Vehicle xenon headlight fixer

A technology of xenon headlights and ballasts is applied in the field of electronics to achieve the effect of reducing manufacturing and installation costs and saving installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

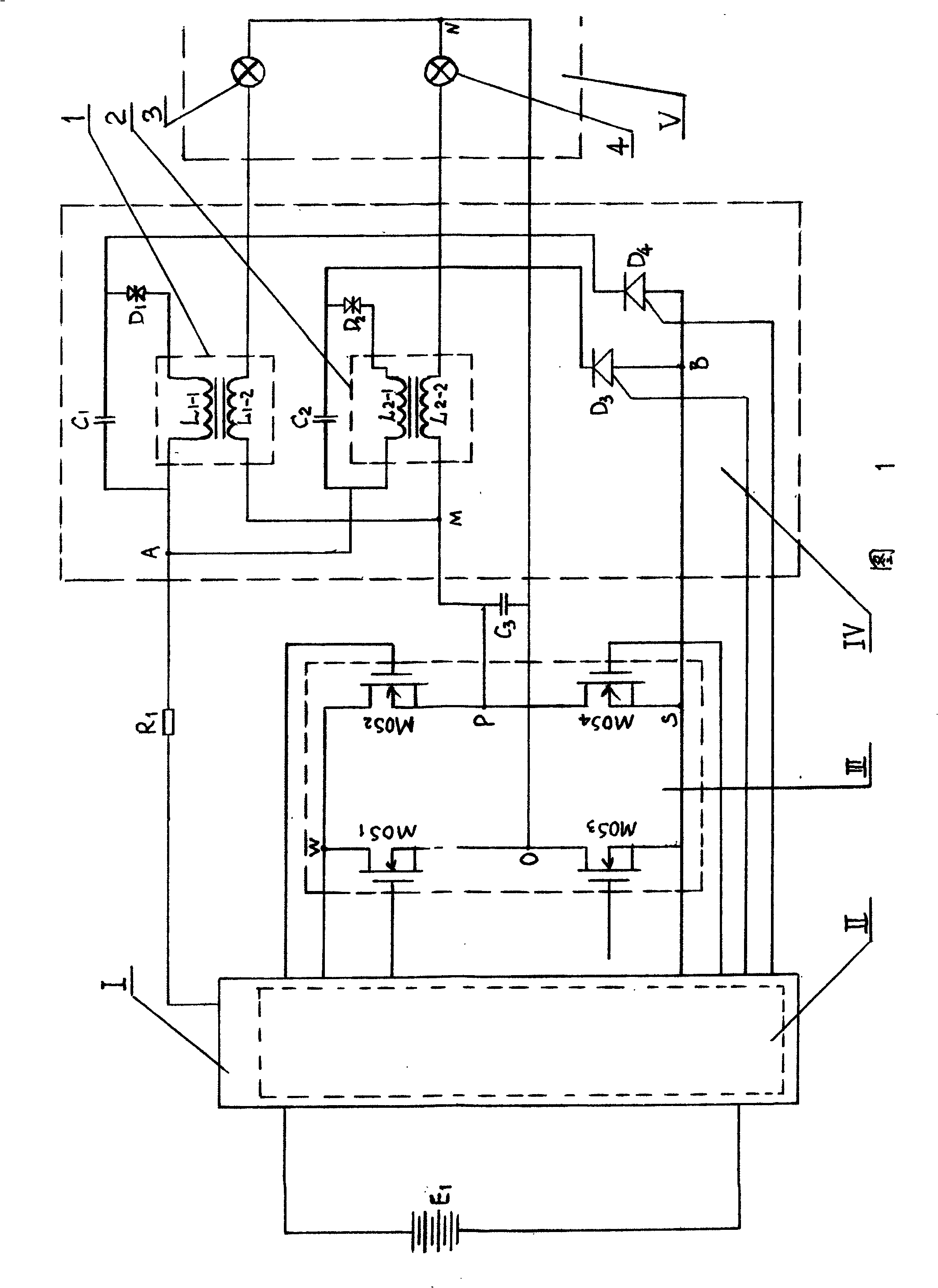

[0013] As shown in Fig. 1, this embodiment includes a boost circuit I and a control circuit II, both of which are of general structure. The boost circuit I converts the car battery E 1 The DC low voltage is raised to the high voltage DC for driving the xenon lamp, and the voltage is applied between the first node W and the second node S of the double-bridge inverter circuit III.

[0014] The double bridge inverter circuit III is composed of the first field effect tube MOS 1 and a third FET MOS 3 Connected in series, the connection node is the eighth node O point, this series circuit forms the first bridge arm, and the second field effect transistor MOS 2 and the fourth FET MOS 4 connected in series, the connection node is point P with the fourth node, and this series circuit forms the second bridge arm. The first bridge arm and the second bridge arm are connected in parallel to form a double-bridge inverter circuit III, and the parallel connection intersects the first node...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com