Drawer guide rail structure

A guide rail and drawer technology, applied in drawers, furniture parts, household appliances, etc., can solve the problems of poor guide rail performance, increased gap between balls and rails, and insufficient strength, so as to improve rigidity, smooth guide rail operation, and increase load bearing effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Further illustrate the present invention below in conjunction with accompanying drawing and embodiment.

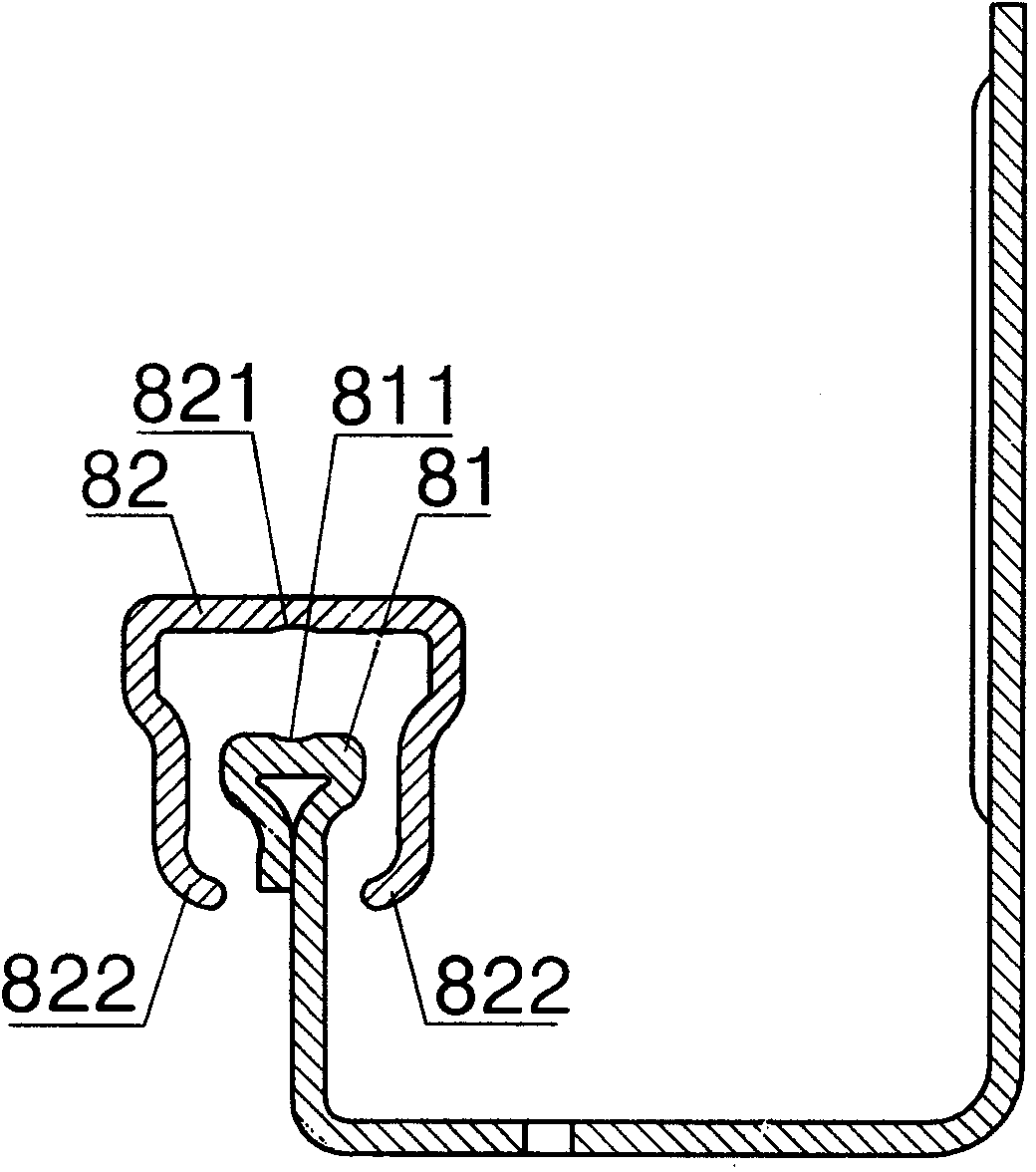

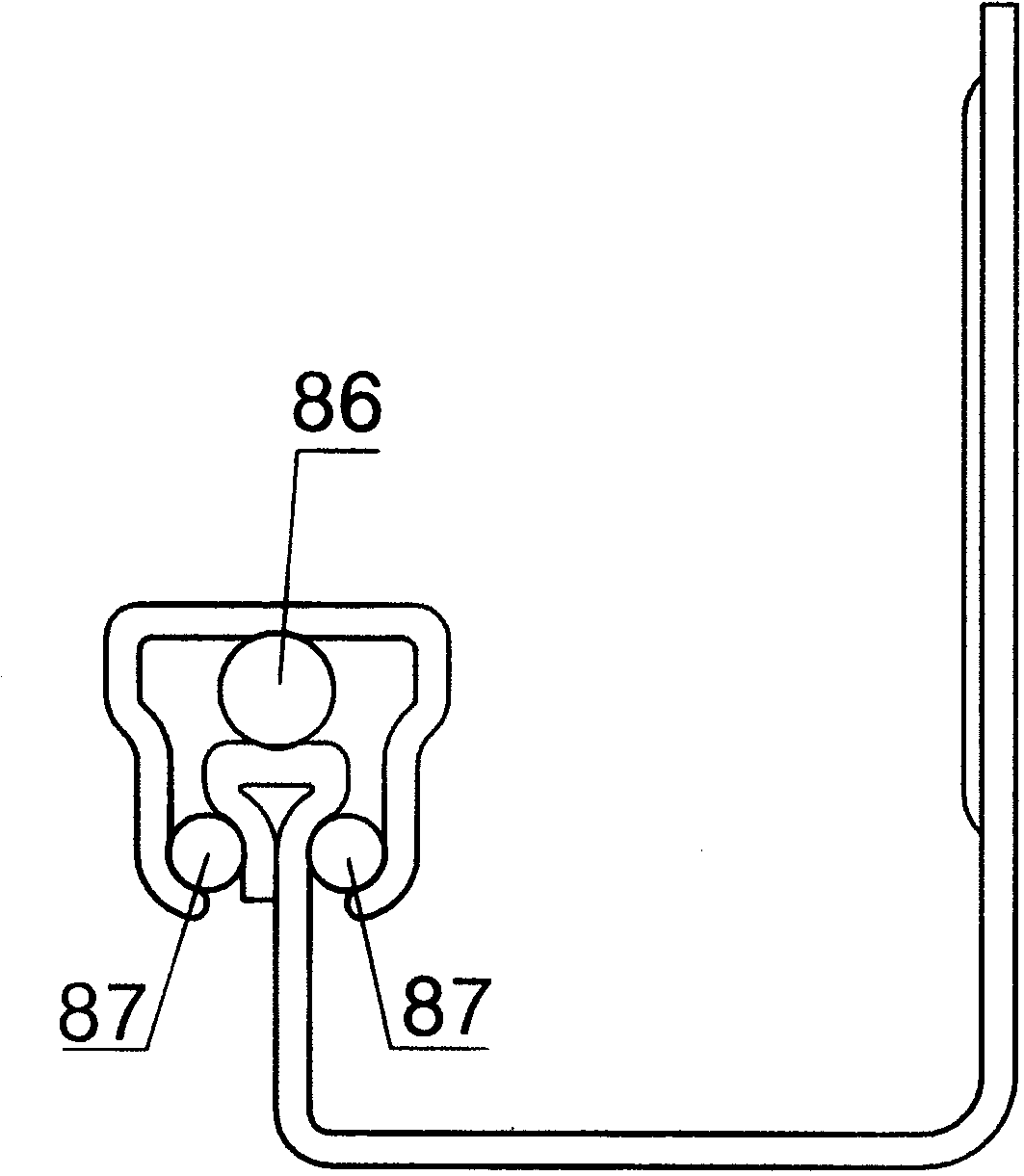

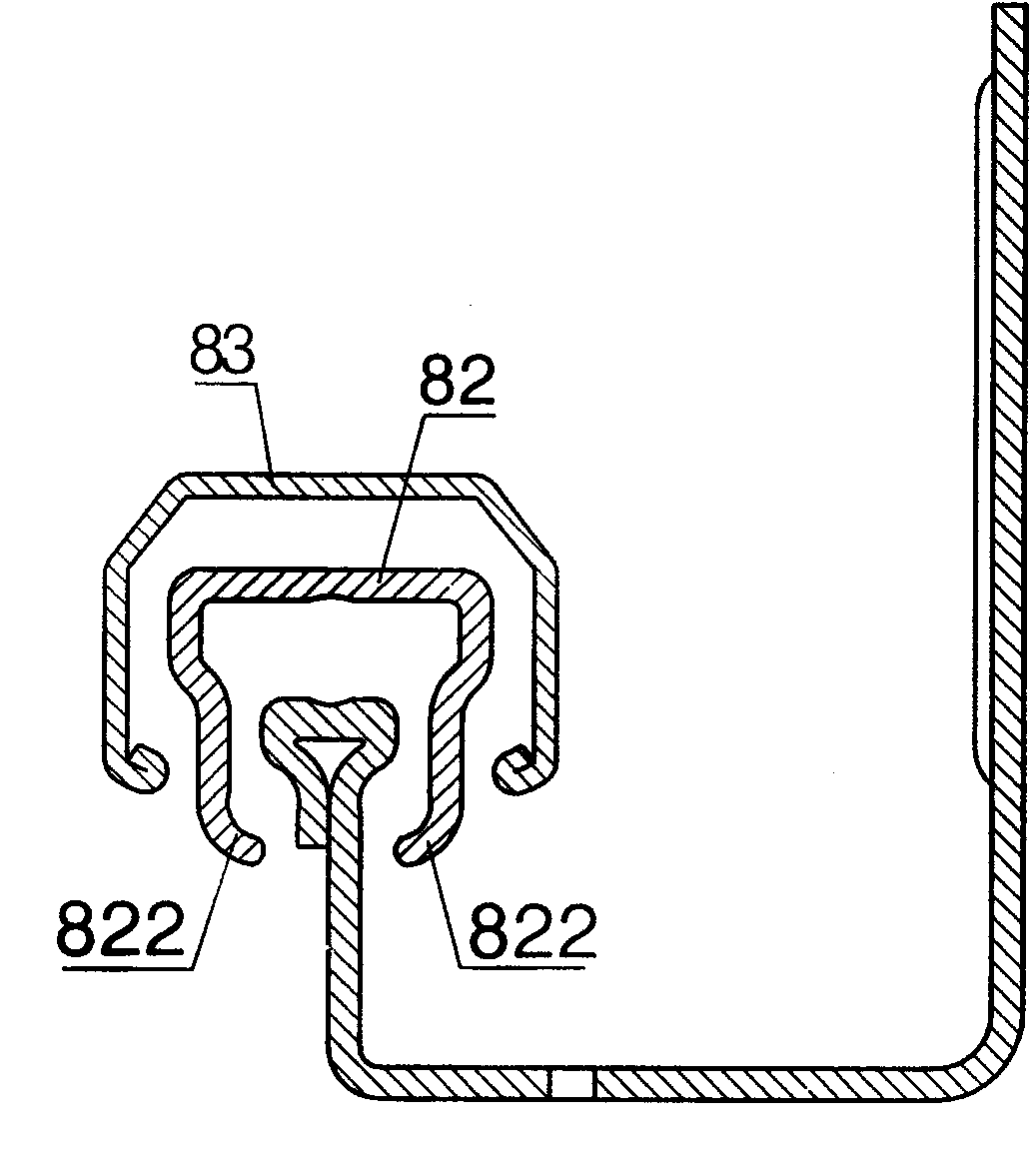

[0024] figure 1 and figure 2 It is a structure of existing guide rail products, which includes a fixed rail 81 and a movable rail 82 surrounded by the fixed rail 81. The loading part of the fixed rail 81 has an inverted triangular cross-section, and the surface of the movable rail 82 is roughly П-shaped; The upper surface of the horizontal edge has a first raceway 811; the lower surface of the horizontal edge of the movable rail 82 has a second raceway 821, and a first ball 86 is embedded between the first raceway 811 and the second raceway 821; the movable rail 81 The lower ends of the two vertical sides have a first bending portion 822; the two first bending portions 822 of the movable rail 82 are opposite to the two triangular hypotenuses of the fixed rail 81, and each first bending portion 822 is connected to the fixed rail. The second ball 87 is embedded res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com