Novel smashing and grinding technology and equipment

A new type of grinding technology, applied in the field of crushing and grinding, can solve the problems of large compression volume ratio, wide particle size distribution, low safety, etc., and achieve the effect of uniform particle size distribution, high controllability and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

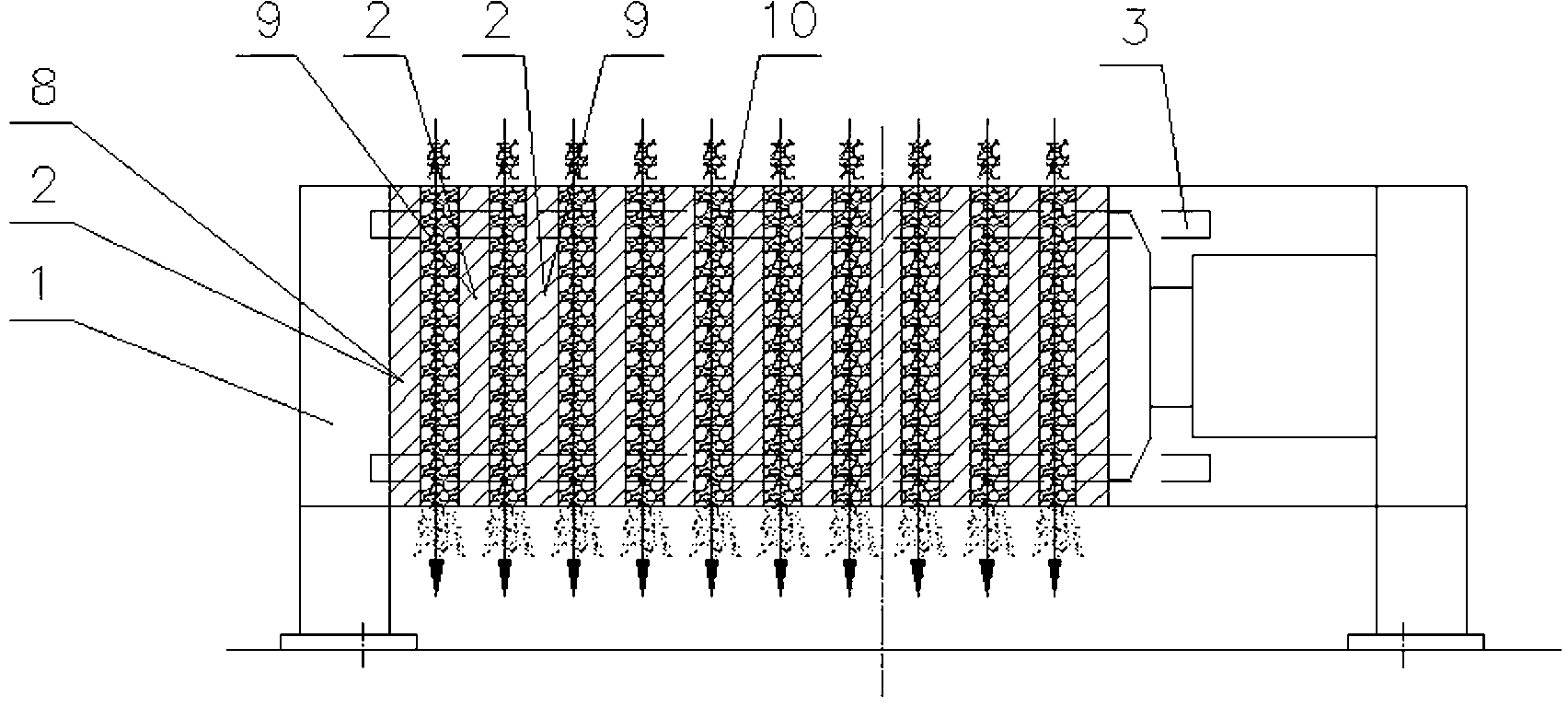

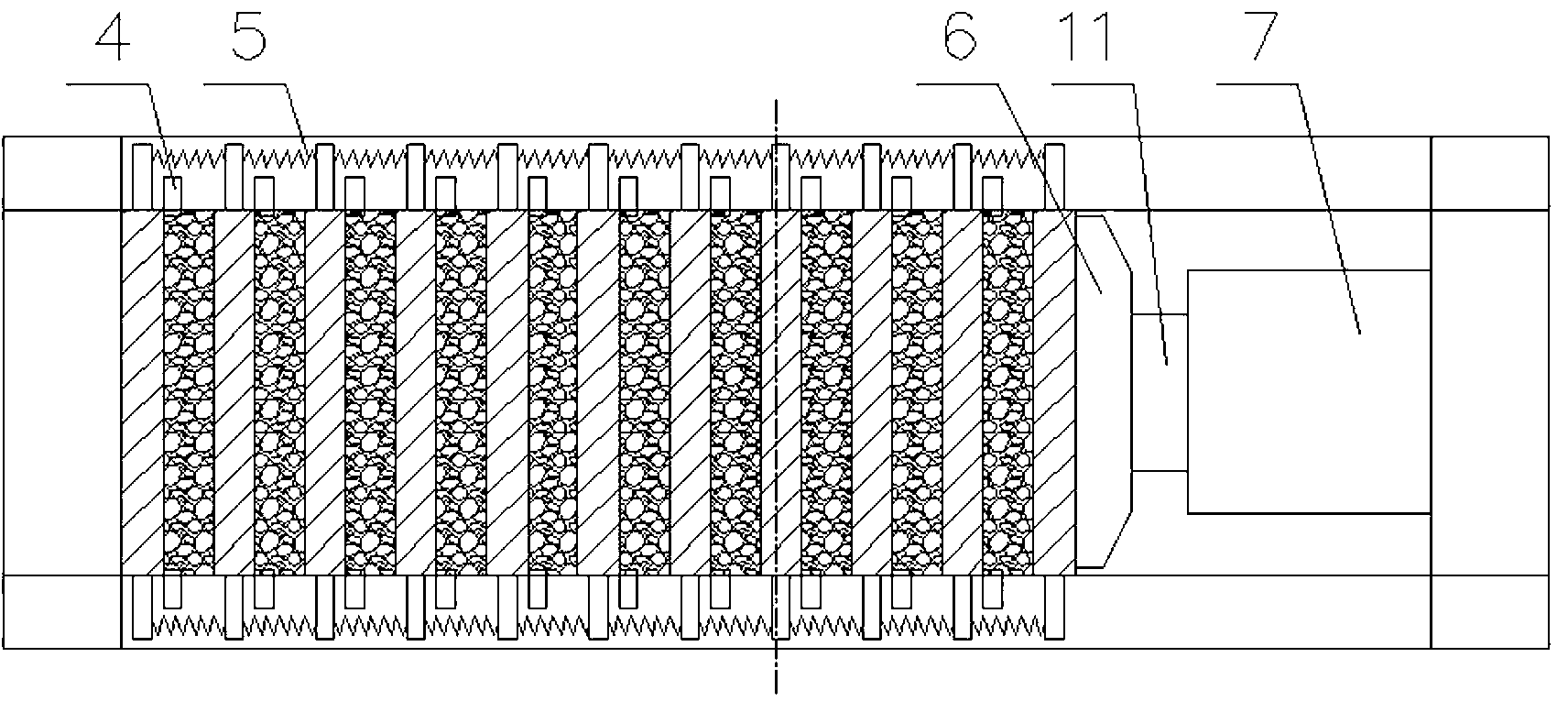

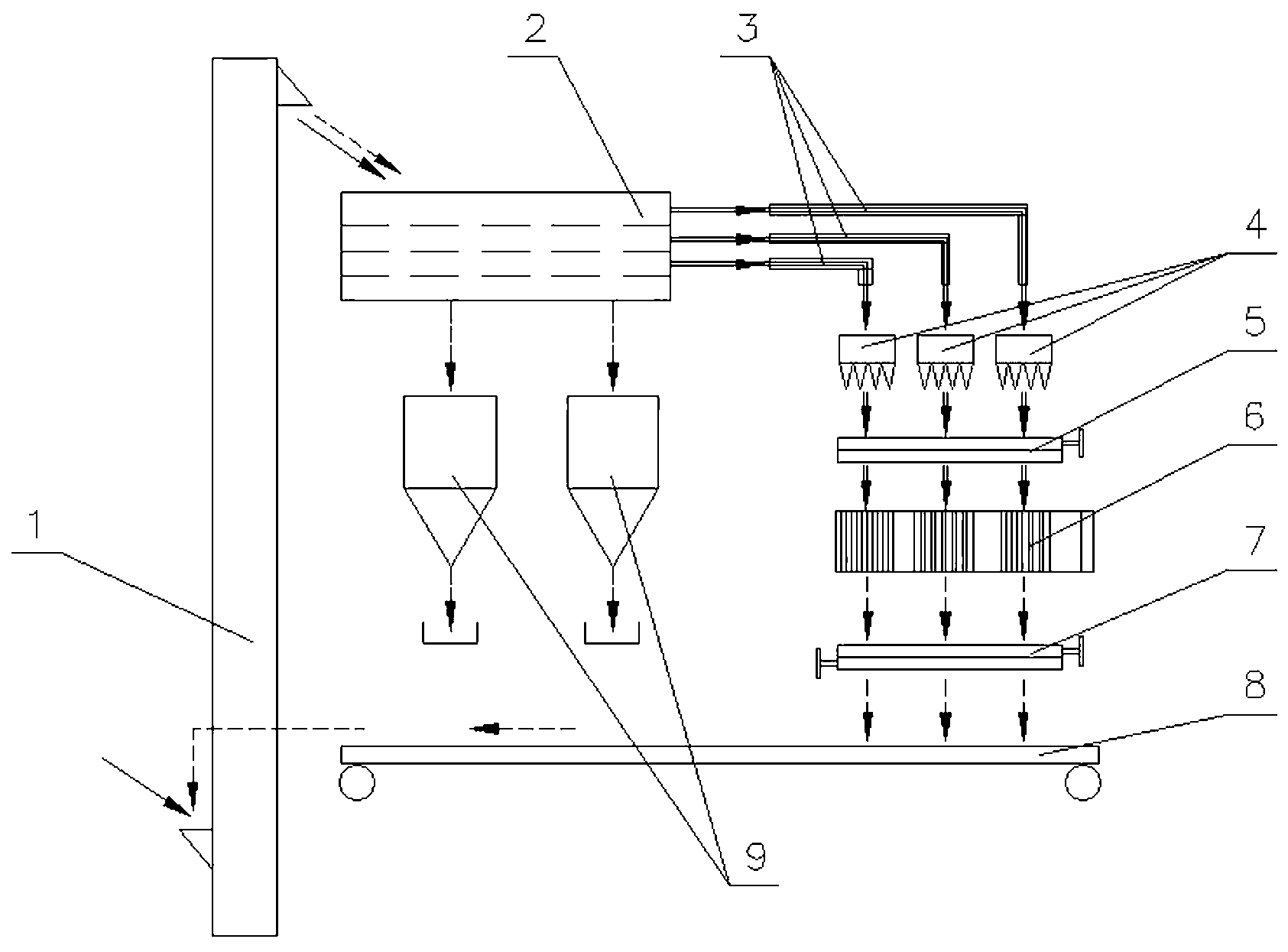

[0027] A new type of crushing and grinding equipment, including a frame 1, at least two working plates 2, a guide mechanism 3, a limit device 4, a reset device 5, an extrusion part 6, and a thrust mechanism 7, such as figure 1 As shown, the material enters from the entrance of each crushing chamber and fills each crushing chamber 10. After each crushing chamber 10 is filled with materials, it is isolated into a relatively closed space. The plate 2 is used as the movable plate 9, all the working plates 2 are adjacently arranged and an independent crushing chamber 10 is formed between each two adjacent working plates 2, and an opening is formed to accommodate materials. Each crushing chamber 10 has an inlet and an outlet, and the thrust mechanism 7 Fixed on the frame 1 or fixed between the frame 1 and the movable plate 9, the thrust mechanism 7 can generate thrust, the thrust rod 11 of the thrust mechanism 7 is pushed out, and simultaneously pushed out together with the extruding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com