Threshed and re-dried tobacco leaf preprocessing technique based on tobacco leaf raw material characteristics

A technology of threshing and redrying and pretreatment, which is applied in the field of threshing and redrying tobacco leaf pretreatment process, and can solve the problems of increased crushing of tobacco leaves, high adhesion, and increased operating costs. Achieve the effect of improving high adhesion and reducing the degree of crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The tobacco leaf raw material in this example is the 2016 Fujian Nanping Central Tobacco Leaf.

[0037] ① Classification of Tobacco Leaf Raw Materials

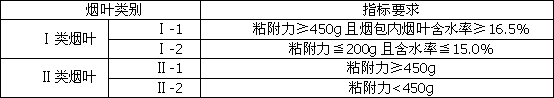

[0038] Table 2 shows the detection results of the adhesion force of the tobacco leaf raw material and the moisture content of the tobacco leaf raw material in the cigarette pack in this embodiment. It can be seen from Table 2 that the adhesive force of the tobacco leaf raw material is 689.56g, and the moisture content of the tobacco leaf raw material in the cigarette pack is 16.58%. The tobacco leaf raw material can be classified as Class I-1 tobacco leaf.

[0039] Table 2 Test results of the adhesion of tobacco leaf raw materials and the moisture content of tobacco leaf raw materials in bales in this example

[0040] Tobacco Raw Materials

Adhesion

Moisture content of tobacco leaf raw materials in cigarette bales

2016 Fujian Nanping Central Tobacco Leaf

689.56 g

16.58%

[0041] ②Thr...

Embodiment 2

[0049] The tobacco leaf raw material in this example is the upper part tobacco leaf of Xuchang, Henan in 2016.

[0050] ① Classification of Tobacco Leaf Raw Materials

[0051] Table 3 shows the test results of the adhesion of the tobacco leaf raw material and the moisture content of the tobacco leaf raw material in the cigarette pack in this embodiment. It can be seen from Table 3 that the adhesive force of the tobacco leaf raw material is 385.26g, and the moisture content of the tobacco leaf raw material in the cigarette pack is 15.47%. The tobacco leaf raw material can be classified as Class II-2 tobacco leaf.

[0052] Table 3 Test results of the adhesion of tobacco leaf raw materials and the moisture content of tobacco leaf raw materials in bales in this example

[0053] Tobacco Raw Materials

Adhesion

Tobacco raw material moisture in cigarette bale

2016 Henan Xuchang Upper Tobacco Leaf

385.26 g

15.47%

[0054] ②Threshing and redrying pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com