Patents

Literature

61results about How to "Reduced manufacturing and installation costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

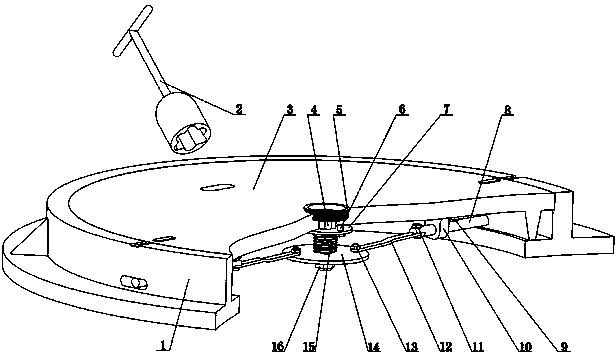

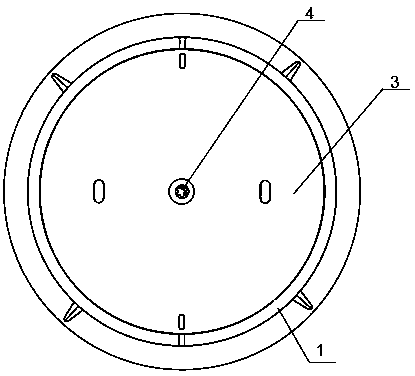

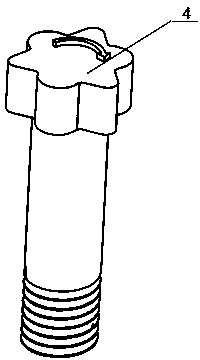

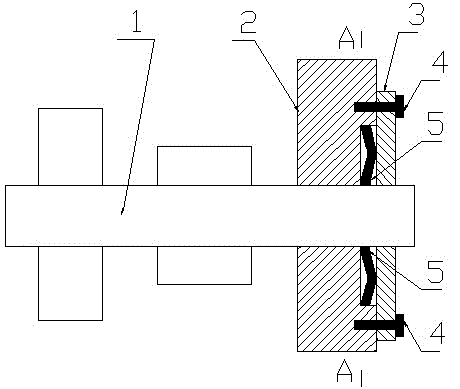

Well lid device with mechanical lock

InactiveCN103741721AComposition is simple and reliableEasy to operateArtificial islandsKeysInterference fitEngineering

The invention relates to a well lid device with a mechanical lock. The well lid device comprises a well lid and a lid opener, the well lid comprises a well lid fixing disc, a connecting rod slider mechanism, the mechanism lock and a seal lid, the well lid is in interference fit with the well lid fixing disc, a small hole is formed in the circle center of the well lid, the seal lid is mounted at the small hole and covers the small hole, the mechanical lock is fixed below the small hole of the well lid through a first screw, one end of the connecting rod slider mechanism is fixed on the mechanical lock through a second screw, and the other end of the connecting rod slider mechanism extends into the well lid fixing disc. The mechanical lock is simple and reliable in composition and simple and convenient to operate, devices below the well lid only include a torsion spring, a rotating disc, a connecting rod, a sliding rod and the like, the well lid device is high in reliability and low in manufacturing and mounting cost, and daily maintenance is omitted.

Owner:SHANGHAI UNIV

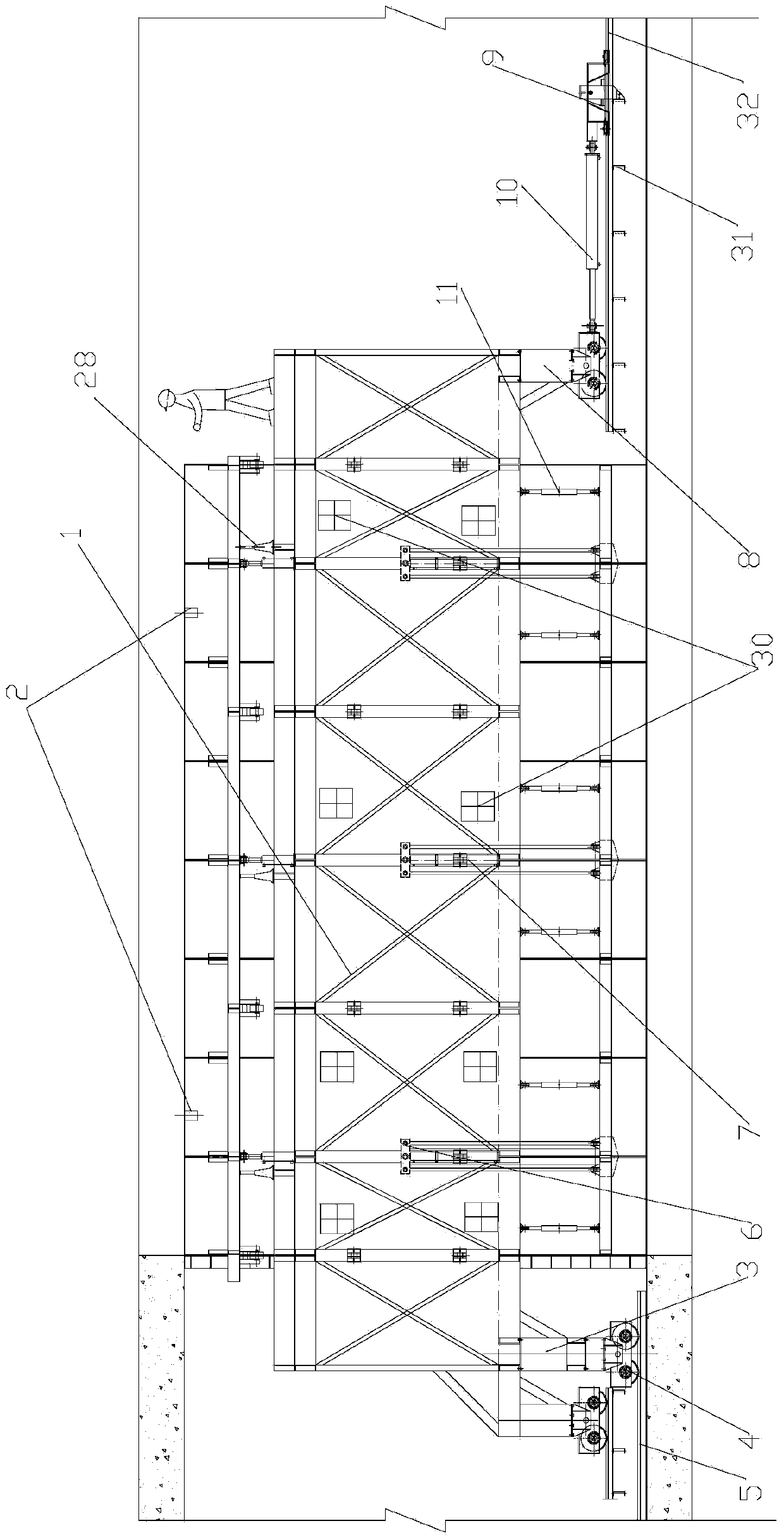

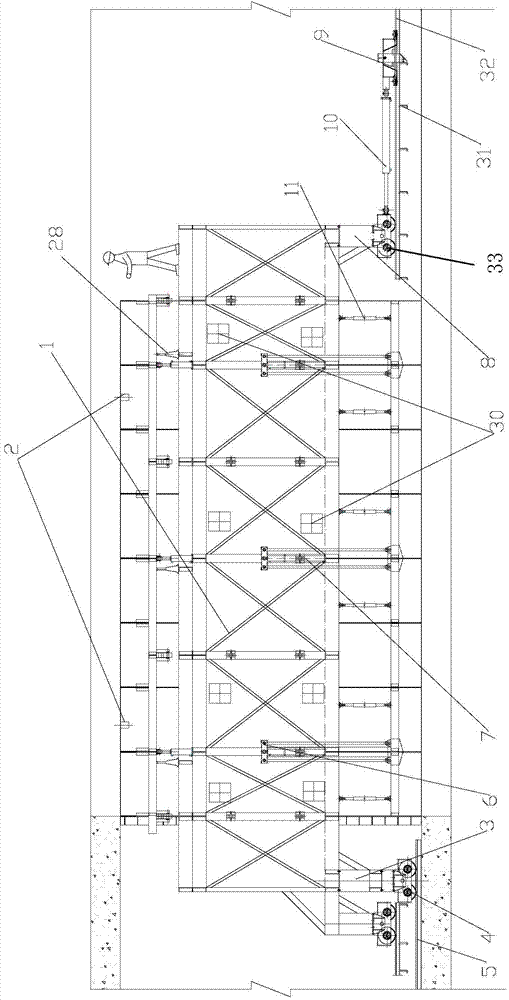

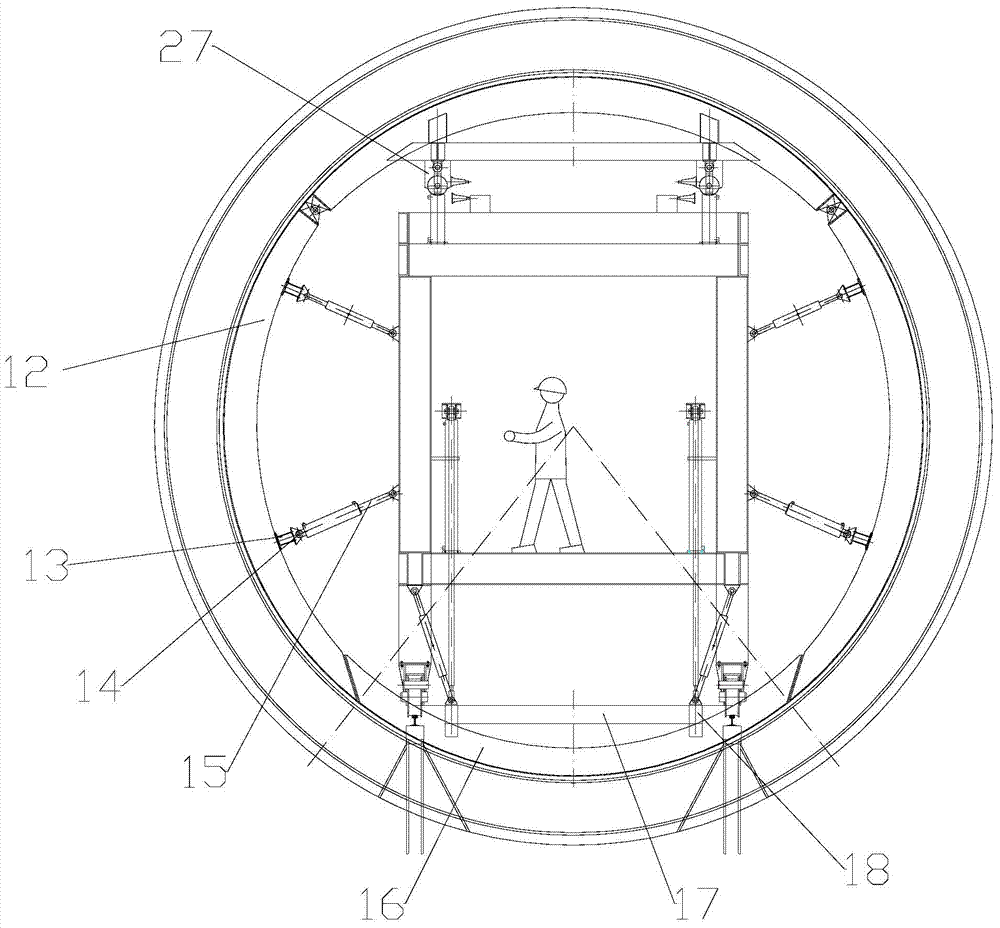

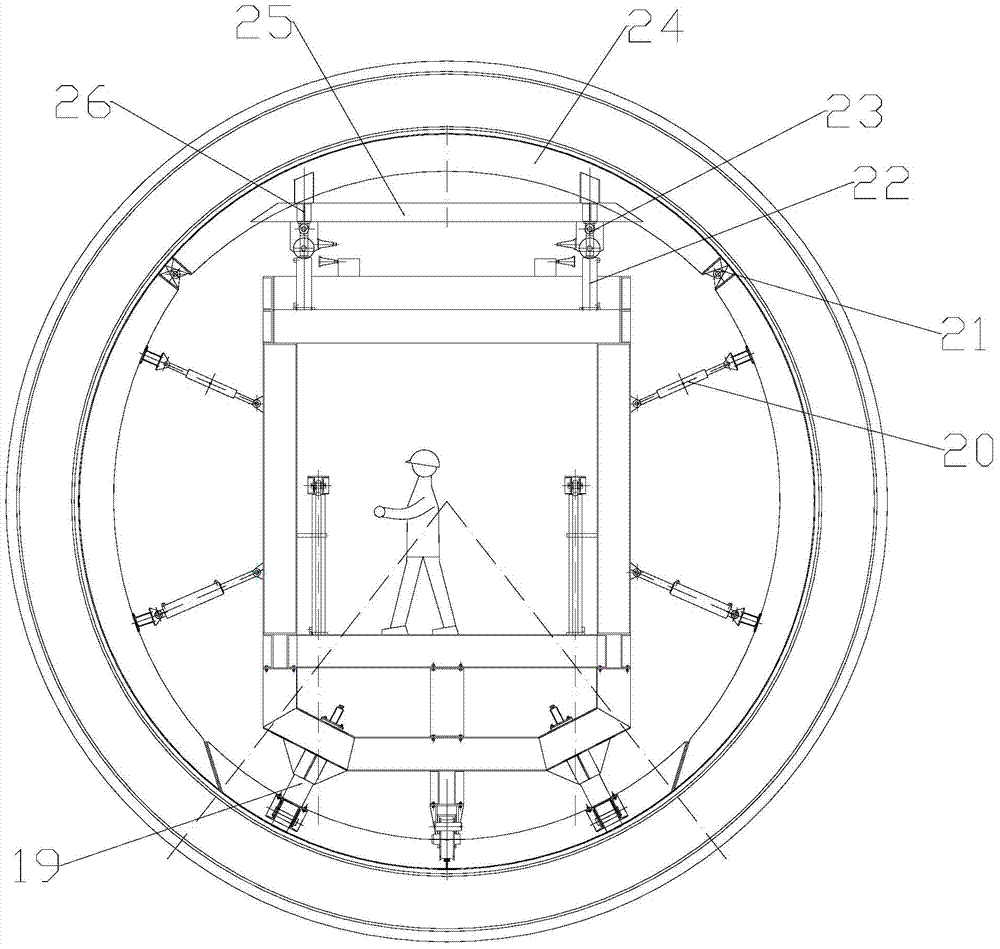

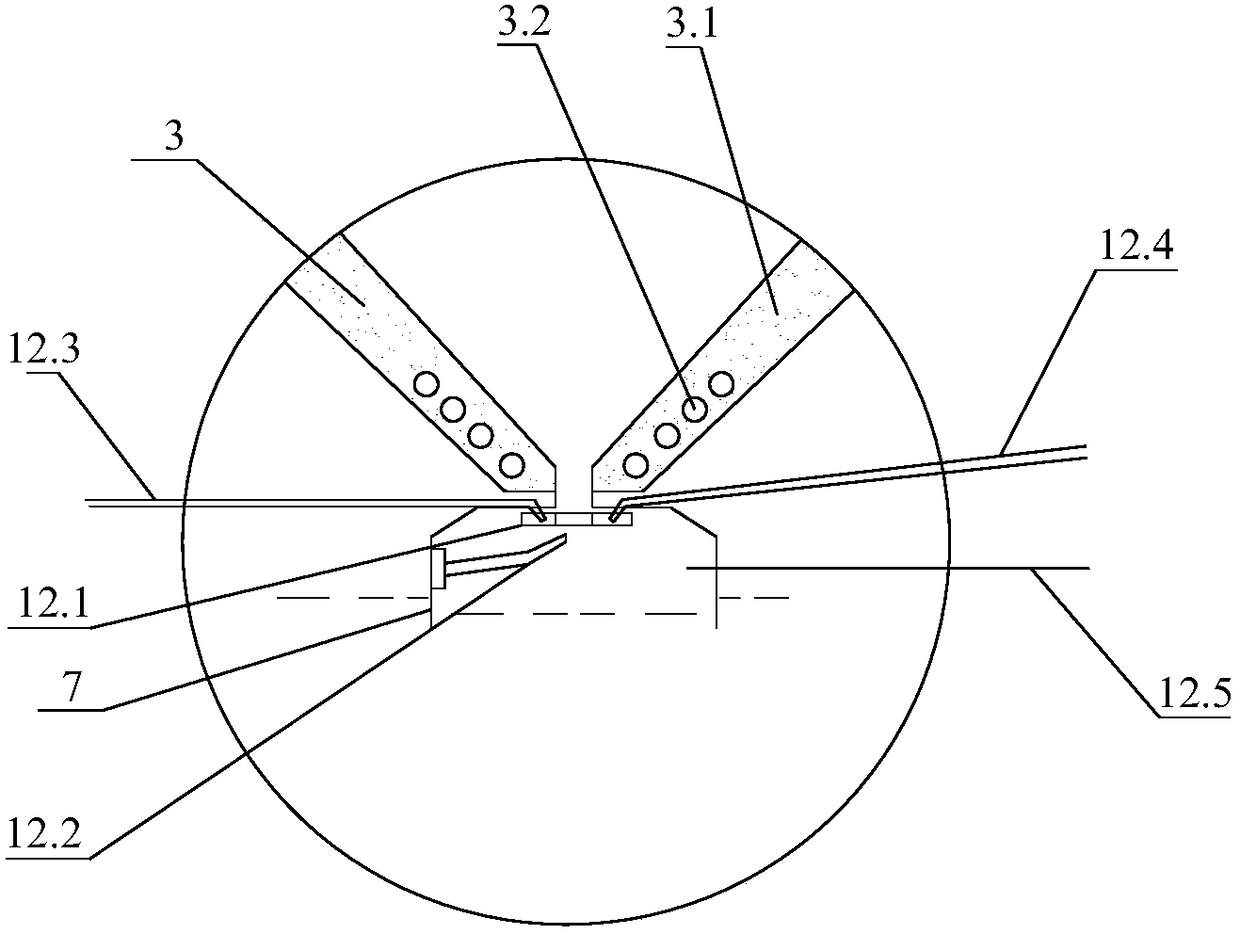

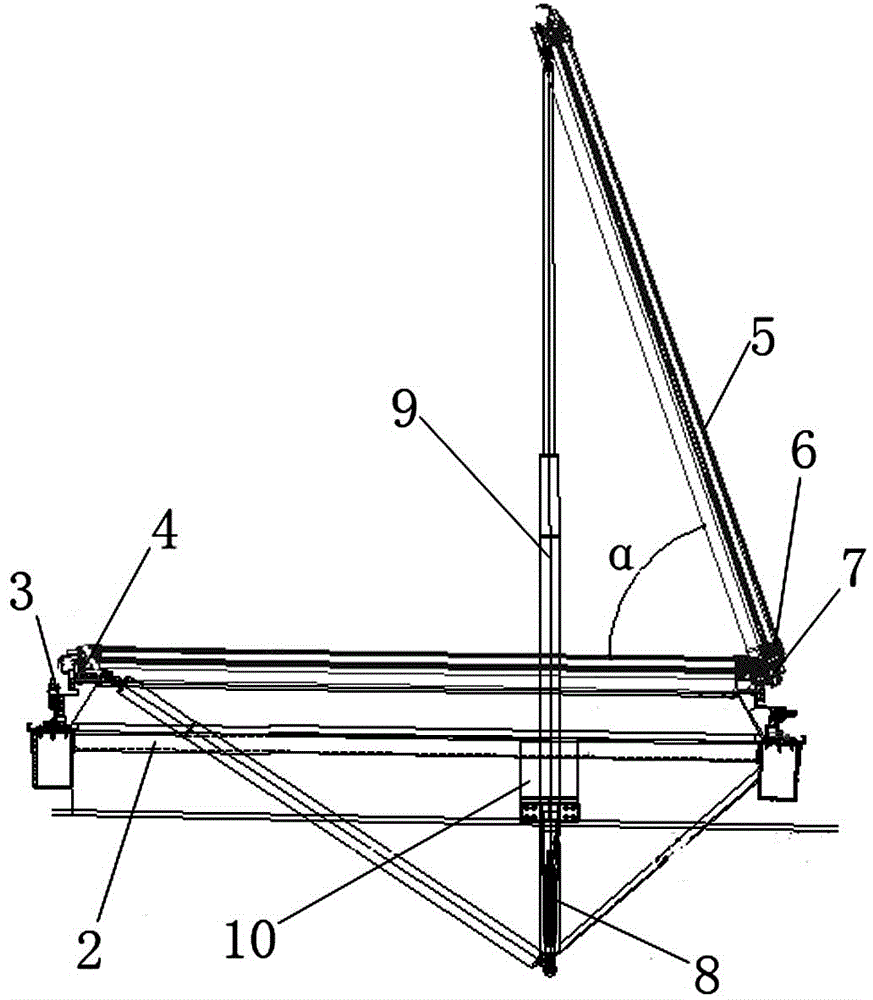

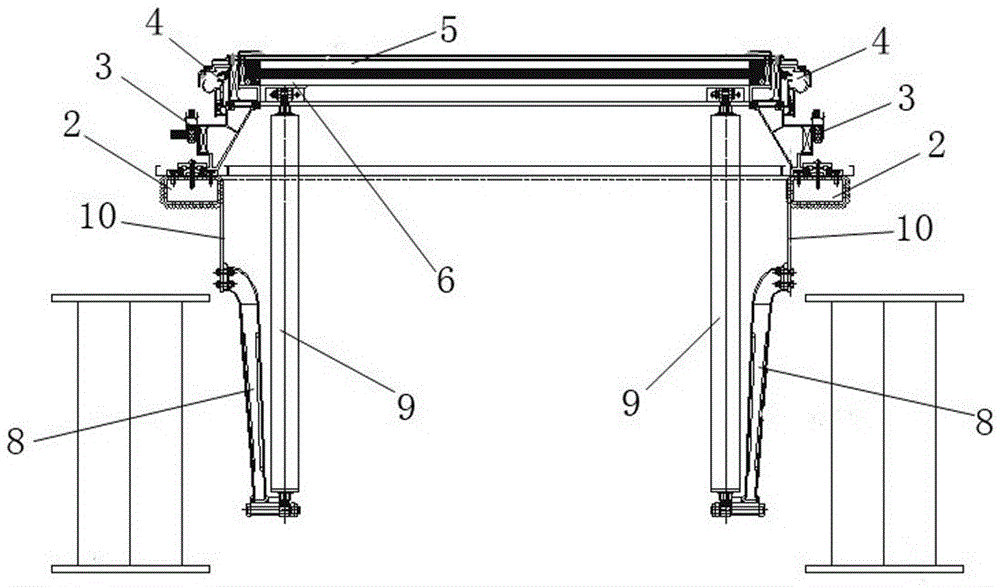

Hydraulic self-moving steel mould trolley and construction method thereof

ActiveCN103437782AFlexible removal locationEasy to moveUnderground chambersTunnel liningHydraulic controlMaterials science

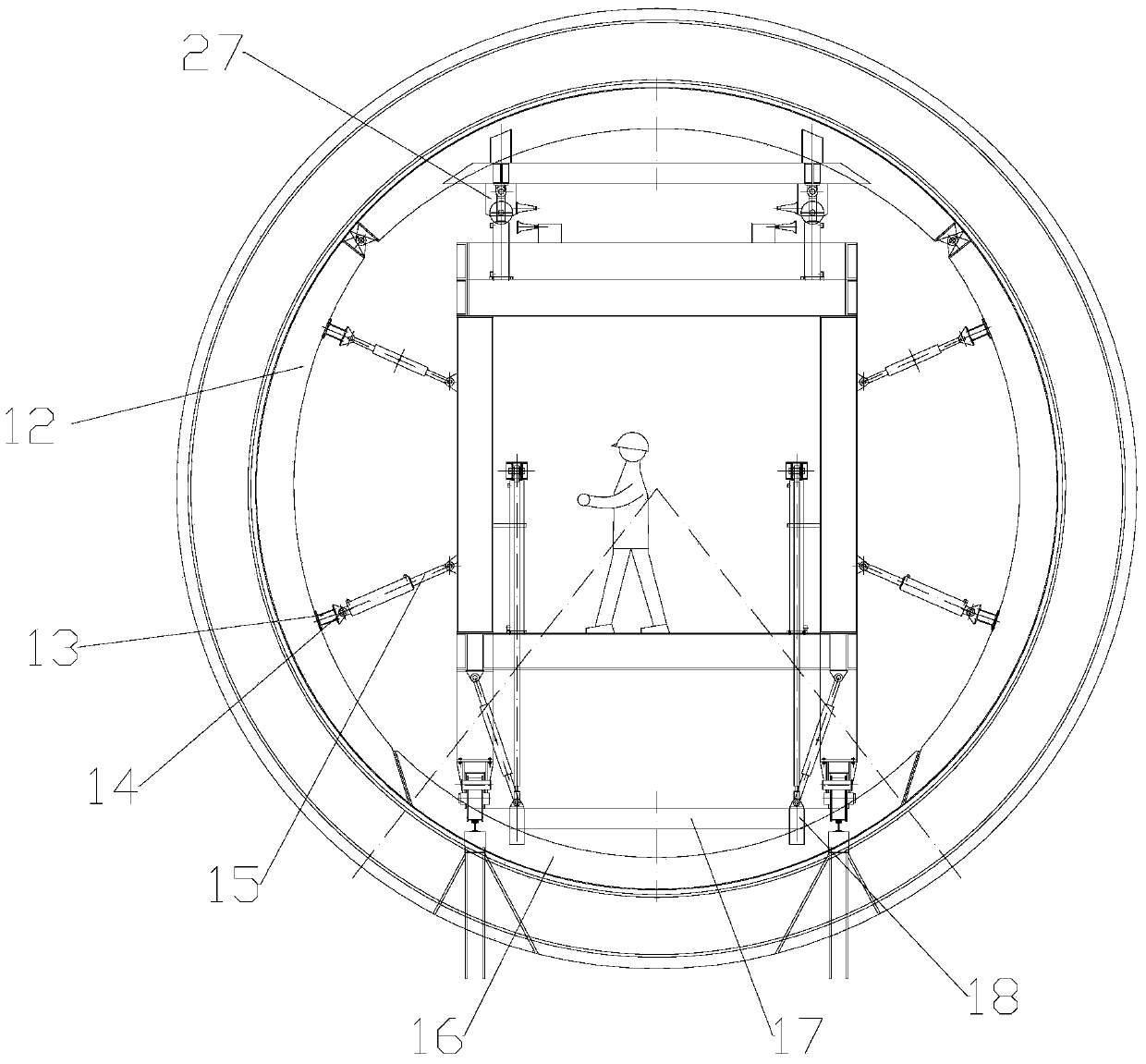

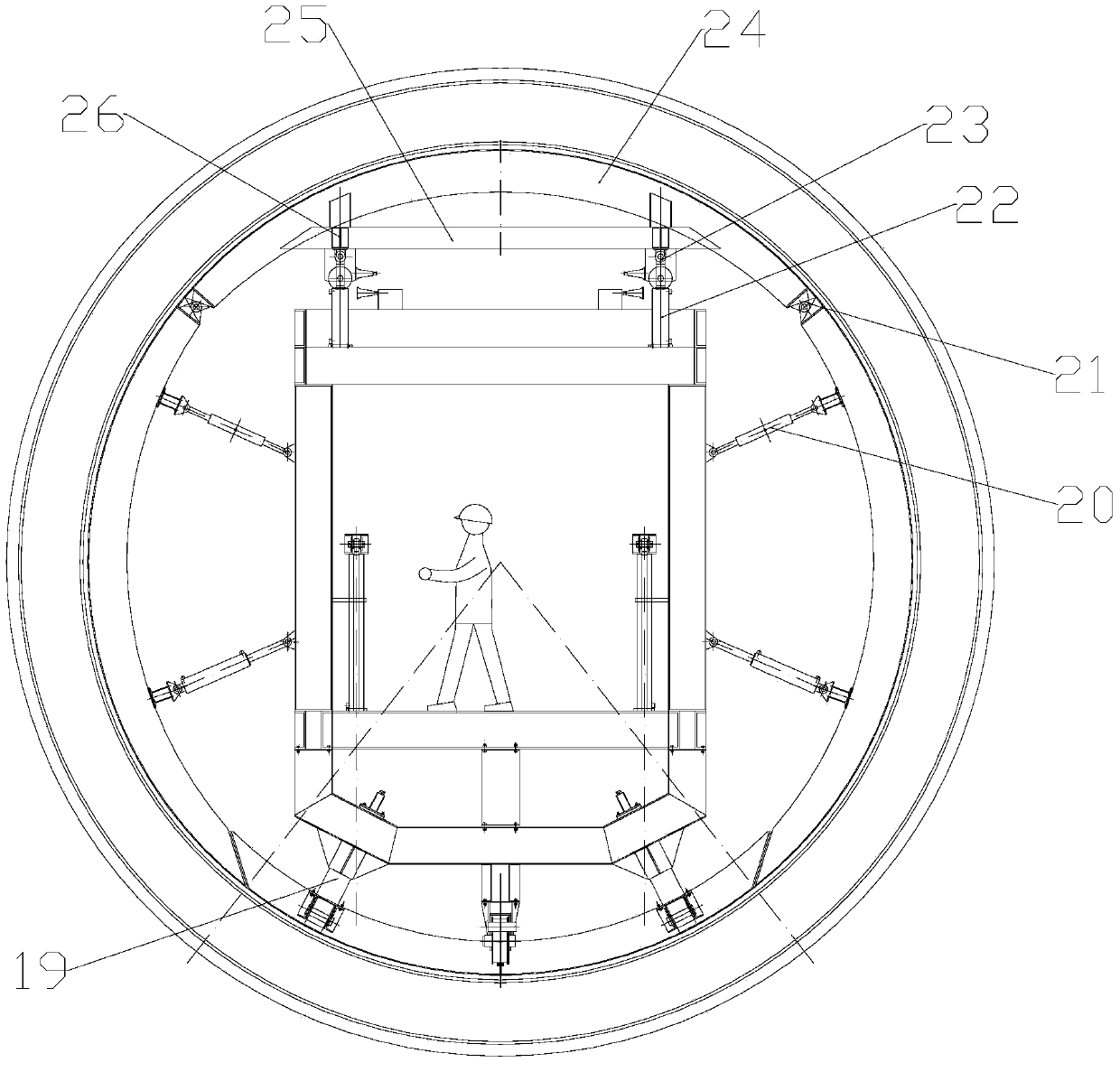

The invention relates to a hydraulic self-moving steel mould trolley and a construction method of the hydraulic self-moving steel mould trolley. The hydraulic self-moving steel mould trolley is used for full-section circular tunnel concrete lining construction. The hydraulic self-moving steel mould trolley comprises a trolley moving device, a trolley structural frame, a steel structure combination formwork and a hydraulic control device, the trolley structural frame is arranged on the trolley moving device, the trolley structural frame is movably connected with the trolley moving device, the steel structure combination formwork is arranged in the trolley structural frame, the steel structure combination formwork is hinged to the trolley structural frame, and the hydraulic control device is used for controlling the hydraulic self-moving type steel mould trolley. The hydraulic self-moving steel mould trolley is simple in structure, convenient to install, strong in adaptability and capable of carrying out demoulding on concrete at the bottom of the tunnel at first and repairing concrete construction defects in time.

Owner:CHINA THREE GORGES CORPORATION +1

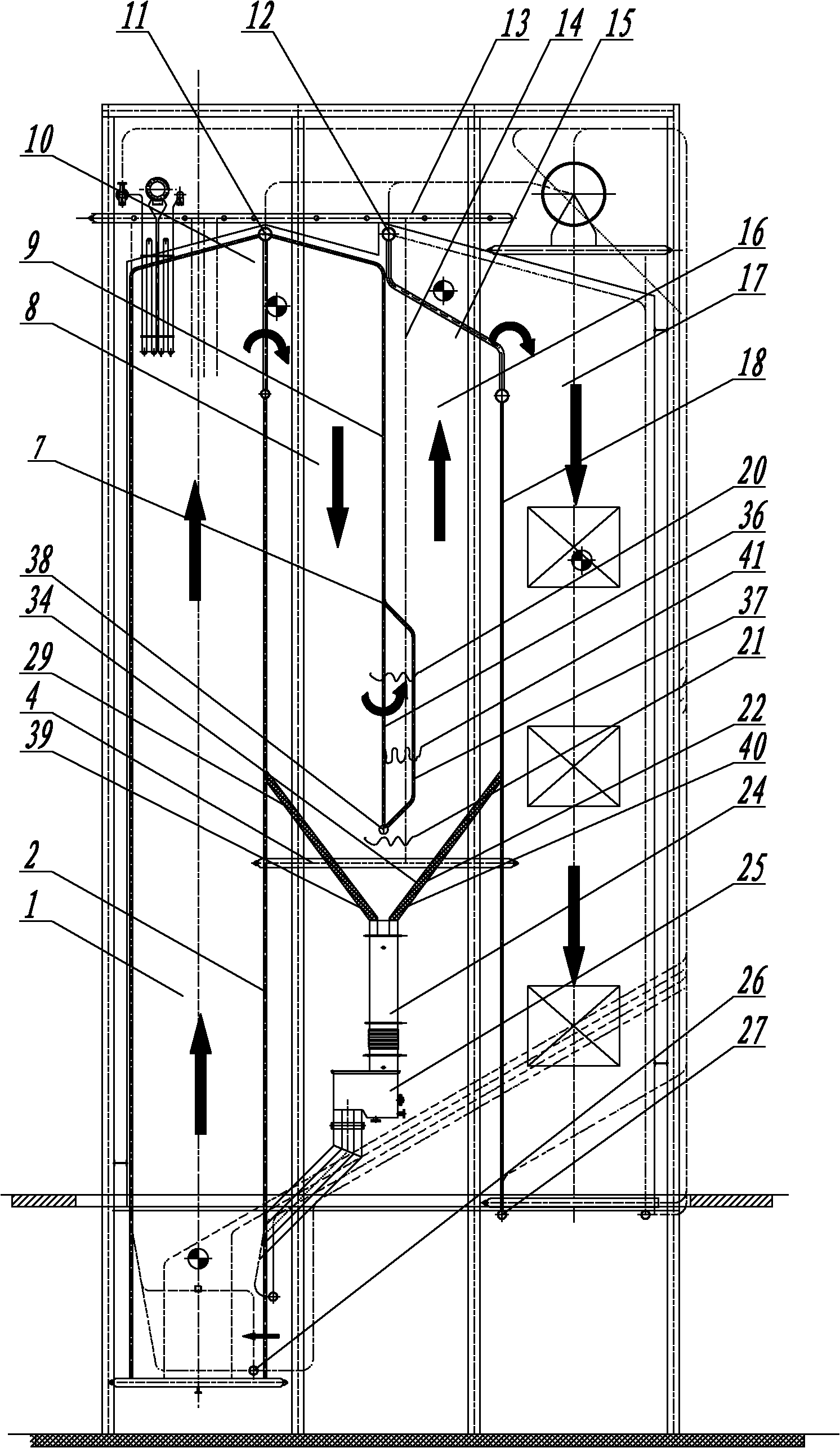

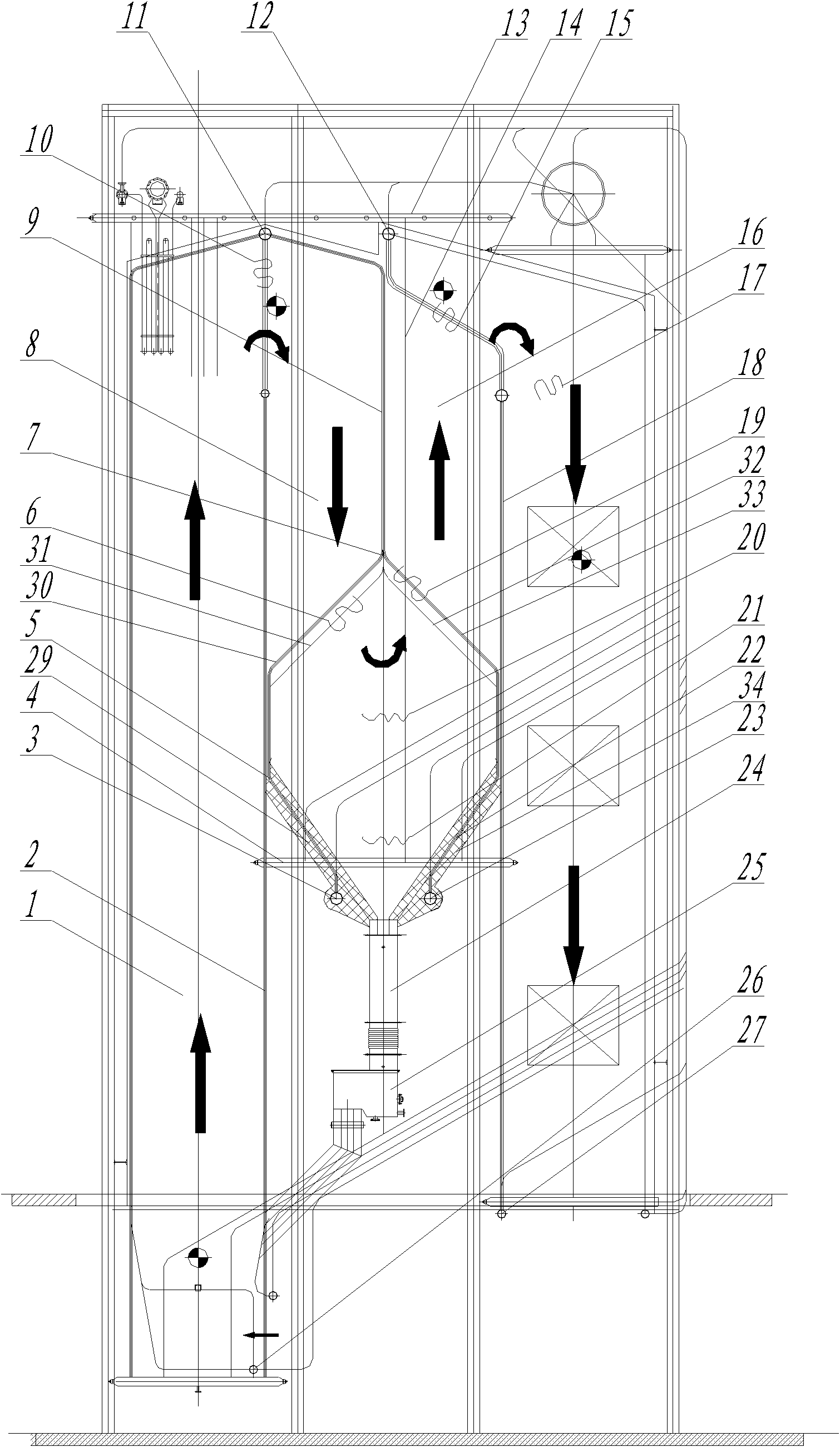

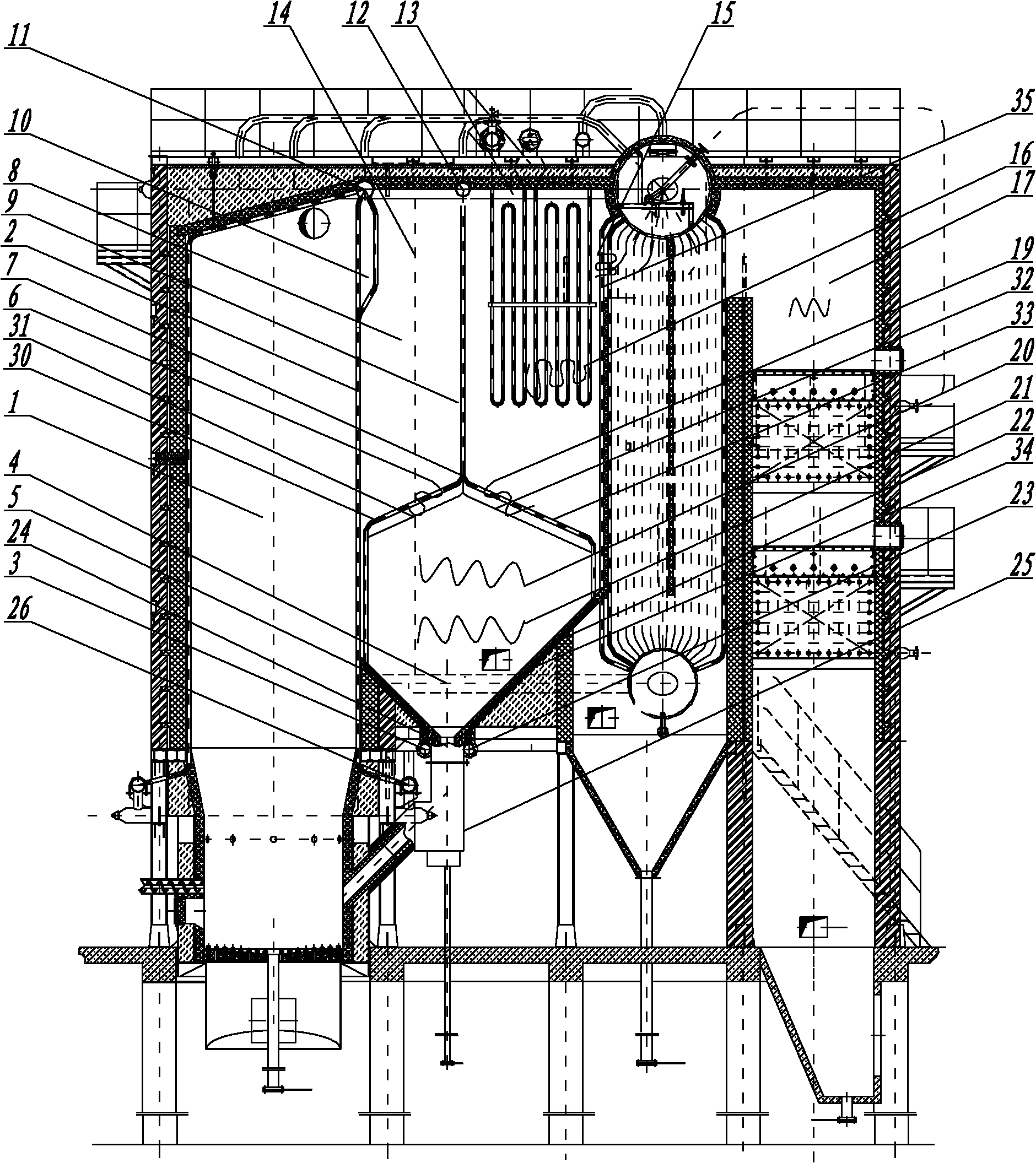

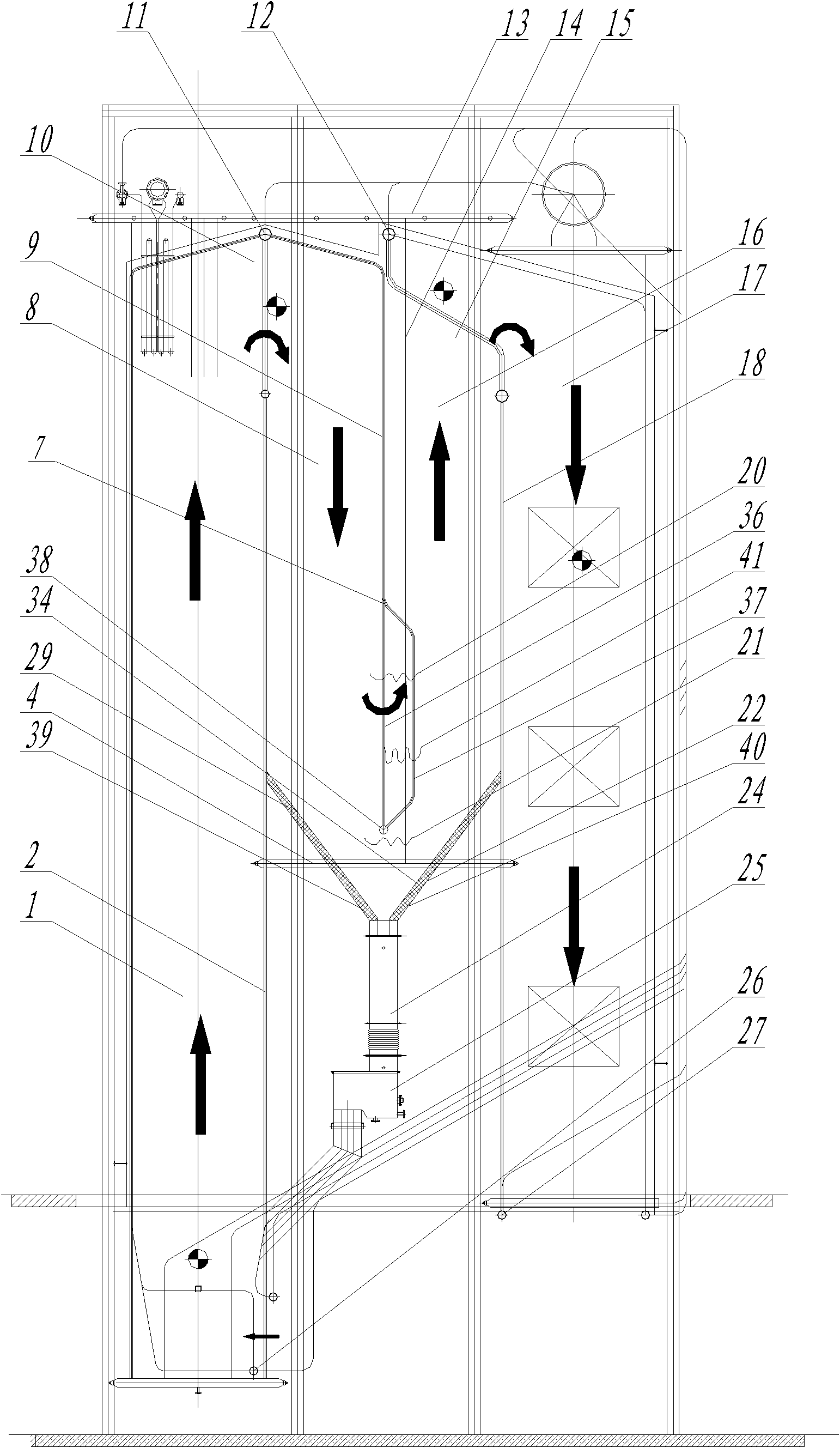

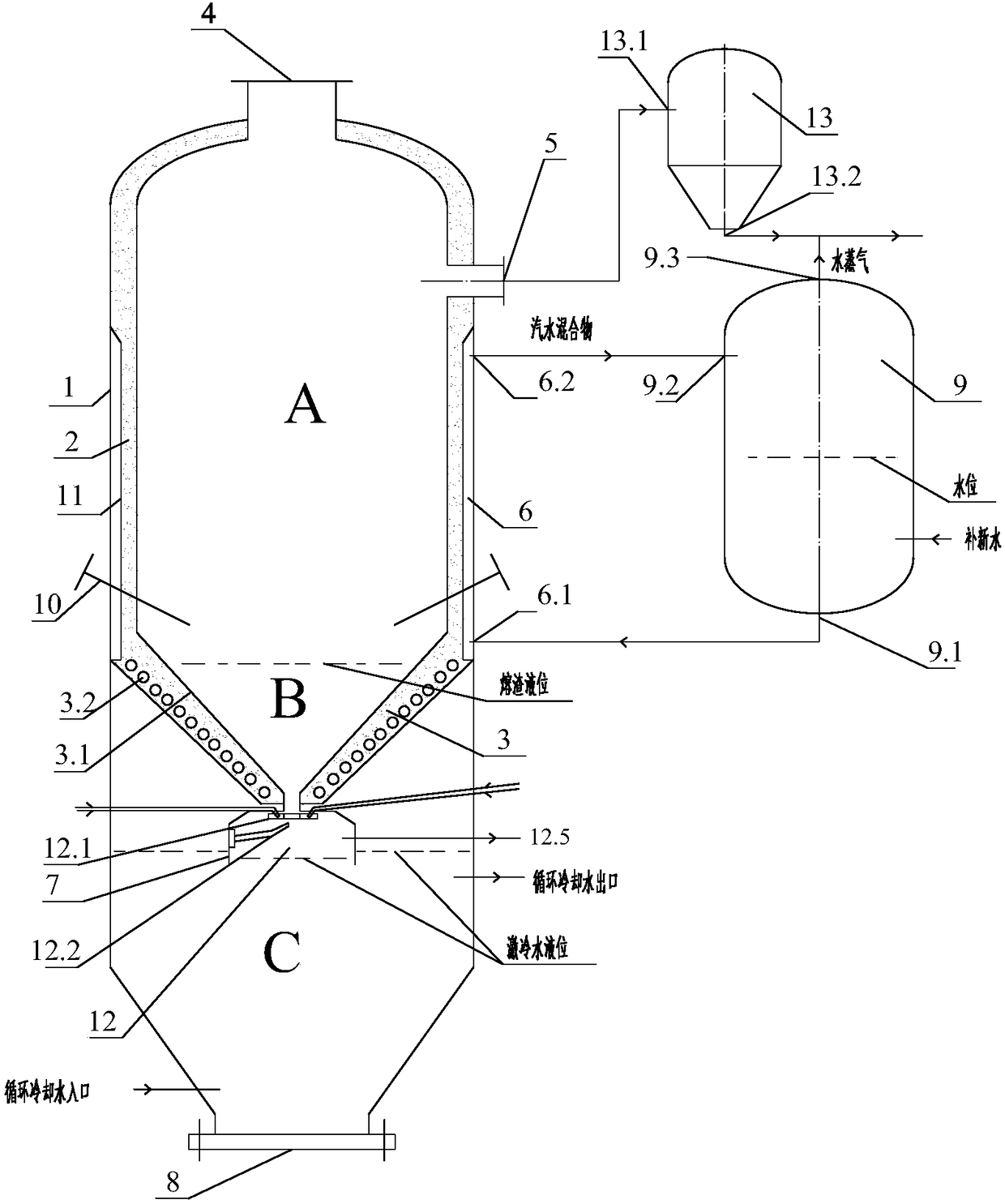

Material separator for circulating fluidized bed boiler

PendingCN101963350AExtended service lifeSave electricityFluidized bed combustionDispersed particle separationFluidized bedPulp and paper industry

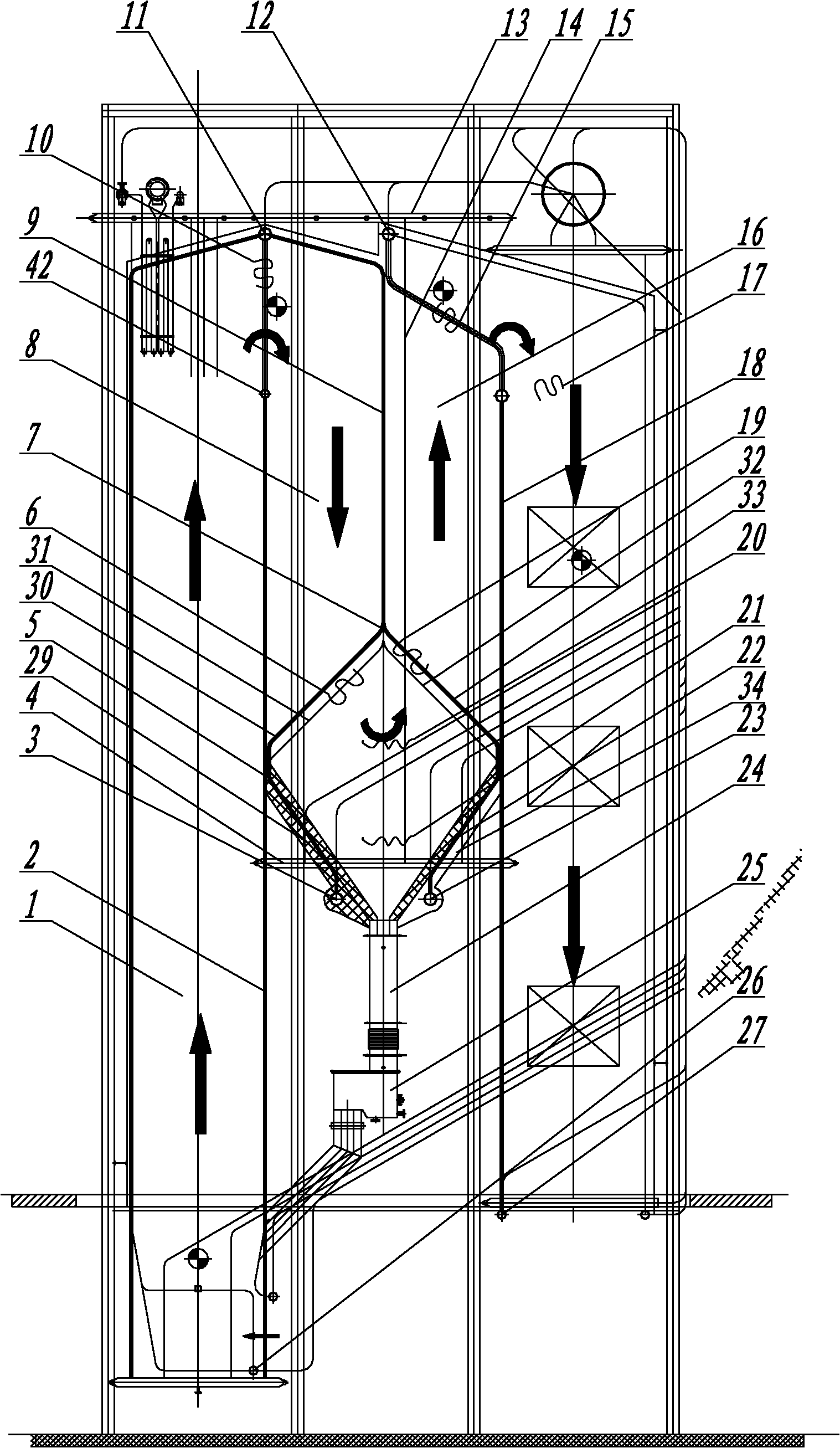

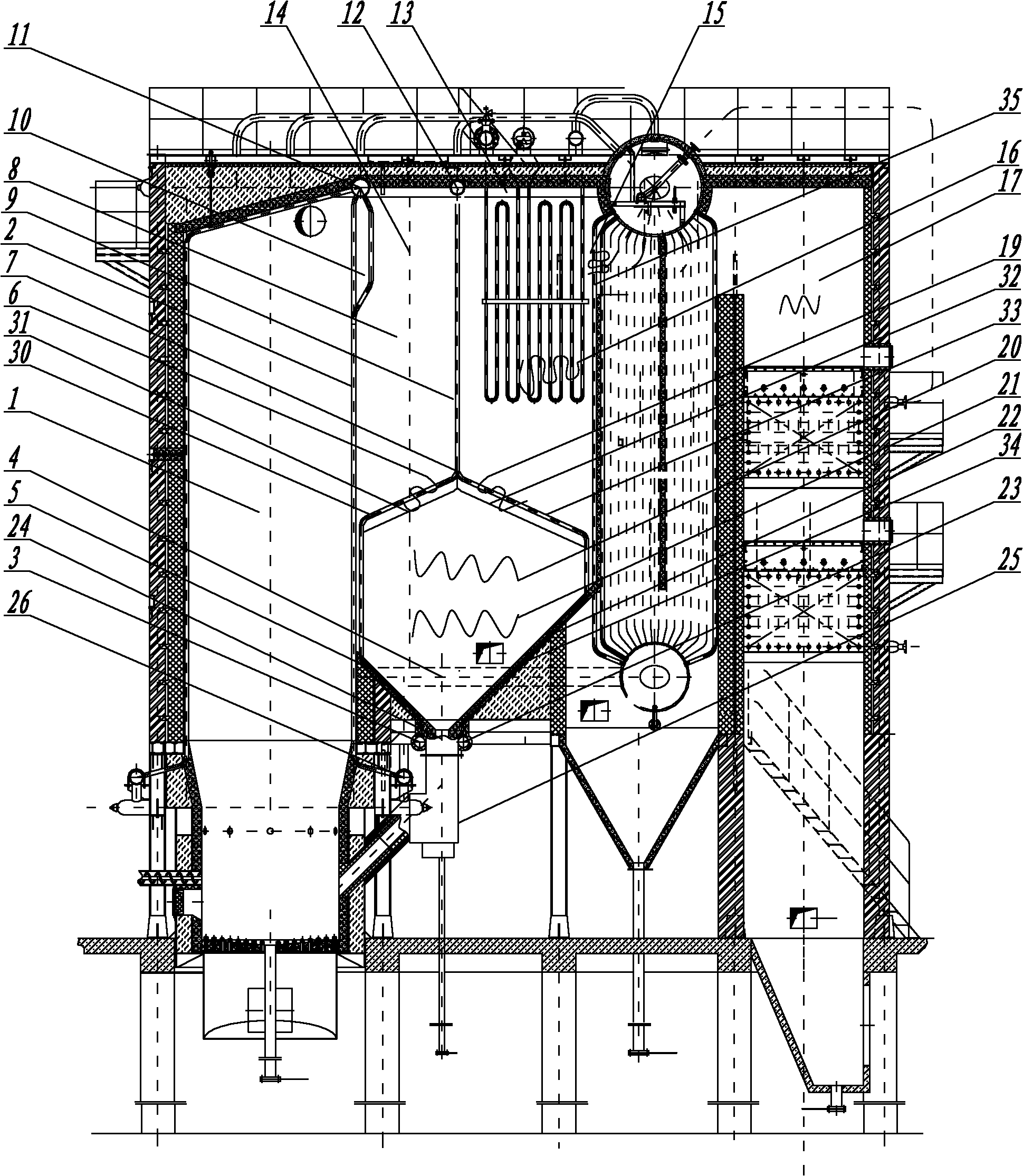

The invention discloses a material separator for a circulating fluidized bed boiler. The material separator is characterized in that: the lower end of a fume guide film-type screen which can be bent over is branched into two front rows of light tube bundles and two back rows of light tube bundles, wherein the two front rows of light tube bundles and the two back rows of light tube bundles are bridged above a storage bin and form a fume inlet and a fume outlet of a turning channel respectively; and the lower ends of the two front rows of light tube bundles and the two back rows of light tube bundles are communicated with a middle transverse collecting box of the boiler. The invention also discloses another material separator for the circulating fluidized bed boiler. The other material separator is characterized in that: the lower end of the fume guide film-type screen which can be bent over is branched into a front row of tube bundles and a back row of tube bundles, wherein the front row of tube bundles and the back row of tube bundles are positioned on the turning channel. The material separator has the advantages of advanced process, simple manufacturing and installation, wide application range, energy conservation, consumption reduction and remarkable emission reduction.

Owner:王森

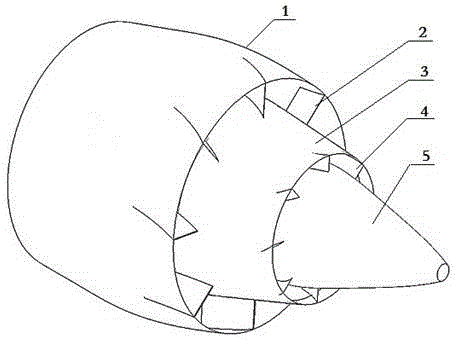

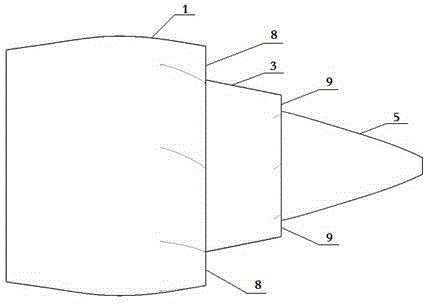

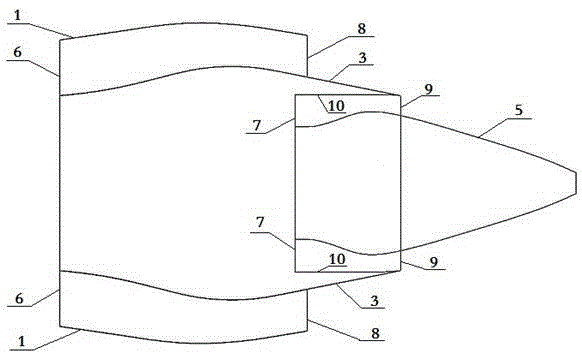

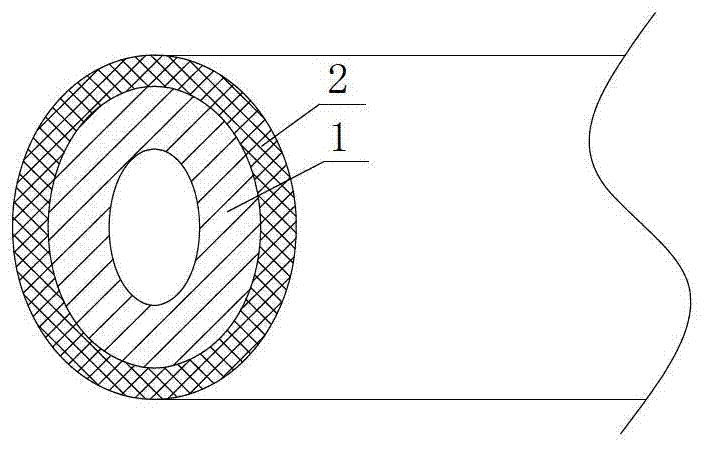

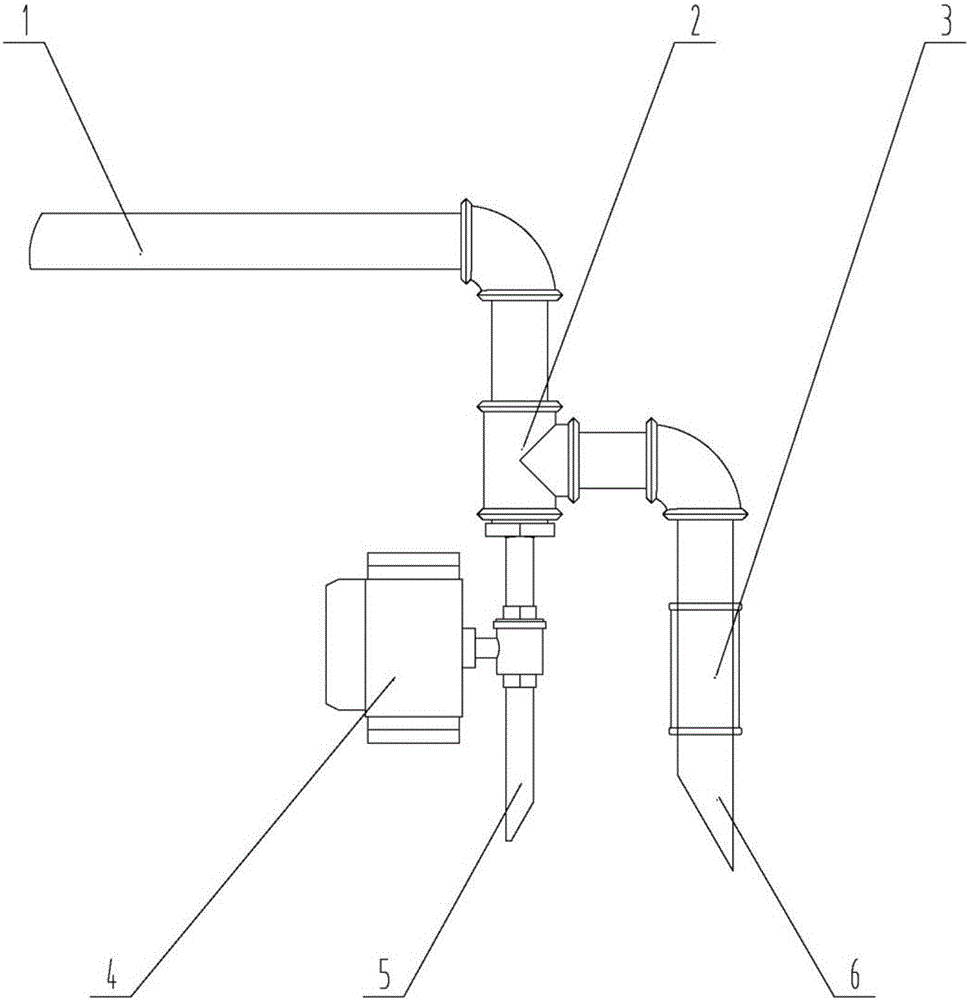

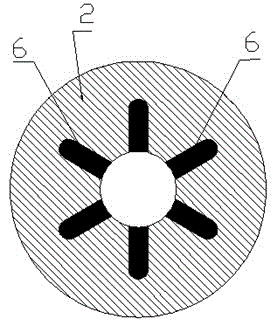

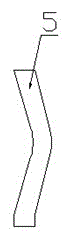

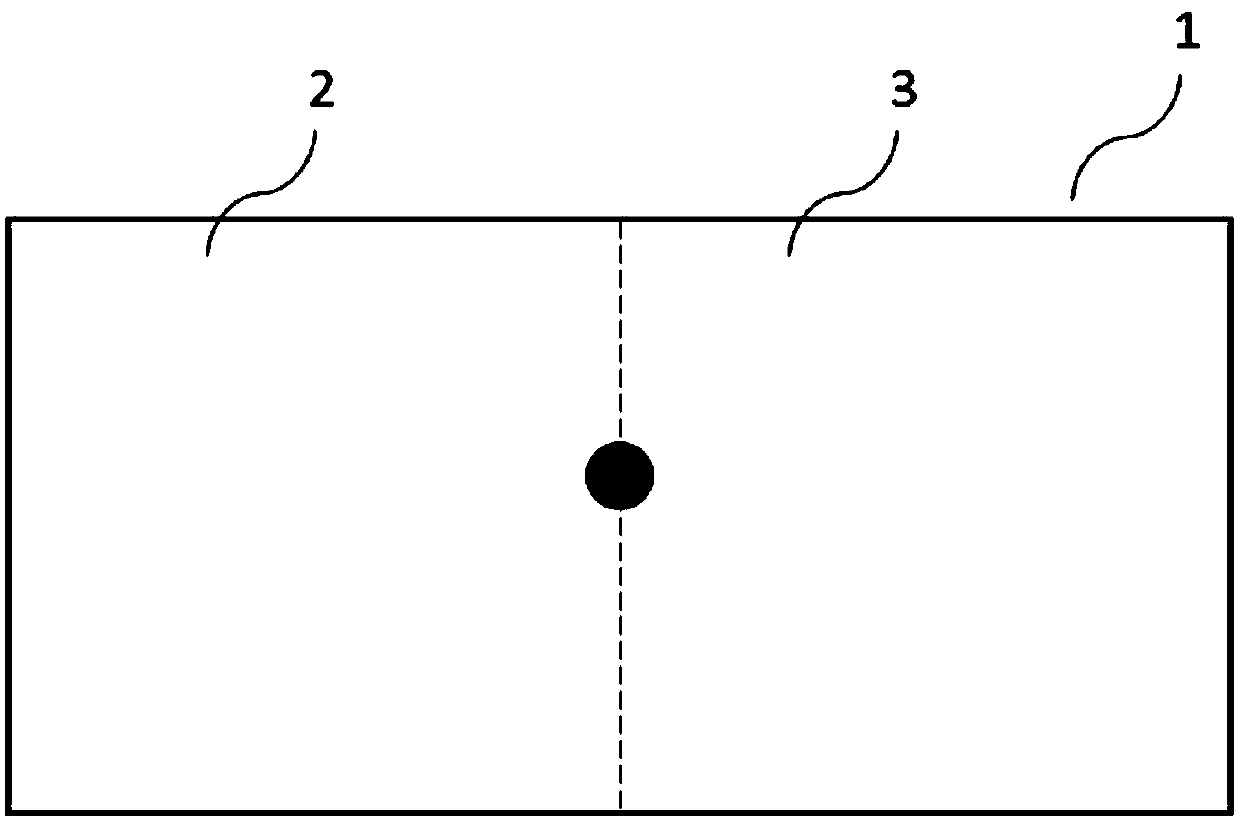

Exhaust noise reduction system of separated exhaust type turbofan engine

InactiveCN104405530ASimple structureReduced manufacturing and installation costsJet propulsion plantsAgricultural engineeringTurbofan

The invention discloses an exhaust noise reduction system of a separated exhaust type turbofan engine, and belongs to the technical field of design of aero-engine exhaust systems and exhaust noise reduction. The exhaust noise reduction system is characterized by being composed of an outer culvert outer wall face (1), outer culvert whirlcones (2), an outer culvert inner wall face (3), inner culvert whirlcones (4), an exhaust rectification inner cone (5), outer culvert exhaust inlets (6), inner culvert exhaust inlets (7), outer culvert exhaust outlets (8), inner culvert exhaust outlets (9) and inner culvert outer wall faces (10). The exhaust noise reduction system is simple in structure and small in influence on engine exhaust performance.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

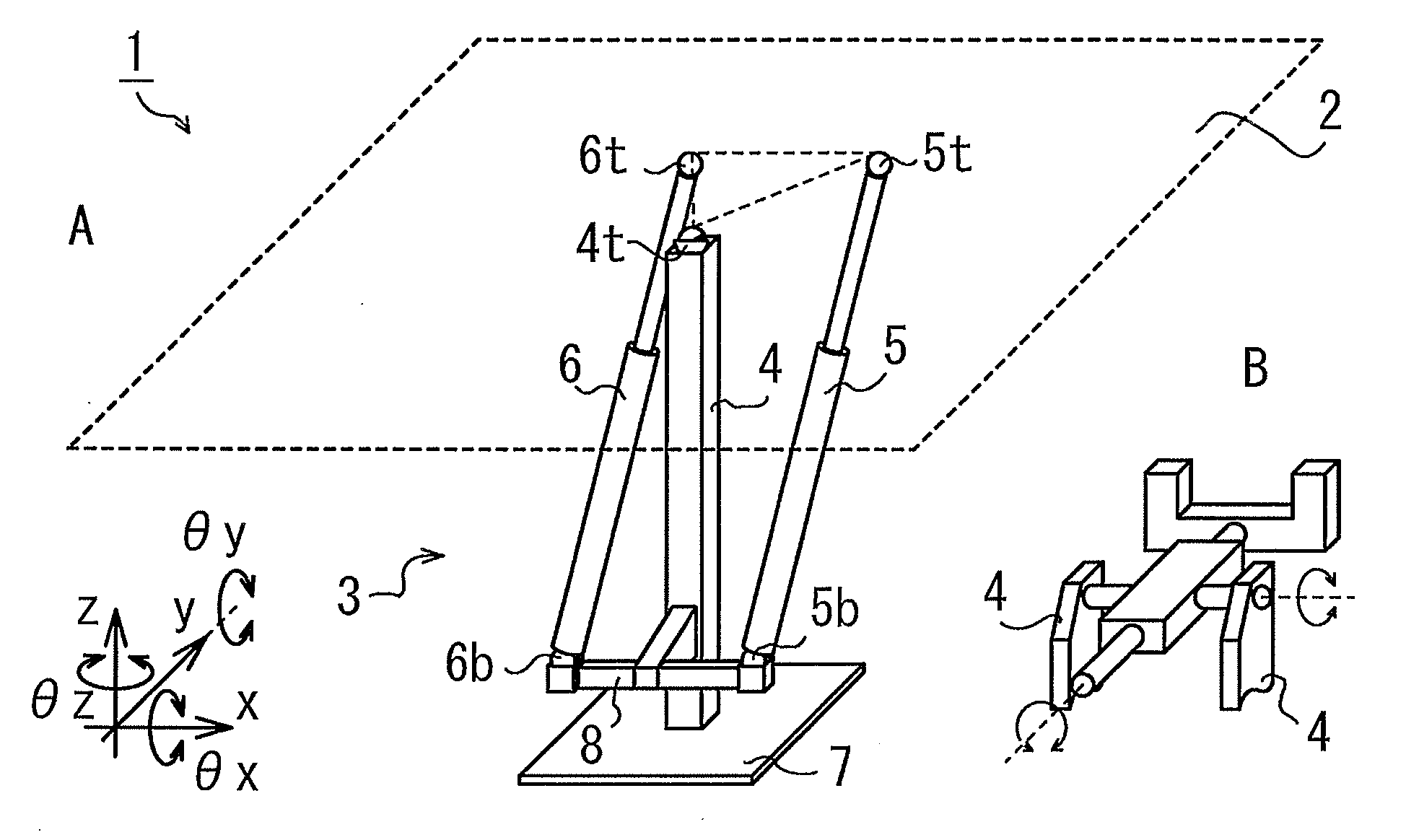

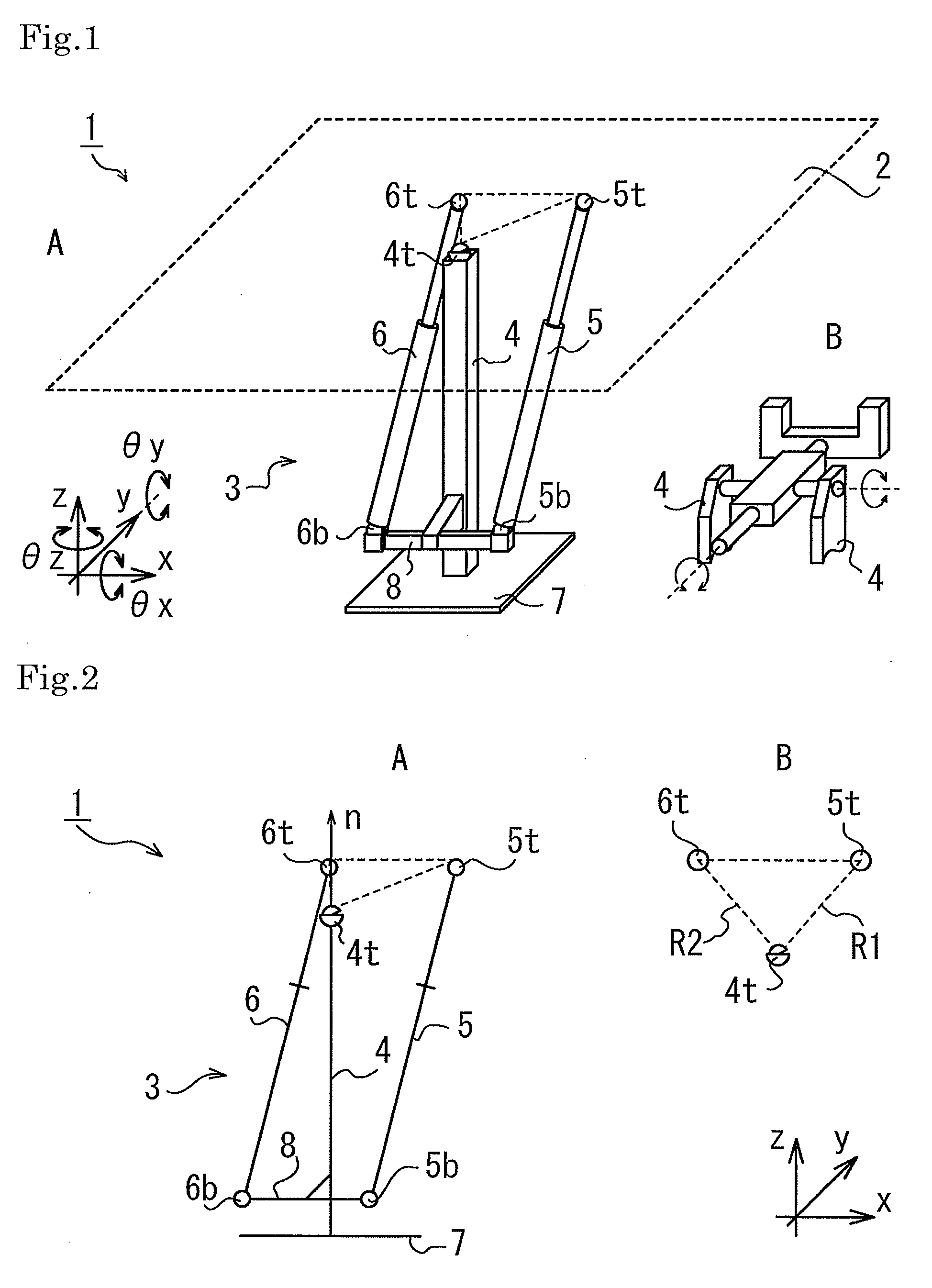

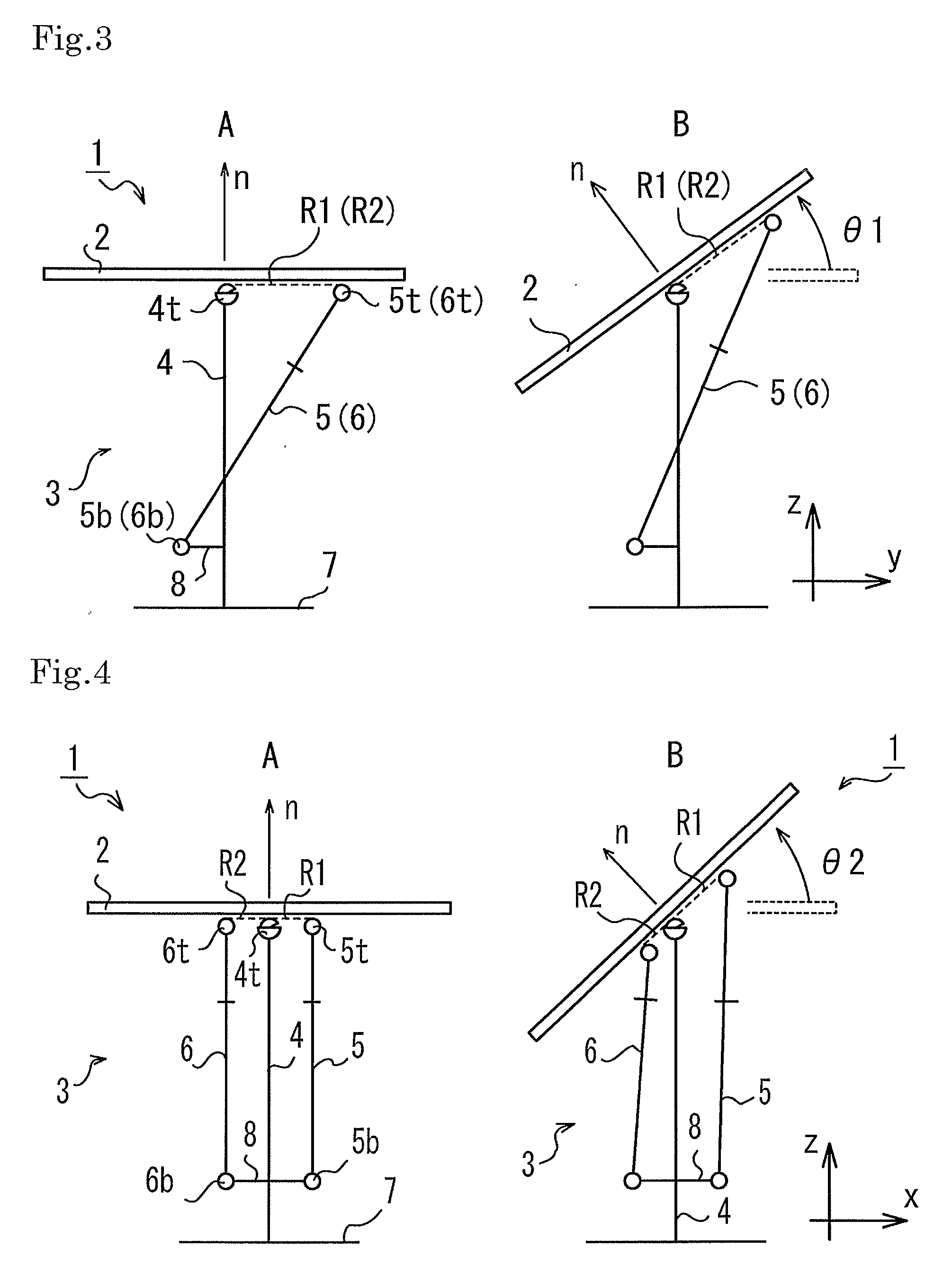

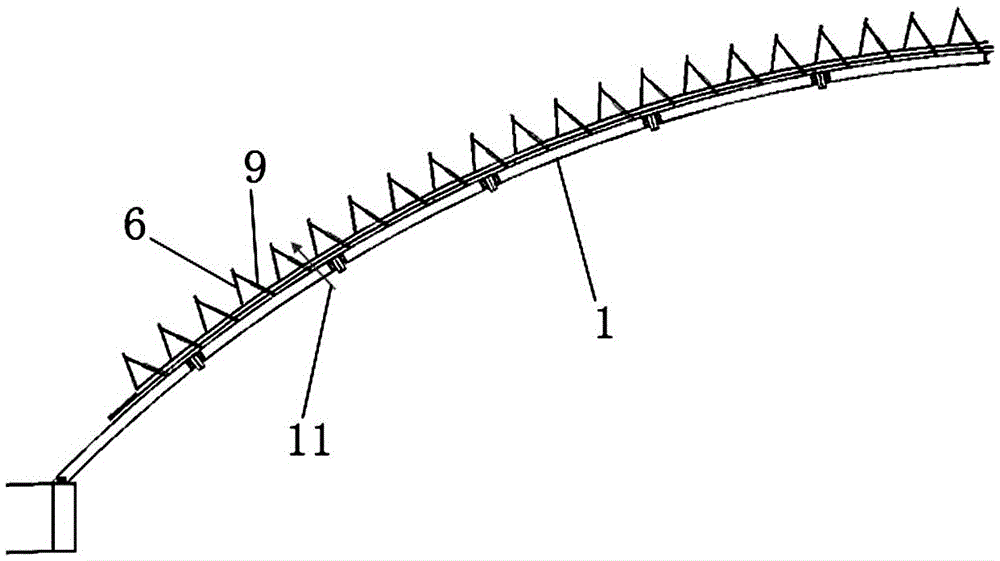

Heliostat for collecting sunlight and method of controlling the same

InactiveUS20120279486A1High efficiencyReduced manufacturing and installation costsSolar heating energySolar heat collector controllersEngineeringSunlight

Owner:MITSUI ENG & SHIPBUILD CO LTD

Gas and solid separator of recirculating fluidized bed boiler and boiler containing same

InactiveCN102062395AExtended service lifeSave wear-resistant and high-temperature resistant materialsFluidized bed combustionDispersed particle separationFlue gasFluidized bed

The invention discloses a gas and solid separator of a recirculating fluidized bed boiler, which comprises a downstream flue and an upstream flue which are partitioned by a guiding flue gas up-down replicating film type screen, wherein the downstream flue and the upstream flue are communicated with storage bins hermetically installed below the downstream flue and the upstream flue through a turning channel, the front upper part of the gas and solid separator is provided with a flue gas inlet, the back upper part of the gas and solid separator is provided with a flue gas outlet, and four walls of the gas and solid separator are all heated water-cooling walls integrated with the boiler; and the gas and solid separator also comprises a uniform flow separating pipe bundle positioned on the turning channel, the upper end of the uniform flow separating pipe bundle on the turning channel is communicated with the guiding flue gas up-down replicating film type screen, and the lower end of the uniform flow separating pipe bundle on the turning channel is communicated with a lower transverse container. The invention also discloses a recirculating fluidized bed boiler containing two sets of gas and solid separators. The recirculating fluidized bed boiler has the advantages of wide application range, advanced process, simple manufacturing and installation, energy saving, consumption reduction and obvious emission reduction.

Owner:王森

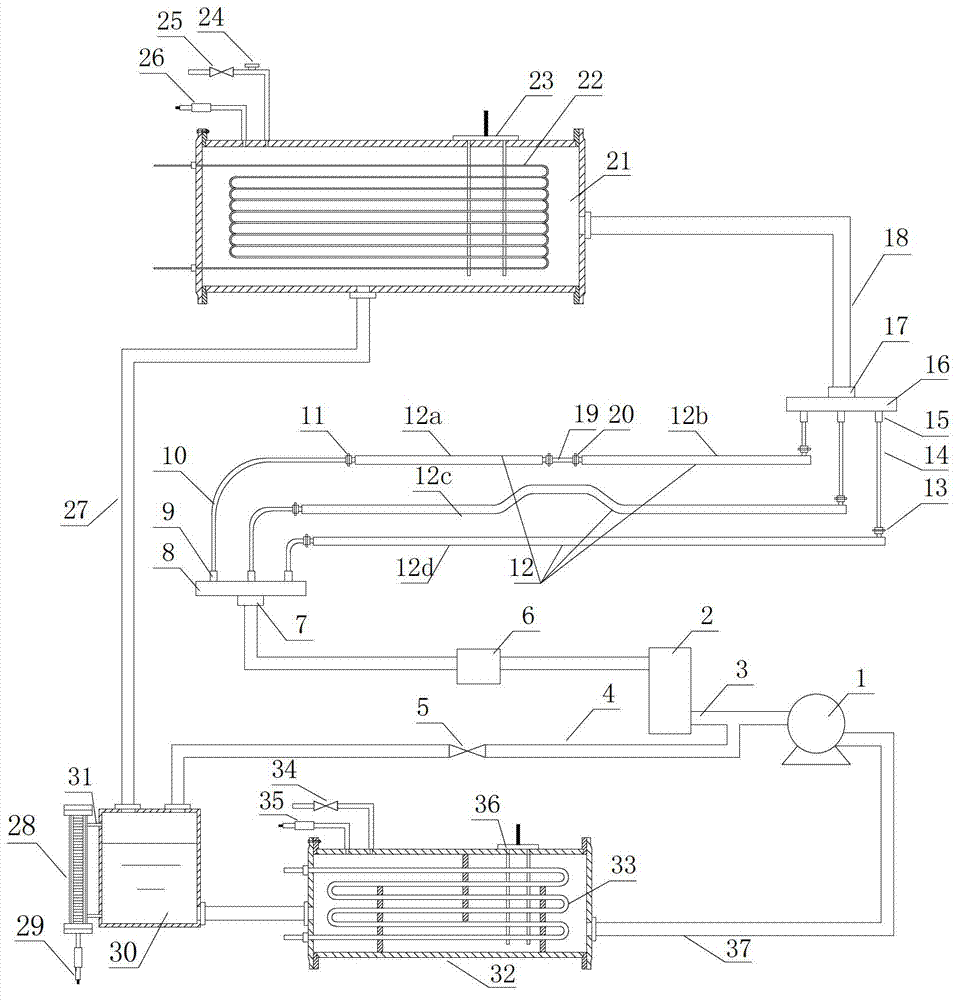

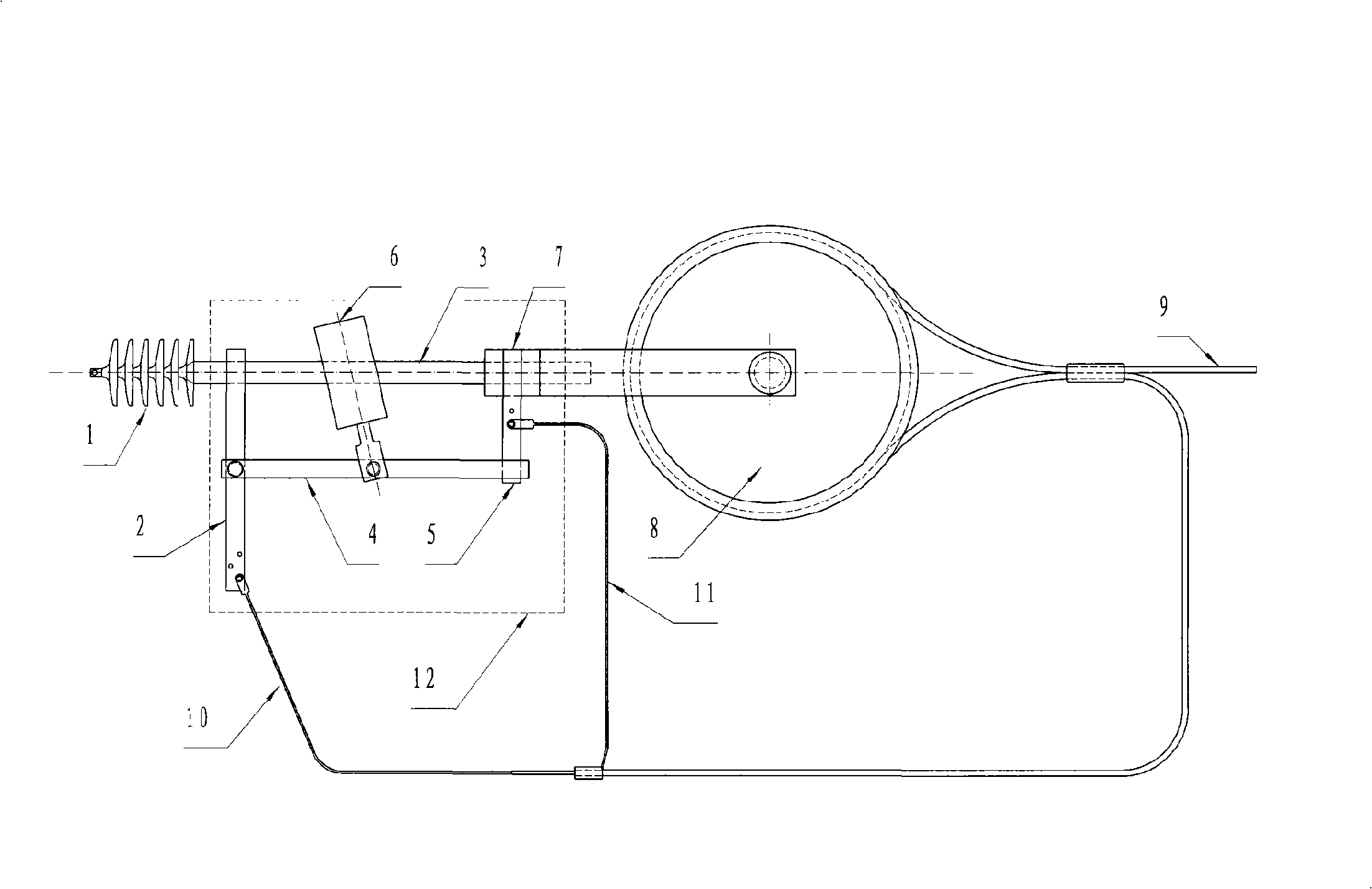

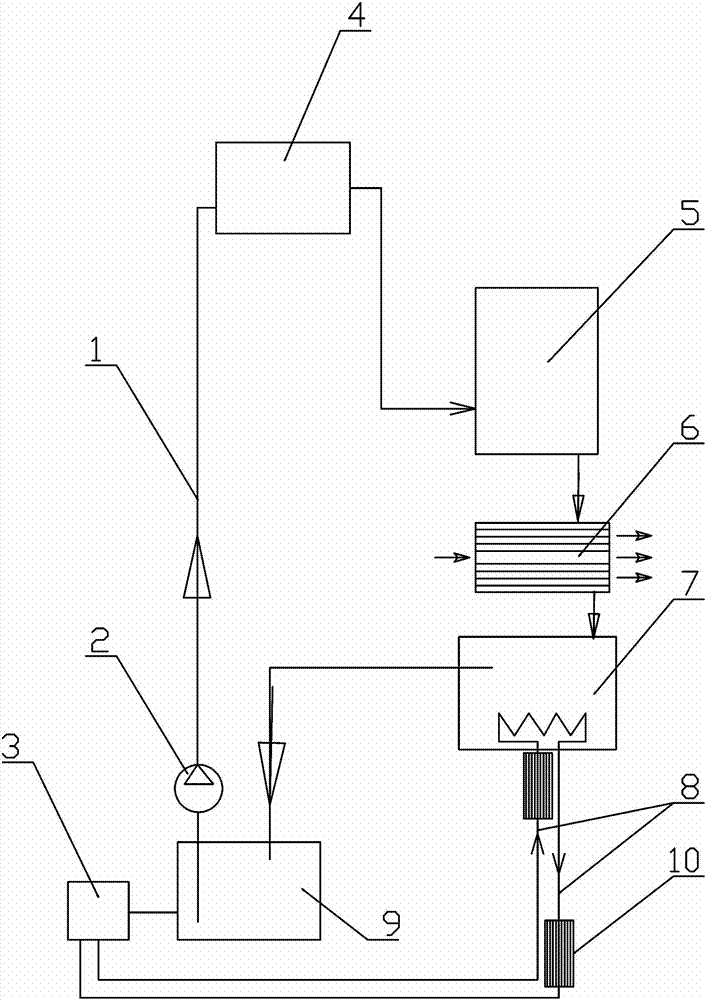

Forced circulation evaporation cooling device of hydro-generator stator busbar

ActiveCN102969838AAvoid short circuit accidentsImprove securityCooling/ventillation arrangementBusbarEvaporation

Provided is a forced circulation evaporation cooling device of a hydro-generator stator busbar. The stator busbar (12), a condenser (21), a liquid storage tank (30), a cooling device (32), a pump (1), a pressure stabilizing tank (2), a flowmeter (6), a liquid dividing pipe (8), a gas collecting pipe (16), a liquid supply main pipe (3), a gas outlet pipe (18), a liquid return main pipe (27), a total liquid return main pipe (37), a by-pass pipe (4) and an electro-liquid separation joint are connected to form an evaporative cooling circulation loop. An evaporative cooling medium in the loop is driven by a pump. The stator busbar includes one or a plurality of busbar branches, an inlet and an outlet of each busbar branch are respectively connected with the liquid dividing pipe and the gas collecting pipe through the electro-liquid separation joint and an insulation guide pipe, the busbar branches are connected in parallel, and the stator busbar is connected with the pump, the condenser, the cooling device and the like to form the independent evaporative cooling circulation loop. The forced circulation evaporation cooling device enables a plurality of busbars to be combined to form a unified parallel-connection pipeline and builds the independent evaporative cooling circulation loop.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

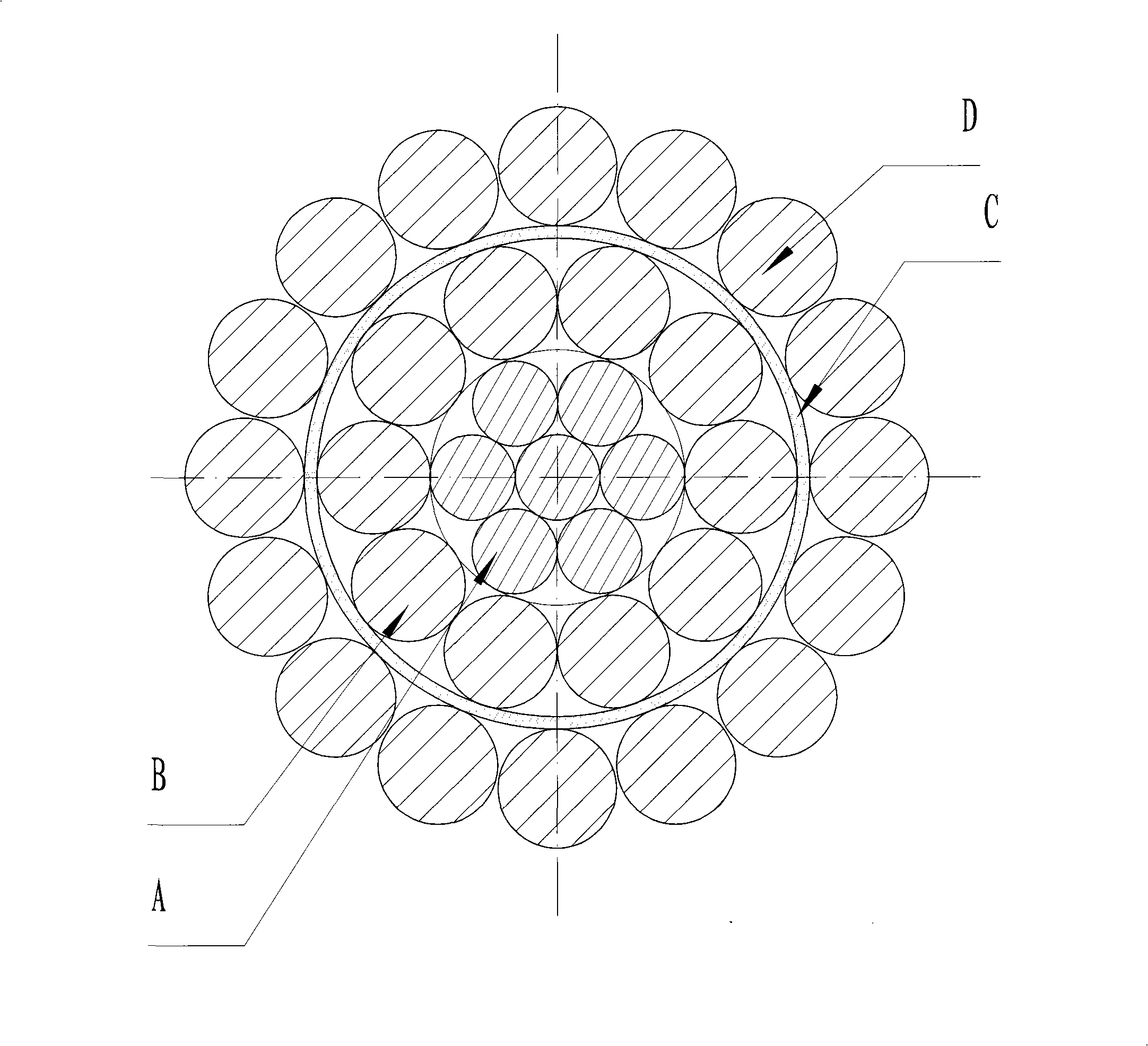

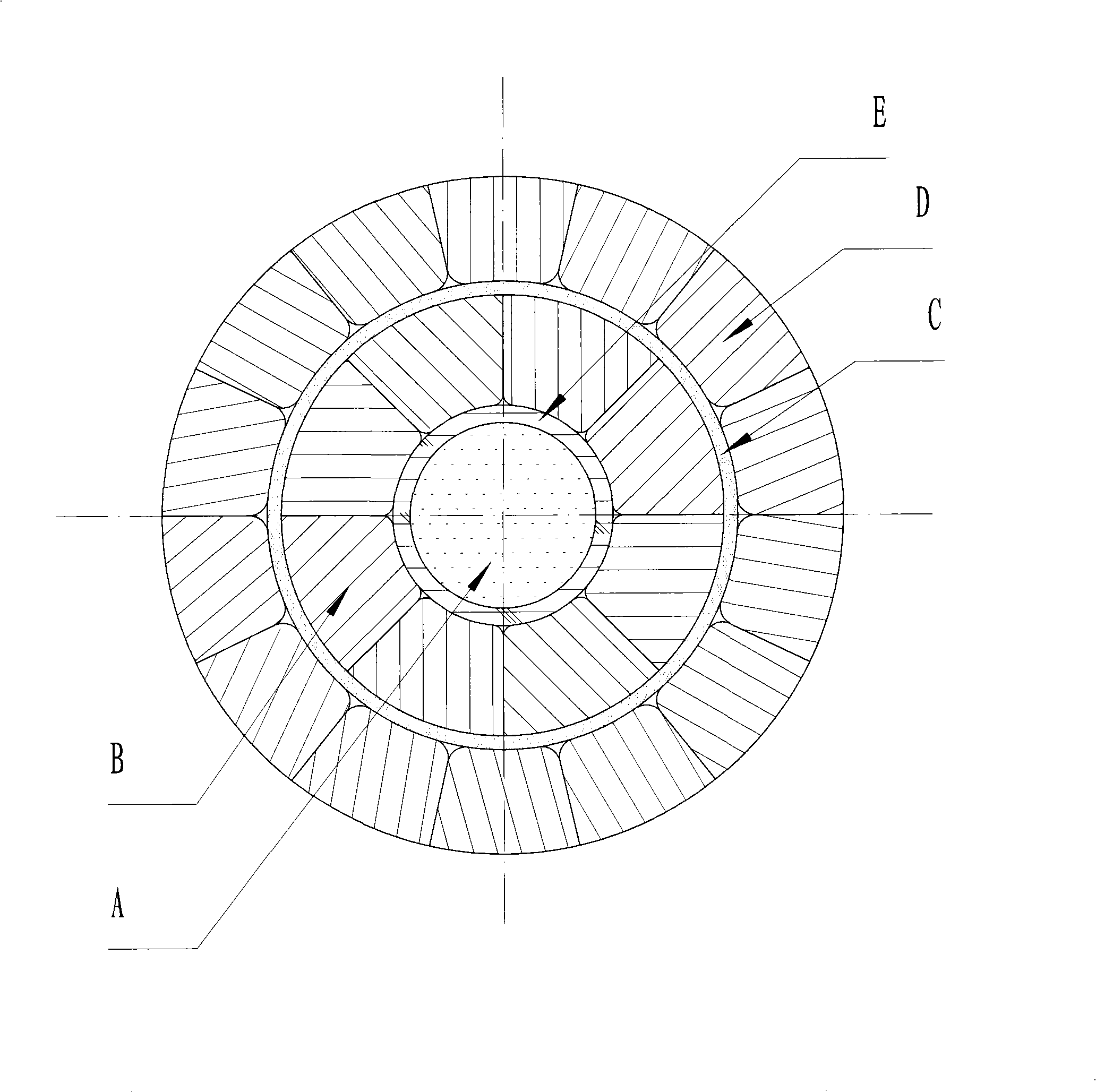

Method for deicing aerial power line with load

InactiveCN101299522AReduced manufacturing and installation costsIncreased line lossOverhead installationInsulatorsEngineeringIce melt

Provided is a method which can change the carrying current section of the power line to increase the line loss to cause the wire heat and reach the aim of ice melting through a switch in operation, wherein the wire is divided into three layers of A, B, D, and the insulating layer C is used to divide the A, B and D; the switch K arranged on the insulator string is used to switch the carrying current section of the power line. The key to realize the technical method is to provide a ice melting overhead power line and a diverter switch.

Owner:华旭东

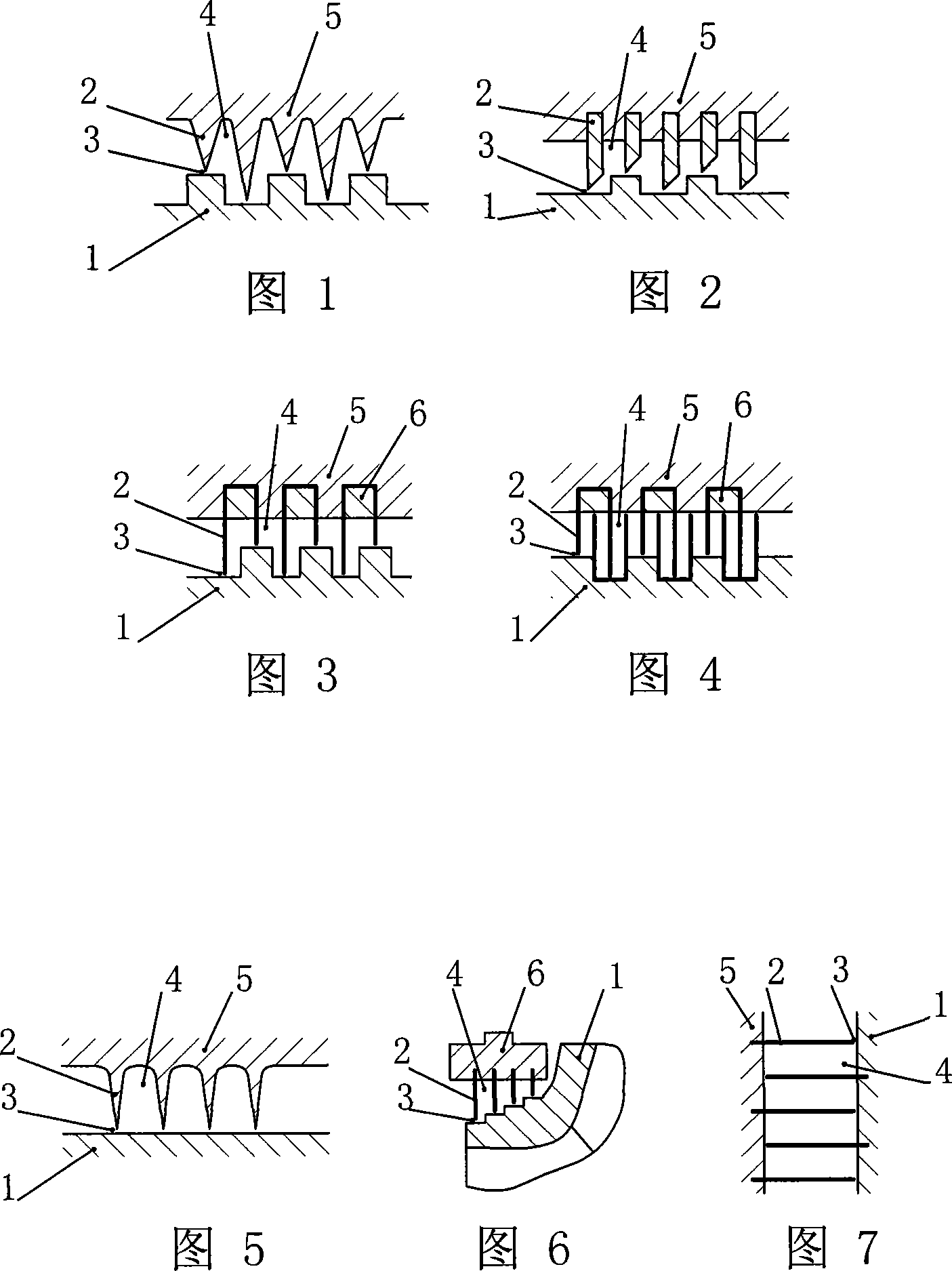

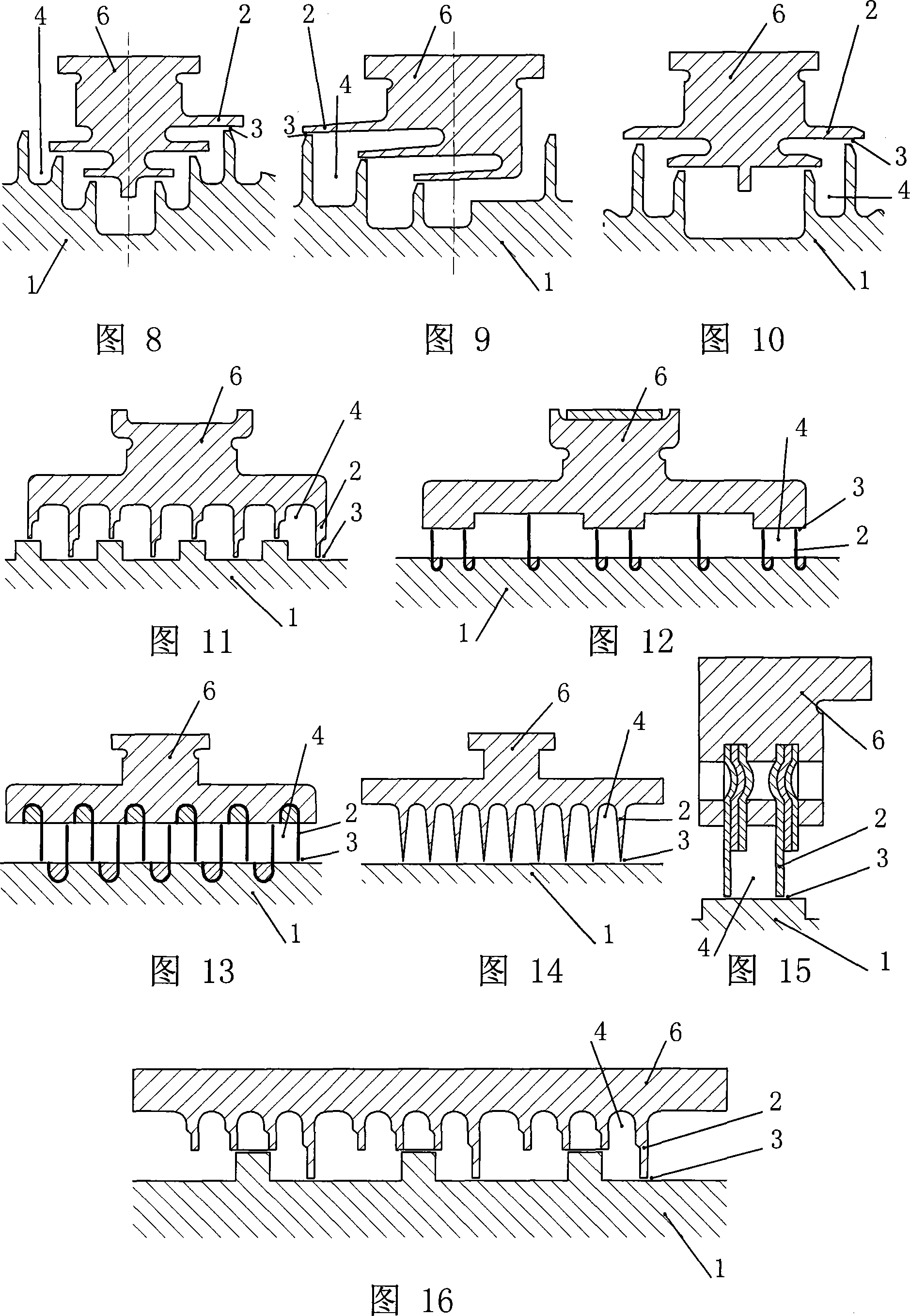

Method for making labyrinth seal

A method to produce labyrinth, the procedures are as following: Install a plurality of comb (2) on the base(5) and / or the rotating parts (1), form expansive cavity (4 )between the adjacent combs(2), cling each point of the comb(2) to the rotating parts (1) and / or the surface of the base (5)respectively when installing , there're wearable material on the surfaces of point and the surface of the rotating parts (1)and / or base(5) which adhere to the point, burnish and cut point of the comb(2) into throttle backlash(3) by the rotational rotating parts (1). Since the throttle backlash comes from burnishing and cutting of the rotational rotating parts, it is much more qualified for seal, and can reduce the leakage of the sealing system. It attempts to provide us a method to produce labyrinth with low cost of production and installation, long life of labyrinth, less leakage of sealing system, also it's easy and convenient to debug.

Owner:孟金来

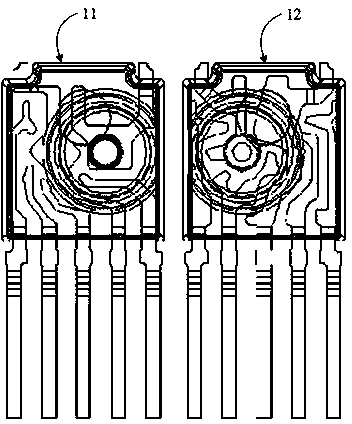

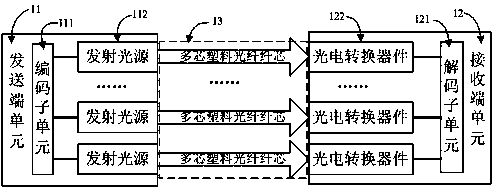

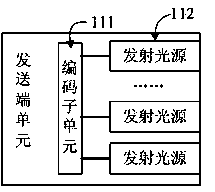

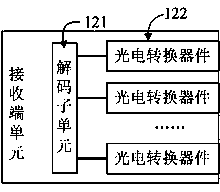

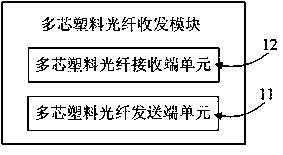

Multi-core plastic optical fiber connector system

InactiveCN104280833AHigh communication rateReduce manufacturing costCladded optical fibreFibre transmissionAccess networkFiber

The invention relates to a multi-core plastic optical fiber connector system which comprises multiple multi-core plastic optical fiber receiving and dispatching module, multi-core plastic optical fibers and a multi-core plastic optical fiber port switch, and each multi-core plastic optical fiber receiving and dispatching module is connected with the multi-core plastic optical fiber port switch through one corresponding multi-core plastic optical fiber to form a star-like structure, wherein the multi-core plastic optical fibers are plastic optical fibers including multiple fiber cores, and a multi-core plastic optical fiber port comprises the built-in multi-core plastic optical fiber receiving and dispatching module. The multi-core plastic optical fiber connector system solves the problems that an existing access network is prone to being interfered by electromagnetism and cost is high and an all-optical transmission network is obtained.

Owner:深圳市中技源专利城有限公司

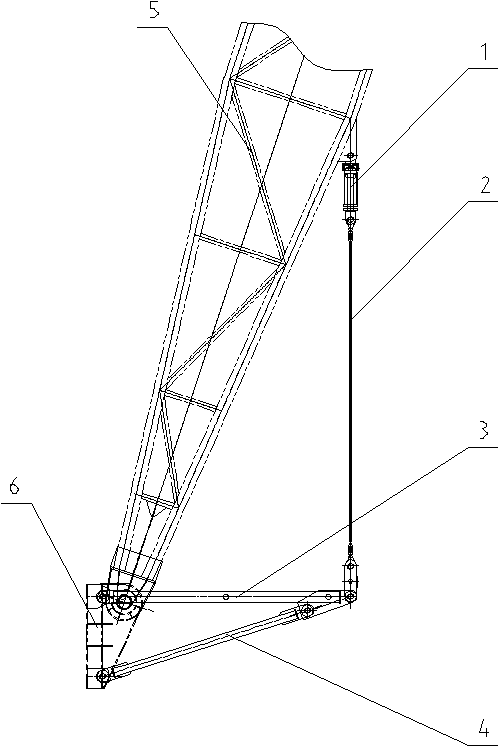

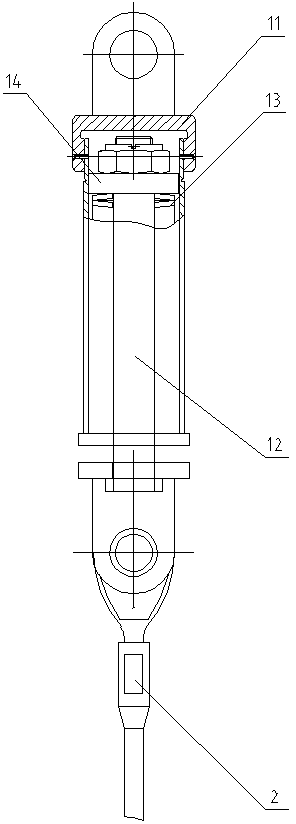

Backward inclining prevention device of stay-rope-type cantilever crane

Owner:JIANGSU DATONG HEAVY IND +1

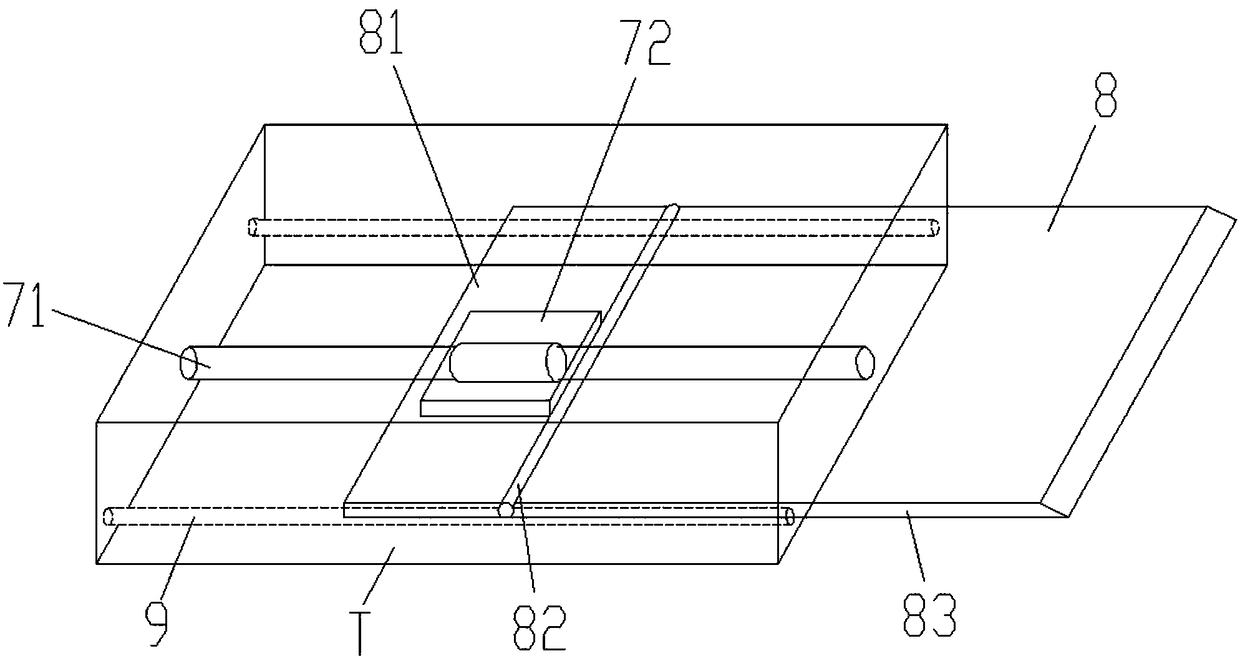

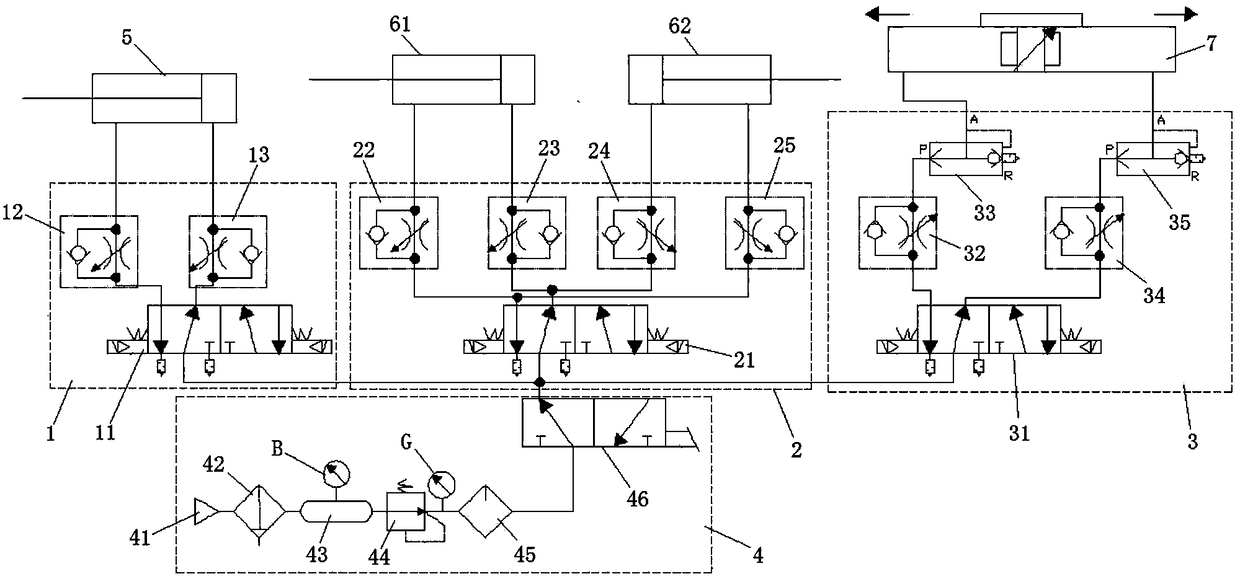

Connecting plate type barrier-free bus door driven by rod-free cylinder

The invention discloses a connecting plate type barrier-free bus door driven by a rod-free cylinder. The connecting plate type barrier-free bus door driven by a rod free cylinder comprises a connecting plate set, an air general control system, a connecting plate rod-free cylinder, a connecting plate rod-free cylinder, a bus front door cylinder and a bus rear door cylinder, wherein the connecting plate set is arranged on the lower portion of a bus rear door floor. The air general control system comprises a front door air control system, a rear door air control system, a connecting plate air control system and an air source general road system, wherein the air source general road system is used for providing pressure source for the front door air control system, rear door air control systemand connecting plate air control system. Two smooth supporting rods are arranged on the lower portion of the bus rear door floor, wherein the two smooth supporting rods are fixedly arranged in parallel, and the two smooth supporting rods are used for supporting the connecting plate set and providing guiding support for the sliding of the connecting plate set. The connecting plate rod-free cylinderis arranged between the two smooth supporting rods. The connecting plate rod-free cylinder comprises a rod-free cylinder guiding rod and a rod-free cylinder sliding platform, wherein the rod-free cylinder guiding rod is fixedly arranged, and the rod-free cylinder sliding platform works on the rod-free cylinder guiding rod to drive the connecting plate set to extend from the bus rear door floor toconnect with a bus platform to achieve the barrier-free accessibility.

Owner:NANJING INST OF RAILWAY TECH

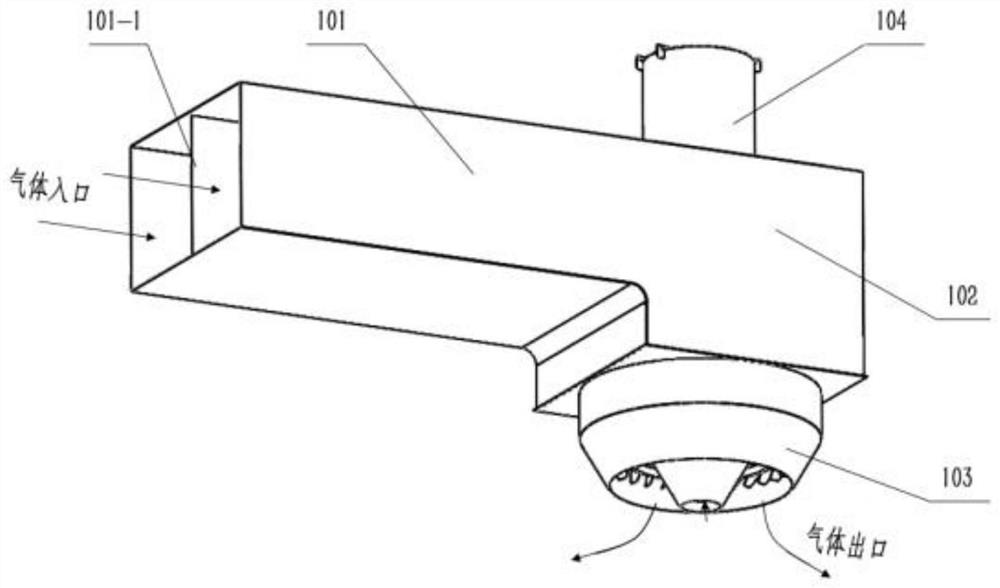

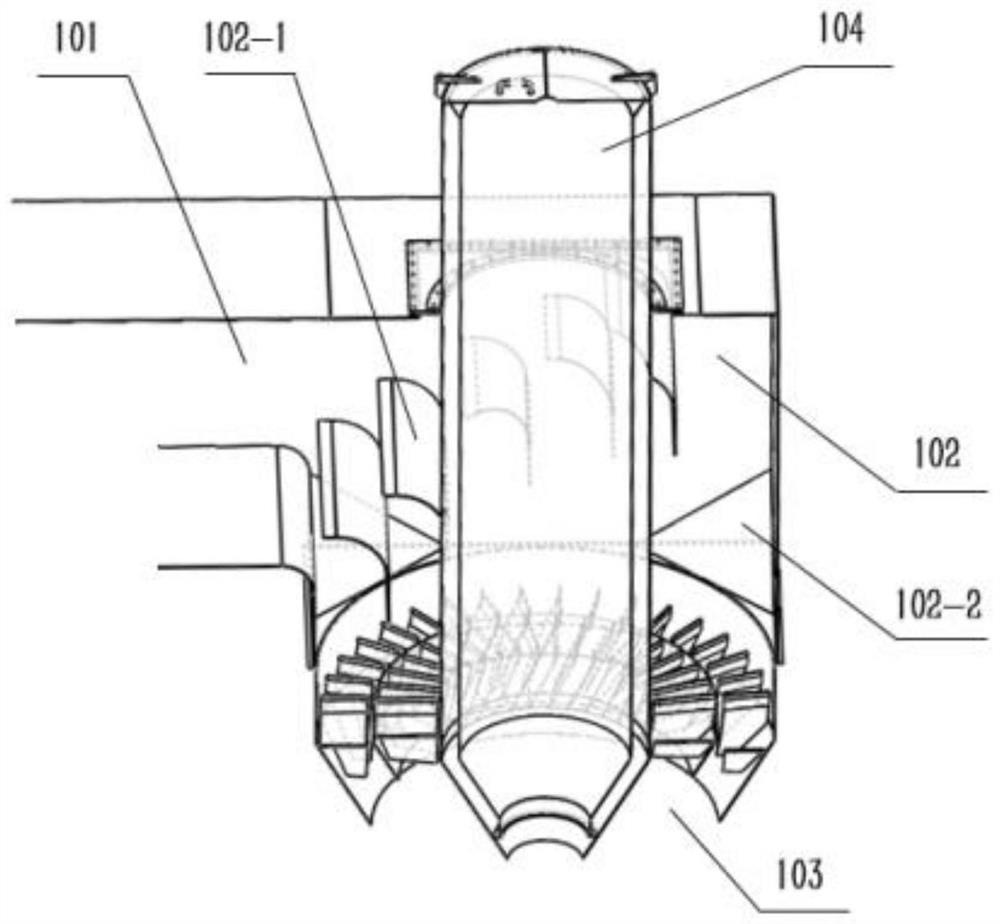

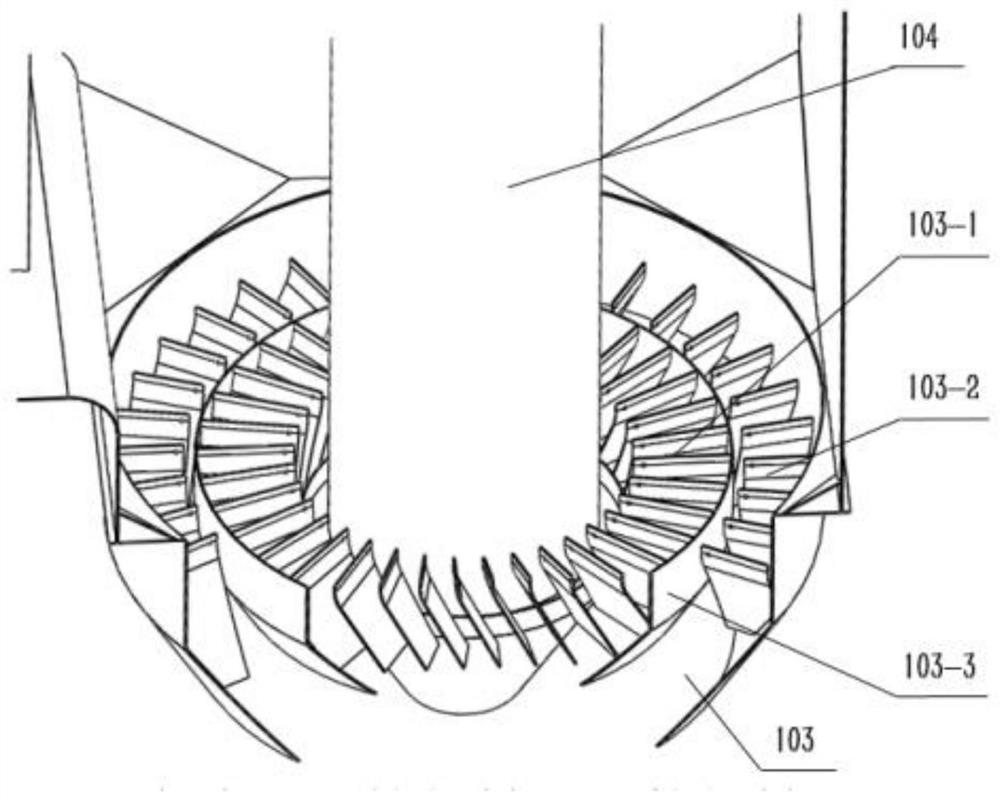

Gas distribution device for rotary atomization and evaporation

PendingCN112403002AIncrease load elasticityShorten the lengthEvaporator accessoriesEngineeringMechanical engineering

The invention discloses a gas distribution device for rotary atomization and evaporation. According to the gas distribution device for rotary atomization evaporation, a gas inlet flow channel is a horizontally-arranged rectangular straight cylinder flow channel, a partition plate is arranged in the gas inlet flow channel and divides the gas inlet flow channel into a left flow channel body and a right flow channel body, a gas distribution flow channel is arranged at the rear end of the gas inlet flow channel, and a flow guide plate is arranged at the joint of the gas inlet flow channel and thegas distribution flow channel; the gas distribution flow channel is vertically arranged, the upper half part of the gas distribution flow channel is a square straight flow channel, the lower half partof the gas distribution flow channel is a cylindrical flow channel, and the joint of the upper half part and the lower half part is in smooth transition by using a triangular flat plate; the lower end of the gas distribution flow channel is connected with a gas outlet flow channel, the gas distribution flow channel and the gas outlet flow channel are concentrically arranged in the vertical direction, and an inner-layer rotational flow blade and an outer-layer rotational flow blade are arranged at the joint of the gas distribution flow channel and the gas outlet flow channel through a layeringpartition plate; the gas outlet flow channel is of a conical structure, a vertical cylindrical center cylinder is arranged in the center of the gas distribution flow channel and the gas outlet flow channel, the lower end of the center cylinder is conical, a heat preservation layer is arranged in the center cylinder, an atomizer installation structure is arranged at the lower end of the center cylinder, and a movable cover plate is arranged at the upper end of the center cylinder.

Owner:JIANGSU JINGYUAN ENVIRONMENTAL PROTECTION

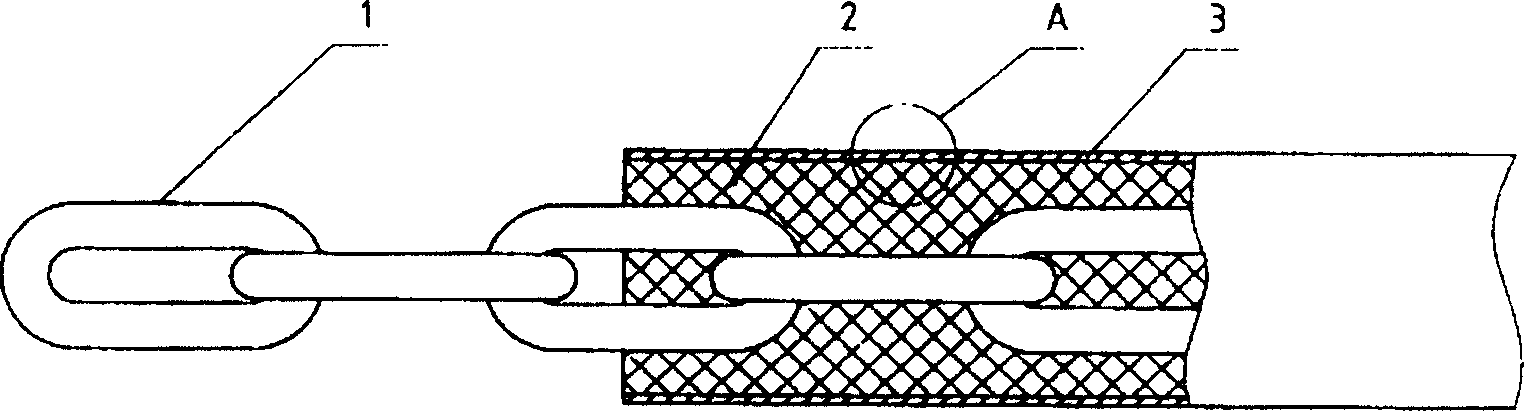

Elevator balance compensating chain and manufacturing method thereof

The present invention discloses a balance compensation chain for elevator and its prdouction method. It comprises iron chain, rubber column and fibre layer. Said iron chain is placed in the rubber column, and said rubber column is wrapped with fibre layer. Said production method includes: removing rust from iron chain; extruding rubber material into mould to cover iron chain to form rubber column; placing the rubber column into mould and extruding the fibre material into mould to cover rubber column surface to form fibre layer; vulcanizing, cooling and setting, trimming and finishing to obtain the invented product with low noise, good wearability and high tearing strength and extensibility at break.

Owner:魏昌林

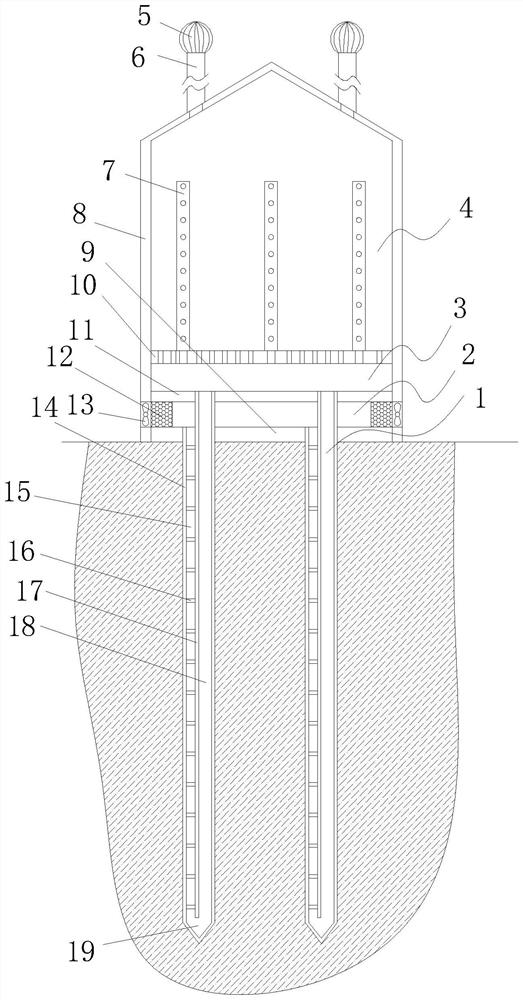

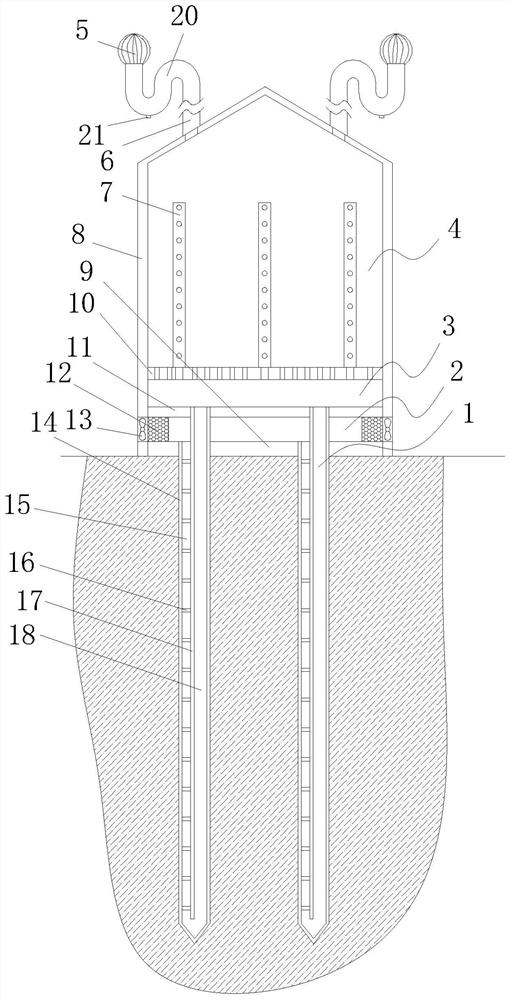

Granary with low-temperature storage function

InactiveCN112352559AImprove securityReduced manufacturing and installation costsAgriculture tools and machinesClimate change adaptationCold airStraight tube

The invention relates to the technical field of granaries, in particular to a granary with a low-temperature storage function. The granary comprises a granary body, wherein the granary bottom of the granary body is sealed by a bottom plate, the granary body is provided with a grain inlet and a grain outlet, and the granary body is arranged above the ground; a partition plate and a supporting plateare sequentially arranged at the positons, above the bottom plate, in the granary body in parallel from bottom to top, a second cavity is formed between the partition plate and the supporting plate,and a third cavity used for storing grain is formed above the supporting plate; a plurality of cold air flow assemblies are arranged at the bottom of the granary body, air inlet flow channels are formed in one sides of heat insulation plates, and air outlet flow channels are formed in the other sides of the heat insulation plates; and communicating holes are reserved between the bottom ends of theheat insulation plates and the bottom walls of heat conduction metal straight pipes, and the air outlet flow channels communicate with the second cavity. The device can achieve the purposes of cooling and ventilation of the granary by utilizing the properties of the device, meanwhile, the device is ingenious in structural design and low in manufacturing and mounting cost, and the possibility of heat accumulation and mildewing is reduced, so that the safety of grain storage is improved.

Owner:安徽宏虎粮油股份有限公司

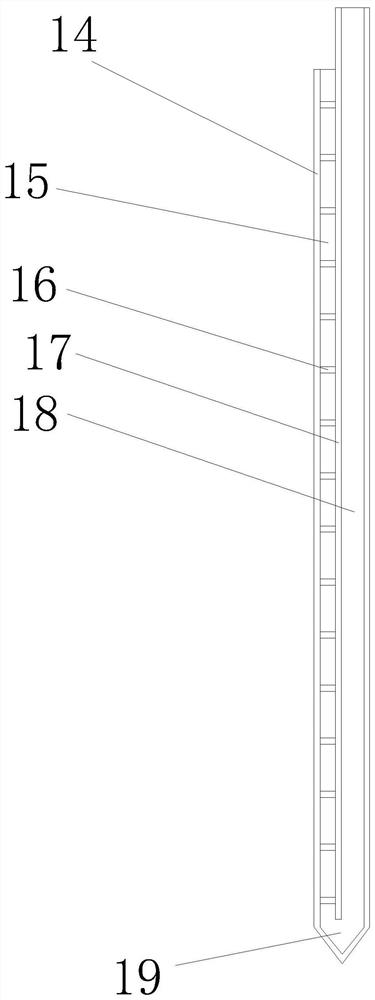

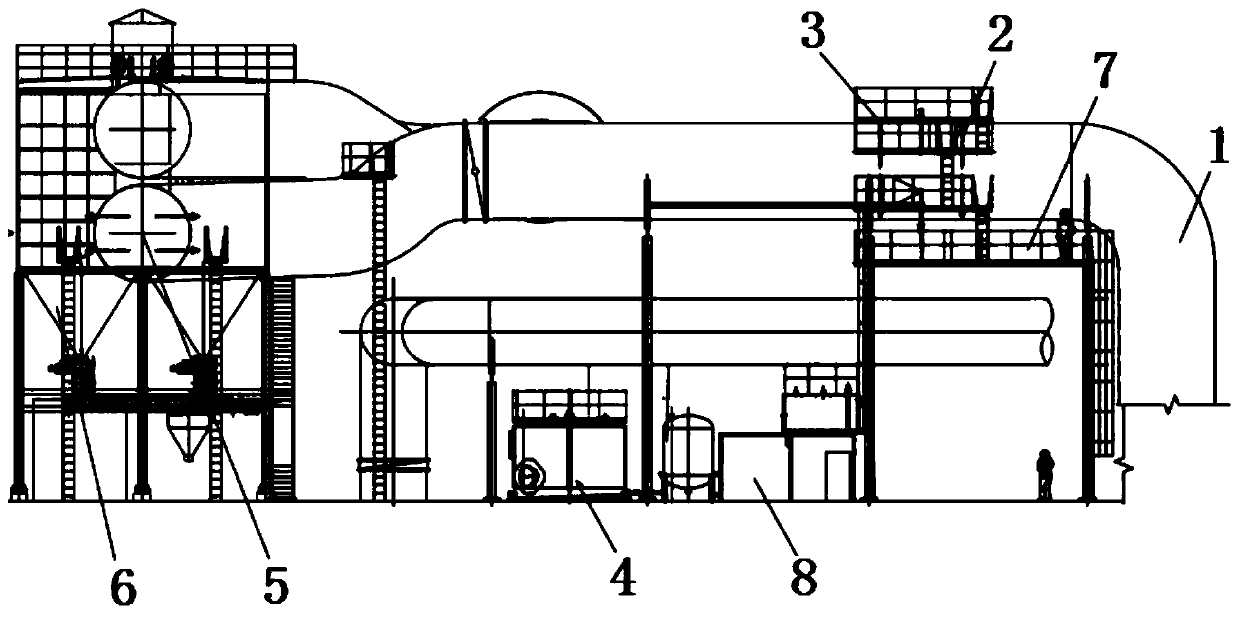

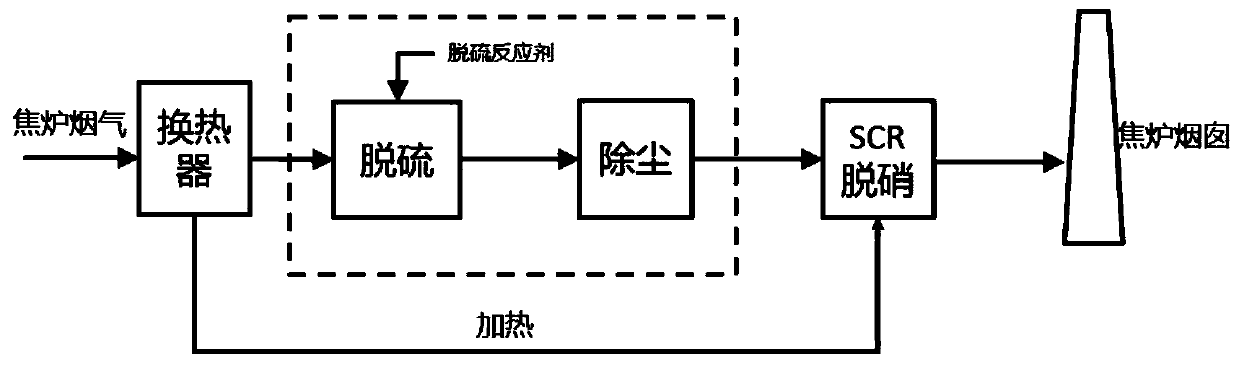

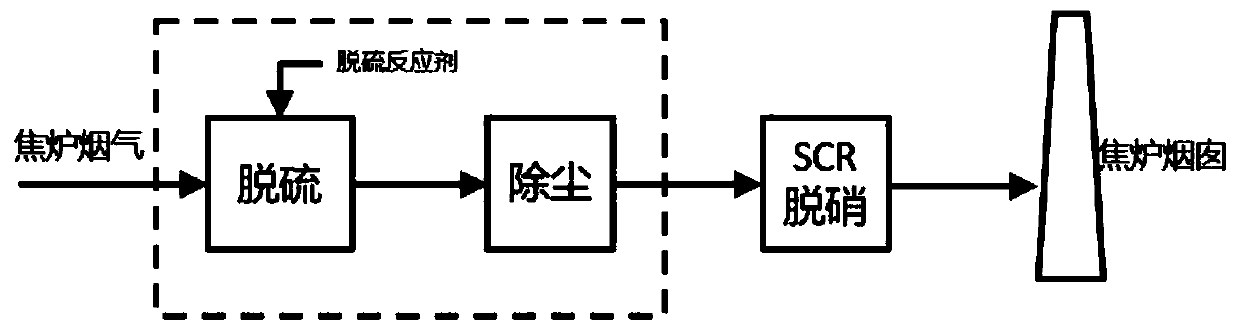

Semi-dry ammonia desulphurization process for coke oven flue gas

InactiveCN111359396ANo generationReduced manufacturing and installation costsGas treatmentDispersed particle filtrationDust controlAmmonium sulfate

The invention relates to the technical field of industrial flue waste gas purification treatment, and relates to a semi-dry ammonia desulfurization process for coke oven flue gas. A flue gas pipelineis adopted, an auxiliary steel structure is mounted on the outer wall of the flue gas pipeline through welding and bolt connection; a dust removal station system and an ammonia escape control system are connected to the bottom outer wall, close to one end, of the flue gas pipeline through welding and bolts; the flue gas pipeline is communicated with the dust removal station system and the ammoniaescape control system, and semi-dry ammonia desulfurization systems are installed on the side, close to the ammonia escape control system, of the outer wall of the top of the flue gas pipeline and theside, close to the ammonia escape control system, of the auxiliary steel structure through welding and bolts. The semi-dry ammonia desulphurization process has the beneficial effects that the flue gas pipeline is used as a desulfurization reactor, a desulfurization tower is not needed, the desulfurization tower manufacturing and mounting cost is saved, no waste liquid is generated, and the byproduct is mainly solid ammonium sulfate and can be sold as a chemical raw material.

Owner:湖南龙立机电技术有限公司

Liquid material accurate weighing device, liquid supply system and concrete stirring station

PendingCN106738354AAvoid phenomena that exceed the desired valueHigh precisionLiquid ingredients supply apparatusPipe fittingEngineering

The invention discloses a liquid material accurate weighing device, a liquid supply system and a concrete stirring station. On the one hand, as the inner diameter of a second liquid outlet pipe is smaller than that of a first liquid outlet pipe, the first liquid outlet pipe can be firstly used for carrying out rough weighing and rapid liquid supply on a liquid storage weighing hopper. When the weight or volume of the liquid in the liquid storage weighing hopper reaches a preset value, the second liquid outlet pipe is used for carrying out accurate weighing and slow supply on the liquid storage weighing hopper until the needed value is reached. The phenomenon that as the inner diameter of the first liquid outlet pipe is large, the flow speed of the liquid is high, timely control is difficult, and the liquid material flowing into the liquid storage weighing hopper exceeds the needed value is avoided, and the accuracy of liquid supply is further improved. On the other hand, in the accurate weighing stage, slow liquid material supply is carried out on the liquid storage weighing hopper through the liquid material left in a liquid inlet pipe and a tee joint pipe fitting. At that time, the liquid inlet pipe and the tee joint pipe fitting are equivalent to a liquid material storage unit. The liquid inlet pipe and the tee joint pipe fitting can be manufactured independently or adopt standard pipelines and pipe fittings, and the cost is lowered.

Owner:SANY AUTOMOBILE MFG CO LTD

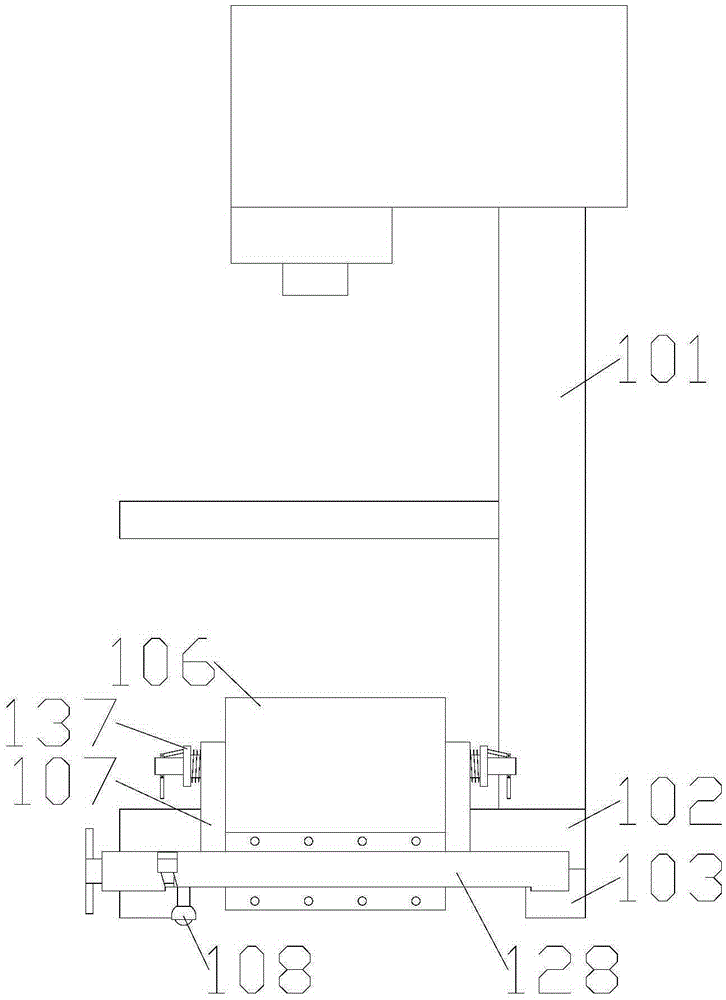

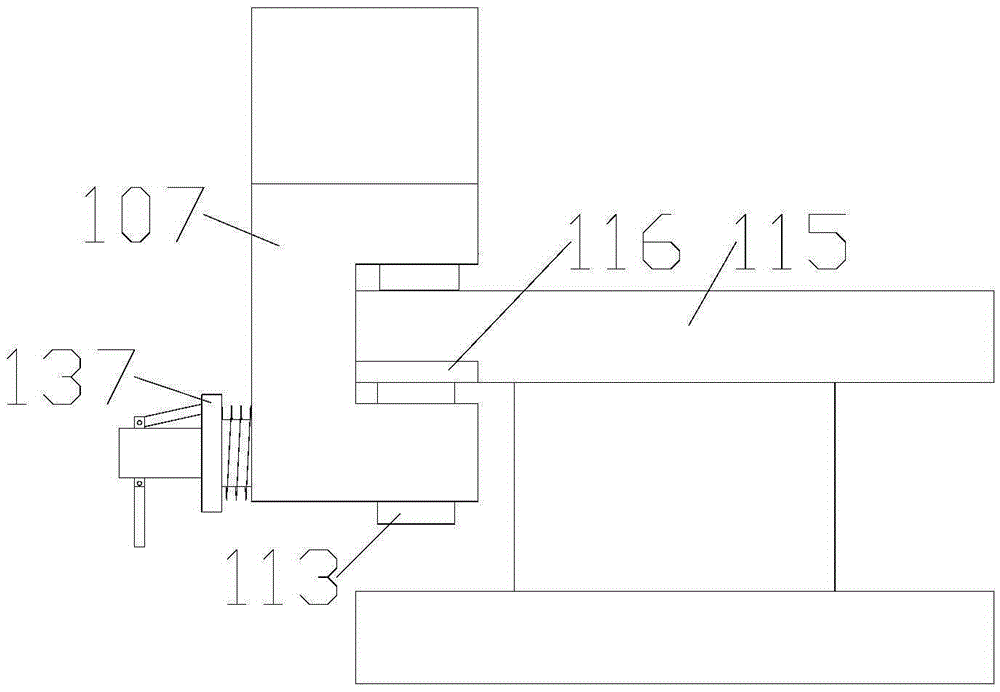

Tapping machine

ActiveCN105290539ASmooth slidingExtended service lifeThread cutting machinesMetal working apparatusPulp and paper industryTransfer mechanism

The invention provides a tapping machine and belongs to the field of processing machine tools. The tapping machine comprises a tapping machine body and at least two transferring mechanisms, wherein the bottom of the tapping machine body is a base; grooves are formed in the two sides of the bottom of the base; first blind holes corresponding to the grooves are formed in the top of the base; each transferring mechanism comprises a lifting part, two fixing parts and at least two travelling parts; U-shaped through grooves and embedded through grooves are formed in the fixing parts; a bulge is arranged in one side wall of each U-shaped through groove and a through hole is formed in the other side wall of each U-shaped through groove; rod pieces are arranged in the through holes in a penetrating manner; gears are rotationally arranged on the side walls of the embedded through grooves; each lifting part comprises a fixing plate; the left end and the right end of each fixing plate are respectively embedded into the embedded through grooves of the two corresponding fixing parts; a rack is vertically arranged on one side of each fixing plate; and the racks are meshed with the gears. By mounting the transferring mechanisms on the tapping machine body and rotating a control handle, the tapping machine body is separated from the ground and the travelling parts are in contact with the ground, so that the tapping machine can move anytime anywhere.

Owner:重庆渝湘精密机械有限公司

Hydraulic self-moving steel formwork trolley and its construction method

ActiveCN103437782BFast implementationAchieve fixationUnderground chambersTunnel liningMaterials scienceHydraulic pressure

The invention relates to a hydraulic self-moving steel mould trolley and a construction method of the hydraulic self-moving steel mould trolley. The hydraulic self-moving steel mould trolley is used for full-section circular tunnel concrete lining construction. The hydraulic self-moving steel mould trolley comprises a trolley moving device, a trolley structural frame, a steel structure combination formwork and a hydraulic control device, the trolley structural frame is arranged on the trolley moving device, the trolley structural frame is movably connected with the trolley moving device, the steel structure combination formwork is arranged in the trolley structural frame, the steel structure combination formwork is hinged to the trolley structural frame, and the hydraulic control device is used for controlling the hydraulic self-moving type steel mould trolley. The hydraulic self-moving steel mould trolley is simple in structure, convenient to install, strong in adaptability and capable of carrying out demoulding on concrete at the bottom of the tunnel at first and repairing concrete construction defects in time.

Owner:CHINA THREE GORGES CORPORATION +1

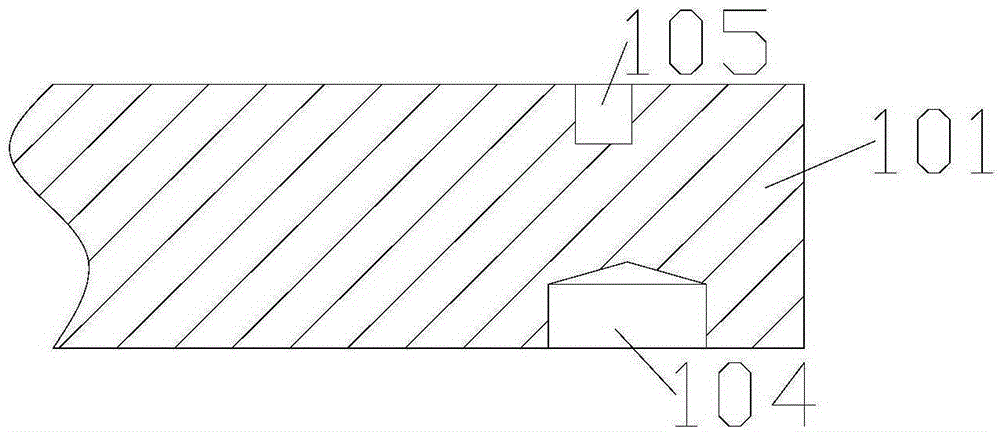

Shaft locating mechanism

InactiveCN102979797ASimple processReduced manufacturing and installation costsFastening meansManufactured materialStructural engineering

A shaft locating mechanism is characterized in that a shaft is arranged in a hole in a locating body, long grooves which are evenly distributed in a radial circumference mode are arranged on the periphery of the hole in the locating body, an arch-shaped spring piece is arranged in each long groove, the arch-shaped spring piece is in an arch shape, the arch back of the arch-shaped spring piece is higher than the outside of each long groove on a free state, a pressing plate is fixedly arranged on the outer side of the hole in the locating body through a bolt, and the pressing plate tends to extrude the arch back of the arch-shaped spring piece. The shaft locating mechanism has the advantages of being simple in technique, and low in manufacturing and mounting cost, raw materials are saved, assembling and disassembling are quick and convenient.

Owner:SUZHOU BLUE KING MACHINE TOOL TECH CO LTD

Touch recognition method

InactiveCN110597405ARealize touch operationEasy to operateInput/output processes for data processingControl signalTouchpad

The invention discloses a touch recognition method. The touch recognition method comprises the following steps that a touchpad comprises a touch area; a touch signal is detected in a touch area, so that the touch area is divided into a plurality of control areas, wherein the touchpad is in signal connection with the controller; and the touch area or the control area is used for acquiring and transmitting a control signal to the controller. By means of the technical scheme, touch recognition of regional control of the button-free touch device can be achieved, and therefore the technical purposes that touch operation is easier and more convenient, and user operation efficiency is improved are achieved.

Owner:肖宏开

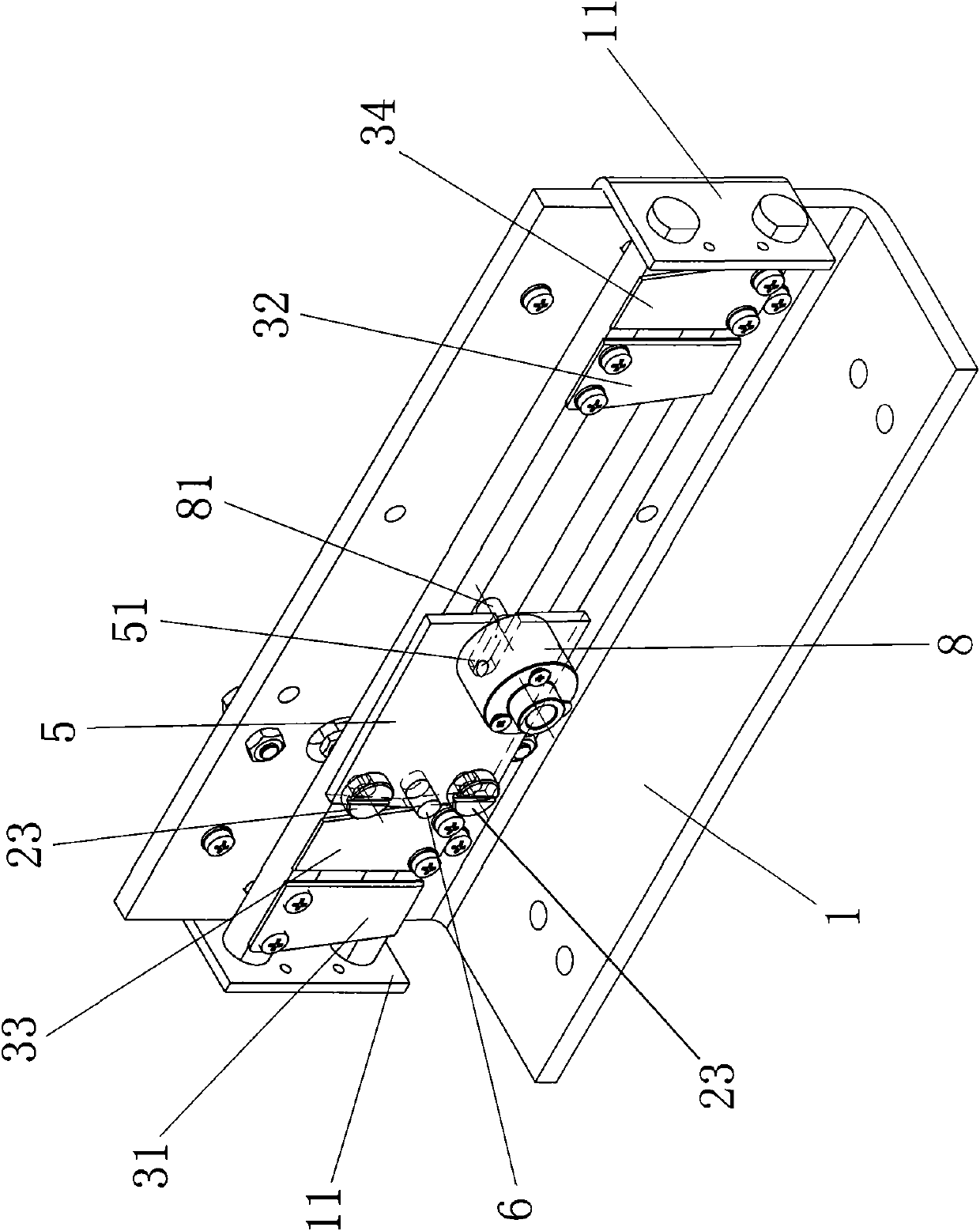

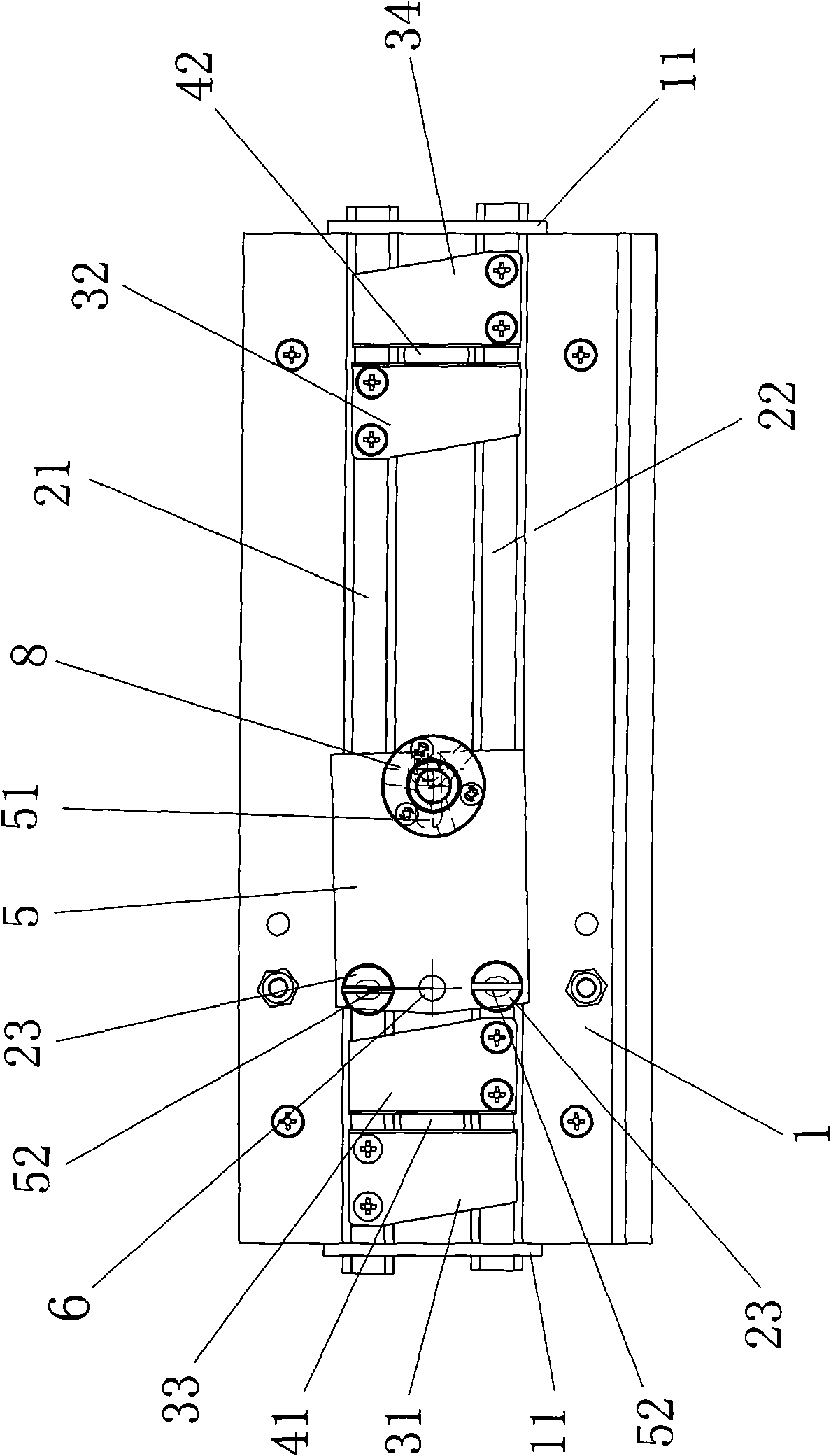

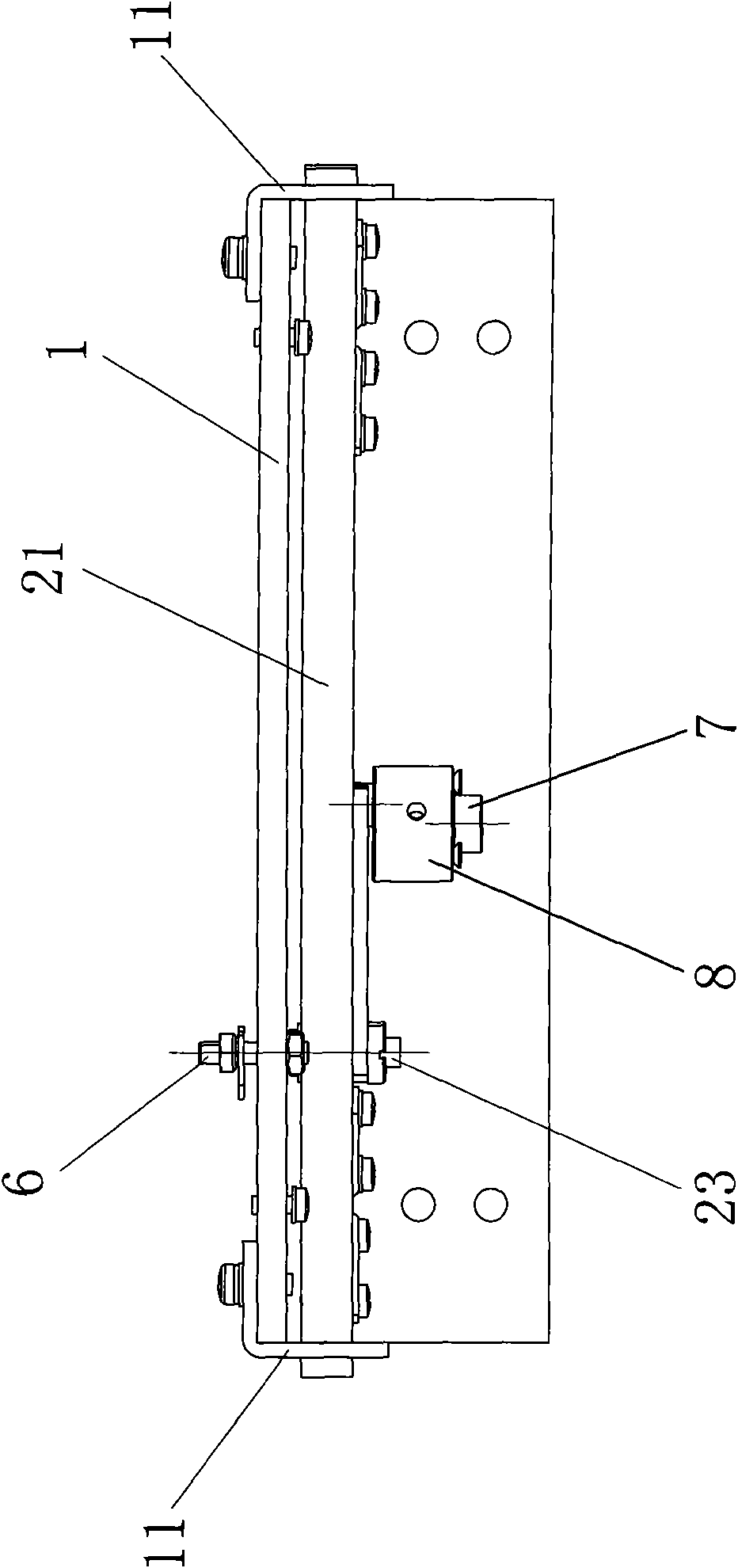

Installation debugging method of continuously variable slit mechanism

ActiveCN102141507BHigh precisionRealize synchronous regulationPhotometryMaterial analysis by optical meansMeasuring instrumentEngineering

The invention provides an installation debugging method of a continuously variable slit mechanism, and the method comprises the following steps: respectively installing first and second left slit slices and first and second right slit slices on first and second slide rods and splicing into zero slit; installing two displacement measuring instruments for measuring the horizontal displacement distances a1 and a2 of the first and second slide rods; and computing a corrected value e' by utilizing the following formulas, wherein the formulas are utilized to compute that a stepper motor is controlled to head n steps and the error of the obtained slit Tr' can be controlled at + / - 0.002mm. The continuously variable slit mechanism with a common accuracy grade can reach high accuracy after using the method provided by the invention.

Owner:BEIJING PURKINJE GENERAL INSTR

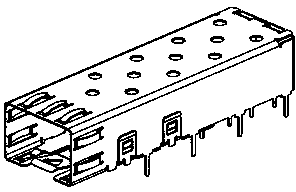

Multi-core plastic optical fiber port device and system

InactiveCN104283613AHigh communication rateReduce volumeFibre transmissionFibre mechanical structuresComputer modulePhysical layer

A multi-core plastic optical fiber port device comprises a switch chip 30, three physical-layer chips 311, 312 and 313, three multi-core plastic optical fiber receiving and dispatching modules 321, 322 and 323 and a power management module 33. The three physical-layer chips 311, 312 and 313 and the power management module 33 are directly connected with the switch chip 30, and the three multi-core plastic optical fiber receiving and dispatching modules 321, 322 and 323 are correspondingly connected with the physical-layer chips 311, 312 and 313 respectively.

Owner:深圳市中技源专利城有限公司

Cold water recycling pipeline device and method for slice ice machine

ActiveCN103486787AWon't meltReduce the temperatureLighting and heating apparatusFood processingWater resourcesEngineering

The invention discloses a cold water recycling pipeline device and a method for a slice ice machine. The cold water recycling pipeline device comprises a spiral pipe evaporator and the slice ice machine, wherein the spiral pipe evaporator is connected with a water tank through a pipeline and a water pump; the water tank is connected with the slice ice machine through a pipeline; the slice ice machine is connected with the evaporator through a pipeline; the evaporator is connected with an evaporative type condenser through a pipeline; and the evaporative type condenser is connected with the spiral pipe evaporator through a pipeline. According to the cold water recycling pipeline device and the method, cooling water of the slice ice machine can be fully used for reducing temperature of air supplied by slice ice, so that during an air supply process, slice ice is guaranteed not to be melted, and energy is saved; the cooling water is also used for reducing the temperature of a refrigerant auxiliarily, and energy consumption is reduced further; and the high-level water tank is arranged, lifting is performed by using a water pump initially, and other circulation is realized through flowing of the cooling water by means of self-weight, so that the manufacturing and installation costs of the pipelines are reduced. According to the cold water recycling pipeline device and the method for the slice ice machine, the energy consumption can be reduced, water resources are saved, and manual operation and maintenance costs are reduced.

Owner:CHINA GEZHOUBA (GRP) FIRST ENG CO LTD

Vehicle xenon headlight fixer

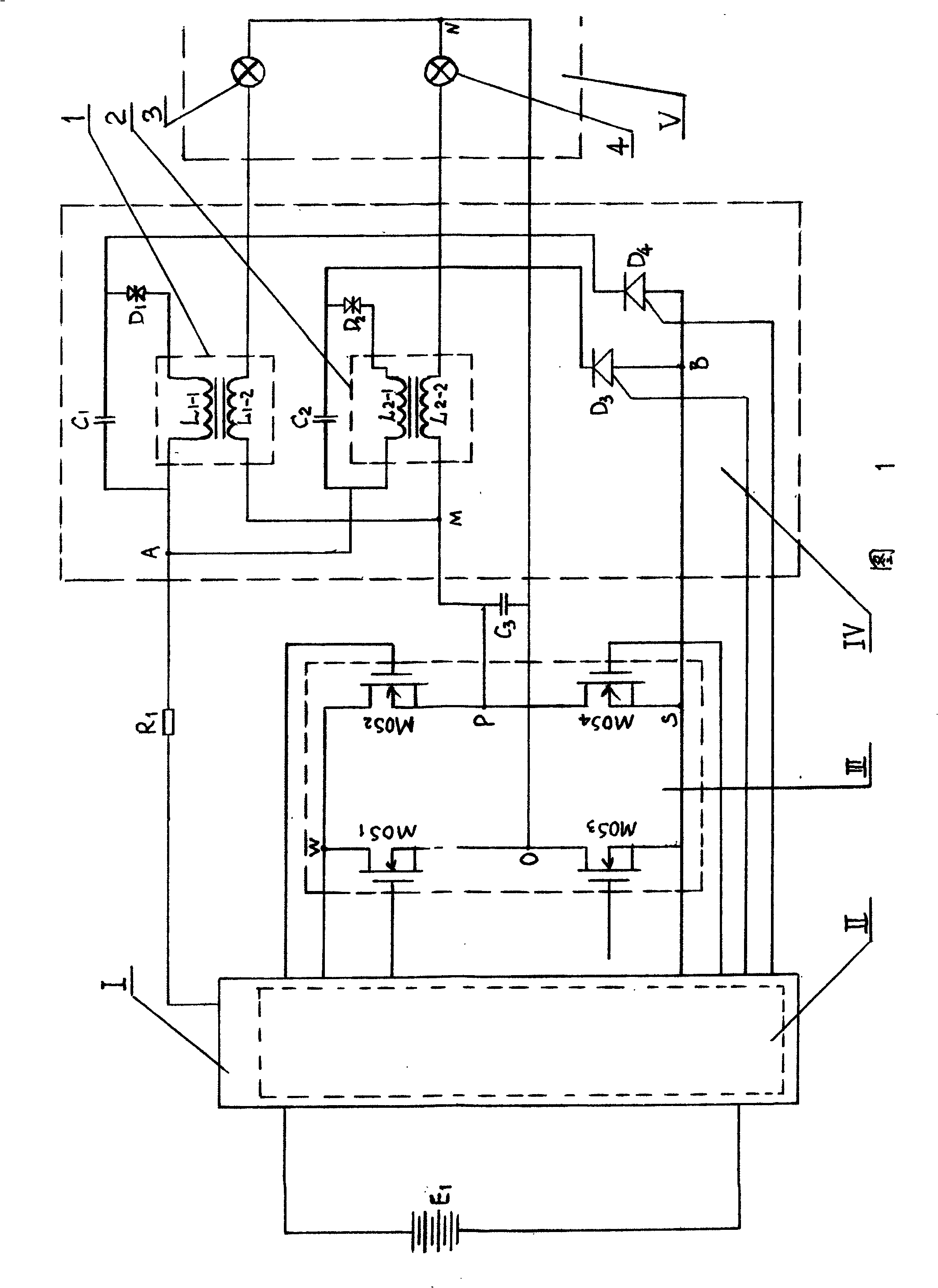

InactiveCN101247690AReduced manufacturing and installation costsSave installation spaceElectrical apparatusElectric lighting sourcesMaximum efficiencyHigh pressure

The invention provides an automotive xenon headlamp stabilizer. Starting ignition circuit (IV) has first FBT (1) and second FBT (2), fourth point (P) of double-bridge inverter circuit (III) simultaneous connects with secondary side coils of first FBT (1) and second FBT (2) in starting ignition circuit. Two FBT is installed in the stabilizer, can start two xenon bulbs respectively and make the bulbs working alternately. The stabilizer function is played at maximum efficiency, manufacturing installing cost is reduced and installing space is saved.

Owner:殷强

Threading machine

ActiveCN105364223ASmooth slidingExtended service lifeThread cutting feeding devicesThread cutting machinesPulp and paper industryTransfer mechanism

The invention provides a threading machine and belongs to the field of machine tools. The threading machine comprises a treading machine body and at least two transferring mechanisms, wherein a base is arranged at the bottom of the threading machine body; grooves are formed in the two sides of the bottom of the base; first blind holes corresponding to the grooves are formed in top of the base; each transferring mechanism comprises a lifting part, two fixing parts and at least two walking parts; a U-shaped groove and an embedded groove are formed in each fixing part; a lug is arranged at the interior of one side wall of the U-shaped groove; a through hole is formed in the other side wall of the U-shaped groove; a rod penetrates through the through hole; gears are rotatably arranged on the side wall of each embedded groove; the lifting part comprises a fixing plate; the left end and the right end of the fixing plate are respectively embedded into the embedded grooves of the two fixing parts; a rack is vertically arranged on one side of the fixing plate and is meshed with the gears. Through the threading machine, the transferring mechanisms are mounted on the threading machine body and a control handle is rotated, so that the threading machine body can get off the ground; the walking parts touch the ground; the position can be transferred at anytime and anywhere.

Owner:CHONGQING RUIJIA MACHINERY CO LTD

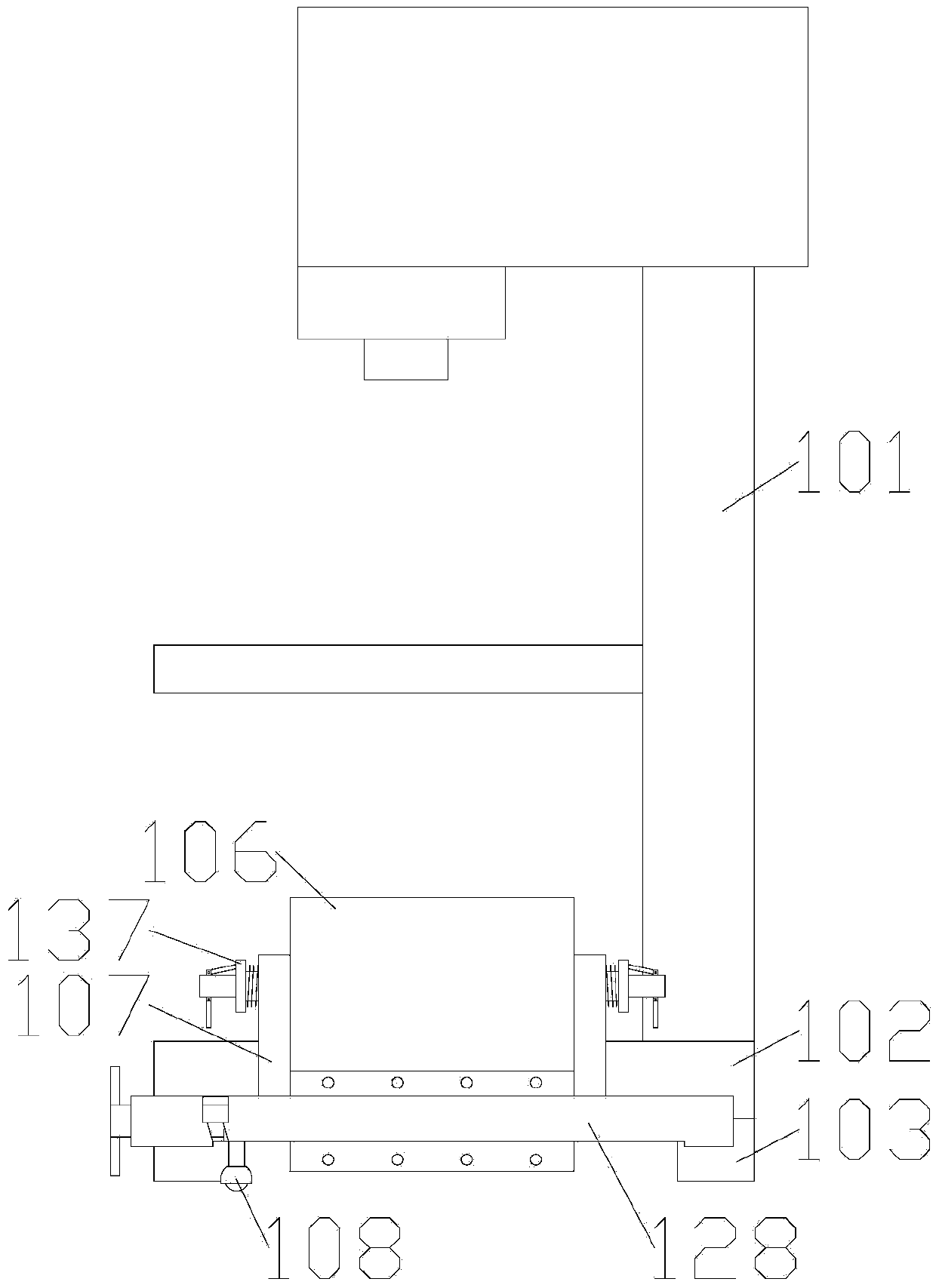

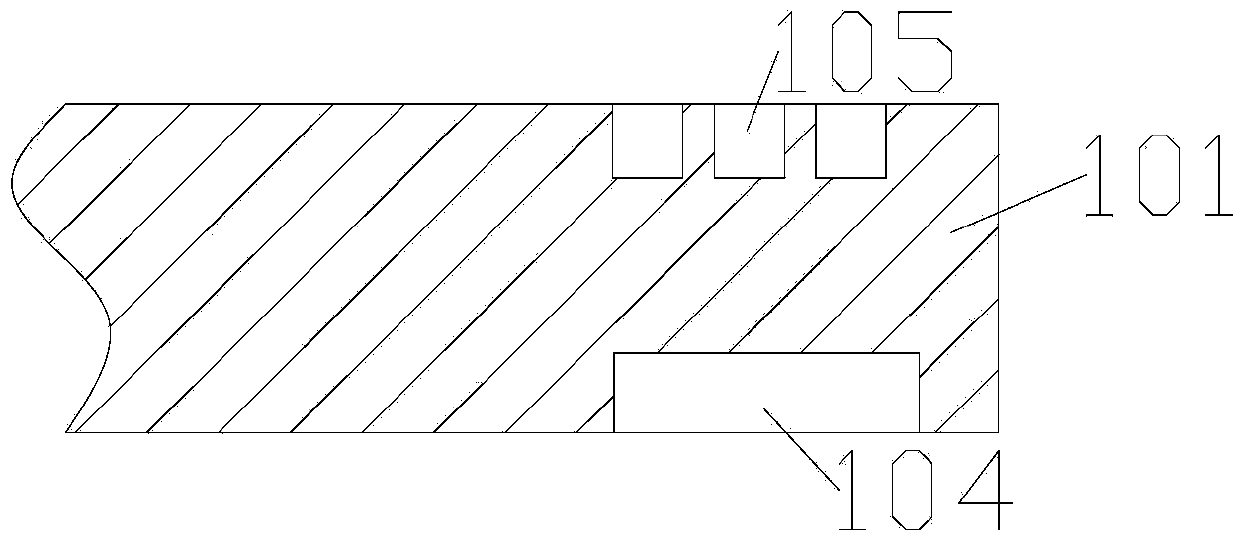

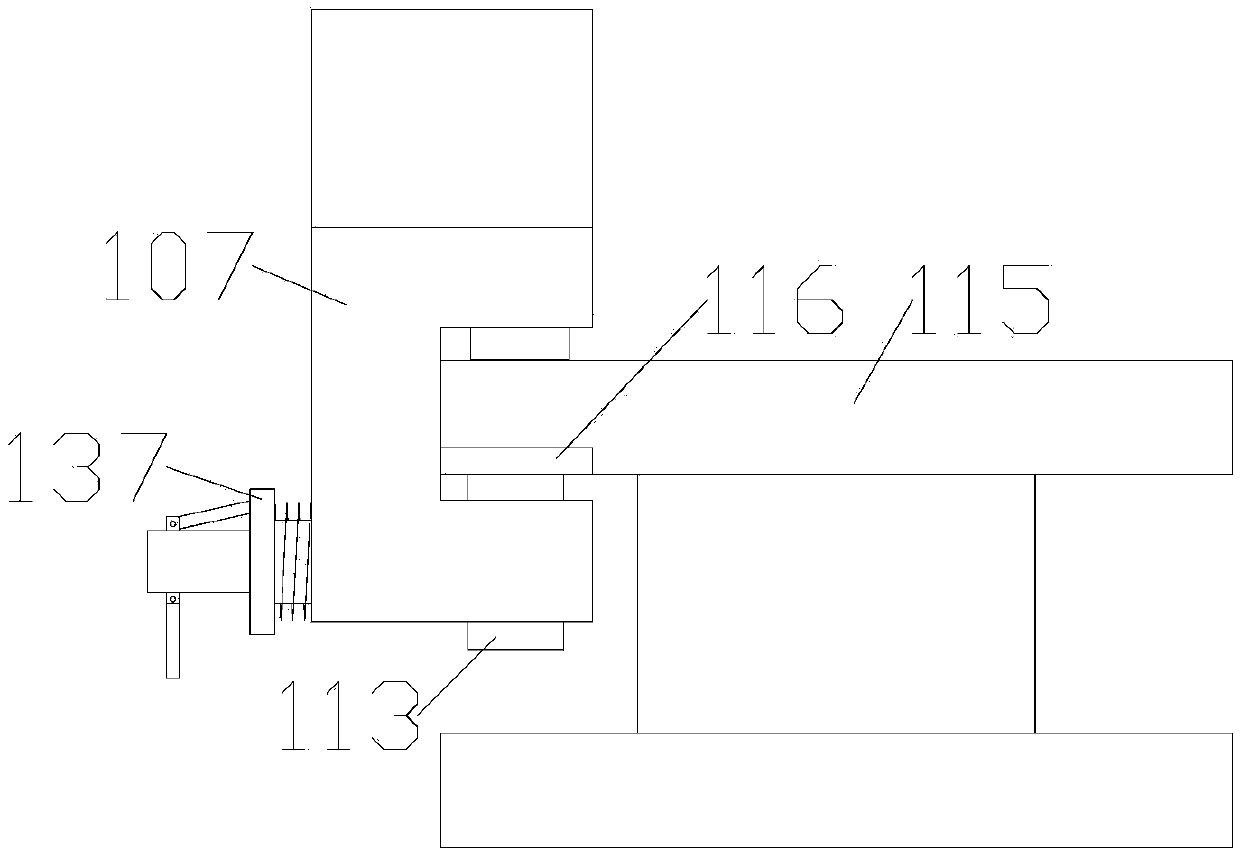

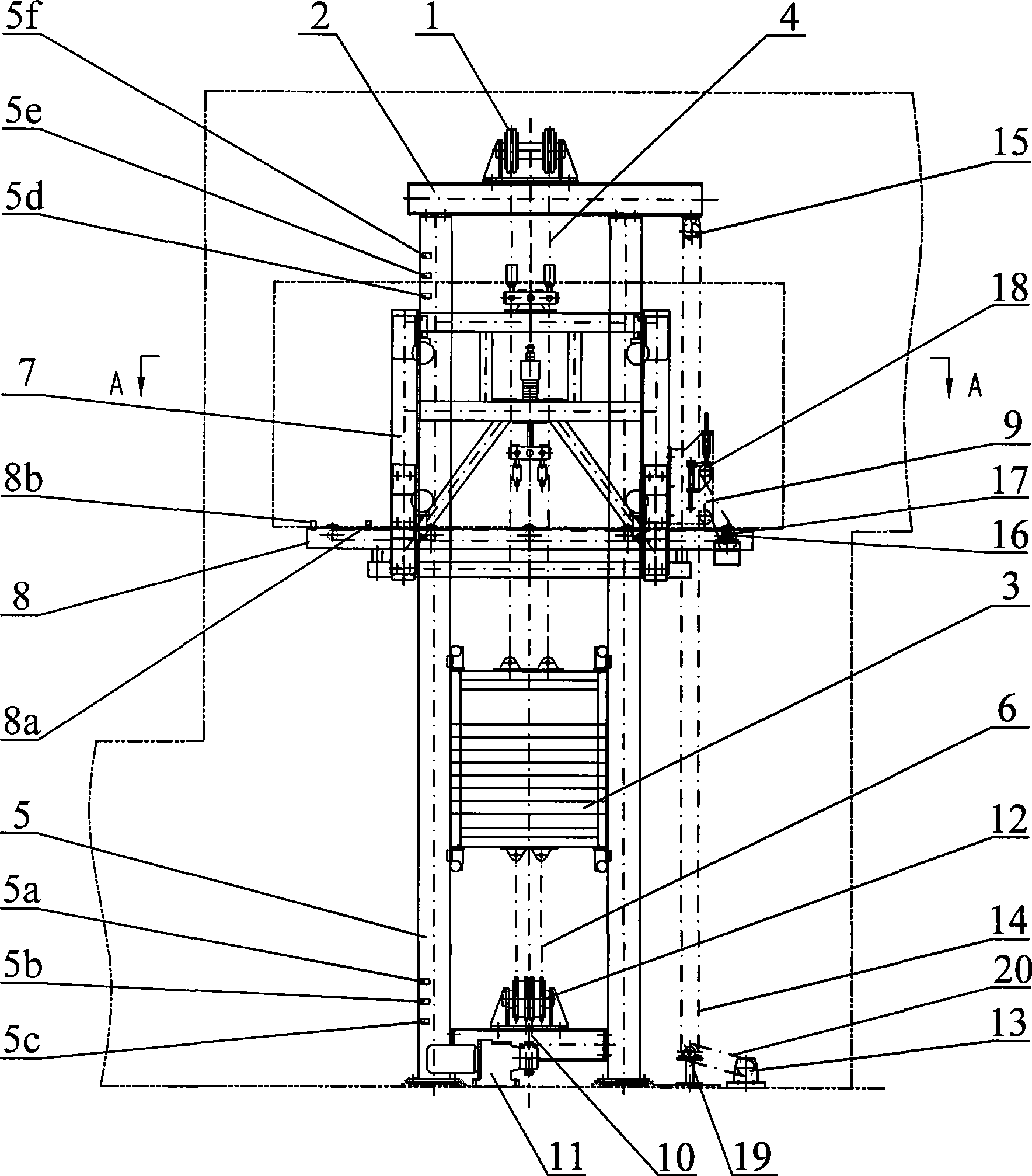

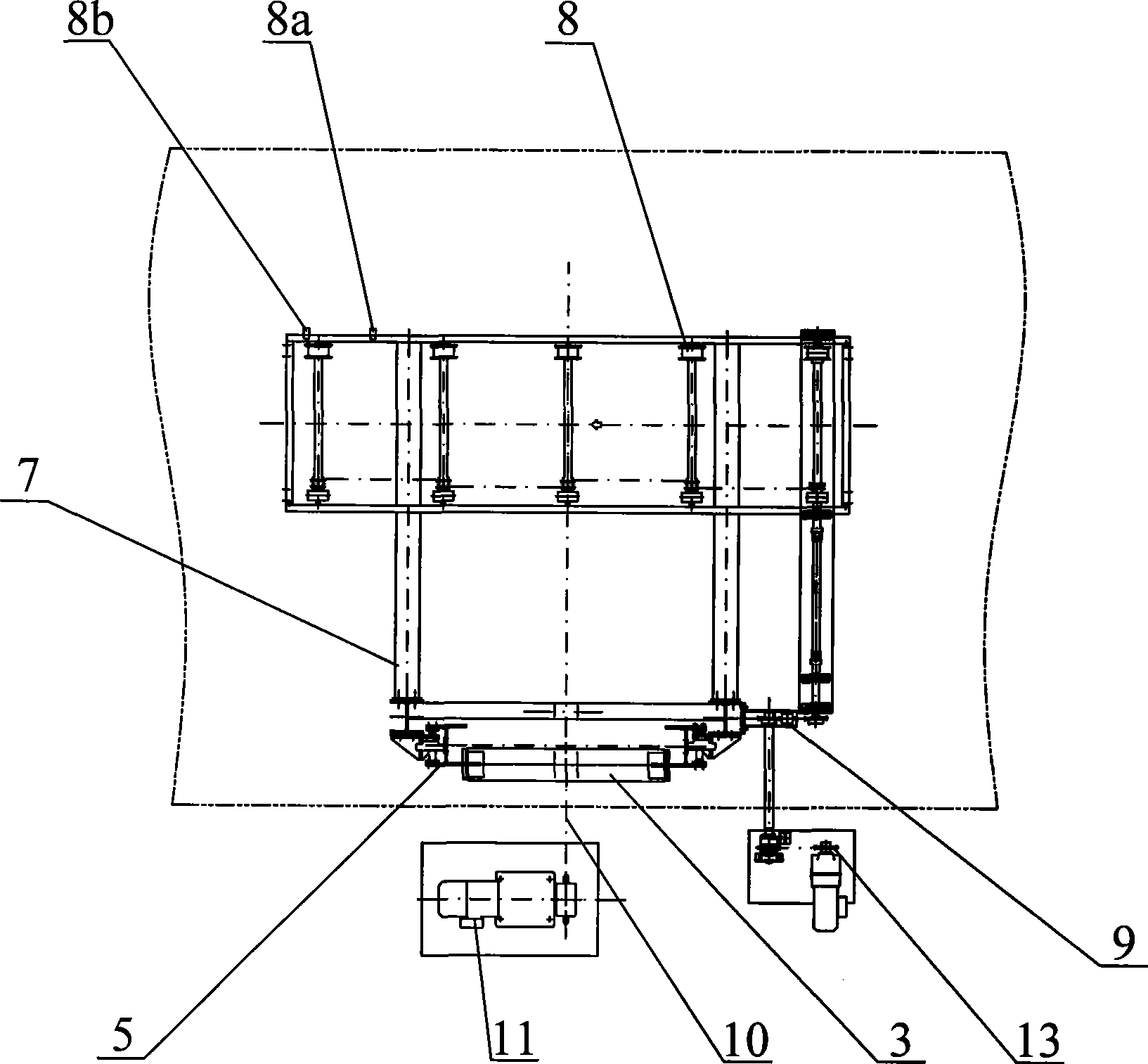

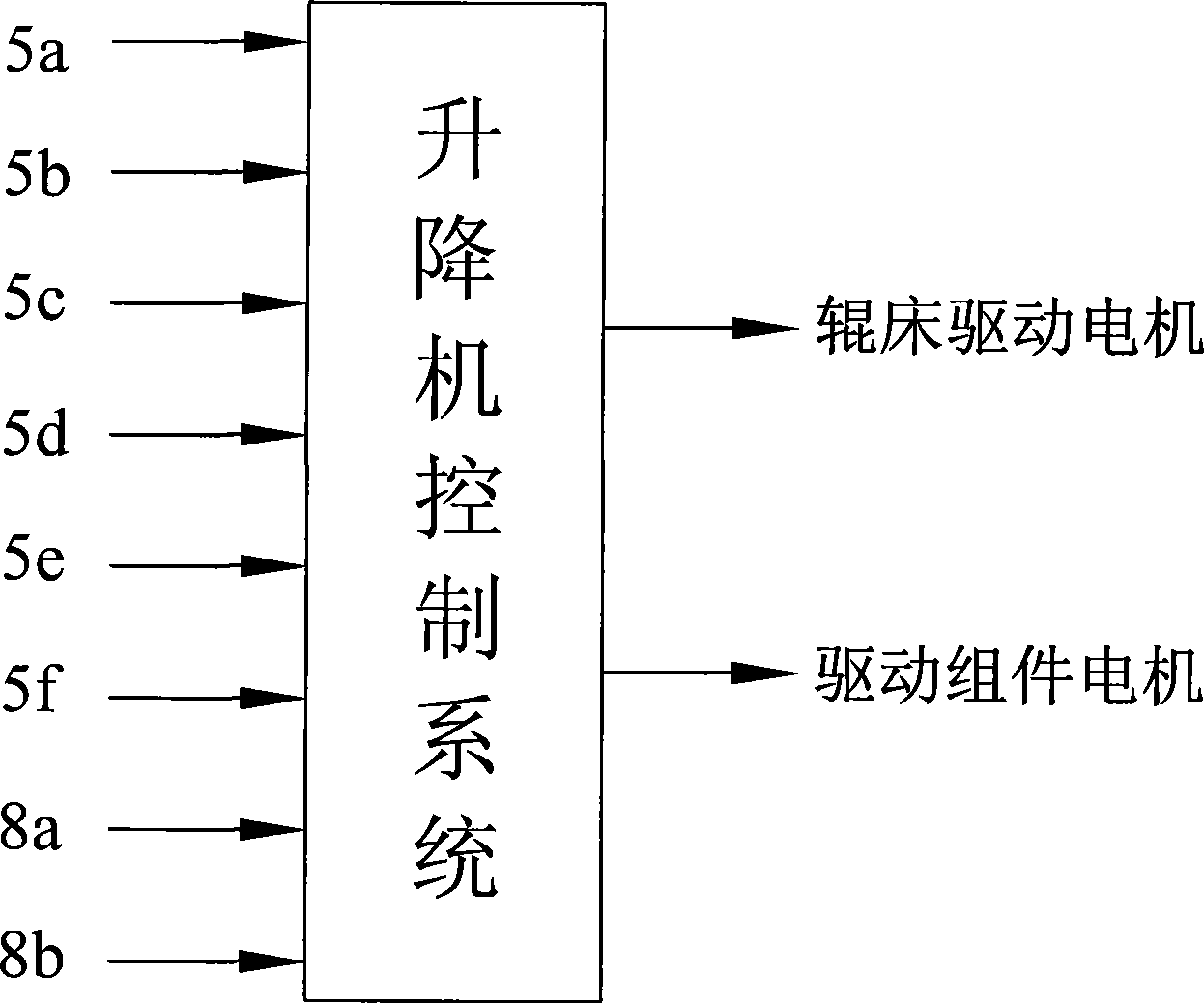

Drive device for external high-temperature lifter

ActiveCN101376130AReduced manufacturing and installation costsIncrease productivityPretreated surfacesCoatingsSprocketEngineering

The invention relates to a driving device for an external high temperature elevator. A top frame is arranged at the top end of an upright column and a transitional sprocket is arranged on the top frame. The driving device is characterized in that a sliding frame and a counterweight device thereof are connected with the upright column in a sliding manner; two ends of an upper chain are respectively and fixedly connected with the sliding frame and the counterweight device; the middle section of the upper chain is wound on the transitional sprocket and meshed therewith; a driven sprocket is fixedly arranged on the upright column; two ends of a lower chain are respectively and fixedly connected with the sliding frame and the counterweight device; the middle section of the lower chain is wound on the driven sprocket and meshed therewith; the driven sprocket is meshed with a driving sprocket through a driving chain; and an output shaft of the driving device is connected with the driving sprocket. In the invention, all motors are mounted in a chamber externally-arranged way, so that the motors can satisfy the requirements by adopting ordinary motors. Therefore, not only the production cost and the installation cost are greatly reduced, but also the production efficiency is improved and the failure rate of the equipment is greatly reduced.

Owner:MIRACLE AUTOMATION ENG CO LTD

Integrated fixed bed gasifier for chilling and deslagging molten slags

PendingCN108165310AReduced manufacturing and installation costsFurnace compact structureCombustible gas productionProduct gasFixed bed

The invention discloses an integrated fixed bed gasifier for chilling and deslagging molten slags. The integrated fixed bed gasifier is provided with a high-pressure-resistant shell with an integral structure; an inner cavity of the high-pressure-resistant shell is sequentially divided into a raw material gasifying area, a liquid-state molten slag area and a molten slag chilling area from top to bottom; the raw material gasifying area is provided with a refractory matter layer and a water-cooling jacket, so that a normal operation condition of the raw material gasifying area is maintained, andraw materials are gasified to produce a crude synthesis gas; the liquid-state molten slag area is provided with a funnel-shaped refractory water-cooling enclosure bulkhead, and is used for collectingliquid-state molten slags produced in the raw material gasifying area; a molten slag discharging ring sleeve is arranged at a bottom molten slag outlet part of the refractory water-cooling enclosurebulkhead, and a molten slag discharging control device is arranged in an inner cavity of the molten slag discharging ring sleeve, so that the molten slags are conveniently adjusted to be downwards discharged continuously or discontinuously; a furnace slag outlet used for discharging the chilled furnace slags and connected with an external slag locker in a sealing way is formed in the bottom part of the molten slag chilling area. The gasifier has the characteristics of high inner cavity volume utilization ratio, capability of avoiding high pressure gas leakage, high molten slag chilling efficiency and the like.

Owner:中薪油武汉化工工程技术有限公司

A curved glass lighting roof and its installation method

ActiveCN103669669BMeet the needs of useRealize the function of exhausting air and smokeRoof covering using slabs/sheetsBuilding roofsSash windowKeel

The invention belongs to the field of building engineering, relates to a glass daylighting roof, in particular to an arc glass daylighting roof which can be turned upwards to be opened, and provides a mounting method of the arc glass daylighting roof. The arc glass daylighting roof comprises a main keel, a sub keel, an aluminum alloy base, an aluminum alloy window frame, a glass panel, an aluminum alloy window sash, hinges, a stainless steel support and an upward-turning type electric opener. The glass panel and the aluminum alloy window sash can be turned upwards to be opened towards the outer side through the upward-opening electric opener and the hinges. According to the arc glass daylighting roof and the mounting method of the arc glass daylighting roof, the glass panel and the aluminum alloy window sash can be turned upwards to be opened towards the outer side through the upward-turning type electric opener and the hinges, the maximum opening angle is 70 degrees, and eventually the air and smoke exhaust function is achieved. The structure and the mounting method are simple, manufacturing and mounting cost is reduced, and the using requirements of the arc glass daylighting roof are met.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD +1

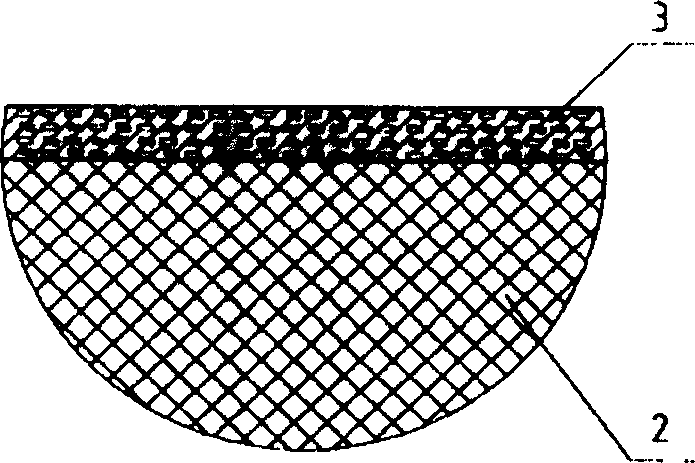

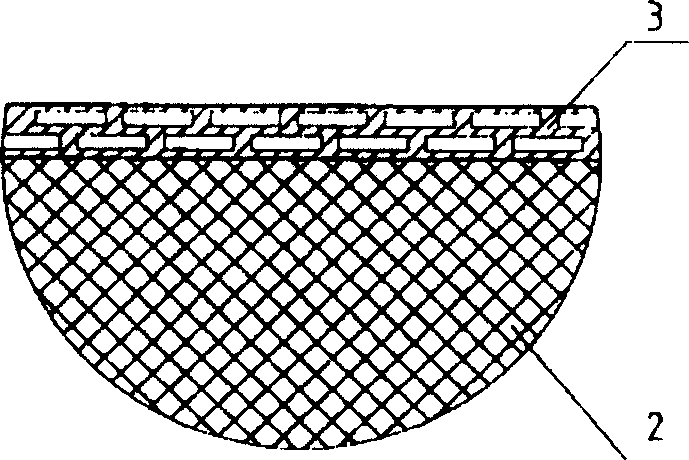

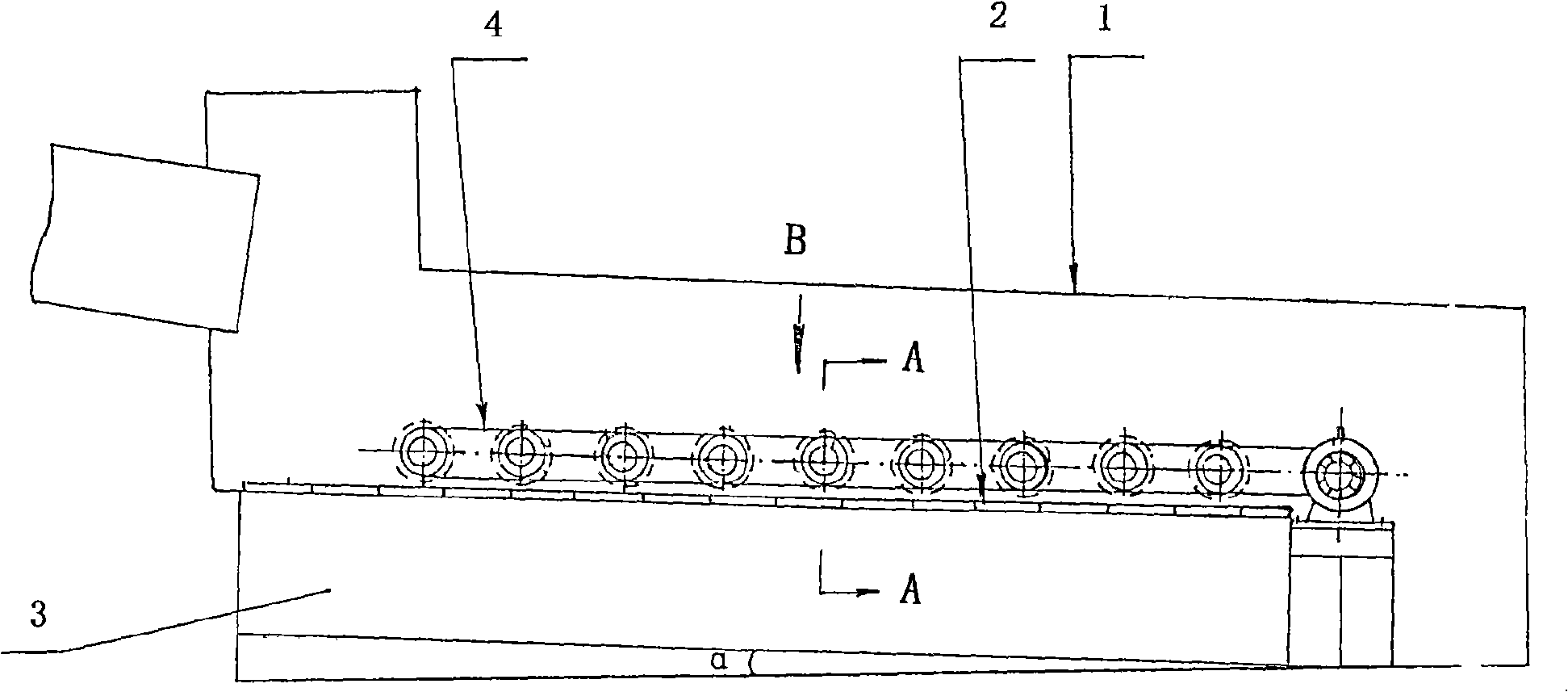

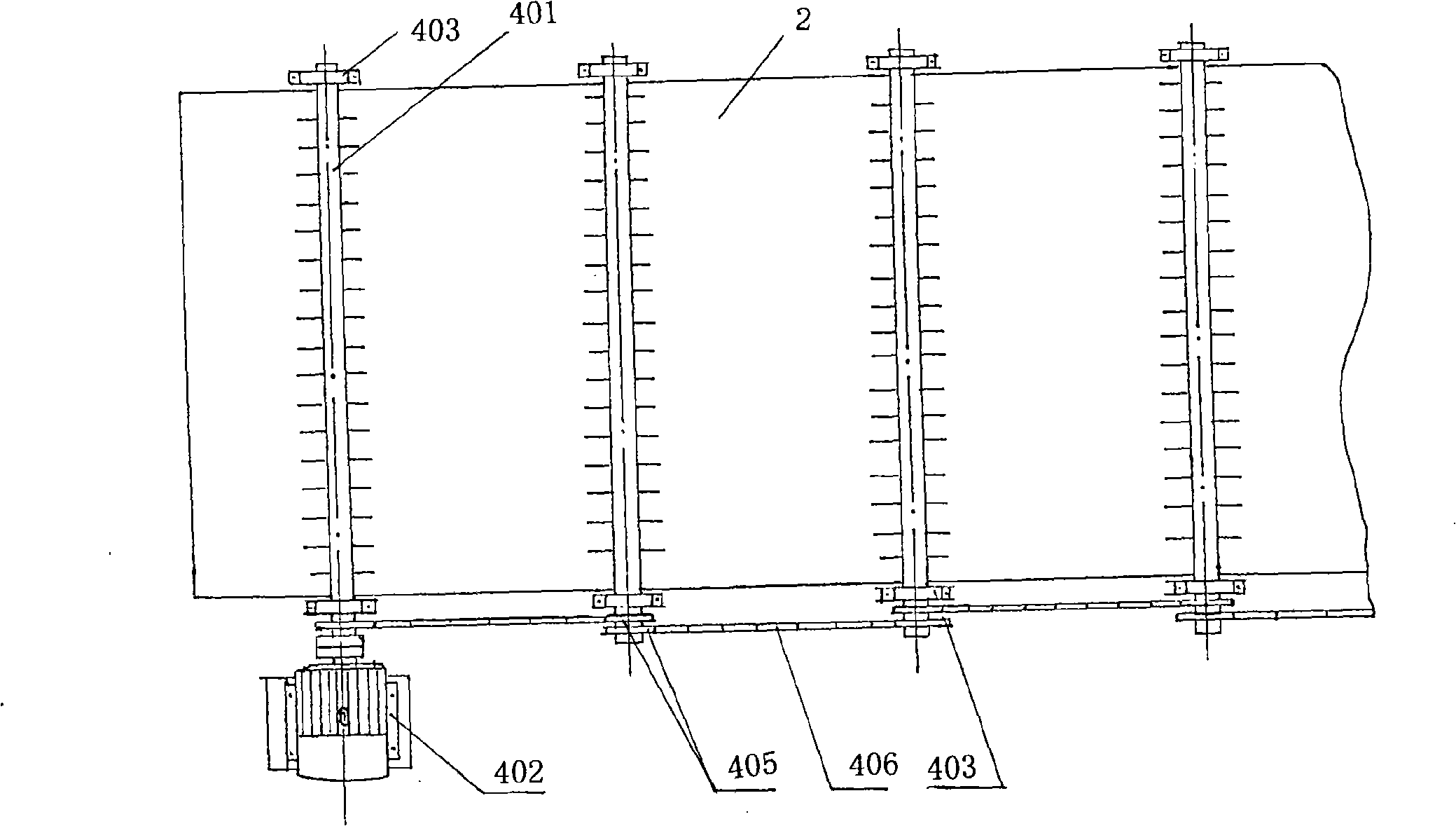

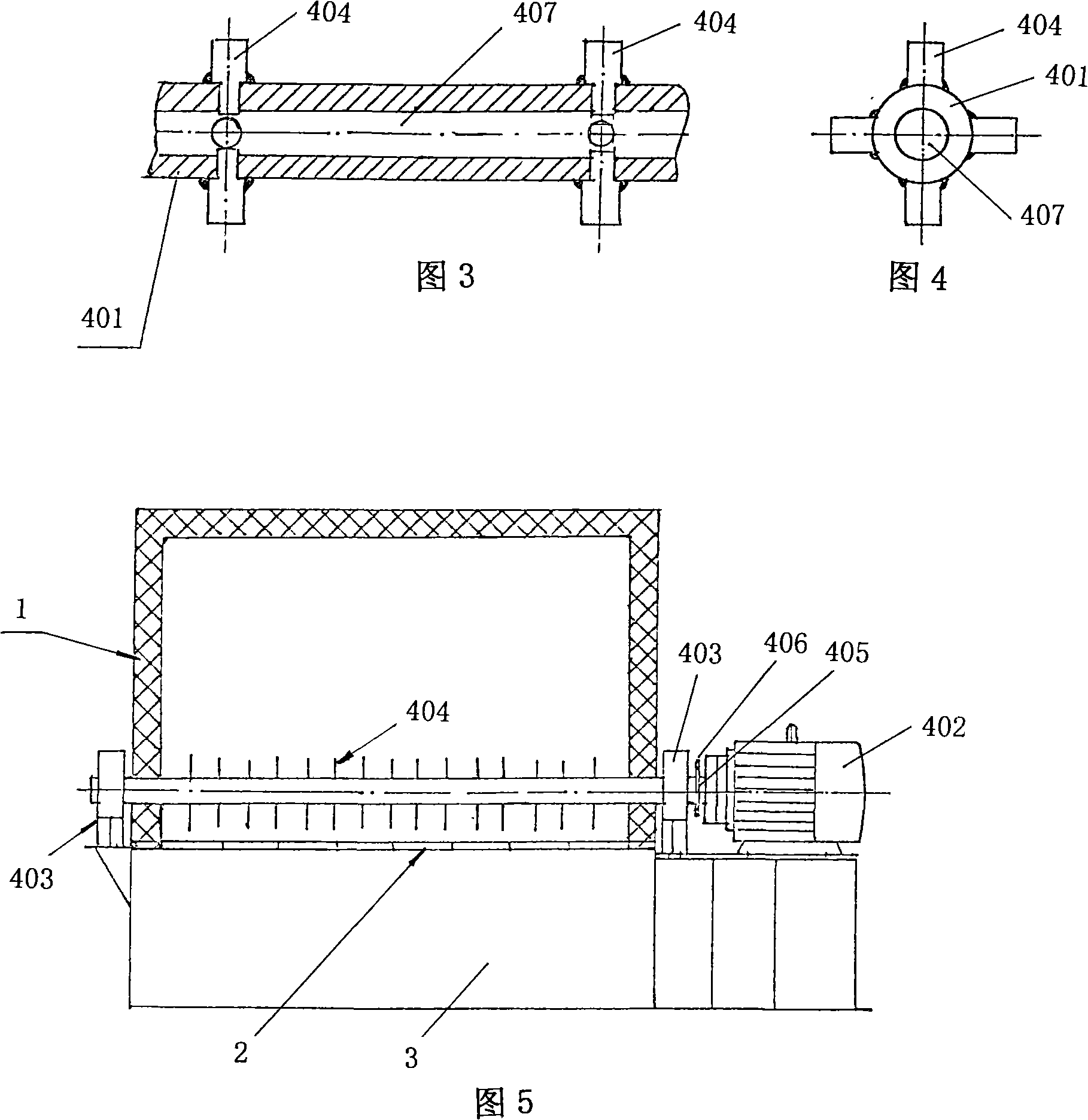

High temperature chamotte cooler for concrete

InactiveCN101269921AReduce manufacturing difficultyReduce installation difficultyClinker productionPropellerEngineering

The present invention discloses a cement high-temperature grog cooler, which comprises a shell (1) and a grog bed (2), wherein, the shell (1) is covered on the grog bed (2); one end of the shell is provided with a feeding port and the other end is provided with a discharging port; the grog bed (2) is supported on a bed body (3). The present invention is characterized in that the grog bed (2) is provided with at least one rolling-harrow-typed grog propeller (4) that pushes the high-temperature grog from the feeding end to the discharging end. The present invention has the advantages of simple structure and convenient manufacture and installation.

Owner:NANJING RUITAI CEMENT MFG EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com