Color-sensor-based device for detecting intensity of stoving

A technology of color sensor and automatic titration, which is applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by making materials undergo chemical reactions, etc. It can solve the problems of low measurement accuracy and reproducibility, and large influence of sulfur fumigation. Devices and adjustments provide information and other issues, so as to achieve the effects of not being easily disturbed by the outside world, accurate measurement, and reducing energy consumption and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The purpose of the invention of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the embodiments cannot be repeated here one by one, but the implementation of the present invention is not therefore limited to the following embodiments.

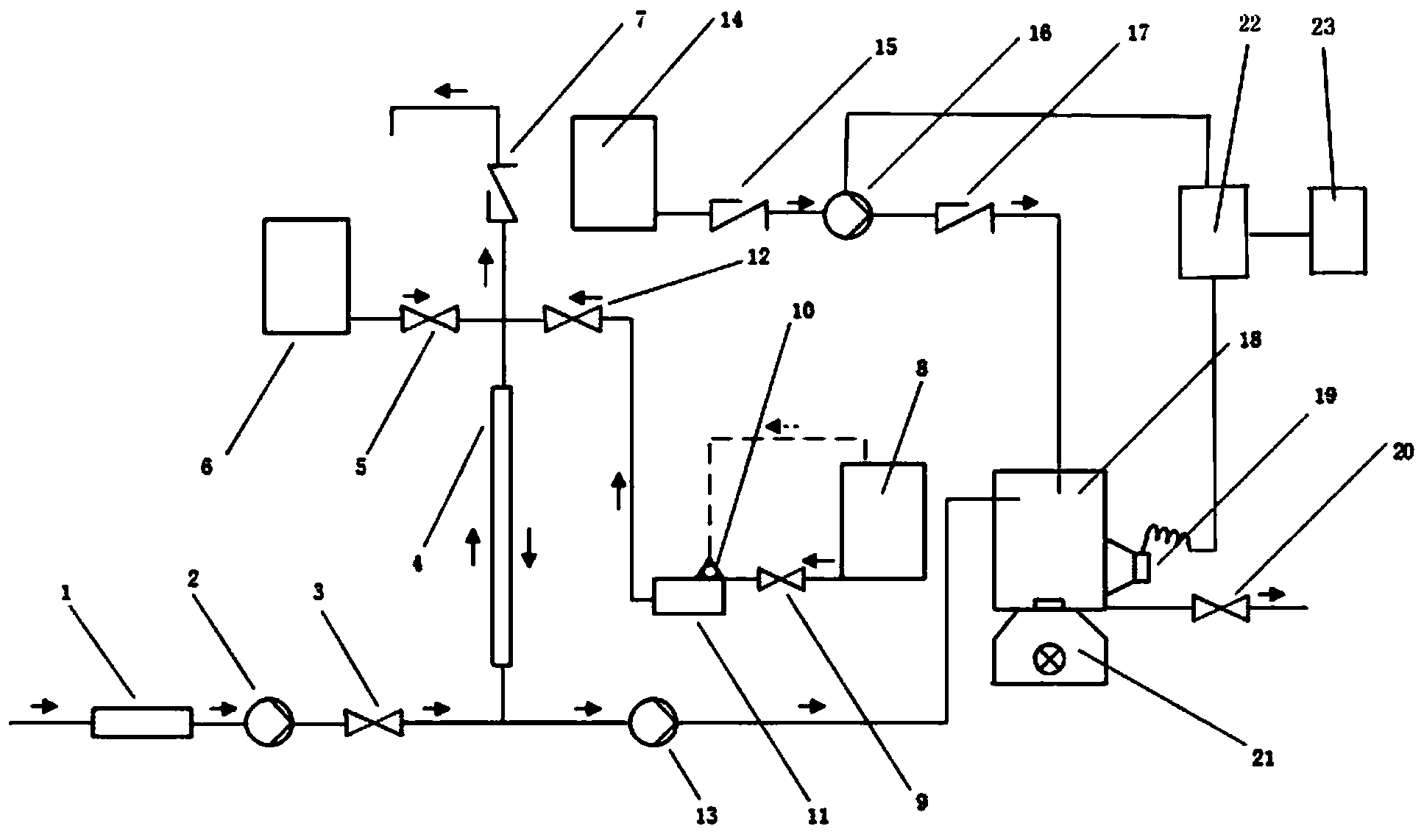

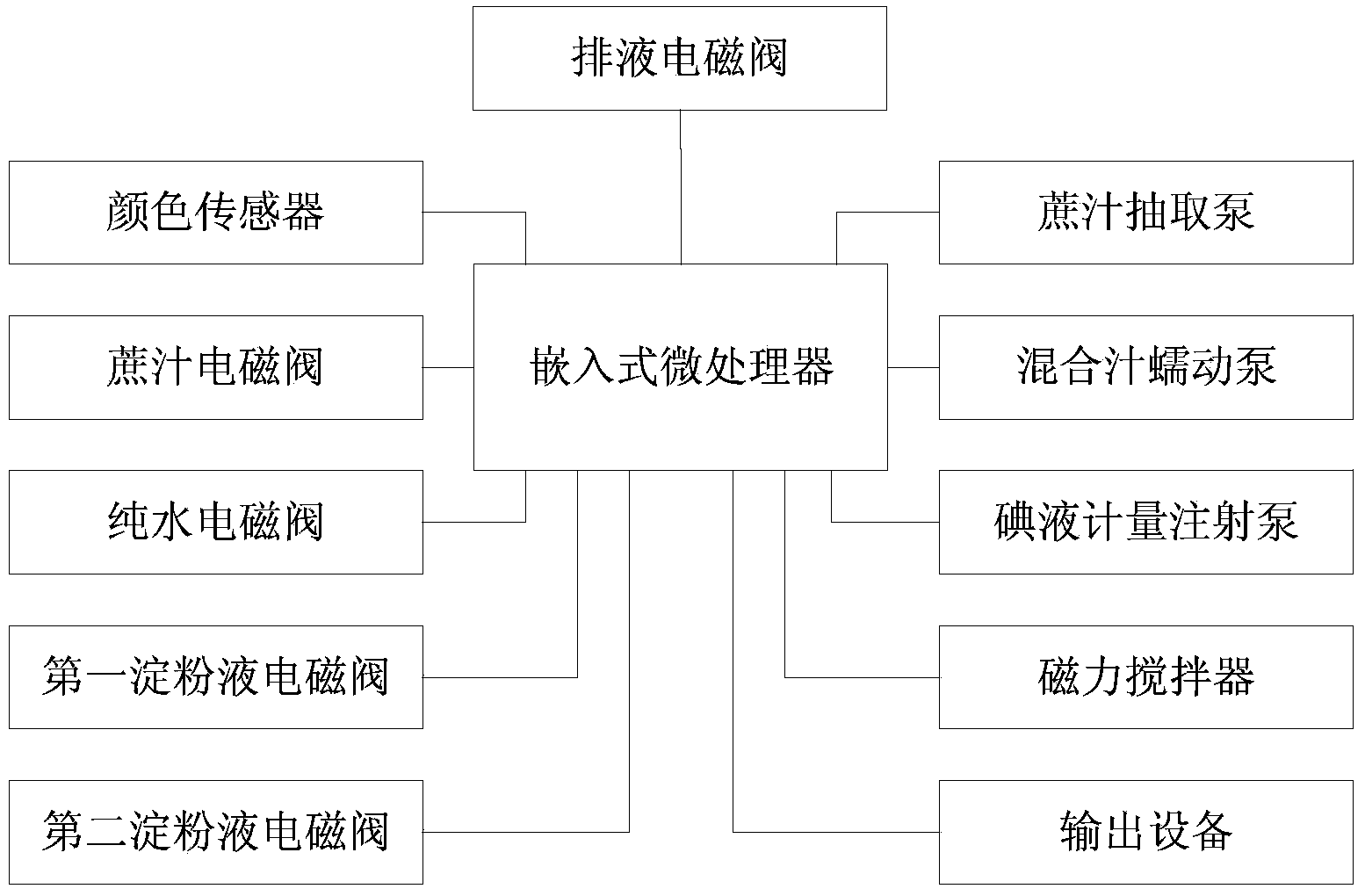

[0017] Such as figure 1 As shown, a device for automatically titrating and detecting the intensity of sulfur fumigation based on a color sensor includes a sugarcane juice filtering and cooling device 1, a sugarcane juice extraction pump 2, a sugarcane juice solenoid valve 3, and a mixed juice peristaltic pump 13 connected in sequence through pipelines. Cane juice quantitative tube 4, iodine solution storage tank 14, embedded microprocessor 22, output device 23, one end of the cane juice quantitative tube 4 is connected between the sugarcane juice solenoid valve 3 and the mixed juice peristaltic pump 13 through a three-way pipe On the pipeline, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com