A kind of non-coupling pre-splitting charge device and using method

A charging and pre-splitting technology, applied in blasting and other directions, can solve the problems of time-consuming, labor-intensive, complicated charging process, etc., and achieve the effect of reducing the amount of dust, having a wide range of sources and being convenient to carry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

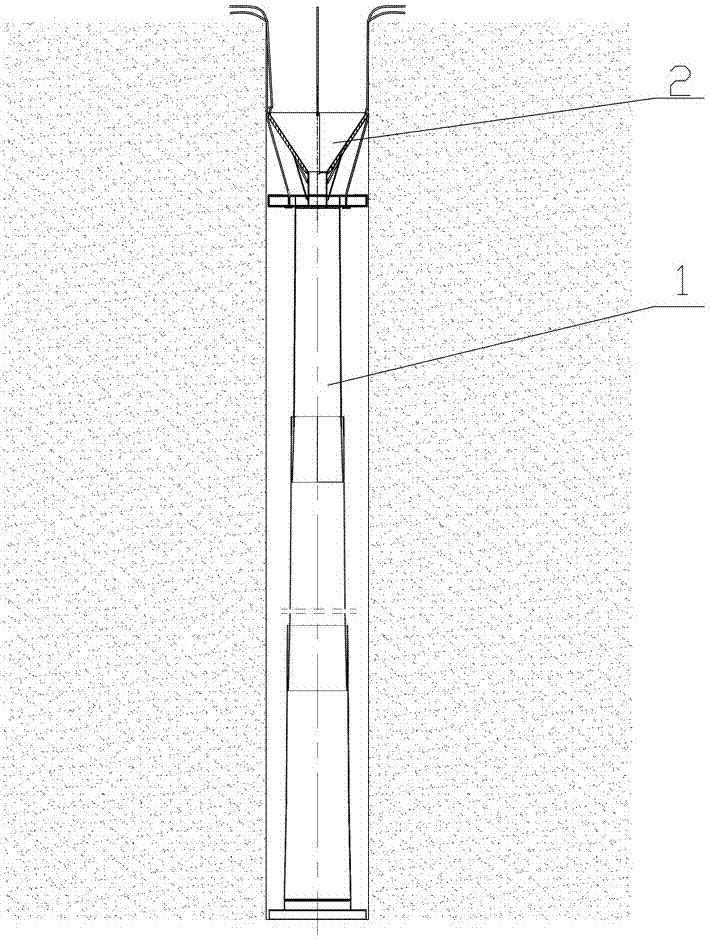

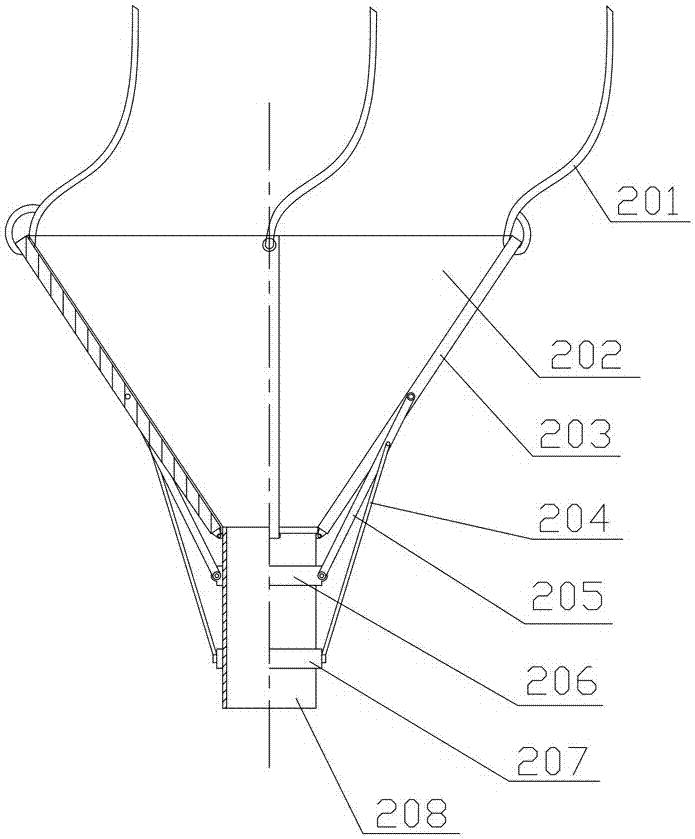

[0030] like figure 1 , 2 , As shown in 3, a non-coupling pre-split charge device is composed of variable-diameter non-coupled pre-split charge cartridge 1 and umbrella-shaped charge device 2.

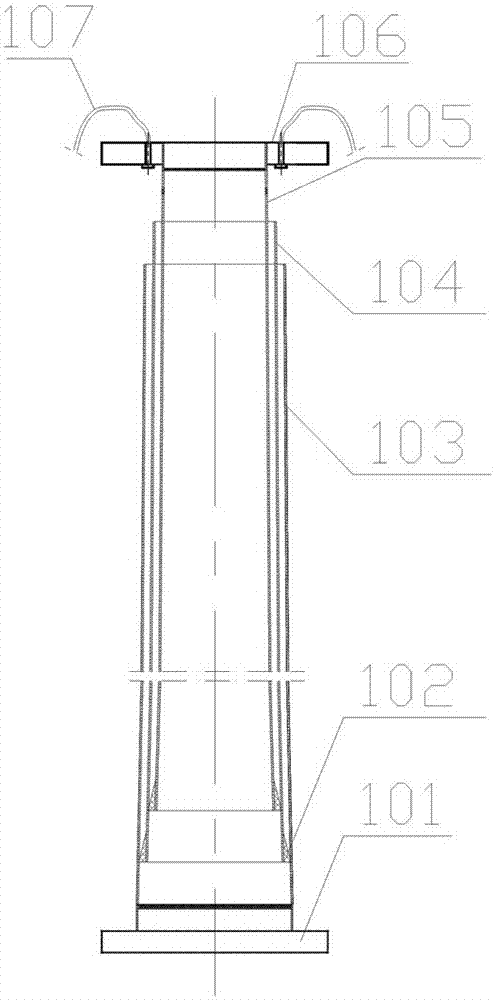

[0031] Variable-diameter non-coupling pre-split cartridge 1 consists of a bottom cover 101, a bottom tube 103 threaded with the bottom cover 101, and a group of intermediate tubes 104 inserted in this bottom tube 103 in turn, and inserted into this group The top cylinder 105 in the middle cylinder 104 is composed of the central positioning ring 106 threadedly connected with the top cylinder 105 and the manual pull rope 107 arranged on the central positioning ring 106. The outer surface of the bottom of the intermediate cylinder 104 and the top cylinder 105 is All have rubber anti-slip sleeves 102, and the cylinder diameters of the set of intermediate cylinders 104 decrease successively from bottom to top;

[0032] The centering ring 106 should be a group of spare parts with different ...

Embodiment 2

[0042] The depth of the pre-splitting hole in the test is 15 m, the diameter of the pre-splitting hole is 250 mm, and the filling length of the blast hole is 4.5 m. In the device of implementation 1, the taper angle of the truncated conical barrel with variable diameter uncoupled pre-split cartridge is 0.4°, the diameter of the upper end of the top barrel is 93 mm, and the diameter of the lower end of the bottom barrel is 240 mm, including each barrel of the middle barrel The length is 1.64 m, and there are 7 barrels in total; the diameter of the barrel of the umbrella-shaped charge used is 50 mm.

[0043] The steps of the specific method of using the uncoupled pre-split charge device are as follows:

[0044] (1) Assemble a top cylinder, a bottom cylinder, and 5 intermediate cylinders into a variable-diameter uncoupled pre-split cartridge, and install the bottom cover on the lower end of the bottom cylinder and tighten it;

[0045] (2) Put the combined cartridges into the hol...

Embodiment 3

[0051] The depth of the pre-splitting hole in the test is 12 m, the diameter of the pre-splitting hole is 220 mm, and the filling length of the blast hole is 3.6 m. In the device of implementation 1, the cone angle of the tapered tube of the variable diameter uncoupled pre-split cartridge is 0.4°, the diameter of the upper end of the top tube is 108 mm, and the diameter of the lower end of the bottom tube is 210 mm, including the diameter of each tube of the middle tube. The length is 1.34 m, and there are 7 cylinders in total; the diameter of the cylinder is 60 mm using the umbrella-shaped charge in the hole.

[0052] The steps of the specific method of using the uncoupled pre-split charge device are as follows:

[0053] (1) Choose one top cylinder, one bottom cylinder, and 5 intermediate cylinders to assemble into a variable-diameter uncoupled pre-split cartridge, install the bottom cover on the lower end of the bottom cylinder and tighten it;

[0054] (2) Put the combined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com