Patents

Literature

32results about How to "Indicator qualified" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Helicid powder injection preparation and its preparation method

InactiveCN1535691AImprove stabilityIndicator qualifiedOrganic active ingredientsPowder deliveryConvulsionSedation

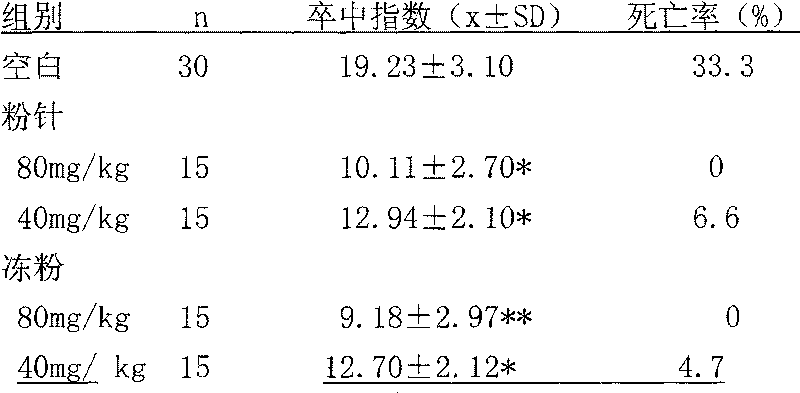

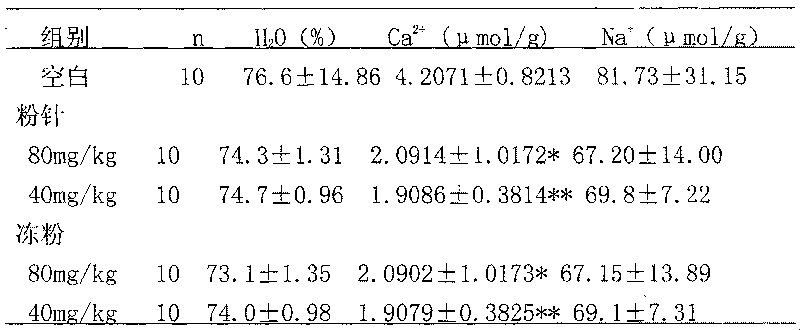

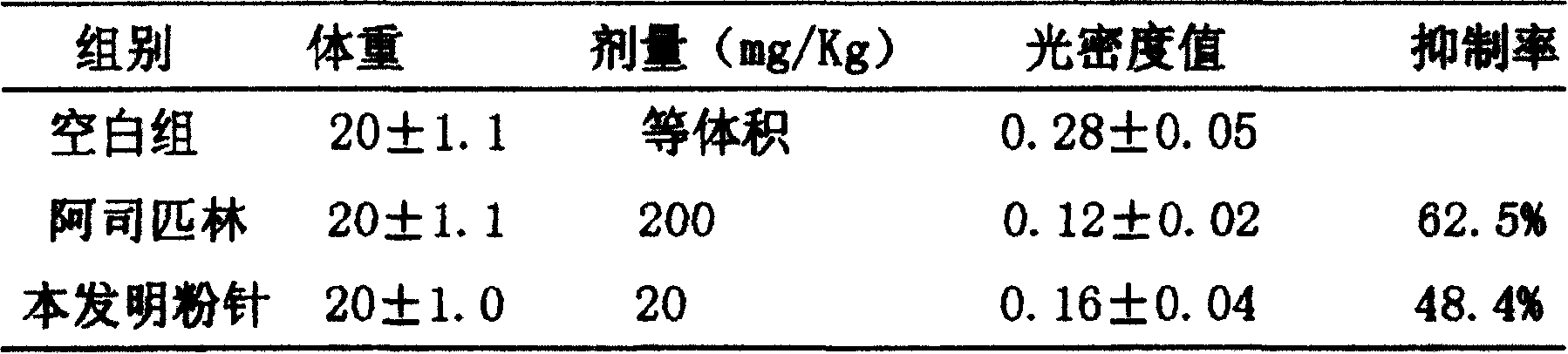

The present invention provides a helicid powder injection and its preparation method. Every powder injection contains 25-600 mg of helicid, and the rest is medicinal auxiliary material for injection. It has good stability, can be stored for 3 years at normal temperature, its irritation is small, and its injection site has no clear change or light hyperemia, and its sedation effect is good, and its convulsion-resisting action is strong, it can obviously reduce coriamyrtin convulsion incidence rate, prolong generative latent period, reduce frequency of attack and shorten time and process of attack. The tests show that said helicid powder injection has the strong action of stopping pain and relieving inflammation.

Owner:KUNMING ZIJIAN BIOTECH

Oral preparation of quick releasing Breviscapini and producing method

InactiveCN1695629AImprove stabilityIndicator qualifiedOrganic active ingredientsPill deliveryDiseaseSecretion

Owner:云南一尧科技开发有限公司

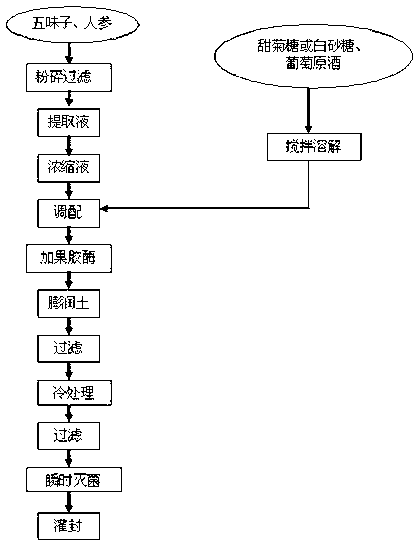

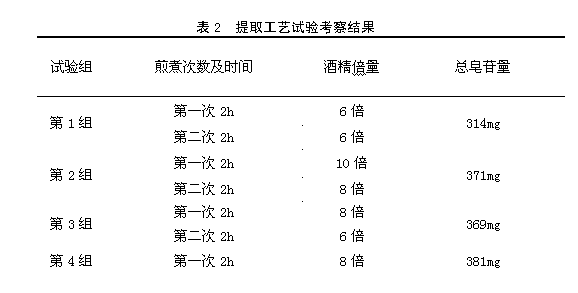

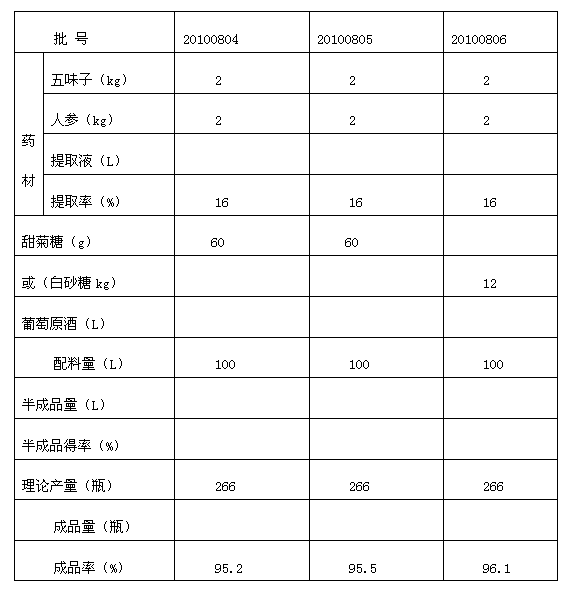

Schisandra chinensis ginseng liquor and preparation method thereof

InactiveCN103131571AHas food propertiesRefreshing tasteNervous disorderWine preparationFlavorGrape wine

The invention relates to schisandra chinensis ginseng liquor and a preparation method thereof, solving the problem that the existing technology has a long production cycle and cannot produce the schisandra chinensis ginseng liquor with refreshing and pure flavor and sour and sweet taste. The schisandra chinensis ginseng liquor is prepared by adding concentrated solution extracted from Chinese traditional medicine and stevioside into grape wine base. The Chinese herbal medicinal ingredients in the concentrated solution extracted from Chinese traditional medicine comprise 50% by weight of schisandra chinensis and 50% by weight of ginseng. The preparation method comprises the preparation of the concentrated solution extracted from Chinese traditional medicine and the preparation of the schisandra chinensis ginseng liquor. The preparation method has the beneficial effects that only two Chinese herbal medicinal ingredients, the schisandra chinensis and the ginseng, are taken for medicine combination, so that the formula is simple, not only the effects of the schisandra chinensis of inducing astringency, supplementing qi and promoting the production of body fluid as well as tonifying kidney and tranquilizing mind are highlighted, but also the effects of the ginseng of reinforcing vital energy, tonifying spleen and lung, promoting the secretion of saliva or body fluid, smoothing the nerves, quenching thirst and increasing the intelligence are highlighted, the schisandra chinensis ginseng liquor has pure and refreshing flavor and sour and sweet taste, the preparation technology is simple, the production efficiency is high, both the equipment investment and the production cost can be lowered, and the preparation method is easy to control and acquire.

Owner:ANSHAN JUYUAN FOOD

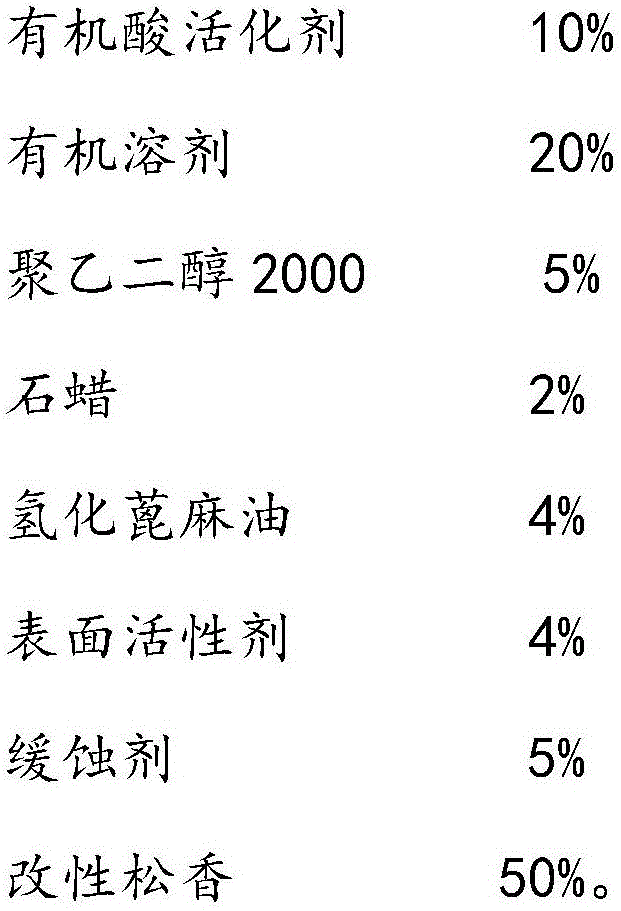

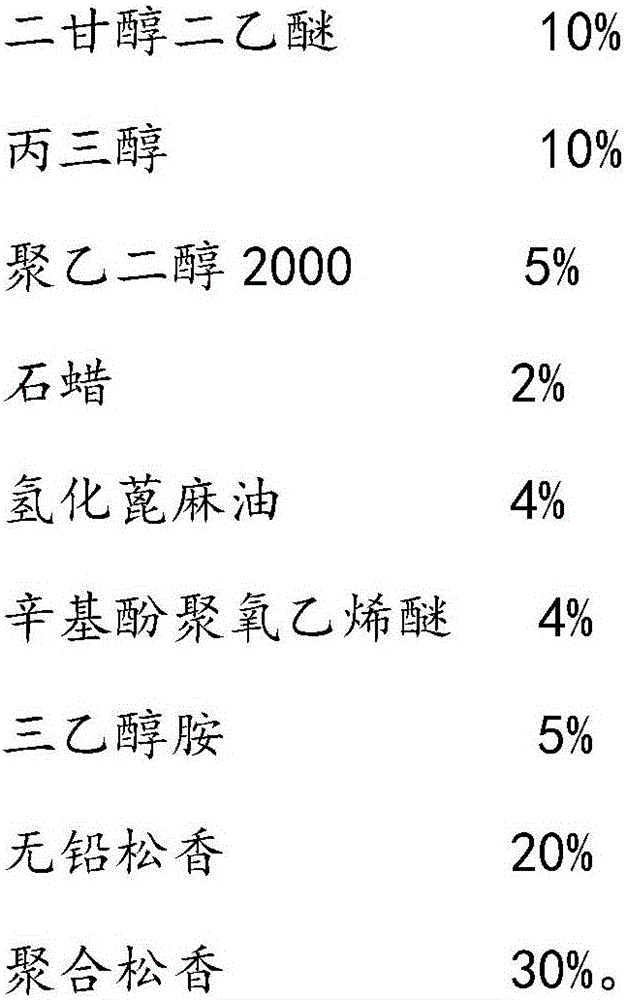

Environment-friendly soldering paste and preparing method thereof

InactiveCN105921905ASuitable for surface mount requirementsAvoid cleaningWelding/cutting media/materialsSoldering mediaPolyethylene glycolSurface-active agents

The invention discloses environment-friendly soldering paste and a preparing method thereof. The environment-friendly soldering paste is composed of, by weight percent, 90% of soldering powder and 10% of flux paste. The soldering powder is composed of, by weight percent, 2% of silver, 0.5% of copper and 97.5% of tin. The flux paste is composed of, by weight percent, 10% of an organic acid activating agent, 20% of an organic solvent, 5% of polyethylene glycol 2000, 2% of paraffin, 4% of hydrogenated castor oil, 4% of a surface active agent, 5% of a corrosion inhibitor and 50% of modified rosin. The preparing method of the environment-friendly soldering paste includes preparing of the soldering powder and preparing of the flux paste; and then the soldering powder and the flux paste are sufficiently mixed to obtain the environment-friendly soldering paste. The soldering powder of the environment-friendly soldering paste does not contain lead, the flux paste does not contain halogen, environment friendliness is better facilitated, residues are few after welding, cleaning is not needed, the spreadability of welding flux is good, a copper mirror cannot be pierced after the prepared soldering paste is welded, and the requirement for packaging high-end precise electronic products can be met.

Owner:深圳市唯特偶新材料股份有限公司

Colchicines microcapsule and preparation method

InactiveCN1695603AIndicator qualifiedIncrease irritationOrganic active ingredientsAntipyreticMedicineIrritation

A microsoftgel of colcin and its preparing process are disclosed. It can be used to prepare any taget medicine by proportionally mixing it with medicinal auxiliary for higher stability and bioactivity and low irritation to stomach and intestine.

Owner:云南一尧科技开发有限公司

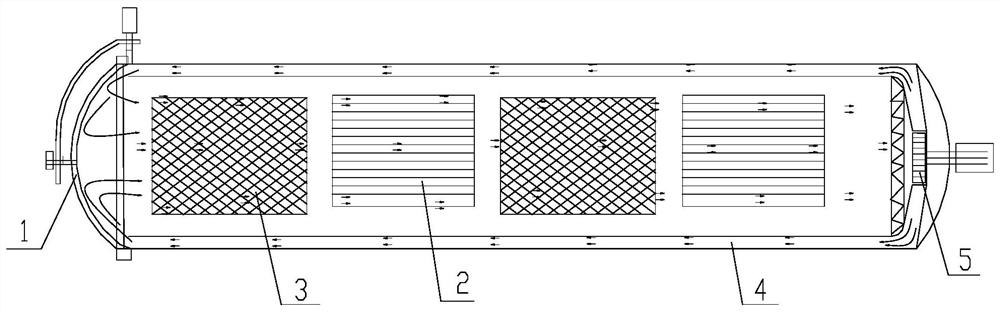

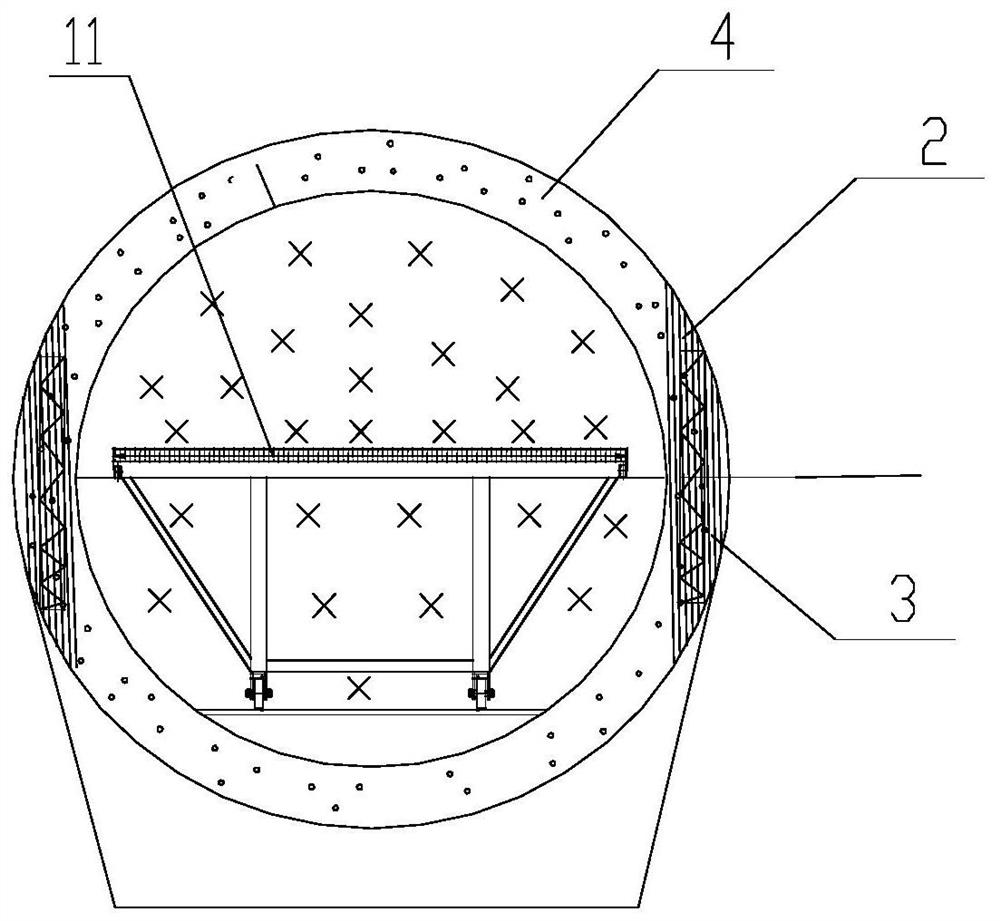

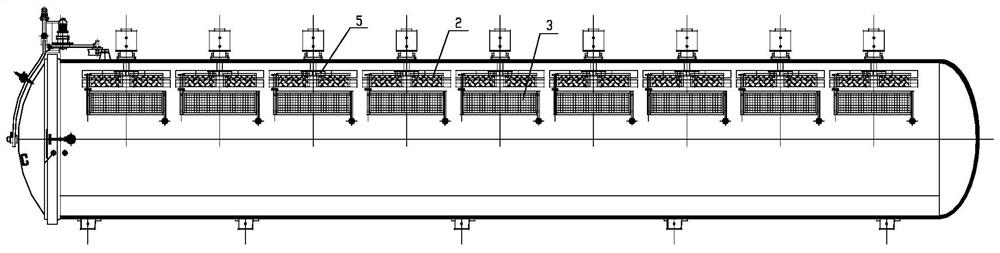

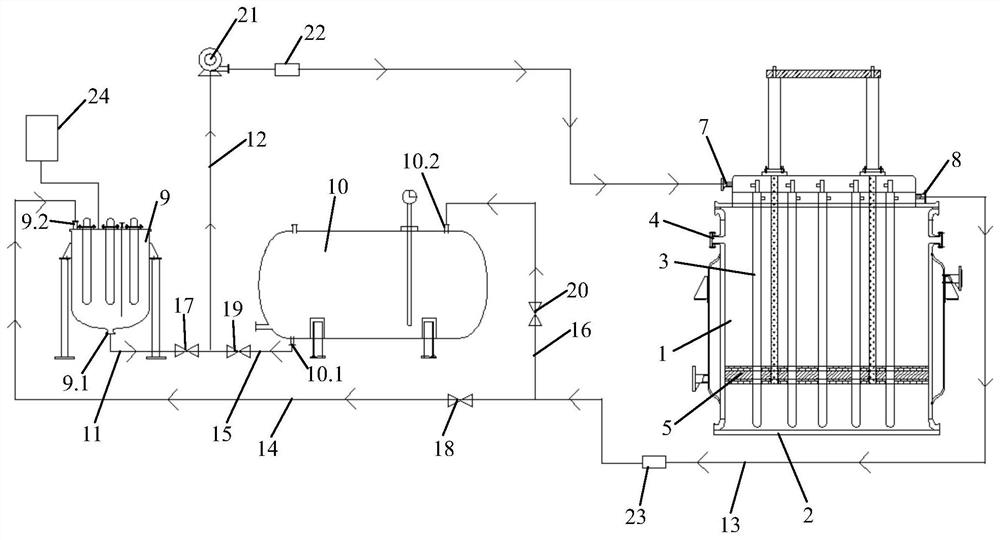

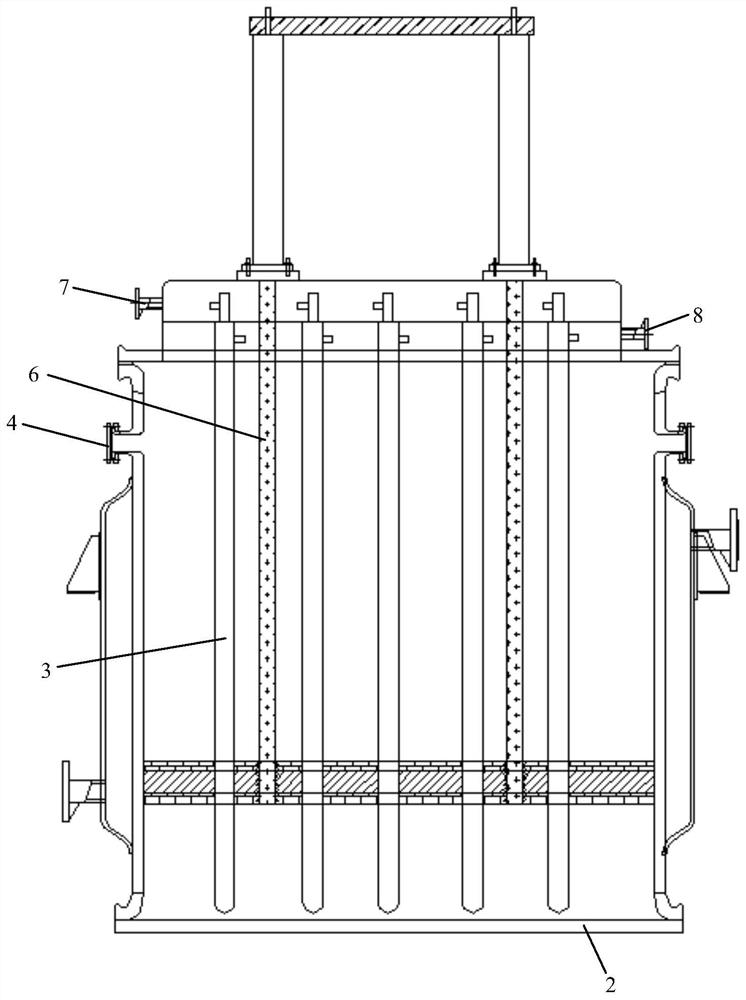

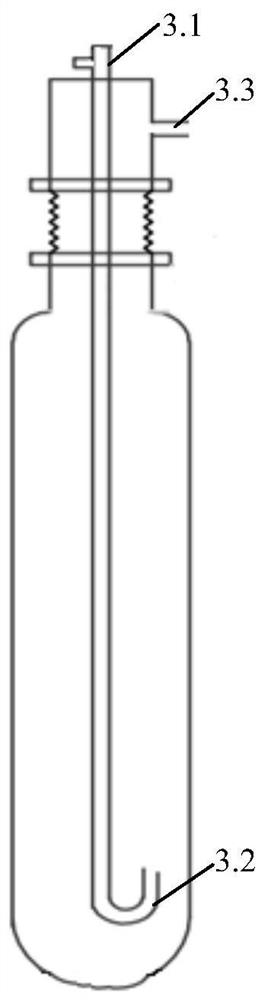

Oversized laminated glass autoclave

ActiveCN113878970AShorten the distance of the loopImprove uniform coolingLaminationLamination apparatusStructural engineeringMechanical engineering

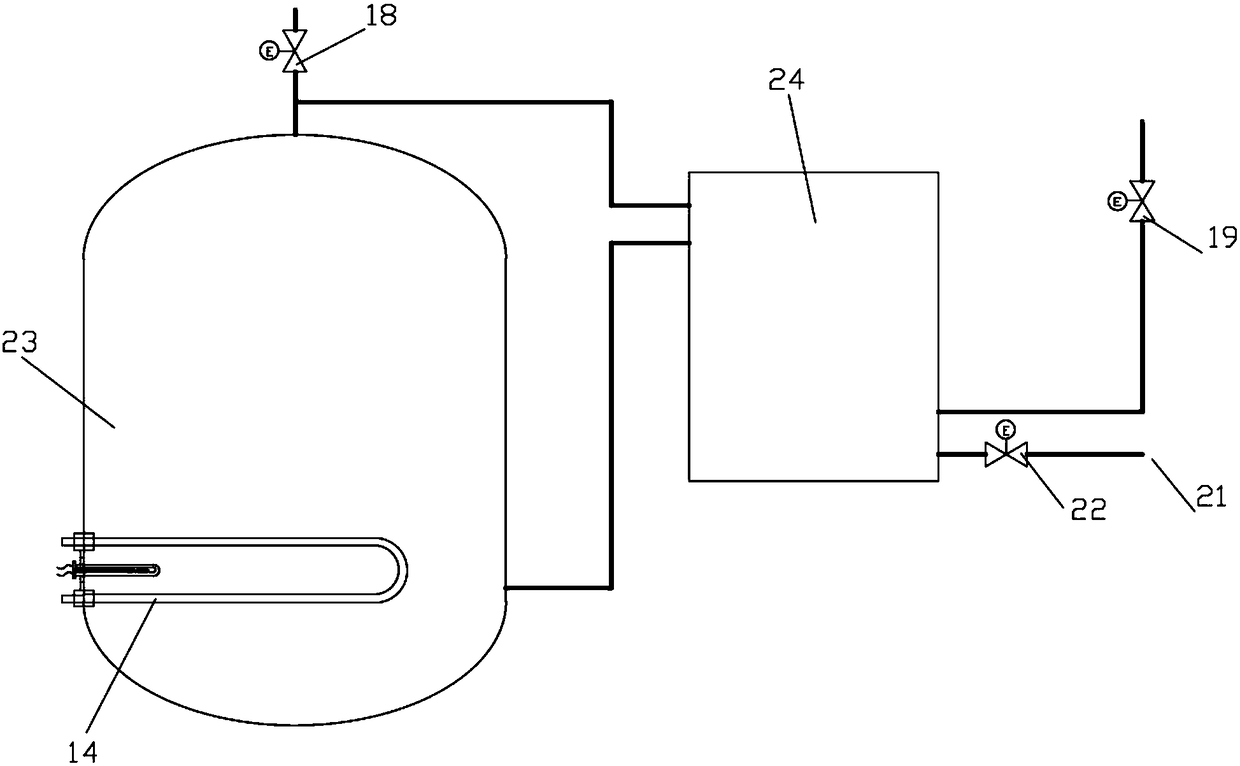

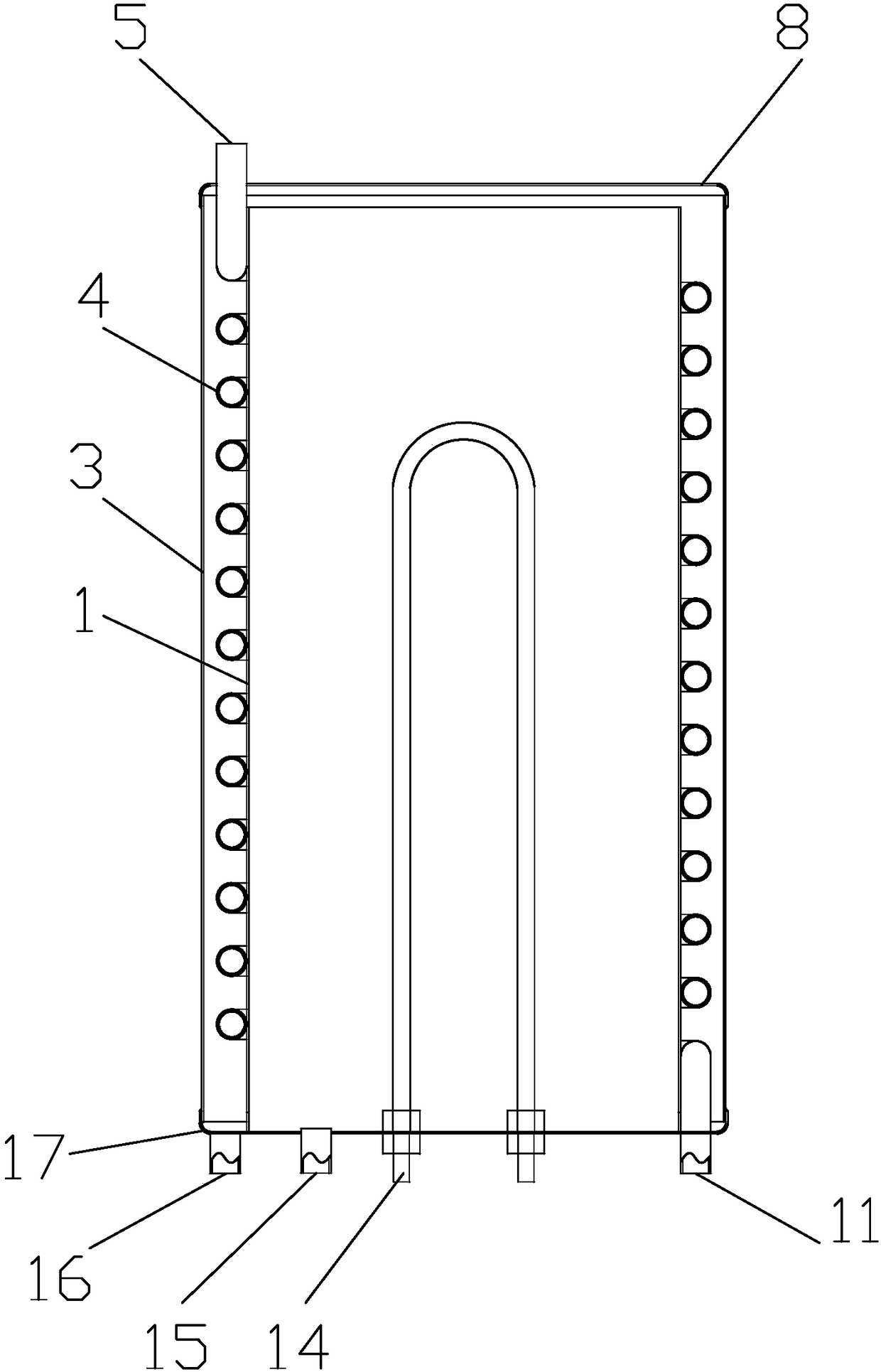

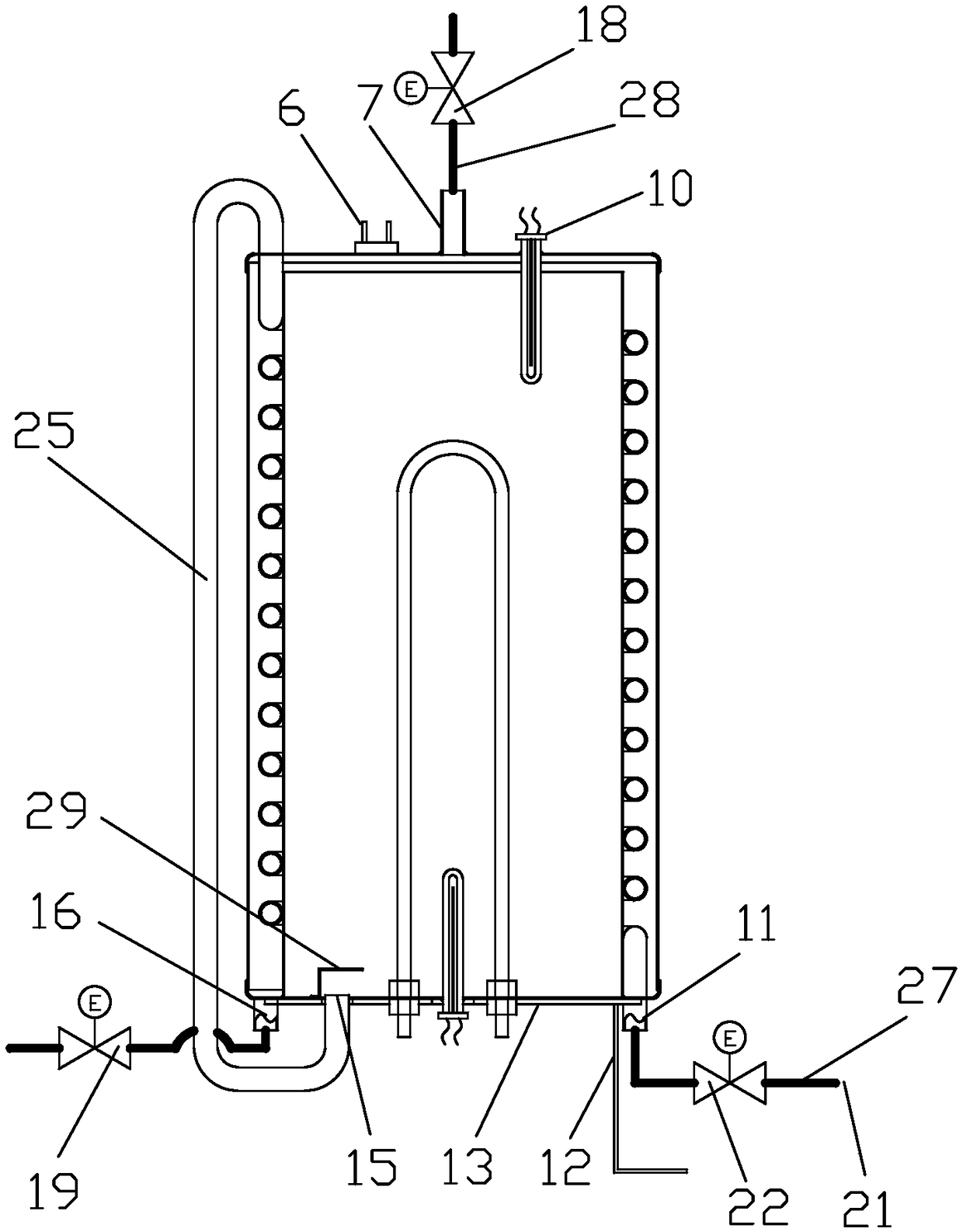

The invention relates to an oversized laminated glass autoclave. An annular air guide plate is fixed to the position, close to the kettle wall, from the top to the lower portion in a kettle body, a kettle body annular air channel is formed between the kettle wall and the air guide plate, lower air outlets are formed in the two sides of the lower portion of the kettle body respectively, middle air openings capable of being opened are formed in the middles of the two sides of the air guide plate respectively, and a detachable horizontal baffle is connected above the position between the two middle air openings; and a fan is fixed at the top of the air channel, a heater and a cooler are fixed on the upper side of the air channel, the fan is fixed in a volute, the volute is respectively provided with an openable upper air outlet opposite to the two upper air channels, and the air inlet of the fan is communicated with one upper air channel through a detachable air guide pipe. According to the invention, wind is changed from the length direction of the original horizontal autoclave to the semicircular annular direction, so that the circulating distance of the air channel is shortened, the circulating frequency is increased, the uniform cooling degree of the whole glass is greatly improved, all indexes of the large glass are ensured to be qualified, rainbow spots are avoided, and the appearance and performance indexes are perfect.

Owner:TIANJIN NORTH GLASS IND TECHN

Membrane process preparation method of electronic-grade 1,3-propanesultone

InactiveCN107043365AQuality improvementIndicator qualifiedOrganic chemistryDistillationReverse osmosis

The invention belongs to the technical field of production of electronic materials, and concretely relates to a membrane process preparation method of electronic-grade 1,3-propanesultone. The method comprises the following steps: standing 1,3-propanesultone in a reactor provided with a molecular sieve, carrying out reduced pressure distillation, removing impurities through a nanofiltration device, concentrating the obtained 1,3-propanesultone through a disc tube type reverse osmosis device, and allowing the obtained 1,3-propanesultone to pass through the glass column of the molecular sieve. The acid value of the prepared 1,3-propanesultone is stably controlled in a required range, all indexes of the prepared 1,3-propanesultone are qualified, the quality of the prepared 1,3-propanesultone is stable, the water content and the sodium content of the prepared 1,3-propanesultone are further reduced and are better than electronic grade standards, and the indexes of the prepared 1,3-propanesultone exceed those of most existing electronic-grade 1,3-propanesultone.

Owner:武汉松石科技股份有限公司

Etamsylate injection and preparation method thereof

InactiveCN107308105ARaise quality standardsSolve the problem of unstable pHOrganic active ingredientsInorganic non-active ingredientsSulfite saltSodium bisulfite

The present invention relates to a kind of ethylamine injection and preparation method thereof, the components of ethylamine injection are proportioned according to the following concentration: ethylamine is 120g / L to 130g / L; sodium bisulfite 1.65g / L to 1.85g / L; sodium sulfite 0.23g / L to 0.27g / L; solvent is water for injection.

Owner:BEIJING LISHIDA PHARMA

Compound notoginsen triterpenes puerarin preparation

InactiveCN1836680AGood dose-response relationshipGood inhibitory effectPowder deliveryOrganic active ingredientsDiseaseAdditive ingredient

The present invention is compound total arasaponin-puerain preparation, and features that total arasaponin in 21-82 wt% and puerain in 18-79 wt% as well as proper amount of medicinal or food supplementary material are produced into medicine or food preparation. The compound total arasaponin-puerain preparation has the synergistic effects of regulating blood function, treating cardiac and cerebral vascular diseases, lowering serum total cholesterol and triglyceride, reducing blood viscosity, improving micro circulation, etc.

Owner:云南一尧科技开发有限公司

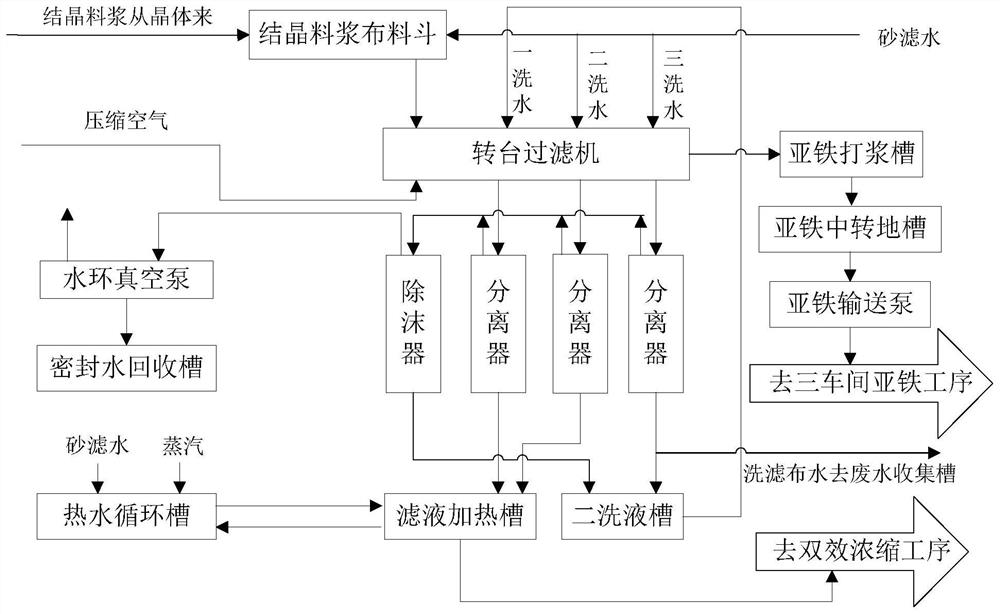

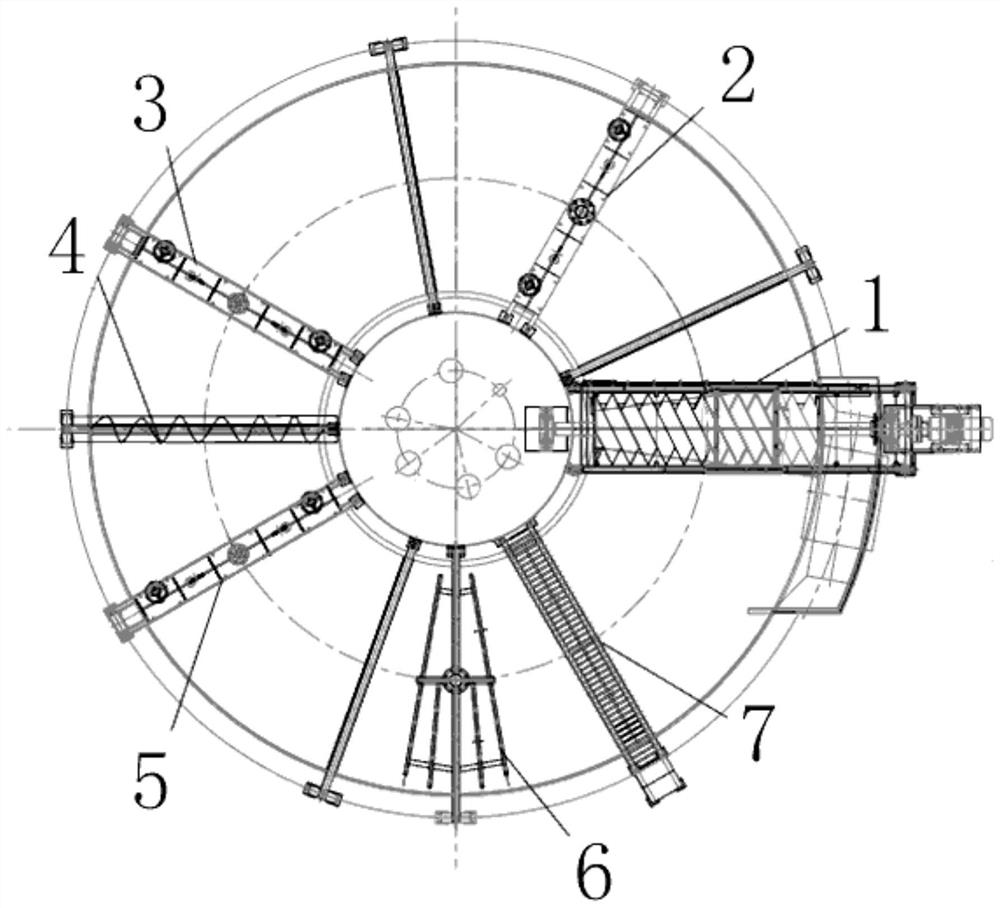

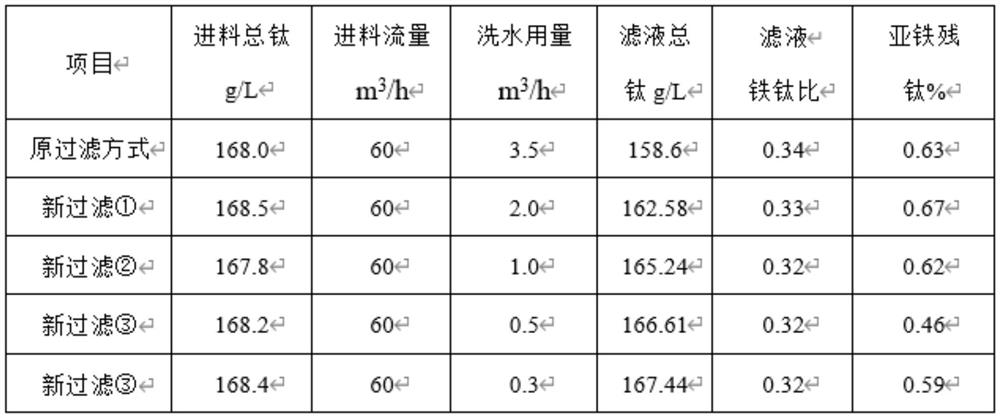

Vacuum rotary table filter and filtering process

PendingCN114130106AReduce the amount of dissolutionReduce titanium contentMoving filtering element filtersFerrous sulfate ironWater flow

The invention discloses a vacuum rotary table filter and a filtering process, and belongs to the technical field of titanium dioxide production, equipment advantages are utilized to monitor the content of residual titanium in filtered ferrous iron and the content of iron in titanium liquid, and the filtering feeding amount and the washing water flow are controlled through automatic interlocking, so that the filtering efficiency is improved. The quality fluctuation of the titanium liquid caused by manual regulation and control of water quantity is reduced, and the cost is reduced and the efficiency is improved; a three-washing process is adopted, so that the influence on the concentration of the titaniferous solution is reduced while ferrous separation is realized, and the dissolved amount of ferrous in the titaniferous solution is reduced; ferrous sulfate blocked in filter holes of the filter cloth is dredged by adopting a compressed air back flushing method, so that continuous and high-efficiency filtration is realized; by adding one or more scrapers and spray pipes matched with the scrapers, ferrous heptahydrate crystals are progressively washed, filtered and discharged one by one for multiple times in multiple layers, so that the filtering effect is improved, the content of titanium entrained in ferrous sulfate is reduced, the titanium yield is further improved, and the service life of filter cloth is prolonged.

Owner:XIANGYANG LOMON TITANIUM IND CO LTD

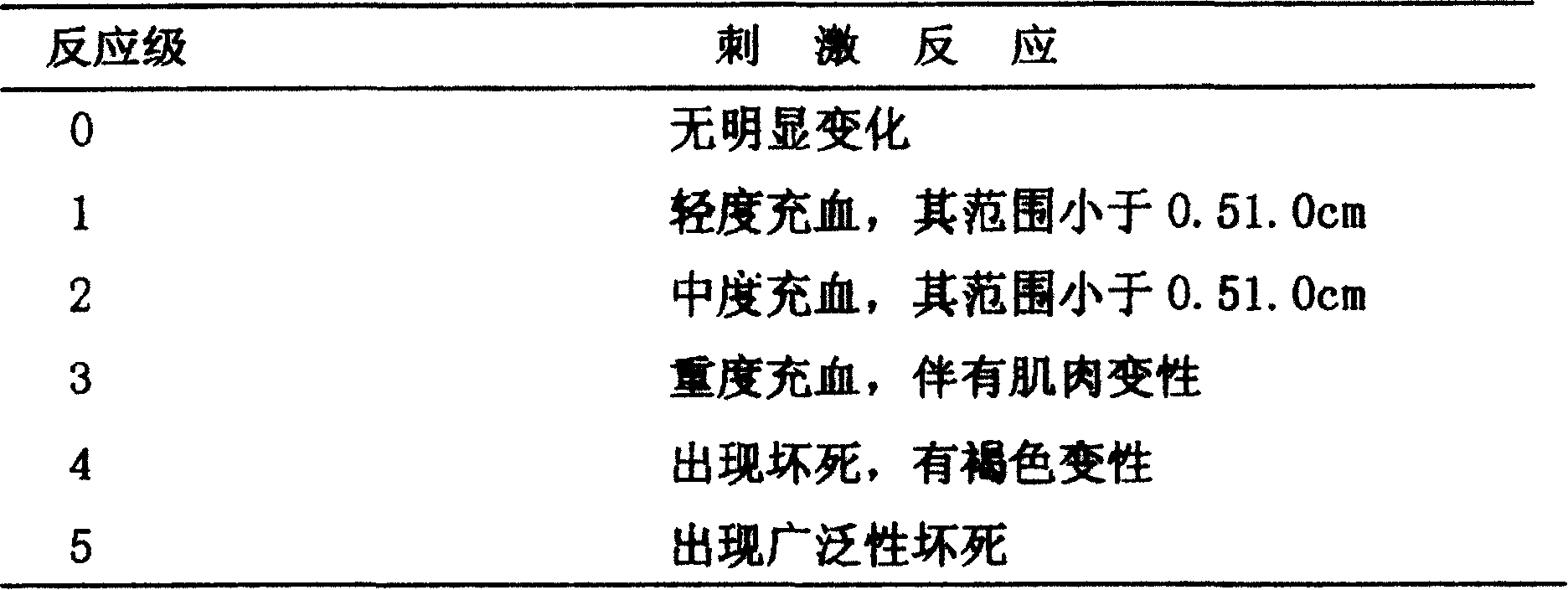

Aconitum kusnezoffii methylsine aerosol and its preparation method

InactiveCN1535683AImprove stabilityIndicator qualifiedOrganic active ingredientsAntipyreticFlavorMedicine

The present invention provides an aconitum kusnezoffii methylsine aerosol and its preparation method. Every ml contains 0.01-0.8 mg of aconitum kusnezoffii methylsine, it can be made into the pharmaceutically-aceptable aerosol, and it can use methol or camphor, etc. which is 0.05-10% of main medicine content as medial permeation p romotor, and can use coumarinic lactone or vanillin, etc. which is 0.002-5% of main medicine content as medical perfume. Said invention has good stability, can be stored for 4 years at normal temp., is small in irritation, can be quickly absorbed and can quickly produce action, and can be used for relieving inflammation and stopping pain obviously.

Owner:KUNMING ZIJIAN BIOTECH

Fat milk infusion with biological activity and production thereof

A bioactive intralipid perfusion is proportionally prepared from p-kaurane diterpenoid and the medical assistant able to provide high-energy fatty acid or its derivative. Its advantages are high biologic utilization rate and stability and no irritation.

Owner:云南一尧科技开发有限公司

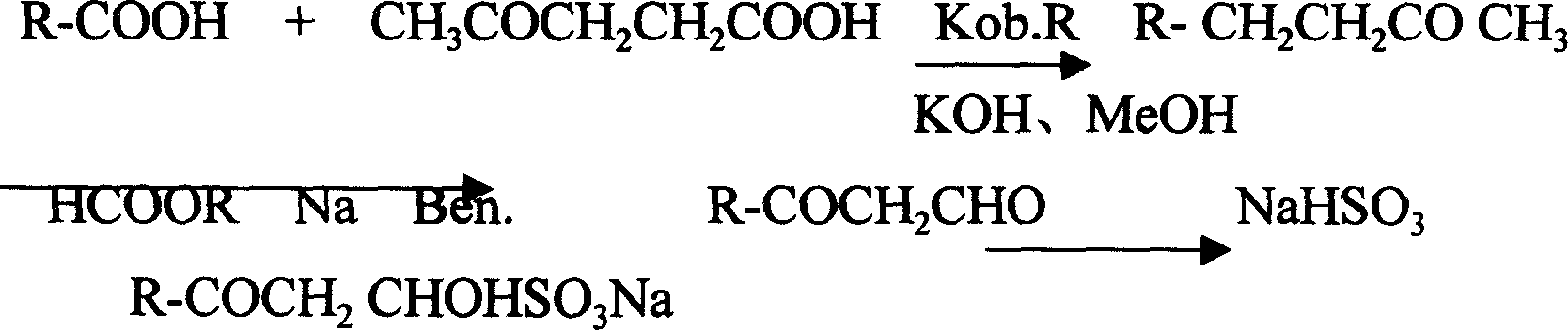

Fatty acyl acetaldehyde transfusion preparation and its preparing method

InactiveCN1647795AIndicator qualifiedMeet the requirements for injectionOrganic active ingredientsAntipyreticUrinary systemIrritation

The present invention provides a kind of fatty acyl acetaldehyde transfusion preparation. The fatty acyl acetaldehyde transfusion preparation includes fatty acyl acetaldehyde as bioactive component and medicinal supplementary material, and features that each dose contains fatty acyl acetaldehyde in 8-100 mg, wherein fatty acyl acetaldehyde is R-COCH2CHO, with R being C8-C14 hydrocarbon compound. The present invention has the effects of clearing away heat and toxic material, eliminating pus, promoting diuresis and relieving stranguria, and has high curative effect, certain delayed releasing effect, no irritation and no toxic side effect.

Owner:KUNMING ZIJIAN BIOTECH

Spray agent of dried powder in use for diminishing inflammation of mucous membrane and preparation method

A powder spray for relieving the inflammation of mucosa is prepared from Yunnan white medicine and the filming auxiliary with high affinity to mucosa. Its advantages are high curative effect and no irritation.

Owner:KUNMING ZIJIAN BIOTECH

Fibrauretine-amino acid fluid for transfusion and its production process

InactiveCN1608615AEasy to operateIndicator qualifiedAntibacterial agentsSenses disorderDiseaseIrritation

The present invention provides one kind of fibrrauretine-amino acid fluid for transfusion and features that each bottle of medicine contains fibrrauretine in 0.02-0.50 g, amino acid 25-60 g, auxiliary medicine 0-10 g and medicinal supplementary material. The present invention may be used a tonic for preventing and treating diseases and may be also injected to patient after some essential treating medicines are added to result in both treating and nourishing effects. Experiment shows that the present invention has high stability, no irritation, and certain antibiotic and antiphlogistic effect.

Owner:KUNMING ZIJIAN BIOTECH

Infusion of gen-seng, lilyturf root and amino acid and its preparing method

InactiveCN1634187AImprove instabilityIndicator qualifiedMetabolism disorderPharmaceutical delivery mechanismAdjuvantMedicine

The invention discloses a Shenmai fluid infusion, which comprises biologically active Shenmai and amino acid for supplying nutrition and energy, and medicinal adjuvant. promoting blood circulation and removing blood stasis.

Owner:KUNMING ZIJIAN BIOTECH

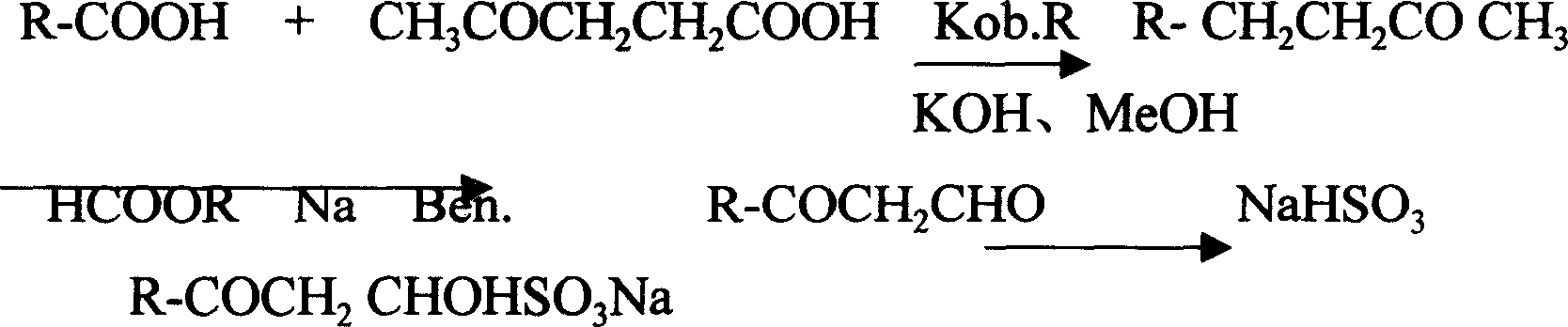

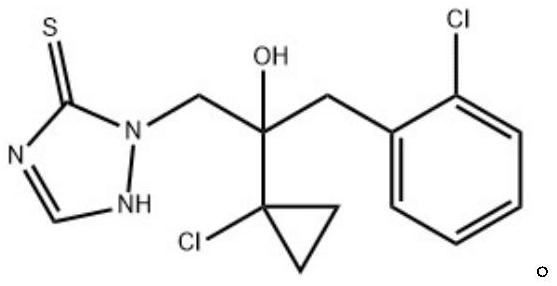

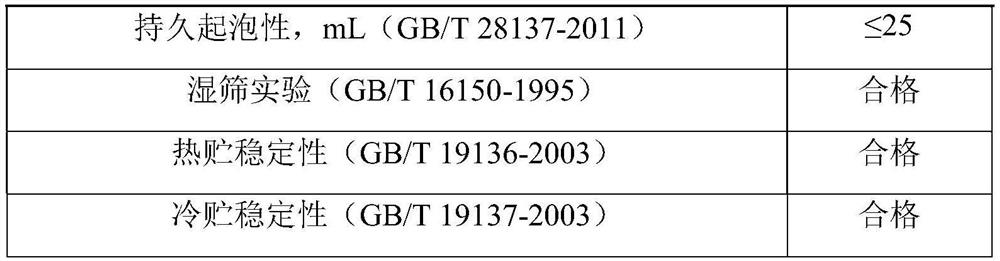

Prothioconazole microcapsule suspending agent as well as preparation method and application thereof

PendingCN114586795AExcellent performanceExcellent storage stabilityBiocideFungicidesIsocyanateAntifoam agent

The invention relates to a prothioconazole micro-capsule suspending agent and a preparation method and application thereof.The prothioconazole micro-capsule suspending agent comprises a micro-capsule core, the micro-capsule core is prothioconazole, the content of prothioconazole in the prothioconazole micro-capsule suspending agent is 1-20% by mass, the micro-capsule suspending agent further comprises a micro-capsule wall, the content of prothioconazole in the micro-capsule suspending agent is 1-20% by mass, and the content of prothioconazole in the micro-capsule wall is 1-20% by mass. The capsule wall of the microcapsule is made of polyurea or polyurethane, and the polyurea is generated by carrying out polymerization reaction on a polymeric monomer isocyanate and a polymeric monomer polyamine; the polyurethane is generated by polymerization reaction of a polymeric monomer isocyanate and a polymeric monomer polyol. The prothioconazole microcapsule suspending agent further comprises a solvent, an emulsifying agent, a dispersing agent, an anti-freezing agent, a thickening agent, a preservative, a defoaming agent and a dispersing medium. The prothioconazole microcapsule suspending agent provided by the invention is good in performance, has a longer lasting period compared with a conventional dosage form, can reduce the prevention and treatment cost of wheat scab, and has a good popularization value.

Owner:宁夏苏融达化工有限公司 +1

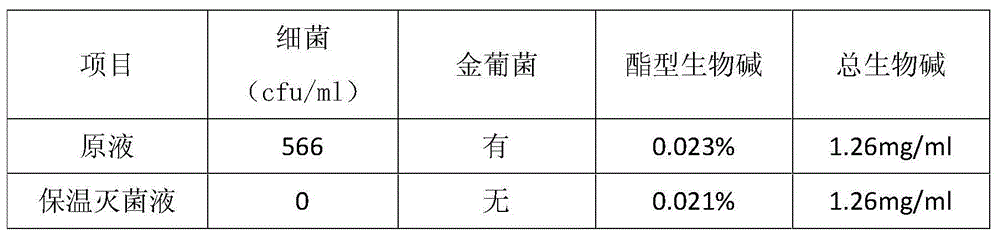

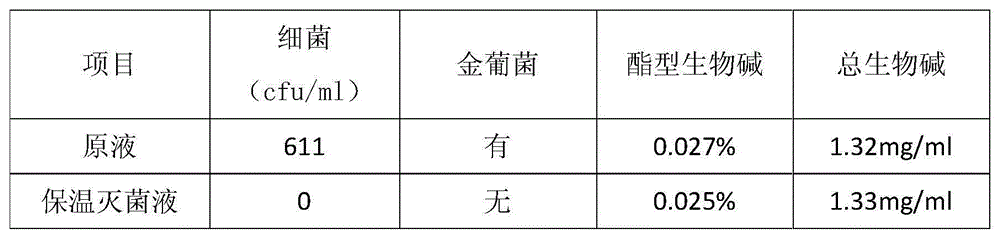

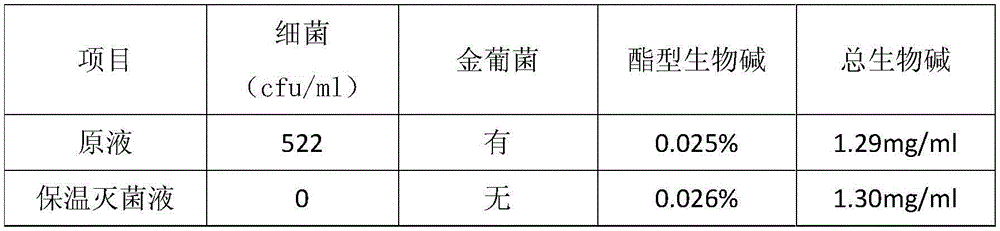

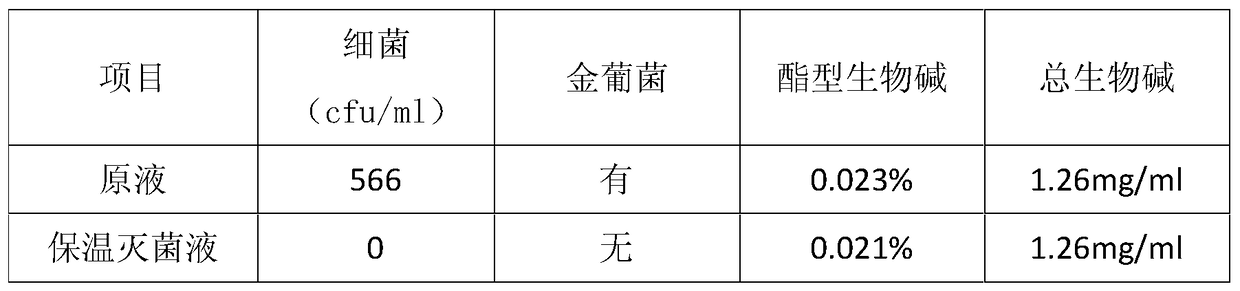

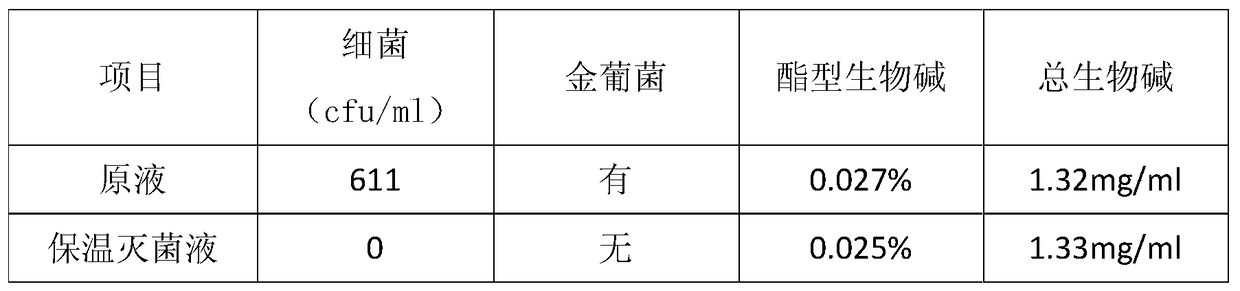

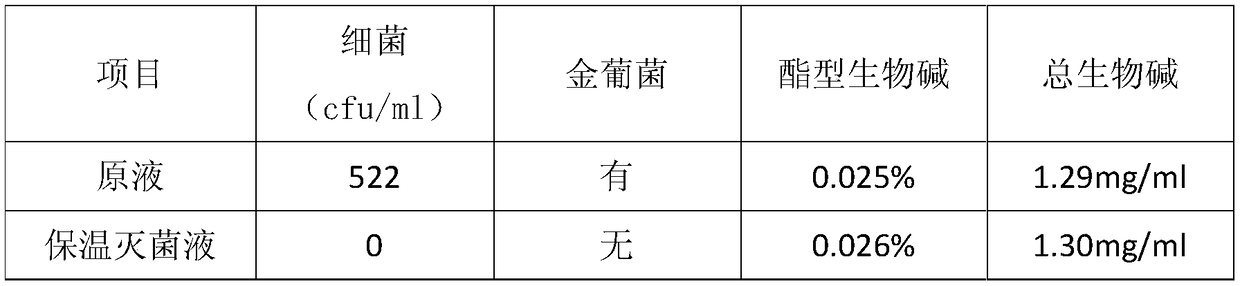

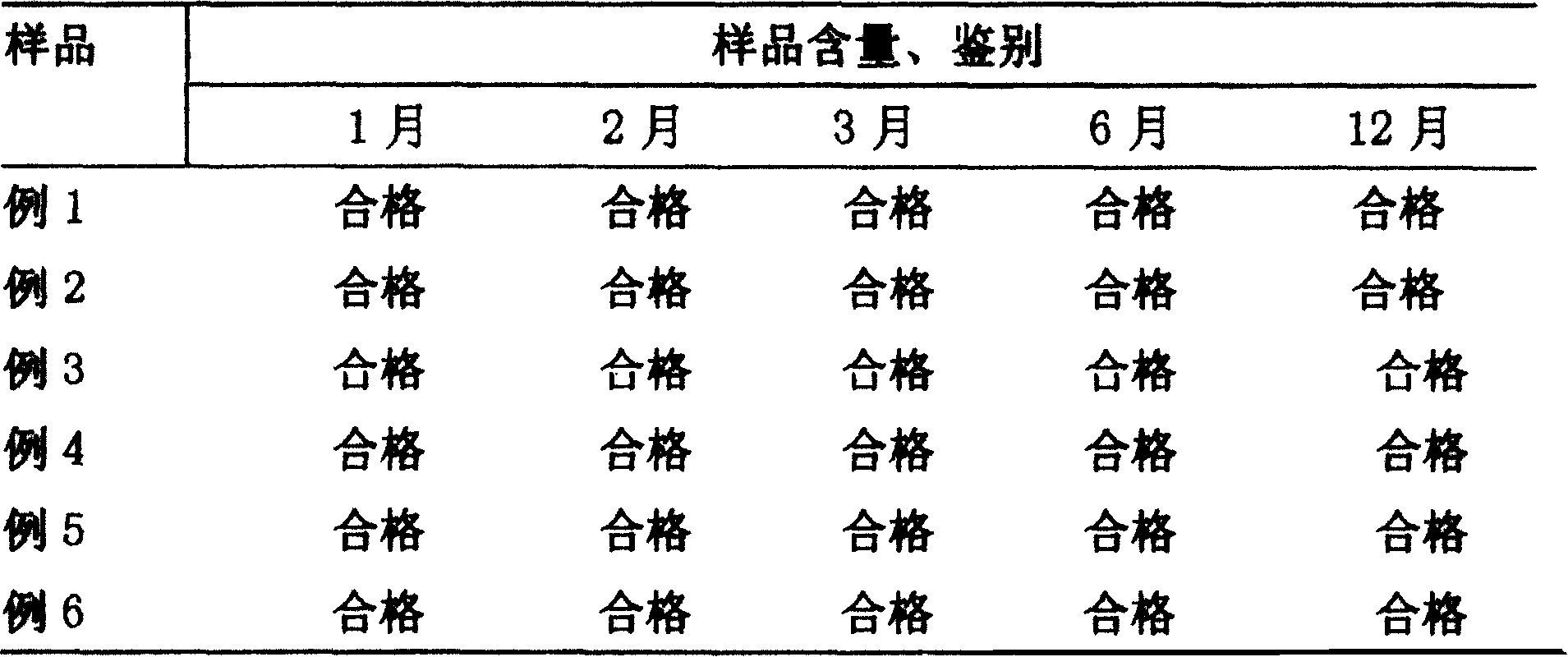

Sterilization method for traditional Chinese medicine preparation

The invention provides a sterilization method for a traditional Chinese medicine preparation. The traditional Chinese medicine preparation is an alcohol extracting solution. The sterilization method comprises the following steps: heating the alcohol extracting solution, preserving the heat and sterilizing. The sterilization method is simple and convenient, practical, efficient, and capable of completely solving a problem that microorganisms in the drug production are unqualified, and avoiding active ingredients in the medical materials from losing.

Owner:SUNFLOWER PHARMA GRP CHONGQING CO LTD

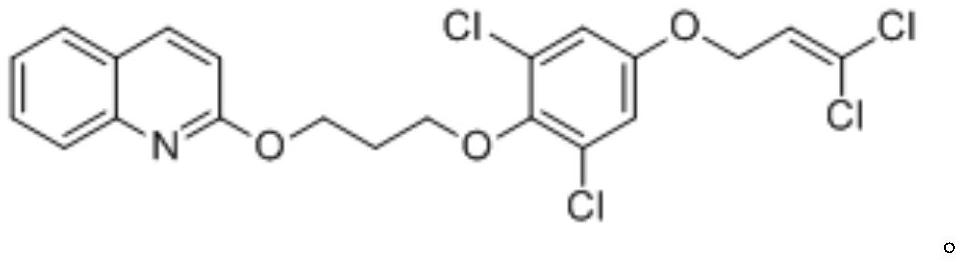

Propinoxaden microcapsule suspending agent as well as preparation method and application thereof

PendingCN114868754AMicroencapsulationImprove performanceBiocideAnimal repellantsPolymer scienceSuspending Agents

The invention relates to a pyriproxyfen microcapsule suspending agent and a preparation method and application thereof.The pyriproxyfen microcapsule suspending agent comprises a microcapsule core, the microcapsule core is pyriproxyfen, the content of pyriproxyfen in the pyriproxyfen microcapsule suspending agent is 1%-10% by mass, the microcapsule suspending agent further comprises a microcapsule wall, and the microcapsule wall is made of water. The capsule wall of the microcapsule is made of polyurea or polyurethane, and the polyurea is generated by carrying out polymerization reaction on a polymeric monomer isocyanate and a polymeric monomer polyamine; the polyurethane is generated by polymerization reaction of a polymeric monomer isocyanate and a polymeric monomer polyol. The pyriproxyfen microcapsule suspending agent further comprises a solvent, an emulsifying agent, a dispersing agent, an anti-freezing agent, a thickening agent, a preservative, a defoaming agent and water. The pyriproxyfen microcapsule suspending agent provided by the invention is good in performance, has a longer lasting period compared with a conventional dosage form, can reduce the prevention and control cost of agricultural pests, and has a good popularization value.

Owner:宁夏苏融达化工有限公司 +1

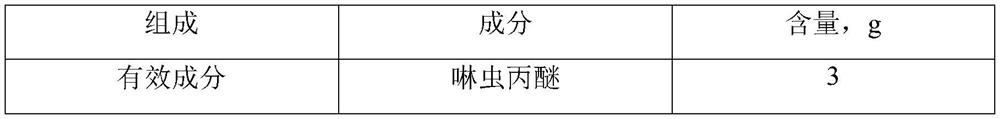

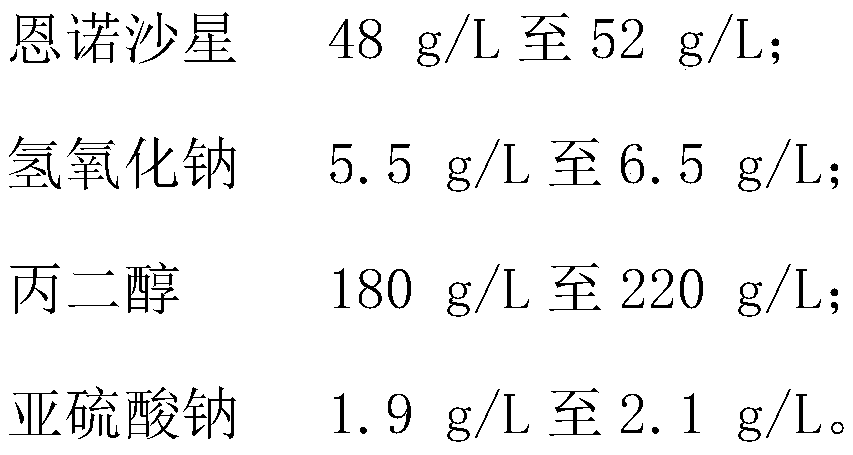

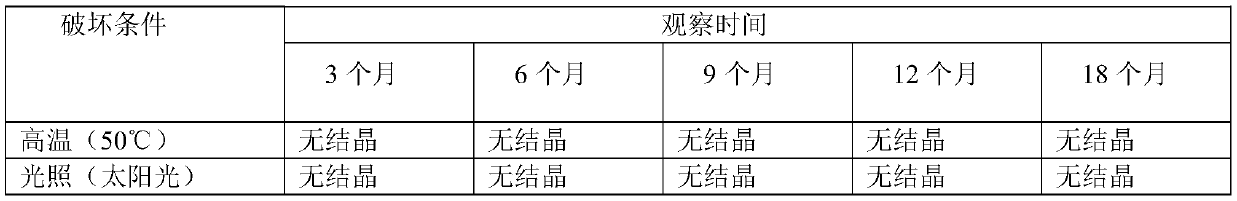

A kind of enrofloxacin injection and preparation method thereof

ActiveCN107362132BRaise quality standardsIncrease dosageOrganic active ingredientsPharmaceutical delivery mechanismBiotechnologyFormulary

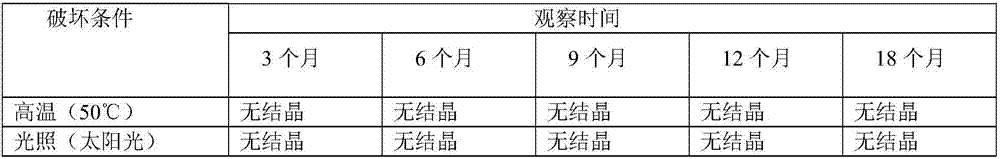

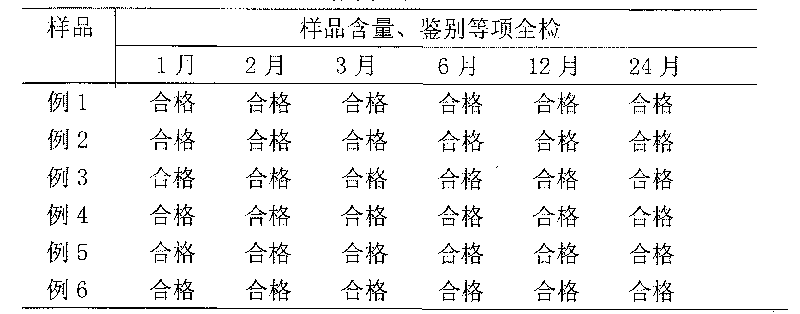

The present invention relates to an enrofloxacin injection and a production method thereof. The enrofloxacin injection comprises enrofloxacin with a concentration of 48-52 g / L, sodium hydroxide with a concentration of 5.5-6.5 g / L, propylene glycol with a concentration of 180-220 g / L, sodium sulfite with a concentration of 1.9-2.1 g / L, and a solvent, wherein the solvent is water for injection. According to the present invention, the use amount of the propylene glycol is increased in the formula or the production process of the enrofloxacin injection, such that the product is stable, and the quality of the product is ensured; specifically various detected indexes are qualified and especially the crystallization problem is effectively solved after the product is stored for more than 2 years; and the product meet the quality standard of the enrofloxacin injection in the new Veterinary Pharmacopoeia of the People's Republic of China, the storage time is prolonged, and it is ensured that various indexes are qualified within the validity period.

Owner:BEIJING LISHIDA PHARMA

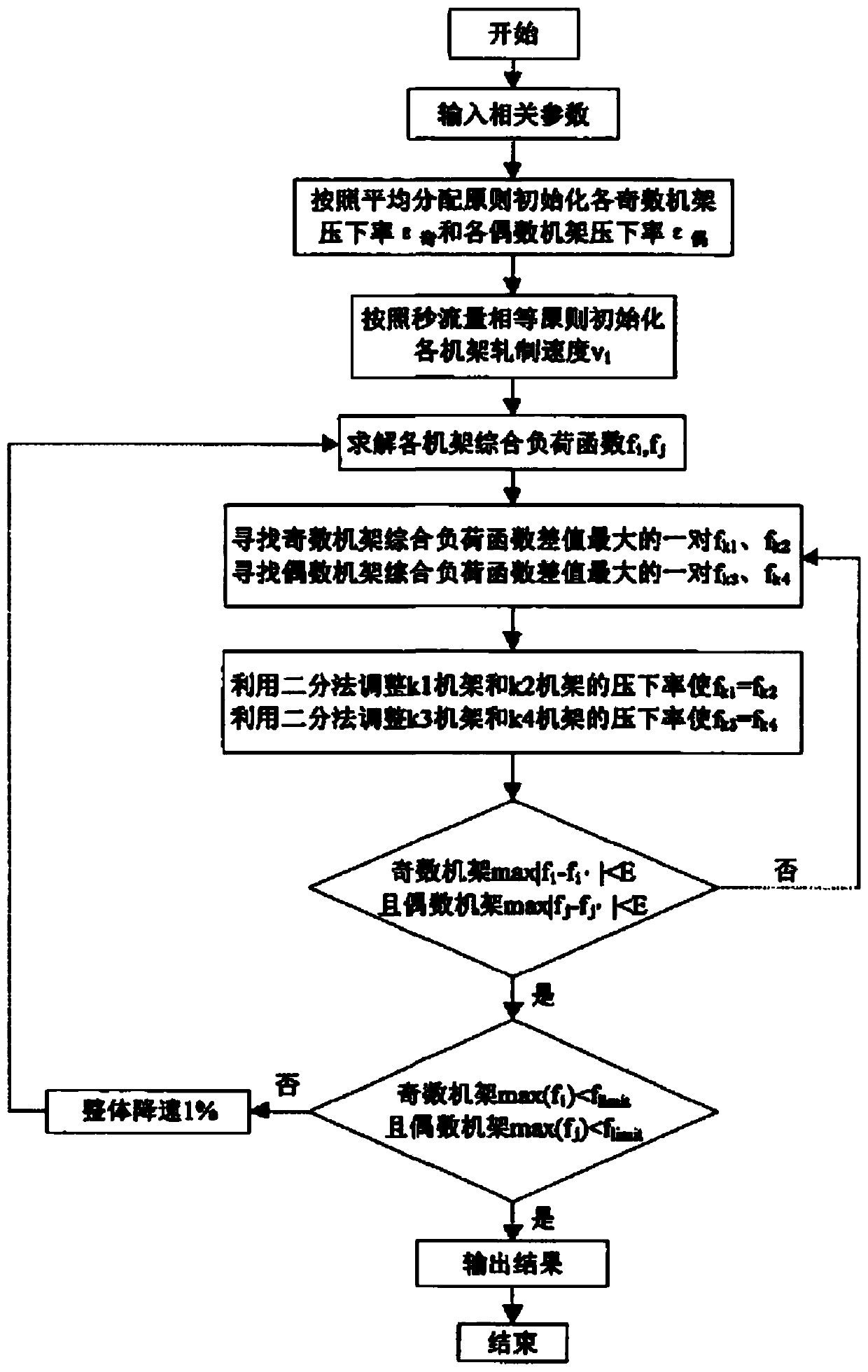

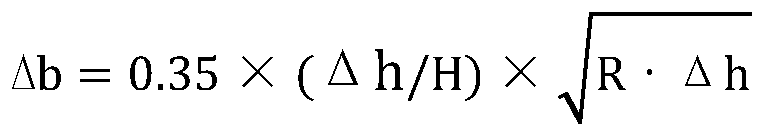

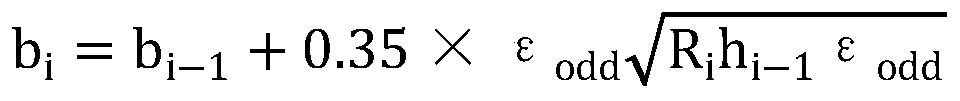

An optimization method for the production process of hot-rolled smooth round steel bar

ActiveCN110551945BImprove performanceImprove product qualityRoll mill control devicesMetal rolling arrangementsRound barRebar

The invention discloses an optimization method for a production process of a hot rolled plain round bar. The optimization method comprises the following steps: optimization of a billet material and optimization of a rough milling process. By scientifically selecting the material and distributing a rough milling load rolling reduction reasonably, equipment ability can be utilized more effectively in a same process condition, the rolling energy consumption is reduced, the yielding strength and the tensile strength of the produced bar are improved, and the bar is uniform in texture and precise insection shape and is qualified in various indexes.

Owner:YANGCHUN NEW STEEL CO LTD

Enrofloxacin injection and production method thereof

ActiveCN107362132AProduct stabilityGuarantee product qualityOrganic active ingredientsPharmaceutical delivery mechanismSodium sulfiteSolvent

The present invention relates to an enrofloxacin injection and a production method thereof. The enrofloxacin injection comprises enrofloxacin with a concentration of 48-52 g / L, sodium hydroxide with a concentration of 5.5-6.5 g / L, propylene glycol with a concentration of 180-220 g / L, sodium sulfite with a concentration of 1.9-2.1 g / L, and a solvent, wherein the solvent is water for injection. According to the present invention, the use amount of the propylene glycol is increased in the formula or the production process of the enrofloxacin injection, such that the product is stable, and the quality of the product is ensured; specifically various detected indexes are qualified and especially the crystallization problem is effectively solved after the product is stored for more than 2 years; and the product meet the quality standard of the enrofloxacin injection in the new Veterinary Pharmacopoeia of the People's Republic of China, the storage time is prolonged, and it is ensured that various indexes are qualified within the validity period.

Owner:BEIJING LISHIDA PHARMA

Lyophilized powder injection of breviscapinum and preparation process thereof

InactiveCN1965848BImprove stabilityIndicator qualifiedOrganic active ingredientsPowder deliveryDiseaseFreeze-drying

The invention relates to a lamp-dish flower freeze dried injection, wherein it comprises lamp-dish flower at 45-57%, 35-47% mannidex, and 8-12% bicarbonate. It has high stability, and since it has high lamp-dish flower content, it has better activate blood circulation and remove stasis functions, with simple application. Via cute toxic test, its LD50 is higher than prevent lamp-dish flower. The invention can improve treatment effect on blood circulation diseases, etc.

Owner:王锦

Process for regenerating hot-wet clay sand for 100% core production

PendingCN114850394AIndicator qualifiedLow costSolid waste managementFoundry mouldsWater treatment systemProcess engineering

The invention discloses a hot-wet process clay sand regeneration 100% core production technology, and particularly relates to the technical field of sand core production, the hot-wet process clay sand regeneration 100% core production technology comprises the following steps: demoulding: using a demoulding machine to carry out secondary demoulding and dedusting treatment on casting waste sand, removing mud and ash in the casting waste sand, and carrying out secondary demoulding and dedusting treatment on the casting waste sand; according to the hot method, resin films on the surfaces of sand grains and pulverized coal in clay sand are burnt out through high-temperature roasting, according to the wet method, casting waste sand is washed for 40-50 minutes through a scrubbing machine, blades in the scrubbing machine rotate to rub with the casting waste sand, mud and clay films in the casting waste sand are washed away through cooperation of water, and washing wastewater is recycled after the mud is filtered out through a water treatment system. And acidizing treatment: acidizing the circulating water. According to the method, 100% of the regenerated clay sand can be used for core making, the acid consumption value and the mud content of the treated regenerated sand are low, indexes are qualified, the regenerated sand can be used without being matched with new sand, and the cost is reduced.

Owner:山西三联顺驰汽车配件有限公司

A profile control agent/water blocking agent polymerization curing device and its working method

ActiveCN111468053BImprove reaction efficiencyNo implosion phenomenonChemical liquid solidificationDrilling compositionLiquid stateEngineering

The invention relates to a profile control agent / water shutoff agent polymerization curing device and its working method, which belongs to the technical field of profile control agent / water shutoff agent processing and processing, and includes a curing device main body, a detachable plugging plate is arranged at the bottom thereof, and An extrusion device and several heat exchange tubes are arranged inside; the extrusion device includes an extrusion plate and a power device that drives the extrusion plate to move up and down; several heat exchange tubes are evenly distributed in the main body of the curing device along the vertical direction, and the main body of the curing device The upper part is provided with a water inlet and a water outlet A, and the water inlet and the water outlet A are connected with a water circulation system, which is used to regulate the temperature of the water in several heat exchange tubes, heat and dissipate heat for the product; A heat exchange tube is arranged in the hole. The present invention can adjust the temperature of the reaction environment during the solidification process of the profile control agent / water shutoff agent in the liquid state, and improve the reaction efficiency. Productivity.

Owner:大庆市新万通科技开发有限公司

Injection solution of freezes dried powder of fibrauretine, and preparation method

InactiveCN101049306AReliable productGood appearance qualityPowder deliveryOrganic active ingredientsUrologyFreeze dry

A freeze-dried powder injection of fibrauretin for treating the diseases in urinary system, especially woman's urinary tract, is proportionally prepared from fibrauretin and mannitol. Its preparing process is also disclosed.

Owner:王锦

A kind of sterilization method of traditional Chinese medicine preparation

The invention provides a sterilization method for a traditional Chinese medicine preparation. The traditional Chinese medicine preparation is an alcohol extracting solution. The sterilization method comprises the following steps: heating the alcohol extracting solution, preserving the heat and sterilizing. The sterilization method is simple and convenient, practical, efficient, and capable of completely solving a problem that microorganisms in the drug production are unqualified, and avoiding active ingredients in the medical materials from losing.

Owner:SUNFLOWER PHARMA GRP CHONGQING CO LTD

Helicid powder injection preparation and its preparation method

InactiveCN1212844CImprove stabilityIndicator qualifiedPowder deliveryOrganic active ingredientsConvulsionSedation

Owner:KUNMING ZIJIAN BIOTECH

Fibrauretine powder for injection and its production process

InactiveCN100381120CGood effectImprove complianceAntibacterial agentsPowder deliveryCurative effectPharmacology

The present invention provides one kind of fibrrauretine powder for injection and features that each ampule contains fibrrauretine in 0.02-0.50 g and one or several kinds of medicinal supplementary material. Compared with available fibrrauretine tablet and fibrrauretine injection, the fibrrauretine powder with fibrrauretine microcapsule for injection has increased dosage, obviously raised medicinal effect and obviously higher compatibility, delayed release and targeting property. The present invention has stable product quality and obvious curative effect.

Owner:KUNMING ZIJIAN BIOTECH

Energy-saving heat tank

The invention provides an energy-saving heat tank. The energy-saving heat tank comprises an outer cylinder, a top plate, a bottom plate, an electrical heating tube and a helix tube; the top end of theouter cylinder is in sealing connection with the top plate, the bottom end of the outer cylinder is in sealing connection with the bottom plate, the energy-saving heat tank further comprises an innercylinder arranged in a cavity of the outer cylinder, an empty area included in that a straight line where the center axis of the inner cylinder locates extends outward to the inner side wall of any cylinder is an inner cavity, an empty area included in the outer cylinder and the outer side wall of an adjacent cylinder is an outer cavity; a water channel is arranged between the upper end of the inner cylinder and the lower surface of the top plate, the lower end of the inner cylinder is in sealing connection with the bottom plate; the electrical heating tube is fixed on the top plate or the bottom plate, a heating part of the electrical heating tube extends into the inner cavity; the helix tube is arranged in the outer cavity or winds on the outer side wall of the cylinder adjacent to theouter cylinder; an upper opening and lower opening of the helix tube both run through the outer cavity; the bottom plate is provided with a water inlet communicated with the inner cavity, and the outer cylinder or the bottom plate is provided with a water outlet communicated with the outer cavity. Compared with the prior art, the scheme has a significant energy-saving effect and low cost.

Owner:JIANGSU CIKON ENVIRONMENTAL APPLIANCE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com