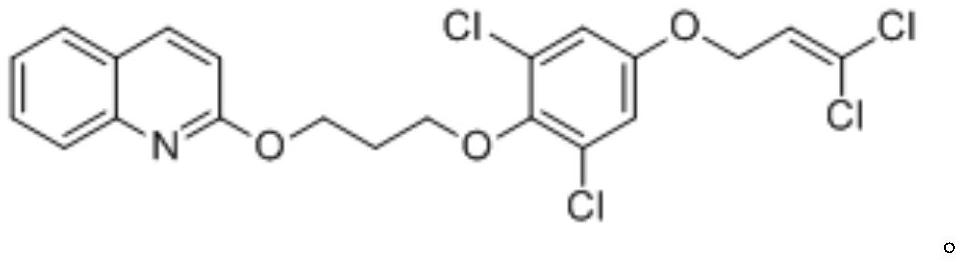

Propinoxaden microcapsule suspending agent as well as preparation method and application thereof

A technology of microcapsule suspension and pyridoxine, which is applied in the direction of botany equipment and methods, applications, pesticides, etc., can solve the problems of harming non-target crops, increasing the cost of medication, and the development of pest resistance, so as to reduce the Pest control cost, good storage stability, long-lasting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] Embodiment 1: 1% chlorfenapyr microcapsule suspension

[0084] Table 1: Composition of 1% chlorfenapyr microcapsule suspension

[0085]

[0086] The preparation method of 1% chlorfenapyr microcapsule suspension is as follows:

[0087] Step 1: Dissolve 1g of chlorfenapyr in 4g of ADMA810, add 4g of Nongmilk 601 and 1g of PAPI, mix and stir to form an oil phase;

[0088] Step 2: Add 0.5g of organosilicon defoamer to 78.8g of deionized water and mix well, as water phase;

[0089] Step 3: mixing the oil phase with the water phase, and emulsification at a high speed of 8000rpm for 3min to obtain an oil-in-water emulsion;

[0090] Step 4: 0.3g of diethylenetriamine is prepared into 3g of 10% diethylenetriamine aqueous solution with deionized water and added to the oil-in-water emulsion, kept at 40°C, stirred at 200rpm for 3h, cooled to room temperature after the polymerization reaction is completed, and obtained intermediate reaction solution;

[0091] Step 5: Put 3g ...

Embodiment 2

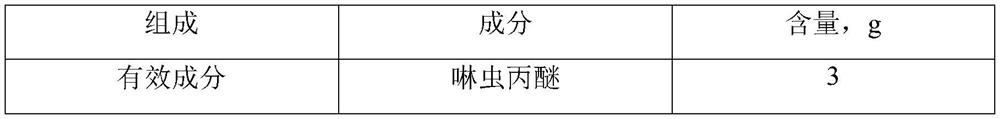

[0092] Embodiment 2:3% chlorfenapyr microcapsule suspension

[0093] Table 2: Composition of 3% chlorfenapyr microcapsule suspension

[0094]

[0095]

[0096] The preparation method of 3% chlorfenapyr microcapsule suspension is as follows:

[0097] Step 1: Dissolve 3g of chlorfenapyr in 20g of No. 200 solvent oil, and add 5g 992 and 1.2g HMDI, mix and stir well as oil phase;

[0098] Step 2: Add 0.5g of organosilicon defoamer to 58.6g of deionized water and mix evenly, as water phase;

[0099] Step 3: mixing the oil phase and the water phase, and emulsification at a high speed of 10000rpm for 5min to obtain an oil-in-water emulsion;

[0100] Step 4: Use deionized water to prepare 0.4 g of ethylene glycol into 4 g of 10% ethylene glycol aqueous solution and add it to the oil-in-water emulsion, keep at 45° C., stir at 300 rpm for 4 h, and cool down to room temperature after the polymerization reaction is completed to obtain an intermediate reaction liquid;

[0101] ...

Embodiment 3

[0102] Example 3: 5% chlorfenapyr microcapsule suspension

[0103] Table 3: Composition of 5% chlorfenapyr microcapsule suspension

[0104]

[0105]

[0106] The preparation method of 5% chlorfenapyr microcapsule suspension is as follows:

[0107] Step 1: Dissolve 5g of chlorfenapyr in 30g of No. 200 solvent oil, add 4g of Nong Milk 601 and 2g of PAPI, mix and stir to serve as an oil phase;

[0108] Step 2: Add 0.5g of organosilicon defoamer to 45.8g of deionized water and mix evenly, as the water phase;

[0109] Step 3: mixing the oil phase with the water phase, and emulsification at a high speed of 10000rpm for 5min to obtain an oil-in-water emulsion;

[0110] Step 4: Use deionized water to prepare 0.5 g of diethylene triamine into 5 g of a 10% diethylene triamine aqueous solution and add it to the oil-in-water emulsion, keep at 50° C., stir at 300 rpm for 4 hours, and cool down to room temperature after the polymerization reaction is completed to obtain Intermediat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com