Small-particle four-section moving bed dry distillation furnace with hydrogen-enriched environment and dry distillation method of small-particle four-section moving bed dry distillation furnace

A technology of moving bed and retort furnace, which is applied in special forms of retort, direct heating retort, coke oven, etc. It can solve the problems of poor oil quality, waste of resources, fine particle size of semi-coke products, etc., and achieve high oil yield and oil The effect of high product quality, low friction probability and low degree of breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

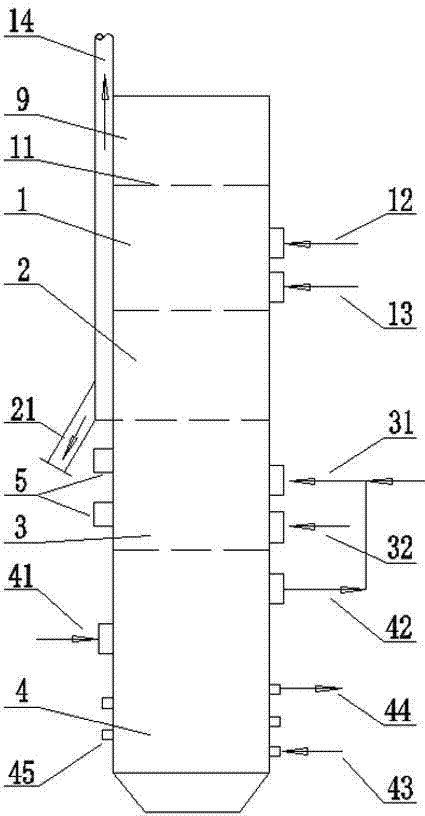

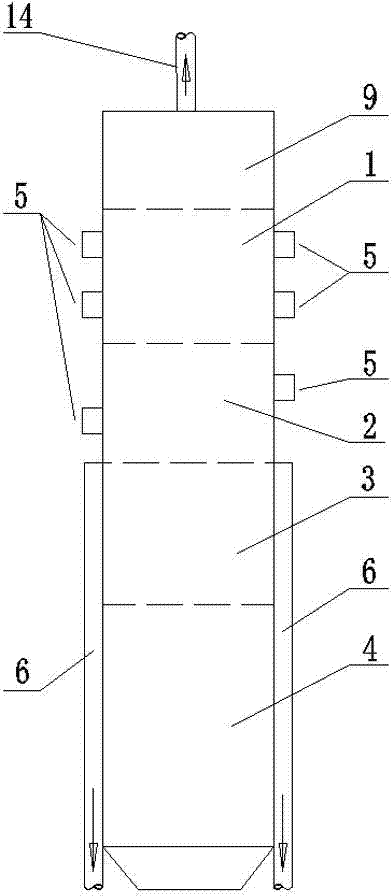

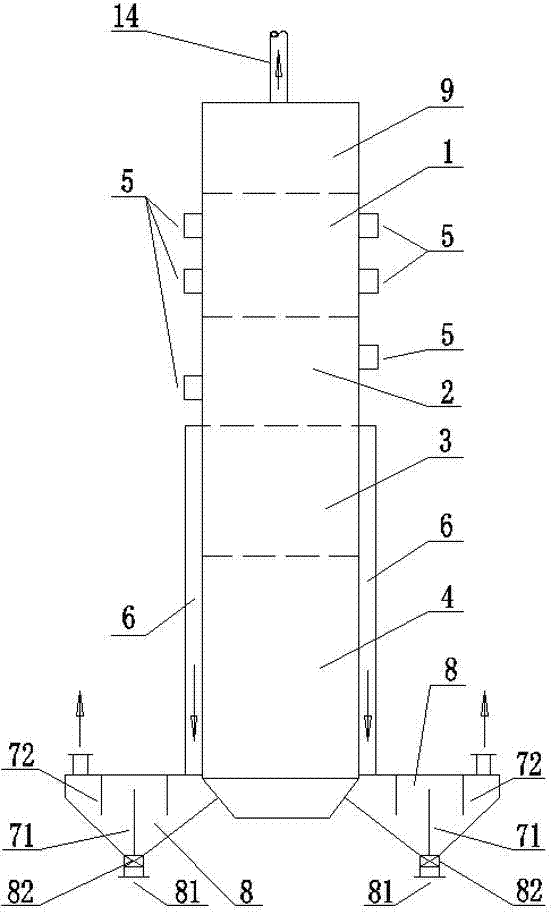

[0045] Such as figure 1 As shown, the retort material is lignite particles with a particle size of 5-6mm accounting for 94%. The specific steps are as follows:

[0046] 1. Put the above-mentioned lignite grains into the drying and preheating section of the retort furnace gradually, and at the same time, pass hot flue gas at 250-300°C into the lignite grains from the middle of the middle drying and preheating section through the multi-layer angular box inside, and self-drying The lower part of the preheating section passes hot flue gas at 300-350°C into the lignite grains through the gas distribution flower wall in it, and directly heats the lignite grains until the moisture content is less than 1% and the temperature is greater than 150°C. After drying the waste gas and flue gas It is discharged through the exhaust port on the upper side of the drying and preheating section, and discharged to the atmosphere after dust removal;

[0047] 2. The dried and preheated lignite p...

Embodiment 2

[0051] The dry distillation material is oil shale particles with a particle size of 13-15 mm, accounting for 89%. The specific steps are as follows:

[0052] 1. Put the above-mentioned oil shale particles into the dry preheating section of the retort furnace gradually, and at the same time, pass hot smoke at 200-250°C into the oil shale particles from the middle of the middle drying preheating section through the multi-layer horn box inside From the lower part of the drying preheating section, through the multi-layer angular box inside, the hot flue gas of 300-350 ℃ is introduced into the oil shale particles, and the oil shale particles are directly heated until the moisture content is 120°C, the dry waste gas and flue gas are collected and discharged through the multi-layer angular box on the upper side of the drying preheating section through the exhaust port, and then discharged to the atmosphere after dust removal;

[0053] 2. The dried and preheated lignite particles...

Embodiment 3

[0057] The retort material is lignite particles with a particle size of 10-12mm accounting for 88%. The specific steps are as follows:

[0058]1. Put the above-mentioned lignite grains into the drying and preheating section of the retort furnace gradually, and at the same time, pass hot flue gas at 250-300°C into the lignite grains from the middle of the middle drying and preheating section through the multi-layer angular box inside, and self-drying The lower part of the preheating section passes hot flue gas at 350-400°C into the lignite particles through the multi-layer horn box inside, and directly heats the lignite particles until the moisture content is less than 1% and the temperature is greater than 140°C, and the waste gas and flue gas are dried. After collection, it is discharged through the exhaust port on the upper side of the drying and preheating section, and is discharged to the atmosphere after dust removal;

[0059] 2. The dried and preheated lignite particles ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com