Patents

Literature

52results about How to "Low degree of fragmentation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for processing green tea

The invention discloses a method for processing green tea. The method comprises the following steps of: fixing, namely, selecting 2 to 3 leaves from each bud of a medium and small-leaf variety; spreading, namely, spreading tea leaves until the water content of the spread tea leaves is lowered to be between 70 and 75 percent; dampening and fixing; slowly twisting, namely, filling dampened tea leaves into a twisting bucket of a twisting machine, wherein the rotating speed of the twisting machine is between 30 and 40 r / min, total twisting time is between 22 and 28 minutes and the tea leaves are pressed lightly for 1 to 5 minutes in the midway; dewatering until water content is between 38 and 46 percent; shaping for three times; drying; spreading dried tea leaves with the thickness of between3 and 5 centimeters for 24 to 32 hours; and performing aroma extracting on the spread tea leaves at the high temperature of between 120 and 140 DEG C for 6 to 8 minutes. A product obtained by the method has attractive appearance and is soaking resistant and the quality of the green tea can be improved greatly.

Owner:GUIYANG CHUNQIU INDAL

Production process for spicy duck neck

InactiveCN104783194AGreat tasteLow degree of fragmentationClimate change adaptationFood preparationMomordicaSpring onion

The invention discloses a production process for a spicy duck neck. The spicy duck neck is prepared from a frozen duck neck, pectin, Chinese prickly ash, star anise, cassia bark, common fennel fruit, clove, licorice, villous amomum fruit, salt, cooking wine, sodium nitrite, scalded duck skeleton, ginger, scallion, plant oil, Capsicum annuum, green Chinese prickly ash, alpinia officinarum hance, myrcia, dahurian angelica root, tsaoko fruit, cardamom, netmeg, kaempferia galamga, dried orange peel, grosvenor momordica fruit, minced ginger, radish seed, cumin, pepper, spicy essential oil, Chinese prickly ash essential oil, etc. through unfreezing, preprocessing, dry salting, marinating and cooking, wet salting, baking and material blending. According to the invention, spicy taste infiltrates the bone of the duck neck, so the taste of the spicy duck neck is improved and the spicy duck neck is more chewy; and as the comfort level of taste is improved, more consumers are allowed to accept spicy taste, and the fragmentation degree of the duck neck is reduced.

Owner:TIANCHANG BAITAHU FOOD

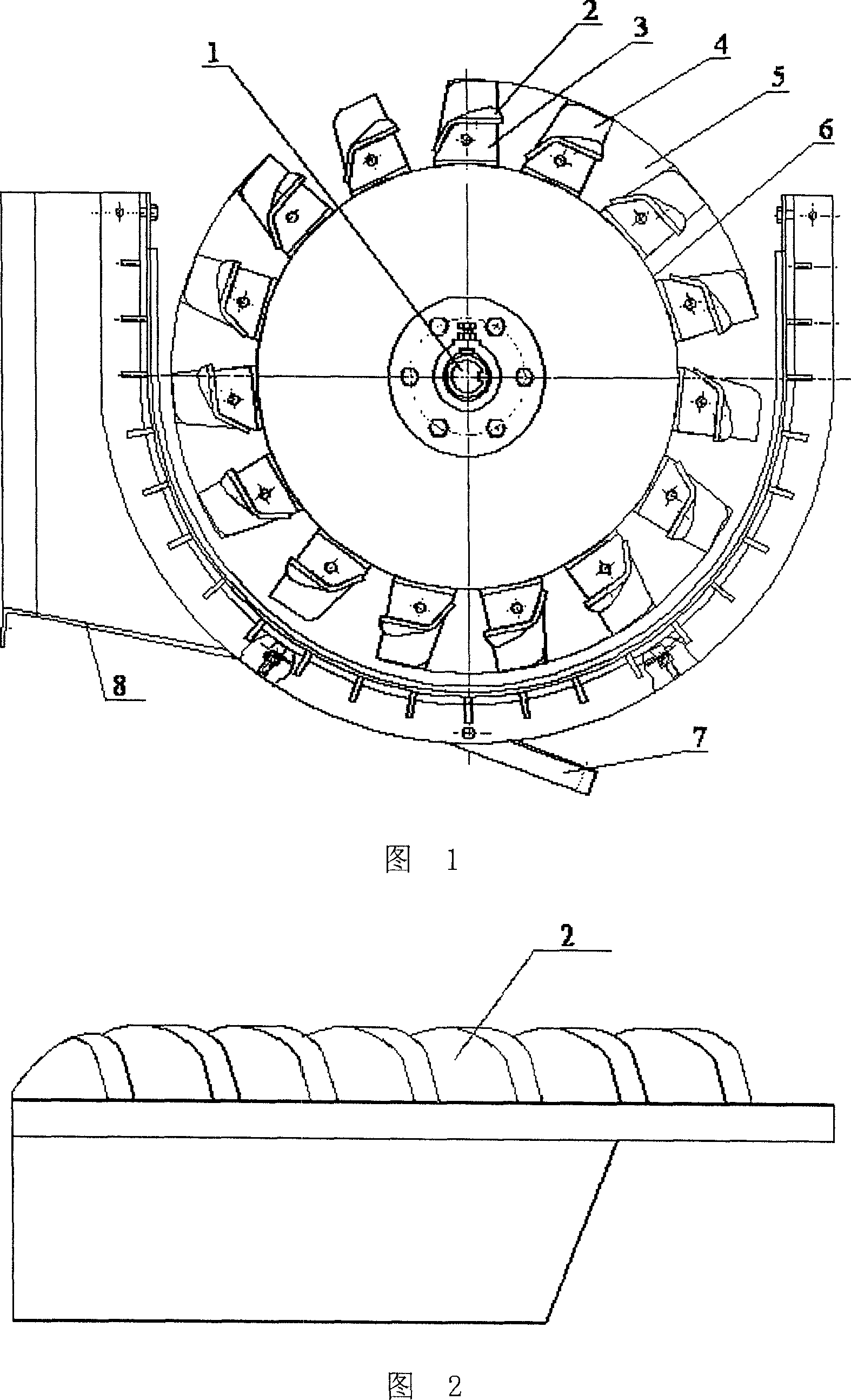

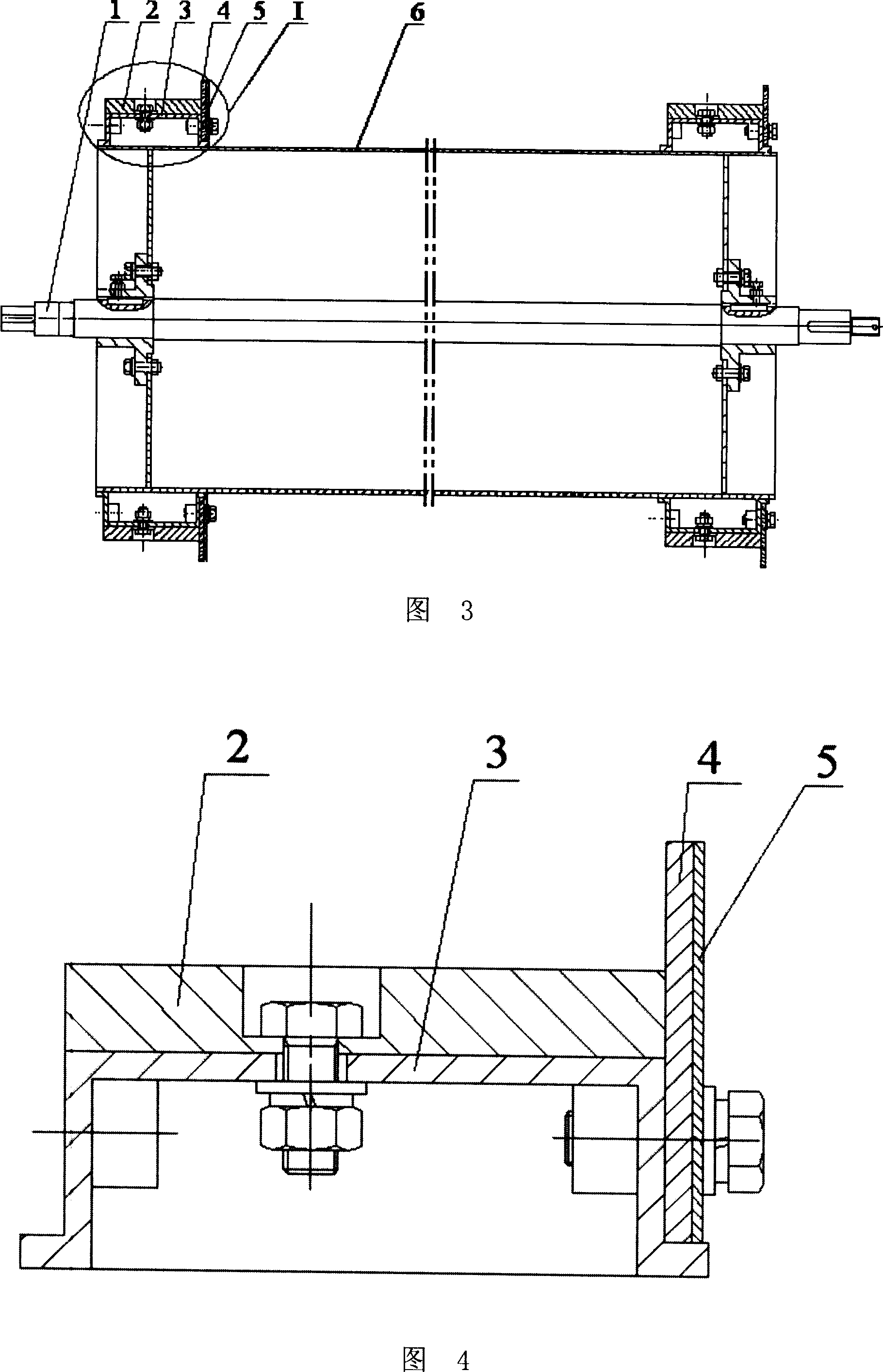

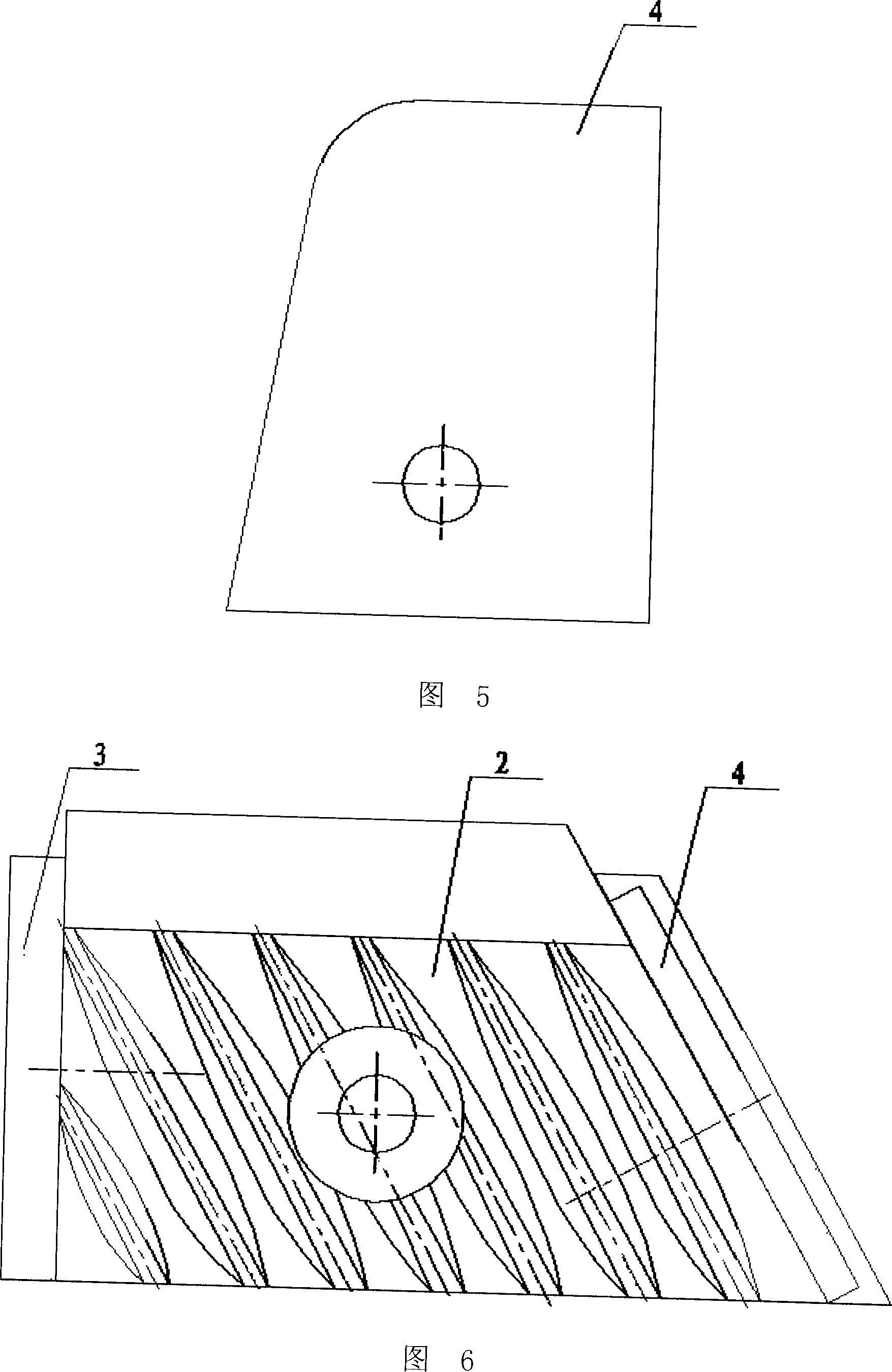

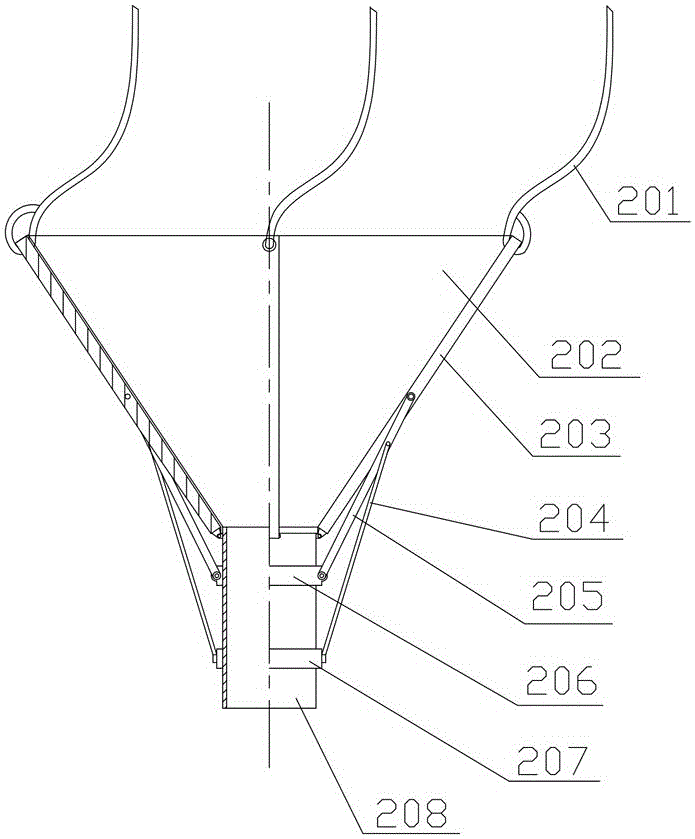

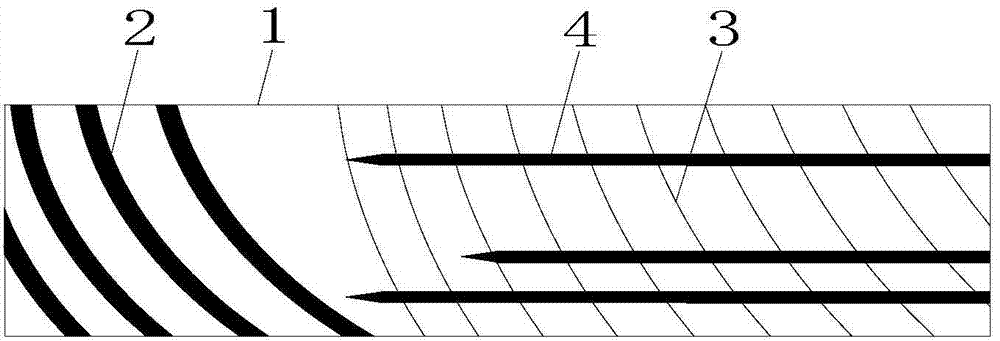

Axial flow threshing separation facility in tangential feeding type

The present invention relates to a tangential feeding axial-flow threshing separation equipment. Its threshing element adopts short threaded rod-toothed bar combination structure, said short threaded rod is mounted on the threaded rod seat, the toothed bar is positioned at one side of threaded rod seat, its recessed plate adopts grid sieve and punching sieve combination structure, the above-mentioned two structures can be matched with threshing drum so as to implement threshing and separation of crops. Said invention can be used for threshing and separation of several crops of rice, wheat, rape and soybean, etc.

Owner:JIANGSU UNIV

Sanchi total saponin free-dried powdery injection against smash and its preparation

ActiveCN1895314AImprove stabilityIndicator qualifiedPowder deliveryOrganic active ingredientsHigh resistanceMANNITOL/SORBITOL

A freeze-dried powder injection of arasaponin with beautiful appearance and high resistance to break is prepared from arasaponin and mannitol proportionally. Its preparing process is also disclosed.

Owner:KPC PHARM INC

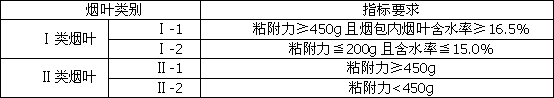

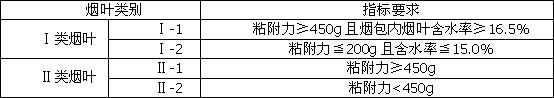

Threshed and re-dried tobacco leaf preprocessing technique based on tobacco leaf raw material characteristics

ActiveCN108523198AImprove adhesionLow degree of fragmentationTobacco preparationEngineeringPre treatment

A threshed and re-dried tobacco leaf preprocessing technique based on tobacco leaf raw material characteristics comprises the process steps of vacuum dampening, primary hot-air leaf wetting and secondary hot-air leaf wetting and is characterized in that the adhesion and moisture of tobacco leaf raw materials are firstly analyzed and tested for classification before the process steps, and preprocessing process technique parameters of different categories of tobacco leaf raw materials are determined according to adhesion and moisture detection results of tobacco leaves. By adopting the technique, the moisture uniformity of different categories of tobacco leaf raw materials in a tobacco leaf threshing and re-drying preprocessing process is improved, caking phenomena of high-adhesion and high-moisture-content threshed and re-dried tobacco leaf raw materials in the threshing and re-drying preprocessing process are decreased, the breaking degrees of different categories of tobacco leaf raw materials in the threshing process are reduced, and the economic efficiency of threshing and re-drying processing is improved on the basis that the processing quality of threshing and re-drying is ensured.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC +4

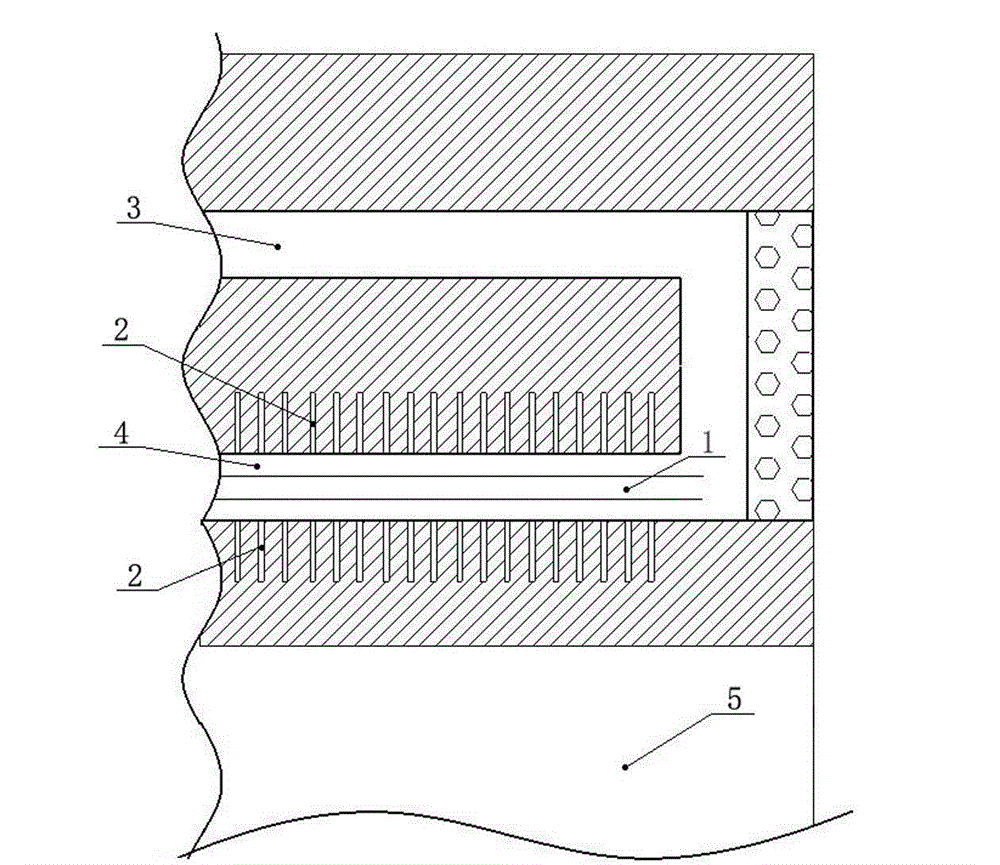

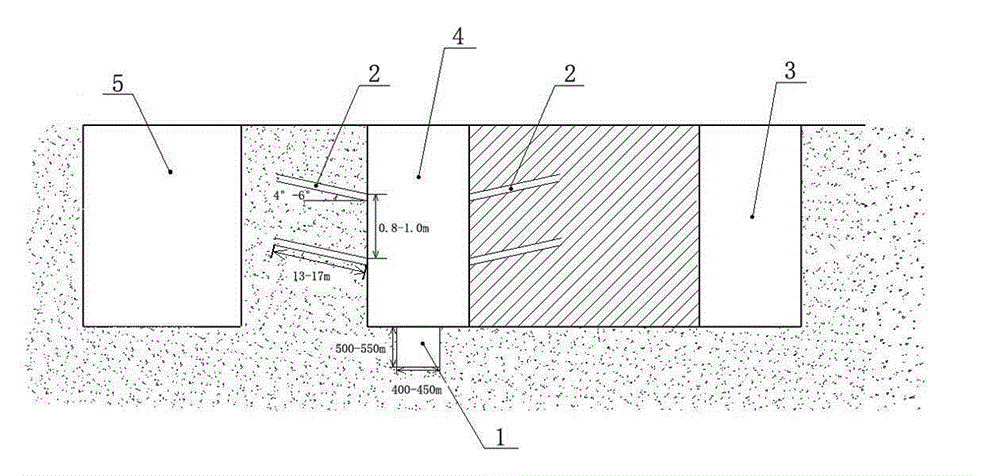

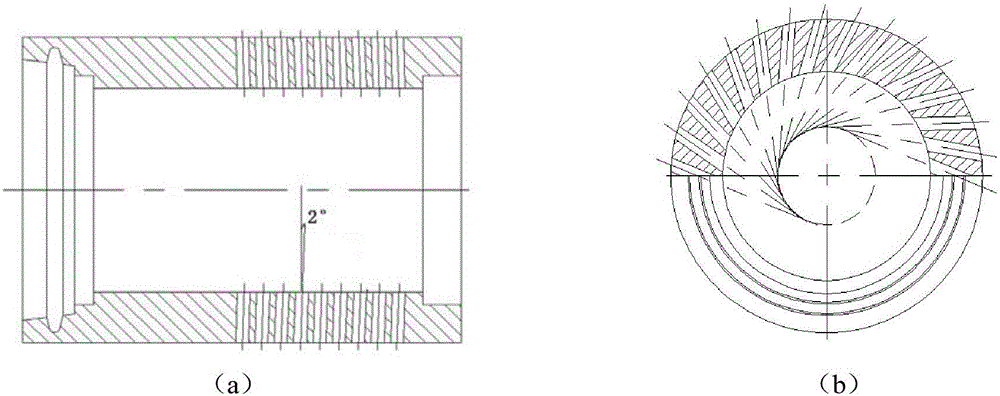

Pressure relief method aimed at strata behaviors of gob side entries of fully mechanized caving faces

InactiveCN103061808AReduce sinkageLow degree of fragmentationMining devicesSpelunkingStress distribution

The invention relates to a pressure relief method aimed at strata behaviors of gob side entries of fully mechanized caving faces and solves the problem of the absence of effective methods for strata behaviors of mines at present. The method comprises building a pressure relief groove which is 500mm to 550mm deep and 400mm to 450mm wide on a center line of a gob side entry bottom plate, and building at least two rows of pressure relief holes which are 13mm to 17mm deep and incline upwards by 4 degrees to 6 degrees from top to bottom on two sides of the gob side entry, wherein the two adjacent rows of the pressure relief holes are arranged in a triangular mode. According to the pressure relief method, the stress distribution of gob side entries is transferred in advance through pressure relief technologies of building of the pressure relief groove and the pressure relief holes and the like, strata behaviors of gob side entries are weakened, the passivity is converted into the initiative, the problem is solved fundamentally from the source, and the mine pressure is controlled.

Owner:DATONG COAL MINE GRP

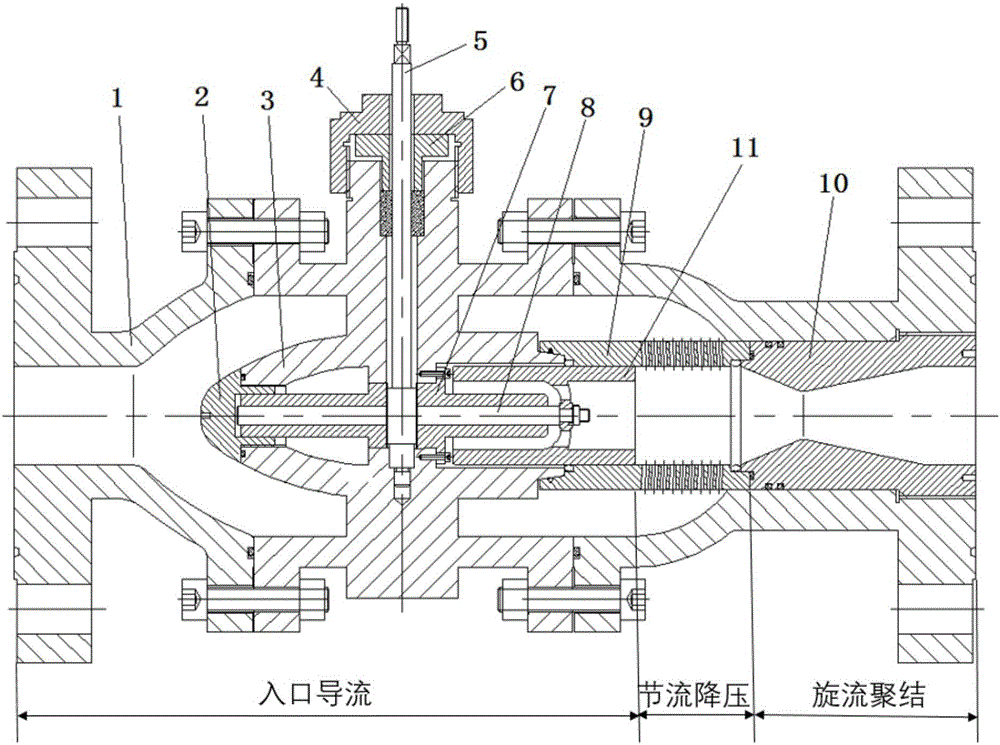

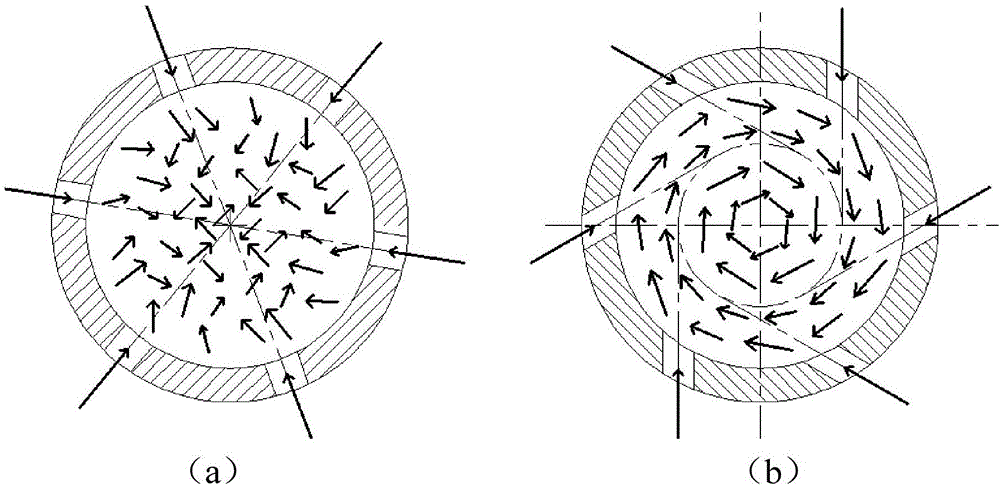

Low shearing plunger type throttling valve used for oil production gathering and transporting

InactiveCN106439137AEnhance swirl effectReduce random vortex motionEqualizing valvesSafety valvesBase functionOil water

The invention discloses a low shearing plunger type throttling valve used for oil production gathering and transporting. Based on a rotational flow agglomeration and unit mass energy dissipation rate control technology, orifices of a valve cage are designed to be in the tangential direction, a rotational flow chamber which is converged firstly and expanded afterwards is connected behind the orifices, the basic function of flow and pressure adjustment can be achieved on the plunger type throttling valve, meanwhile, the velocity gradient and the turbulence energy dissipation rate in a flow field are reduced, the shearing force of the orifices for fluid is reduced, the liquid drop breaking degree is lowered, and the subsequent oil water separation difficulty is lowered.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Technique for preparing high active full-defatted peanut protein powder

InactiveCN101233897ANo thermal denaturationHigh water soluble protein contentProtein composition from vegetable seedsFood industryPeanut meal

The invention discloses a technique for preparing high-active wholly-degreased peanut protein powder. Semi-degreased peanut white kernel with a grease content ranging from 18-30 percent is used as raw materials which are then pre-treated by crushing, quality modulation and flaking to be sent into a continuous leaching device and leached by food industry grade hexane, and a wet peanut meal and mixed oil which contain the solvent are respectively obtained. The mixed oil containing the solvent is vaporized for two times and steam stripped for one time in sequence to remove the solvent, and a leached raw peanut oil with light color is prepared; after the wet peanut meal containing the solvent is sent into a horizontal low temperature solvent removing system to eliminate the solvent, a low denatured wholly degreased peanut meal is obtained; the high active wholly degreased peanut protein powder is prepared after superfine comminution treatment of the low denatured wholly degreased peanut meal .

Owner:北京硕泰生物技术有限责任公司

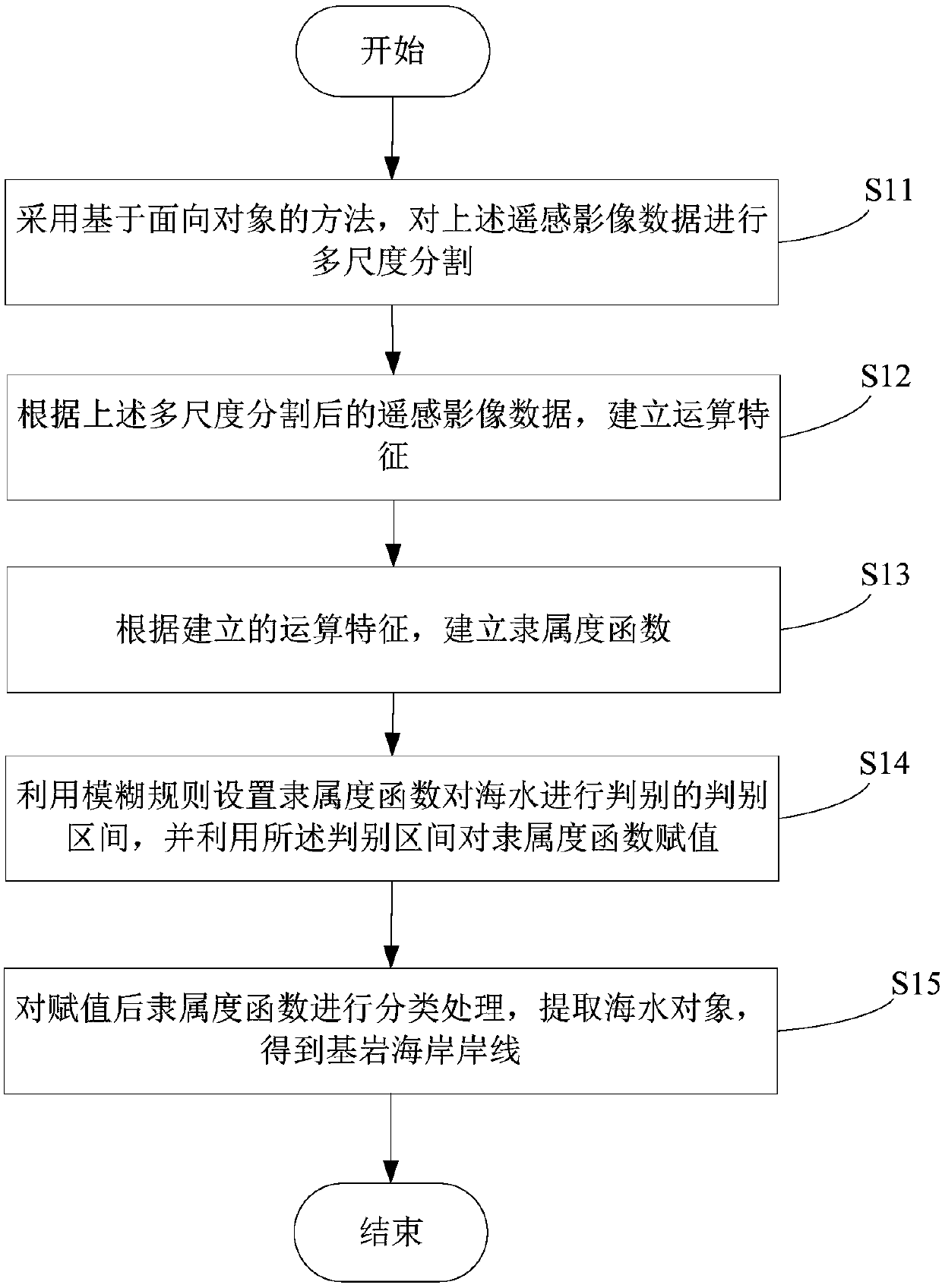

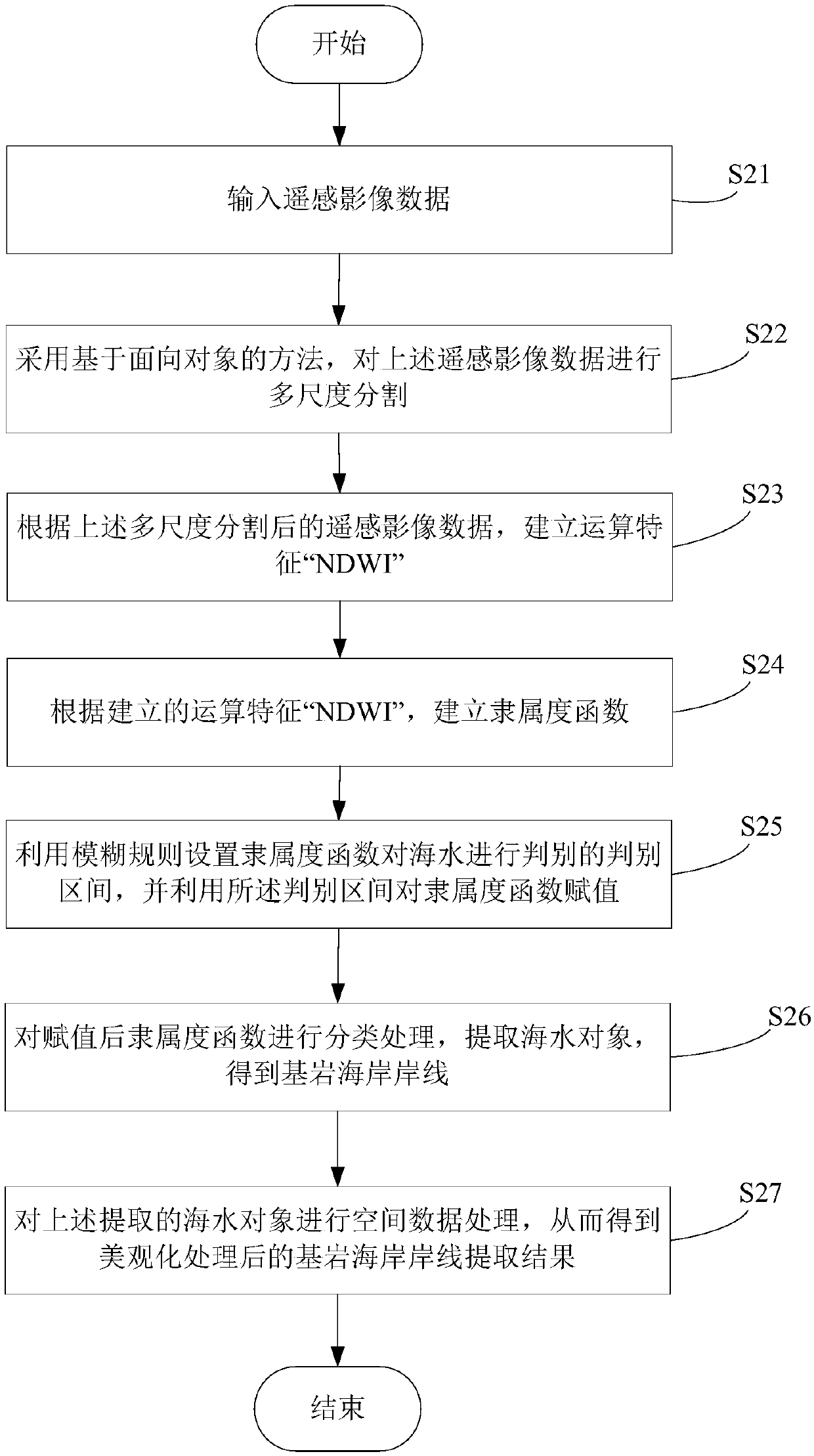

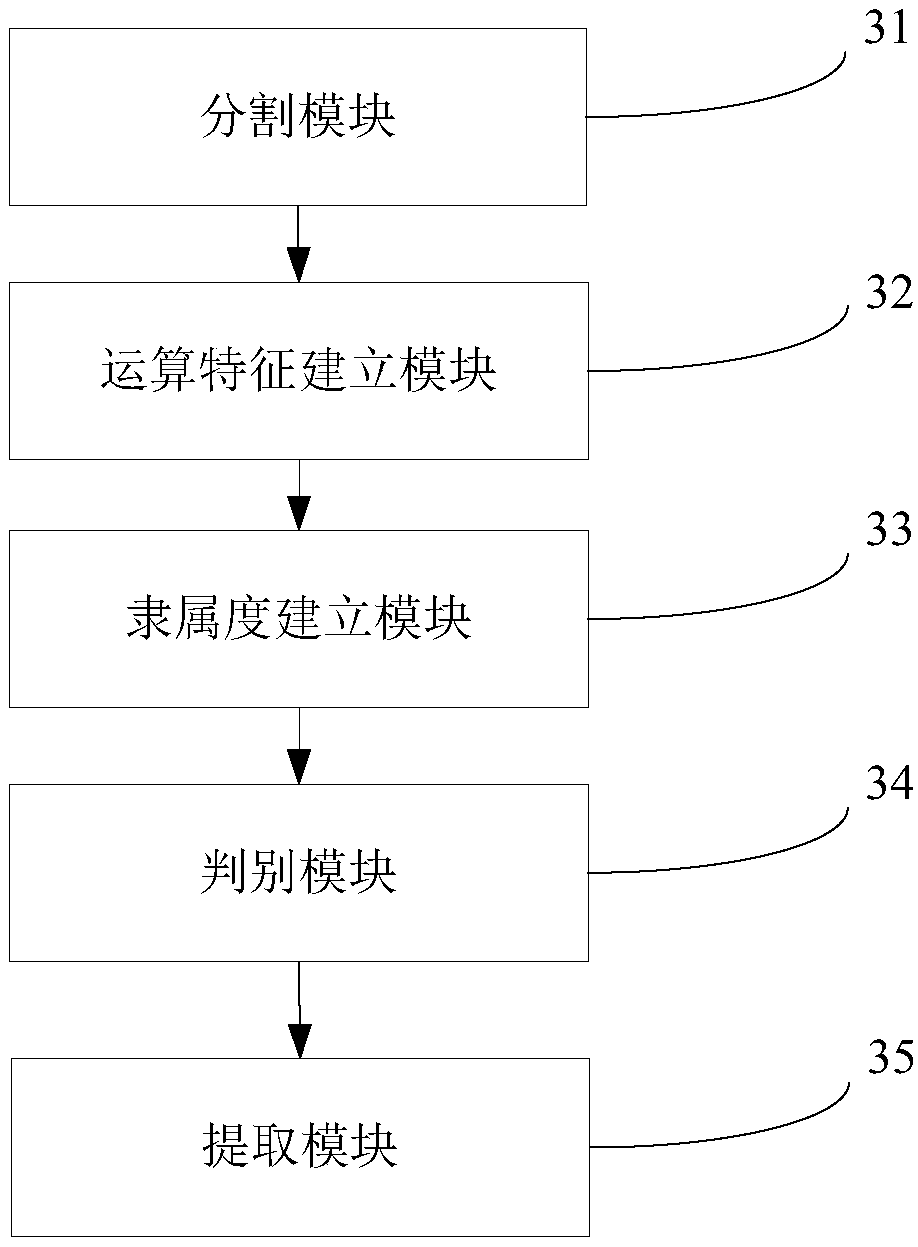

Extraction method and system for bedrock coast line

ActiveCN107563296AAvoiding the limitations of fuzzy classificationClear outlineCharacter and pattern recognitionCoast lineBedrock

The invention relates to an extraction method for a bedrock coast line, comprising: based on an object-oriented method, performing multi-scale segmentation on remote sensing image data from which thebedrock coast line is going to be extracted; establishing operating characteristics according to the remote sensing image data after the multi-scale segmentation; establishing a membership functionaccording to the established operating characteristics; setting adiscrimination interval of the membership function for discriminating seawater by using a fuzzy rule, and assigning the membership function by using the discrimination interval; classifying the assigned membership function, and extracting a seawater object to obtain the bedrock coast line. The invention further relates to an extractionsystem for a bedrock coast line. The method and the system have strong global search capability and robustness, can better distinguish, extract and amplify the characteristics useful for classification, and are clear in classification result contour and low in degree of fragmentation of classification results.

Owner:SHENZHEN INST OF ADVANCED TECH

Method for removing streak defects on hot rolled steel plate surface

ActiveCN104998917AReduce thicknessReduce difficultyWork treatment devicesProfile control deviceSteel platesSheet steel

The invention discloses a method for removing streak defects on a hot rolled steel plate surface and relates to a steel plate surface treatment method. The method comprises the following process: heating plate blank to 1200-1250 DEG C, and then, descaling by high pressure water at a descaling temperature of 1100-1200 DEG C, wherein water pressure required for descaling is at least 16 MPa; carrying out rough rolling on a descaled steel plate at a rough rolling temperature of 1100-1200 DEG C; carrying out finish rolling on the steel plate subjected to rough rolling, wherein a final rolling temperature of the finish rolling is 900-990 DEG C, and the speed of a roller way is 1.3-1.8m / s; after the finish rolling is ended, carrying out water-cooling by adopting a laminar cooling mode, and adopting sectional type cooling, wherein a water ratio is 2.2-2.6, the cooling water consumption is 150-250m<3> / h, and a red temperature of the cooled steel plate is 670-750 DEG C; and cooling the water-cooled steel plate in air at a cold bed. According to the method, oxide iron scale on the surface of the steel plate is easy to remove in a follow-up shot blasting process, thereby removing the streak defects on the steel plate surface subjected to shot blasting.

Owner:沈阳诚伟机械制造有限公司

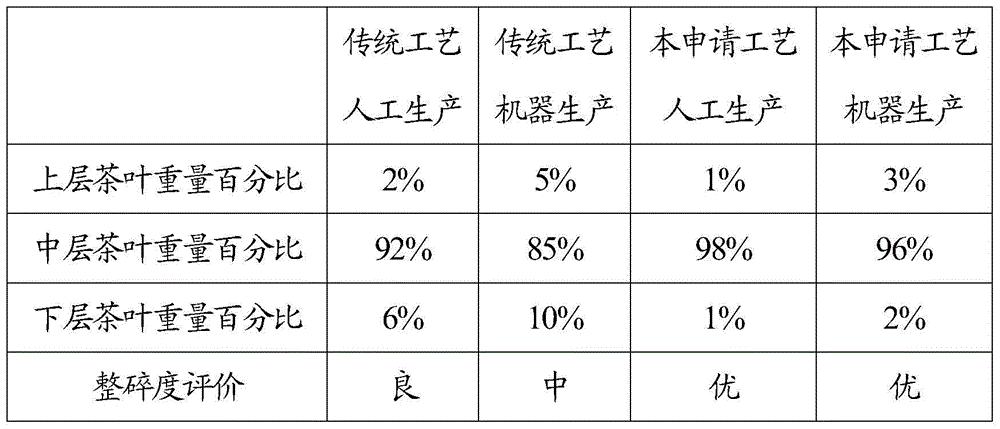

Method of preparing black tea leaves

The invention discloses a method of preparing black tea leaves. The method comprises the steps of de-enzyming, kneading, piling, rolling and drying; the integrity of the produced black tea leaves is better by controlling the parameters such as time, temperature, humidity and flipping frequency of each step; the finished tea leaves do not have more broken tea leaves because of the machining process of the tea leaves; the tea leaves evaluated by the whole or broken standard for tea leaves in the industry have better results; and the method is particularly applicable to make tea leaves by using machines.

Owner:雅安农耕时代生态农业有限公司

Asphalt melting device for highway engineering

The invention discloses an asphalt melting device for highway engineering, and belongs to the field of highway engineering. The asphalt melting device for highway engineering includes a crushing mechanism, a melting mechanism, a filtering mechanism and an insulation mechanism, a fixing clamping piece is fixedly connected to the side end of the crushing mechanism, and the crushing mechanism is connected to the upper end of the melting mechanism through the fixing clamping piece in a clamped mode; and the outer end of the melting mechanism is fixedly connected with an auxiliary motor unit, the auxiliary motor unit includes two pairs of auxiliary motors, a through hole matched with the auxiliary motor unit is formed in the side end of the melting mechanism, the power output ends of the auxiliary motors penetrate through the through hole and are fixedly connected with rotary heating spike assemblies, the two pairs of rotary heating spike assemblies are arranged in the melting area, and opposite rotation of the two adjacent pairs of rotary heating spike assemblies is used for making asphalt blocks mix evenly. On the one hand, the multiple crushing effect is further achieved, on the other hand, the melting time of the asphalt blocks in melting mechanism can be prolonged, and compared with original melting devices, the melting rate can be increased.

Owner:刘文伟 +6

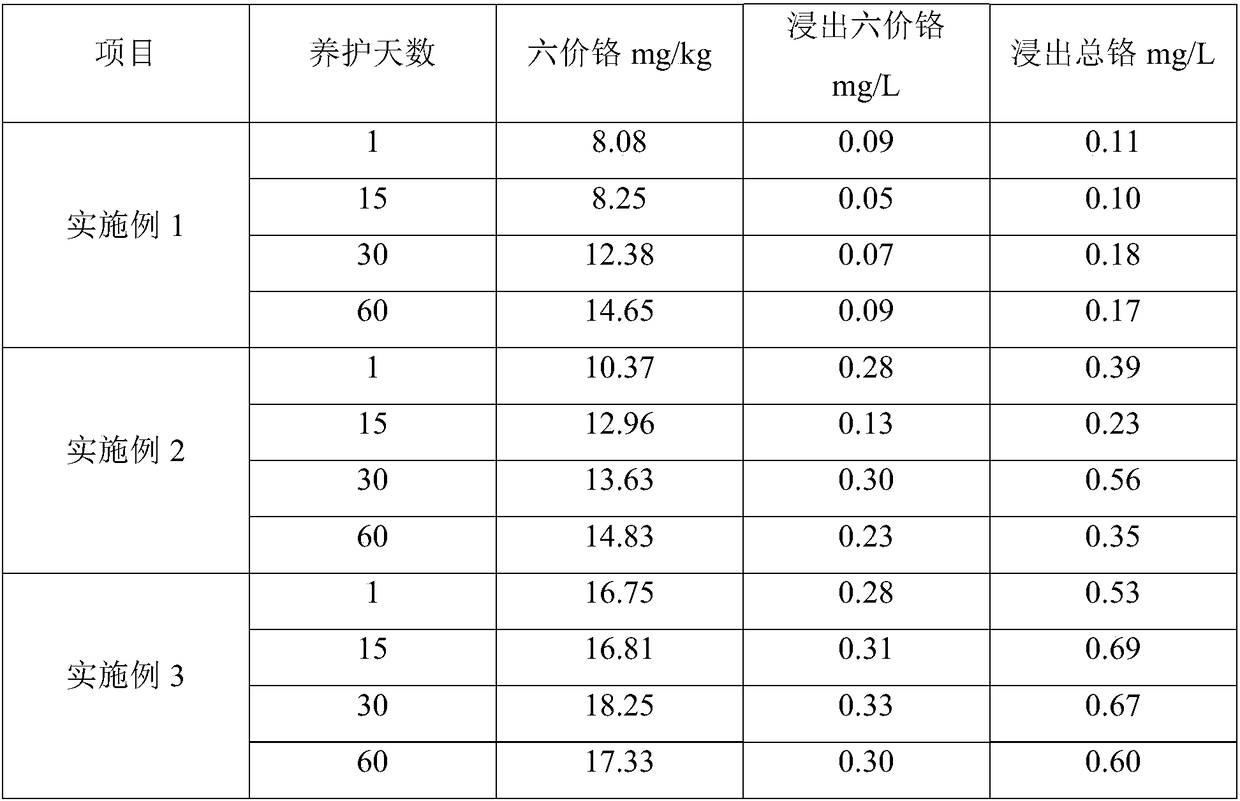

Agent composition and method for restoring chromium-pollution soil

InactiveCN108405602ALow degree of fragmentationSimple construction processContaminated soil reclamationOrganic fertilisersChromiumEnvironmental chemistry

The invention discloses an agent composition and a method for restoring chromium-pollution soil. The agent composition comprises, by weight, 10-70 parts of ferrous sulfate, 2-10 parts of iron powder,2-10 parts of alkaline agent and 1-8 parts of organic fertilizer. Compared with the prior art, the agent composition has the advantages of being easy-to-obtain in raw material, proper in cost, simplein operation and high in restoration effect long-time stability; adding proportion of the agent composition is determined according to soil pollution degree and physiochemical properties, agent wastecaused by excessive restoration is avoided, and secondary pollution risk is lowered.

Owner:BEIJING GEOENVIRON ENG & TECH +1

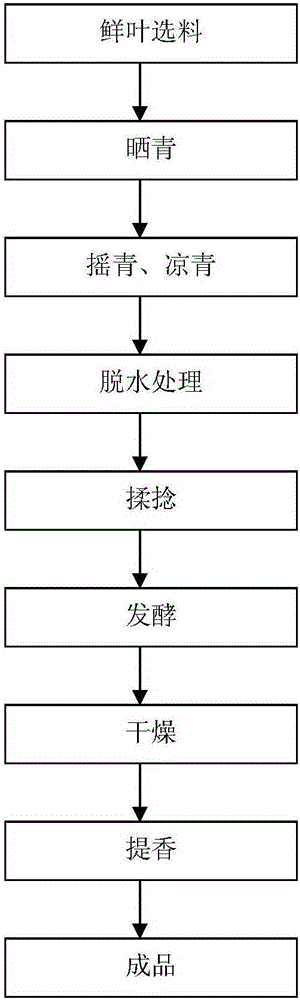

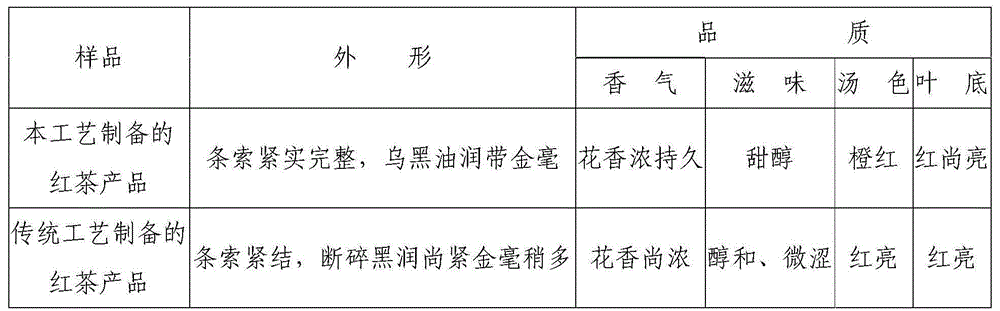

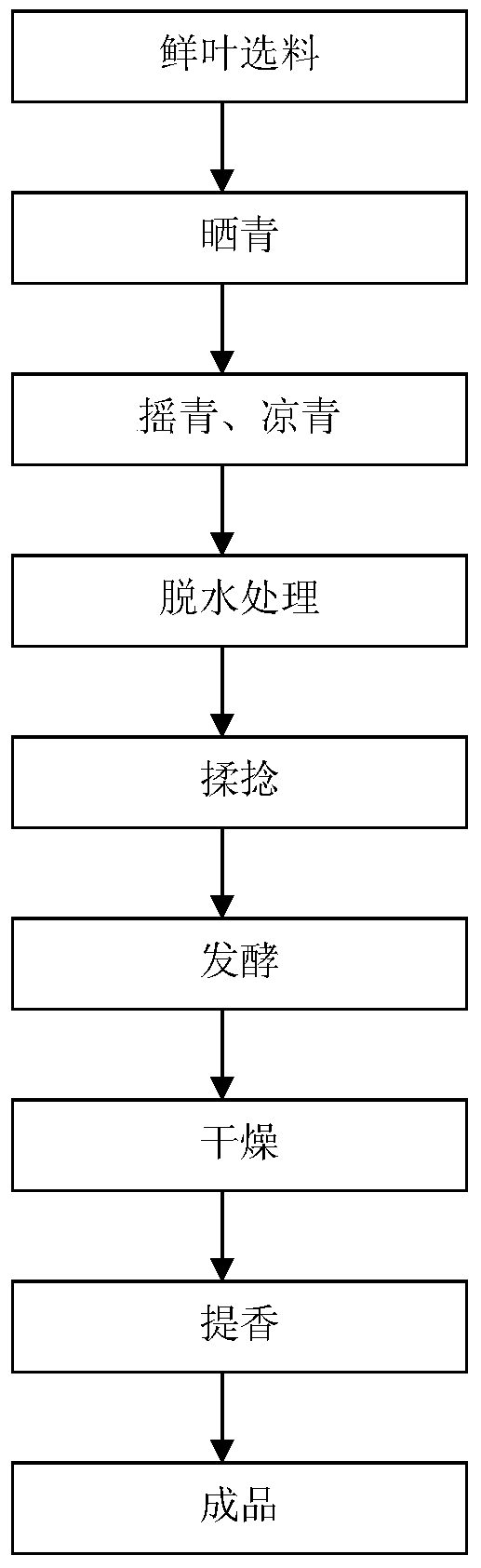

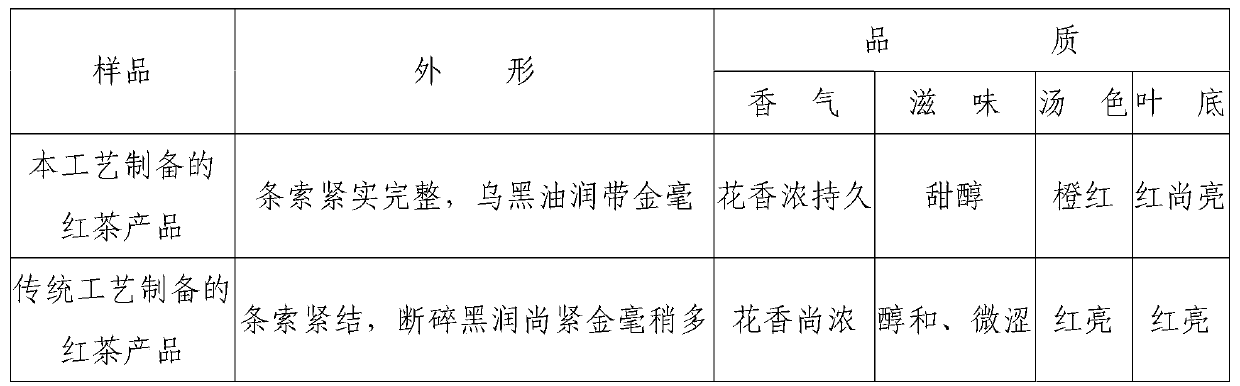

Process for improving quality of black tea

ActiveCN105211354AImprove appearance qualityKeep the aromaPre-extraction tea treatmentBlack teaMoisture

The invention provides a new process for improving quality of black tea. The process comprises the steps of fresh leave selecting, sun drying, rocking, cooling, dehydration, rolling, fermenting, drying, aroma extracting and the like. The black tea product prepared by adopting the process is attractive in appearance and is sweet and mellow after being drunk, and the astringent taste is lightened. The process can effectively improve the appearance quality of the black tea (especially flowery Congou black tea); in the condition that aroma forming and water loss are out-of-step, a method of rocking and then low-temperature quick dehydration is adopted, so that the aroma of the tea leaves is kept, only partial moisture of the fresh leaves is removed, no fracture is caused during rolling, and therefore, development of subsequent process is benefited. The process can effectively promote the taste of the black tea, and after low-temperature quick dehydration, low-pressure long-time rolling is adopted, so that the crushing degree of leave cells is reduced, the crushing rate is not affected, and the taste of the product is remarkably improved. Meanwhile, dissolving of astringent substances in the tea leaves is reduced.

Owner:湖南省茶叶研究所

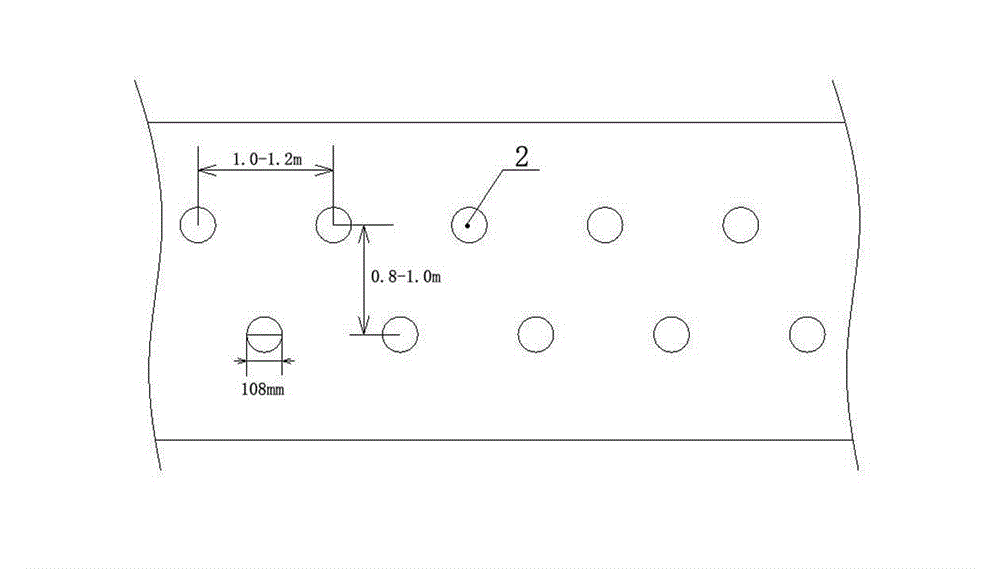

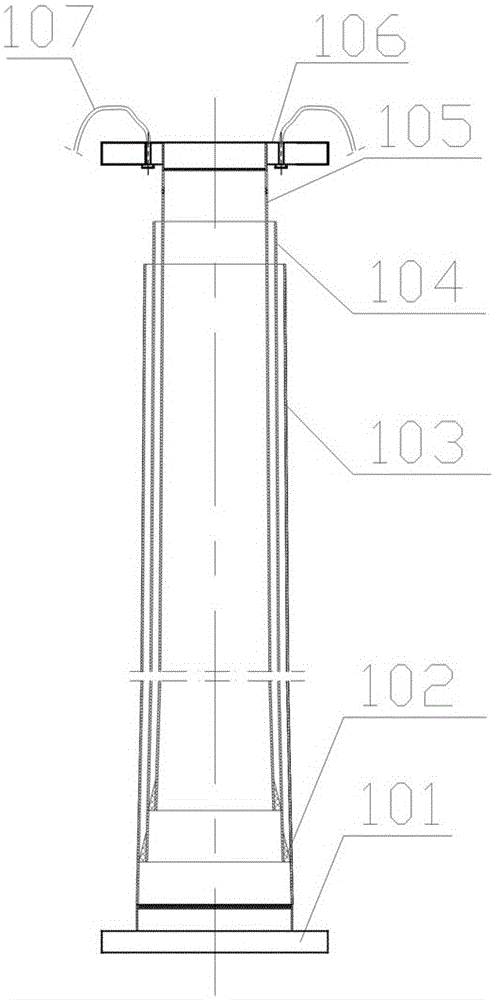

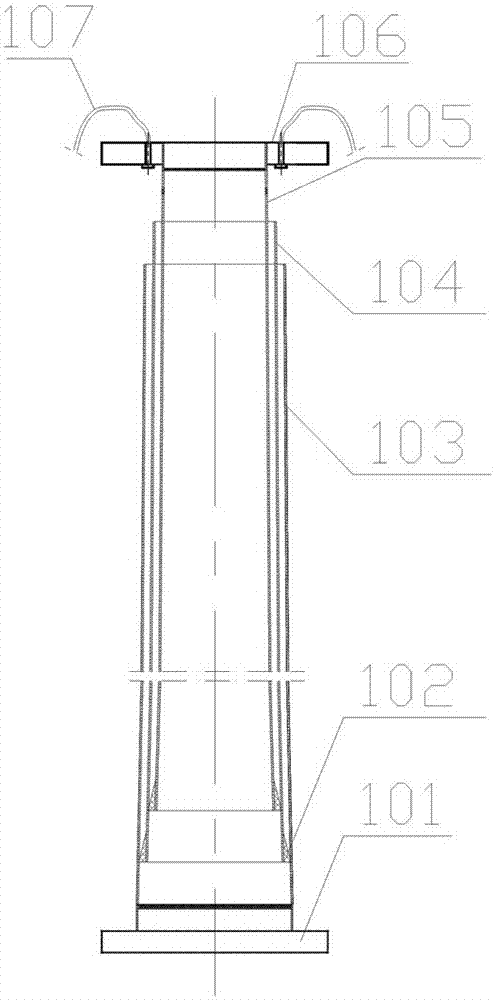

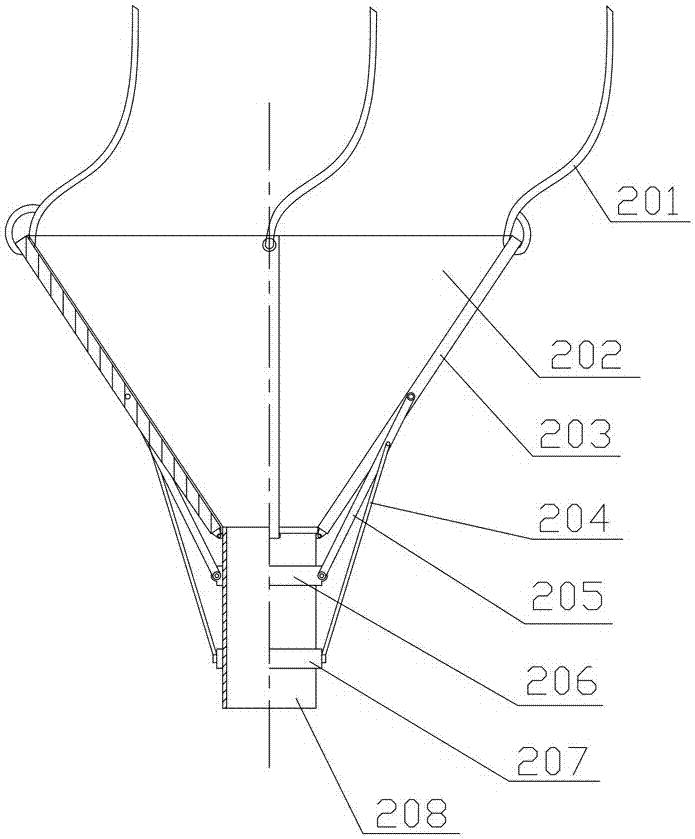

Non-coupling pre-splitting explosive charging device and using method

ActiveCN106123716ALow degree of fragmentationOvercome the effects of blasting effectsBlastingCouplingHole size

The invention aims to solve the actual engineering construction problems that the explosive charging process is complex, time is consumed and labor is consumed, provides a non-coupling pre-splitting explosive charging device and a using method, and belongs to the technical field of surface blasting engineering. The device is composed of a variable-diameter non-coupling pre-splitting explosive charging barrel and an umbrella-shaped explosive charging device; and the umbrella-shaped explosive charging device is located on the upper portion of the variable-diameter non-coupling pre-splitting explosive charging barrel. According to the device, the length of the explosive charging barrel can be flexibly and fast changed according to the on-site hole depth changing length and the non-coupling coefficient, and the requirement that the explosive charging non-coupling coefficient is sequentially decreased from bottom to top in the whole explosive charging device is met; the device can enter blast holes of different diameters and is automatically opened according to the size of the blast holes, and explosives can be conveniently injected into an explosive charging vehicle; and blasting crushing regions and the blasting tight bottom can be reduced, and side walls are effectively protected.

Owner:ANSTEEL GRP MINING CO LTD

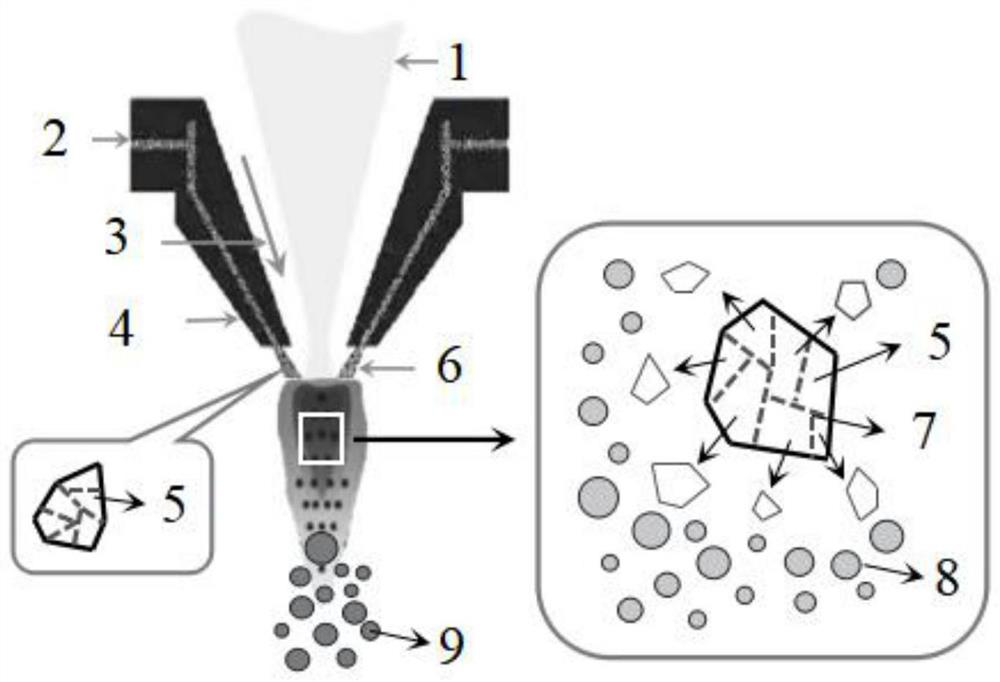

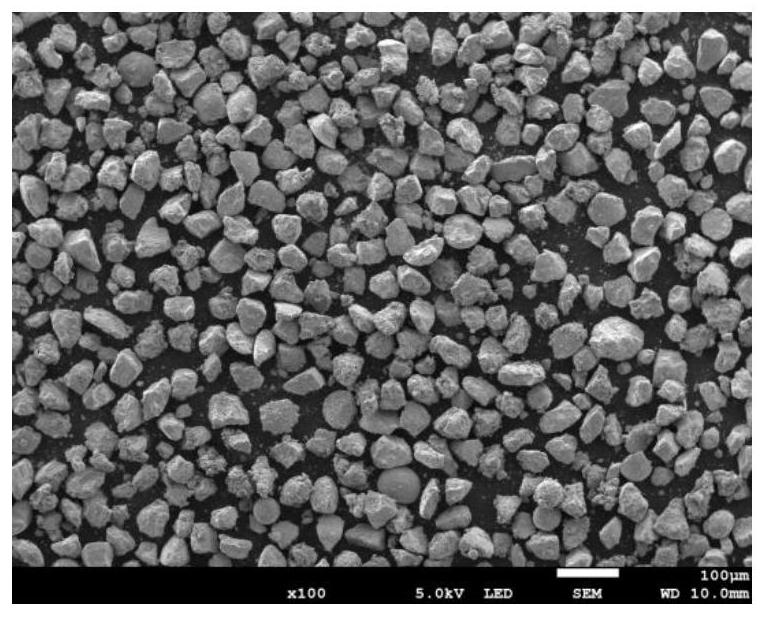

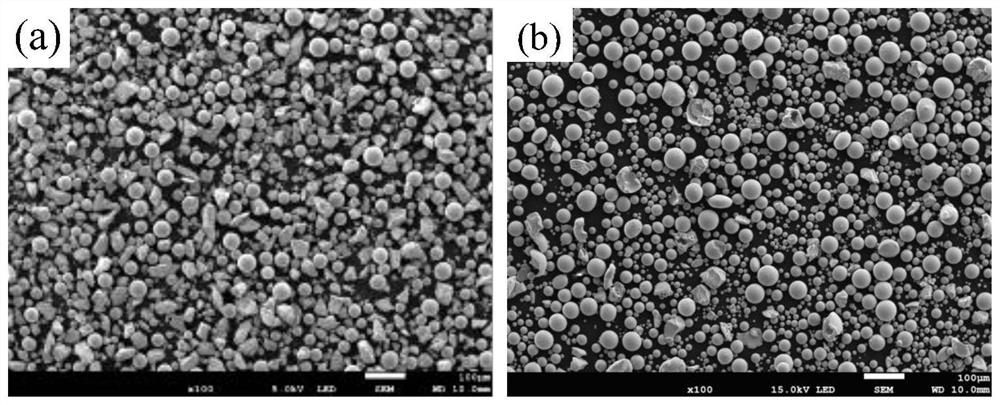

Preparation method of high-quality spherical metal powder

PendingCN114260454AParticle size controllableControl the degree of fragmentationAdditive manufacturing apparatusTransportation and packagingMetal powderLaser beams

The invention discloses a preparation method of high-quality spherical powder. The metal powder comprises a metal simple substance or / and a metal alloy capable of absorbing hydrogen and dehydrogenating. The method comprises the steps that metal elementary substance or alloy powder with the hydrogenation degree of 10%-100% is introduced into a laser beam at the powder feeding airflow of 2-10 L / min; in the inert gas atmosphere, by controlling laser power and powder physical properties, common coupling of a laser beam focusing spot and a powder beam convergent point is achieved, and meanwhile powder feeding airflow and protection airflow are regulated and controlled to be matched; under the action of laser energy, the metal elementary substance or alloy powder subjected to hydrogen absorption and hydrogenation is heated to expand, break and dehydrogenate and is quickly melted to form fine molten drops, and the molten drops are spheroidized under the action of surface tension, separated from a heating area and then quickly cooled and solidified to form spherical powder. The spherical powder obtained through the method is good in spheroidizing effect, the one-time spheroidizing rate of the powder exceeds 80%, and the powder is good in sphericity degree, concentrated in particle size distribution, high in fine powder yield and few in impurities.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD +1

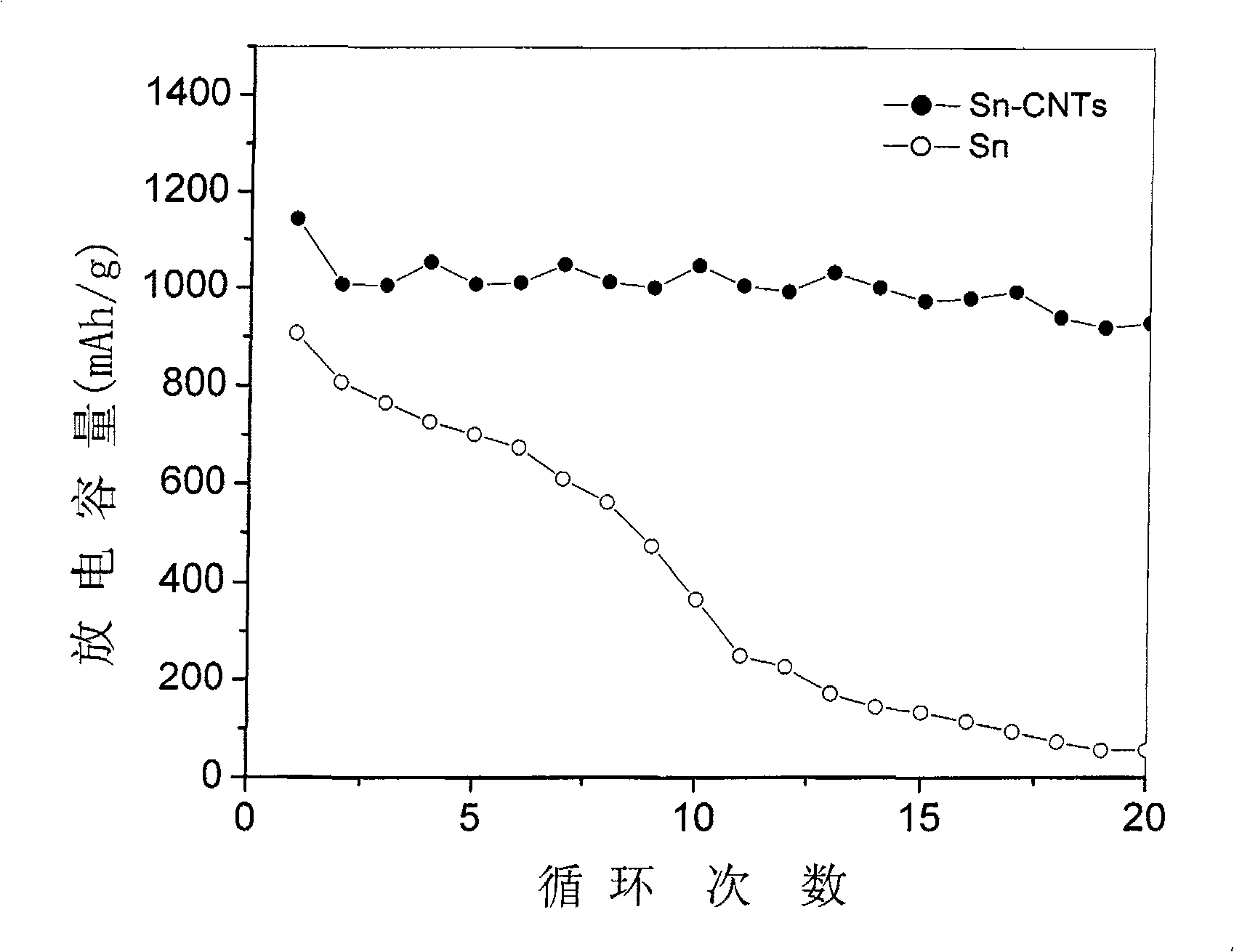

Lithium ion battery tin-carbon nanometer tube negative pole material and preparation method thereof

InactiveCN100536200CLow degree of fragmentationImprove cycle performanceElectrode manufacturing processesChemical/physical/physico-chemical processesElectrical batteryCarbon nanotube

The invention discloses tin-carbon nanotube negative pole material used for a lithium ion battery and the preparation method thereof; wherein, tin is adopted as active substance, and carbon nanotube of network structure is embedded in the tin layer in a network structure. In the tin-carbon nanotube negative pole material, because a great amount of the carbon nanotube is embedded in the tin coating layer, during the charging and discharging cyclical process of the working electrode made of negative pole material, an embedding and disengaging channel for the lithium ion is provided through the network structure established by the carbon nanotube in the tin active substance; simultaneously, the carbon nanotube plays the strengthening and toughening effect, the breaking degree of the electrode because the volume changing is reduced, and the circulation performance of the electrode is improved. The process of the invention is simple, the operation is simple and convenient, the invention provides conditions for industrial production, and has remarkable practical value and economic benefit.

Owner:SOUTH CHINA NORMAL UNIVERSITY

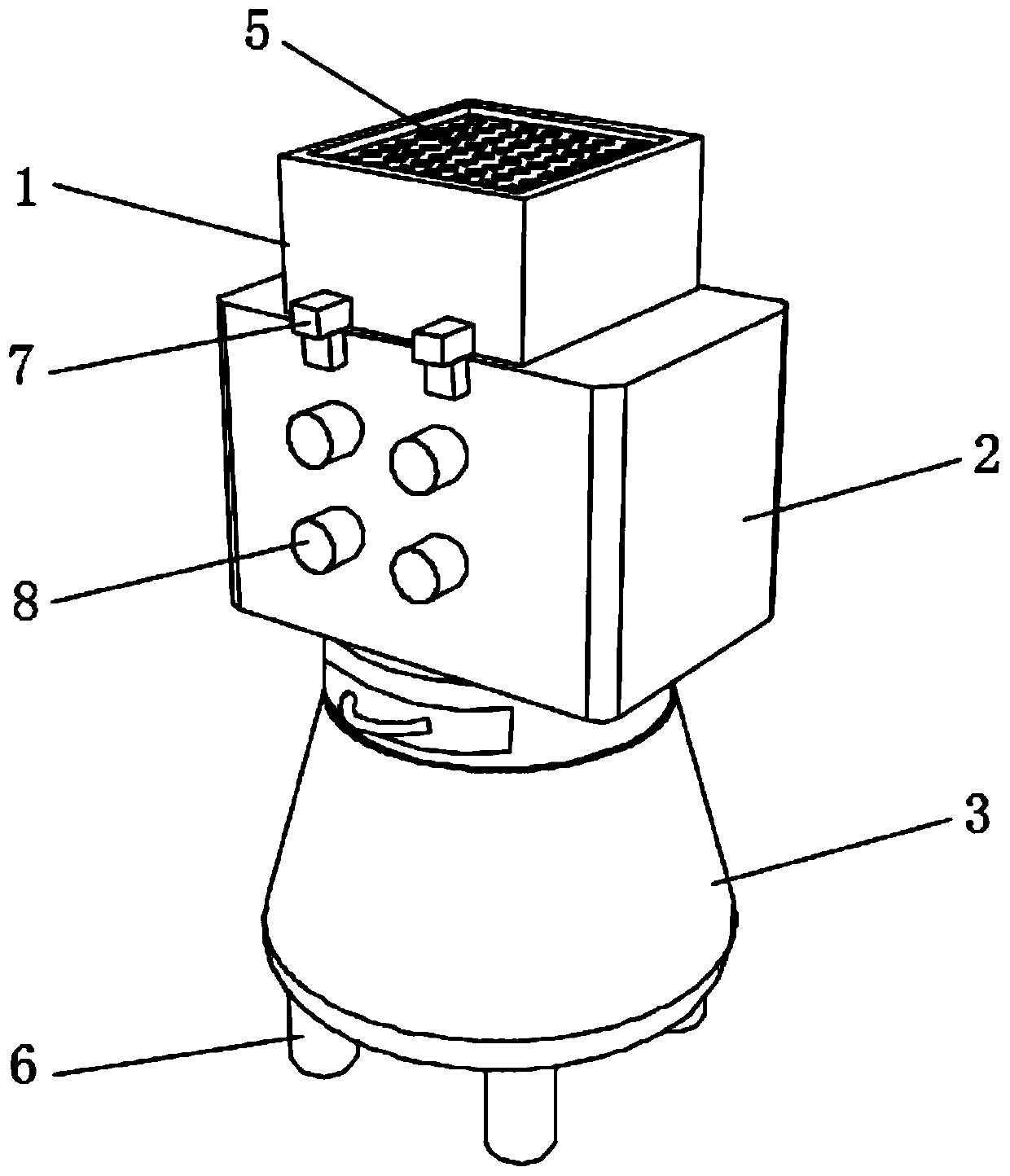

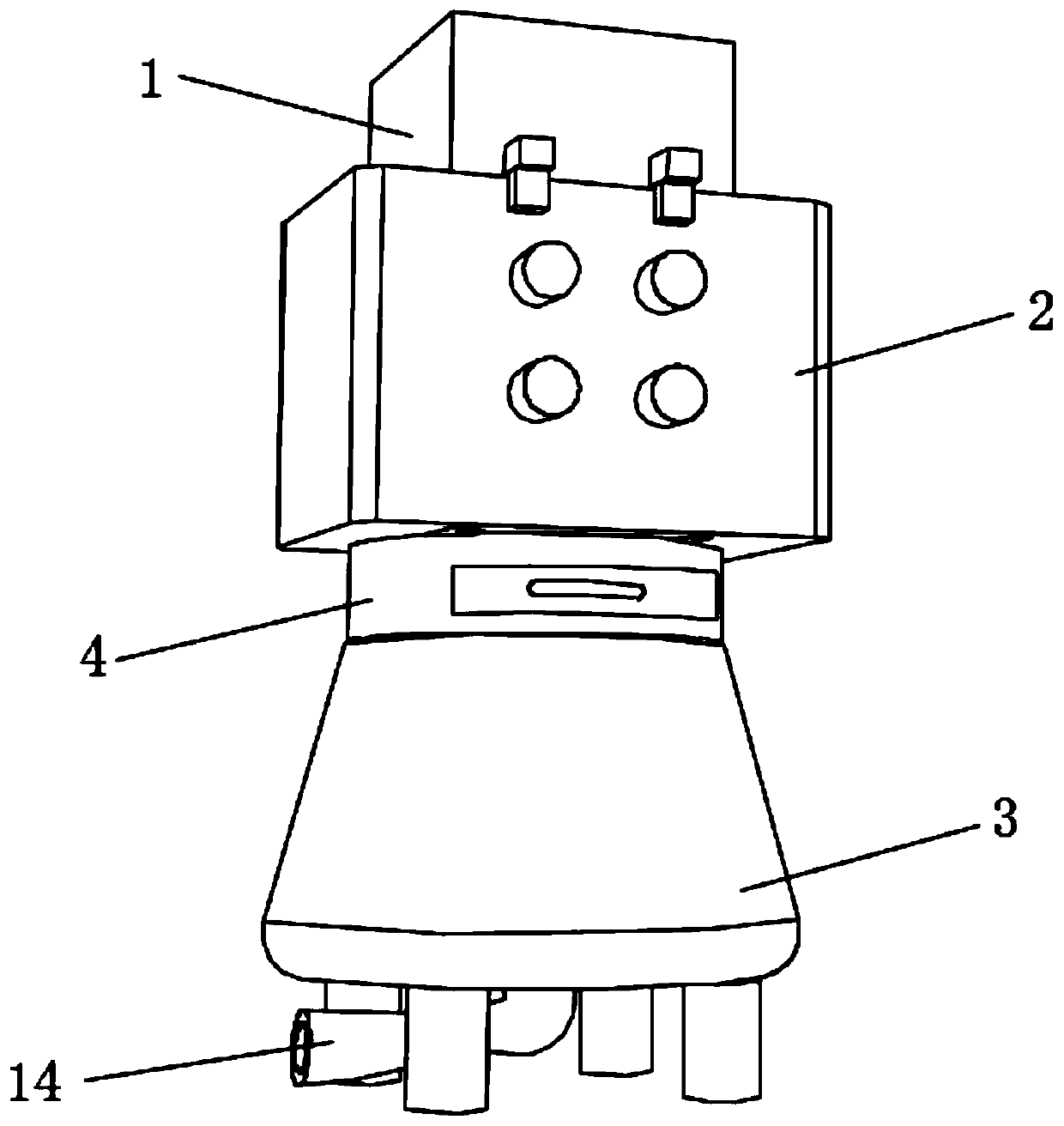

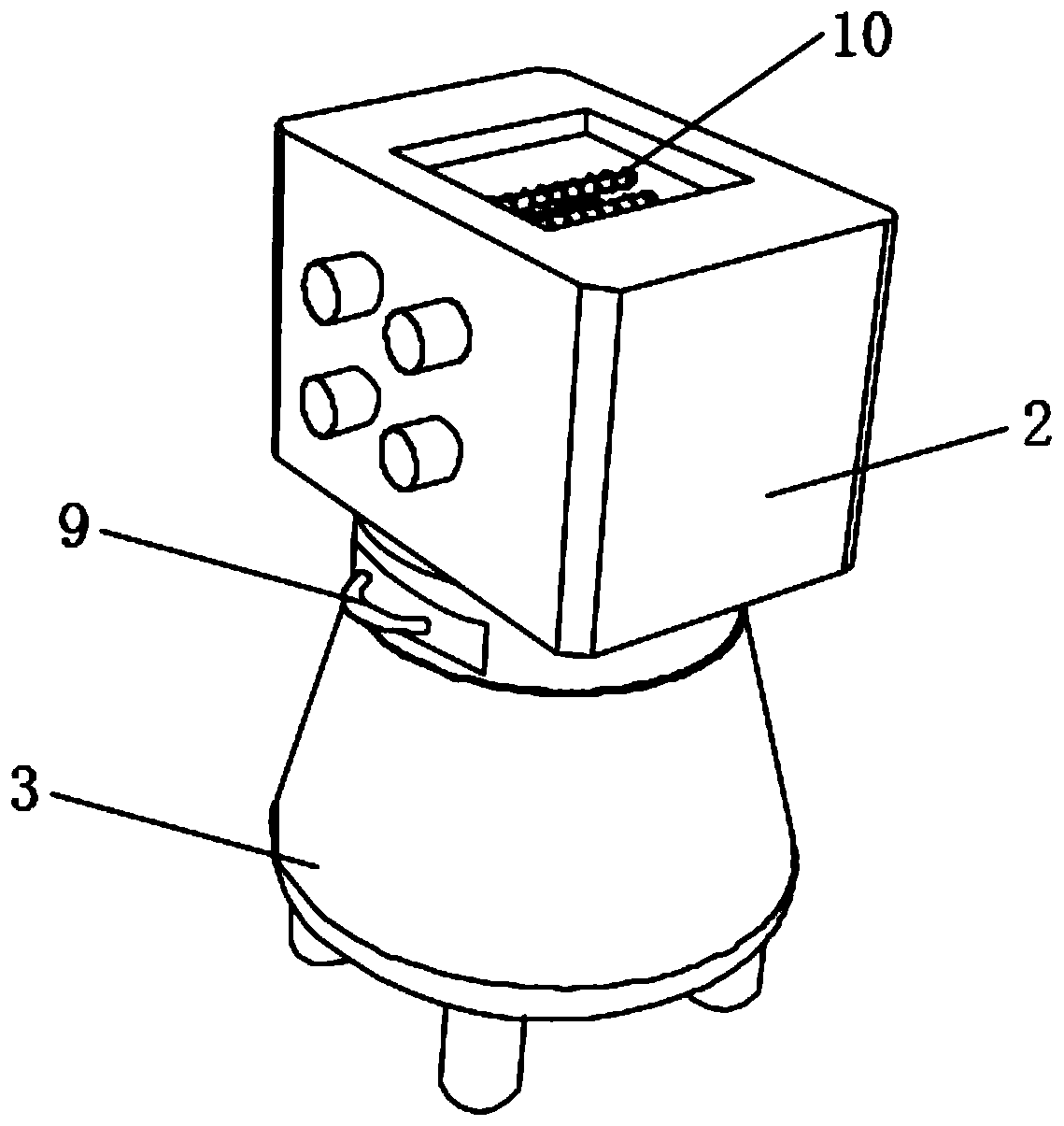

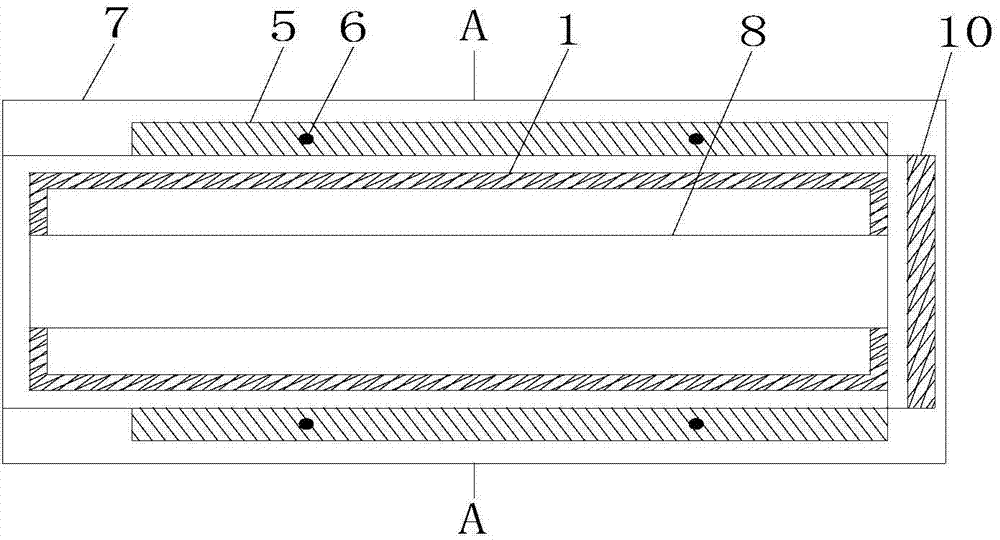

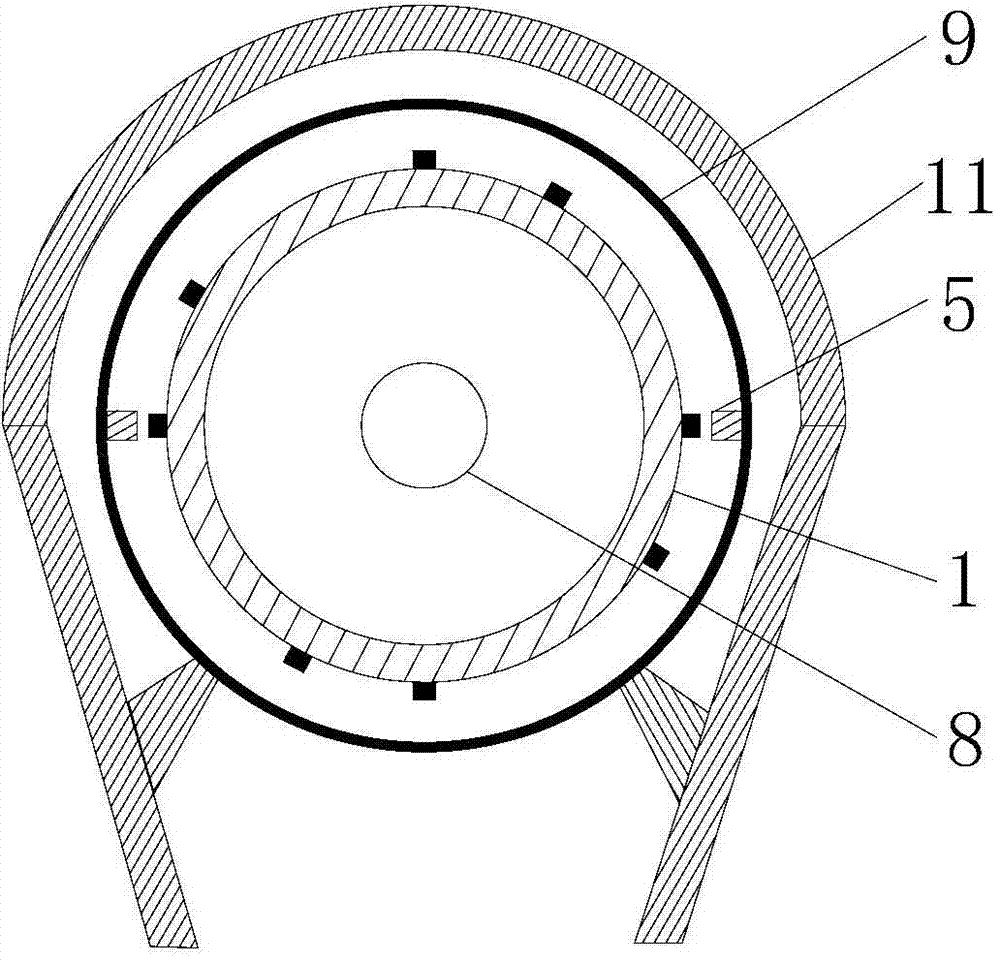

Roller type rice machine

InactiveCN104759308ALow degree of fragmentationSolve the problem of more broken riceGrain huskingGrain polishingPulp and paper industrySieve

The invention discloses a roller type rice machine. The machine comprises a rice cutter (5), a lower housing (7), a main shaft (8), a rice sieve (9), a rice discharging baffle (10), an upper housing (11) and a rice roller (1); guide thread (3) which are one-way threads are formed from one end of the surface of the rice roller (1). The roller type rice machine can solve the problem that the rice processed by the roller type rice machine and discharged is broken can be solved.

Owner:湖南湘南农机机电制造有限公司

Delicious bamboo-bee naked barley oatmeal

InactiveCN104872547AOutstanding roasted aromaLow degree of fragmentationNatural extract food ingredientsFood ingredient functionsAdditive ingredientOfficinalis

The invention discloses delicious bamboo-bee naked barley oatmeal. The delicious bamboo-bee naked barley oatmeal comprises, by weight, 90-120 parts of barley, 25-34 parts of flavored nutrient ingredient and the balance of water. The flavored nutrient ingredient comprises, by weight, 5-8 parts of flour, 10-15 pars of bamboo bees, 6-10 parts of tea-seed oil, 9-11 parts of broccoli, 0.8-1 parts of mosla herb,0.4-0.5 part of mangnolia officinalis, 0.4-0.5 part of white hyacinth beans and 2-3 parts of spiced salt powder. Barley grains in the delicious bamboo-bee naked barley oatmeal are low in smashing degrees and contain proper brans, and the delicious bamboo-bee naked barley oatmeal has outstanding baking scent as dried by microwaves. The delicious bamboo-bee naked barley oatmeal uses fine sand as medium and is fried at high temperature in short time, so that loss of thermosensitive nutrient substances and physiologically active ingredients in the barley can be avoided.

Owner:毛庆云

A process for improving the quality of black tea

ActiveCN105211354BImprove appearance qualityKeep the aromaPre-extraction tea treatmentBlack teaMoisture

The invention provides a new process for improving quality of black tea. The process comprises the steps of fresh leave selecting, sun drying, rocking, cooling, dehydration, rolling, fermenting, drying, aroma extracting and the like. The black tea product prepared by adopting the process is attractive in appearance and is sweet and mellow after being drunk, and the astringent taste is lightened. The process can effectively improve the appearance quality of the black tea (especially flowery Congou black tea); in the condition that aroma forming and water loss are out-of-step, a method of rocking and then low-temperature quick dehydration is adopted, so that the aroma of the tea leaves is kept, only partial moisture of the fresh leaves is removed, no fracture is caused during rolling, and therefore, development of subsequent process is benefited. The process can effectively promote the taste of the black tea, and after low-temperature quick dehydration, low-pressure long-time rolling is adopted, so that the crushing degree of leave cells is reduced, the crushing rate is not affected, and the taste of the product is remarkably improved. Meanwhile, dissolving of astringent substances in the tea leaves is reduced.

Owner:湖南省茶叶研究所

Milk-flavor nut coffee highland barley oatmeal

InactiveCN104872556ALow degree of fragmentationOutstanding roasted aromaNatural extract food ingredientsFood dryingSunflower seedCoffea

The invention discloses milk-flavor nut coffee highland barley oatmeal. The milk-flavor nut coffee highland barley oatmeal is composed of, by weight, 108-129 parts of highland barley, 25-33 parts of flavored nutrient ingredients and a proper amount of water, the flavored nutrient ingredients are composed of, by weight, 5-7 parts of sunflower seed kernels, 4-6 parts of walnut kernels, 5-6 parts of coffee powder, 7-8 parts of white sugar, 4-6 parts of milk powder, 0.6-0.9 part of sophora flower, 1-1.2 parts of cedar leaf and 0.7-0.8 part of schizonepeta spike. Highland barley seeds in the milk-flavor nut coffee highland barley oatmeal are low in breaking degree and contain a proper amount of bran, and highland barley pieces are subjected to microwave drying to enable baking flavor of the highland barley pieces to be protruding. Fine sand is adopted as a medium, and a mode of high-temperature short-time frying is adopted, so that loss of thermosensitive nutrient substance and physiological active ingredients in highland barley can be avoided.

Owner:毛庆云

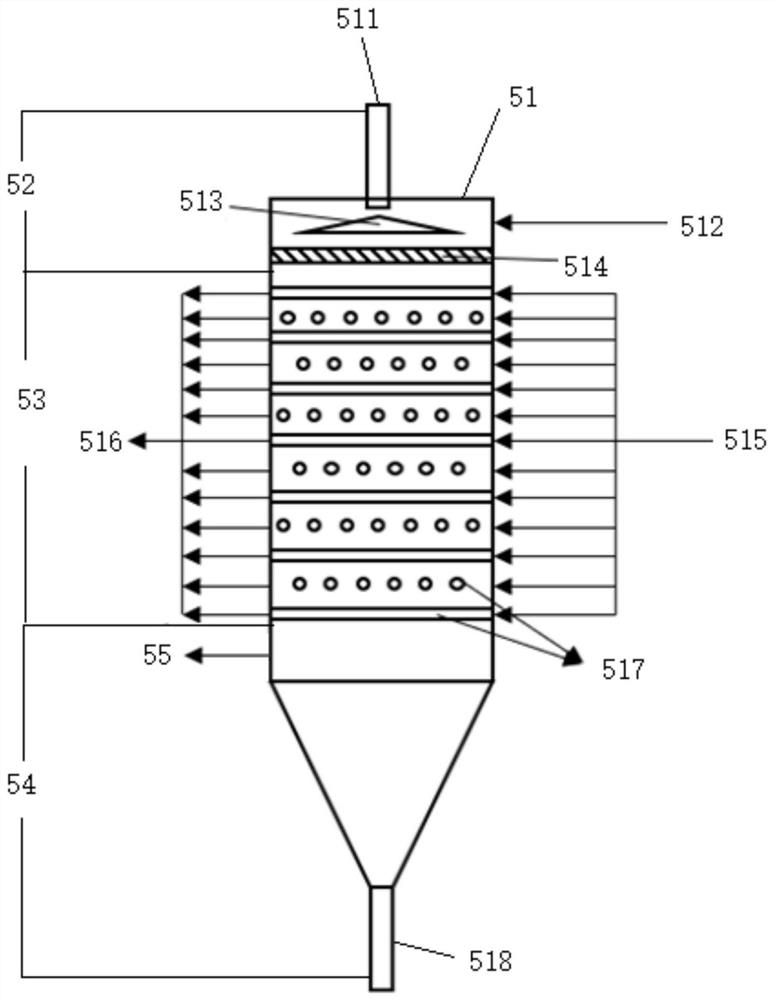

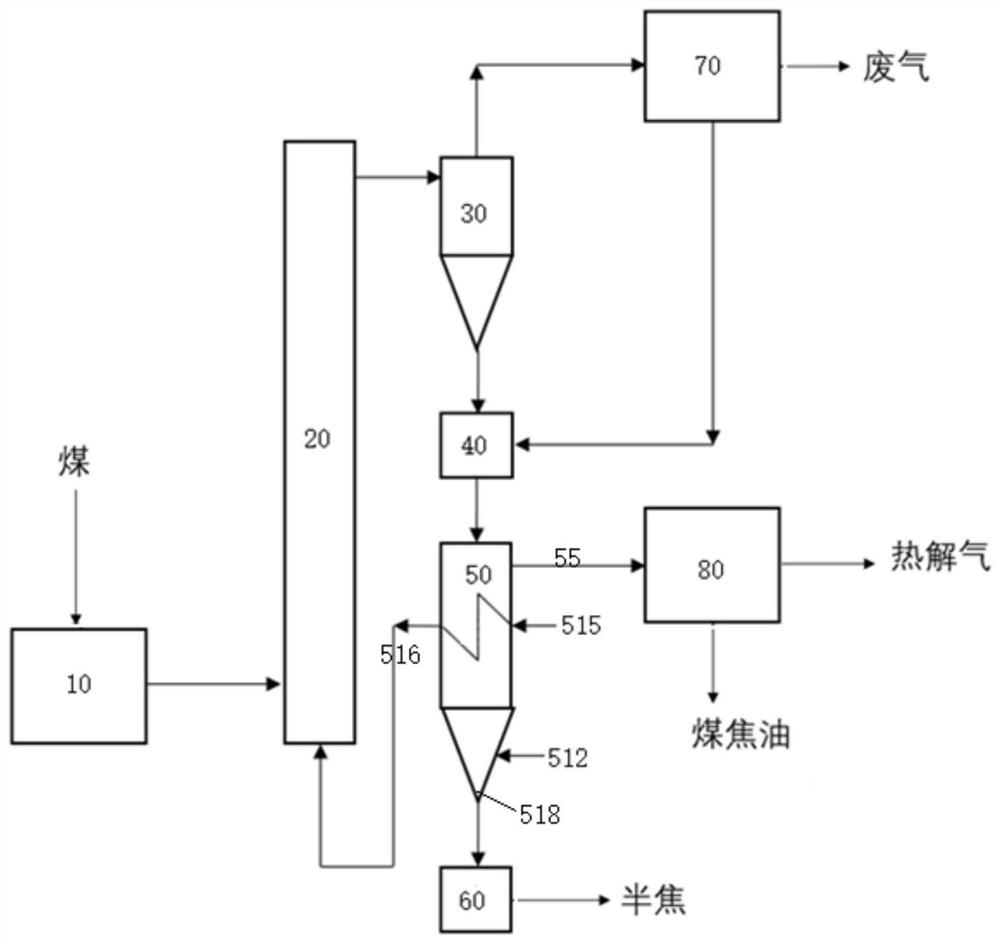

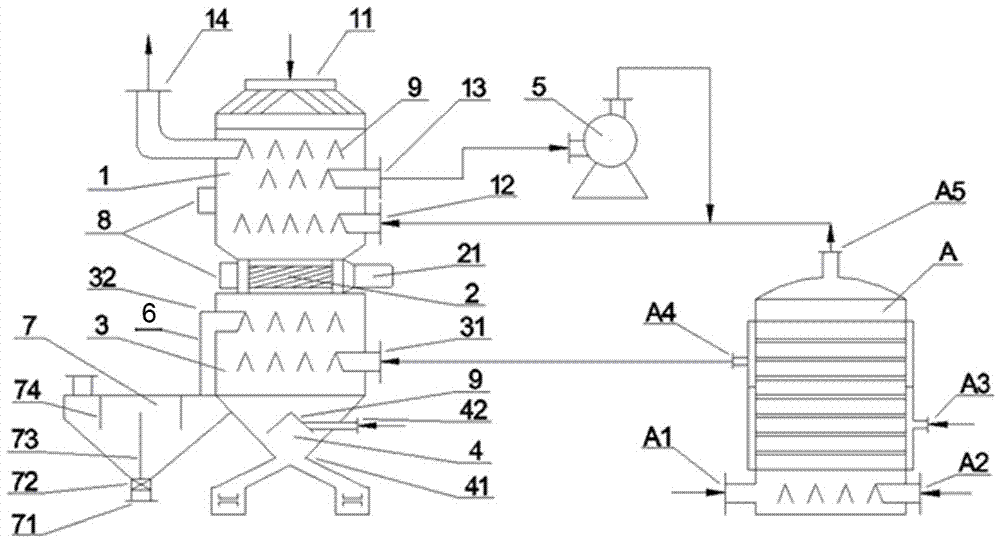

Pyrolysis device and pyrolysis system and pyrolysis method for coal and biological carbonaceous raw materials

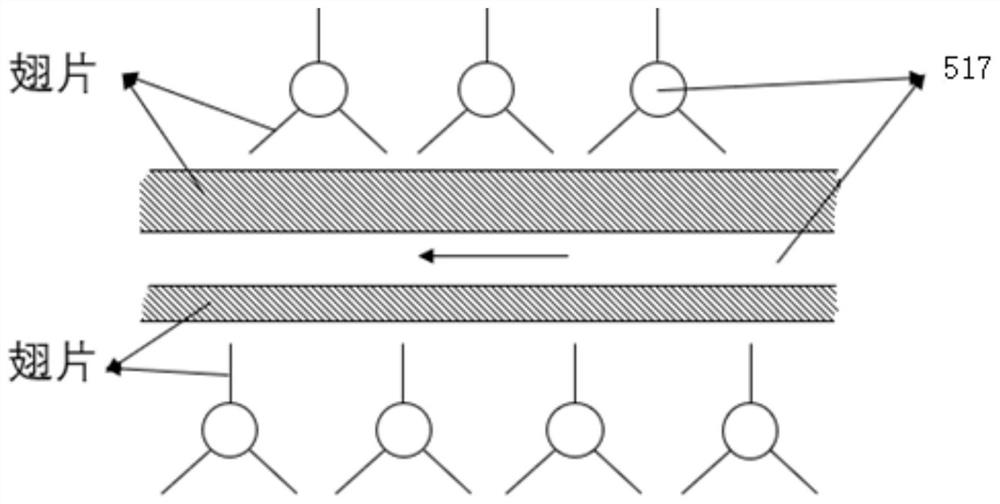

InactiveCN112745868AAvoid enteringImprove real reaction throughputIndirect heating destructive distillationSpecial form destructive distillationMaterial distributionReagent

The invention provides a carbonaceous raw material pyrolysis device, a pyrolysis system and a pyrolysis method.The carbonaceous raw material pyrolysis device comprises a reactor body and a collection section, and the reactor body comprises a feeding section, a pyrolysis section and a collection section which are communicated from top to bottom; the feeding section comprises a feeding opening, a conical disperser, a material distribution plate and a pyrolysis oil gas outlet from top to bottom, the conical disperser and the material distribution plate are fixed to the inner wall of the reactor body, the pyrolysis oil gas outlet is formed in the side wall of the reactor body, and the pyrolysis section comprises multiple layers of heat exchange pipes which are arranged in the reactor body and are arranged in a criss-cross mode; and the collection section is fixed at the bottom of the reaction body. By adopting the pyrolytic reaction device disclosed by the invention, the flux of reaction materials in the reaction device is improved, the particle crushing degree and the dust amount are reduced, and the treatment cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Tonifying Chinese yam highland barley oatmeal

InactiveCN104872548ALow degree of fragmentationOutstanding roasted aromaNatural extract food ingredientsFood ingredient functionsNutrientFritillaria cirrhosa

The invention discloses tonifying Chinese yam highland barley oatmeal which comprises, by weight, 110-130 parts of highland barley, 28-37 parts of flavor nutritious ingredients and appropriate amount of water. The flavor nutritious ingredients include, by weight, 12-14 parts of kiwi fruit, 3-5 parts of milk powder, 6-9 parts of white granulated sugar, 10-15 parts of Chinese yam, 0.5-0.6 part of ginseng, 0.6-0.8 part of poria, 0.7-0.9 part of white mulberry root bark and 0.8-1 part of fritillaria cirrhosa. The tonifying Chinese yam highland barley oatmeal has the advantages that the oatmeal is low in highland barley grain crushing degree, the oatmeal contains appropriate amount of bran, and highland barley pieces are dried with microwaves to allow the baking fragrance of the highland barley pieces to stand out; fine sands are used as media and high-temperature and short-time frying is used, and loss of heat-sensitive nutrients and biological activity ingredients in the highland barley can be avoided.

Owner:毛庆云

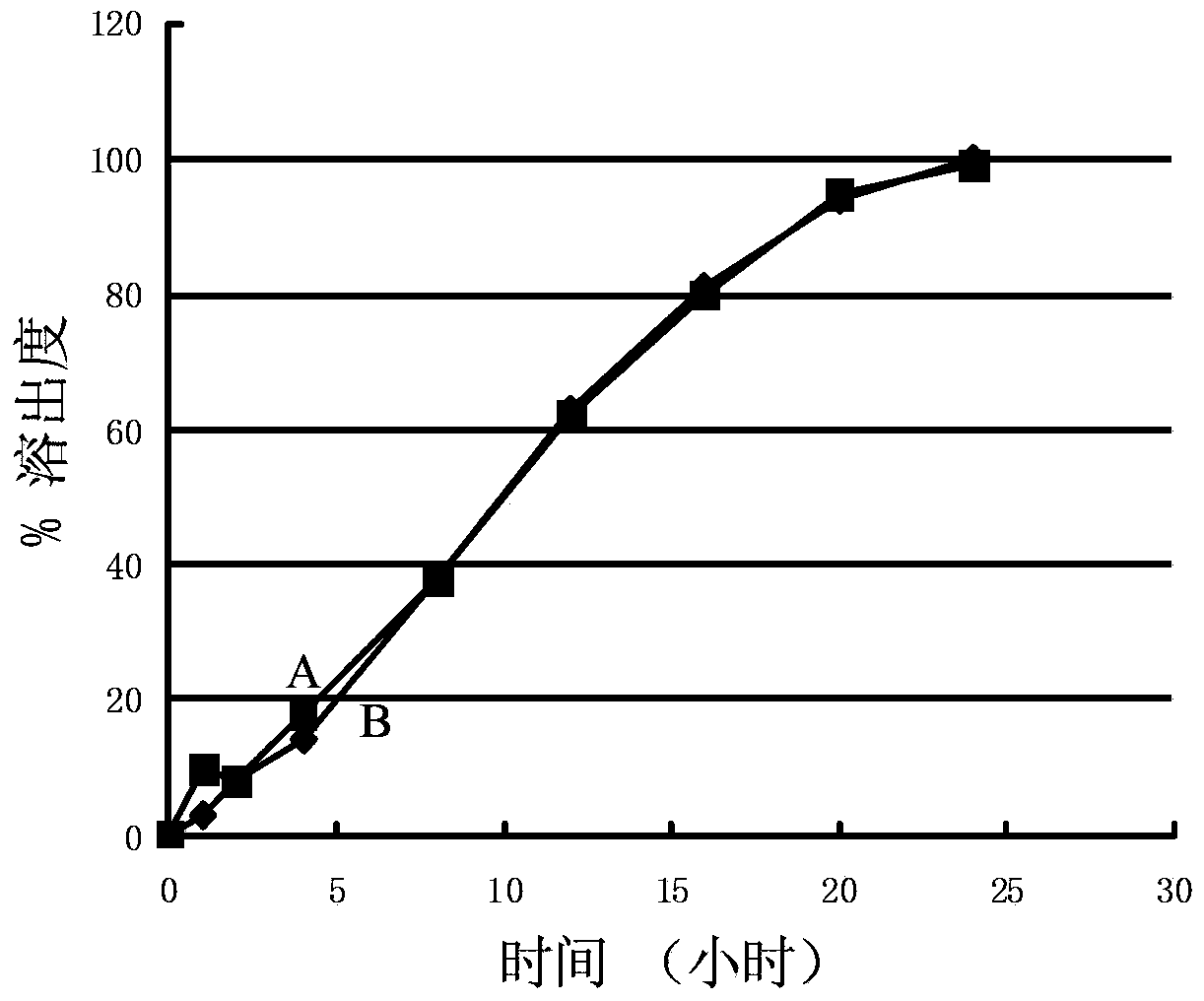

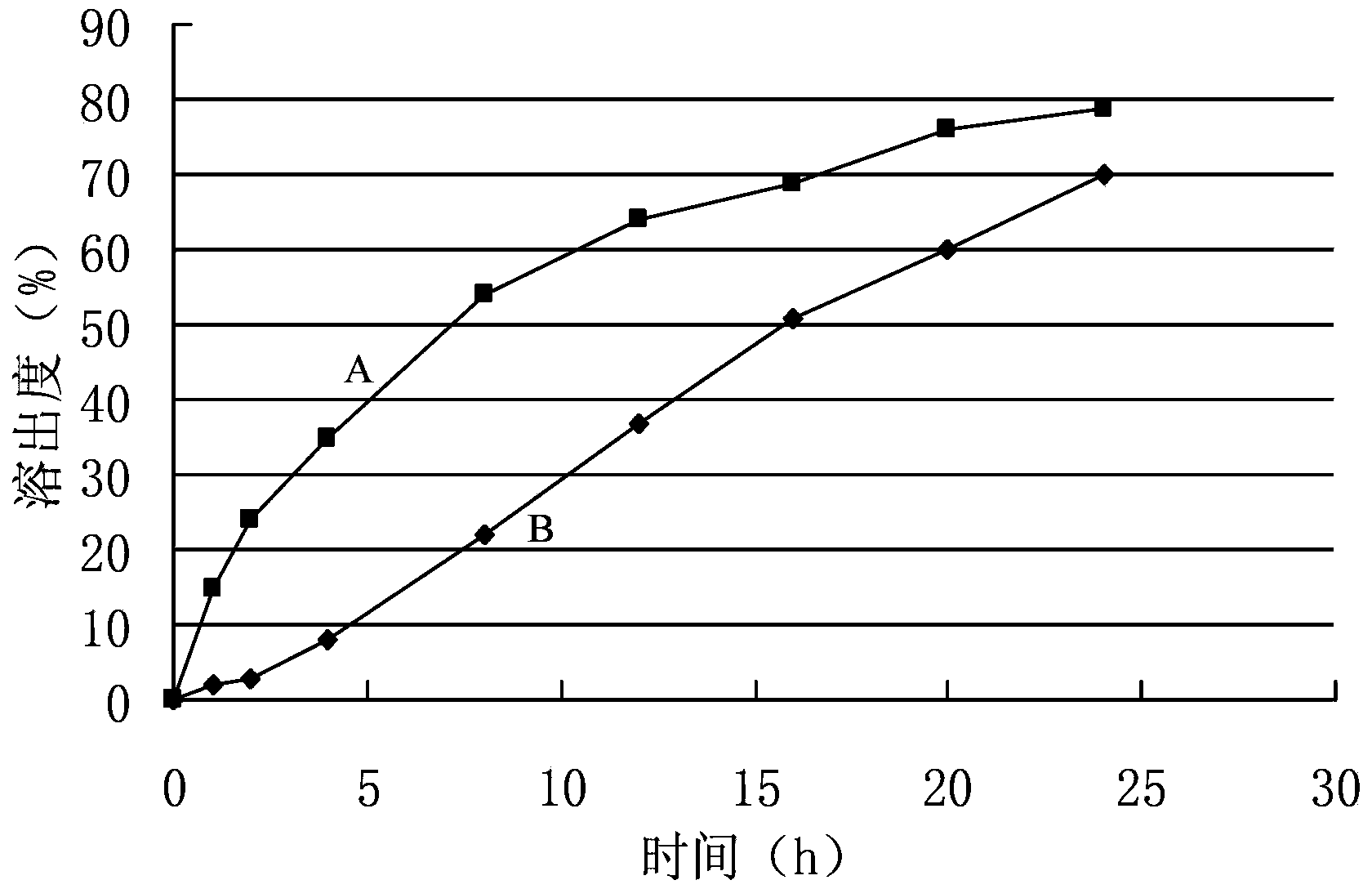

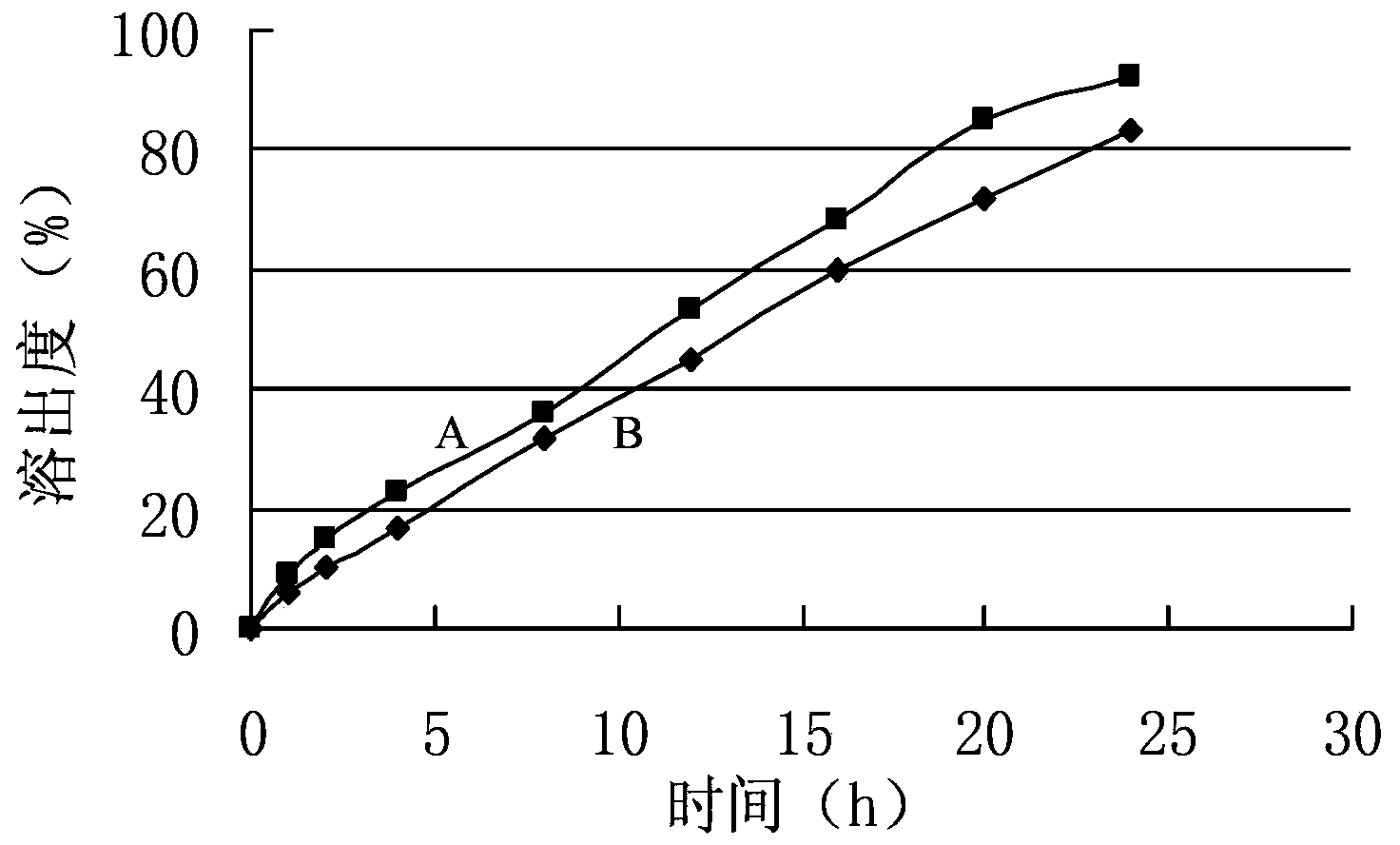

Metoprolol slow-release tablet and preparation method thereof

ActiveCN102626396BRelease stabilityAvoid burst phenomenonOrganic active ingredientsNervous disorderPlastic materialsPlastic property

The invention relates to the technical field of pharmaceutics and discloses a metoprolol slow-release tablet and a preparation method thereof. The preparation method provided by the invention comprises the following steps: preparing a metoprolol active drug and a first plastic material into a pastille pill; obtaining slow-release pastille pill by coating a slow-release layer; and tabletting together with a tablet agent containing at least 90wt% of second plastic material. During the process of preparing the metoprolol slow-release tablet according to the invention, the specific material is added to the active drug and the tablet accessory, so that the crushing degree of the slow-release pastille pill is relieved, the stable releasing of the active drug of the slow-release tablet is ensured and the sudden releasing phenomenon of the drug is avoided.

Owner:华益泰康药业股份有限公司

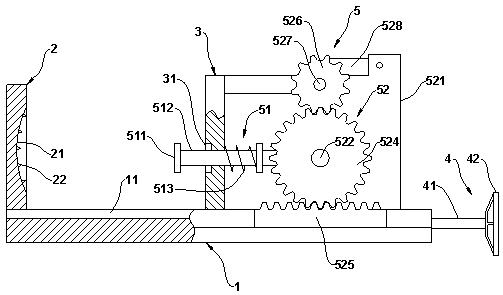

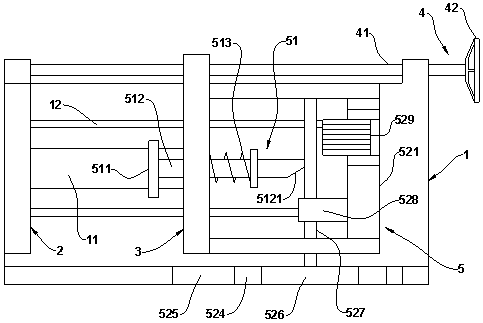

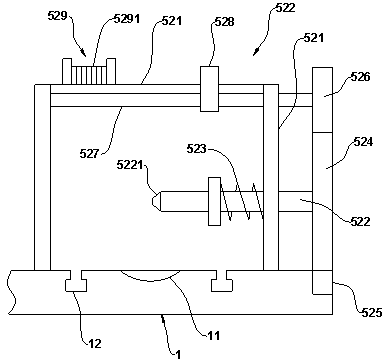

Squeeze type walnut sheller with adjustable extrusion distance

ActiveCN106983399BThe joy of eating walnutsLow degree of fragmentationKitchen equipmentWalnut NutEngineering

The invention relates to an extrusion-type walnut shell breaker with adjustable extrusion distance, which includes a base, a fixed clamping plate and a first movable clamping plate arranged oppositely on the base, and a device for driving the first movable clamping plate. The driving mechanism also includes a distance limiting device. The distance limiting device includes a triggering mechanism and a fixed distance mechanism. The triggering mechanism It is used to trigger the fixed-distance mechanism when the first movable splint comes into contact with the walnut shell. The fixed-distance mechanism causes the first movable splint to advance a set distance under the drive of the driving mechanism, so that after the walnut shell is broken, The walnut kernels are less broken, which reduces the loss of walnut kernels and makes people feel more comfortable eating walnuts.

Owner:巫溪银汉农业有限公司

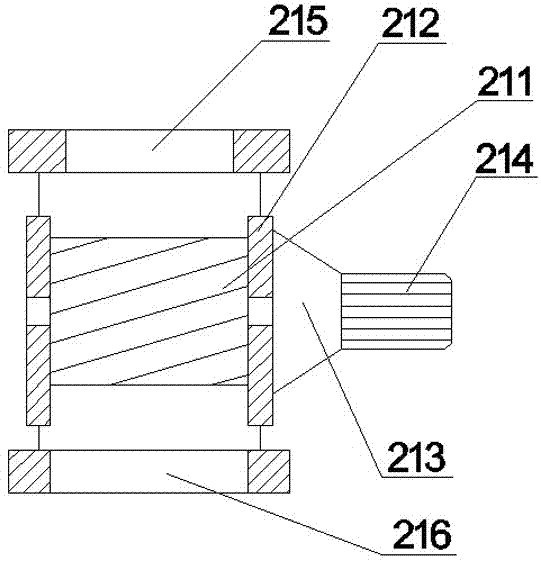

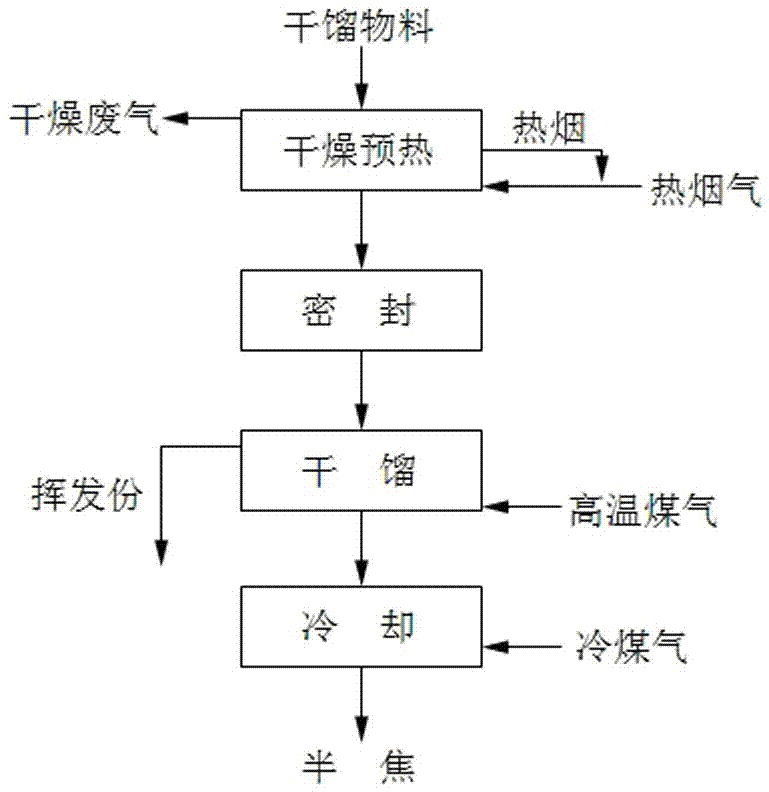

A massive four-stage moving bed hydrogen-rich environment retort furnace and retort method thereof

ActiveCN104726113BReduce heat supplyReduce the overall heightDirect heating destructive distillationEnergy inputHydrogenResource utilization

The invention discloses a massive four-stage moving bed carbonization furnace in a hydrogen-rich environment and a carbonization method thereof. The dry distillation furnace includes a drying preheating section, a sealing section, a dry distillation section, and a cooling section arranged sequentially from top to bottom. The upper part of the drying preheating section is provided with a feed port and the lower part is provided with an air inlet, and the upper part is far away from the air inlet end. There is an exhaust port, and the sealing section is connected to the upper drying and preheating section and the lower retort section through the star feeder installed inside. The oil and gas outlet, the cooling section is connected with the dry distillation section, the bottom of the cooling section is provided with a coke discharge port to connect with the coke discharge system and the lower part is provided with a cold gas inlet. The dry distillation method includes the steps of drying and preheating, sealing, dry distillation and cooling. The invention has the characteristics of low power consumption, high energy utilization rate, high oil production rate, good oil quality, less oil and gas dust, high gas calorific value and high resource utilization rate.

Owner:QUJING ZHONGYI FINE CHEMICAL INDUSTRY CO LTD

Oyster highland barley cereal for eliminating dampness

InactiveCN104938957ALow degree of fragmentationOutstanding roasted aromaNatural extract food ingredientsFood ingredient functionsNutrientFlavor

The invention discloses oyster highland barley cereal for eliminating dampness. The oyster highland barley cereal comprise the following raw materials, by weight, 100-120 parts of highland barley, 25-35 parts of flavor nutritional seasonings and a proper amount of water. The flavor nutritional seasonings comprise the following raw materials, by weight, 8-10 parts of oyster, 12-14 parts of lotus rhizome, 4-6 parts of pea, 5-7 parts of red bayberry, 0.5-1 part of bitter apricot seed, 0.2-0.4 part of magnolia officinalis, 0.2-0.4 part of bamboo leaf, a proper amount of sunflower oil and a proper amount of salt. Hullessbarley seeds crushing degree of the oyster highland barley cereal for eliminating dampness is low, and the oyster highland barley cereal contain a proper amount of bran. By microwave drying of highland barley cereal, baking fragrance of the highland barley cereal is prominent. As fine sand is used as a medium and high-temperature short-time stir-frying is adopted, loss of thermosensitive nutrient substances and physiologically active ingredients in highland barley can be avoided.

Owner:毛庆云

Pretreatment process of threshing and re-cured tobacco leaves based on characteristics of tobacco raw materials

A threshed and re-dried tobacco leaf preprocessing technique based on tobacco leaf raw material characteristics comprises the process steps of vacuum dampening, primary hot-air leaf wetting and secondary hot-air leaf wetting and is characterized in that the adhesion and moisture of tobacco leaf raw materials are firstly analyzed and tested for classification before the process steps, and preprocessing process technique parameters of different categories of tobacco leaf raw materials are determined according to adhesion and moisture detection results of tobacco leaves. By adopting the technique, the moisture uniformity of different categories of tobacco leaf raw materials in a tobacco leaf threshing and re-drying preprocessing process is improved, caking phenomena of high-adhesion and high-moisture-content threshed and re-dried tobacco leaf raw materials in the threshing and re-drying preprocessing process are decreased, the breaking degrees of different categories of tobacco leaf raw materials in the threshing process are reduced, and the economic efficiency of threshing and re-drying processing is improved on the basis that the processing quality of threshing and re-drying is ensured.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC +4

A method for eliminating mottled defects on the surface of hot-rolled steel plates

ActiveCN104998917BReduce interface lengthLow degree of fragmentationWork treatment devicesProfile control deviceSheet steelLaminar cooling

A method for eliminating mottled defects on the surface of a hot-rolled steel plate, relating to a method for treating the surface of a steel plate, the method comprising the following process: heating the slab to 1200-1250°C, and then descaling with high-pressure water, and the descaling temperature is 1100°C ~1200°C, the water pressure is required to be at least 16MPa during descaling; the steel plate after descaling is subjected to rough rolling, and the rough rolling temperature is 1100~1200°C; the rough rolled steel plate is subjected to finish rolling, and the finishing rolling temperature is 900~990℃, the speed of the roller table is 1.3~1.8m / s; after finishing rolling, laminar flow cooling is adopted for water cooling, and segmental cooling is adopted, the water ratio is 2.2~2.6; the cooling water volume is 150~250m³ / h; the reddening temperature of the steel plate after cooling is 670~750°C; the water-cooled steel plate is cooled in the air on the cooling bed. The method makes it easy to remove the iron oxide scale on the surface of the steel plate in the subsequent shot blasting process, thereby eliminating the mottled defect on the surface of the steel plate after shot blasting.

Owner:沈阳诚伟机械制造有限公司

A kind of non-coupling pre-splitting charge device and using method

ActiveCN106123716BLow degree of fragmentationOvercome the effects of blasting effectsBlastingCouplingEngineering

The invention aims to solve the actual engineering construction problems that the explosive charging process is complex, time is consumed and labor is consumed, provides a non-coupling pre-splitting explosive charging device and a using method, and belongs to the technical field of surface blasting engineering. The device is composed of a variable-diameter non-coupling pre-splitting explosive charging barrel and an umbrella-shaped explosive charging device; and the umbrella-shaped explosive charging device is located on the upper portion of the variable-diameter non-coupling pre-splitting explosive charging barrel. According to the device, the length of the explosive charging barrel can be flexibly and fast changed according to the on-site hole depth changing length and the non-coupling coefficient, and the requirement that the explosive charging non-coupling coefficient is sequentially decreased from bottom to top in the whole explosive charging device is met; the device can enter blast holes of different diameters and is automatically opened according to the size of the blast holes, and explosives can be conveniently injected into an explosive charging vehicle; and blasting crushing regions and the blasting tight bottom can be reduced, and side walls are effectively protected.

Owner:ANSTEEL GRP MINING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com