Shaft locating mechanism

A technology of shaft positioning and positioning body, applied in mechanical equipment, connecting components and other directions, can solve the problems of complex structure, installation and manufacturing process, waste of raw materials, inappropriateness, etc., and achieve the effect of low manufacturing and installation cost, saving raw materials, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

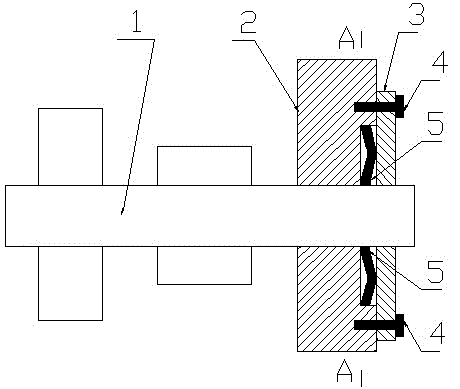

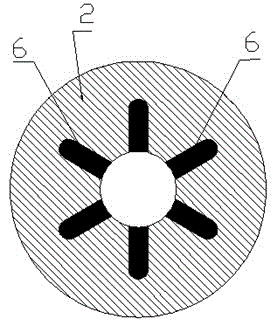

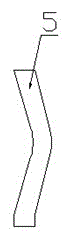

[0011] A shaft positioning mechanism, which includes a shaft (1), a positioning body (2), a pressure plate (3), a bolt (4), and a bow-shaped spring piece (5), and is characterized in that: the shaft (1) is installed on the positioning body (2 In the hole on the positioning body (2), there are long slots (6) uniformly distributed radially around the hole of the positioning body (2), and a bow-shaped spring piece (5) is arranged in each long slot (6). The arched spring sheet (5) described above is arcuate in shape, and in a free state, the arched back of the arched spring sheet (5) is higher than the outside of the long groove (6), and the bolt (4) is used outside the orifice of the positioning body (2). A pressing plate (3) is installed and fixed, and said pressing plate (3) forms an extrusion tendency to the back of the arched spring leaf (5).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com