Low-content modified rosin halogen-free soldering flux for lead-free solder wires

A lead-free soldering technology with low content, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., to achieve good air tightness, improve solderability, and overcome adverse phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The low-content modified rosin-type halogen-free flux for lead-free solder wire of the present embodiment has components and weight percentages as follows:

[0031] DL malic acid 2.25%

[0032] Succinic Acid 4.5%

[0033] Glutaric acid 2.25%

[0034] Tween 20 2%

[0035] Span 60 3%

[0036] Benzotriazole 0.01%

[0037] Hydroquinone 0.1%

[0038] Ethylene bis stearamide 4%

[0039] Water white rosin 3%

[0040] Polymerized Rosin 2%

[0041] Absolute Ethanol 12.8%

[0042] Nitroethane 25.6%

[0043] Tetrahydrofurfuryl alcohol 25.67%

[0044] Diethylene glycol monoethyl ether 12.82%

[0045] Specific preparation method:

[0046] Weigh each component by weight percentage, put the organic solvent in a reaction kettle with a stirrer at room temperature, heat it slowly to 30°C, add modified rosin while stirring until it is completely dissolved, then add activator, surface Active agent, corrosion inhibitor, antioxidant and film-forming agent are continuously stirre...

Embodiment 2

[0049] The low-content modified rosin-type halogen-free flux for lead-free solder wire of the present embodiment has components and weight percentages as follows:

[0050] DL malic acid 2%

[0051] Succinic acid 2%

[0052] Adipic acid 8%

[0053] Tween 60 1%

[0054] Span 60 3%

[0055] Benzotriazole 0.01%

[0056] Triethylamine 0.02%

[0057] tert-butylhydroquinone 0.25%

[0058] Ethylene bis stearic acid amide 1%

[0059] Polyacrylamide 3000000 1%

[0060] Water white rosin 3%

[0061] Lead-free Rosin 3%

[0062] Absolute Ethanol 12.61%

[0063] Tetrahydrofurfuryl alcohol 37.87%

[0064] Diethylene glycol monoethyl ether 25.24%

[0065] Specific preparation method:

[0066]Weigh each component by weight percentage, first place the organic solvent in a reaction kettle with a stirrer at normal temperature, and slowly heat to 35° C., and the rest are the same as in Example 1.

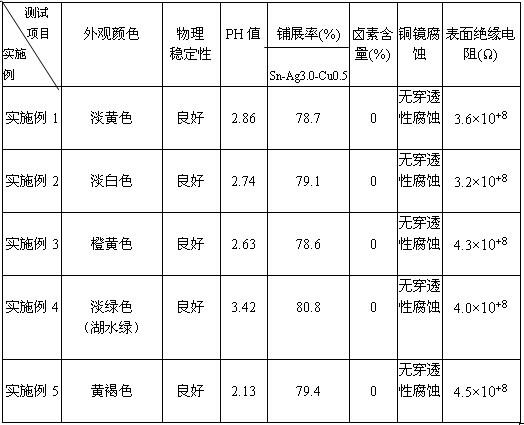

[0067] The test results of various performance parameters are shown in Example 2 in...

Embodiment 3

[0069] The low-content modified rosin-type halogen-free flux for lead-free solder wire of the present embodiment has components and weight percentages as follows:

[0070] DL malic acid 4.5%

[0071] Succinic Acid 4.5%

[0072] Adipic acid 9%

[0073] Span 20 2%

[0074] Span 60 1%

[0075] Benzotriazole 0.1%

[0076] Triethylamine 0.1%

[0077] 2,5-tert-Butylhydroquinone 0.15%

[0078] Polyethylene glycol 2000 2%

[0079] Polymerized Rosin 4%

[0080] Disproportionated Rosin 4%

[0081] Absolute Ethanol 17%

[0082] Nitroethane 34.43%

[0083] Tetrahydrofurfuryl alcohol 17.22%

[0084] Specific preparation method:

[0085] Weigh each component by weight percentage, first place the organic solvent in a reaction kettle with a stirrer at normal temperature, and slowly heat to 40° C., and the rest are the same as in Example 1.

[0086] The test results of various performance parameters are shown in Example 3 in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com