Oven hinge with two-section type transmission mechanism

A transmission mechanism, two-stage technology, applied in the field of oven hinges, can solve the problems affecting the opening and use of the oven door, the laborious opening or closing of the oven door, and the limitation of the use state of the oven door, so as to ensure the normal opening and use, and strengthen the smoothness. Performance and stability, the effect of reducing the amount of sinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

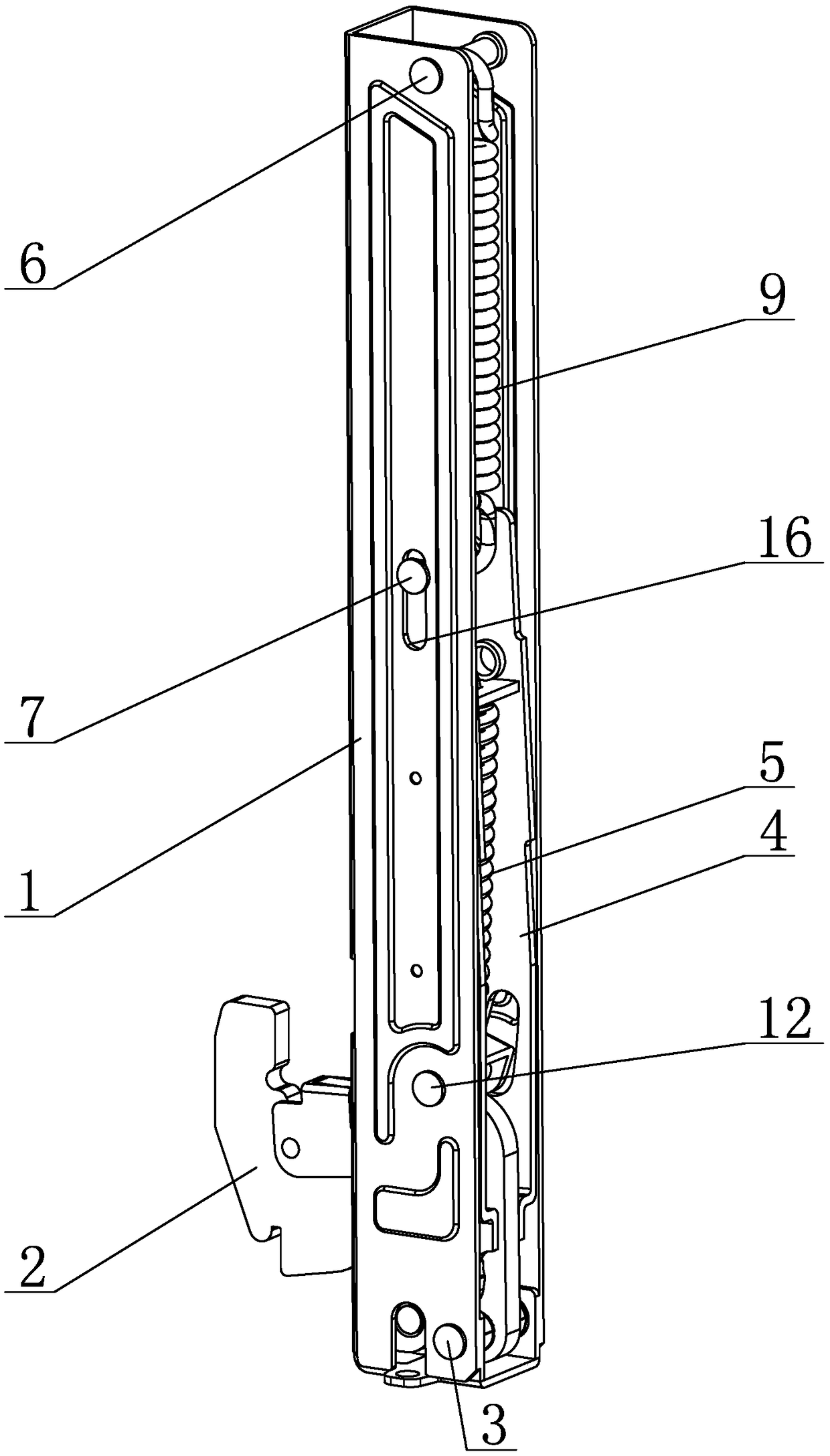

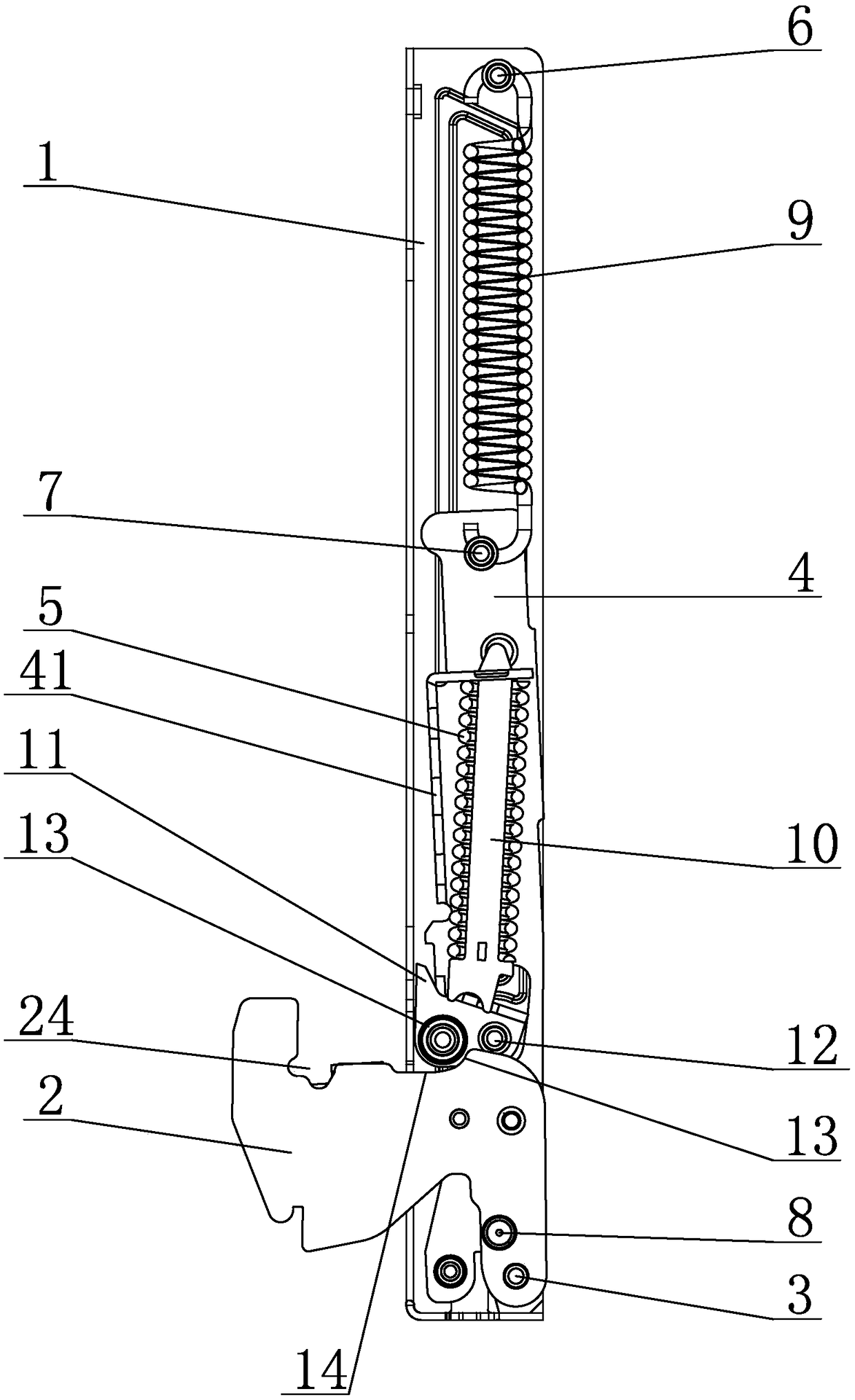

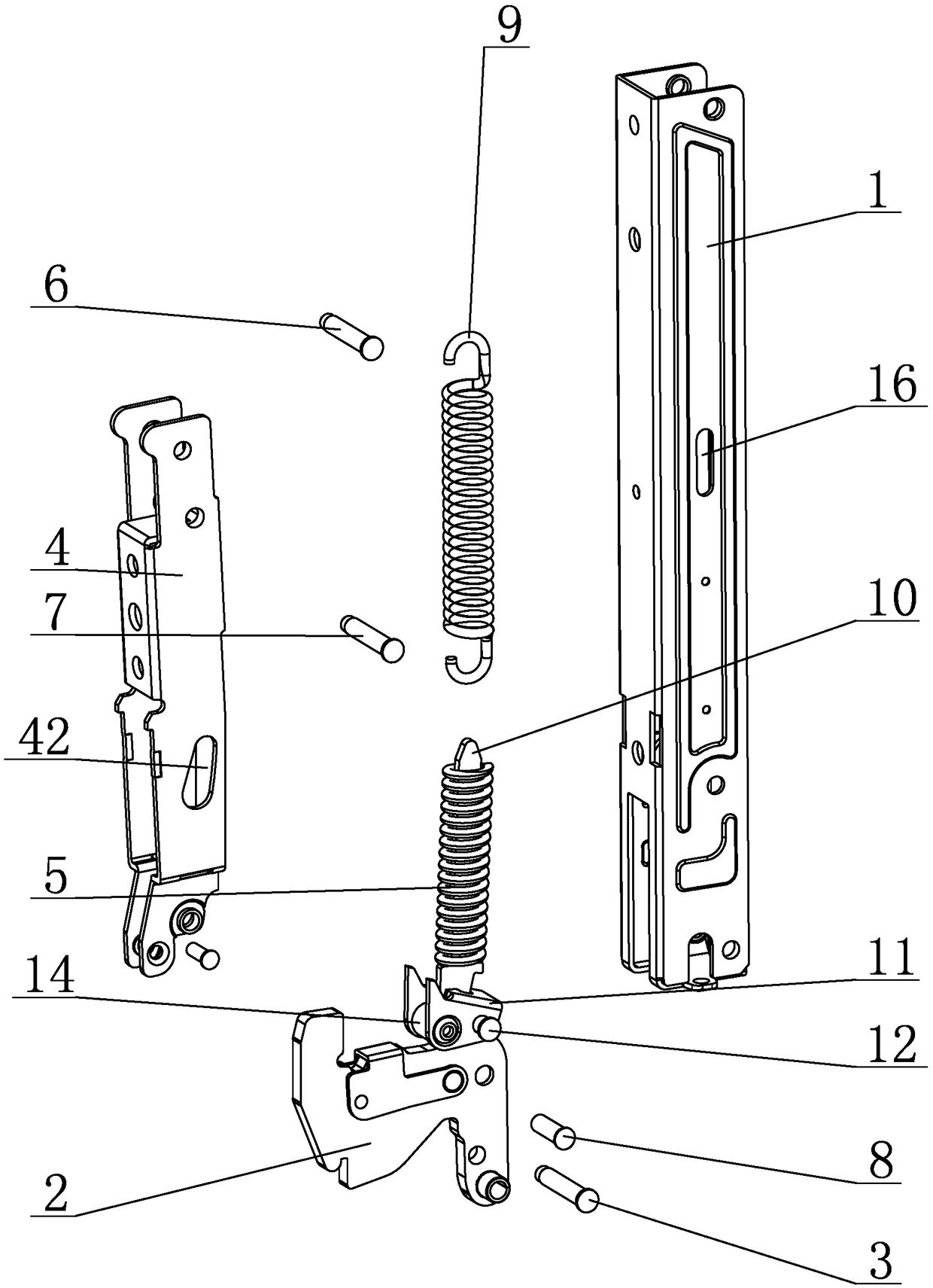

[0029] According to attached Figures 1 to 4 As shown in the figure, the oven hinge with a two-stage transmission mechanism of the present invention includes a hinge seat 1 installed on the oven door and a hinge arm 2 installed on the oven cabinet. The lower end of the hinged arm 2 is provided with a hinged shaft 3 hinged to the hinged seat 1, and the hinged shaft 3 is installed at a position close to the bottom inner wall of the hinged seat 1, so that during the rotation process of the oven door from closing to opening, The bottom of the oven door only sinks about 2.8mm to 3.5mm during the door opening process, so that the downward movement of the bottom of the oven door is smaller than that of traditional hinges. In this way, the amount of sinking when the oven door is opened is effectively reduced, and the oven door is prevented from interfering with the furniture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com