Pyrolysis device and pyrolysis system and pyrolysis method for coal and biological carbonaceous raw materials

A technology of biochar and pyrolysis, which is applied in the direction of indirect heating dry distillation, special form dry distillation, petroleum industry, etc., can solve the problems of increasing dust removal equipment and operating costs, low hardness of solid particles, high dust content of tar, etc., to improve the actual The effect of reaction flux, low degree of fragmentation and high calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

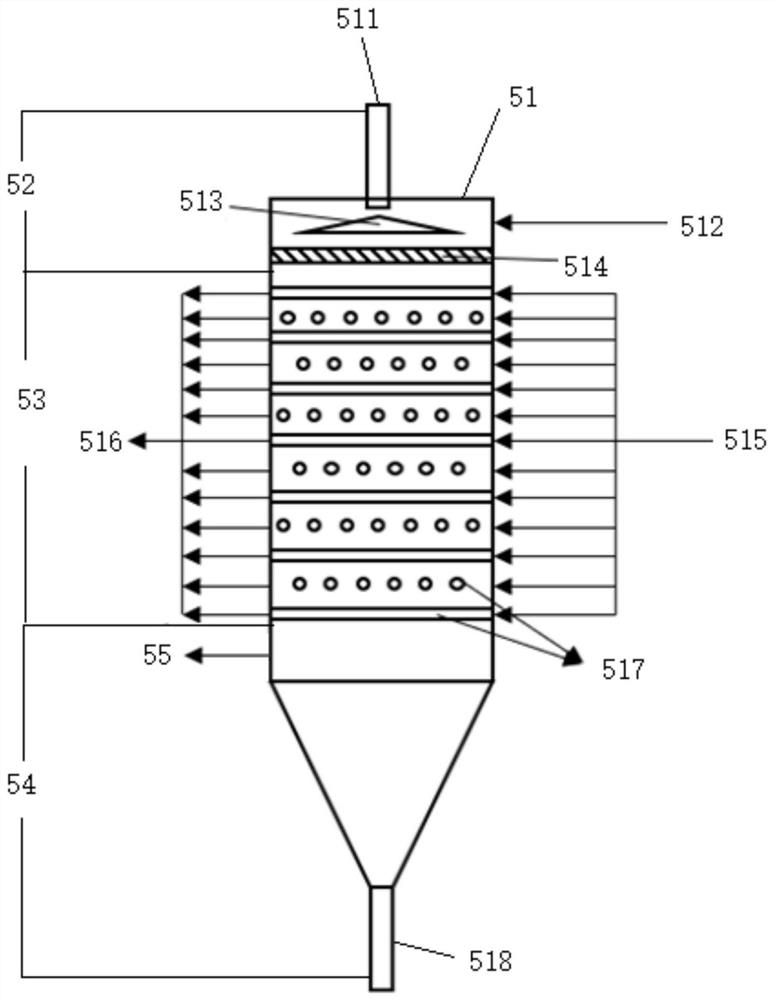

[0055] According to a preferred embodiment of the present invention, the conical surface of the conical disperser 513 has staggered openings, the preferred opening diameter is 20-50mm, and the distribution plate 514 is a wire mesh or a grid, and the wire mesh or The grid can make the material fall into the pyrolysis section 53 more evenly, and the staggered holes on the conical disperser 513 can effectively make the material evenly disperse and fall into the pyrolysis section, so that the solid material can fully react in the pyrolysis section 53, significantly Improve the pyrolysis efficiency of the pyrolysis section 53.

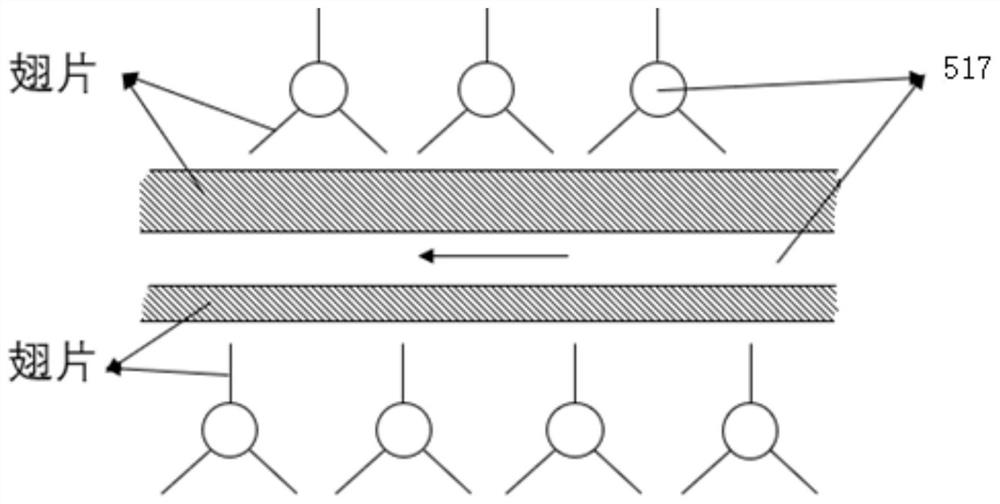

[0056] According to a preferred embodiment of the present invention, the reactor body 51 is a straight tube, and the heat exchange tube 517 is a round tube with fins, wherein the diameter of the heat exchange tube 517 is 200-400 mm, and the heat exchange tube 517 The distance between them is 400-700 mm, and the distance between the heat exchange tube 517 on...

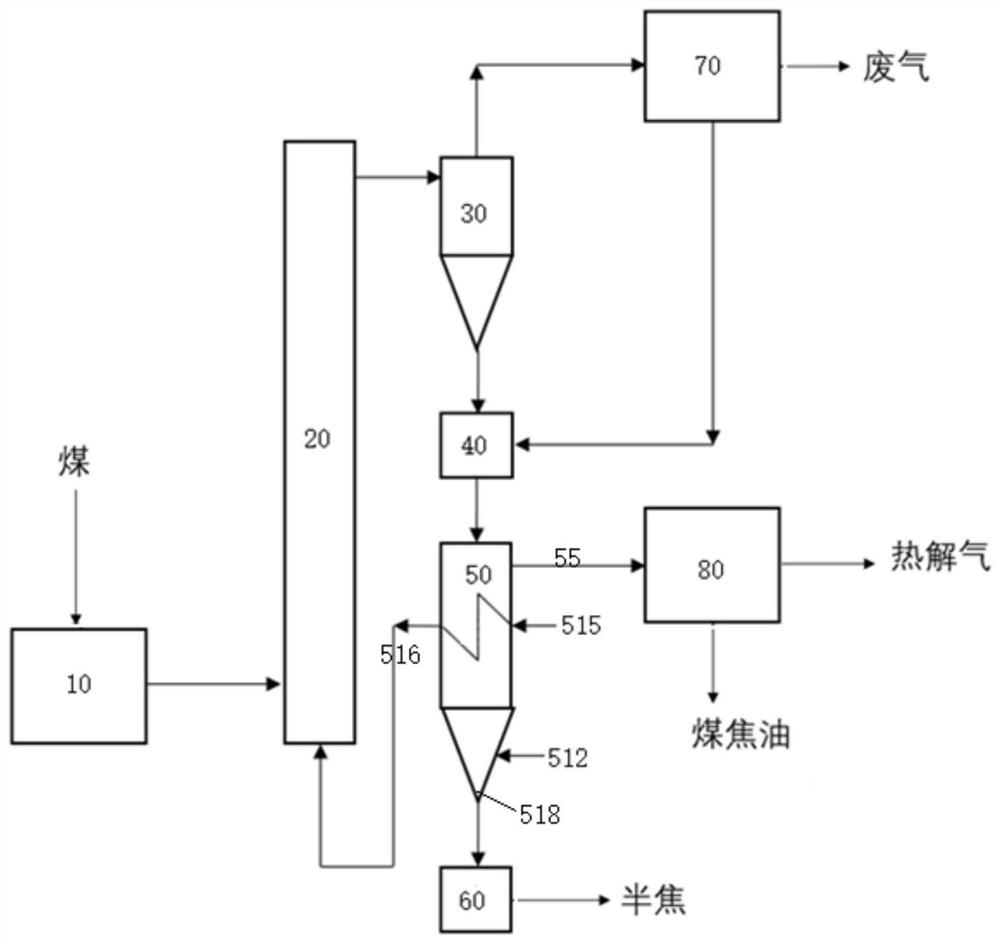

Embodiment 1

[0085] use figure 1 with figure 2 The pyrolysis apparatus shown, according to image 3 The process shown is carried out, and the industrial analysis and elemental analysis of the required coal samples are shown in Table 1. The crushing unit 10 crushes the raw materials to 40-80 meshes, the pyrolysis reaction temperature is 600° C., and the feeding amount of the selected raw materials is 100 t / h. The selected reaction atmosphere is water vapor with a superficial gas velocity of 0.1 m / s. The high-temperature medium is the high-temperature synthesis gas from the gasifier, and the temperature of the synthesis gas is 900°C.

[0086] Table 1 Industrial analysis and elemental analysis of coal samples (ad)

[0087]

[0088]

[0089] After the reaction, the semi-coke bin 60 at the bottom of the pyrolysis reactor body 51 can obtain 60.3t / h of semi-coke, and the semi-coke breakage rate is 8.44%. gas9830m 3 / h.

Embodiment 2

[0091] use figure 1 with figure 2 The pyrolysis apparatus shown, according to Figure 4 The process shown is carried out, and the industrial analysis and elemental analysis of the required biomass are shown in Table 2. The crushing unit 10 crushes the biomass to 40-80 meshes, the pyrolysis reaction temperature is 600° C., and the feed rate of the selected raw materials is 10 t / h. The selected reaction atmosphere is N 2 , the superficial gas velocity is 0.1m / s. The high-temperature medium is the high-temperature flue gas generated by the combustion furnace, and the temperature of the flue gas is 800°C.

[0092] Table 2 Industrial analysis and elemental analysis of biomass (d)

[0093]

[0094] After the reaction, the semi-coke bin 60 at the bottom of the pyrolysis reactor body 50 can obtain 2.79t / h of semi-coke, and the semi-coke breakage rate is 15.73%. Degassing 1034.6m 3 / h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com