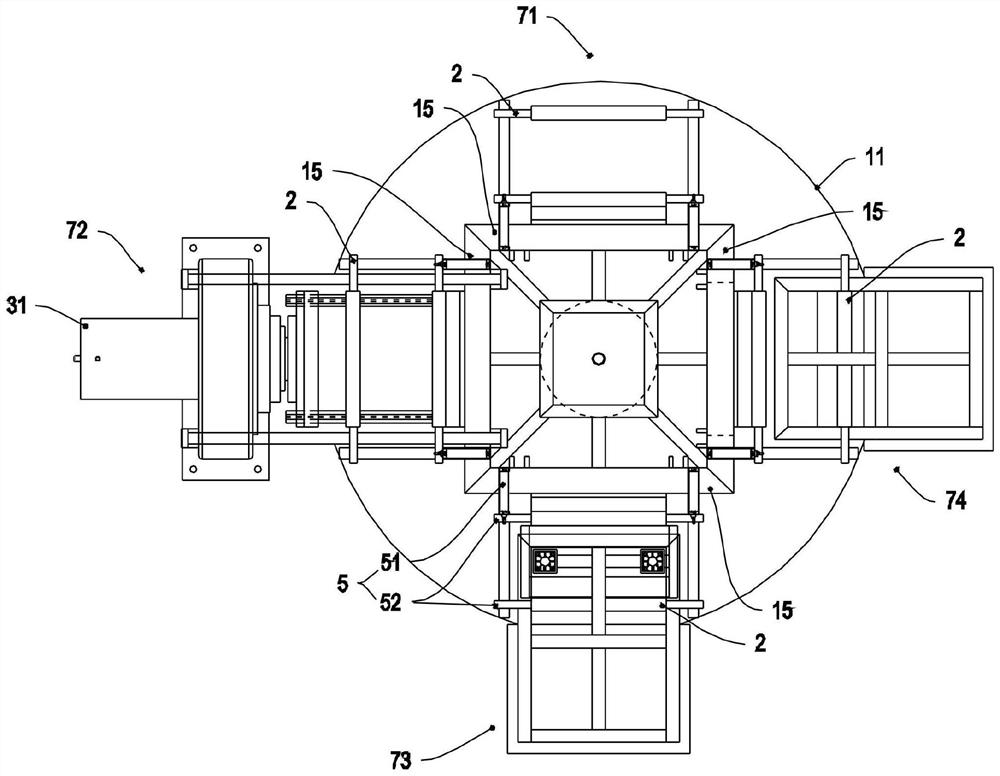

[0070] The rotating frame 11 is provided with 6 plate group fixing frames 15 and 6 groups of filter plate groups 2 equally divided along the circumferential direction, and the 6 groups of filter plate groups 2 are arranged on the 6 plate group fixing frames 15 in a one-to-one correspondence, and 6 sets of filter plate groups can be displaced sequentially with the rotation of the rotating frame 11.

[0071] Such as Figure 7 In this embodiment, the outside of the rotating frame 11 is equally divided into 6 station areas, and the 6 areas are successively the first grouting filter press area 101, the first film opening and discharge area 102, the first automatic cleaning area 103, the first The second grouting filter press area 104, the second film opening and unloading area 105, and the second automatic cleaning area 106. The distribution of the six areas corresponds to the positions of the six filter plate gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com