Energy-saving heat tank

A technology of a hot tank and an electric heating tube, which is applied to beverage preparation devices, household appliances, applications, etc., can solve the problems of high shell manufacturing cost, high manufacturing and installation cost, limited use range, etc., achieve compact size, reduce manufacturing and installation cost, Ensure thorough disinfection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

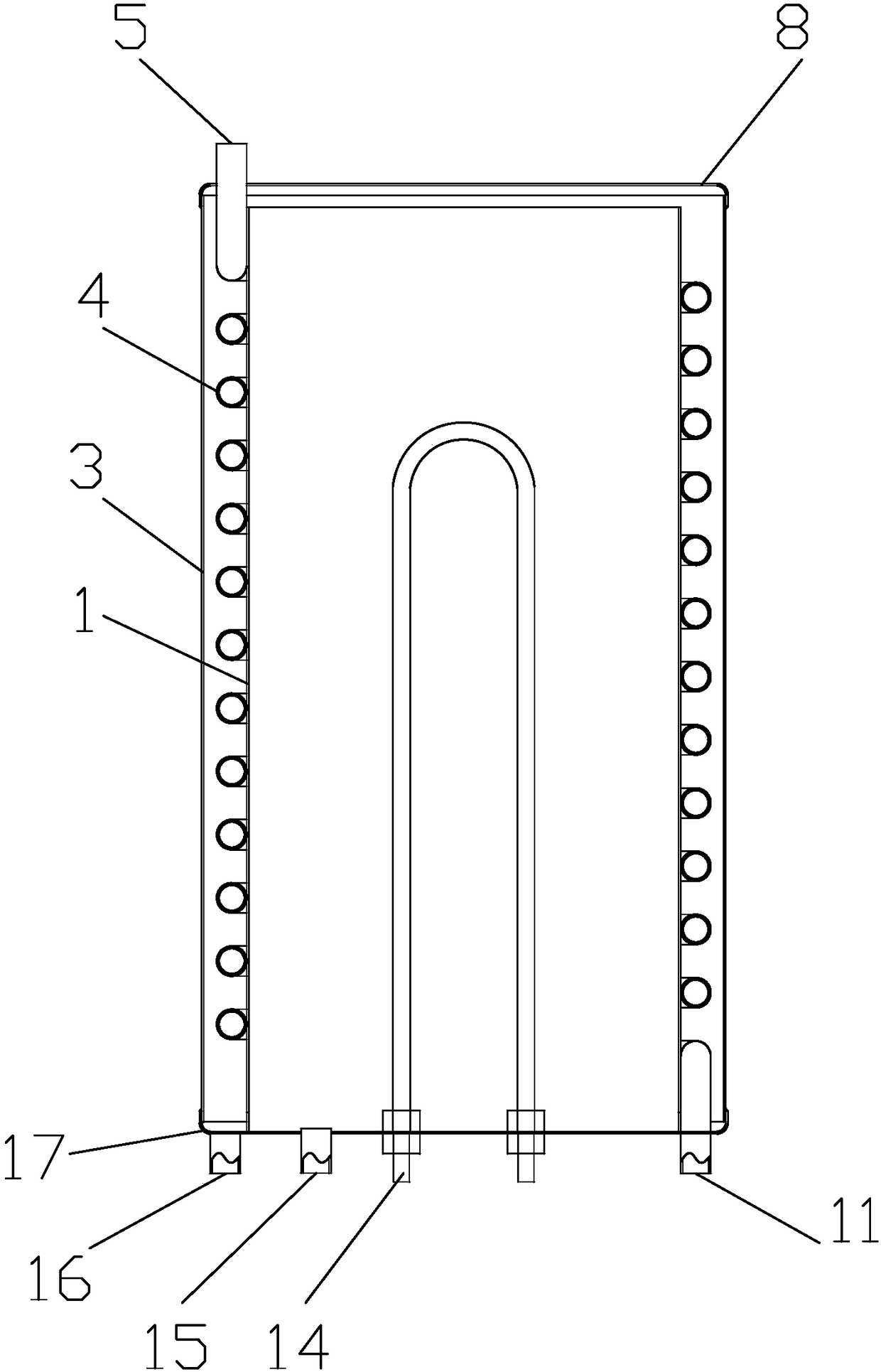

[0042] like figure 2 Shown is a schematic structural diagram of an energy-saving heat tank provided in this embodiment. This energy-saving heat tank includes an inner cylinder 1, an outer cylinder 3, a spiral pipe 4, an upper opening 5, a top plate 8, a lower opening 11, an electric heating pipe 14, a water inlet 15, a water outlet 16 and a bottom plate 17.

[0043] The top end of the outer cylinder 3 is in sealing connection with the top plate 8, and the bottom end of the outer cylinder 3 is in sealing connection with the bottom plate 17; the inner cylinder 1 is arranged in the cavity of the outer cylinder 3, and the straight line where the central axis of the inner cylinder 1 is located radiates outward to any The airspace included in the inner side wall of the cylinder is the inner chamber, the airspace included in the outer cylinder 3 and the outer sidewall of the adjacent cylinder is the outer chamber, the inner space of the inner cylinder 1 is the inner chamber in the p...

Embodiment 2

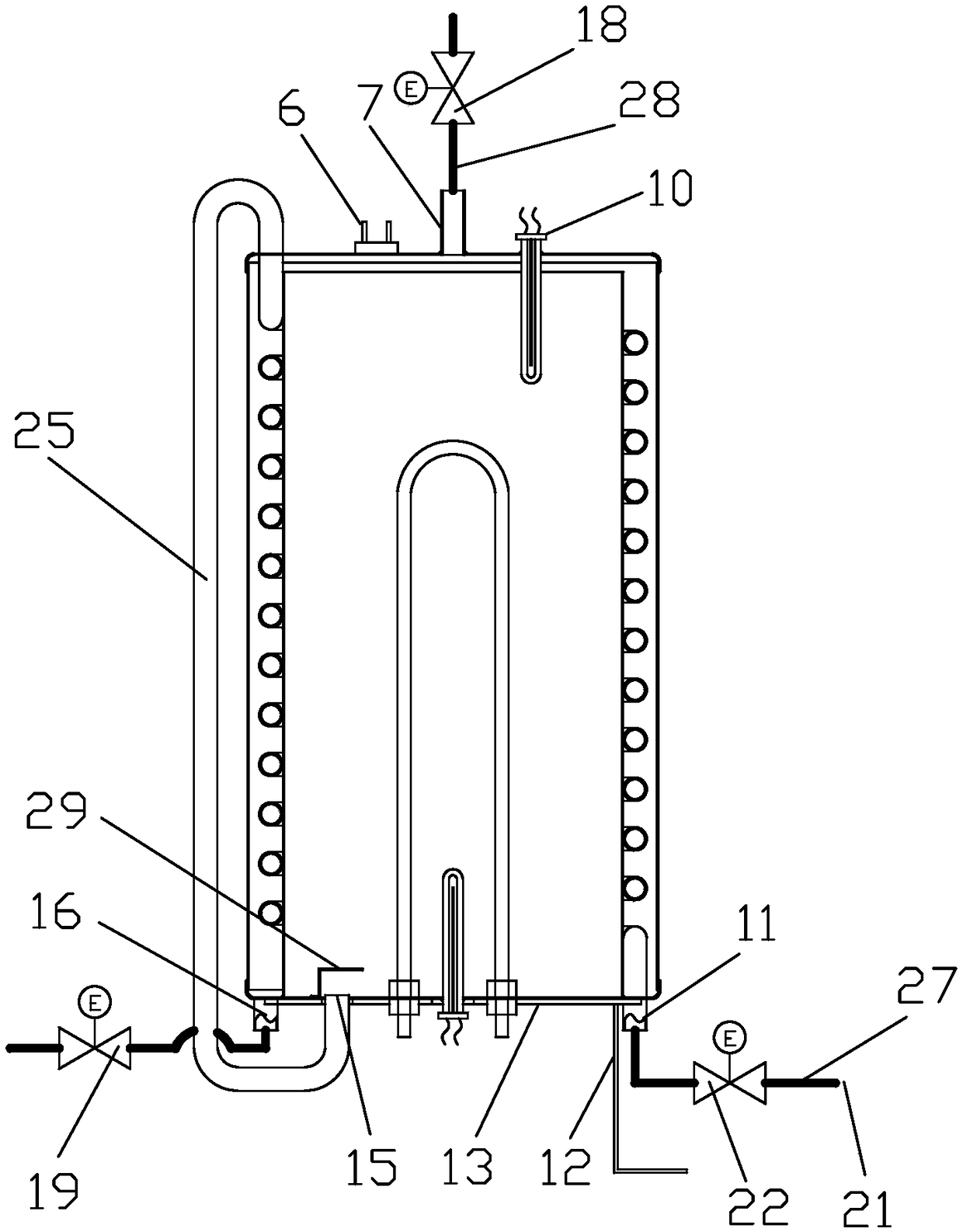

[0046] like image 3 Shown is a schematic structural diagram of the energy-saving heat tank and connecting pipelines provided in this embodiment. The difference between this embodiment and Embodiment 1 is that it also includes a water inlet pipe 27, a water inlet valve 22, a connecting pipe 25, a cold boiled water outlet valve 19, a cold boiled water outlet pipe, a hot water outlet 7, a hot water pipe 28 and a hot water outlet. Water valve 18.

[0047] The top plate 8 is provided with a hot water port 7 connected to the top of the inner cavity; a hot water pipe 28 is connected to the hot water port 7, and a hot water valve 18 is arranged on the hot water pipe 28; Valve 22 is installed on the water inlet pipe 27; One end of connecting pipe 25 is connected with upper opening 5, and the other end is connected with water inlet 15;

[0048] During operation, water enters from the water inlet 21 at normal temperature through the water inlet pipe 27 from the lower opening 11, flows...

Embodiment 3

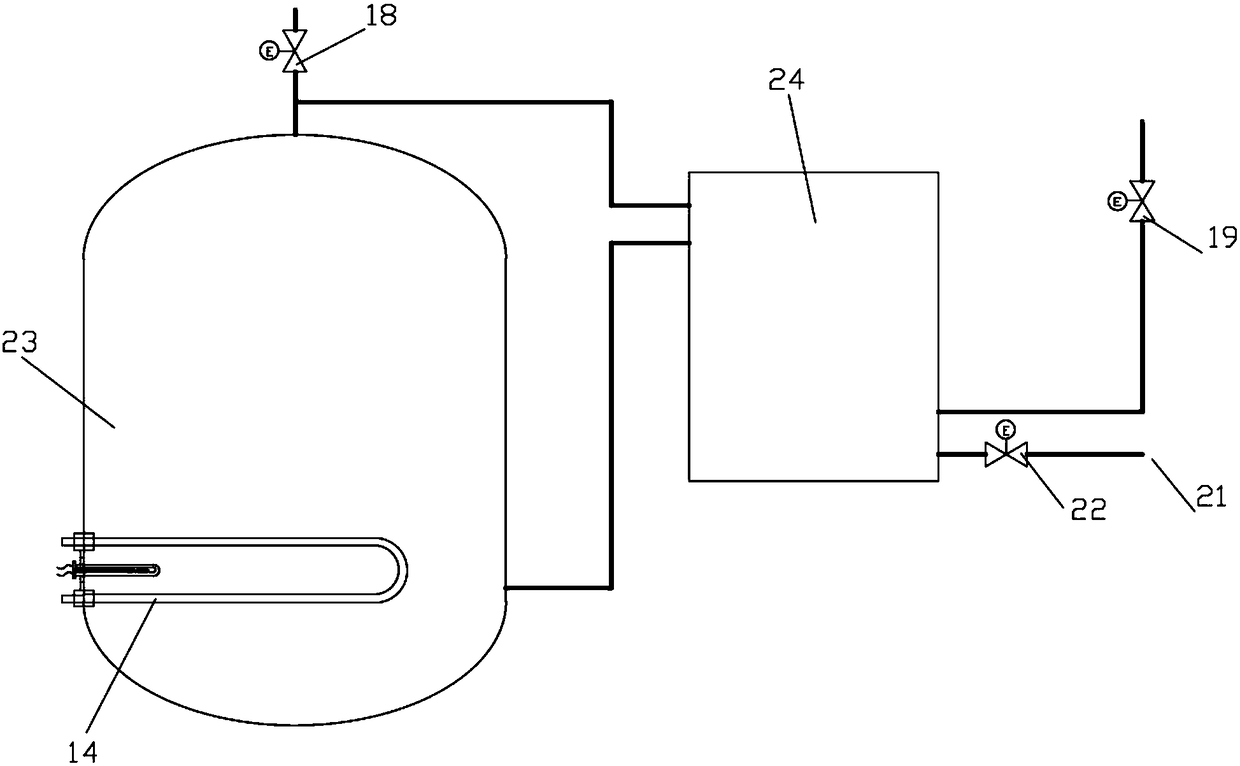

[0058] like Figure 5 Shown is a schematic structural diagram of the energy-saving heat tank and connecting pipelines provided in this embodiment. The difference between this embodiment and the second embodiment is that: a bypass pipe 26 and a bypass valve 20 are also included. The water source inlet 21 is also connected with a bypass pipe 26, and the other end of the bypass pipe 26 is communicated with the connecting pipe 25, and the bypass valve 20 is installed on the bypass pipe 26. The effect of setting the external pipeline like this is to be able to carry out high-temperature hot water disinfection to the cold boiled water outlet pipeline. The water temperature of the cold boiled water pipeline is usually controlled at about 40°C when the water outlet is normal. Such water temperature is easy to breed bacteria, so it is necessary to regularly sterilize the cold boiled water outlet pipeline.

[0059] The energy-saving heat tank is in a non-sterile state, the bypass valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com