Pressure relief method aimed at strata behaviors of gob side entries of fully mechanized caving faces

A technology of roadway and work, which is applied in mining equipment, mining equipment, earth-moving drilling, etc., can solve the problems of uncontrolled mine pressure and roadway deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

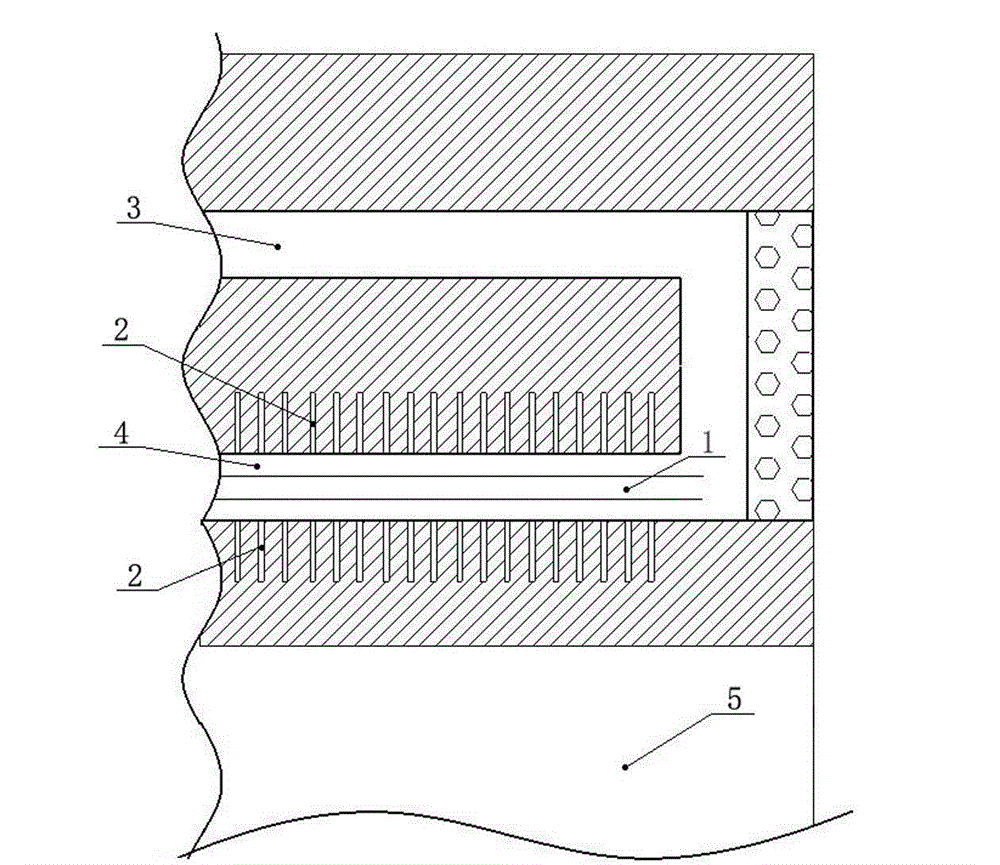

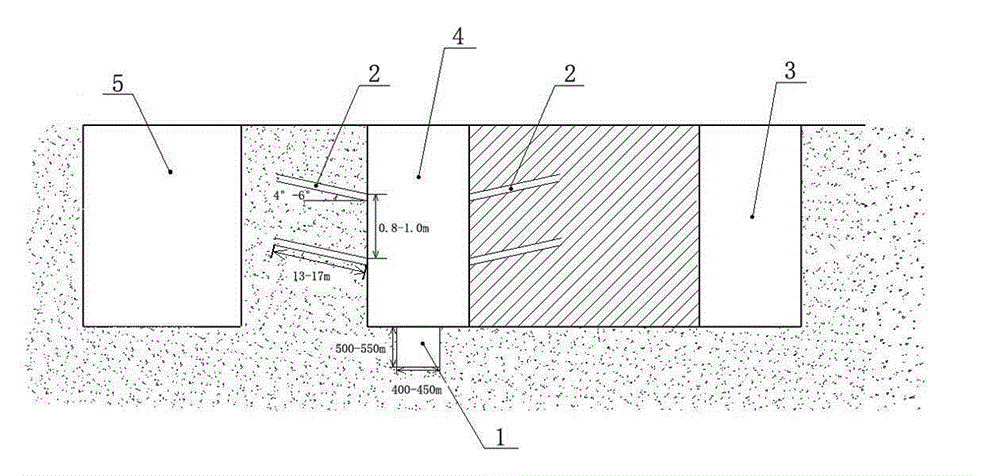

[0016] A pressure relief method for fully mechanized caving work faced with the appearance of mine pressure in empty roadways, comprising the following steps:

[0017] 1) Construction pressure relief groove: construct pressure relief groove 1 from inside to outside on the bottom plate of the roadway, and arrange pressure relief groove 1 at the center line of the bottom plate of the roadway.

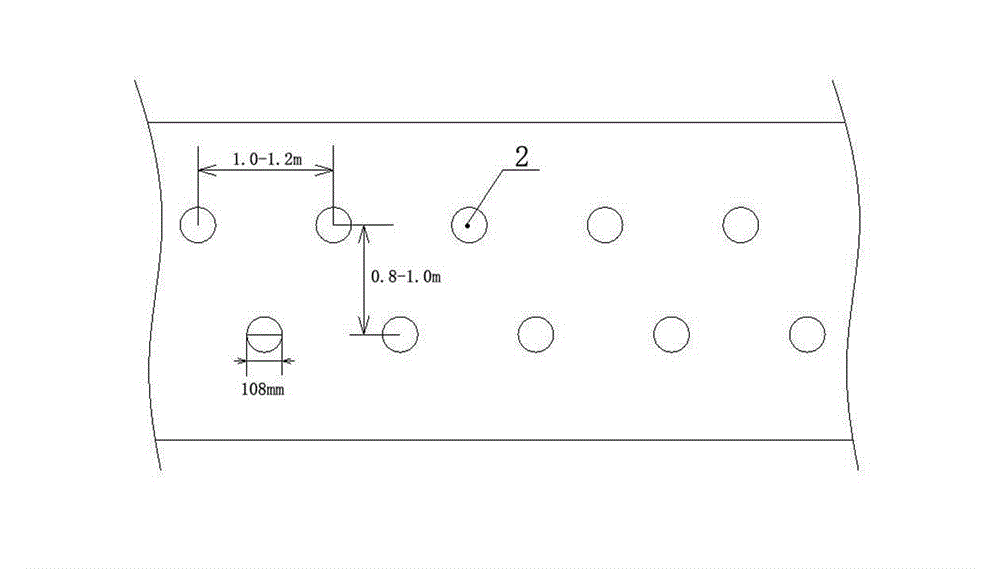

[0018] 2) Construction of pressure relief holes: construct two rows of pressure relief holes 2 from top to bottom on both sides of the roadway, each row of pressure relief holes 2 has a diameter of 108mm, a hole depth of 17m, and an upward inclination of 5° 1. The hole spacing is 1.2m; the row spacing of two adjacent rows of pressure relief holes 2 is 0.8m, and the two adjacent rows of pressure relief holes 2 are arranged with triple eyelets.

Embodiment 2

[0020] A pressure relief method for fully mechanized caving work faced with the appearance of mine pressure in empty roadways, comprising the following steps:

[0021] 1) Construction pressure relief groove: construct pressure relief groove 1 from the inside to the outside on the bottom plate of the roadway.

[0022] 2) Construction of pressure relief holes: construct three rows of pressure relief holes 2 from top to bottom on both sides of the roadway, each row of pressure relief holes 2 has a diameter of 108mm, a hole depth of 15m, and an upward inclination of 4° 1. The hole spacing is 1.0m; the row spacing of two adjacent rows of pressure relief holes 2 is 1.0m, and the two adjacent rows of pressure relief holes 2 are arranged with triple eyelets.

Embodiment 3

[0024] A pressure relief method for fully mechanized caving work faced with the appearance of mine pressure in empty roadways, comprising the following steps:

[0025] 1) Construction of pressure relief groove: construct pressure relief groove 1 from inside to outside on the roadway floor of the adjacent roadway. Pressure relief groove 1 is arranged at the center line of the roadway floor. Pressure relief groove 1 is 500mm deep and 425mm wide;

[0026] 2) Construction of pressure relief holes: construct four rows of pressure relief holes 2 from top to bottom on both sides of the roadway, each row of pressure relief holes 2 has a diameter of 108mm, a hole depth of 13m, and an upward inclination of 6° 1. The hole spacing is 1.1m; the row spacing of the two adjacent rows of pressure relief holes 2 is 0.9m, and the two adjacent rows of pressure relief holes 2 are arranged with triple eyelets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com