Polishing method for zinc oxide single crystal substrate level substrate

A technology of zinc oxide single crystal and zinc oxide, which is applied to polishing compositions containing abrasives, grinding/polishing equipment, surface polishing machine tools, etc., can solve the problem that no ZnO single crystal substrate polishing process and process have been found, and the disclosure And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

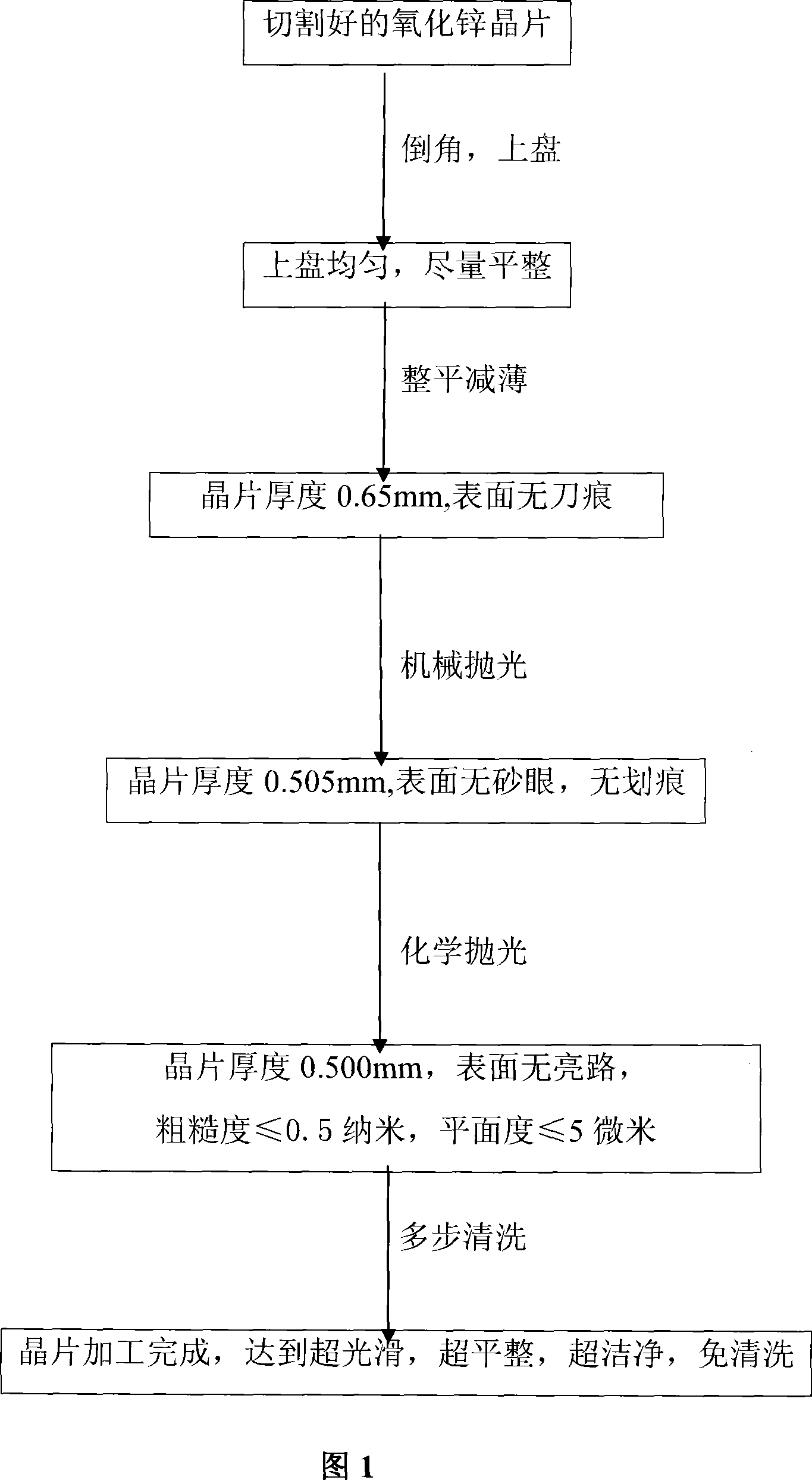

Image

Examples

Embodiment 1

[0031] 1. Chamfer the cut zinc oxide wafer first, and then put it on the heating platform with the bare glue board to heat at a temperature of 120°C. Bond the zinc oxide wafer to the bare glue board evenly and firmly with an adhesive.

[0032] 2. Leveling and thinning: On the surface grinding machine, a cast iron grinding disc is used, and the abrasive material is silicon carbide (SiC) suspension (SiC:H 2 O weight ratio 1: 20), the pressure is set to 60g / cm 2 , Speed: 70 rpm, flow rate of polishing liquid: 150ml / min, when the thickness reaches 0.65mm, the grinding rate is relatively high, the grinding time is 2h, the surface of the wafer has no knife marks, and is relatively smooth.

[0033] 3. Mechanical polishing: On the grinding machine, use polyurethane grinding disc, first use W7 boron carbide (B 4 C) the suspension is used as a grinding liquid, (B 4 C:H 2 O weight ratio is 1:20), flow rate is 10ml / min, pressure: 70g / cm 2 , rotating speed: 100 rpm, grind to a thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com