Environment-friendly soldering paste and preparing method thereof

A solder paste, environmental protection technology, applied in the direction of welding equipment, welding medium, manufacturing tools, etc., can solve the problems of physical and environmental hazards, failure of electronic product parts, etc., and achieve the effect of good printing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] An environmentally friendly solder paste is composed of 90wt% solder powder and 10wt% solder paste, and the solder powder is composed of the following weight ratios:

[0029] Silver (Ag) 2%

[0030] Copper (Cu) 0.5%

[0031] Tin (Sn) 97.5%;

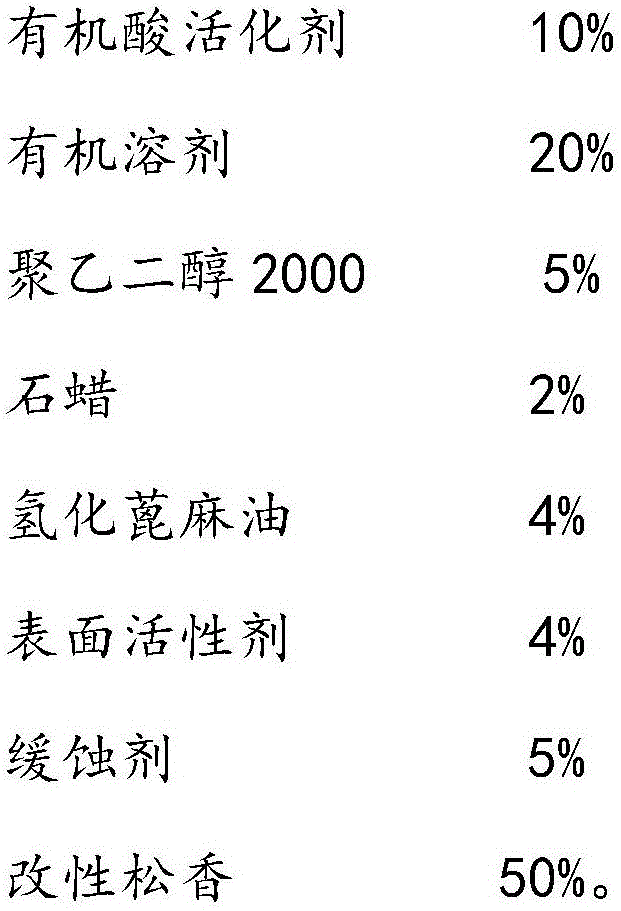

[0032] Described flux paste is made up of the material of following weight ratio:

[0033]

[0034]

[0035] Concrete preparation method comprises the following steps:

[0036] 1. Preparation of solder powder

[0037] Put tin, silver and copper in the container, stir and mix to become solder powder;

[0038] 2. Preparation of solder paste

[0039] Put the organic solvent and organic acid activator in a reaction kettle with a stirrer, heat to 110°C-130°C, stir to mix evenly, after the solid content is completely dissolved, add the modified rosin; after it is completely dissolved Add corrosion inhibitor, hydrogenated castor oil and surfactant; after they are mixed evenly, add paraffin wax and polyethylene glycol 2000, sti...

Embodiment 2

[0042] An environmentally friendly solder paste is composed of 90wt% solder powder and 10wt% solder paste, and the solder powder is composed of the following weight ratios:

[0043] Silver (Ag) 2%

[0044] Copper (Cu) 0.5%

[0045] Tin (Sn) 97.5%;

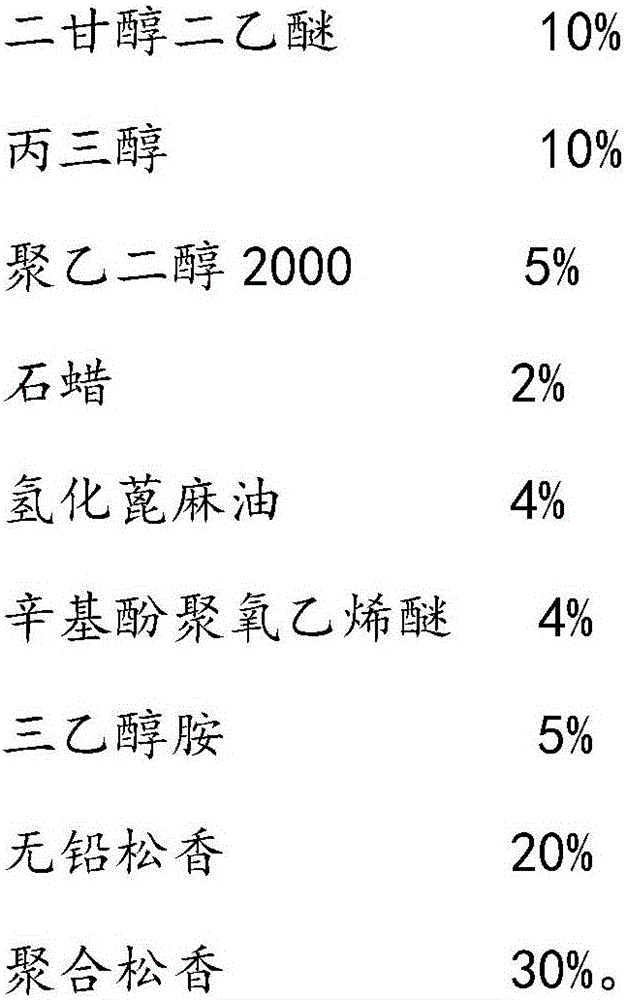

[0046] Described flux paste is made up of the material of following weight ratio:

[0047]

[0048] Concrete preparation method is identical with embodiment 1.

Embodiment 3

[0050] An environmentally friendly solder paste is composed of 90wt% solder powder and 10wt% solder paste, and the solder powder is composed of the following weight ratios:

[0051] Silver (Ag) 2%

[0052] Copper (Cu) 0.5%

[0053] Tin (Sn) 97.5%;

[0054] Described flux paste is made up of the material of following weight ratio:

[0055]

[0056]

[0057] Concrete preparation method is identical with embodiment 1.

[0058] The solder pastes of Examples 1-3 above were inspected according to the standard SJ / T11188, and the indicators are shown in Table 1 below.

[0059] Table 1

[0060]

[0061] After testing, the solder paste of the present invention does not contain halogen, and the insulation resistance of the printed board after welding and power-on wet test is >1.8×10 9 Ω, expansion rate ≥ 75%, solder paste physical stability, copper mirror corrosion test, viscosity are all qualified, the residue after soldering is a colorless and transparent film, stable at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com