Oversized laminated glass autoclave

A technology of laminated glass and autoclave, applied in lamination, lamination devices, layered products, etc., can solve the problems of affecting the appearance of glass performance, large temperature difference, and difficulty in ensuring consistent glass temperature, etc., to achieve perfect performance indicators, The effect of increasing the cycle frequency and shortening the distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

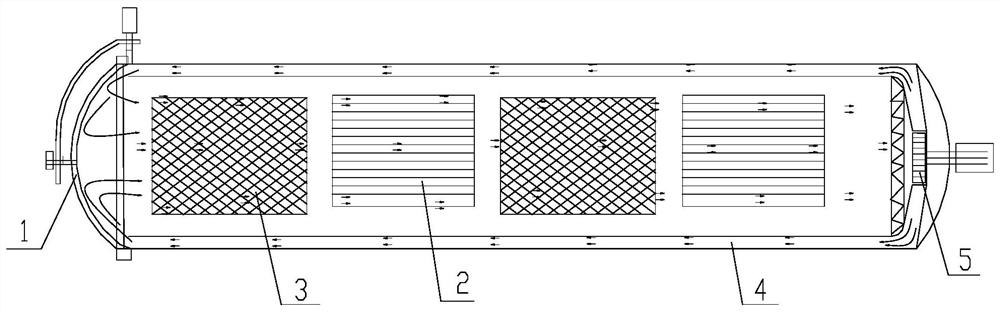

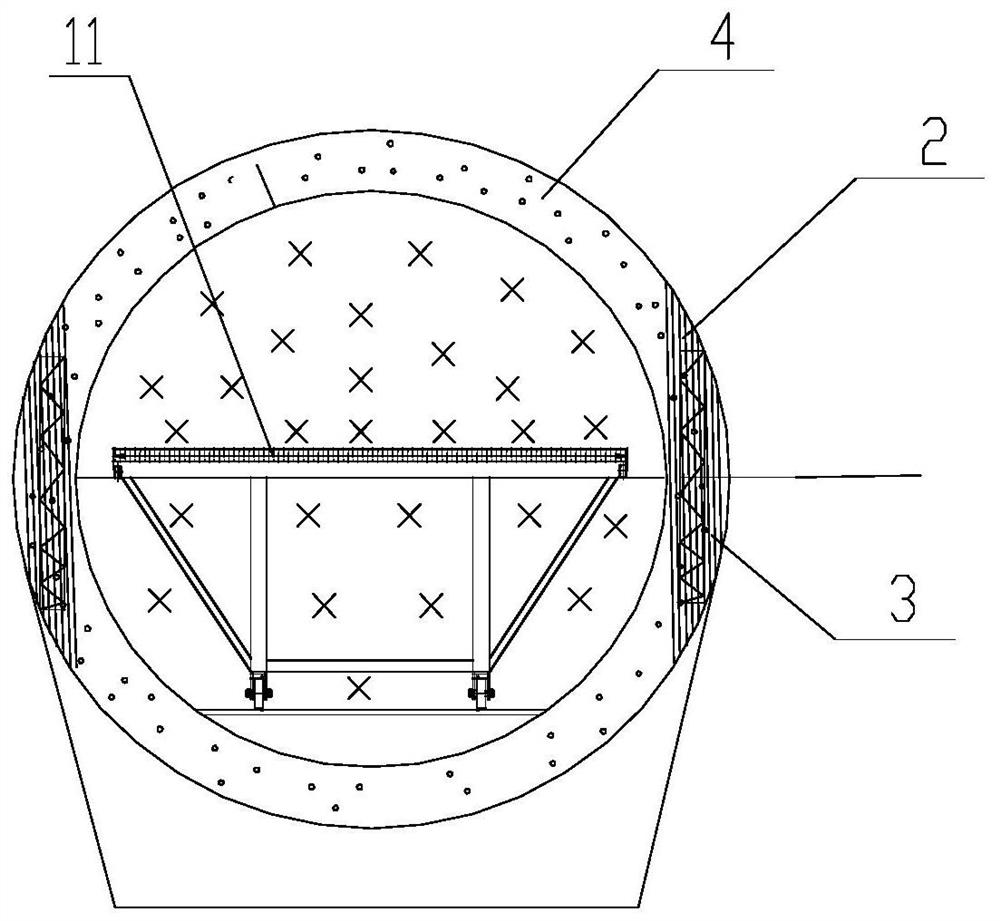

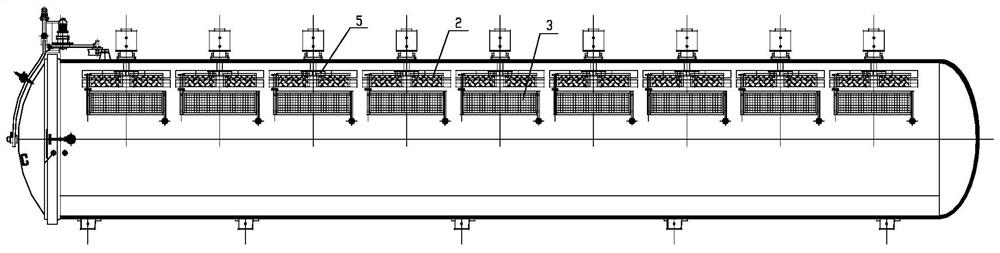

[0020] like Figure 3-6 As shown, a super large laminated glass autoclave includes a horizontal kettle body 12, and a wind deflector 10 is fixed at a position adjacent to the kettle wall from the top to the bottom of the horizontal kettle body 12, so that the kettle wall of the kettle body 12 Between the air deflector 10 and the kettle body circumferential air channel 4 is formed, wherein the lower sides of the kettle body 12 have lower air outlets 13 respectively, and the middle parts of the two sides of the air deflector have openable middle air outlets 14 respectively, and the middle air outlets 14 is controlled by rotatable windshield 8. A detachable horizontal baffle 9 is connected above between the two middle air outlets 14; 9 blowers 5 are fixed on the top of the air duct 4, and 9 blowers 5 are respectively fixed in one upper side and the other upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com