Numerical control metal cutting machine tool

A metal cutting and machine tool technology, applied in the field of mechanical parts processing, can solve problems such as friction heating, affecting metal cutting work, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

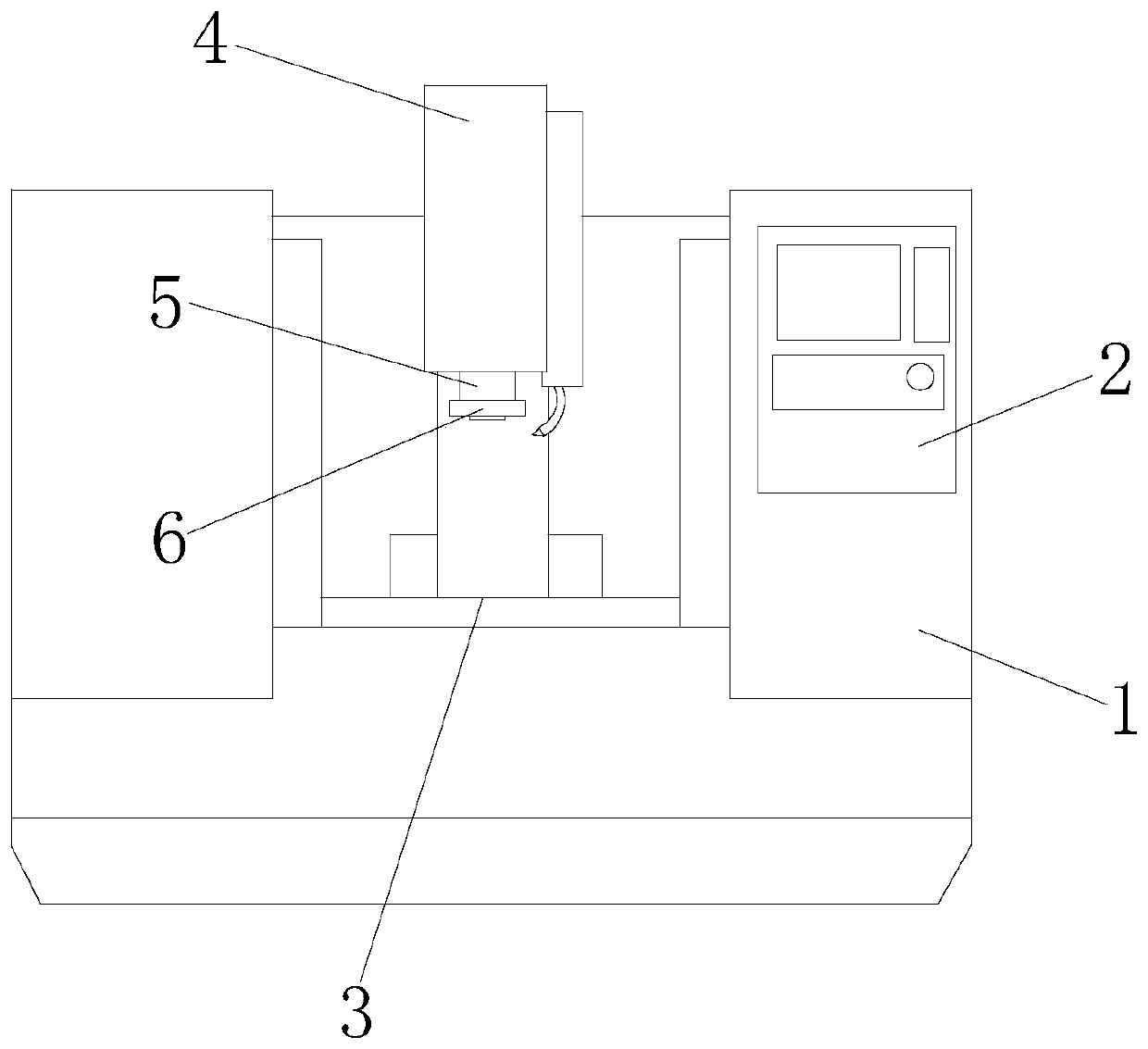

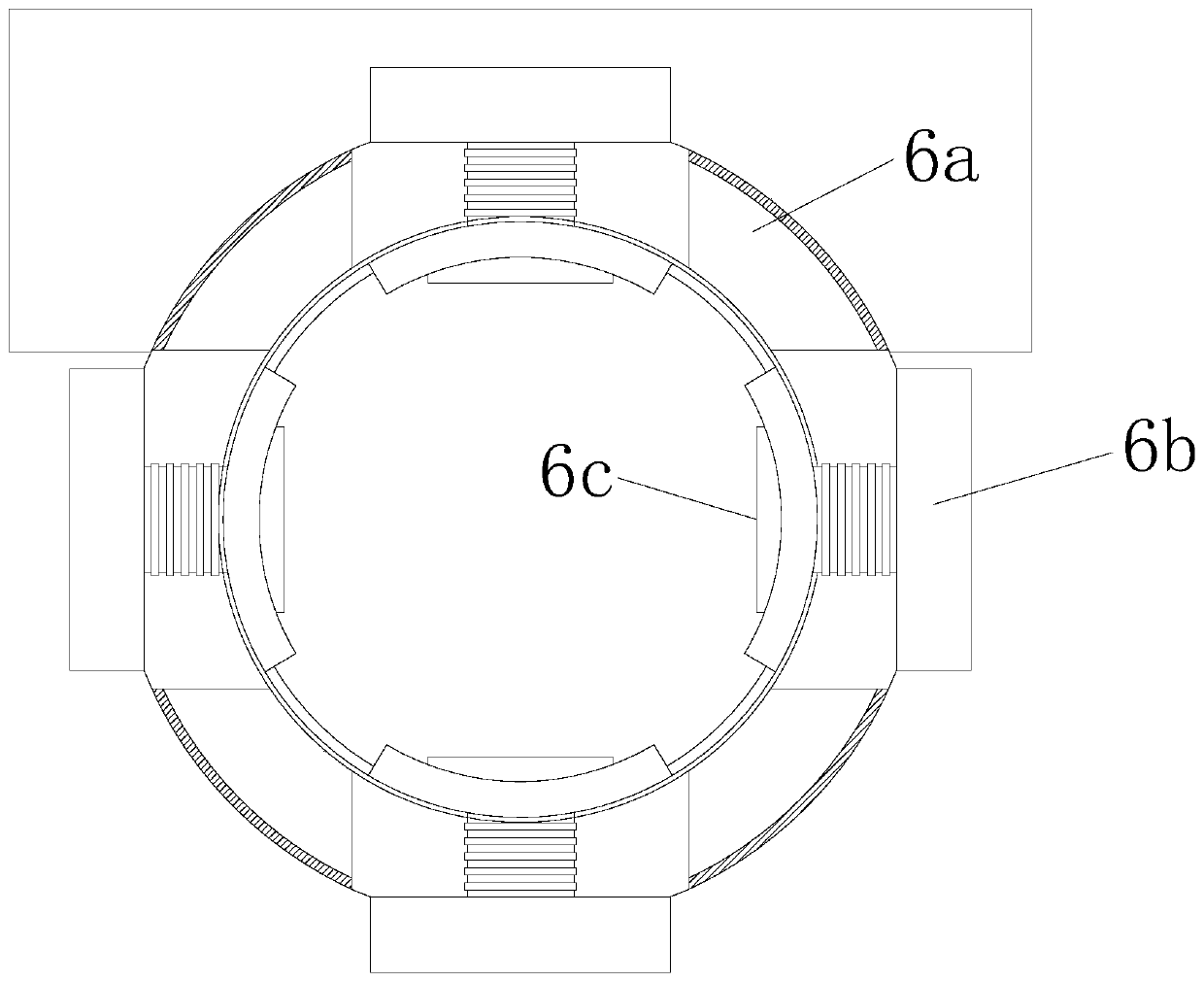

[0029] Such as Figure 1-Figure 5 As shown, the present invention provides a technical scheme of a numerically controlled metal cutting machine tool:

[0030] Such as Figure 1-Figure 2 As shown, a numerically controlled metal cutting machine tool, its structure includes a main body 1, a controller 2, a workbench 3, a column 4, a machine head 5, and a cleaning device 6, and the controller 2 is installed on the right side of the front surface of the main body 1. side and connected by electric welding, the workbench 3 is set on the upper part of the equipment main body 1 and is an integrated structure, the column 4 is set on the middle part of the front surface of the equipment main body 1 and is located directly above the workbench 3, the machine head 5 Installed on the lower surface of the column 4 and connected by electric welding, the dirt cleaning device 6 is installed on the outer surface of the machine head 5 and connected by buckling, the dirt cleaning device 6 includes...

no. 2 example

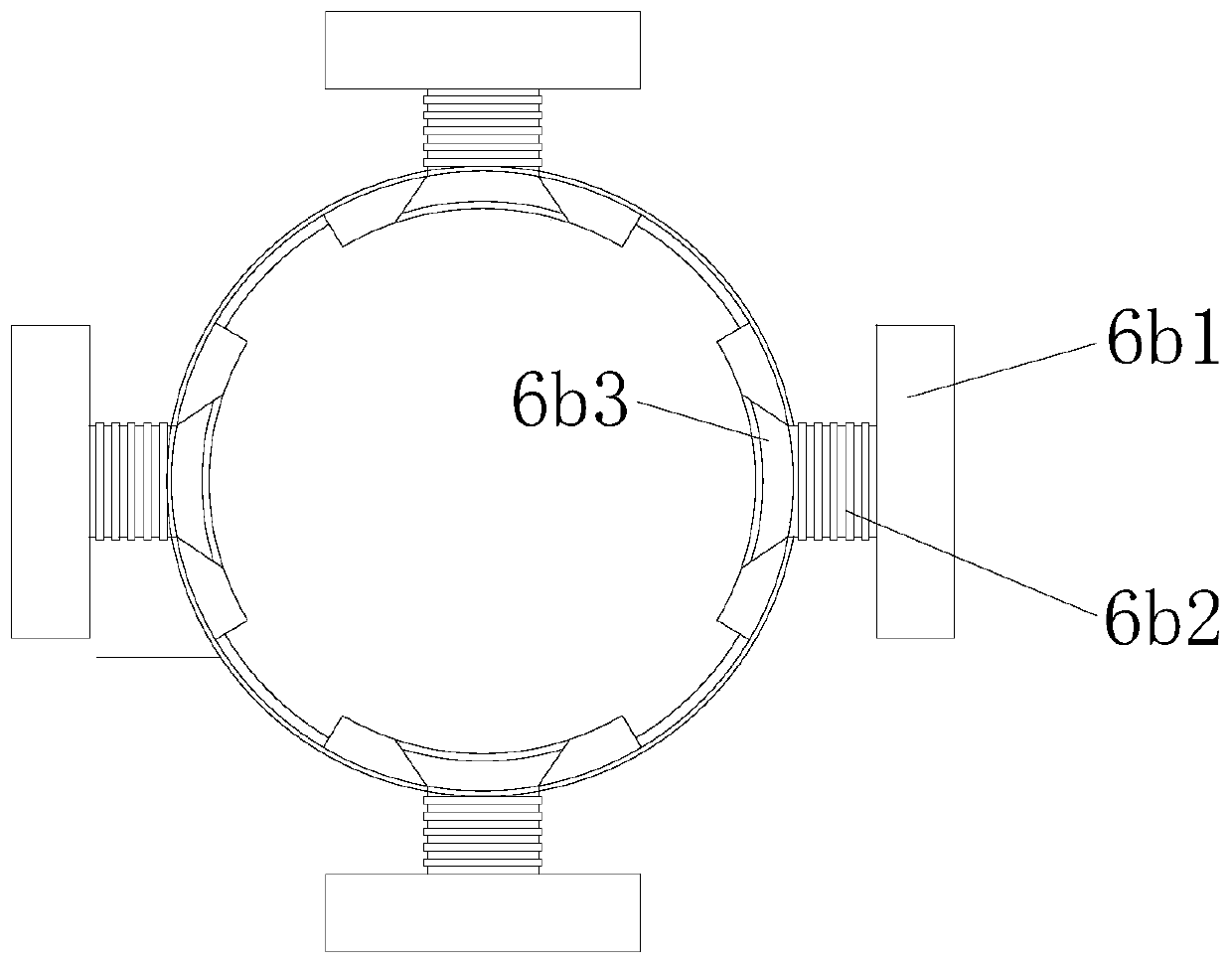

[0039] Such as figure 1 , figure 2 , Image 6 As shown, the present invention provides a technical scheme of a numerically controlled metal cutting machine tool:

[0040] Such as Figure 1-Figure 2As shown, a numerically controlled metal cutting machine tool, its structure includes a main body 1, a controller 2, a workbench 3, a column 4, a machine head 5, and a cleaning device 6, and the controller 2 is installed on the right side of the front surface of the main body 1. side and connected by electric welding, the workbench 3 is set on the upper part of the equipment main body 1 and is an integrated structure, the column 4 is set on the middle part of the front surface of the equipment main body 1 and is located directly above the workbench 3, the machine head 5 Installed on the lower surface of the column 4 and connected by electric welding, the dirt cleaning device 6 is installed on the outer surface of the machine head 5 and connected by buckling, the dirt cleaning de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com