Integrated fixed bed gasifier for chilling and deslagging molten slags

A fixed-bed gasifier and an integrated technology, applied in the field of slag gasifier, can solve the problems of low fuel gasification efficiency, fast consumption of quenching liquid, high-pressure gas leakage, etc., to increase liquid storage and reduce equipment The effect of small fluctuations in frame height and liquid level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

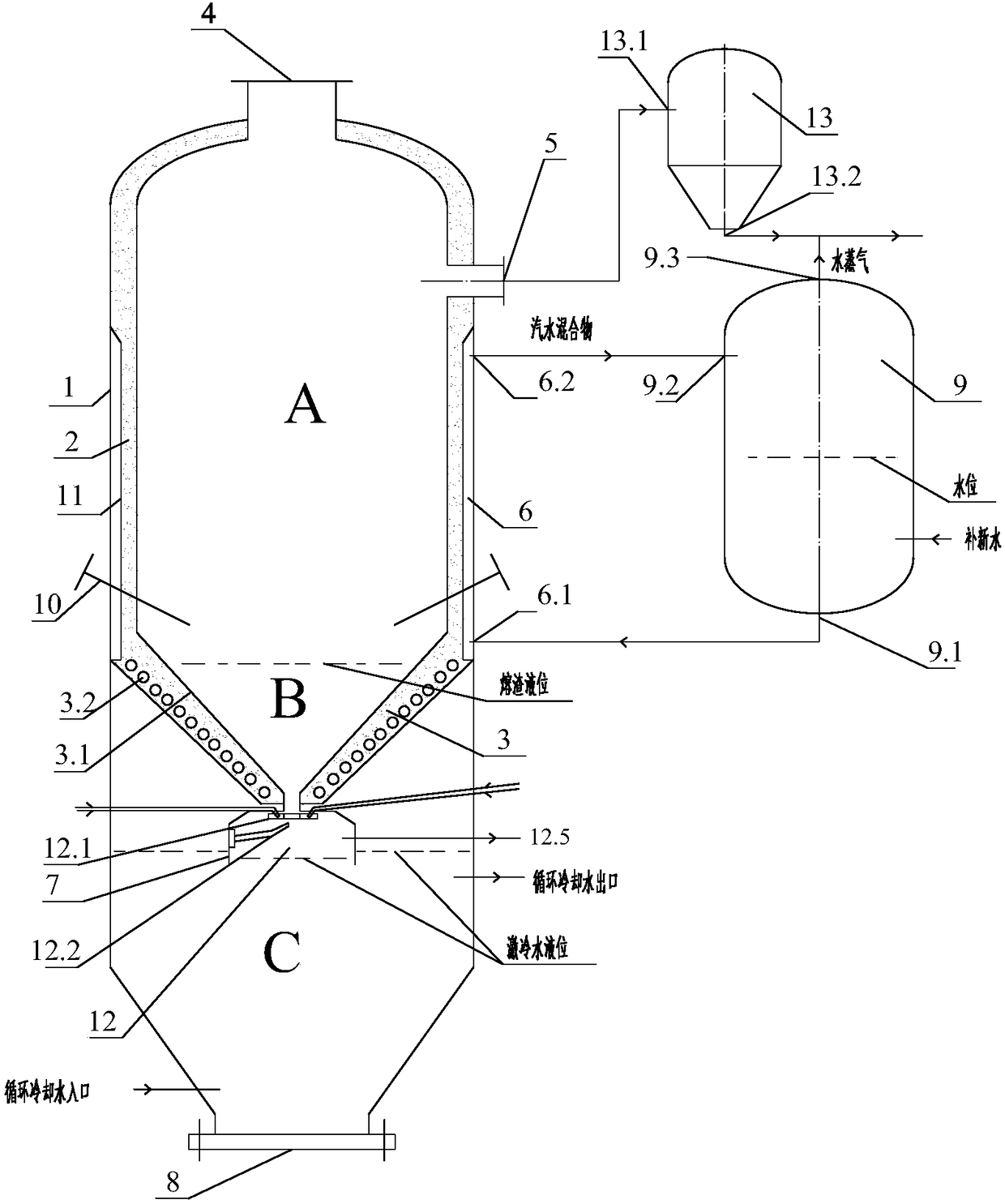

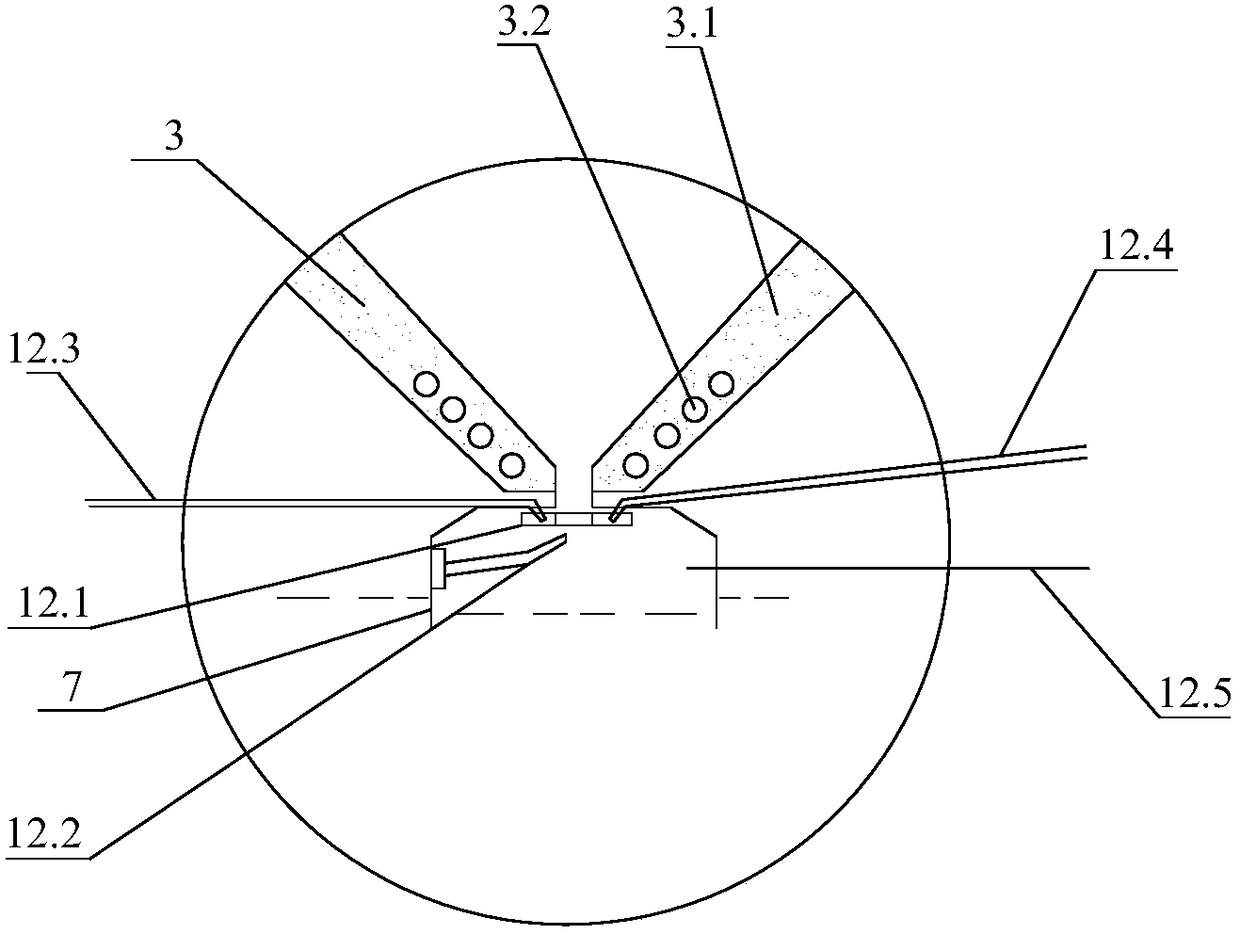

[0027] Figure 1~2 The slag quenching and slag discharge integrated fixed-bed gasifier shown in the figure has a high-pressure resistant casing 1 with an integral structure. The inner cavity of the high-pressure resistant casing 1 is divided into raw material gasification zone A and liquid slag Zone B and slag chilling zone C;

[0028] The top of the high-pressure shell 1 corresponding to the raw material gasification area A is provided with a raw material inlet 4, and the inner side of the high-pressure shell 1 corresponding to the raw material gasification area A is provided with a refractory material layer 2, of which the outer side of the refractory material layer 2 is located at the main gasification reaction site A high-temperature-resistant inner shell 11 is provided, and a water-cooled jacket 6 is formed between the high-temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com