Rotary oil smoke filter

A technology of oil fume filter and oil fume filtration, which is applied in the direction of oil fume removal, dispersed particle filtration, heating method, etc., which can solve the problems of easy accumulation of condensed oil, low efficiency of condensation and settlement, and difficult cleaning, etc., to ensure long-term maintenance Stable work, reliable and sufficient oil fume separation, and small wind pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

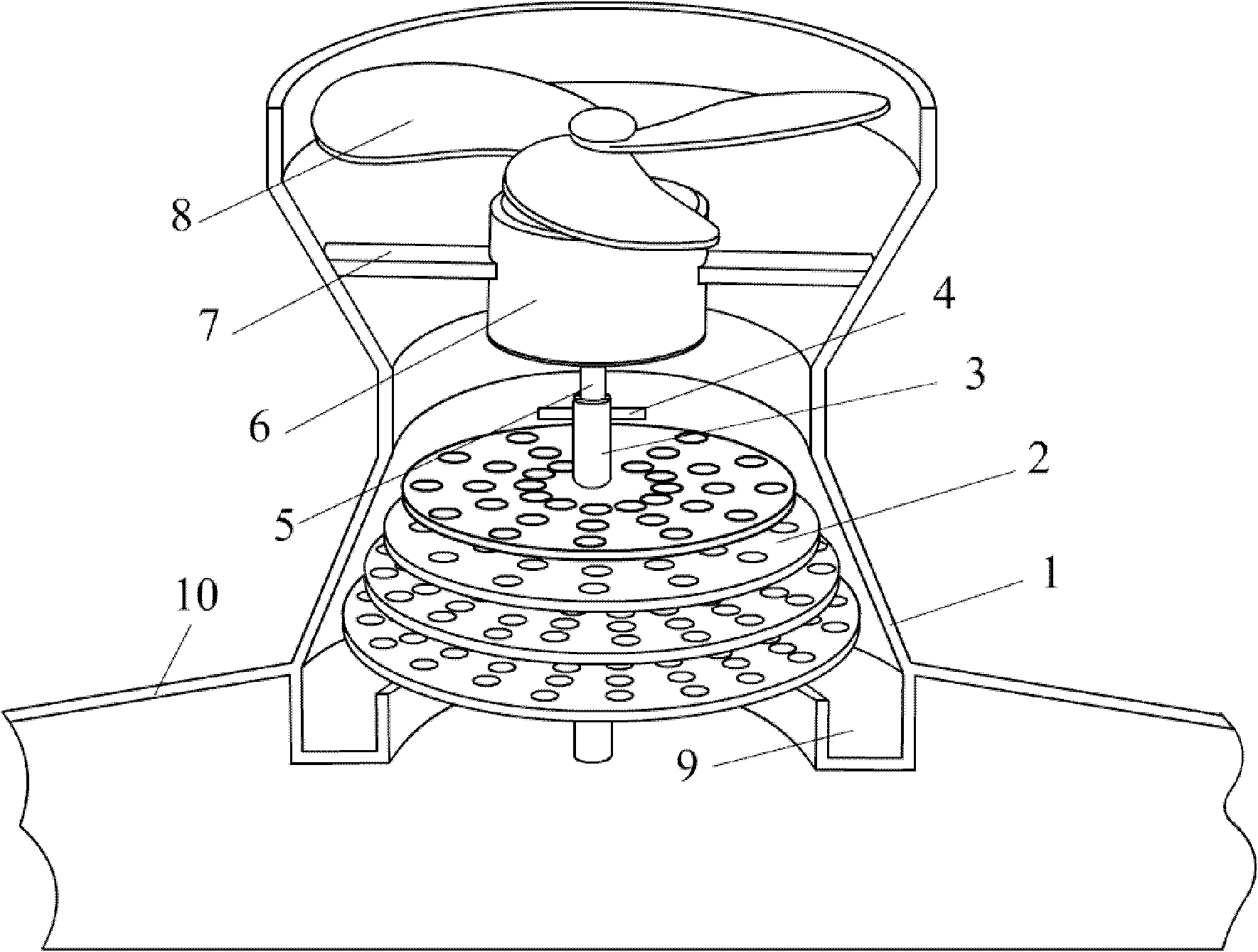

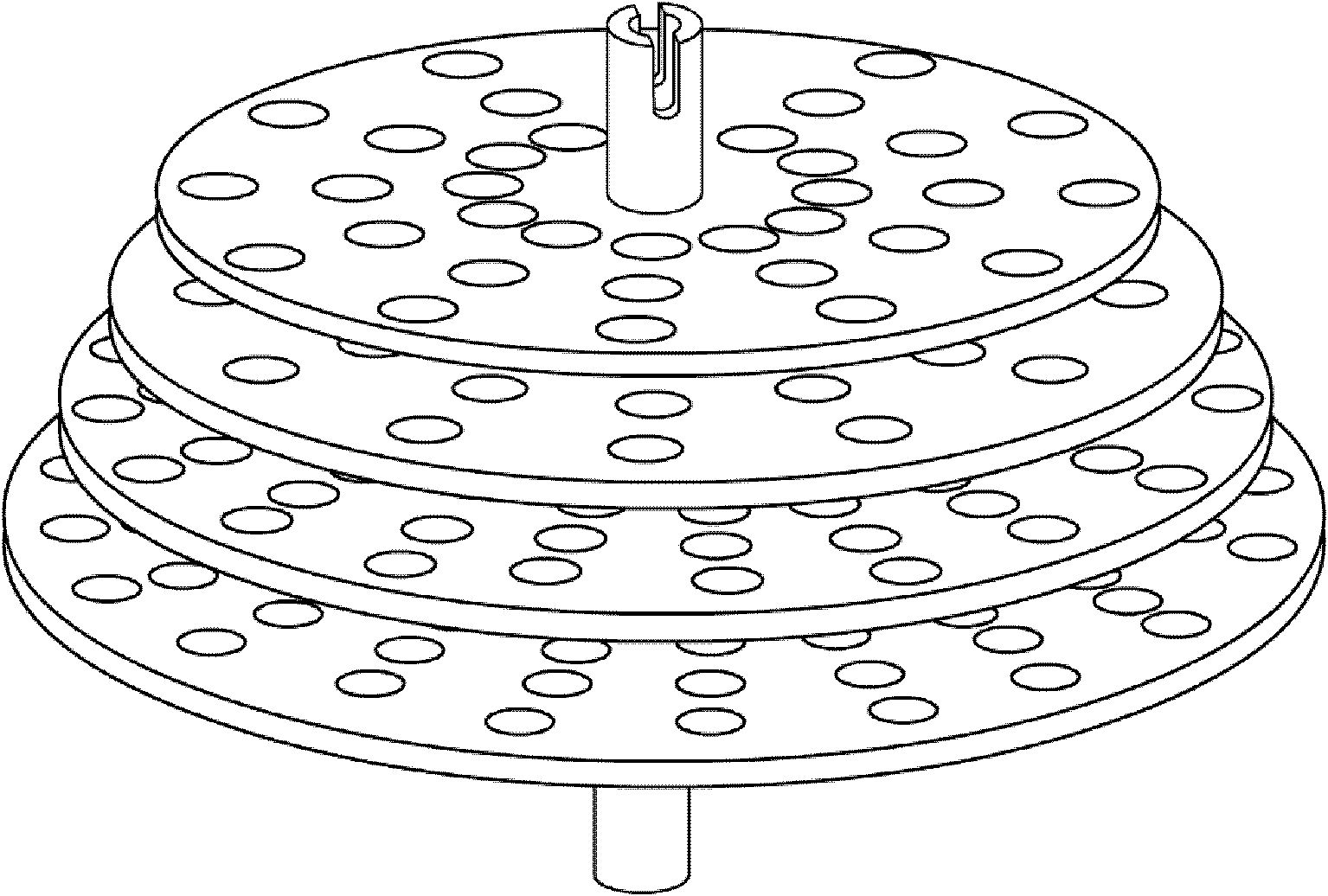

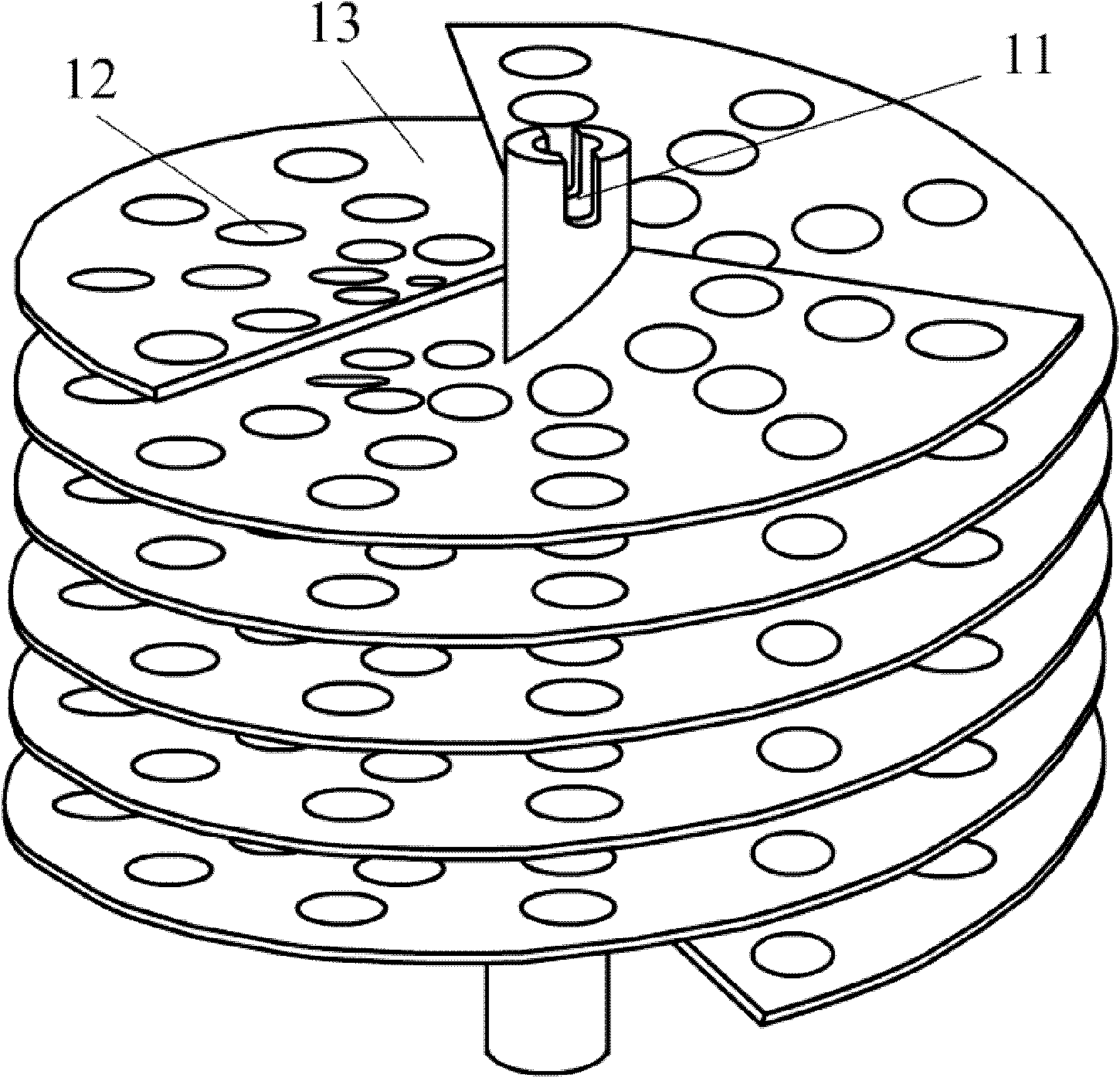

[0025] exist figure 1 In the shown embodiment, the dual-shaft output motor is fixed on the bracket at the throat of the Venturi tube purification device, the impeller is installed on one shaft end, and the present invention is installed on the other shaft end. The motor shaft passes through the central circular tube hole of the present invention, the fixed pin on the motor shaft snaps into the groove at the upper end of the circular tube, and the motor shaft end is fixed with a round nut to fix the present invention. During work, the motor shaft drives the blades to rotate together with the present invention.

[0026] The rotating impeller generates negative pressure, and under the action of negative pressure, the oil fume enters the air chamber along the axial direction, and hits the horizontal high-speed rotating filter plate vertically. Due to the large radial size and large area of the filter plate, the number of soot particles that collide per unit time is large. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com