Preparation method of high-quality spherical metal powder

A metal powder, high-quality technology, applied in metal processing equipment, additive processing, transportation and packaging, etc., can solve the problems of easy powder aggregation, complex plasma system, system energy consumption, high powder cost, etc., to reduce oxygen content and Effects of other impurity content, improvement of powder spheroidization rate, and high degree of directionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

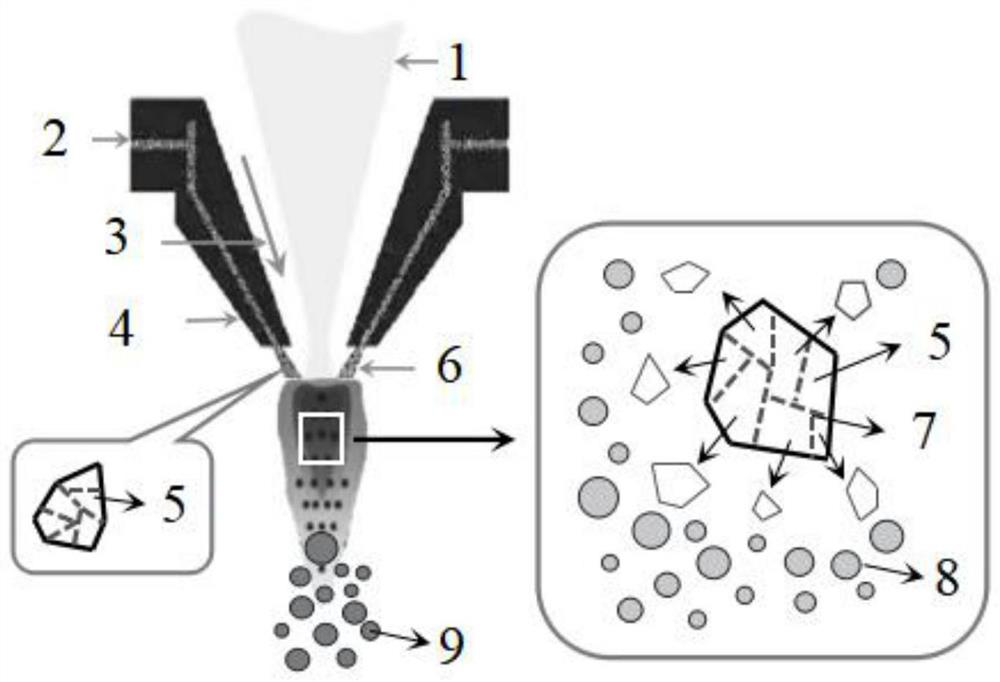

[0032] A kind of preparation method of metal titanium spherical powder, see figure 1 , including the following steps:

[0033]Step S1: Hydrogen absorption treatment of the raw material powder, that is, the non-spherical metal powder with large particle size is subjected to hydrogenation treatment, followed by crushing and sieving to obtain a metal powder that completely absorbs hydrogen or partially absorbs hydrogen; specifically, in a hydrodehydrogenation furnace Intermediate treatment of sponge titanium particles, the temperature is 600-700 ℃, the hydrogen pressure is 100-200kpa, the hydrogen absorption time is 10-120min, the hydrogenation degree of the powder is controlled by controlling the hydrogen absorption time, so that the titanium powder can completely absorb hydrogen, and then cool down with the furnace; Then mechanically crush the obtained particles, and sieve the irregular titanium hydride powder of 53-75 μm as the raw material powder 5 for laser spheroidization; ...

Embodiment 2

[0038] A preparation method of titanium alloy spherical powder, comprising the steps of:

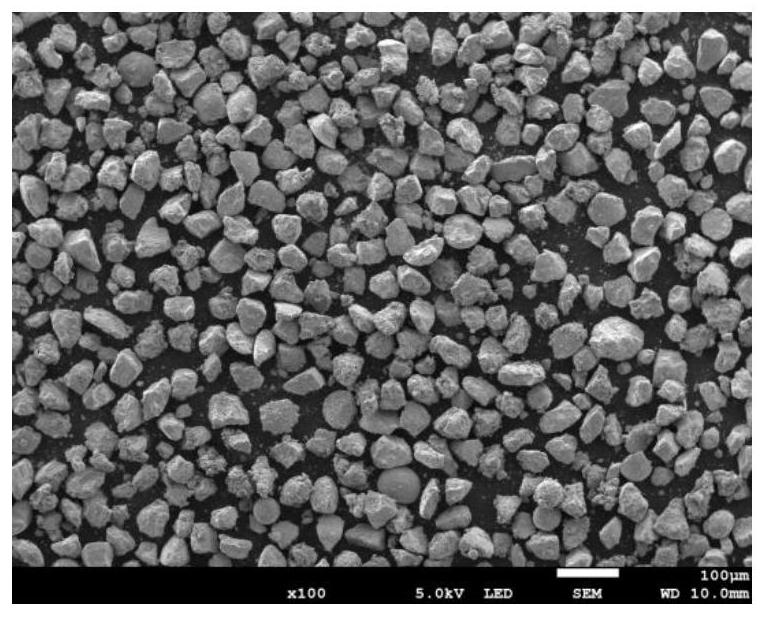

[0039] Step S1: sieve fully hydrogenated TC4 titanium alloy powder as a raw material, and sieve the powder with a size of 53-75 μm for laser treatment, and the powder shape is irregular (see figure 2 );

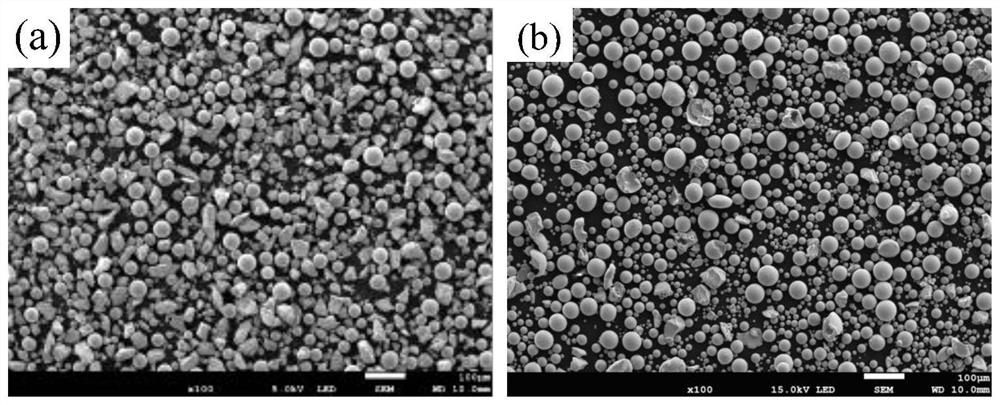

[0040] Step S2: Laser spheroidization treatment: The hydrogen-absorbing TC4 titanium alloy powder is uniformly and continuously delivered to the high-energy laser beam through the powder feeding equipment and powder feeding gas (Ar, 99.999%). According to the physical properties of the titanium alloy powder, the powder feeding The gas flow rate is 3-6L / min, the protective gas flow rate is 2-6L / min, and the laser power of 3-6kw is selected to cooperate to melt the titanium alloy powder transported into the laser beam and dehydrogenate it during the heating and melting process. The hydrogen generated by the dehydrogenation breaks the metal powder and forms fine droplets after melting, a...

Embodiment 3

[0046] A preparation method of titanium alloy spherical powder, which is basically the same as that of Example 2, the difference is that the hydrogen absorption degree of TC4 titanium alloy powder is 50%, the spheroidization rate is 85%, and the powder particle size (<53 μm, accounts for 80% ), decreased compared to Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com